Exploring the Infiltration Features of Perovskite within Mesoporous Carbon Stack Solar Cells Using Broad Beam Ion Milling

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of the C-PSC Triple Stack

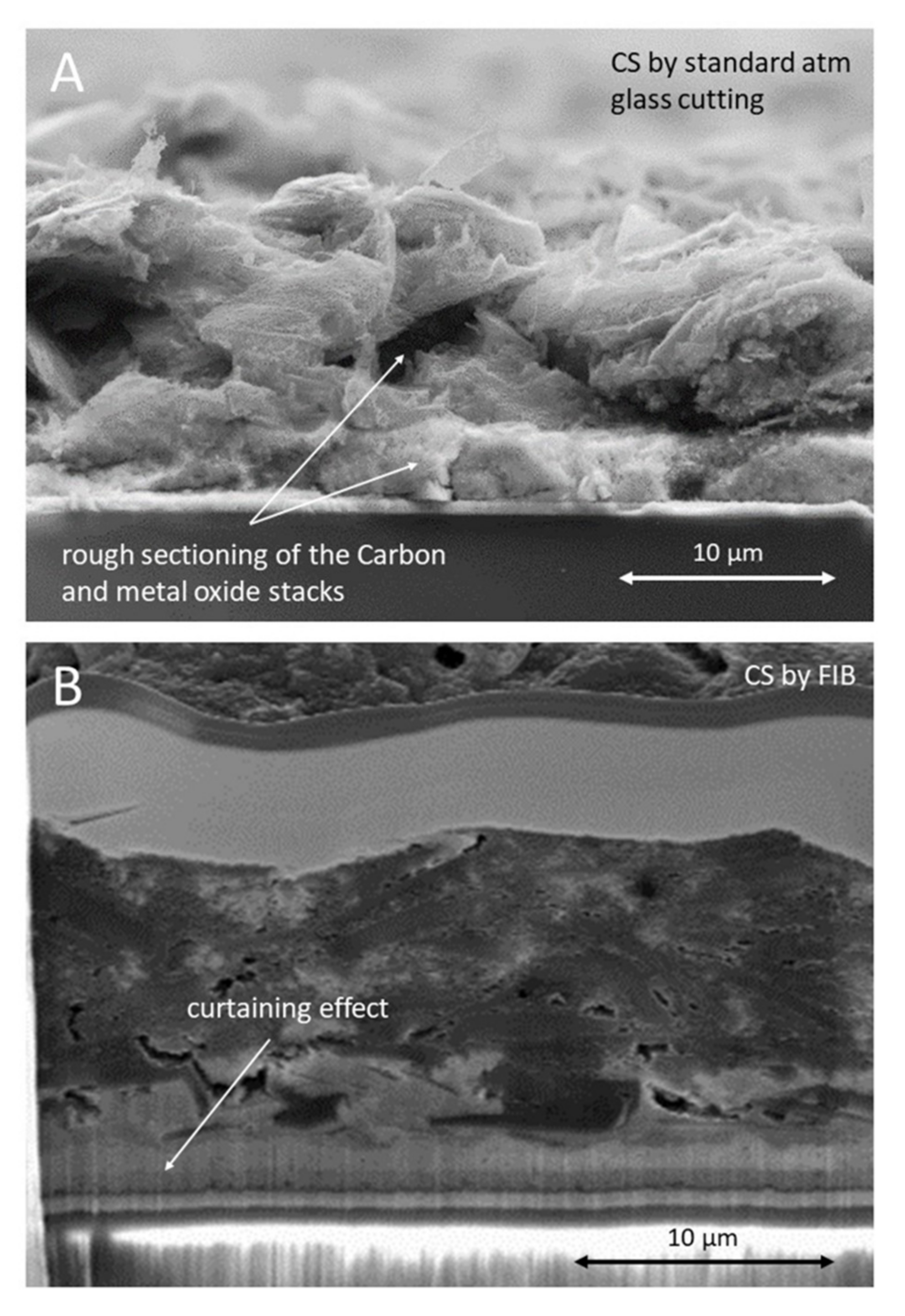

2.2. Cross-Sectioning Techniques

2.2.1. Glass Cutting

2.2.2. Focused Ion Beam

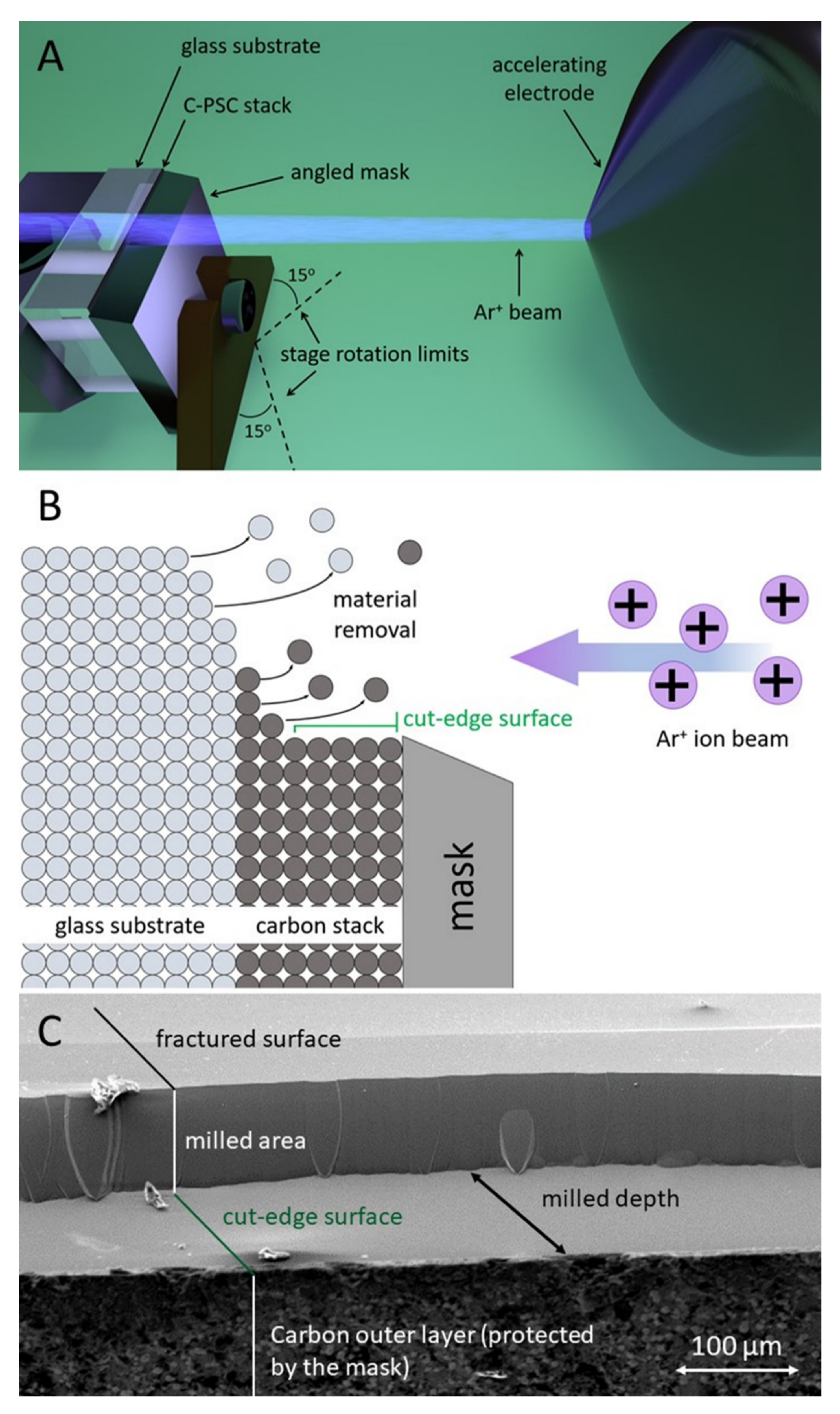

2.2.3. Broad Beam Ion Milling

2.3. Electron Microscopy

3. Results and Discussion

3.1. Optimisation of Broad Beam Ion Milling Operating Parameters

3.2. Features within the Perovskite Carbon Stack

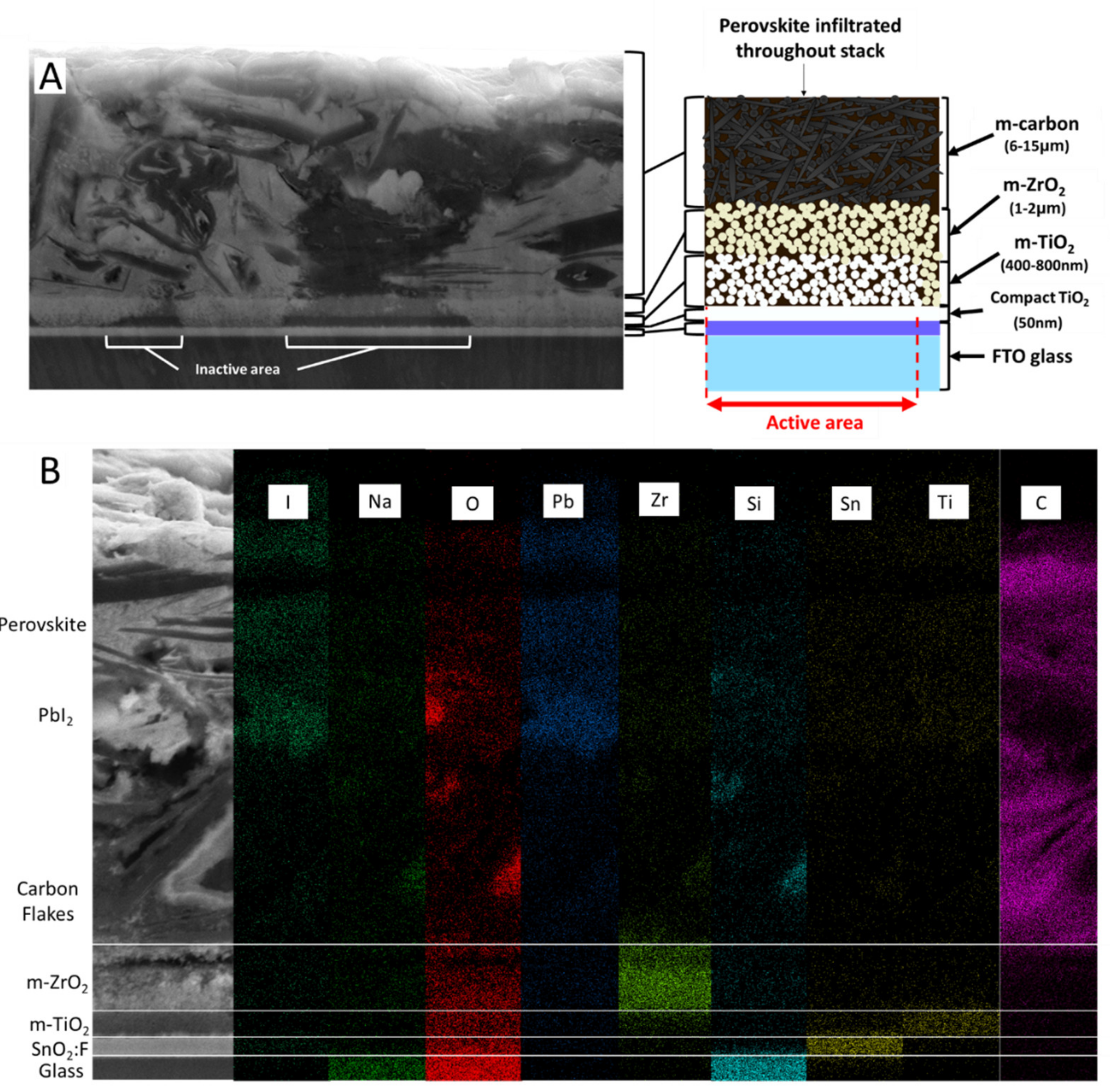

3.2.1. Structure of the Mesoporous Stack

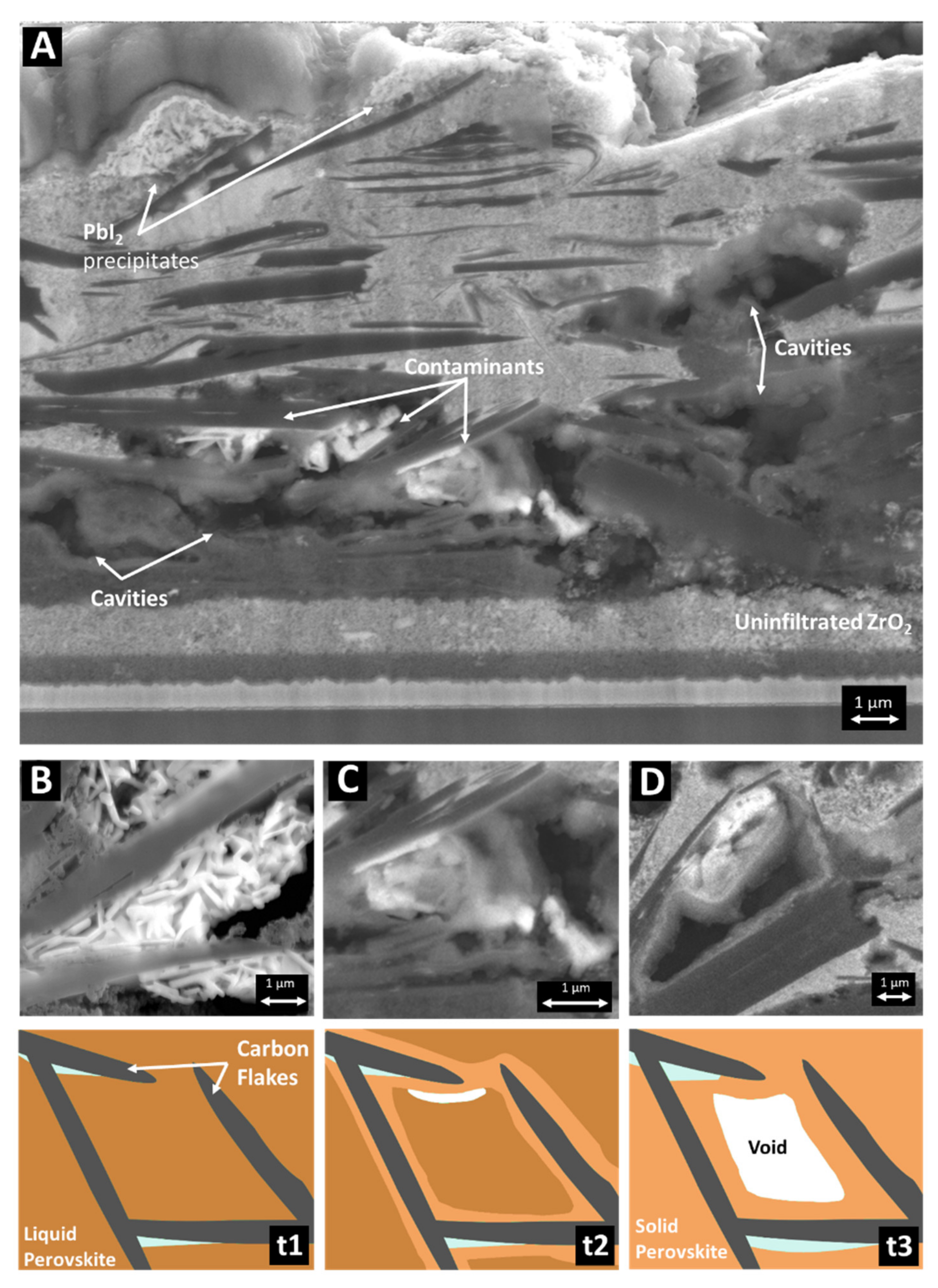

3.2.2. By-Products, Infiltration, and Structural Defects within the Carbon Layer

3.3. Infiltration Defects within the Active Layers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Snaith, H.J. A decade of perovskite photovoltaics. Nat. Energy 2019, 4, 1. [Google Scholar] [CrossRef]

- Ma, C.; Park, N.-G. A Realistic Methodology for 30% Efficient Perovskite Solar Cells. Chem 2020, 6, 1254–1264. [Google Scholar] [CrossRef]

- Green, M.; Dunlop, E.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar cell efficiency tables (version 57). Prog. Photovolt. Res. Appl. 2020, 29, 3–15. [Google Scholar] [CrossRef]

- Ku, Z.; Rong, Y.; Xu, M.; Liu, T.; Han, H. Full Printable Processed Mesoscopic CH3NH3PbI3/TiO2 Heterojunction Solar Cells with Carbon Counter Electrode. Sci. Rep. 2013, 3, 3132. [Google Scholar] [CrossRef] [PubMed]

- Alberola-Borràs, J.-A.; Baker, J.; De Rossi, F.; Vidal, R.; Beynon, D.; Hooper, K.; Watson, T.M.; Mora-Seró, I. Perovskite Photovoltaic Modules: Life Cycle Assessment of Pre-industrial Production Process. iScience 2018, 9, 542–551. [Google Scholar] [CrossRef]

- Alberola-Borràs, J.-A.; Vidal, R.; Juarez-Perez, E.J.; Mas, E.; Guerrero, A.; Mora-Seró, I. Relative impacts of methylammonium lead triiodide perovskite solar cells based on life cycle assessment. Sol. Energy Mater. Sol. Cells 2018, 179, 169–177. [Google Scholar] [CrossRef]

- Cai, M.; Wu, Y.; Chen, H.; Yang, X.; Qiang, Y.; Han, L. Cost-Performance Analysis of Perovskite Solar Modules. Adv. Sci. 2016, 4, 1600269. [Google Scholar] [CrossRef]

- Kim, D.I.; Lee, J.W.; Jeong, R.H.; Nam, S.-H.; Hwang, K.-H.; Boo, J.-H. Oxygen-plasma processed Spiro-OMeTAD toward high performance for perovskite solar cell. Surf. Coat. Technol. 2018, 357, 189–194. [Google Scholar] [CrossRef]

- Connell, A.; Wang, Z.; Lin, Y.-H.; Greenwood, P.C.; Wiles, A.A.; Jones, E.W.; Furnell, L.; Anthony, R.; Kershaw, C.P.; Cooke, G.; et al. Low cost triazatruxene hole transporting material for >20% efficiency perovskite solar cells. J. Mater. Chem. C 2018, 7, 5235–5243. [Google Scholar] [CrossRef]

- Grancini, G.; Carmona, C.R.; Zimmermann, I.; Mosconi, E.; Lee, X.; Martineau, D.; Narbey, S.; Oswald, F.; De Angelis, F.; Graetzel, M.; et al. One-Year stable perovskite solar cells by 2D/3D interface engineering. Nat. Commun. 2017, 8, 15684. [Google Scholar] [CrossRef]

- Baker, J.; Hooper, K.; Meroni, S.; Pockett, A.; McGettrick, J.; Wei, Z.; Escalante, R.; Oskam, G.; Carnie, M.; Watson, T. High throughput fabrication of mesoporous carbon perovskite solar cells. J. Mater. Chem. A 2017, 5, 18643–18650. [Google Scholar] [CrossRef]

- Meroni, S. Large area homogeneous deposition of perovskite in fully-printable perovskite solar cells. Sci. Technol. Adv. Mater. 2017. under review. [Google Scholar]

- De Rossi, F.; Baker, J.A.; Beynon, D.; Hooper, K.E.A.; Meroni, S.M.P.; Williams, D.; Wei, Z.; Yasin, A.; Charbonneau, C.; Jewell, E.H.; et al. All Printable Perovskite Solar Modules with 198 cm2 Active Area and Over 6% Efficiency. Adv. Mater. Technol. 2018, 3, 1800156. [Google Scholar] [CrossRef]

- Liu, L.; Mei, A.; Liu, T.; Jiang, P.; Sheng, Y.; Zhang, L.; Han, H. Fully Printable Mesoscopic Perovskite Solar Cells with Organic Silane Self-Assembled Monolayer. J. Am. Chem. Soc. 2015, 137, 1790–1793. [Google Scholar] [CrossRef]

- Hashmi, S.G.; Martineau, D.; Li, X.; Ozkan, M.; Tiihonen, A.; Dar, M.I.; Sarikka, T.; Zakeeruddin, S.M.; Paltakari, J.; Lund, P.D.; et al. Air Processed Inkjet Infiltrated Carbon Based Printed Perovskite Solar Cells with High Stability and Reproducibility. Adv. Mater. Technol. 2016, 2, 1600183. [Google Scholar] [CrossRef]

- Meroni, S.M.P.; Mouhamad, Y.; De Rossi, F.; Pockett, A.; Baker, J.; Escalante, R.; Searle, J.; Carnie, M.J.; Jewell, E.; Oskam, G.; et al. Homogeneous and highly controlled deposition of low viscosity inks and application on fully printable perovskite solar cells. Sci. Technol. Adv. Mater. 2017, 19, 1–9. [Google Scholar] [CrossRef]

- Lakhiani, H.; Dunlop, T.; De Rossi, F.; Dimitrov, S.; Kerremans, R.; Charbonneau, C.; Watson, T.; Barbé, J.; Tsoi, W.C. Variations of Infiltration and Electronic Contact in Mesoscopic Perovskite Solar Cells Revealed by High-Resolution Multi-Mapping Techniques. Adv. Funct. Mater. 2019, 29, 1900885. [Google Scholar] [CrossRef]

- Baker, J.A.; Mouhamad, Y.; Hooper, K.E.; Burkitt, D.; Geoghegan, M.; Watson, T.M. From spin coating to roll-to-roll: Investigating the challenge of upscaling lead halide perovskite solar cells. IET Renew. Power Gener. 2017, 11, 546–549. [Google Scholar] [CrossRef]

- Chen, J.; Xiong, Y.; Rong, Y.; Mei, A.; Sheng, Y.; Jiang, P.; Hu, Y.; Li, X.; Han, H. Solvent effect on the hole-conductor-free fully printable perovskite solar cells. Nano Energy 2016, 27, 130–137. [Google Scholar] [CrossRef]

- Mei, A.; Li, X.; Liu, L.; Ku, Z.; Liu, T.; Rong, Y.; Xu, M.; Hu, M.; Chen, J.; Yang, Y.; et al. A hole-conductor-free, fully printable mesoscopic perovskite solar cell with high stability. Science 2014, 345, 295–298. [Google Scholar] [CrossRef]

- Lin, C.-T.; De Rossi, F.; Kim, J.; Baker, J.; Ngiam, J.; Xu, B.; Pont, S.; Aristidou, N.; Haque, S.A.; Watson, T.; et al. Evidence for surface defect passivation as the origin of the remarkable photostability of unencapsulated perovskite solar cells employing aminovaleric acid as a processing additive. J. Mater. Chem. A 2019, 7, 3006–3011. [Google Scholar] [CrossRef]

- Hu, Y.; Si, S.; Mei, A.; Rong, Y.; Liu, H.; Li, X.; Han, H. Stable Large-Area (10 × 10 cm2) Printable Mesoscopic Perovskite Module Exceeding 10% Efficiency. Sol. RRL 2017, 1, 1600019. [Google Scholar] [CrossRef]

- Liu, T.; Liu, L.; Hu, M.; Yang, Y.; Zhang, L.; Mei, A.; Han, H. Critical parameters in TiO2/ZrO2/Carbon-based mesoscopic perovskite solar cell. J. Power Sources 2015, 293, 533–538. [Google Scholar] [CrossRef]

- Bella, F.; Griffini, G.; Correa-Baena, J.P.; Gratzel, G.; Hagfeldt, A.; Turri, S.; Gerbaldi, C. Improving efficiency and stability of perovskite solar cells with photocurable fluoropolymers. Science 2016, 354, 203–206. [Google Scholar] [CrossRef]

- Filonik, O.; Thordardottir, M.E.; Lebert, J.; Pröller, S.; Weiß, S.; Haur, L.J.; Priyadarshi, A.; Fontaine, P.; Müller-Buschbaum, P.; Mathews, N.; et al. Evolution of Perovskite Crystallization in Printed Mesoscopic Perovskite Solar Cells. Energy Technol. 2019, 7, 1900343. [Google Scholar] [CrossRef]

- Wei, Z.; Smith, B.; De Rossi, F.; Searle, J.R.; Worsley, D.A.; Watson, T.M. Efficient and semi-transparent perovskite solar cells using a room-temperature processed MoOx/ITO/Ag/ITO electrode. J. Mater. Chem. C 2019, 7, 10981–10987. [Google Scholar] [CrossRef]

- Cousland, G.; Cui, X.; Smith, A.; Stampfl, A.; Stampfl, C. Mechanical properties of zirconia, doped and undoped yttria-stabilized cubic zirconia from first-principles. J. Phys. Chem. Solids 2018, 122, 51–71. [Google Scholar] [CrossRef]

- Rakita, Y.; Cohen, S.R.; Kedem, N.K.; Hodes, G.; Cahen, D. Mechanical properties of APbX3 (A = Cs or CH3NH3; X = I or Br) perovskite single crystals. MRS Commun. 2015, 5, 623–629. [Google Scholar]

- Borgese, L.; Gelfi, M.; Bontempi, E.; Goudeau, P.; Geandier, G.; Thiaudière, D.; Depero, L. Young modulus and Poisson ratio measurements of TiO2 thin films deposited with Atomic Layer Deposition. Surf. Coat. Technol. 2012, 206, 2459–2463. [Google Scholar] [CrossRef]

- Desbois, G.; Urai, J.; Pérez-Willard, F.; Radi, Z.; Offern, S.; Burkart, I.; Kukla, P.; Wollenberg, U. Argon broad ion beam tomography in a cryogenic scanning electron microscope: A novel tool for the investigation of representative microstructures in sedimentary rocks containing pore fluid. J. Microsc. 2013, 249, 215–235. [Google Scholar] [CrossRef]

- Kaczmarek, D.; Domaradzki, J.; Wojcieszak, D.; Prociow, E.; Mazur, M.; Placido, F.; Lapp, S. Hardness of Nanocrystalline TiO2 Thin Films. J. Nano Res. 2012, 18–19, 195–200. [Google Scholar] [CrossRef]

- Mokhtar, M.; Basahel, S.N.; Ali, T.T. Effect of synthesis methods for mesoporous zirconia on its structural and textural properties. J. Mater. Sci. 2012, 48, 2705–2713. [Google Scholar] [CrossRef]

- Sun, S.; Fang, Y.; Kieslich, G.; White, T.J.; Cheetham, A.K. Mechanical properties of organic–inorganic halide perovskites, CH3NH3PbX3(X = I, Br and Cl), by nanoindentation. J. Mater. Chem. A 2015, 3, 18450–18455. [Google Scholar] [CrossRef]

- Schneider, A.; Alon, S.; Etgar, L. Evolution of Photovoltaic Performance in Fully Printable Mesoscopic Carbon-Based Perovskite Solar Cells. Energy Technol. 2019, 7, 1900481. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, B.; Liu, X.; Han, J.; Ye, H.; Shi, T.; Tang, Z.; Liao, G. Efficient Carbon-Based CsPbBr3 Inorganic Perovskite Solar Cells by Using Cu-Phthalocyanine as Hole Transport Material. Nano-Micro Lett. 2018, 10, 1–13. [Google Scholar] [CrossRef]

- Schlipf, J.; Hu, Y.; Pratap, S.; Bießmann, L.; Hohn, N.; Porcar, L.; Bein, T.; Docampo, P.; Müller-Buschbaum, P. Shedding Light on the Moisture Stability of 3D/2D Hybrid Perovskite Heterojunction Thin Films. ACS Appl. Energy Mater. 2019, 2, 1011–1018. [Google Scholar] [CrossRef]

- Erdman, N.; Campbell, R.; Asahina, S. Precise SEM Cross Section Polishing via Argon Beam Milling. Microsc. Today 2006, 14, 22–25. [Google Scholar] [CrossRef]

- Winiarski, B.; Gholinia, A.; Mingard, K.; Gee, M.; Thompson, G.; Withers, P. Broad ion beam serial section tomography. Ultramicroscopy 2017, 172, 52–64. [Google Scholar] [CrossRef]

- Overwijk, M.; Heuvel, F.V.D. Focused-ion-beam-induced tungsten deposition: Theory and experiment. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1993, 80-81, 1324–1327. [Google Scholar] [CrossRef]

- Lehrer, C.; Frey, L.; Petersen, S.A.; Mizutani, M.; Takai, M.; Ryssel, H. Defects and gallium-contamination during focused ion beam micro machining. In Proceedings of the 2000 International Conference on Ion Implantation Technology, Alpbach, Austria, 17–22 September 2000. [Google Scholar] [CrossRef]

- Daniel, J.H.; Moore, D.F.; Walker, J.F. Focused ion beams for microfabrication. Eng. Sci. Educ. J. 1998, 7, 53–56. [Google Scholar] [CrossRef]

- Jeong, S.; Na, H.; Lee, G.; Son, S.H.; Choi, H. Cross-sectional analysis of W-cored Ni nanoparticle via focused ion beam milling with impregnation. Nanoscale Res. Lett. 2014, 9, 533. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Wehrs, J.; Ma, H.; Al-Samman, T.; Korte-Kerzel, S.; Göken, M.; Michler, J.; Spolenak, R.; Wheeler, J. Investigation of the deformation behavior of aluminum micropillars produced by focused ion beam machining using Ga and Xe ions. Scr. Mater. 2016, 127, 191–194. [Google Scholar] [CrossRef]

- Park, J.S.; Kim, S.; Xie, Z.; Walsh, A. Point defect engineering in thin-film solar cells. Nat. Rev. Mater. 2018, 3, 194–210. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dunlop, T.; Kesteven, O.; De Rossi, F.; Davies, P.; Watson, T.; Charbonneau, C. Exploring the Infiltration Features of Perovskite within Mesoporous Carbon Stack Solar Cells Using Broad Beam Ion Milling. Materials 2021, 14, 5852. https://doi.org/10.3390/ma14195852

Dunlop T, Kesteven O, De Rossi F, Davies P, Watson T, Charbonneau C. Exploring the Infiltration Features of Perovskite within Mesoporous Carbon Stack Solar Cells Using Broad Beam Ion Milling. Materials. 2021; 14(19):5852. https://doi.org/10.3390/ma14195852

Chicago/Turabian StyleDunlop, Tom, Owen Kesteven, Francesca De Rossi, Pete Davies, Trystan Watson, and Cecile Charbonneau. 2021. "Exploring the Infiltration Features of Perovskite within Mesoporous Carbon Stack Solar Cells Using Broad Beam Ion Milling" Materials 14, no. 19: 5852. https://doi.org/10.3390/ma14195852

APA StyleDunlop, T., Kesteven, O., De Rossi, F., Davies, P., Watson, T., & Charbonneau, C. (2021). Exploring the Infiltration Features of Perovskite within Mesoporous Carbon Stack Solar Cells Using Broad Beam Ion Milling. Materials, 14(19), 5852. https://doi.org/10.3390/ma14195852