Shape Memory and Mechanical Properties of Cold Rolled and Annealed Fe-17Mn-5Si-5Cr-4Ni-1Ti-0.3C Alloy

Abstract

1. Introduction

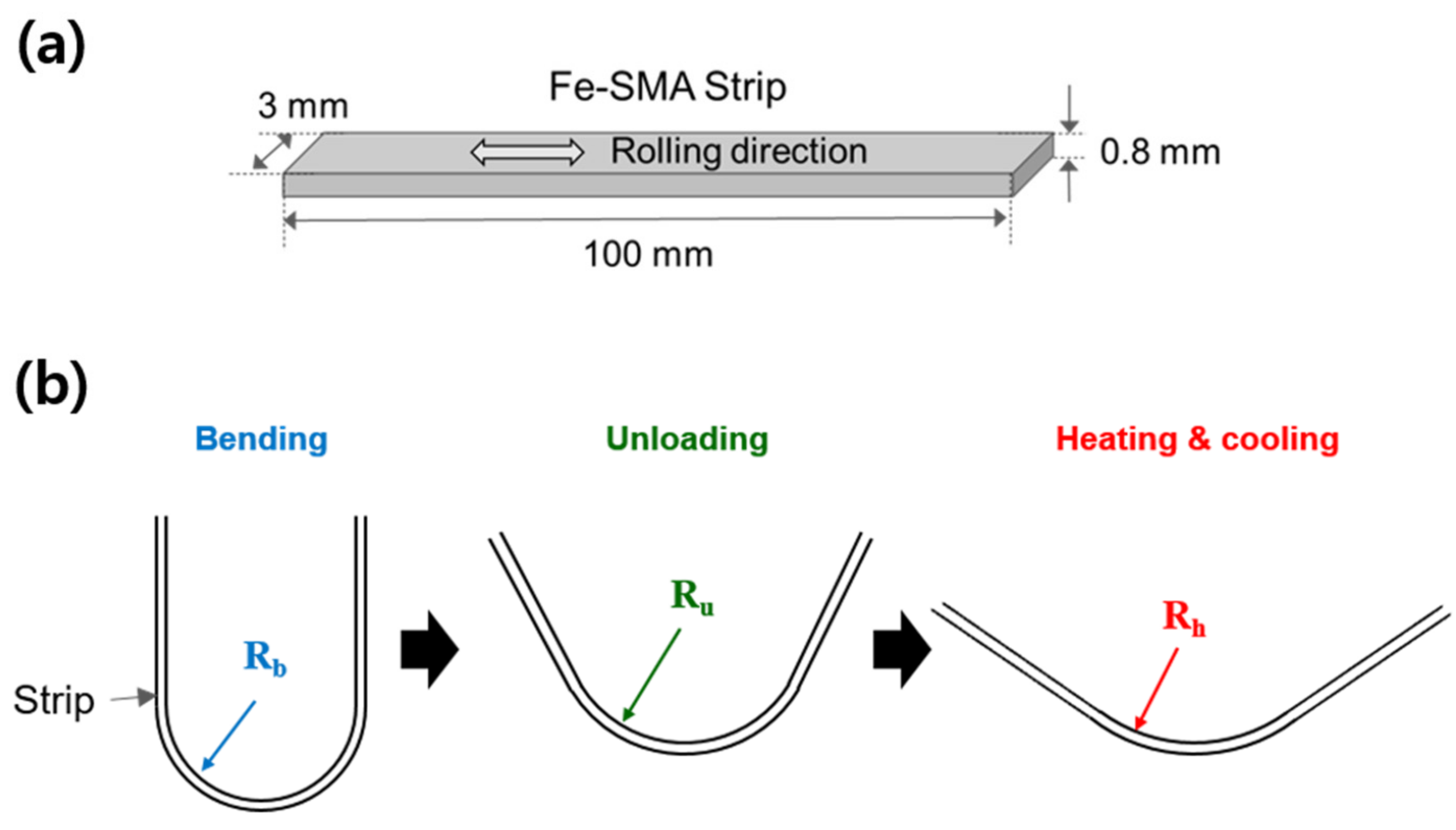

2. Materials and Methods

3. Results and Discussions

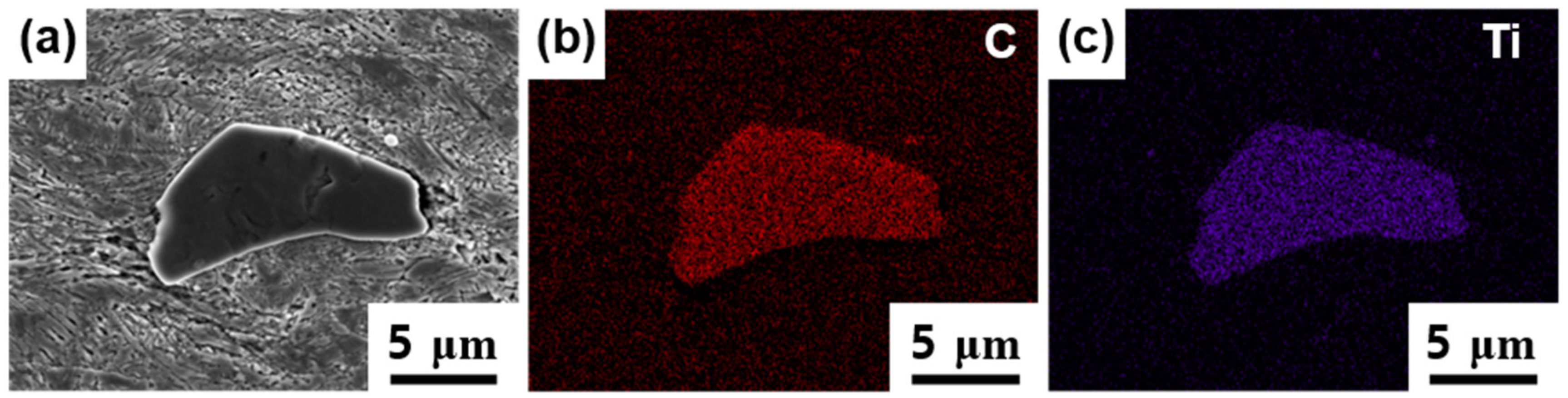

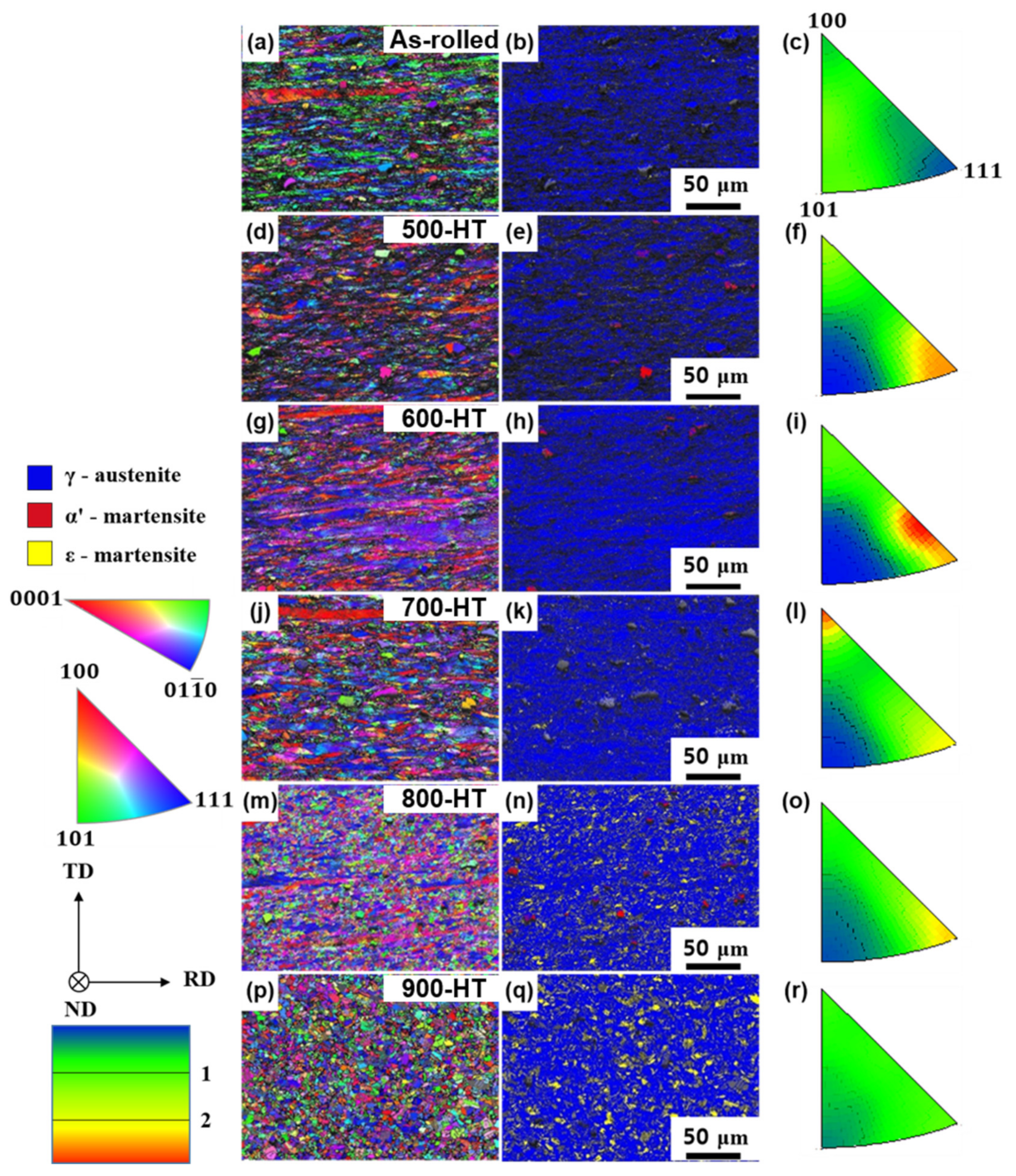

3.1. Microstructures

3.2. Shape Recovery Behavior

3.3. Mechanical Properties

4. Summary

- The Fe-SMA containing TiC showed a strong work hardening capability. The Fe-SMA cold-rolled to 10% reduction of the thickness exhibited a yield strength over 900 MPa, which is more than 1.5 times larger than the strength of the same hot-rolled alloy.

- The alloy in the as-rolled state exhibited very small shape recovery, i.e., less than 0.5% while heating to 400 °C. This result indicates that microstructural defects such as dislocations and shear bands produced during the severe plastic deformation by cold-rolling suppressed the γ to ε phase transformation. When the heat-treated alloy was annealing heat-treated, pronounced shape recovery took place. Increasing the annealing temperature resulted in a sharp increase in the shape recovery and then a decrease due to recrystallization.

- When the alloy was annealing heat-treated at a temperature range of 500–700 °C, there were strong {111}//RD and {100}//RD crystallographic textures due to the severe cold-rolling process. The intensities of the textures decreased when the alloy was annealed at above 800 °C due to the recrystallization. However, the texture effect was not prominent in determining the recovery strain.

- The hardness and the yield strength of the alloy gradually decreased with increasing annealing temperature. In reviewing the application of this alloy as a prestressing reinforcement of concrete structures, annealing at 500 or 600 °C seems to be effective in obtaining a large recovery stress. In these annealing conditions, a good combination of yield strength near 700 MPa and ductility higher than 20% are obtained.

- The largest shape recovery was obtained by annealing the alloy at 700 °C. In this condition, the Fe-SMA exhibited a large recovery strain of up to 2.5%, comparably low yield strength of approximately 500 MPa, and excellent ductility over 30%. This annealing condition would be favored for the applications where a large shape recovery is required, e.g., for joint components or pipe clamping.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sato, A.; Chishima, E.; Soma, K.; Mori, T. Shape memory effect in γ⇄ϵ transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall. 1982, 30, 1177–1183. [Google Scholar] [CrossRef]

- Lee, W.J.; Weber, B.; Leinenbach, C. Recovery stress formation in a restrained Fe-Mn-Si-based shape memory alloy used for prestressing or mechanical joining. Constr. Build. Mater. 2015, 95, 600–610. [Google Scholar] [CrossRef]

- Rong, L.J.; Ping, D.H.; Li, Y.Y.; Shi, C.X. Improvement of shape memory effect in Fe-Mn-Si alloy by Cr and Ni addition. Scr. Metall. Mater. 1995, 32, 1905–1909. [Google Scholar] [CrossRef]

- Otsuka, H.; Yamada, H.; Tanahashi, H.; Maruyama, T. Shape Memory Effect in Fe-Mn-Si-Cr-Ni Polycrystalline Alloys. Mater. Sci. Forum 1991, 56–58, 655–660. [Google Scholar] [CrossRef]

- Janke, L.; Czaderski, C.; Motavalli, M.; Ruth, J. Applications of shape memory alloys in civil engineering structures—Overview, limits and new ideas. Mater. Struct. 2005, 38, 578–592. [Google Scholar]

- Dong, Z.; Klotz, U.E.; Leinenbach, C.; Bergamini, A.; Czaderski, C.; Motavalli, M. A novel Fe-Mn-Si shape memory alloy with improved shape recovery properties by VC precipitation. Adv. Eng. Mater. 2009, 11, 40–44. [Google Scholar] [CrossRef]

- Lee, W.J.; Weber, B.; Feltrin, G.; Czaderski, C.; Motavalli, M.; Leinenbach, C. Phase transformation behavior under uniaxial deformation of an Fe-Mn-Si-Cr-Ni-VC shape memory alloy. Mater. Sci. Eng. A 2013, 581, 1–7. [Google Scholar] [CrossRef]

- Weber, B.; Feltrin, G.; Lee, W.J.; Czaderski, C.; Motavalli, M.; Leinenbach, C.; Weber, B.; Feltrin, G.; Czaderski, C.; Motavalli, M.; et al. Stress recovery behaviour of an Fe–Mn–Si–Cr–Ni–VC shape memory alloy used for prestressing. Smart Mater. Struct. 2013, 22, 125037–125045. [Google Scholar]

- Leinenbach, C.; Lee, W.J.; Lis, A.; Arabi-Hashemi, A.; Cayron, C.; Weber, B. Creep and stress relaxation of a FeMnSi-based shape memory alloy at low temperatures. Mater. Sci. Eng. A 2016, 677, 106–115. [Google Scholar] [CrossRef]

- Arabi-Hashemi, A.; Lee, W.J.; Leinenbach, C. Recovery stress formation in FeMnSi based shape memory alloys: Impact of precipitates, texture and grain size. Mater. Des. 2018, 139, 258–268. [Google Scholar] [CrossRef]

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. Constr. Build. Mater. 2014, 63, 281–293. [Google Scholar] [CrossRef]

- Koster, M.; Lee, W.W.J.; Schwarzenberger, M.; Leinenbach, C. Cyclic deformation and structural fatigue behavior of an FE–Mn–Si shape memory alloy. Mater. Sci. Eng. A 2015, 637, 29–39. [Google Scholar] [CrossRef]

- Lee, W.J.; Partovi-Nia, R.; Suter, T.; Leinenbach, C. Electrochemical characterization and corrosion behavior of an Fe-Mn-Si shape memory alloy in simulated concrete pore solutions. Mater. Corros. 2016, 67, 839–846. [Google Scholar] [CrossRef]

- Kajiwara, S.; Liu, D.; Kikuchi, T.; Shinya, N. Remarkable improvement of shape memory effect in Fe-Mn-Si based shape memory alloys by producing NbC precipitates. Scr. Mater. 2001, 44, 2809–2814. [Google Scholar] [CrossRef]

- Dong, Z.Z.; Kajiwara, S.; Kikuchi, T.; Sawaguchi, T. Effect of pre-deformation at room temperature on shape memory properties of stainless type Fe-15Mn-5Si-9Cr-5Ni-(0.5-1.5)NbC alloys. Acta Mater. 2005, 53, 4009–4018. [Google Scholar] [CrossRef]

- Farjami, S.; Hiraga, K.; Kubo, H. Shape Memory Effect and Crystallographic Investigation in VN Containing Fe-Mn-Si-Cr Alloys. Mater. Trans. 2004, 45, 930–935. [Google Scholar] [CrossRef]

- Leinenbach, C.; Kramer, H.; Bernhard, C.; Eifler, D. Thermo-mechanical properties of an Fe-Mn-Si-Cr-Ni-VC shape memory alloy with low transformation temperature. Adv. Eng. Mater. 2012, 14, 62–67. [Google Scholar] [CrossRef]

- Hong, K.N.; Yeon, Y.M.; Shim, W.B.; Kim, D.H. Recovery behavior of fe-based shape memory alloys under different restraints. Appl. Sci. 2020, 10, 3441. [Google Scholar] [CrossRef]

- Hong, K.N.; Yeon, Y.M.; Shim, W.B.; Ji, S.W. Fatigue characteristics of Fe-based shape-memory alloys. Appl. Sci. 2020, 10, 5812. [Google Scholar] [CrossRef]

- KSA. 0801 Test Pieces for Tensile Test for Metallic Materials 2007; KSA: Seoul, Korea, 2007. [Google Scholar]

- Stanford, N.E.; Chen, K.; Dunne, D.P.; Jin, X.-J. Effect of Alloying Additions on the SFE, Neel Temperature and Shape Memory Effect in Fe-Mn-Si-based Alloys. ISIJ Int. 2007, 47, 883–889. [Google Scholar] [CrossRef]

- Lim, Y.G.; Han, S.H.; Choi, E.; Kim, W.J. Shape memory and superelasticity of nanograined Ti-51.2 at.% Ni alloy processed by severe plastic deformation via high-ratio differential speed rolling. Mater. Charact. 2018, 145, 284–293. [Google Scholar] [CrossRef]

- Leinenbach, C.; Arabi-Hashemi, A.; Lee, W.J.; Lis, A.; Sadegh-Ahmadi, M.; Van Petegem, S.; Panzner, T.; Van Swygenhoven, H. Characterization of the deformation and phase transformation behavior of VC-free and VC-containing FeMnSi-based shape memory alloys by in situ neutron diffraction. Mater. Sci. Eng. A 2017, 703, 314–323. [Google Scholar] [CrossRef]

- Johnson, W.; Mellor, P.B. Engineering Plasticity; Ellis Horwood Limited: Van Nostrand Reinhold, UK, 1973. [Google Scholar]

| Elements | Fe | Mn | Si | Cr | Ni | Ti | C |

|---|---|---|---|---|---|---|---|

| Contents (wt.%) | balance | 17 | 5 | 5 | 4 | 1 | 0.3 |

| EBSD Phase Fraction (%). | As-Rolled | 500-HT | 600-HT | 700-HT | 800-HT | 900-HT |

|---|---|---|---|---|---|---|

| γ-austenite | 37.52 | 32.00 | 53.71 | 58.54 | 63.52 | 65.51 |

| ε-martensite | 0.16 | 0.72 | 0.29 | 0.78 | 8.81 | 10.86 |

| α′-martensite | 0.86 | 0.7 | 0.54 | 1.18 | 0.71 | 0.57 |

| Non-indexed | 61.45 | 66.55 | 45.45 | 39.50 | 26.96 | 23.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.; Hong, K.; Sim, J.; Lee, J.; Lee, W. Shape Memory and Mechanical Properties of Cold Rolled and Annealed Fe-17Mn-5Si-5Cr-4Ni-1Ti-0.3C Alloy. Materials 2021, 14, 255. https://doi.org/10.3390/ma14020255

Kim D, Hong K, Sim J, Lee J, Lee W. Shape Memory and Mechanical Properties of Cold Rolled and Annealed Fe-17Mn-5Si-5Cr-4Ni-1Ti-0.3C Alloy. Materials. 2021; 14(2):255. https://doi.org/10.3390/ma14020255

Chicago/Turabian StyleKim, Dohyung, Kinam Hong, Jeesoo Sim, Junghoon Lee, and Wookjin Lee. 2021. "Shape Memory and Mechanical Properties of Cold Rolled and Annealed Fe-17Mn-5Si-5Cr-4Ni-1Ti-0.3C Alloy" Materials 14, no. 2: 255. https://doi.org/10.3390/ma14020255

APA StyleKim, D., Hong, K., Sim, J., Lee, J., & Lee, W. (2021). Shape Memory and Mechanical Properties of Cold Rolled and Annealed Fe-17Mn-5Si-5Cr-4Ni-1Ti-0.3C Alloy. Materials, 14(2), 255. https://doi.org/10.3390/ma14020255