Effects of Different Types of Fibers on the Physical and Mechanical Properties of MICP-Treated Calcareous Sand

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Bacterial Culture and Cementation Solution

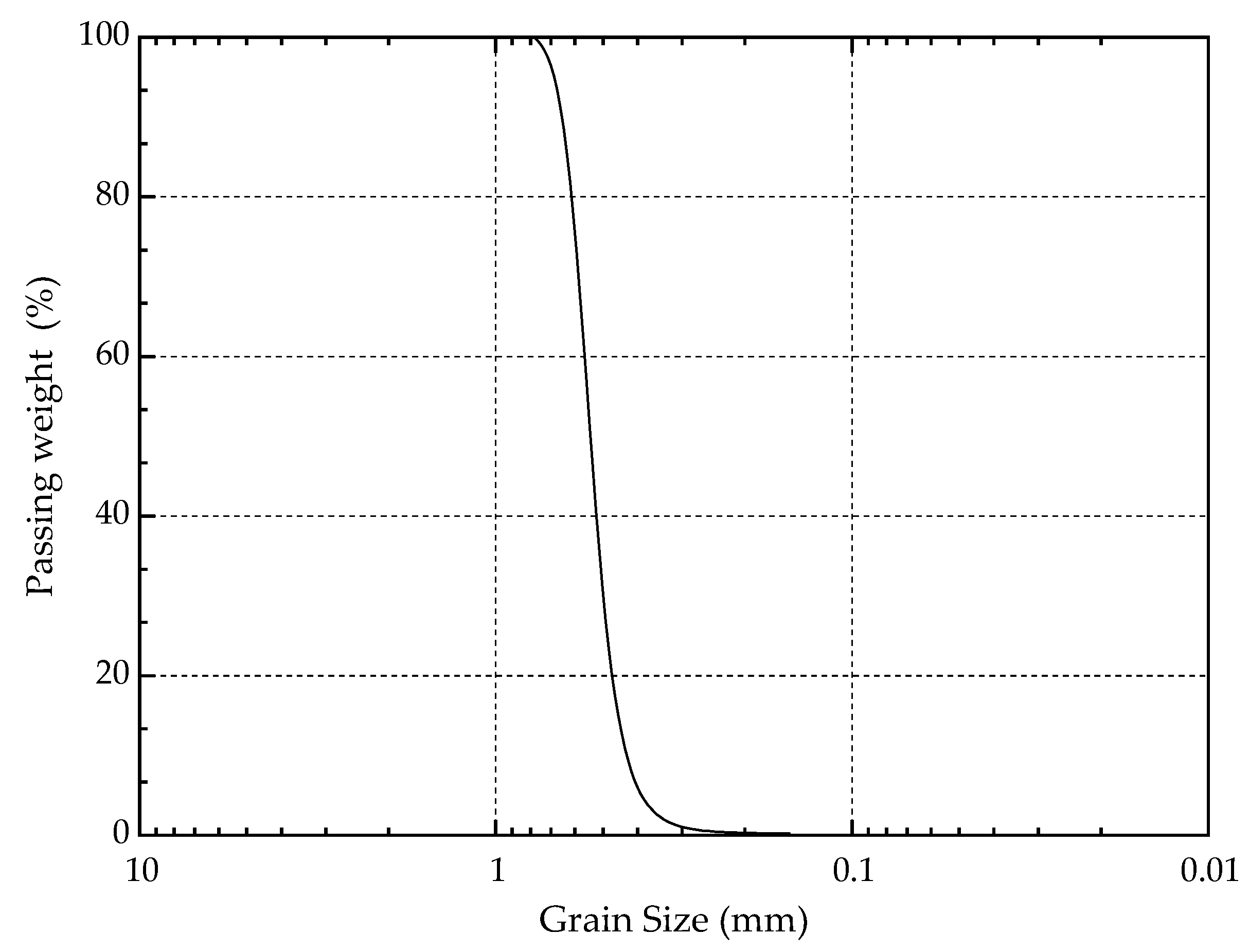

2.1.2. Characteristics of Calcareous Sand

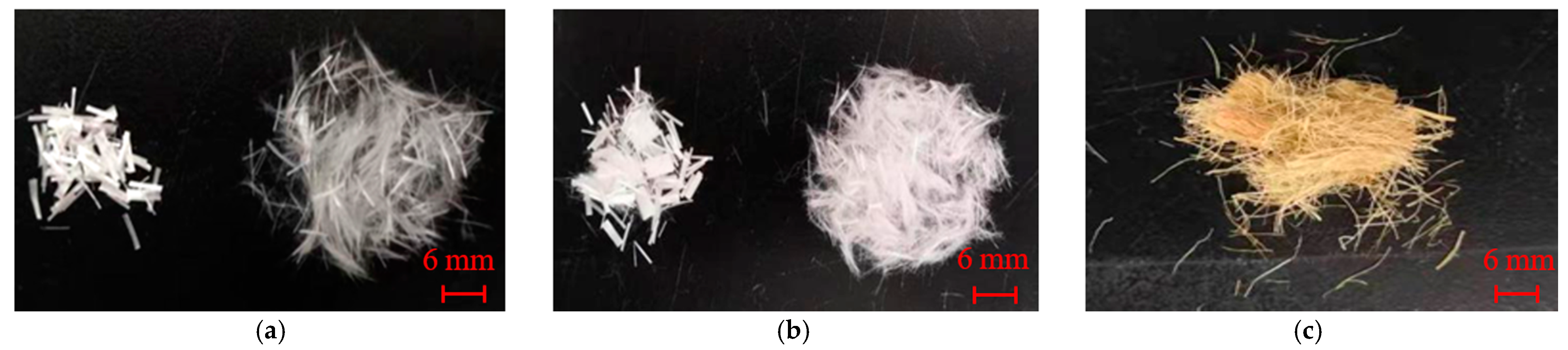

2.1.3. Fiber Types

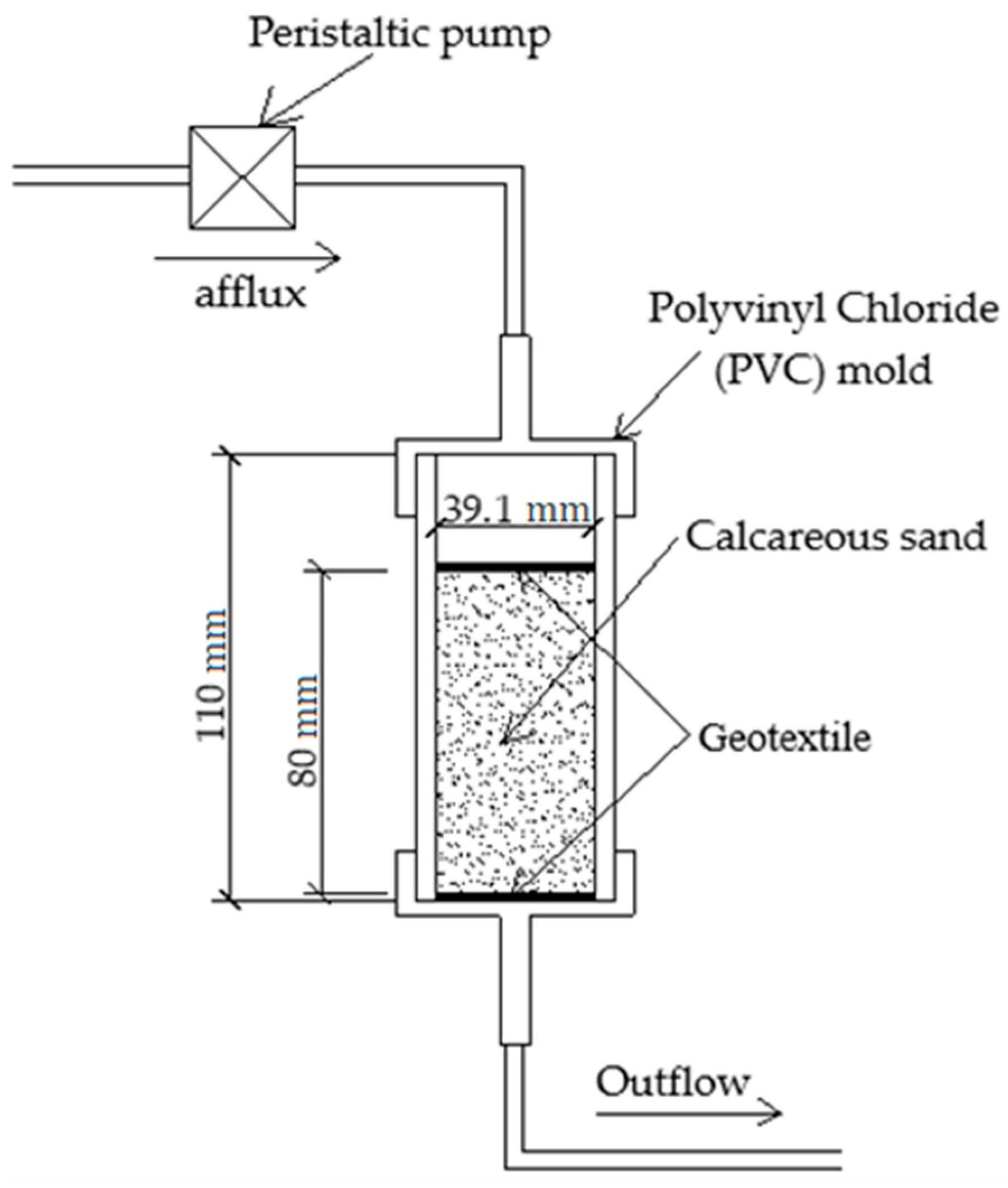

2.2. Specimen Preparation

2.2.1. The Clean and Fiber-Reinforced Sand

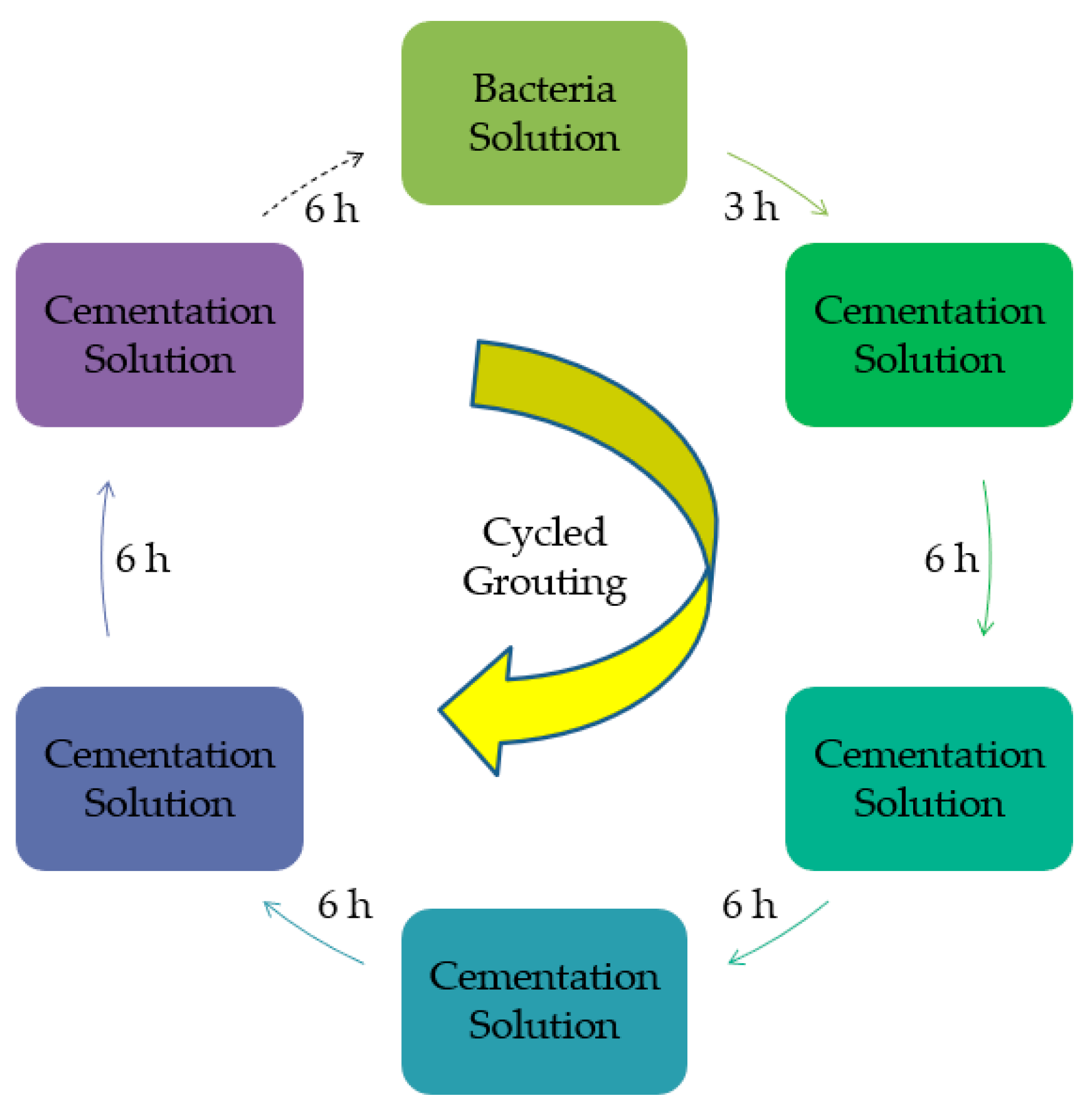

2.2.2. Grouting Procedure

2.3. Testing Method

2.3.1. Water Absorption Test

2.3.2. Unconfined Compressive Strength Test

3. Results

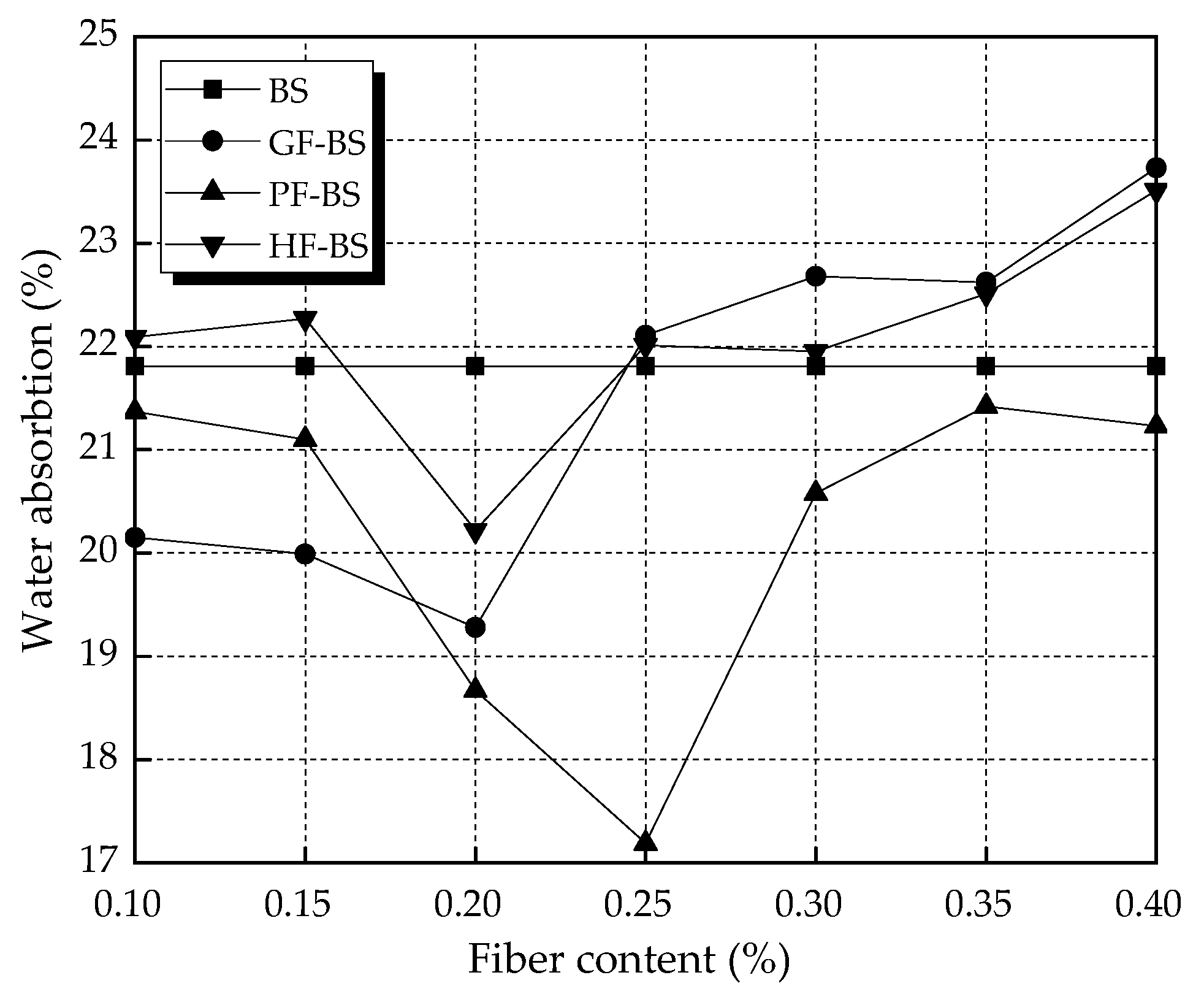

3.1. Water Absorption Test Results

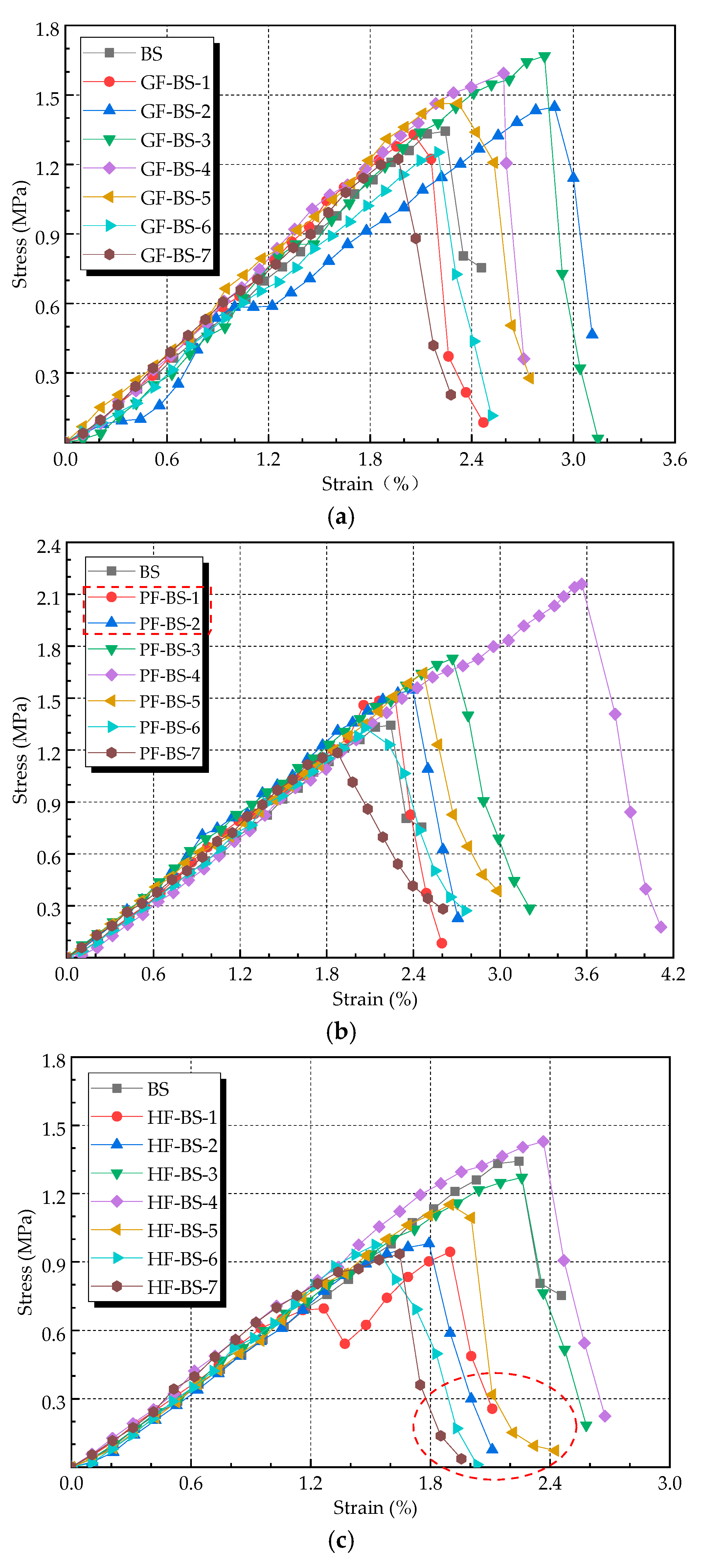

3.2. Stress-Strain Curve of UCS Test Results

3.3. Unconfined Compressive Strength Test Results

4. Discussion

4.1. UCS Versus Water Absorption

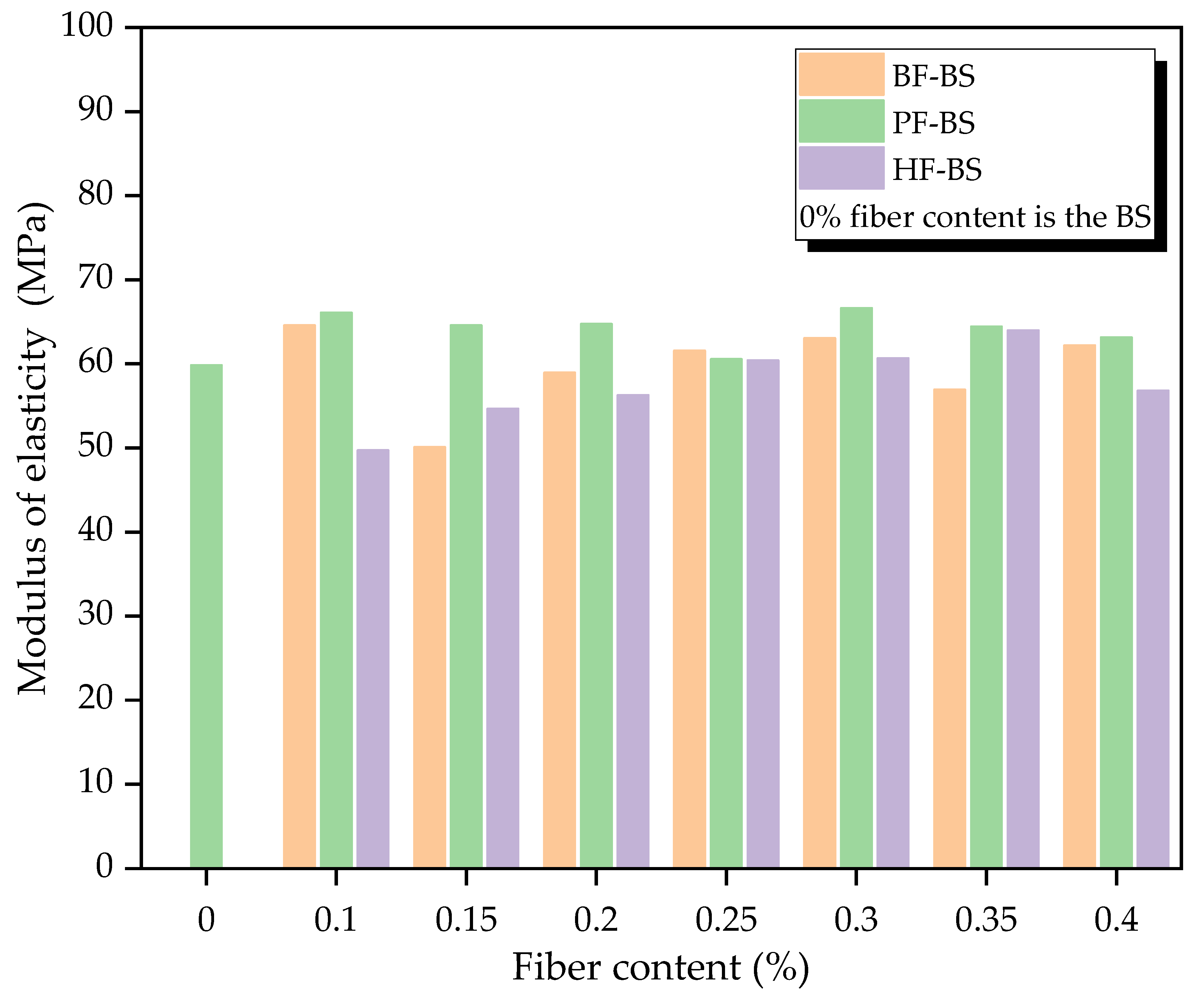

4.2. The Modulus of Elasticity

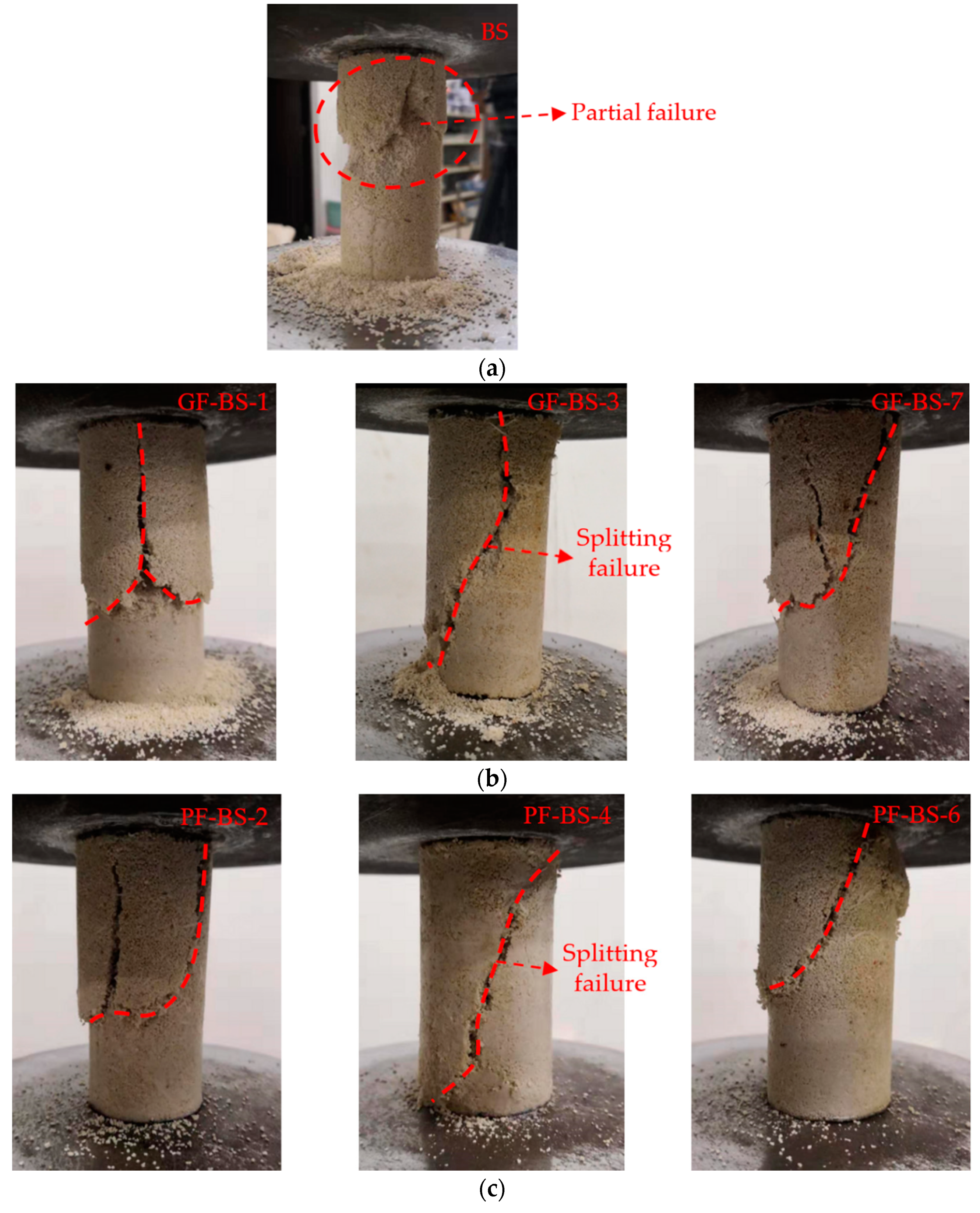

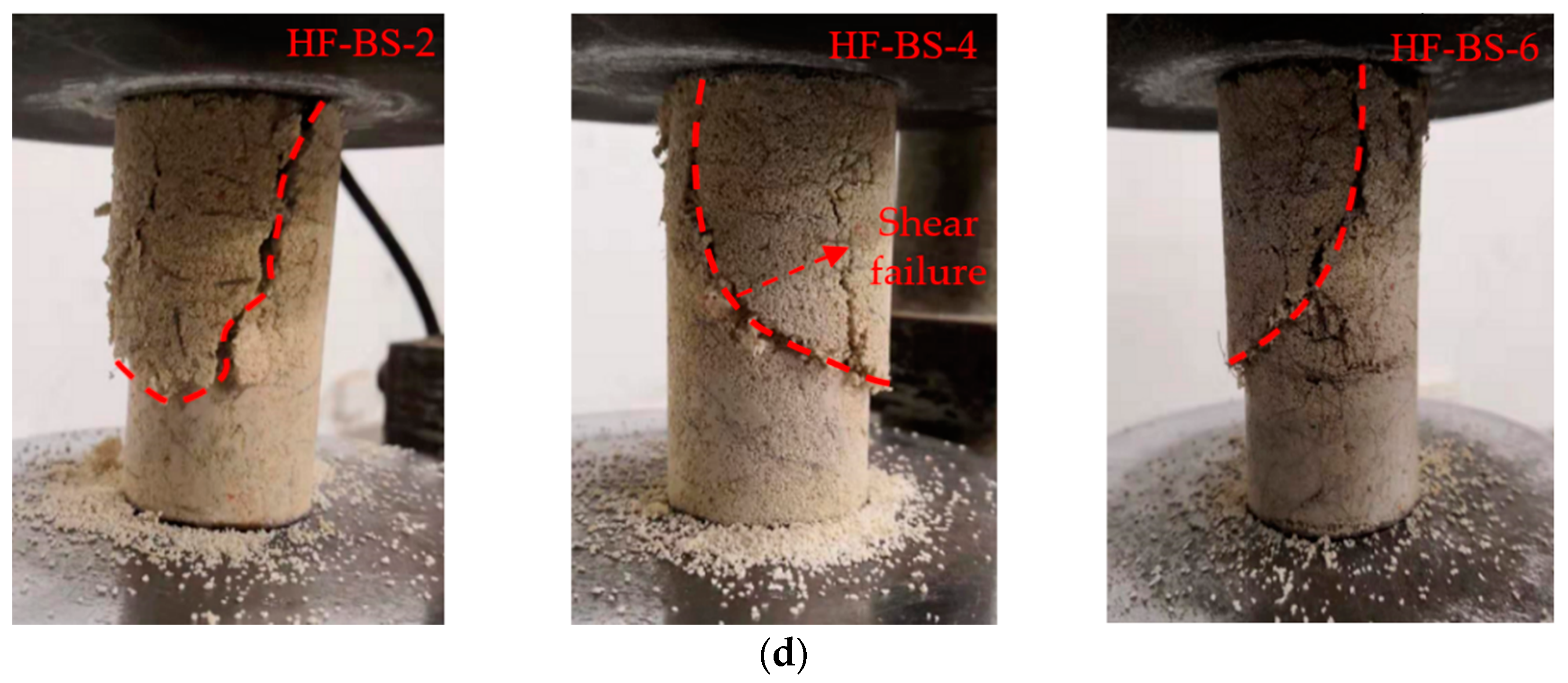

4.3. Analysis of the Failure Pattern of Biocemented Sand

4.4. Microscopic Analysis

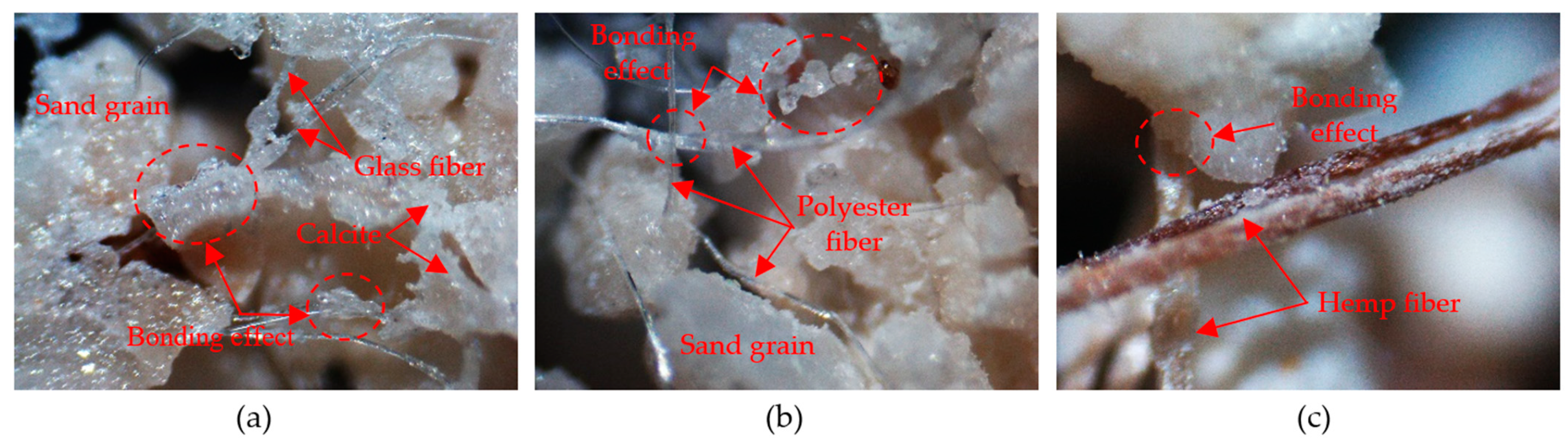

4.4.1. Digital LED Microscope Scanning

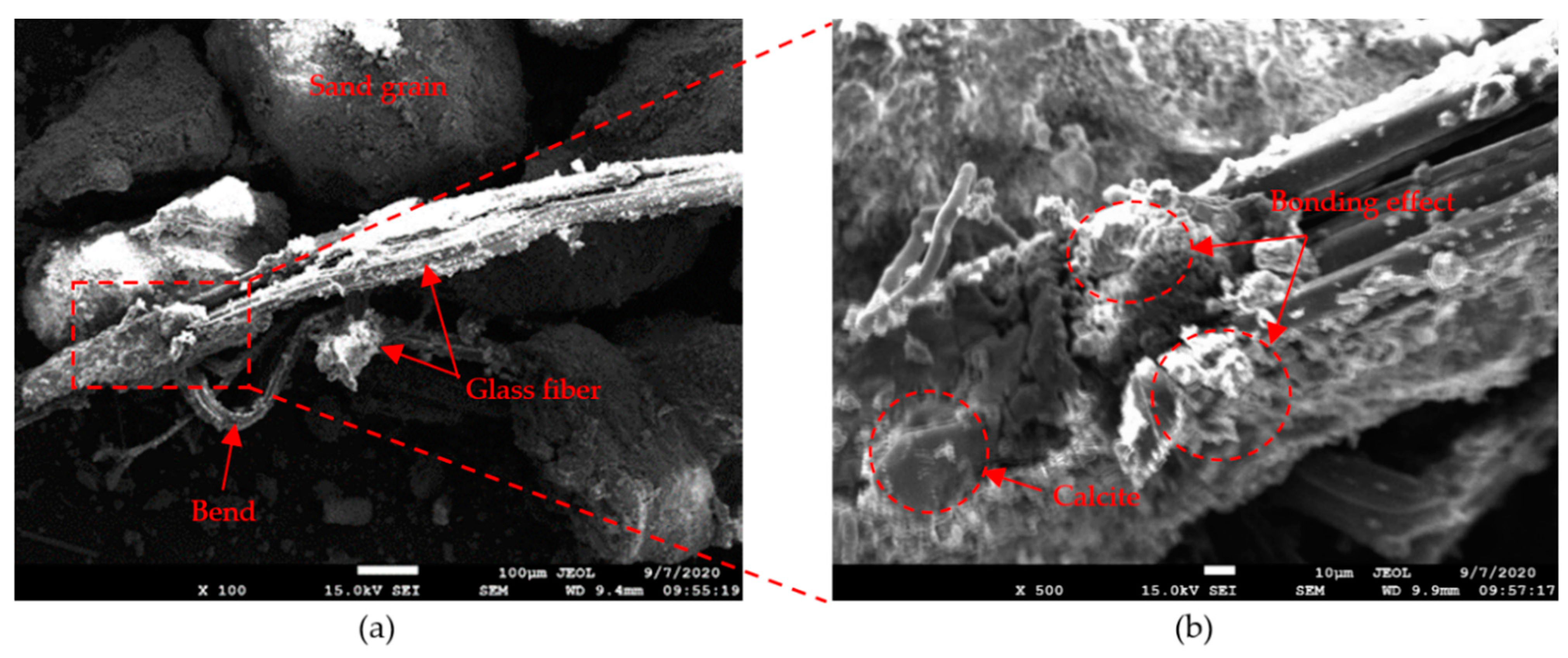

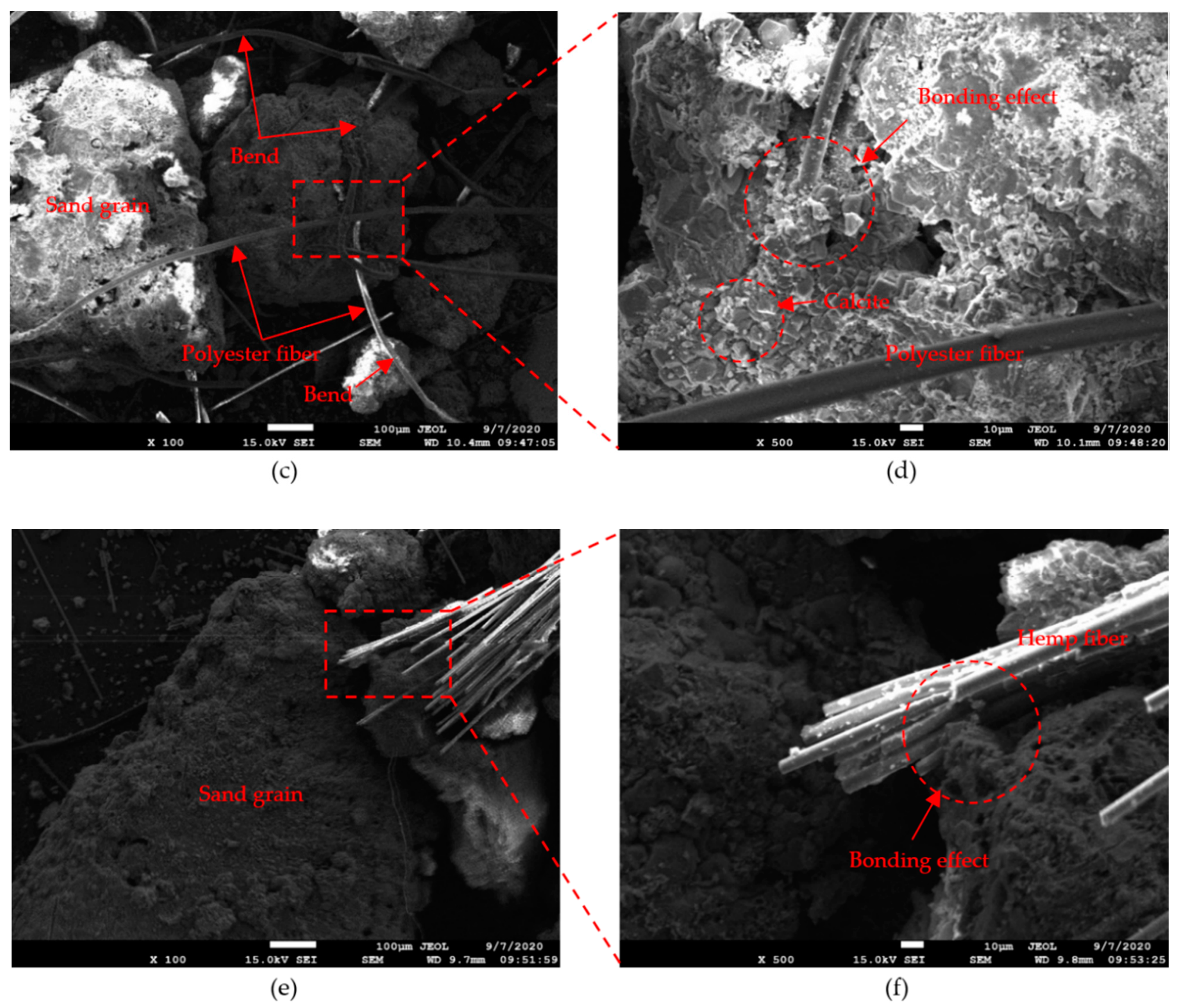

4.4.2. SEM Scanning

4.5. Discussion on the Optimum Fiber Content

5. Conclusions

- For fiber-reinforced biocemented sand, water absorption decreased with increased fiber content. When fiber content rose to a threshold, the water absorption increased as fiber content increased. The minimum water absorption obtained for the GF-BS, PF-BS, and HF-BS was at 0.20%, 0.25%, and 0.20% of fiber content, respectively. This showed a reduction of 11.60%, 21.18%, and 7.29%, respectively, in water absorption over the BS. The unconfined compressive strength displayed the opposite trend. The maximum UCS of the GF-BS, PF-BS, and HF-BS obtained was at 0.20%, 0.25%, and 0.25% of fiber content, respectively. The maximum strengths were 1.668 MPa, 2.159 MPa, and 1.429 MPa. This showed an increase of 24.20%, 60.76%, and 6.40%, respectively, in strength over the BS. On the whole, with the increase in water absorption, the UCS of the sample decreased. This indicated that the pores on the surface of the sample had a negative effect on the strength of the sample.

- For the PF-BS, when the polyester fiber content was 0.2% to 0.4%, the ductility of the sample could be increased. For the HF-BS, only when the stress value of the sample decreased to a low level, did the decreasing trend of the stress and strain become slow. This indicated that the hemp fiber was unable to play an immediate role when the sample was destroyed. For the modulus of elasticity of these three fibers, the PF-BS was the highest, followed by the GF-BS and HF-BS. This indicated that the stress of PF-BS was the highest under the same strain conditions. In other words, the PF-BS achieved the strongest stiffness.

- The failure patterns of different fiber-reinforced biocemented sands indicated that the glass fiber and polyester fiber were more effective in improving the properties of the biocemented sand. The failure form of the samples mixed with these two types of fibers was damaged by splitting failure at the maximum unconfined compressive strength, while the hemp fiber sample was damaged by shear failure. The BS was damaged by partial failure. Therefore, the fiber-reinforced biocemented sands displayed better integrity after damage.

- The digital LED microscope and SEM scanning images demonstrated that the calcite on the fiber and sand contacts formed a bonding effect between fiber and sand grains, which was identified as the key factor for fiber to play a role in biocemented sands. In contrast, in the case of hemp fiber, little calcite precipitation was noted around it, leading to a poor bonding effect. It was speculated that hemp fiber was smooth compared with glass and polyester fiber, which had a detrimental effect on the retention of bacterial and cementation solution during grouting, so the strength of the HF-BS was reduced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, X.-Z.; Wang, X.; Chen, J.-W.; Wang, R.; Hu, M.-J.; Meng, Q.-S. Experimental study on permeability characteristics of calcareous soil. Bull. Int. Assoc. Eng. Geol. 2017, 77, 1753–1762. [Google Scholar] [CrossRef]

- Jafarian, Y.; Javdanian, H. Dynamic Properties of Calcareous Sand from the Persian Gulf in Comparison with Siliceous Sands Database. Int. J. Civ. Eng. 2019, 18, 245–249. [Google Scholar] [CrossRef]

- Wang, S.; Lei, X.-W.; Meng, Q.; Xu, J.-L.; Xie, L.-F.; Li, Y.-J. Influence of Particle Shape on the Density and Compressive Performance of Calcareous Sand. KSCE J. Civ. Eng. 2019, 24, 49–62. [Google Scholar] [CrossRef]

- Umar, M.; Kassim, K.A.; Chiet, K.T.P. Biological process of soil improvement in civil engineering: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 767–774. [Google Scholar] [CrossRef]

- Phillips, A.J.; Gerlach, R.; Lauchnor, E.; Mitchell, A.C.; Cunningham, A.B.; Spangler, L. Engineered applications of ureolytic biomineralization: A review. Biofouling 2013, 29, 715–733. [Google Scholar] [CrossRef] [PubMed]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Perth, WA, Australia, 2004. [Google Scholar]

- Dejong, J.T.; Soga, K.; Kavazanjian, E.; Burns, S.E.; Van Paassen, L.A.; Al Qabany, A.; Aydilek, A.; Bang, S.S.; Burbank, M.; Caslake, L.F.; et al. Biogeochemical processes and geotechnical ap-plications: Progress, opportunities and challenges. Geotechnique 2013, 63, 287–301. [Google Scholar] [CrossRef]

- DeJong, J.T.; Fritzges, M.B.; Nüsslein, K. Microbially Induced Cementation to Control Sand Response to Undrained Shear. J. Geotech. Geoenviron. Eng. 2006, 132, 1381–1392. [Google Scholar] [CrossRef]

- Whiffin, V.S.; Van Paassen, L.A.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- van Paassen, L.A.; Ghose, R.; van der Linden, T.J.M.; van der Star, W.R.L.; van Loosdrecht, M.C.M. Quantifying Biome-diated Ground Improvement by Ureolysis: Large-Scale Biogrout Experiment. J. Geotech. Geoenviron. Eng. 2010, 136, 1721–1728. [Google Scholar] [CrossRef]

- Van Wijngaarden, W.K.; Vermolen, F.; Van Meurs, G.A.M.; Vuik, C. Modelling Biogrout: A New Ground Improvement Method Based on Microbial-Induced Carbonate Precipitation. Transp. Porous Media 2010, 87, 397–420. [Google Scholar] [CrossRef]

- Montoya, B.M.; DeJong, J.T. Stress-Strain Behavior of Sands Cemented by Microbially Induced Calcite Precipitation. J. Geotech. Geoenviron. Eng. 2015, 141, 04015019. [Google Scholar] [CrossRef]

- Chu, J.; Ivanov, V.; Stabnikov, V.; Li, B. Microbial method for construction of an aquaculture pond in sand. Bio- and Chemo-Mech. Process. Geotech. Eng. 2014, 63, 215–219. [Google Scholar] [CrossRef]

- Cuthbert, M.O.; McMillan, L.A.; Handley-Sidhu, S.; Riley, M.S.; Tobler, D.J.; Phoenix, V.R. A Field and Modeling Study of Fractured Rock Permeability Reduction Using Microbially Induced Calcite Precipitation. Environ. Sci. Technol. 2013, 47, 13637–13643. [Google Scholar] [CrossRef] [PubMed]

- Phillips, A.J.; Cunningham, A.B.; Gerlach, R.; Hiebert, R.; Hwang, C.; Lomans, B.P.; Westrich, J.; Mantilla, C.; Kirksey, J.; Esposito, R.; et al. Fracture Sealing with Microbially-Induced Calcium Carbonate Precipitation: A Field Study. Environ. Sci. Technol. 2016, 50, 4111–4117. [Google Scholar] [CrossRef] [PubMed]

- Minto, J.M.; Lunn, R.J.; El Mountassir, G. Development of a Reactive Transport Model for Field-Scale Simulation of Microbially Induced Carbonate Precipitation. Water Resour. Res. 2019, 55, 7229–7245. [Google Scholar] [CrossRef]

- Montoya, B.M.; Dejong, J.T.; Boulanger, R.W.; Wilson, D.W.; Gerhard, R.; Chou, J.-C. In Liquefaction Mitigation Using Microbial Induced Calcite Precipitation. GeoCongress 2012, 1918–1927. [Google Scholar] [CrossRef]

- Montoya, B.M.; DeJong, J.T.; Boulanger, R.W. Dynamic response of liquefiable sand improved by microbial-induced calcite precipitation. Bio- Chemo-Mech. Proc. Geotech. Eng. 2014, 63, 125–135. [Google Scholar] [CrossRef]

- Xiao, P.; Liu, H.; Xiao, Y.; Stuedlein, A.W.; Evans, T.M. Liquefaction resistance of bio-cemented calcareous sand. Soil Dyn. Earthq. Eng. 2018, 107, 9–19. [Google Scholar] [CrossRef]

- Wang, J.; Ersan, Y.C.; Boon, N.; De Belie, N. Application of microorganisms in concrete: A promising sustainable strategy to improve concrete durability. Appl. Microbiol. Biotechnol. 2016, 100, 2993–3007. [Google Scholar] [CrossRef]

- Zhang, Z.; Weng, Y.; Ding, Y.; Qian, S. Use of Genetically Modified Bacteria to Repair Cracks in Concrete. Materials 2019, 12, 3912. [Google Scholar] [CrossRef]

- Chen, H.-J.; Peng, C.-F.; Tang, C.-W.; Chen, Y.-T. Self-Healing Concrete by Biological Substrate. Materials 2019, 12, 4099. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.-G.; Wang, K.; Chu, J. Properties of biocemented, fiber reinforced sand. Constr. Build. Mater. 2016, 120, 623–629. [Google Scholar] [CrossRef]

- Choi, S.-G.; Hoang, T.; Alleman, E.J.; Chu, J. Splitting Tensile Strength of Fiber-Reinforced and Biocemented Sand. J. Mater. Civ. Eng. 2019, 31, 06019007. [Google Scholar] [CrossRef]

- Xiao, Y.; He, X.; Evans, T.M.; Stuedlein, A.W.; Liu, H. Unconfined Compressive and Splitting Tensile Strength of Basalt Fiber–Reinforced Biocemented Sand. J. Geotech. Geoenviron. Eng. 2019, 145, 04019048. [Google Scholar] [CrossRef]

- Imran, A.; Gowthaman, S.; Nakashima, K.; Kawasaki, S. The Influence of the Addition of Plant-Based Natural Fibers (Jute) on Biocemented Sand Using MICP Method. Materials 2020, 13, 4198. [Google Scholar] [CrossRef]

- Benessalah, I.; Arab, A.; Villard, P.; Sadek, M.; Kadri, A. Laboratory Study on Shear Strength Behaviour of Reinforced Sandy Soil: Effect of Glass-Fibre Content and Other Parameters. Arab. J. Sci. Eng. 2015, 41, 1343–1353. [Google Scholar] [CrossRef]

- Orakoglu, M.E.; Liu, J.; Niu, F. Dynamic behavior of fiber-reinforced soil under freeze-thaw cycles. Soil Dyn. Earthq. Eng. 2017, 101, 269–284. [Google Scholar] [CrossRef]

- Wang, L.; He, C. Thermal and wear behavior of three inorganic fiber-reinforced wood-plastic composites in simulated soil aging conditions. Polym. Test. 2019, 80, 106129. [Google Scholar] [CrossRef]

- Chaduvula, U.; Viswanadham, B.; Kodikara, J. A study on desiccation cracking behavior of polyester fiber-reinforced expansive clay. Appl. Clay Sci. 2017, 142, 163–172. [Google Scholar] [CrossRef]

- Lv, X.; Zhou, H. Shear Characteristics of Cement-Stabilized Sand Reinforced with Waste Polyester Fiber Fabric Blocks. Adv. Mater. Sci. Eng. 2019, 2019, 3758413. [Google Scholar] [CrossRef]

- Diab, A.A.; Najjar, S.S.; Sadek, S.; Taha, H.; Jaffal, H.; Alahmad, M. Effect of compaction method on the undrained strength of fiber-reinforced clay. Soils Found. 2018, 58, 462–480. [Google Scholar] [CrossRef]

- Ammar, A.; Najjar, S.S.; Sadek, S. Mechanics of the Interface Interaction between Hemp Fibers and Compacted Clay. Int. J. Géoméch. 2019, 19, 04019015. [Google Scholar] [CrossRef]

- Soon, N.W.; Lee, L.M.; Khun, T.C.; Ling, H.S. Factors Affecting Improvement in Engineering Properties of Residual Soil through Microbial-Induced Calcite Precipitation. J. Geotech. Geoenviron. Eng. 2014, 140, 04014006. [Google Scholar] [CrossRef]

- Ahmad, F.; Mujah, D.; Hazarika, H.; Safari, A. Assessing the potential reuse of recycled glass fibre in problematic soil appli-cations. J. Clean. Prod. 2012, 35, 102–107. [Google Scholar] [CrossRef]

- Xiao, P.; Liu, H.; Stuedlein, A.W.; Evans, T.M.; Xiao, Y. Effect of relative density and biocementation on cyclic response of calcareous sand. Can. Geotech. J. 2019, 56, 1849–1862. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, C.; Sun, Y.; Wang, S.; Wu, H.; Chen, H.; Liu, H. Compression behavior of MICP-treated sand with various gradations. Acta Geotech. 2020, 1–10. [Google Scholar] [CrossRef]

- Manzur, T.; Rahman, F.; Afroz, S.; Huq, R.S.; Efaz, I.H. Potential of a Microbiologically Induced Calcite Precipitation Process for Durability Enhancement of Masonry Aggregate Concrete. J. Mater. Civ. Eng. 2017, 29, 04016290. [Google Scholar] [CrossRef]

- Prabakar, J.; Sridhar, R. Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Akbulut, S.; Arasan, S.; Kalkan, E. Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl. Clay Sci. 2007, 38, 23–32. [Google Scholar] [CrossRef]

- Fang, X.; Yang, Y.; Chen, Z.; Liu, H.; Xiao, Y.; Shen, C. Influence of Fiber Content and Length on Engineering Properties of MICP-Treated Coral Sand. Geomicrobiol. J. 2020, 37, 582–594. [Google Scholar] [CrossRef]

- Xie, Y.; Tang, C.; Yin, L.; Lv, C.; Jiang, N.; Shi, B. Mechanical behavior of microbial-induced calcite precipitation (MICP)-treated soil with fiber reinforcement. Chi. J. Geotech. Eng. 2019, 41, 675–682. [Google Scholar] [CrossRef]

- Qiu, R.; Tong, H.; Gu, M.; Yuan, J. Strength and Micromechanism Analysis of Microbial Solidified Sand with Carbon Fiber. Adv. Civ. Eng. 2020, 2020, 1–10. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Specific gravity Gs | 2.76 |

| Maximum dry density (g/cm3) | 1.524 |

| Minimum dry density (g/cm3) | 1.230 |

| d10 (mm) | 0.26 |

| d30 (mm) | 0.42 |

| d60 (mm) | 0.58 |

| Uniformity coefficient Cu | 2.231 |

| Coefficient of curvature Cc | 1.170 |

| Fiber Types | Color | Length (mm) | Tensile Strength (MPa) | Density (g/cm3) | Modulus of Elasticity (GPa) | Fusion Point (°C) | Elongation (%) |

|---|---|---|---|---|---|---|---|

| Glass fiber | White | 6 | 346 | 0.91 | 4.286 | 169 | 36.4 |

| Polyester fiber | White | 6 | 550 | 1.36 | 13.500 | 259 | 13.8 |

| Hemp fiber | Yellow | 6 | 255 | 1.12 | 5.369 | 189 | 26.6 |

| Group | Test No. | Fiber Content (%) | Dr a (%) | m b (g) | c (g/cm3) | ωd (%) | UCS e (MPa) | Modulus of Elasticity (MPa) |

|---|---|---|---|---|---|---|---|---|

| Biocemented sand (BS) | BS | 0 | 48 | 24.86 | 1.676 | 21.81 | 1.343 | 59.848 |

| Glass fiber biocemented sand (GF-BS) | GF-BS-1 | 0.10 | 49 | 25.14 | 1.689 | 20.15 | 1.329 | 64.577 |

| GF-BS-2 | 0.15 | 50 | 26.73 | 1.706 | 19.99 | 1.448 | 50.121 | |

| GF-BS-3 | 0.20 | 49 | 26.04 | 1.737 | 19.28 | 1.668 | 58.940 | |

| GF-BS-4 | 0.25 | 48 | 24.58 | 1.684 | 22.11 | 1.593 | 61.553 | |

| GF-BS-5 | 0.30 | 49 | 24.77 | 1.676 | 22.68 | 1.464 | 63.076 | |

| GF-BS-6 | 0.35 | 49 | 24.02 | 1.654 | 22.62 | 1.253 | 56.929 | |

| GF-BS-7 | 0.40 | 50 | 24.12 | 1.612 | 23.73 | 1.223 | 62.176 | |

| Polyester fiber biocemented sand (PF-BS) | PF-BS-1 | 0.10 | 49 | 26.33 | 1.707 | 21.37 | 1.502 | 66.080 |

| PF-BS-2 | 0.15 | 48 | 27.14 | 1.711 | 21.10 | 1.547 | 64.566 | |

| PF-BS-3 | 0.20 | 50 | 27.31 | 1.724 | 18.67 | 1.729 | 64.732 | |

| PF-BS-4 | 0.25 | 49 | 28.48 | 1.839 | 17.19 | 2.159 | 60.544 | |

| PF-BS-5 | 0.30 | 50 | 25.42 | 1.742 | 20.58 | 1.645 | 66.626 | |

| PF-BS-6 | 0.35 | 48 | 25.04 | 1.701 | 21.42 | 1.329 | 64.421 | |

| PF-BS-7 | 0.40 | 49 | 25.26 | 1.707 | 21.23 | 1.184 | 63.147 | |

| Hemp fiber biocemented sand (HF-BS) | HF-BS-1 | 0.10 | 49 | 23.32 | 1.641 | 22.09 | 0.944 | 49.710 |

| HF-BS-2 | 0.15 | 50 | 23.97 | 1.649 | 22.27 | 0.980 | 54.657 | |

| HF-BS-3 | 0.20 | 48 | 23.87 | 1.705 | 20.22 | 1.271 | 56.289 | |

| HF-BS-4 | 0.25 | 49 | 25.84 | 1.657 | 22.01 | 1.429 | 60.397 | |

| HF-BS-5 | 0.30 | 50 | 24.05 | 1.673 | 21.95 | 1.152 | 60.663 | |

| HF-BS-6 | 0.35 | 50 | 24.36 | 1.640 | 22.51 | 0.975 | 63.976 | |

| HF-BS-7 | 0.40 | 49 | 23.60 | 1.580 | 23.51 | 0.935 | 56.804 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Tong, H.; Shan, Y.; Yuan, J.; Peng, Q.; Liang, J. Effects of Different Types of Fibers on the Physical and Mechanical Properties of MICP-Treated Calcareous Sand. Materials 2021, 14, 268. https://doi.org/10.3390/ma14020268

Zhao J, Tong H, Shan Y, Yuan J, Peng Q, Liang J. Effects of Different Types of Fibers on the Physical and Mechanical Properties of MICP-Treated Calcareous Sand. Materials. 2021; 14(2):268. https://doi.org/10.3390/ma14020268

Chicago/Turabian StyleZhao, Jitong, Huawei Tong, Yi Shan, Jie Yuan, Qiuwang Peng, and Junling Liang. 2021. "Effects of Different Types of Fibers on the Physical and Mechanical Properties of MICP-Treated Calcareous Sand" Materials 14, no. 2: 268. https://doi.org/10.3390/ma14020268

APA StyleZhao, J., Tong, H., Shan, Y., Yuan, J., Peng, Q., & Liang, J. (2021). Effects of Different Types of Fibers on the Physical and Mechanical Properties of MICP-Treated Calcareous Sand. Materials, 14(2), 268. https://doi.org/10.3390/ma14020268