Effect of Steel Fibre Reinforcement on Flexural Fatigue Behaviour of Notched Structural Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

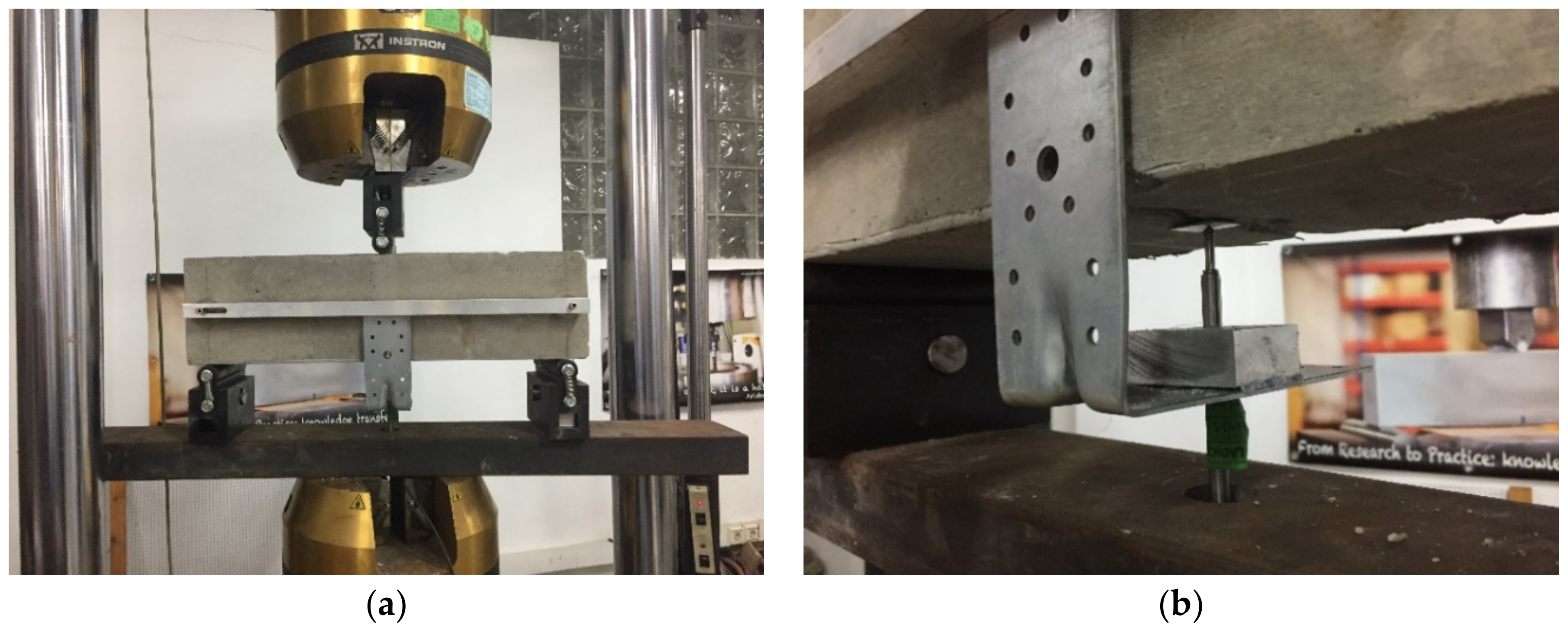

2.2. Methods

2.2.1. Conventional Mechanical Properties

2.2.2. Fatigue Tests

3. Results and Discussion

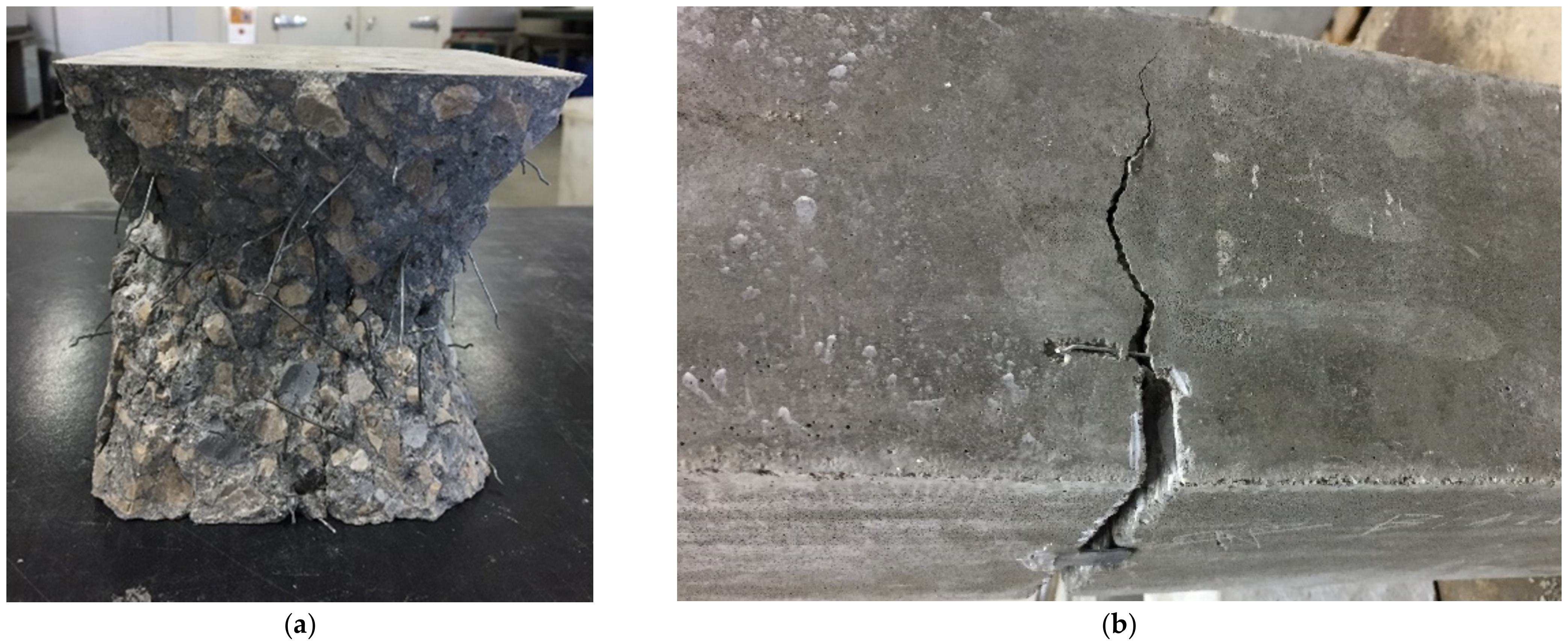

3.1. Mechanical Properties

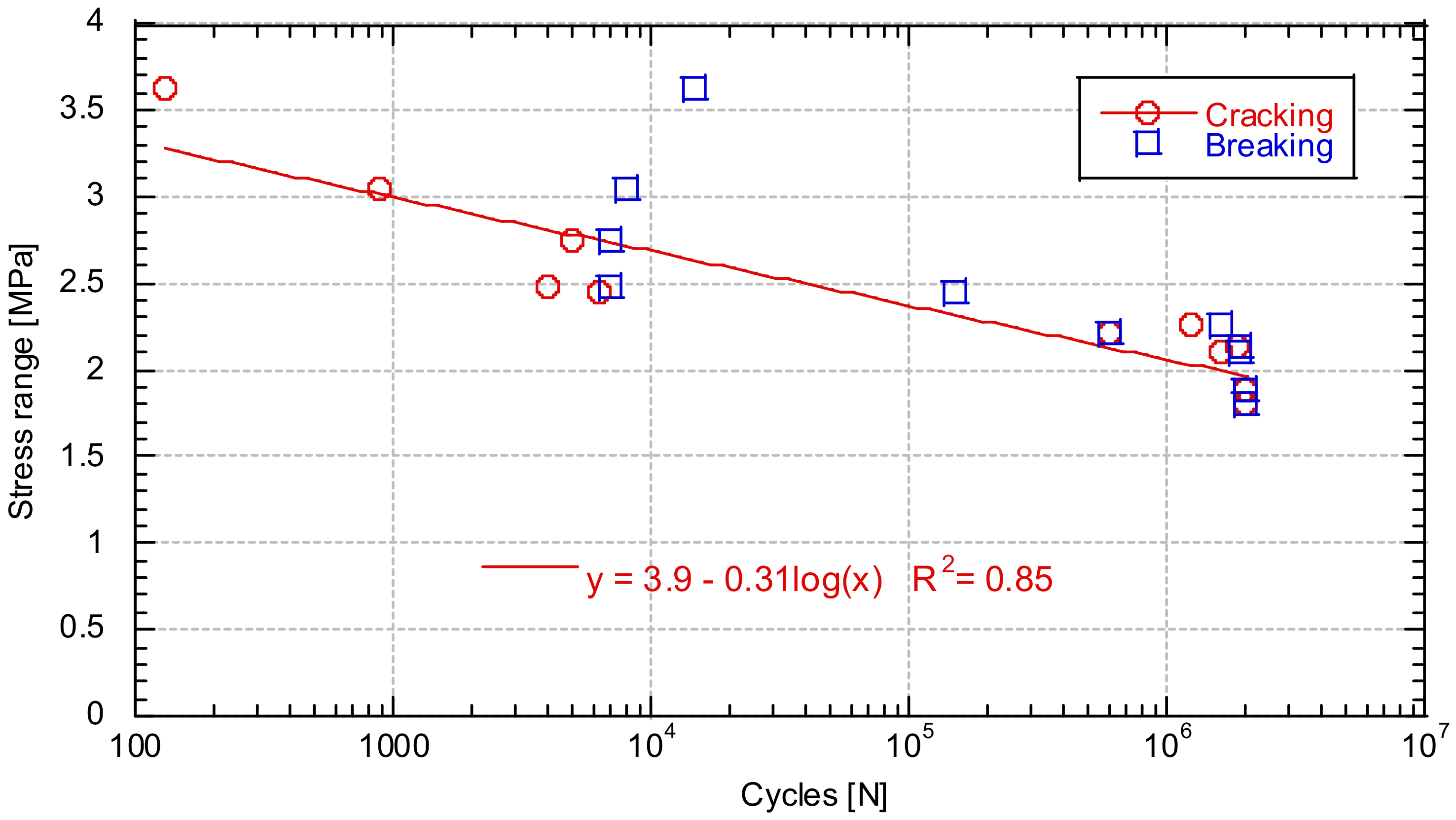

3.2. S-N Curve

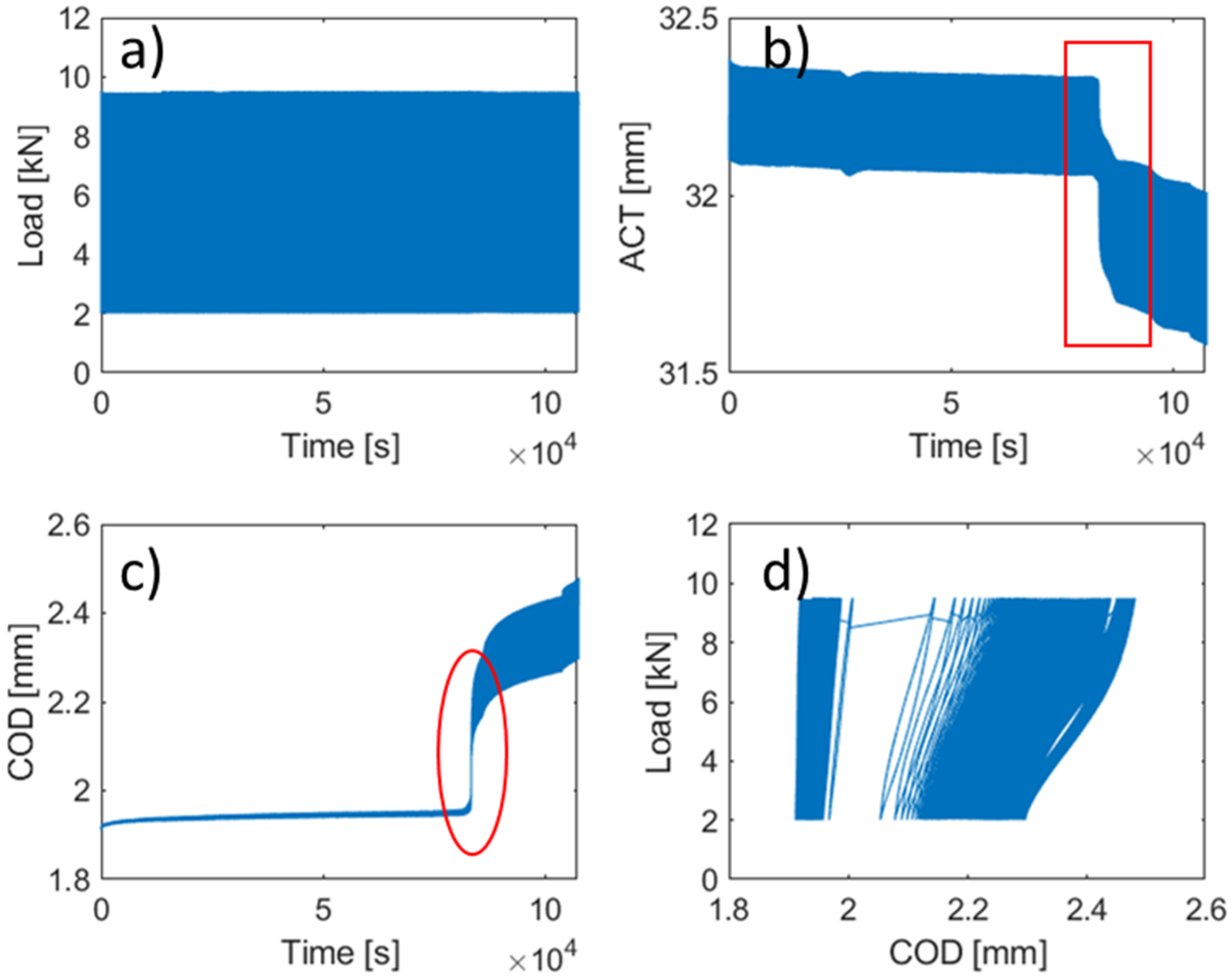

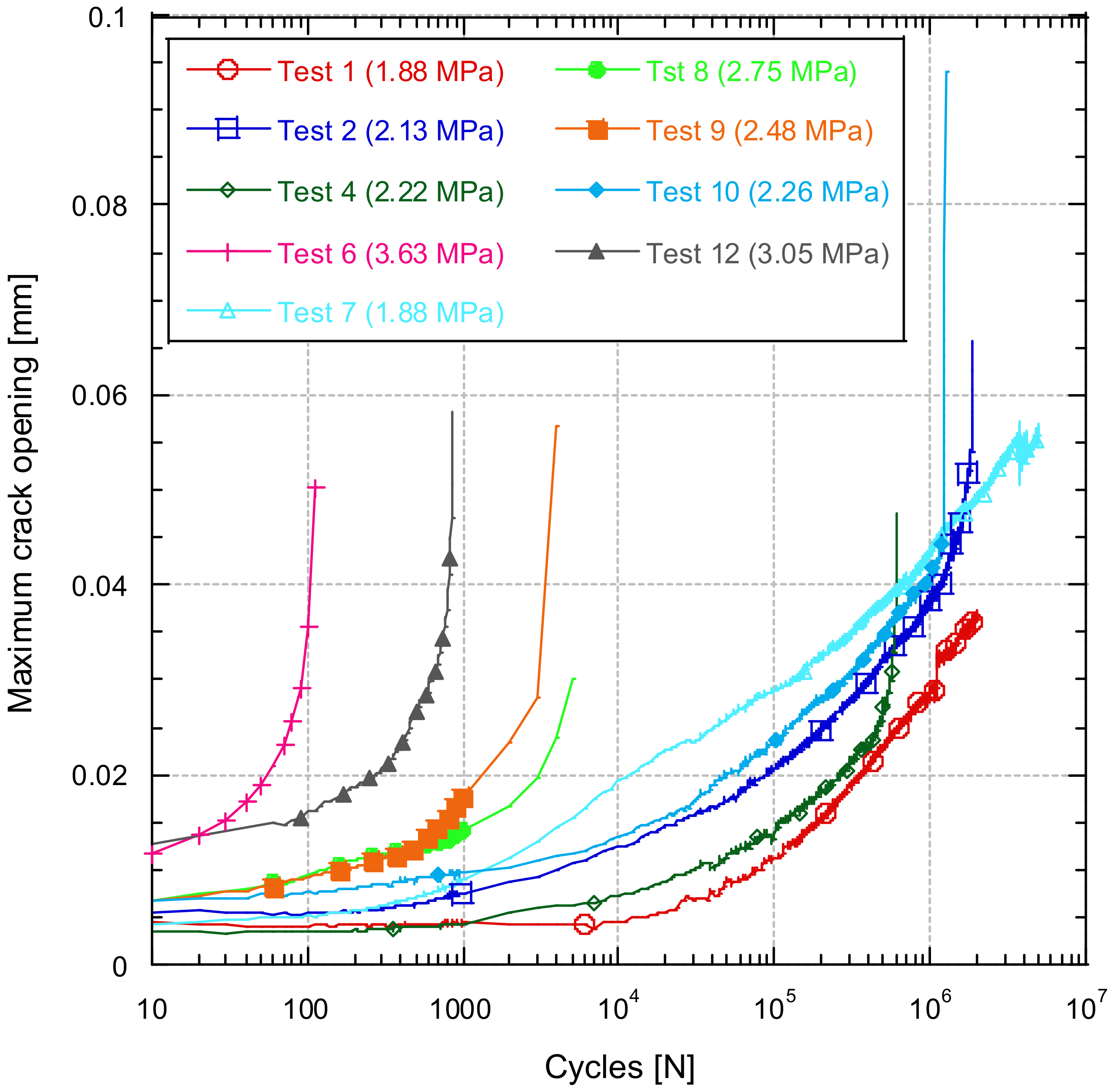

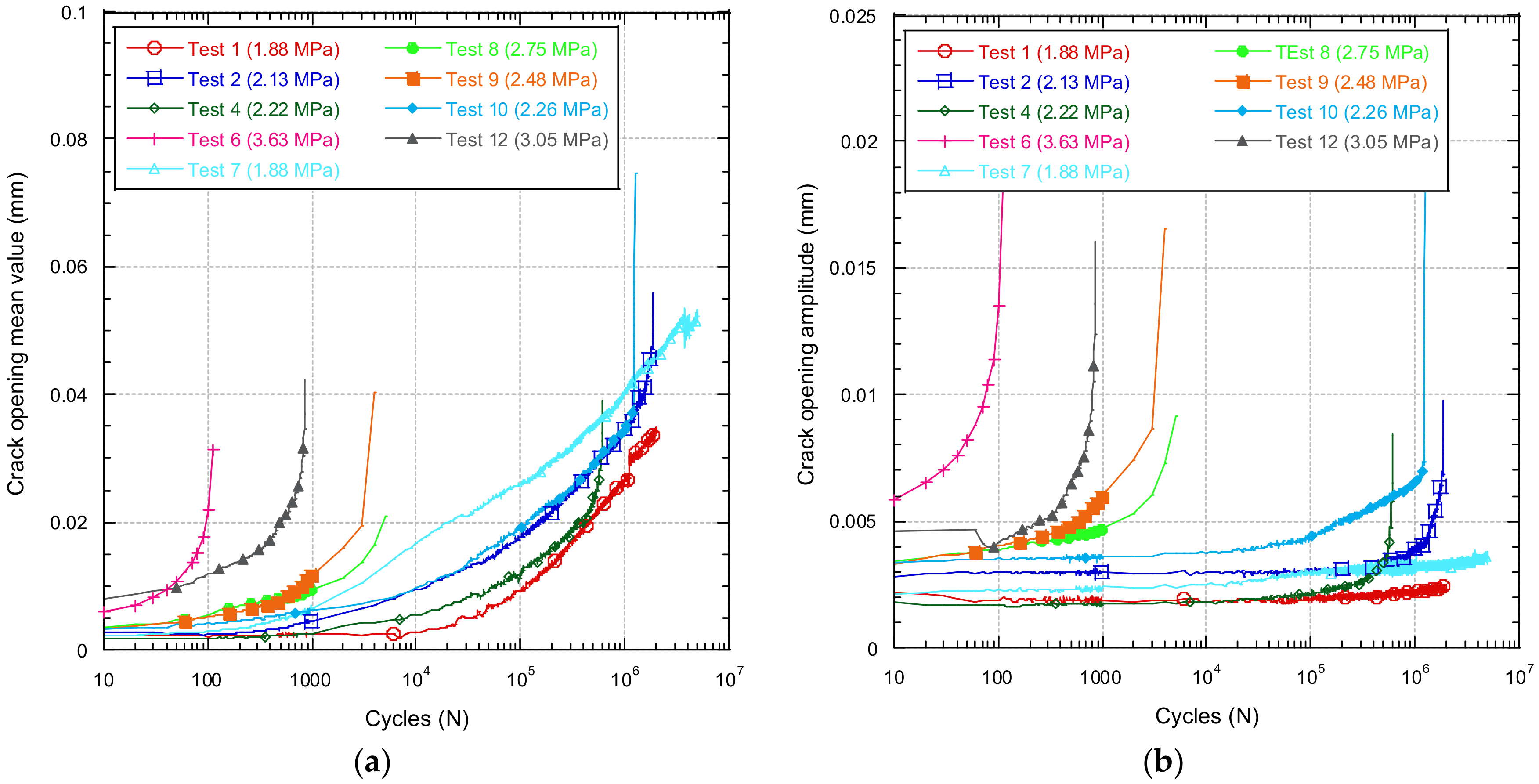

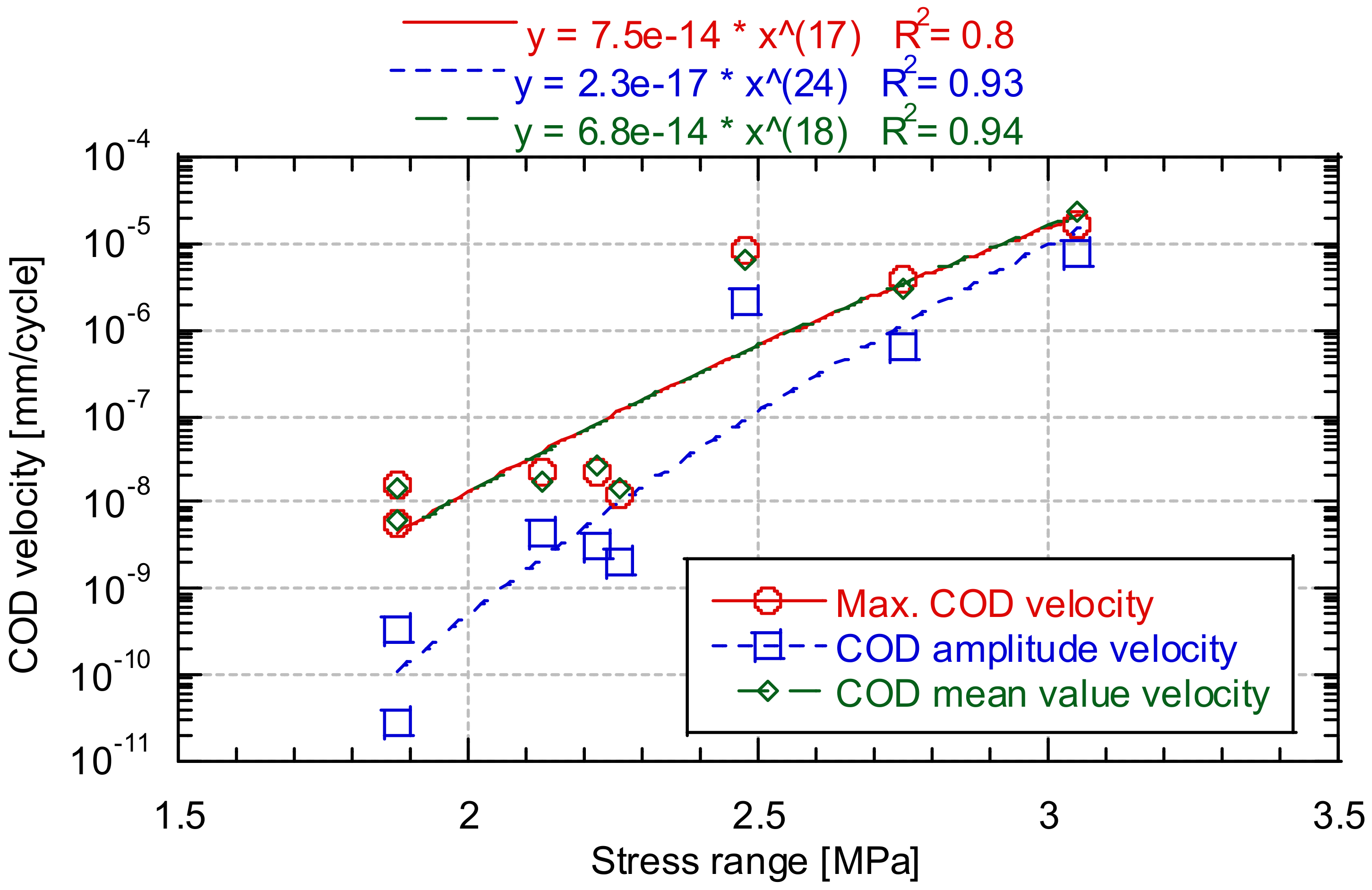

3.3. Crack Opening during the Fatigue Tests

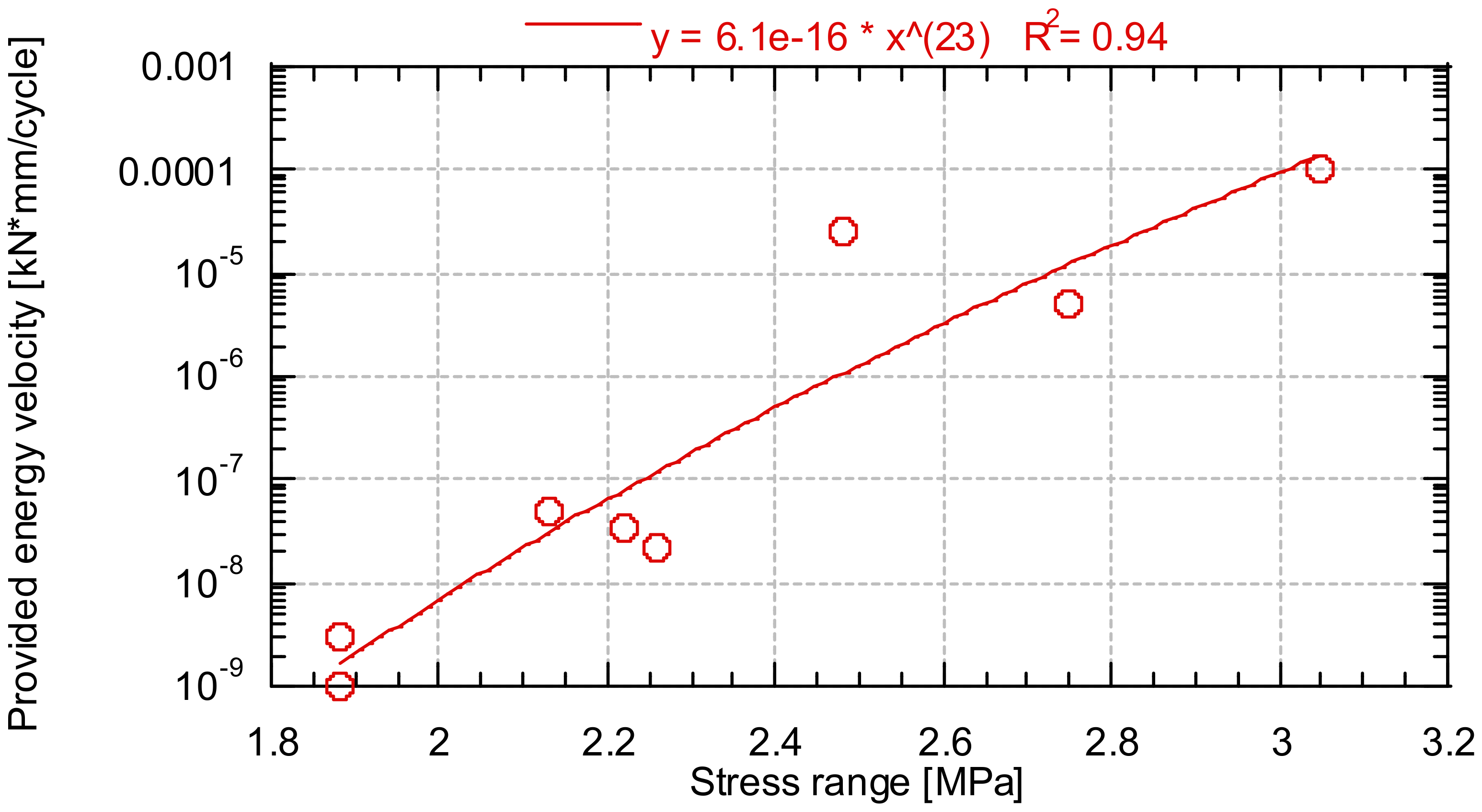

3.4. Energy Evolution during the Fatigue Tests

4. Conclusions

- An S-N curve of the material was obtained before it was cracked. Once the concrete has cracked, the quantity and orientation of the fibres is so important in the response of the concrete to cyclic loads that it leads to extremely heterogeneous behaviour.

- The presence of fibres was proven to increases the fatigue life of concrete, even in tests carried out under load control. This provides a time between the concrete breakage and the structural breakage, which can be used to take appropriate corrective measures.

- A critical crack opening was detected after which concrete cracking occurs, which could be used as an indicator the premature failure of the specimen.

- A critical energy value was observed that indicates that the test specimen will break, so it could be used as a parameter to determine the remaining life of the concrete. However, it should be noted that since it is an energy parameter, it is specific to each geometry.

- It was verified that the mechanism producing failure of the concrete is caused by microcracks inherent to concrete in the notch beginning to grow due to the loads applied. The velocity of growth of the cracks depends on the range of stress applied in the test, a correlation existing between them. However, geometry probably also has an influence.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cao, Q.; Tao, J.; Wu, Z.; Ma, Z.J. Behavior of FRP-Steel Confined Concrete Tubular Columns Made of Expansive Self-Consolidating Concrete under Axial Compression. J. Compos. Constr. 2017, 21, 04017037. [Google Scholar] [CrossRef]

- Tang, Y.; Fang, S.; Chen, J.; Ma, L.; Li, L.; Wu, X. Axial compression behavior of recycled-aggregate-concrete-filled GFRP–steel composite tube columns. Eng. Struct. 2020, 216, 110676. [Google Scholar] [CrossRef]

- Fang, S.; Liu, F.; Xiong, Z.; Fang, J.; Li, L. Seismic performance of recycled aggregate concrete-filled glass fibre-reinforced polymer-steel composite tube columns. Constr. Build. Mater. 2019, 225, 997–1010. [Google Scholar] [CrossRef]

- Spanish Ministry of Public Works. Code on Structural Concrete EHE-08, R. Decree 1247/2008—Bol. Of. del Estado N 203—Spanish; Spanish Ministry of Public Works: Madrid, Spain, 2008.

- Álvarez, A.B.; Álvarez, P.P.; de la Antequera, A.F.; de Cea, A.A. Comparative analysis of constitutive modelsof fibre reinforced concrete. Hormigón Acero 2010, 61, 83–101. [Google Scholar]

- Wong, C.M. Use of Short Fibres in Structural Concrete to Enhance Mechanical Properties. 2004. Available online: https://core.ac.uk/display/11034540 (accessed on 1 October 2021).

- Olivito, R.; Zuccarello, F. An experimental study on the tensile strength of steel fiber reinforced concrete. Compos. Part B Eng. 2010, 41, 246–255. [Google Scholar] [CrossRef]

- Gao, J.; Sun, W.; Morino, K. Mechanical properties of steel fiber-reinforced, high-strength, lightweight concrete. Cem. Concr. Compos. 1997, 19, 307–313. [Google Scholar] [CrossRef]

- Ezeldin, A.S.; Balaguru, P.N. Normal- and High-Strength Fiber-Reinforced Concrete under Compression. J. Mater. Civ. Eng. 1992, 4, 415–429. [Google Scholar] [CrossRef]

- Altun, F.; Haktanir, T. A comparative experimental study of steel fibre-additive reinforced concrete beams. Mater. Constr. 2004, 54, 5–15. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile behavior of Ultra High Performance Hybrid Fiber Reinforced Concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical Properties of Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- Kang, S.-T.; Lee, Y.; Park, Y.-D.; Kim, J.-K. Tensile fracture properties of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) with steel fiber. Compos. Struct. 2010, 92, 61–71. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Li, L.; Wang, H. Improvement effect of steel fiber orientation control on mechanical performance of UHPC. Constr. Build. Mater. 2018, 188, 709–721. [Google Scholar] [CrossRef]

- Nataraja, M.; Dhang, N.; Gupta, A. Stress–strain curves for steel-fiber reinforced concrete under compression. Cem. Concr. Compos. 1999, 21, 383–390. [Google Scholar] [CrossRef]

- Wille, K.; Kim, D.J.; Naaman, A.E. Strain-hardening UHP-FRC with low fiber contents. Mater. Struct. 2011, 44, 583–598. [Google Scholar] [CrossRef]

- Jhatial, A.A.; Inn, G.W.; Mohamad, N.; Alengaram, U.J.; Mo, K.H.; Abdullah, R. Influence of polypropylene fibres on the tensile strength and thermal properties of various densities of foamed concrete. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 12058. [Google Scholar] [CrossRef]

- Jhatial, A.A.; Goh, W.I.; Mohamad, N.; Alengaram, U.J.; Mo, K.H. Effect of Polypropylene Fibres on the Thermal Conductivity of Lightweight Foamed Concrete. MATEC Web Conf. 2018, 150, 03008. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. How do fiber shape and matrix composition affect fiber pullout behavior and flexural properties of UHPC? Cem. Concr. Compos. 2018, 90, 193–201. [Google Scholar] [CrossRef]

- Sainz-Aja, J.; Thomas, C.; Polanco, J.A.; Carrascal, I. High-Frequency Fatigue Testing of Recycled Aggregate Concrete. Appl. Sci. 2019, 10, 10. [Google Scholar] [CrossRef]

- Xiao, J.; Li, H.; Yang, Z. Fatigue behavior of recycled aggregate concrete under compression and bending cyclic loadings. Constr. Build. Mater. 2013, 38, 681–688. [Google Scholar] [CrossRef]

- Alliche, A. Damage model for fatigue loading of concrete. Int. J. Fatigue 2004, 26, 915–921. [Google Scholar] [CrossRef]

- Skarżyński, Ł.; Marzec, I.; Tejchman, J. Fracture evolution in concrete compressive fatigue experiments based on X-ray micro-CT images. Int. J. Fatigue 2019, 122, 256–272. [Google Scholar] [CrossRef]

- Thomas, C.; Sainz-Aja, J.; Setien, J.; Cimentada, A.; Polanco, J. Resonance fatigue testing on high-strength self-compacting concrete. J. Build. Eng. 2021, 35, 102057. [Google Scholar] [CrossRef]

- Sainz-Aja, J.; Thomas, C.; Carrascal, I.; Polanco, J.A.; de Brito, J. Fast fatigue method for self-compacting recycled aggregate concrete characterization. J. Clean. Prod. 2020, 277, 123263. [Google Scholar] [CrossRef]

- Ferreño, D.; Casado, J.A.; Carrascal, I.A.; Diego, S.; Ruiz, E.; Saiz, M.; Sainz-Aja, J.A.; Cimentada, A.I. Experimental and finite element fatigue assessment of the spring clip of the SKL-1 railway fastening system. Eng. Struct. 2019, 188, 553–563. [Google Scholar] [CrossRef]

- Peña-Manjarrez, J. Cysts of lingulodinium polyedrum, red tide producing organism in the todos santos bay (winter-spring, 2000). Cienc. Mar. 2001, 27, 543–558. [Google Scholar] [CrossRef][Green Version]

- Banjara, N.K.; Ramanjaneyulu, K. Experimental and numerical study on behaviour of HSFRC overlay strip strengthened flexural deficient RC beams. Eng. Struct. 2019, 198, 109561. [Google Scholar] [CrossRef]

- Holschemacher, K.; Mueller, T.; Ribakov, Y. Effect of steel fibres on mechanical properties of high-strength concrete. Mater. Des. 2010, 31, 2604–2615. [Google Scholar] [CrossRef]

- Neocleous, K.; Angelakopoulos, H.; Pilakoutas, K.; Guadagnini, M. Fibre-reinforced roller-compacted concrete transport pavements. Proc. Inst. Civ. Eng. Transp. 2011, 164, 97–109. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.; Ma, A. Investigation into the Fatigue Damage Process of Rubberized Concrete and Plain Concrete by AE Analysis. J. Mater. Civ. Eng. 2011, 23, 953–960. [Google Scholar] [CrossRef]

- Ma, Y.; Gu, J.; Li, Y.; Li, Y. The bending fatigue performance of cement-stabilized aggregate reinforced with polypropylene filament fiber. Constr. Build. Mater. 2015, 83, 230–236. [Google Scholar] [CrossRef]

- Saoudi, N.; Bezzazi, B. Flexural fatigue failure of concrete reinforced with smooth and mixing hooked-end steel fibers. Cogent Eng. 2019, 6. [Google Scholar] [CrossRef]

- Valencia, D.; León-Neira, M. Study of fatigue performance of a concrete mix for pavements reinforced with steel fibers. Rev. Ing. Constr. 2017, 32, 45–58. [Google Scholar]

- Fatigue Performance in Flexure of Fiber Reinforced Concrete. ACI Mater. J. 1998, 95, 351. [CrossRef]

- Stephen, S.J.; Gettu, R. Fatigue fracture of fibre reinforced concrete in flexure. Mater. Struct. 2020, 53, 56. [Google Scholar] [CrossRef]

- Johnston, C.D.; Zemp, R.W. Flexural Fatigue Performance of Steel Fiber Reinforced Concrete—Influence of Fiber Content, Aspect Ratio and Type. ACI Mater. J. 1991, 88. [Google Scholar] [CrossRef]

- Goel, S.; Singh, S.; Singh, P. Flexural fatigue strength and failure probability of Self Compacting Fibre Reinforced Concrete beams. Eng. Struct. 2012, 40, 131–140. [Google Scholar] [CrossRef]

- Carlesso, D.M.; de la Fuente, A.; Cavalaro, S.H.P. Fatigue of cracked high performance fiber reinforced concrete subjected to bending. Constr. Build. Mater. 2019, 220, 444–455. [Google Scholar] [CrossRef]

- Zhang, J.; Stang, H.; Li, V. Fatigue life prediction of fiber reinforced concrete under flexural load. Int. J. Fatigue 1999, 21, 1033–1049. [Google Scholar] [CrossRef]

- EN 197-1. Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- EN 80103:2013. Test Methods of Cements. Physical Analysis. Actual Density Determination; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- EN-933-1. Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- EN 83507. Concrete with Fibres. Testing in Compression; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- AENOR. UNE-EN 14651:2007. Test Method for Metallic Fibre Concrete—Measuring the Flexural Tensile Strength (Limit of Pro-Portionality (LOP), Residual); European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- Thomas, C.; Sosa, I.; Setién, J.; Polanco, J.A.; Cimentada, A.I. Evaluation of the fatigue behavior of recycled aggregate concrete. J. Clean. Prod. 2014, 65, 397–405. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Lombillo, I.; Cimentada, A.I. Fatigue limit of recycled aggregate concrete. Constr. Build. Mater. 2014, 52, 146–154. [Google Scholar] [CrossRef]

- Sainz-Aja, J.; Pombo, J.; Tholken, D.; Carrascal, I.; Polanco, J.; Ferreño, D.; Casado, J.; Diego, S.; Perez, A.; Filho, J.E.A.; et al. Dynamic calibration of slab track models for railway applications using full-scale testing. Comput. Struct. 2020, 228, 106180. [Google Scholar] [CrossRef]

- Mathworks Software, Fourier Serie. Available online: https://www.mathworks.com (accessed on 6 September 2021).

- Alonso, Á.M.; Algarra, J.M.; Cabrera, D.C.G.; Cabrera, M.Á.V. La tomografía computerizada más allá de la medicina: Aplicaciones al estudio microestructural del hormigón y otros materiales de la ingeniería (versión inglesa). Hormigón Acero 2020, 71, e1–e12. [Google Scholar] [CrossRef]

- Rios, J.D.; Cifuentes, H. Probabilistic fatigue analysis of ultra-high-performance fibre-reinforced concrete under thermal effects. In Proceedings of the MATEC Web of Conferences, 12th International Fatigue Congress, Bordeaux, France, 27 May–1 June 2018. [Google Scholar]

| Size [mm] | Sand Equivalent | Absorption [%] | Density [g/cm3] |

|---|---|---|---|

| 0/2 | >75 | 0.49 | 2.69 |

| 0/4 | >80 | 0.49 | 2.69 |

| 4/12 | - | 0.54 | 2.70 |

| 10/20 | - | 0.54 | 2.68 |

| Material | Mix [kg/m3] |

|---|---|

| 0/2 | 480 |

| 0/4 | 480 |

| 4/12 | 480 |

| 10/20 | 480 |

| Cement | 390 |

| Water | 165 |

| Additive | 3.9 |

| Fibres | 35 |

| Specimen | Fmin [kN] | Fmax [kN] | R | b [mm] | h [mm] | Δσ [MPa] |

|---|---|---|---|---|---|---|

| F-01 | 2 | 8 | 0.25 | 153.6 | 124.8 | 1.881 |

| F-02 | 2 | 9 | 0.22 | 154.6 | 126.2 | 2.132 |

| F-03 | 2 | 8 | 0.25 | 153.0 | 127.6 | 1.806 |

| F-04 | 2 | 9 | 0.22 | 156.4 | 123.0 | 2.219 |

| F-05 | 2 | 10 | 0.20 | 162.0 | 124.0 | 2.109 |

| F-06 | 2 | 15 | 0.13 | 159.0 | 130.0 | 3.628 |

| F-07 | 2 | 8.5 | 0.24 | 163.5 | 125.8 | 1.884 |

| F-08 | 2 | 11 | 0.18 | 157.0 | 125.0 | 2.752 |

| F-09 | 2 | 10 | 0.20 | 160.0 | 123.0 | 2.479 |

| F-10 | 2 | 9.5 | 0.21 | 157.0 | 126.0 | 2.257 |

| F-11 | 2 | 9.8 | 0.20 | 153.0 | 125.0 | 2.447 |

| F-12 | 2 | 12 | 0.17 | 160.0 | 124.0 | 3.049 |

| Specimen Code | Compressive Strength [MPa] |

|---|---|

| Specimen C1 | 53.80 |

| Specimen C2 | 51.28 |

| Specimen C3 | 46.48 |

| Specimen Code | fR,3 [MPa] |

|---|---|

| Specimen F1 | 5.80 |

| Specimen F2 | 6.83 |

| Specimen F3 | 6.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sainz-Aja, J.A.; Gonzalez, L.; Thomas, C.; Rico, J.; Polanco, J.A.; Carrascal, I.; Setién, J. Effect of Steel Fibre Reinforcement on Flexural Fatigue Behaviour of Notched Structural Concrete. Materials 2021, 14, 5854. https://doi.org/10.3390/ma14195854

Sainz-Aja JA, Gonzalez L, Thomas C, Rico J, Polanco JA, Carrascal I, Setién J. Effect of Steel Fibre Reinforcement on Flexural Fatigue Behaviour of Notched Structural Concrete. Materials. 2021; 14(19):5854. https://doi.org/10.3390/ma14195854

Chicago/Turabian StyleSainz-Aja, Jose A., Laura Gonzalez, Carlos Thomas, Jokin Rico, Juan A. Polanco, Isidro Carrascal, and Jesús Setién. 2021. "Effect of Steel Fibre Reinforcement on Flexural Fatigue Behaviour of Notched Structural Concrete" Materials 14, no. 19: 5854. https://doi.org/10.3390/ma14195854

APA StyleSainz-Aja, J. A., Gonzalez, L., Thomas, C., Rico, J., Polanco, J. A., Carrascal, I., & Setién, J. (2021). Effect of Steel Fibre Reinforcement on Flexural Fatigue Behaviour of Notched Structural Concrete. Materials, 14(19), 5854. https://doi.org/10.3390/ma14195854