Study on Possible Application of Rubber Granulate from the Recycled Tires as an Elastic Cover of Prototype Rail Dampers, with a Focus on Their Operational Durability

Abstract

:1. Introduction

- Dampers with an elastic cover that either fully or partially fills the rail chambers and, in some cases, also surrounds the surface of the rail base. The rail cover exhibits the same characteristics of vibration as the rail, so it does not change the general dynamic characteristics of the rail system. This type of damper will be referred to as “static dampers” or “dampers with cover” (Figure 1b);

- Dampers with an element or a group of elements with a certain mass that are distributed periodically along the rail chambers and fixed to the rail using an elastic elastomeric layer (usually polyurethane resin). The elastically attached damping mass (usually a steel insert) is excited by the moving trains; due to the elastic layer, the induced vibrations can undergo a phase shift compared to the rail vibrations. This phenomenon changes the general dynamic characteristics of the rail, and thereby suppresses the acoustic wave emitted by the rail, especially its web. This version of rail damper will be referred to as “mass dampers” or “dynamic dampers” (Figure 1c).

2. Experimental Identification of Static and Dynamic Elastic Characteristics

2.1. Standards and Test Procedures

2.2. Description of the Samples

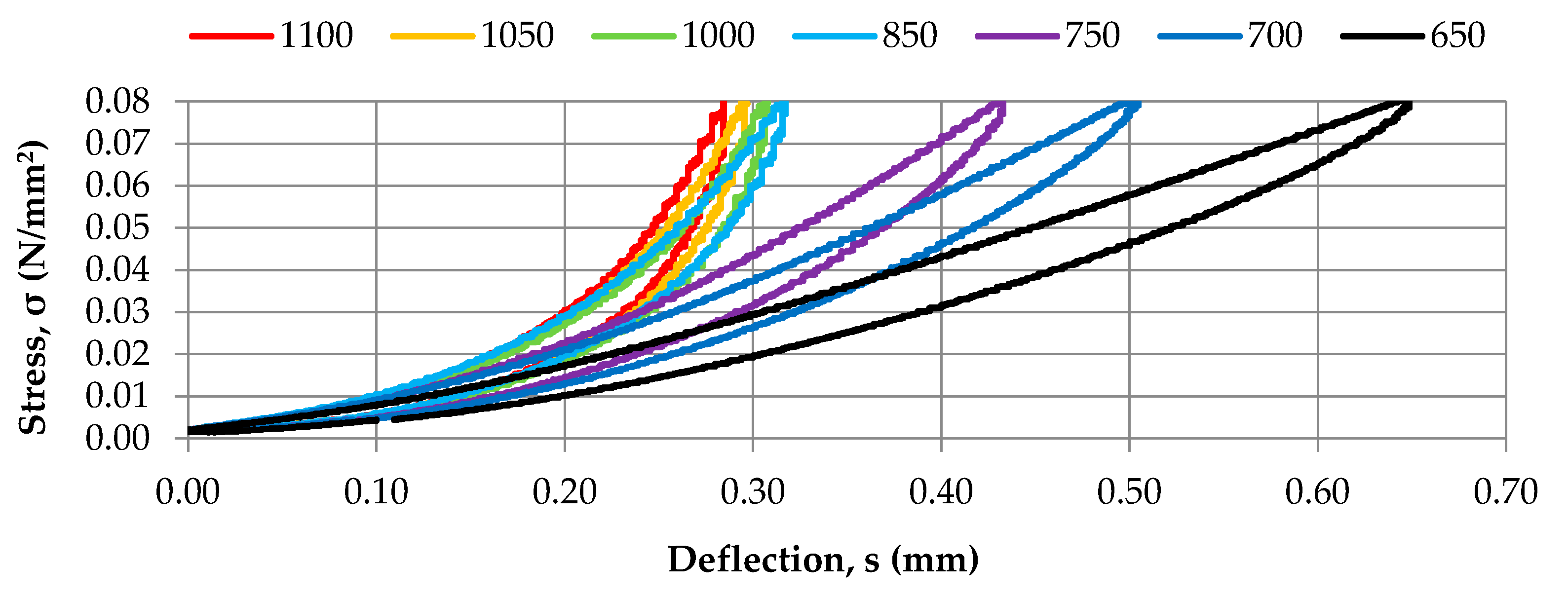

2.3. Identification of Static Elastic Properties

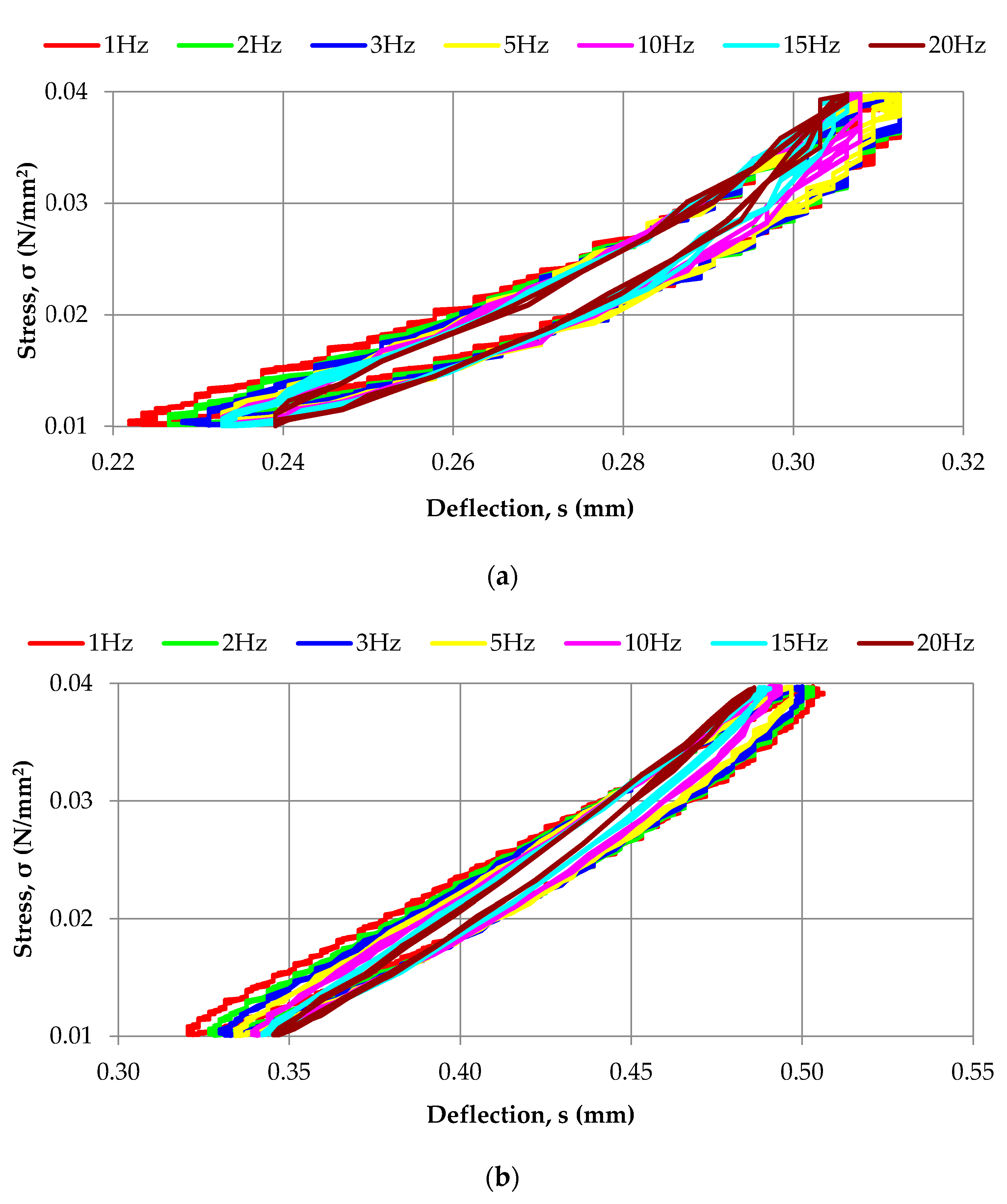

2.4. Identification of Dynamic Elastic Properties

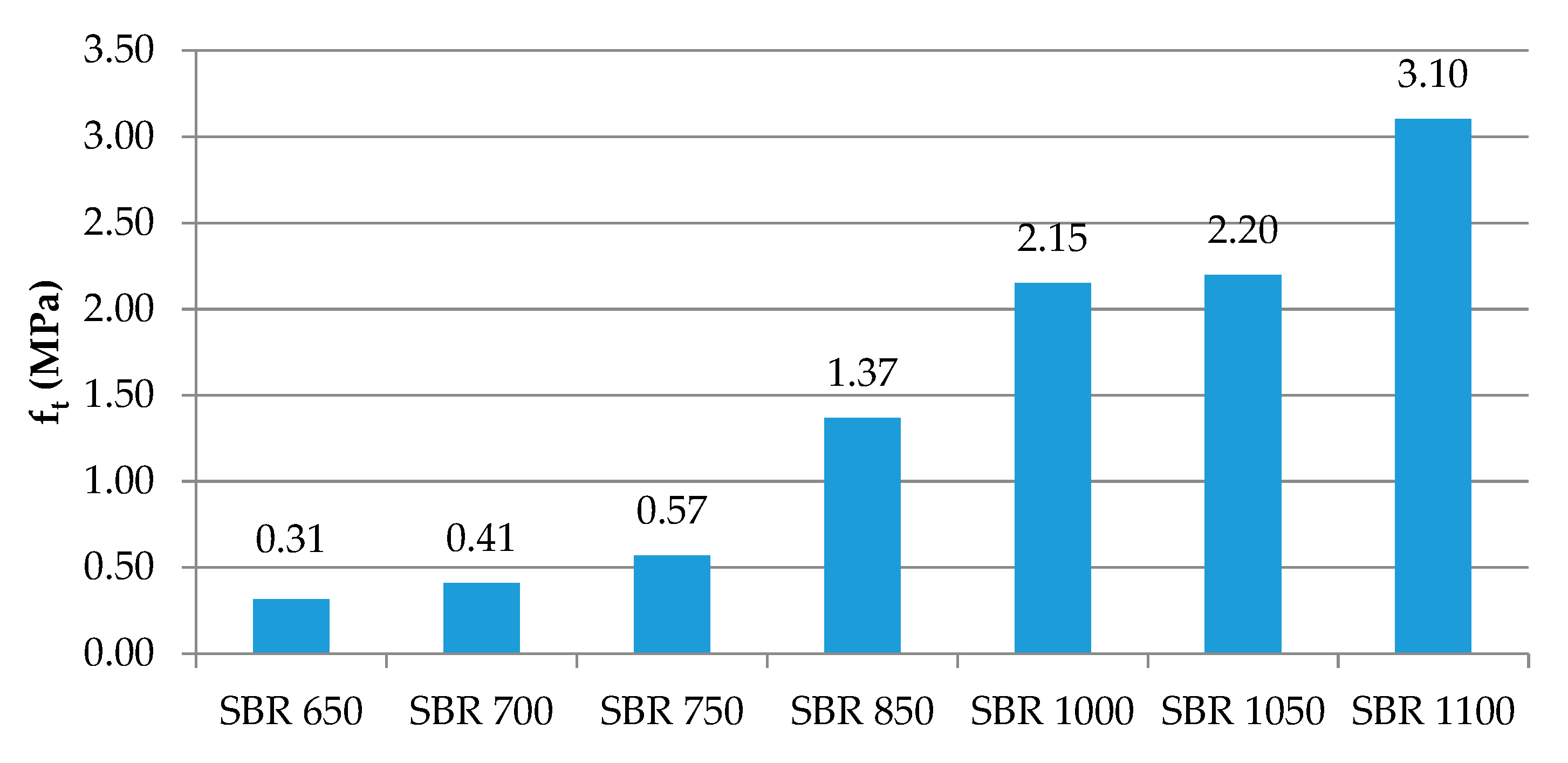

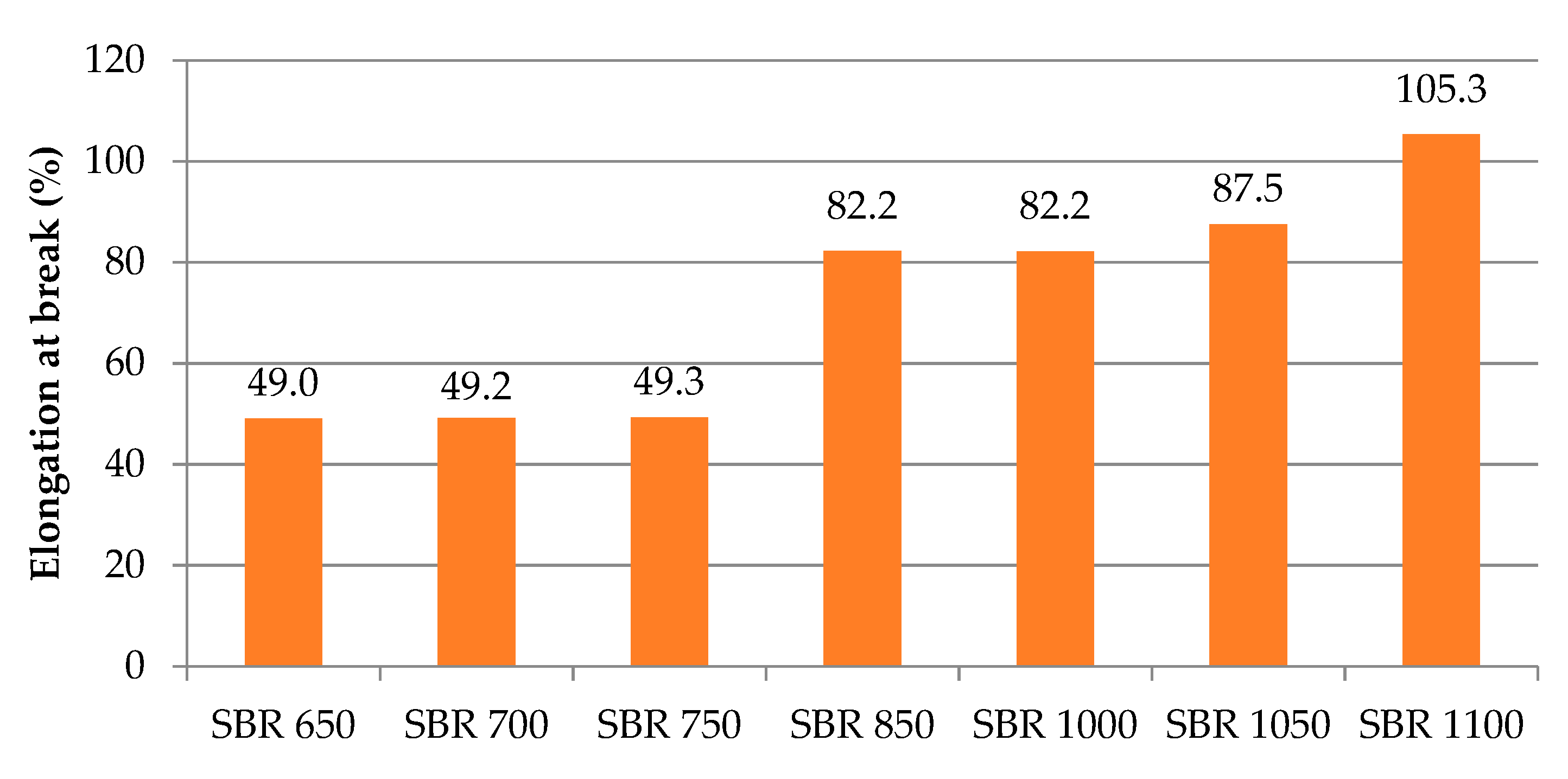

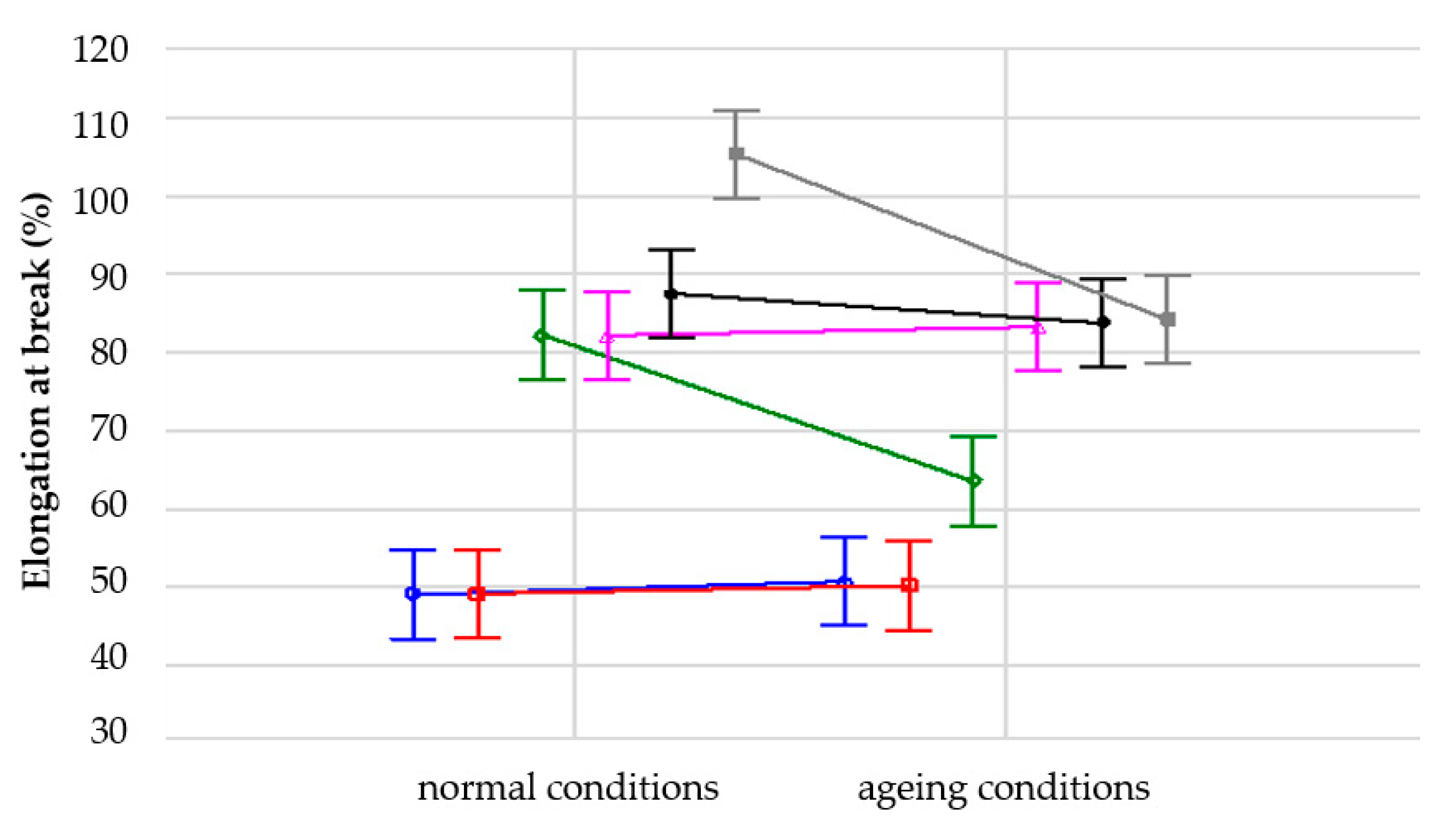

2.5. Tensile Strength and Elongation at Break

2.6. Conclusions from the Experimental Identification of Elastic Properties

- Variations of the static and dynamic elastic properties are small in the case of SBR samples with densities of 1000 kg/m3 or higher (SBR 1000, SBR 1050 and SBR 1100);

- Variations of the static and dynamic elastic properties are significant in the case of SBR samples with densities below 1000 kg/m3 (SBR 850, SBR 750, SBR 700 and SBR 650);

- Tensile strength and elongation at break decrease significantly in the case of SBR samples with densities below 1000 kg/m3 (SBR 850, SBR 750, SBR 700 and SBR 650).

3. Experimental Verification of the Operational Durability

3.1. Adopted Assumptions

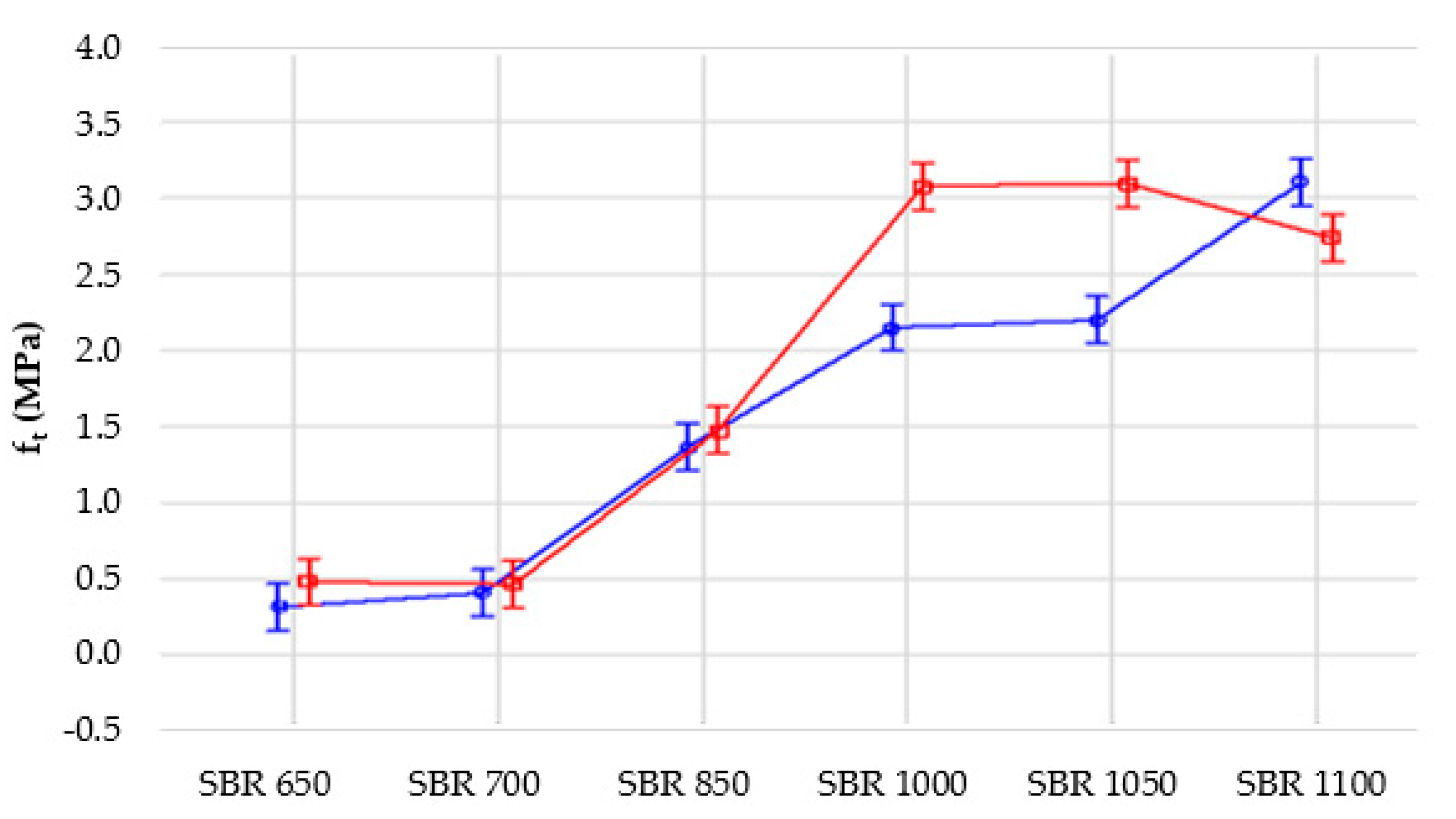

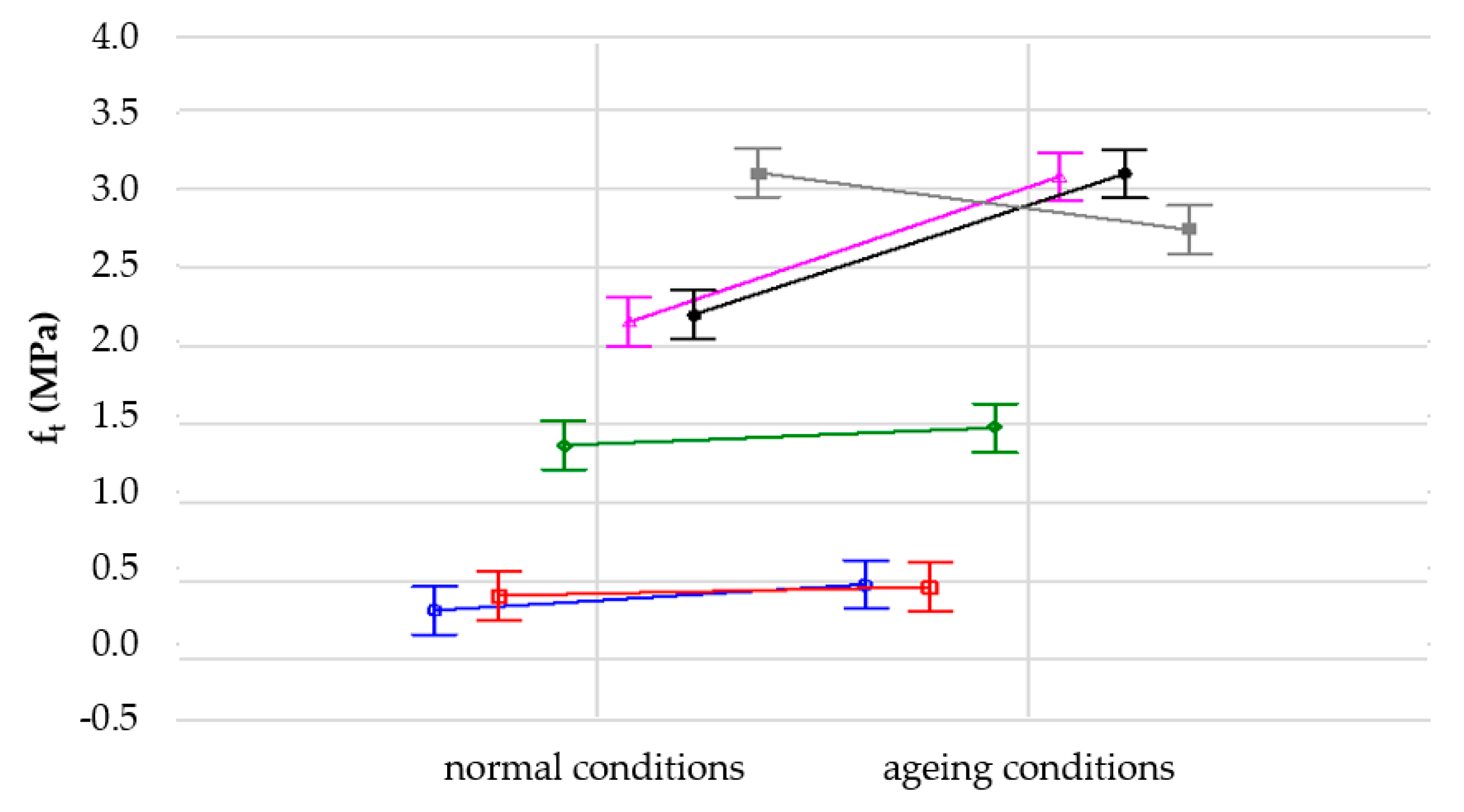

3.2. Influence of High Temperature and UV Radiation on Tensile Strength and Elongation at Break

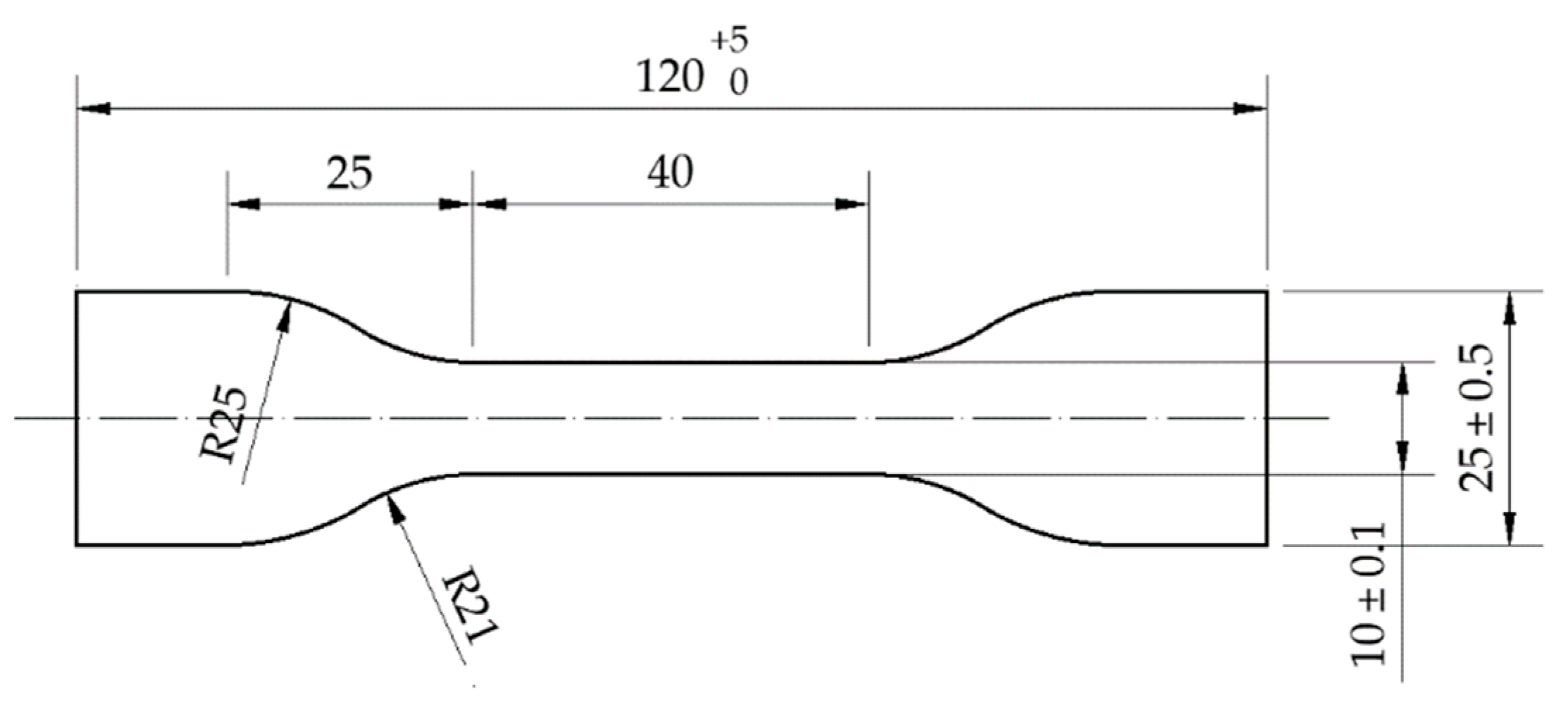

- Oar-shaped samples with the dimensions of 120 × 25 × 10 mm;

- Number of samples: 5;

- Test temperature: +70 °C;

- UV radiation corresponding to the solar radiation;

- Testing period: 168 h (7 days).

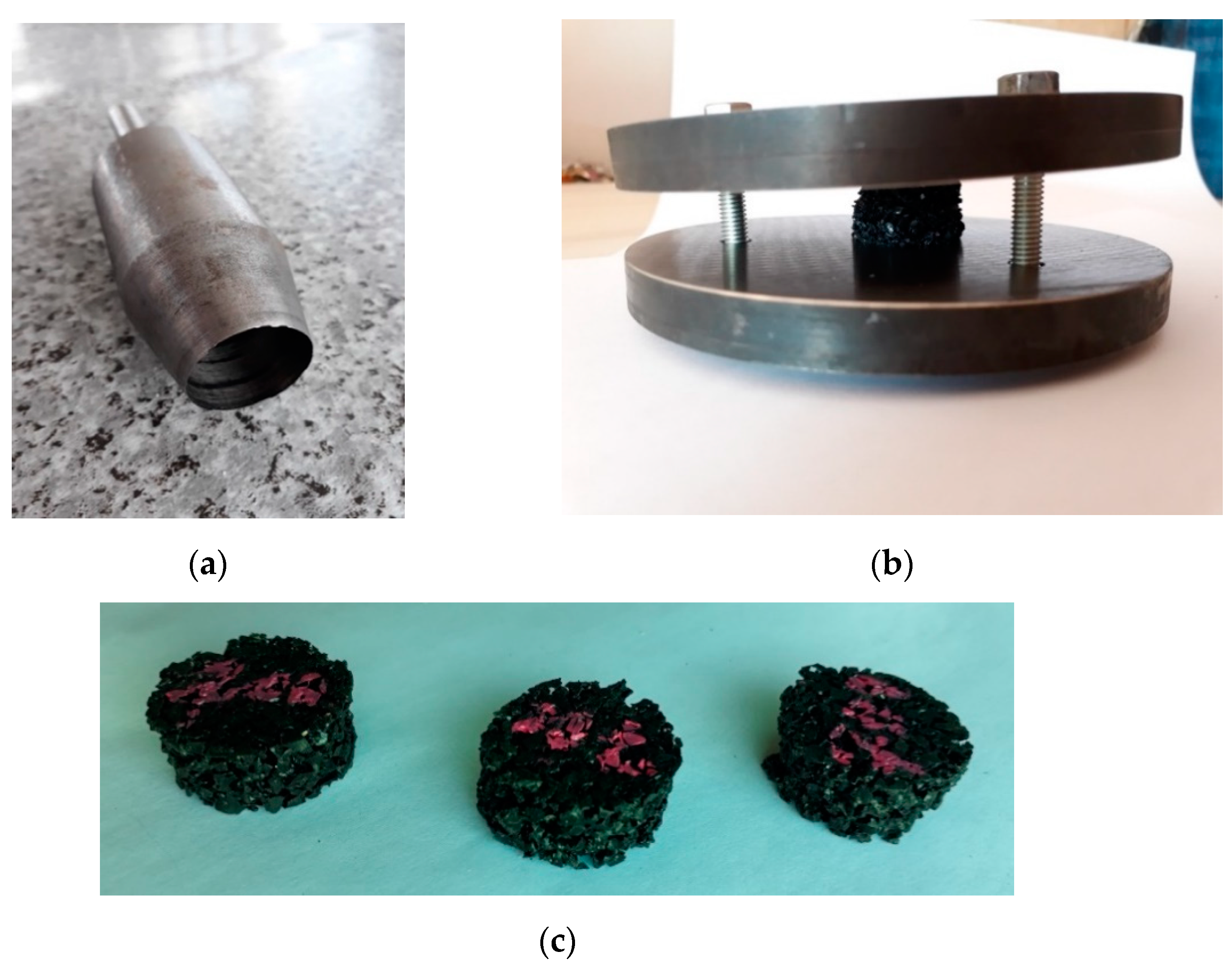

3.3. Permanent Deformation under Compression in Sub-Zero Temperatures

- Cylindrical samples with the diameter of 25 mm and the height corresponding to the material thickness of ca. 10–12 mm;

- Number of samples: 3;

- Initial deformation: 10% of the initial height;

- Test temperature: −30 °C;

- Testing period: 168 h (7 days).

- For around 50% of the samples (11 out of 21) extensive deformation (140–180%) caused by shrinkage was observed at the temperature of −30 °C, which exceeded the initial compressive deformation of 100%;

- All samples had a tendency to return to their initial shape after relaxation;

- For 2 out of 21 samples the height after relaxation was bigger than the initial dimension;

- 5 out of 6 samples representing the materials with the highest shrinkage of 170–180% (SBR 850 and SBR 1100) did not return to shape after initial deformation of 100%, and thus did not regain their shape from before the applied initial deformation;

- In the case of four samples the permanent deformation was higher than 50% of the initial deformation, and in the case of 10 samples it was lower than 50%, which is around 5% of the real deformation.

3.4. Influence of Mineral Oil on the Dimensions of Samples

- The samples lost some of their strength after they were taken out of oil and drained;

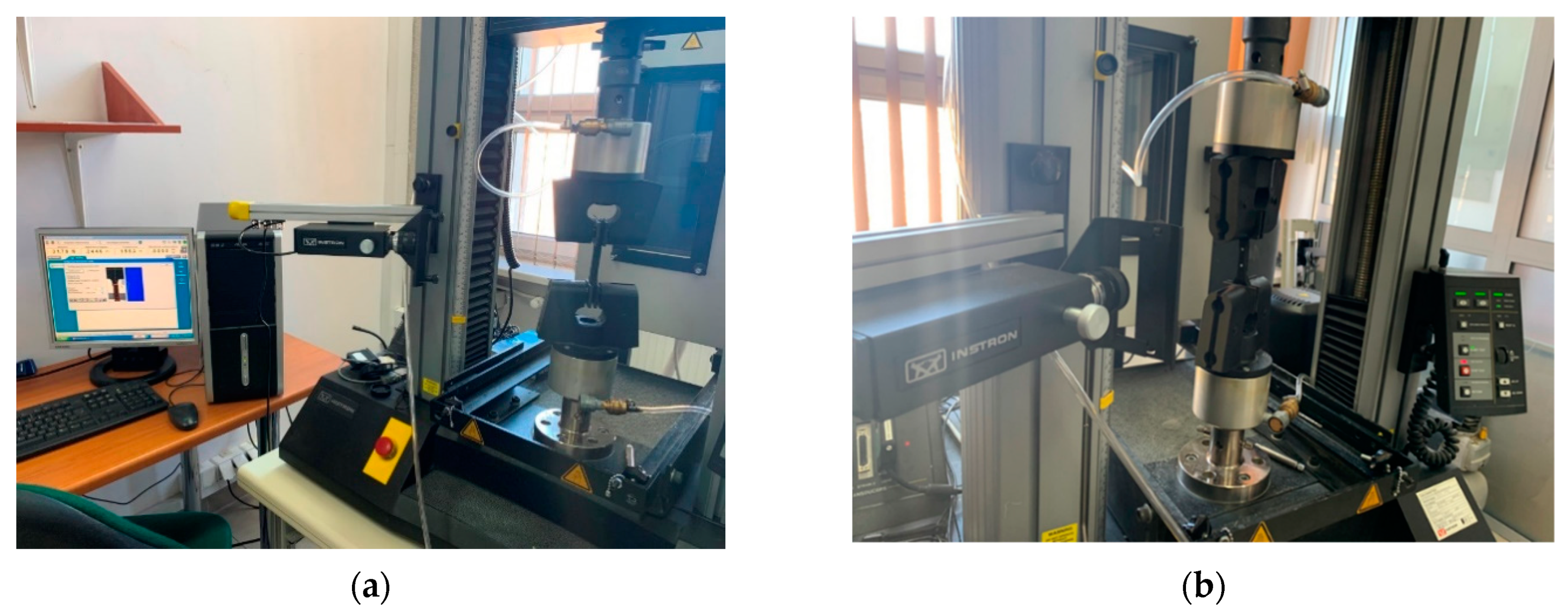

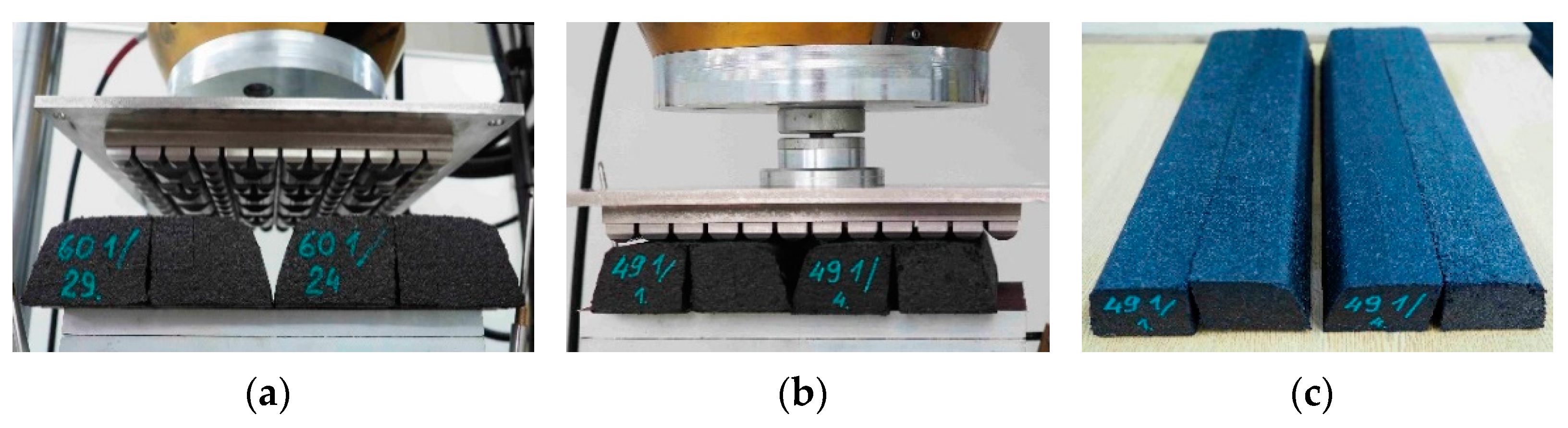

3.5. Resistance in Contact with Ballast Grains

3.6. Conclusions from the Experimental Verification of the Operational Durability

- The best results from the point of view of operational durability were exhibited by the samples of SBR granulate with high densities, that is, SBR 1000, SBR 1050 and SBR 1100;

- The worst results were obtained for the samples with lower densities, that is, SBR 850, SBR 750, SBR 700 and SBR 650;

- In severe freezing conditions the materials kept the ability to return to their initial shape, in spite of the observed shrinkage. In more than half of the tested samples, from the initial deformation of 10%, less than 5% was permanent. The most stable material was SBR 1050;

- Samples with lower densities (SBR 850, SBR 700 and SBR 650) exhibited significant swelling after contact with oil (the volume increase above 10%), which is an unacceptable result;

- In the resistance test conducted on the elastomeric material with a high density (SBR 1050), no damages or permanent deformations of the elastic cover were noticed after 100 thousand cycles of dynamic loading;

- The obtained results proved that the analysed materials did not lose their structural continuity under tension or compression; the determined elongation at break for porous SBR-based samples with densities over 850 kg/m3 was higher than 80% and there were no damages on the outer surface of prototypical rail dampers with a density of 1050 kg/m3 after 100 thousand load cycles.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scossa-Romano, E.; Oertli, J. Rail Dampers, Acoustic Rail Grinding, Low Height Noise Barriers. A Report on the State of the Art. Bern. 2012. Available online: https://uic.org/IMG/pdf/2012_dampers_grinding_lowbarriers.pdf (accessed on 29 September 2021).

- Kraśkiewicz, C.; Mossakowski, P.; Zbiciak, A.; Al Sabouni-Zawadzka, A. Experimental identification of dynamic characteristics of a track structure influencing the level of noise emission. Arch. Civ. Eng. 2021, 4. in press. [Google Scholar]

- EN 15461:2008+A1:2010 Railway Applications—Noise Emission—Characterization of the Dynamic Properties of Track Sections for Pass by Noise Measurements. Available online: https://standards.iteh.ai/catalog/standards/cen/26269fce-8011-4fbf-a206-b4b5f0cca0a4/en-15461-2008a1-2010 (accessed on 29 September 2021).

- Sieglitz, R.; Czolbe, C. Wirsamkeit von Schienenabsorbern in Abhaegigkeit Verschiedener Fahrzeugtypen; DAGA: Darmstadt, Germany, 2012. [Google Scholar]

- Sol-Sánchez, M.; Moreno-Navarro, F.; Gámez, M. The Use of Deconstructed Tires as Elastic Elements in Railway Tracks. Materials 2014, 7, 5903–5919. [Google Scholar] [CrossRef] [Green Version]

- Sol-Sánchez, M.; Moreno-Navarro, F.; Rubio-Gámez, M.C. Viability of using end-of-life tire pads as under sleeper pads in railway. Constr. Build. Mater. 2014, 64, 150–156. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Pirozzolo, L.; Moreno-Navarro, F.; Rubio-Gámez, C. A study into the mechanical performance of different configurations for the railway track section: A laboratory approach. Eng. Struct. 2016, 119, 13–23. [Google Scholar] [CrossRef]

- Onorii, C. Mechanical Behaviour of Traditional and Antivibration Railway Tracks with Recycled Rubber Materials. Ph.D. Thesis, Università Degli Studi Di Napoli Federico II, Neapol, Italy, 2007. [Google Scholar]

- Gardziejczyk, W.; Plewa, A.; Pakholak, R. Effect of Addition of Rubber Granulate and Type of Modified Binder on the Viscoelastic Properties of Stone Mastic Asphalt Reducing Tire/Road Noise (SMA LA). Materials 2020, 13, 3446. [Google Scholar] [CrossRef]

- Contreras-Marín, E.; Anguita-García, M.; Alonso-Guzmán, E.M.; Jaramillo-Morilla, A.; Mascort-Albea, E.J.; Romero-Hernández, R.; Soriano-Cuesta, C. Use of Granulated Rubber Tyre Waste as Lightweight Backfill Material for Retaining Walls. Appl. Sci. 2021, 11, 6159. [Google Scholar] [CrossRef]

- Klajn, K.; Gozdek, T.; Bieliński, D.M.; Siciński, M.; Zarzecka-Napierała, M.; Pędzich, Z. SBR Vulcanizates Filled with Modified Ground Tire Rubber. Materials 2021, 14, 3991. [Google Scholar] [CrossRef]

- Kim, S.; Shin, H.-O.; Yoo, D.-Y. Mechanical and Dynamic Behavior of an Elastic Rubber Layer with Recycled Styrene-Butadiene Rubber Granules. Polymers 2020, 12, 3022. [Google Scholar] [CrossRef]

- Toward, M.; Squicciarini, G.; Thompson, D.; Gao, Y. Estimating the performance of rail dampers using laboratory methods and software predictions. In Noise and Vibration Mitigation for Rail Transportation Systems; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Starnberg, M. STARDAMP—Ein Deutsch-Französisches Kooperationsprojekt zur Minderung des Schienenlärms; DAGA: Darmstadt, Germany, 2012. [Google Scholar]

- Betgen, B.; Bouvet, P.; Squicciarini, G.; Thompson, D. The STARDAMP Software: An Assessment Tool for Wheel and Rail Damper Efficiency. In Proceedings of the AIA-DAGA 2013 Conference on Acoustics, Merano, Italy, 18–21 March 2013. [Google Scholar]

- Betgen, B.; Squicciarini, G. On the prediction of rail cross mobility and track decay rates using Finite Element Models. In Proceedings of the 10th European Congress and Exposition on Noise Control Engineering, Maastricht, The Netherlands, 31 May–3 June 2015. [Google Scholar]

- Squicciarini, G.; Toward, M.; Thompson, D. Experimental procedures for testing the performance of rail dampers. J. Sound Vib. 2015, 359, 21–39. [Google Scholar] [CrossRef] [Green Version]

- Haladin, I.; Lakusic, S.; Košćak, J. Measuring vibration damping level on conventional rail track structures. Građevinar 2016, 68, 461–476. [Google Scholar]

- Qian, W.; Wu, Y.; Chen, G.; Ouyang, H. Experimental and numerical studies of the effects of a rail vibration absorber on suppressing short pitch rail corrugation. J. Vibroengineering 2016, 18, 1133–1144. [Google Scholar]

- Michalczyk, R.; Brzeziński, K.; Zbiciak, A. Numerical Vibration Response of Railway Track Retrofitted with Single Degree of Freedom Rail Dampers. IOP Conf. Ser. Mater. Sci. Eng. 2019, 661, 012151. [Google Scholar] [CrossRef]

- Zoontjens, L.; Welsh, L.; Croft, B. Predicting and Managing Rolling Noise Emissions from Trains on the Perth Metro Passenger Rail Network; Acoustics 2017, Sound, Science and Society: Perth, Australia, 2017. [Google Scholar]

- DIN 45673-7: 2010-08 Mechanical Vibration—Resilient Elements Used in Railway Tracks—Part 7: Laboratory Test Procedures for Resilient Elements of Floating Slab Track Systems. Available online: https://www.beuth.de/de/norm/din-45673-7/132140083 (accessed on 29 September 2021).

- EN ISO 1798:2008 Flexible Cellular Polymeric Materials—Determination of Tensile Strength and Elongation at Break. Available online: https://www.iso.org/standard/41059.html (accessed on 29 September 2021).

- Bałuch, H. Wybrane Zagadnienia Trwałości i Niezawodności Szyn Kolejowych; Spawalnictwo Dróg Szynowych: Warsaw, Poland, 2007. (In Polish) [Google Scholar]

- Nguyen, T.; Indraratna, B.; Singh, M. Dynamic Parameters of Subgrade Soils Prone to Mud Pumping Considering the Influence of Kaolin Content and the Cyclic Stress Ratio. Transp. Geotech. 2021, 29, 100581. [Google Scholar] [CrossRef]

- EN ISO 10846-2:2008 Acoustics and Vibration—Laboratory Measurement of Vibro-Acoustic Transfer Properties of Resilient Elements—Part 2: Direct Method for Determination of the Dynamic Stiffness of Resilient Supports for Translatory Motion. Available online: https://www.iso.org/standard/38937.html (accessed on 29 September 2021).

- Lapcik, L.; Augustin, P.; Píštěk, A.; Bujnoch, L. Measurement of the dynamic stiffness of recycled rubber based railway track mats according to the DB-TL 918.071 standard. Appl. Acoust. 2001, 62, 1123–1128. [Google Scholar] [CrossRef]

- Nguyen, T.; Indraratna, B. Rail track degradation under mud pumping evaluated through site and laboratory investigations. Int. J. Rail Transp. 2021. [Google Scholar] [CrossRef]

- Deutsche Bahn-Standard DBS 918 290:2017 Schienenstegdämpfer. Available online: https://www.deutschebahn.com/resource/blob/6031370/15b1397feac086853d7f6c5cdafec7ba/DBS918290_V2_0_DE-data.pdf (accessed on 29 September 2021).

- DIN 4102-1:1998 Brandverhalten von Baustoffen und Bauteilen—Teil 1: Baustoffe; Begriffe, Anforderungen und Prüfungen. Available online: https://www.beuth.de/de/norm/din-4102-1/5241696 (accessed on 29 September 2021).

- EN 13501-1:2002 Fire Classification of Construction Products and Building Elements—Part 1: Classification Using Test Data from Reaction to Fire Tests. Available online: https://standards.iteh.ai/catalog/standards/cen/4a4a36a4-4741-4f71-8010-ea7f35b48c65/en-13501-1-2002 (accessed on 29 September 2021).

- EN ISO 2440:2019 Flexible and Rigid Cellular Polymeric Materials—Accelerated Ageing Tests. Available online: https://standards.iteh.ai/catalog/standards/cen/3343ed11-dc7b-43e6-ae60-268b86d1654a/en-iso-2440-2019 (accessed on 29 September 2021).

- EN ISO 4892-3:2016 Plastics—Methods of Exposure to Laboratory Light Sources—Part 3: Fluorescent UV Lamps. Available online: https://www.iso.org/standard/67793.html (accessed on 29 September 2021).

- ISO 815-2:2019 Rubber, Vulcanized or Thermoplastic—Determination of Compression Set—Part 2: At Low Temperatures. Available online: https://www.iso.org/standard/74944.html (accessed on 29 September 2021).

- ISO 1817:2015 Rubber, Vulcanized or Thermoplastic—Determination of the Effect of Liquids. Available online: https://www.iso.org/standard/63612.html (accessed on 29 September 2021).

- Zbiciak, A.; Kraśkiewicz, C.; Al Sabouni-Zawadzka, A.; Pełczyński, J.; Dudziak, S. A novel approach to the analysis of under sleeper pads (USP) applied in the ballasted track structures. Materials 2020, 13, 2438. [Google Scholar] [CrossRef]

- Kraśkiewicz, C.; Zbiciak, A.; Al Sabouni-Zawadzka, A.; Piotrowski, A. Experimental research on fatigue strength of prototype under sleeper pads used in the ballasted rail track systems. Arch. Civ. Eng. 2020, 66, 244–255. [Google Scholar]

- EN 16730:2016-08 Railway Applications—Track—Concrete Sleepers and Bearers with under Sleeper Pads. Available online: https://sklep.pkn.pl/pn-en-16730-2016-08e.html (accessed on 29 September 2021).

- Kraśkiewicz, C.; Zbiciak, A.; Al Sabouni-Zawadzka, A.; Marczak, M. Analysis of the Influence of Fatigue Strength of Prototype Under Ballast Mats (UBMs) on the Effectiveness of Protection against Vibration Caused by Railway Traffic. Materials 2021, 14, 2125. [Google Scholar] [CrossRef] [PubMed]

- EN 17282:2020-10 Railway Applications—Infrastructure—Under Ballast Mats. Available online: https://standards.iteh.ai/catalog/standards/cen/cd51e8dd-01f7-47ef-bbac-eceadce54a13/en-17282-2020 (accessed on 29 September 2021).

| Assessed Loads Range (N/mm2) | Density (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| 1100 | 1050 | 1000 | 850 | 750 | 700 | 650 | |

| Static Bedding Modulus (N/mm3) | |||||||

| 0.005 ÷ 0.02 | 0.125 | 0.126 | 0.130 | 0.129 | 0.115 | 0.104 | 0.091 |

| 0.01 ÷ 0.04 | 0.230 | 0.225 | 0.231 | 0.218 | 0.173 | 0.148 | 0.121 |

| 0.02 ÷ 0.05 | 0.347 | 0.328 | 0.337 | 0.307 | 0.214 | 0.177 | 0.136 |

| 0.02 ÷ 0.07 | 0.438 | 0.407 | 0.426 | 0.369 | 0.235 | 0.189 | 0.143 |

| Load Frequency f (Hz) | Density (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| 1100 | 1050 | 1000 | 850 | 750 | 700 | 650 | |

| Dynamic Bedding Modulus (N/mm3) | |||||||

| 1 | 0.287 | 0.275 | 0.219 | 0.207 | 0.137 | 0.131 | 0.126 |

| 2 | 0.365 | 0.347 | 0.365 | 0.343 | 0.260 | 0.221 | 0.176 |

| 3 | 0.380 | 0.367 | 0.377 | 0.357 | 0.269 | 0.228 | 0.182 |

| 5 | 0.394 | 0.393 | 0.390 | 0.376 | 0.278 | 0.238 | 0.188 |

| 10 | 0.420 | 0.402 | 0.422 | 0.401 | 0.295 | 0.252 | 0.200 |

| 15 | 0.430 | 0.408 | 0.438 | 0.402 | 0.306 | 0.257 | 0.206 |

| 20 | 0.457 | 0.435 | 0.448 | 0.418 | 0.314 | 0.274 | 0.217 |

| Factor | df | ft (MPa) | |||

|---|---|---|---|---|---|

| SS | MS | F | p | ||

| Density | 65.8293 | 5 | 13.1659 | 447.945 | 0.000000 |

| Conditions | 1.3380 | 1 | 1.3380 | 45.524 | 0.000000 |

| Density*Conditions | 3.2602 | 5 | 0.6520 | 22.184 | 0.000000 |

| Sampling error | 1.4108 | 48 | 0.0294 | ||

| General | 65.8293 | 5 | 13.1659 | 447.945 | 0.000000 |

| Factor | df | Elongation at Break (%) | |||

|---|---|---|---|---|---|

| SS | MS | F | p | ||

| Density | 5 | 18,058.4 | 3611.7 | 91.798 | 0.000000 |

| Conditions | 1 | 660.4 | 660.4 | 16.786 | 0.000160 |

| Density*Conditions | 5 | 1378.2 | 275.6 | 7.006 | 0.000055 |

| Sampling error | 48 | 1888.5 | 39.3 | ||

| General | 59 | 21,985.5 | |||

| Density (kg/m3) | 650 | 700 | 850 | ||||||

| Change of Length | Change of Length | Change of Length | |||||||

| No. | l0 (mm) | lk (mm) | Δl (%) | l0 (mm) | lk (mm) | Δl (%) | l0 (mm) | lk (mm) | Δl (%) |

| 1 | 12.9 | 15.2 | 17.8 | 12.8 | 15.1 | 18.0 | 12.9 | 14.2 | 10.1 |

| 2 | 13.0 | 15.4 | 18.5 | 12.9 | 15.0 | 16.3 | 13.0 | 14.4 | 10.8 |

| 3 | 13.1 | 15.4 | 17.6 | 12.9 | 15.0 | 16.3 | 12.9 | 14.4 | 11.6 |

| 4 | 12.9 | 15.1 | 17.1 | 13.0 | 15.1 | 16.2 | 13.0 | 14.5 | 11.5 |

| 5 | 12.9 | 15.4 | 19.4 | 12.9 | 15.1 | 17.1 | 13.0 | 14.1 | 8.5 |

| Mean value | 13.0 | 15.3 | 18.1 | 12.9 | 15.1 | 16.7 | 13.0 | 14.3 | 10.5 |

| Standard deviation | 0.1 | 0.1 | 0.9 | 0.1 | 0.1 | 0.8 | 0.1 | 0.2 | 1.3 |

| Density (kg/m3) | 1000 | 1050 | 1100 | ||||||

| Change of Length | Change of Length | Change of Length | |||||||

| No. | l0 (mm) | lk (mm) | Δl (%) | l0 (mm) | lk (mm) | Δl (%) | l0 (mm) | lk (mm) | Δl (%) |

| 1 | 12.0 | 12.7 | 5.8 | 13.0 | 14.3 | 10.0 | 13.0 | 13.8 | 6.2 |

| 2 | 12.2 | 12.7 | 4.1 | 13.0 | 13.9 | 6.9 | 12.9 | 13.8 | 7.0 |

| 3 | 12.2 | 13.0 | 6.6 | 13.1 | 14.2 | 8.4 | 12.8 | 13.4 | 4.7 |

| 4 | 12.3 | 13.0 | 5.7 | 12.9 | 13.8 | 7.0 | 12.9 | 13.7 | 6.2 |

| 5 | 12.2 | 13.0 | 6.6 | 13.0 | 14.0 | 7.7 | 13.0 | 13.7 | 5.4 |

| Mean value | 12.2 | 12.9 | 5.7 | 13.0 | 14.0 | 8.0 | 12.9 | 13.7 | 5.9 |

| Standard deviation | 0.1 | 0.2 | 1.0 | 0.1 | 0.2 | 1.3 | 0.1 | 0.2 | 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kraśkiewicz, C.; Chmielewska, B.; Zbiciak, A.; Al Sabouni-Zawadzka, A. Study on Possible Application of Rubber Granulate from the Recycled Tires as an Elastic Cover of Prototype Rail Dampers, with a Focus on Their Operational Durability. Materials 2021, 14, 5711. https://doi.org/10.3390/ma14195711

Kraśkiewicz C, Chmielewska B, Zbiciak A, Al Sabouni-Zawadzka A. Study on Possible Application of Rubber Granulate from the Recycled Tires as an Elastic Cover of Prototype Rail Dampers, with a Focus on Their Operational Durability. Materials. 2021; 14(19):5711. https://doi.org/10.3390/ma14195711

Chicago/Turabian StyleKraśkiewicz, Cezary, Bogumiła Chmielewska, Artur Zbiciak, and Anna Al Sabouni-Zawadzka. 2021. "Study on Possible Application of Rubber Granulate from the Recycled Tires as an Elastic Cover of Prototype Rail Dampers, with a Focus on Their Operational Durability" Materials 14, no. 19: 5711. https://doi.org/10.3390/ma14195711

APA StyleKraśkiewicz, C., Chmielewska, B., Zbiciak, A., & Al Sabouni-Zawadzka, A. (2021). Study on Possible Application of Rubber Granulate from the Recycled Tires as an Elastic Cover of Prototype Rail Dampers, with a Focus on Their Operational Durability. Materials, 14(19), 5711. https://doi.org/10.3390/ma14195711