Factors Affecting the Microstructure, Tensile Properties and Corrosion Resistance of AA7075 Forgings

Abstract

:1. Introduction

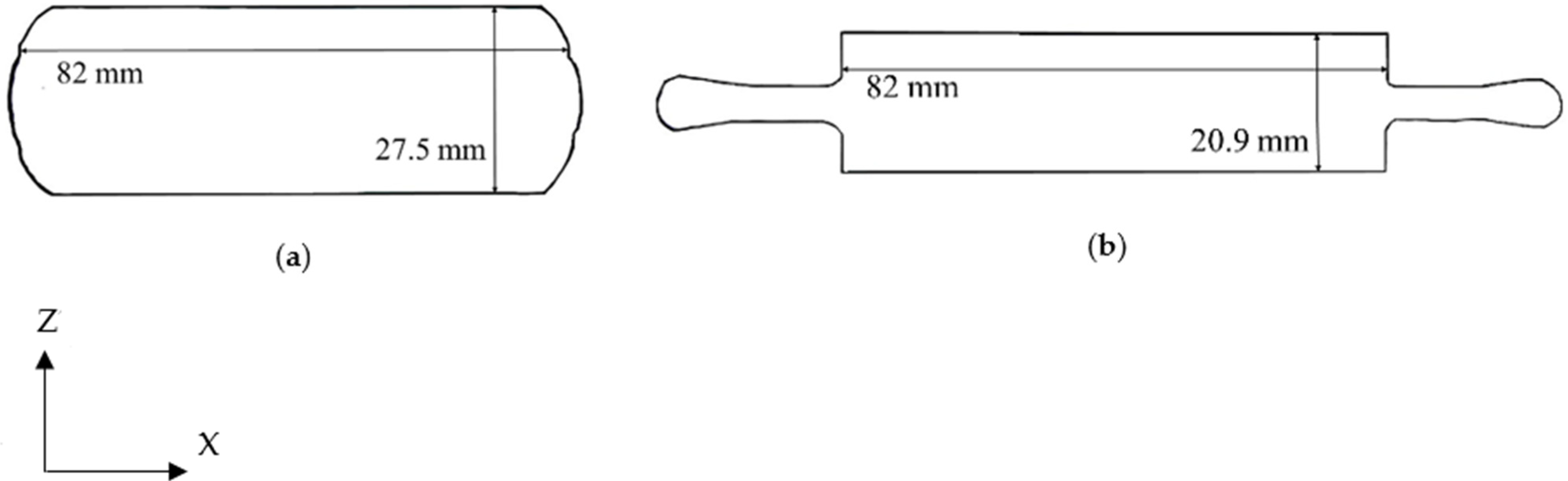

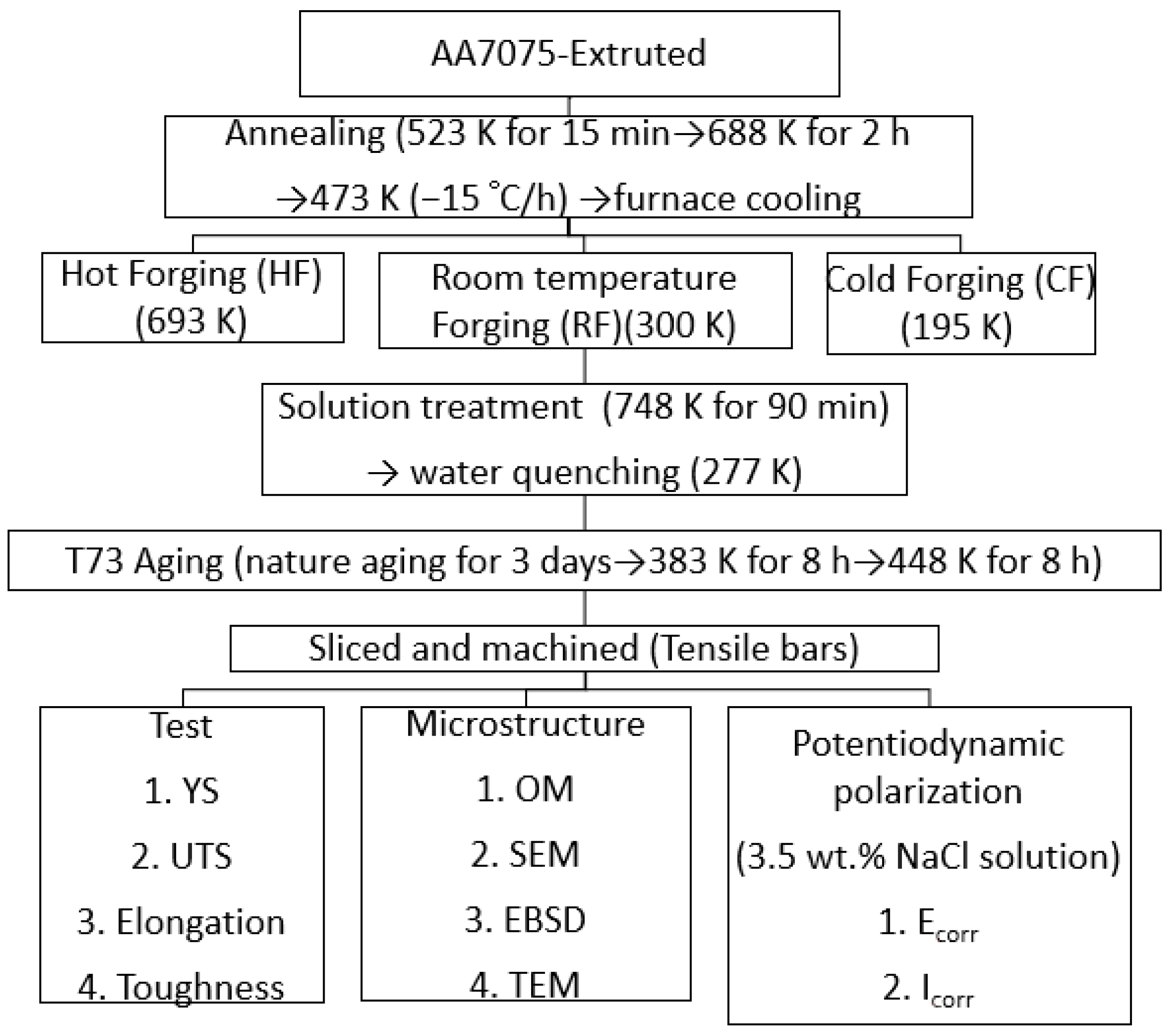

2. Materials and Methods

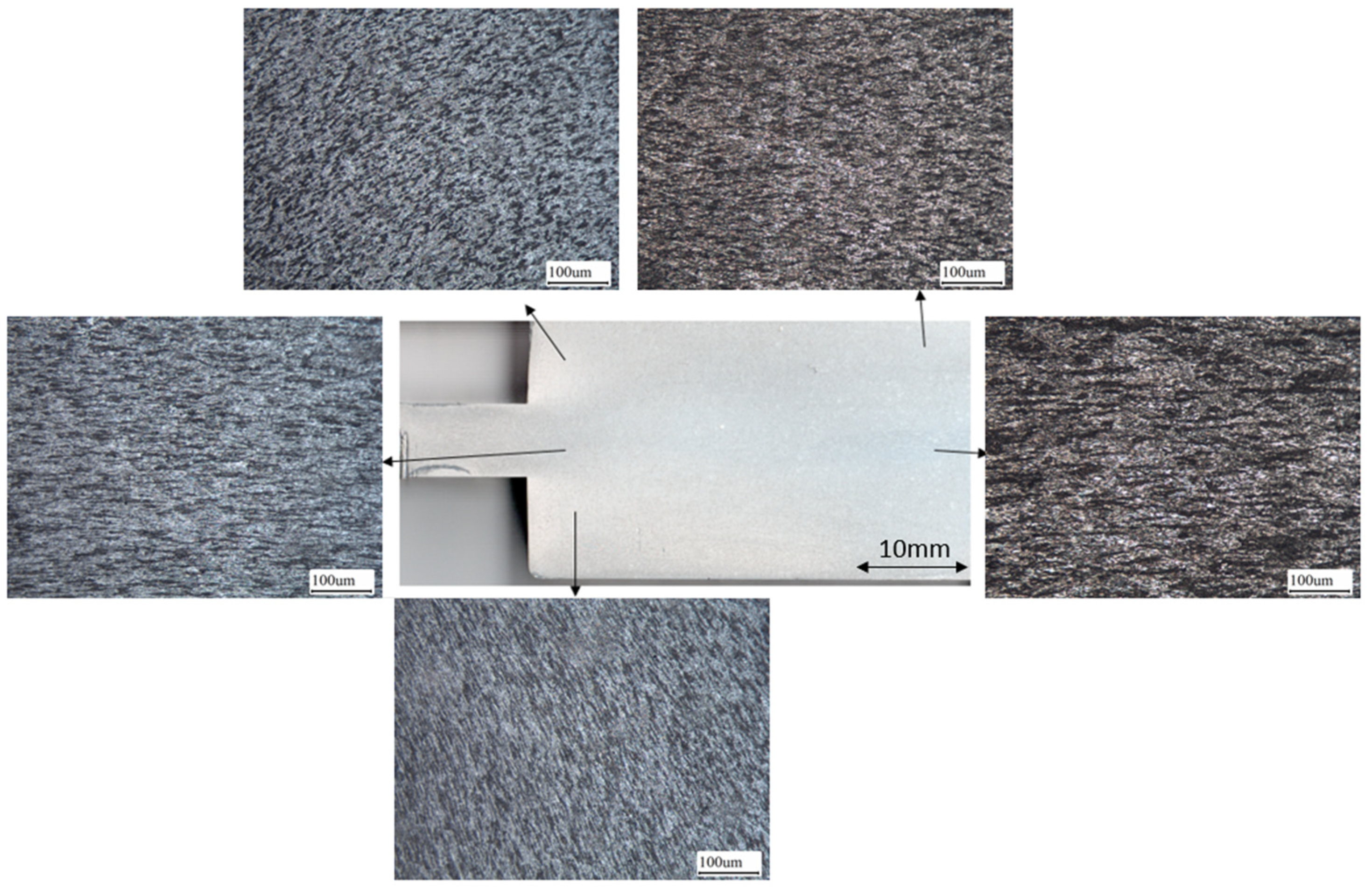

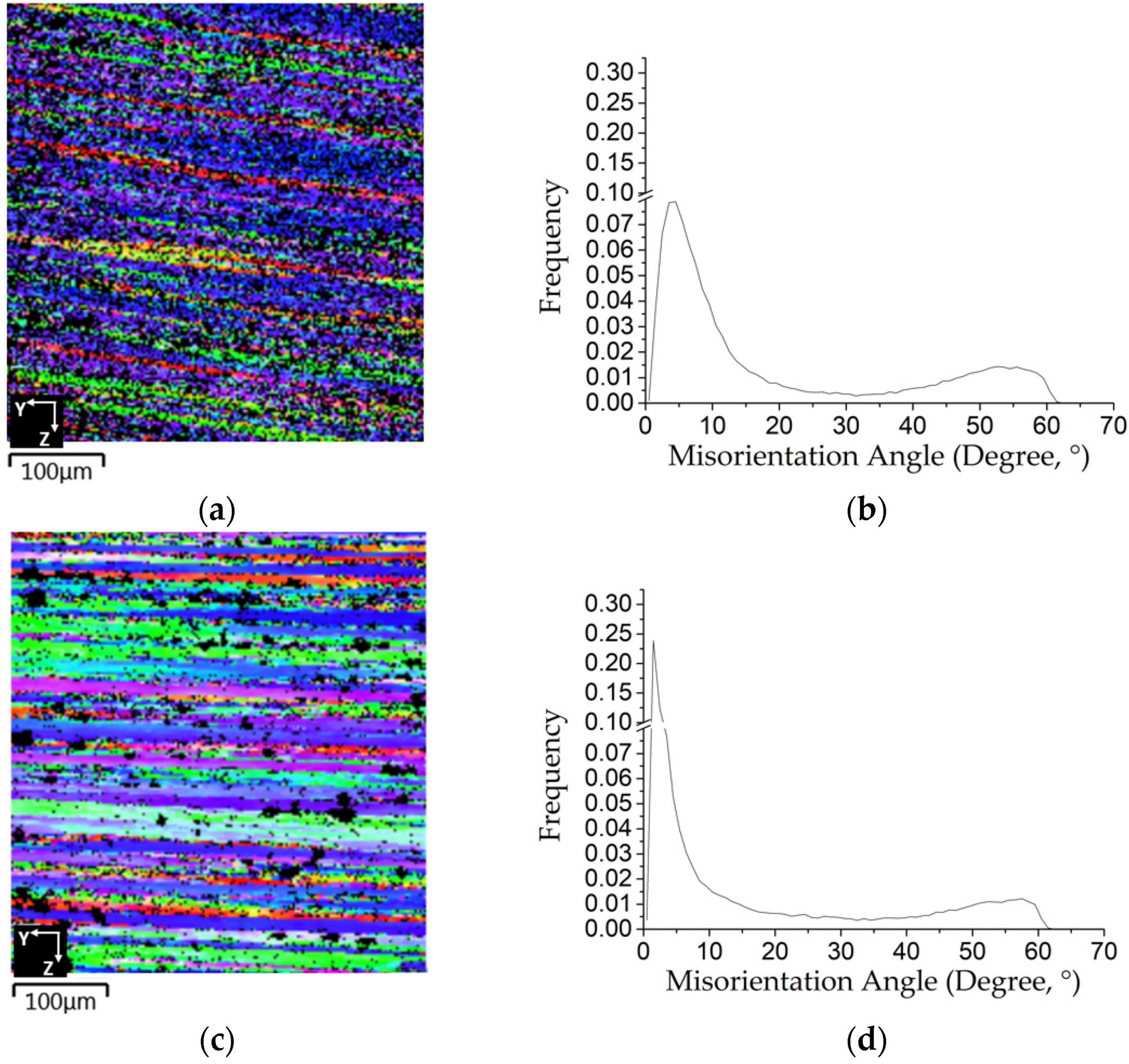

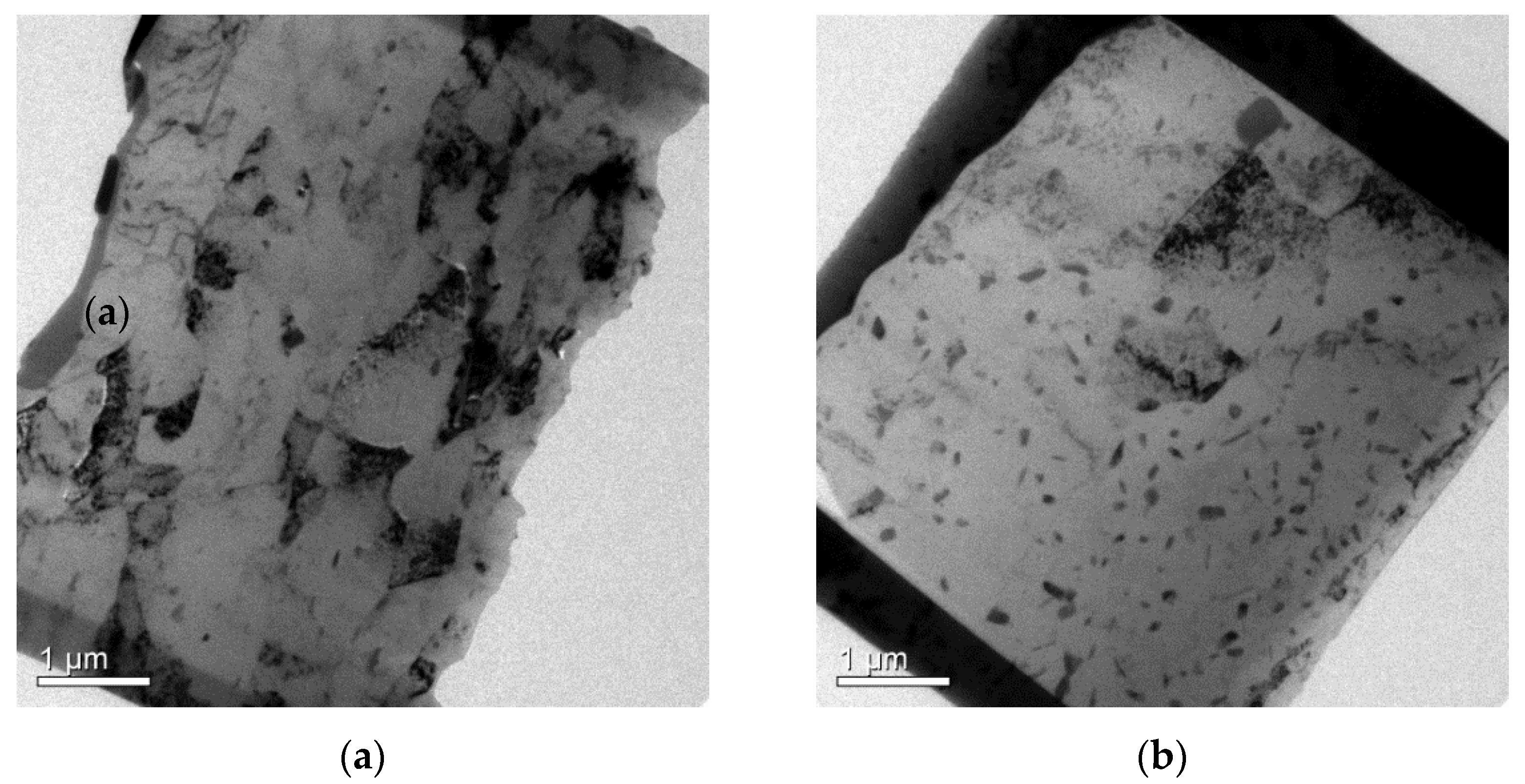

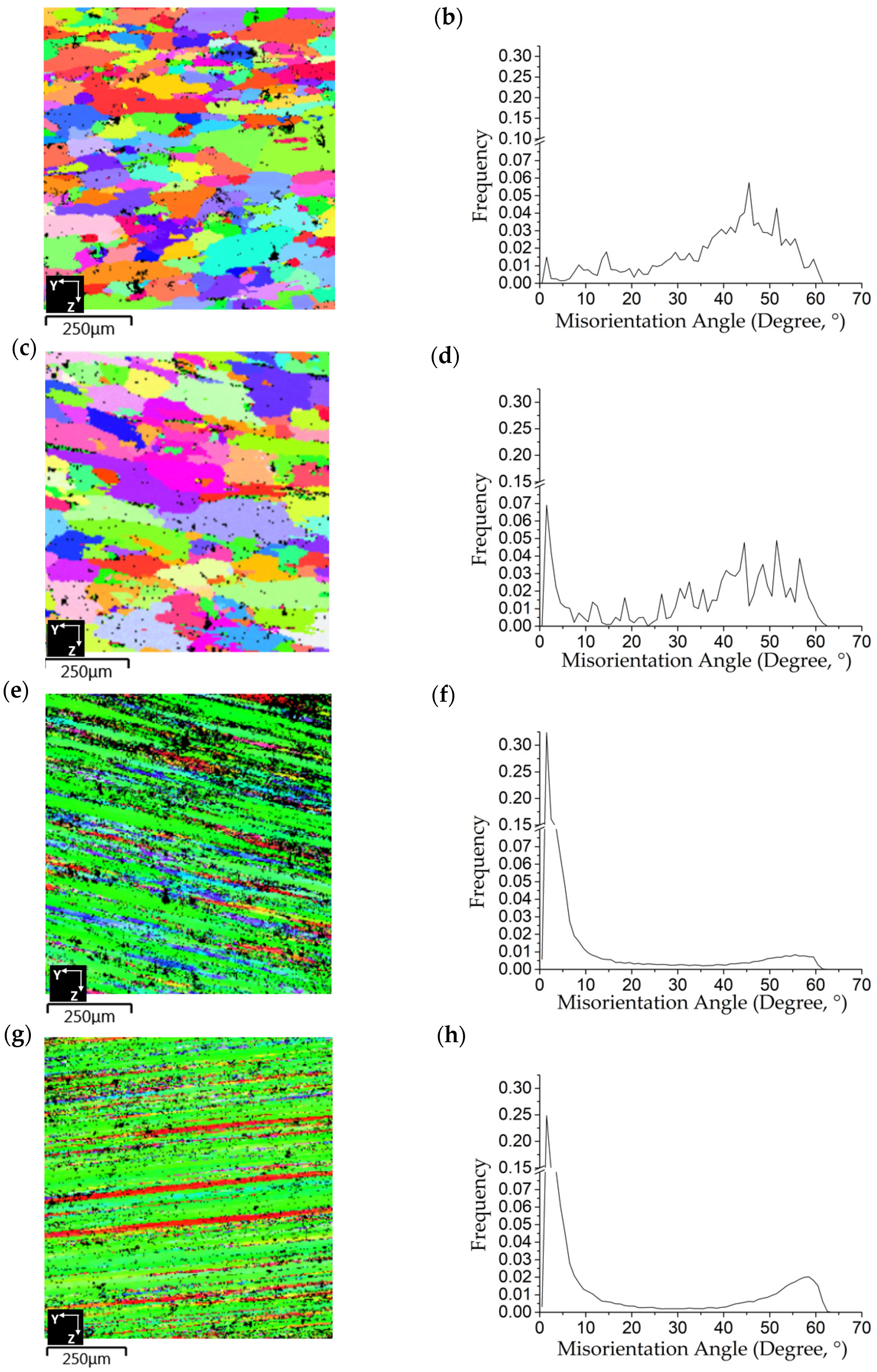

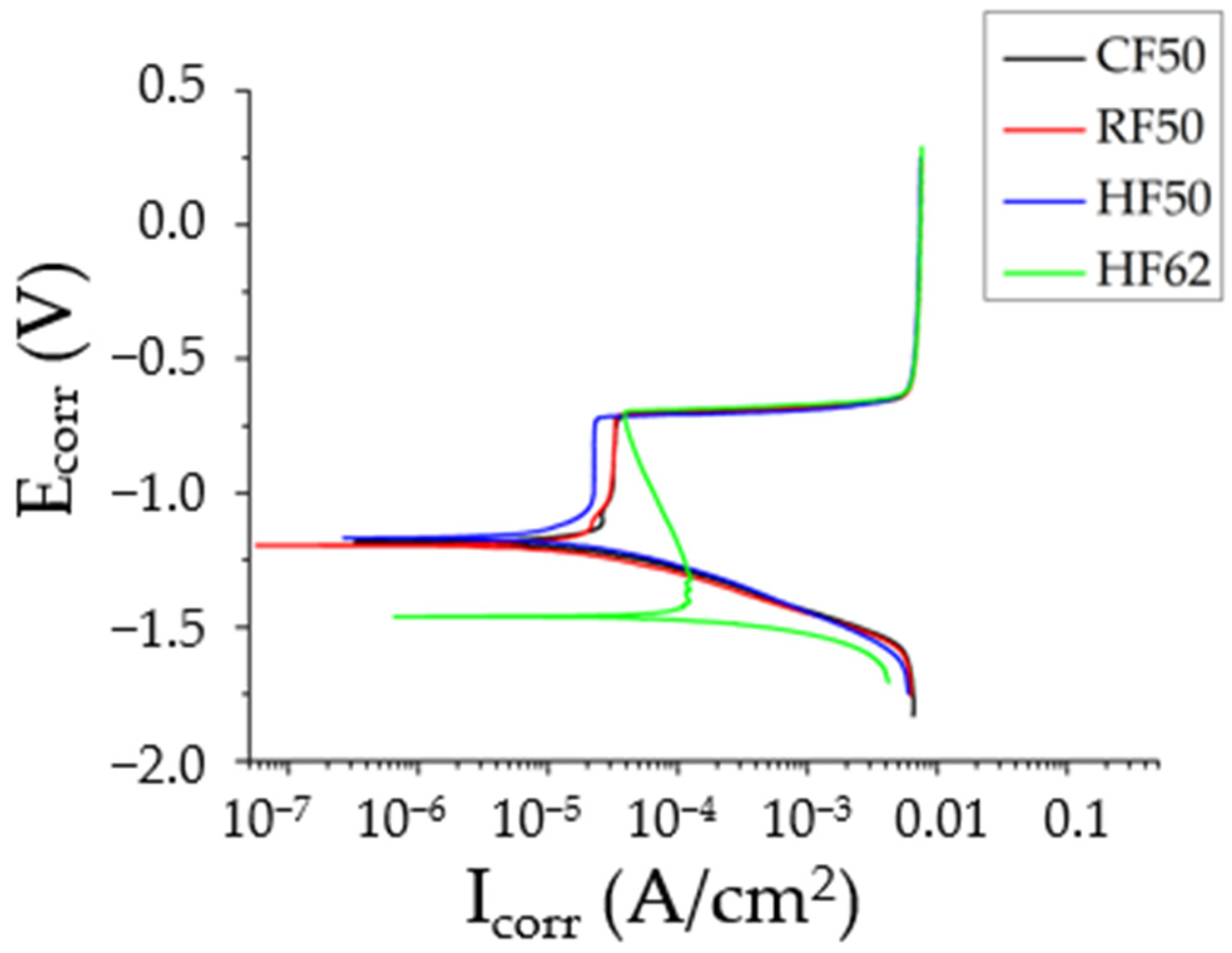

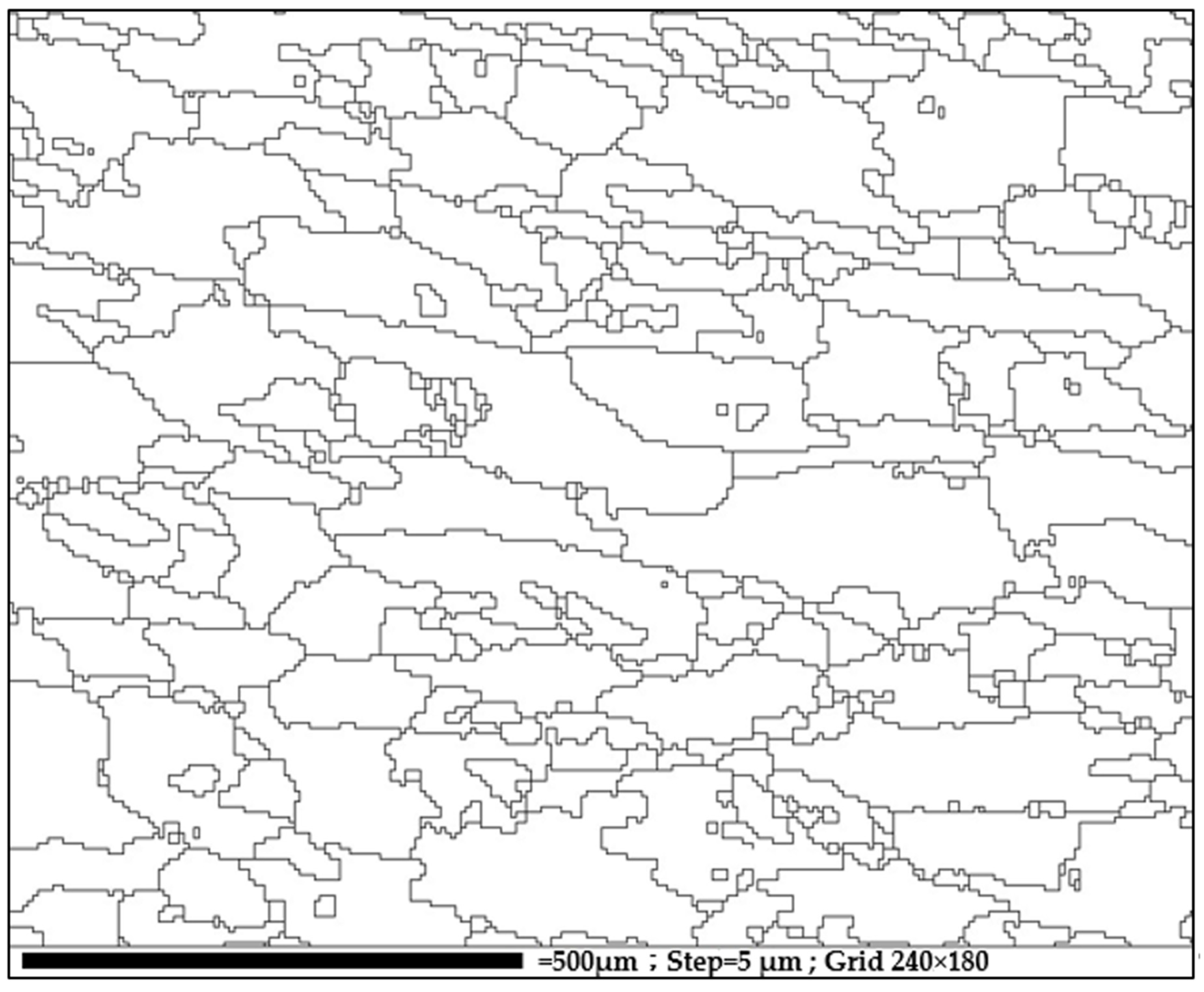

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Viana, F.; Pinto, A.M.P.; Santos, H.M.C.; Lopes, A.B. Retrogression and re-ageing of 7075 aluminium alloy: Microstructural characterization. J. Mater. Process. Technol. 1999, 92–93, 54–59. [Google Scholar] [CrossRef] [Green Version]

- Umamaheshwer Rao, A.C.; Vasu, V.; Govindaraju, M.; Sai Srinadh, K.V. Stress corrosion cracking behavior of 7xxx aluminum alloys: A literature review. TNMSC 2016, 26, 1447–1471. [Google Scholar]

- Savas, T.P.; Earthman, J.C. Surface Characterization of 7075-T73 Aluminum Exposed to Anodizing Pretreatment Solutions. J. Mater. Eng. Perform. 2008, 17, 674–681. [Google Scholar] [CrossRef]

- Miera, M.S.de.; Curioni, M.; Skeldon, P.; Thompson, G.E. Preferential anodic oxidation of second-phase constituents during anodising of AA2024-T3 and AA7075-T6 alloys . Surf. Interface Anal. 2010, 42, 241–246. [Google Scholar] [CrossRef]

- Miera, M.S.de.; Curioni, M.; Skeldon, P.; Thompson, G.E. The behaviour of second phase particles during anodizing of aluminium alloys. Corros. Sci. 2010, 52, 2489–2497. [Google Scholar] [CrossRef]

- Cirik, E.; Genel, K. Effect of anodic oxidation on fatigue performance of 7075-T6 alloy. Surf. Coat. Technol. 2008, 202, 5190–5201. [Google Scholar] [CrossRef]

- Kuhlman, G.W. ASM Handbook, Volume 14A: Metalworking: Bulk Forming; Semiatin, S.L., Ed.; Metalworking Consultant Group LLC: Mentor, OH, USA, 2005; pp. 299–312. [Google Scholar]

- Angella, G.; Schino, A.D.; Donnini, R.; Richetta, M.; Testani, C.; Varone, A. AA7050 Al Alloy Hot-Forging Process for Improved Fracture Toughness Properties. Metal 2019, 9, 64. [Google Scholar] [CrossRef] [Green Version]

- Ngernbamrung, S.; Suzuki, Y.; Takatsuju, N.; Dohda, K. Investigation of suface cracking of hot-extruded AA7075 billet. Procedia Manuf. 2018, 15, 217–224. [Google Scholar]

- Krishna, K.G.; Sivaprasad, K.; Venkateswarlu, K.; HariKumar, K.C. Microstructural Evolution and Aging Behavior of Cryorolled Al-4Zn-2Mg Alloy. Mater. Sci. Eng. A 2012, 535, 129–135. [Google Scholar] [CrossRef]

- Das, P.; Rengaswamy, J.; Singh, I.V. Tensile and Impact-Toughness Behaviour of Cryorolled Al 7075 Alloy. Mater. Des. 2011, 32, 1298–1305. [Google Scholar] [CrossRef]

- Panigrahi, S.K.; Jayaganthan, R. Effect of Ageing on Microstructure and Mechanical Properties of Bulk, Cryorolled, and Room Temperature Rolled Al 7075 Alloy. J. Alloys Compd. 2011, 509, 9609–9616. [Google Scholar] [CrossRef]

- Yin, J.; Lu, J.; Ma, H.; Zhang, P. Nanostructural Formation of Fine Grained Aluminum Alloy by Severe Plastic Deformation at Cryogenic Temperature. J. Mater. Sci. 2004, 39, 2851–2854. [Google Scholar] [CrossRef]

- Jayaganthan, R.; Brokmeier, H.G.; Schwebke, S.; Panigrah, S.K. Microstructure and texture evolution in cryorolled Al 7075 alloy. J. Alloys Compd. 2010, 496, 183–188. [Google Scholar] [CrossRef]

- Sun, Z.C.; Zheng, L.S.; Yang, H. Softening mechanism and microstructure evolution of as-extruded 7075 aluminum alloy during hot deformation. Mater. Charact. 2014, 90, 71–80. [Google Scholar] [CrossRef]

- Feng, D.; Wang, G.; Chen, H.; Zhang, X.M. Effect of Grain Size Inhomogeneity of Ingot on Dynamic Softening Behavior and Processing Map of Al-8Zn-2Mg-2Cu alloy. Met. Mater. Int. 2018, 24, 195–204. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, X.M.; Liu, S.D.; Deng, Y.L. Constitutive equation and hot deformation behavior of homogenized Al-7.68Zn-2.12Mg-1.98Cu-0.12Zr alloy during compression at elevated temperature. Mater. Sci. Eng. A 2014, 608, 63–72. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z.; Li, X.; Wang, Q.; Zhang, Y. The effects of grain size on the hot deformation and processing map for 7075 aluminum alloy. Mater. Des. 2013, 51, 592–597. [Google Scholar] [CrossRef]

- Rokni, M.R.; Zarei-HAnzaki, A.; Roostaei, A.; Abedi, H.R. An Investigation into the hot deformation characteristics of 7075 aluminum alloy. Mater. Des. 2011, 32, 2339–2344. [Google Scholar] [CrossRef]

- Zuo, J.; Hou, L.; Shi, J.; Cui, H.; Zhuang, L.; Zhang, J. Effect of deformation induced precipitation on grain refinement and improvement of mechanical properties of AA7055 alluminum alloy. Mater. Charact. 2017, 130, 123–134. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kumar, V.A.; Krishnan, A.S.; Niteshraj, J. Hot Deformation Behavior of Aluminum Alloys AA7010 and AA7075. J. Mater. Eng. Perform. 2019, 28, 5021–5038. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, Y.; Yasin, G.; Nazeer, F.; Malik, A.; Khan, W.Q.; Ahmad, T.; Zhang, H.; Afifi, M.A. The effect of strain rates on the microstructure and the mechanical properties of an over-aged Al-Zn-Mg-Cu alloy. Mater. Charact. 2020, 167, 110472. [Google Scholar] [CrossRef]

- Shih, T.S.; Lin, S.T.; Hwang, L.R. Factors Affecting Toughness and Corrosion Resistance of AA6082 Forgings. J. Mater. Eng. Perform. 2021, 30, 367–378. [Google Scholar] [CrossRef]

- Xiao, G.; Jiang, J.; Liu, Y.; Wang, Y.; Guo, B. Recrystallization and microstructure evolution of hot extruded 7075 aluminum alloy during semi-solid isothermal treatment. Mater. Charact. 2019, 156, 109874. [Google Scholar] [CrossRef]

- Hua, L.; Hu, X.; Han, X. Microstructure evolution of annealed 7075 aluminum alloy and its influence on room-temperature plasticity. Mater. Des. 2020, 196, 109–192. [Google Scholar] [CrossRef]

- Mondal, C.; Mukhopadhyay, A.K. On the nature of T(Al2Mg3Zn3) and S(Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy. Mater. Sci. Eng. A 2005, 391, 367–376. [Google Scholar] [CrossRef]

- Lang, Y.; Cui, H.; Cai, Y.; Zhang, J. Evolution of nanometer precipitates in AA7050 Alloy subjected to overaging treatment and warm deformation. In Proceedings of the 13th International Conference on Aluminum Alloys (ICAA13), Pittsburgh, PA, USA, 3–7 June 2012; Weiland, H., Rollett, A.D., Cassada, W.A., Eds.; Springer: Cham, Switzerland, 2012; pp. 1223–1226. [Google Scholar]

- Du, Y.; Chang, Y.A.; Huang, B.; Gong, W.; Jin, Z.; Xu, H.; Yuan, Z.; Liu, Y.; He, Y.; Xie, F.Y. Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation. Mater. Sci. Eng. A 2003, 363, 140–151. [Google Scholar] [CrossRef]

- Cabibbo, M. Microstructure strengthening mechanisms in different equal channel angular pressed aluminum alloys. Mater. Sci. Eng. A 2012, 560, 413–432. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthend aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Fan, X.; Jiang, D.; Meng, Q.; Zhong, L. The microstructural evolution of an Al-Zn-Mg-Cu alloy during homogenization. Mater. Lett. 2006, 60, 1475–1479. [Google Scholar] [CrossRef]

- Andreatta, F.; Terryn, H.; de Wit, J.H.W. Corrosion behaviour of different tempers of AA7075 aluminum alloy. Electrochim. Acta 2004, 49, 2851–2862. [Google Scholar] [CrossRef]

| Element | Zn | Mg | Fe | Mn | Cr | Ti | Si | Cu |

|---|---|---|---|---|---|---|---|---|

| Content | 5.63 | 2.45 | 0.12 | 0.03 | 0.22 | 0.03 | 0.09 | 1.57 |

| Sample Code | Ultimate Tensile Stress (MPa) | Yield Stress (MPa) | Total Elongation (%) | Toughness (10−6 J/m3) |

|---|---|---|---|---|

| 7075 * | 505 | 435 | 13 | NA |

| 7075 ** | 591 (9.8) | 564 (12) | 13.4 (0.5) | NA |

| CF50 | 525.2 (3.4) | 467.0 (10.9) | 17.4 (1.7) | 71.3 (2.1) |

| RF50 | 525.2 (26.8) | 465.7 (28.1) | 16.4 (2.5) | 70.5 (4.1) |

| HF50 | 547.4 (36.9) | 491.8 (39.7) | 14.0 (2.0) | 53.9 (3.4) |

| HF62 | 591.8 (13.9) | 538.3 (11.4) | 13.4 (0.9) | 60.1 (2.9) |

| Al | Zn | Mg | Cu | Si | Fe | Mn | Cr | Ti | Phase | Sample |

|---|---|---|---|---|---|---|---|---|---|---|

| 33.06 | 35.19 | 9.99 | 20.32 | 0.14 | 0.76 | 0.14 | 0.22 | 0.08 | η-base * | CF50 |

| 69.98 | 3.27 | 6.30 | 14.39 | 0 | 0.52 | 0.13 | 5.38 | 0 | S-base ** | CF50 |

| 57.13 | 15.52 | 6.23 | 18.54 | 0.01 | 0.74 | 0 | 1.79 | 0 | η-base * | RF50 |

| 69.03 | 3.42 | 5.57 | 15.73 | 0 | 0.48 | 0.3 | 5.39 | 0.05 | S-base ** | RF50 |

| 25.05 | 38.19 | 13.08 | 21.34 | 0 | 0.96 | 0 | 1.08 | 0.27 | T-base *** | HF50 |

| 56.80 | 12.77 | 5.54 | 22.61 | 0.19 | 1.29 | 0 | 0.51 | 0.25 | η-base * | HF50 |

| 47.89 | 4.16 | 8.09 | 29.23 | 0 | 0.92 | 0.10 | 9.28 | 0.29 | S-base ** | HF62 |

| 8.69 | 47.79 | 16.55 | 25.20 | 0.1 | 1.3 | 0.19 | 0.08 | 0.06 | η-base * | HF62 |

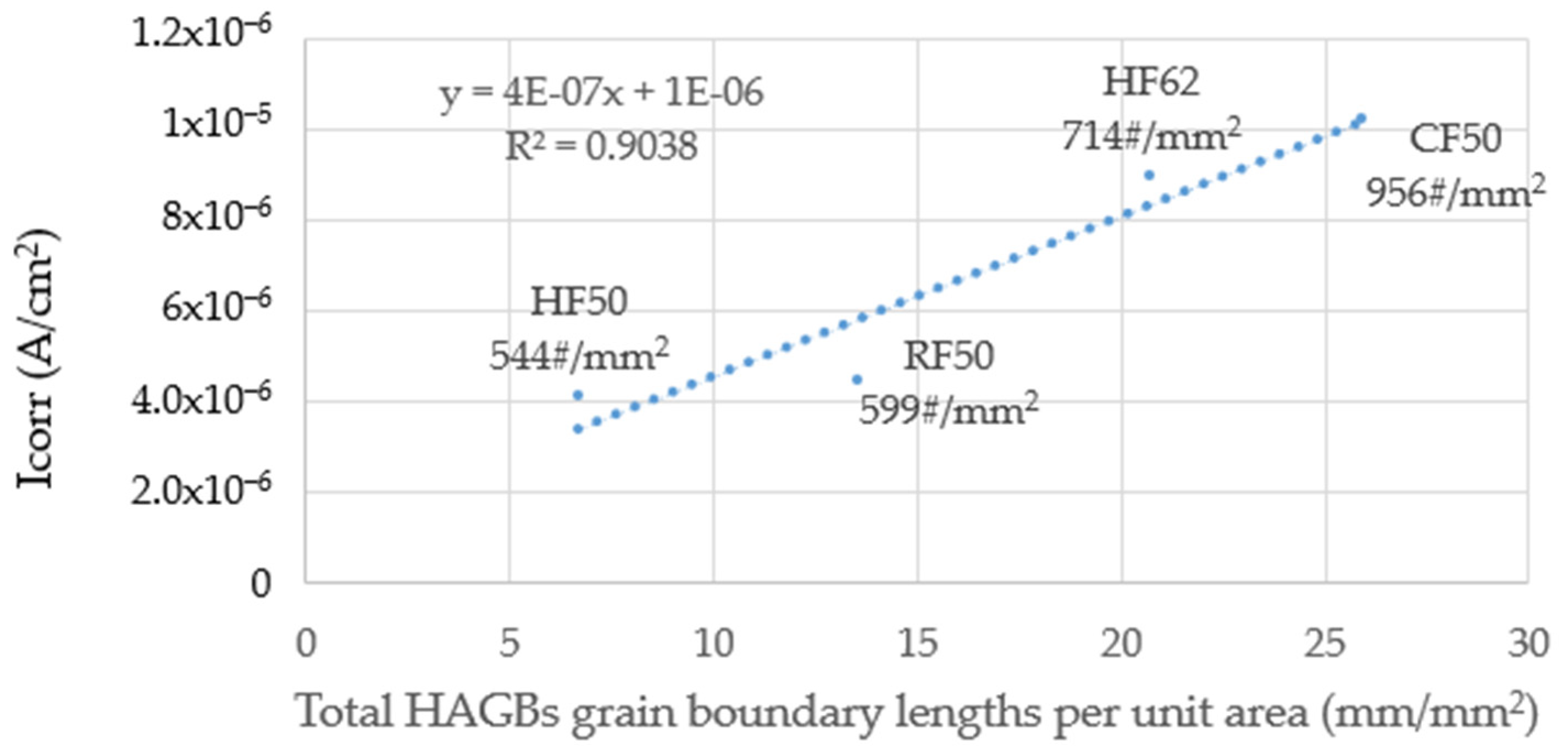

| Sample | Ecorr(V) | Icorr(A/cm2) | Epit(V) | Ipit(A/cm2) |

|---|---|---|---|---|

| A-T73 * | −1.11 | 2.71 × 10−7 | NA | NA |

| CF50 | −1.15 | 1.02 × 10−5 | −0.70 | 2.30 × 10−4 |

| RF50 | −1.19 | 4.45 × 10−6 | −0.71 | 3.42 × 10−5 |

| HF50 | −1.17 | 4.12 × 10−6 | −0.72 | 2.43 × 10−5 |

| HF62 | −1.46 | 8.96 × 10−6 | −0.69 | 3.89 × 10−5 |

| Sample Code | Total Grain Boundary Lengths per Unit Area (mm/mm2) |

|---|---|

| CF50 | 28.5 |

| RF50 | 17.4 |

| HF50 | 37.2 |

| HF62 | 66.9 |

| Samples | 2nd Phase Particle Counts, (#/mm2) | Max. Diameter | Average Diameter | ||||

|---|---|---|---|---|---|---|---|

| 0.2–1 μm | 1–5 μm | 5–10 Μm | >10 μm | Total | 2nd Phase Particles (μm) | ||

| CF50 | 663 | 281 | 11 | 1 | 956 | 14.4 | 1.1 |

| RF50 | 322 | 269 | 8 | 0 | 599 | 9.6 | 1.3 |

| HF50 | 317 | 216 | 11 | 0 | 544 | 9.0 | 1.2 |

| HF62 | 570 | 199 | 3 | 0 | 714 | 8.9 | 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shih, T.-S.; Hsu, H.-T.; Hwang, L.-R. Factors Affecting the Microstructure, Tensile Properties and Corrosion Resistance of AA7075 Forgings. Materials 2021, 14, 5776. https://doi.org/10.3390/ma14195776

Shih T-S, Hsu H-T, Hwang L-R. Factors Affecting the Microstructure, Tensile Properties and Corrosion Resistance of AA7075 Forgings. Materials. 2021; 14(19):5776. https://doi.org/10.3390/ma14195776

Chicago/Turabian StyleShih, Teng-Shih, Ho-Tieh Hsu, and Lih-Ren Hwang. 2021. "Factors Affecting the Microstructure, Tensile Properties and Corrosion Resistance of AA7075 Forgings" Materials 14, no. 19: 5776. https://doi.org/10.3390/ma14195776

APA StyleShih, T.-S., Hsu, H.-T., & Hwang, L.-R. (2021). Factors Affecting the Microstructure, Tensile Properties and Corrosion Resistance of AA7075 Forgings. Materials, 14(19), 5776. https://doi.org/10.3390/ma14195776