Piezoelectric Based Touch Sensing for Interactive Displays—A Short Review

Abstract

:1. Introduction

2. Principle and Broadly Used Materials

2.1. Principle

2.2. Broadly Used Materials

2.2.1. Piezoceramic

2.2.2. Single Crystal Materials

2.2.3. Piezoelectric Polymers

2.2.4. Ceramic-Polymer Composite

2.2.5. Piezoelectric Fabric

2.3. The Growth of Piezoelectric Materials

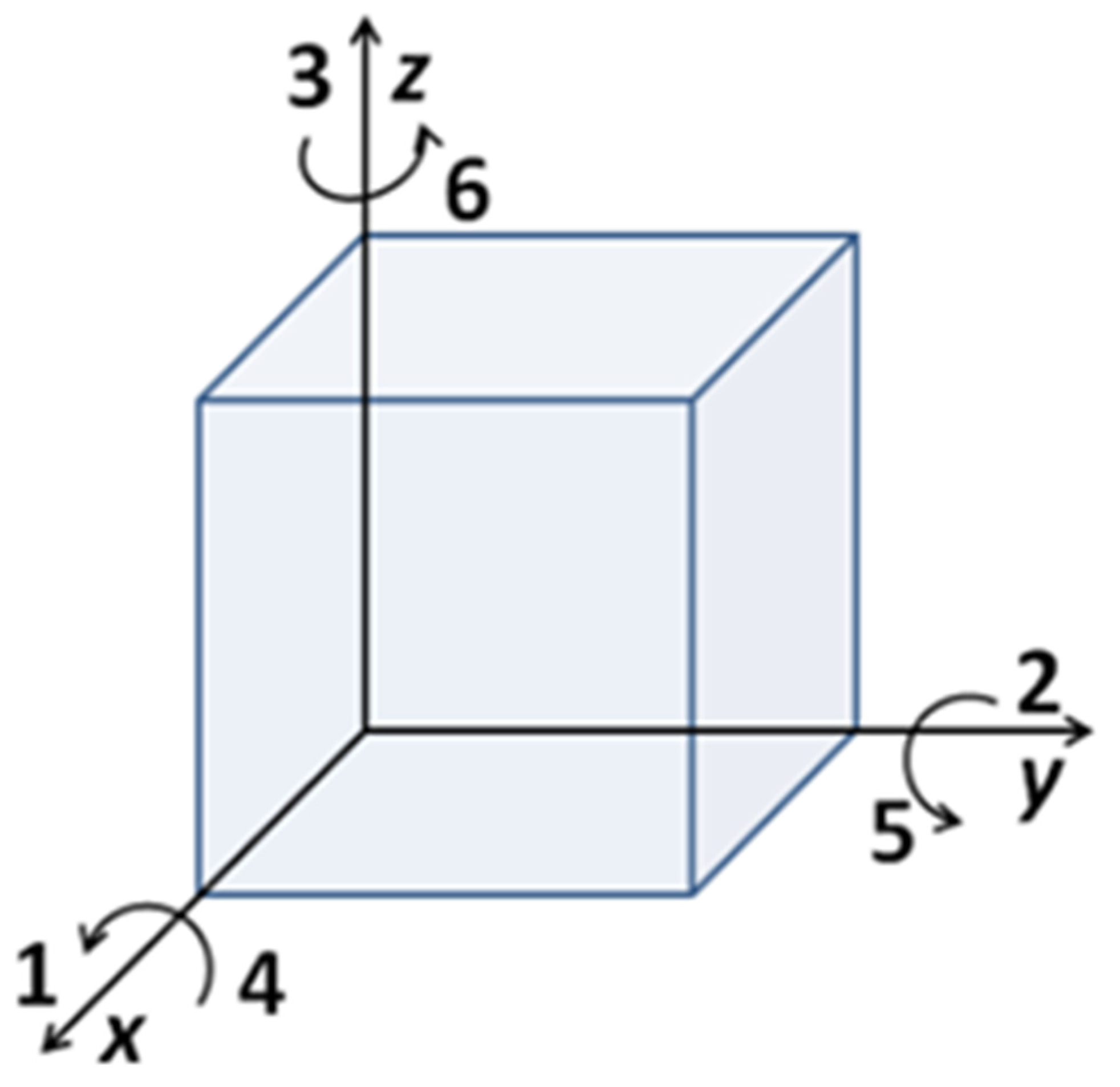

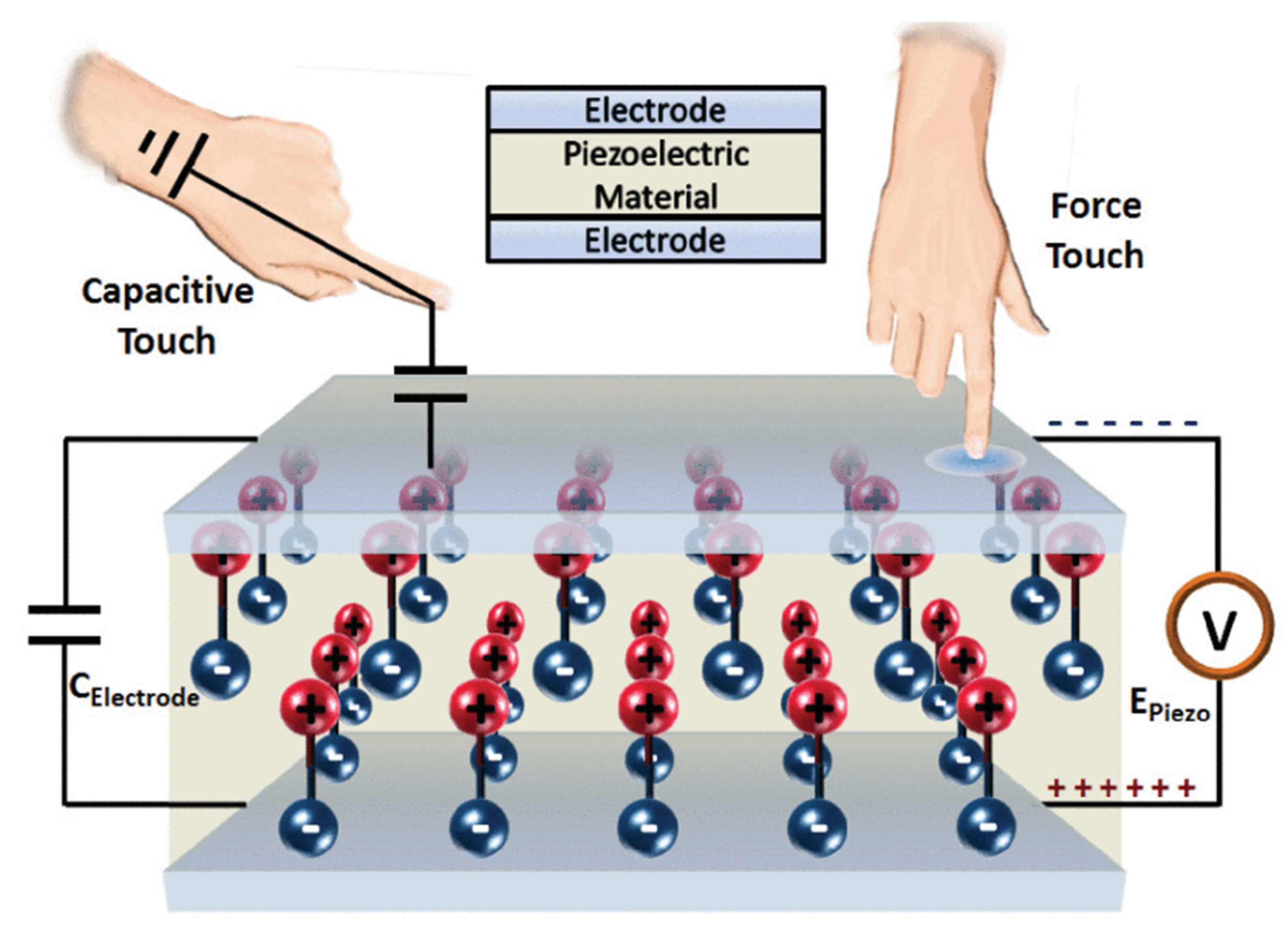

3. Piezoelectric-Based Touch Sensing Architecture

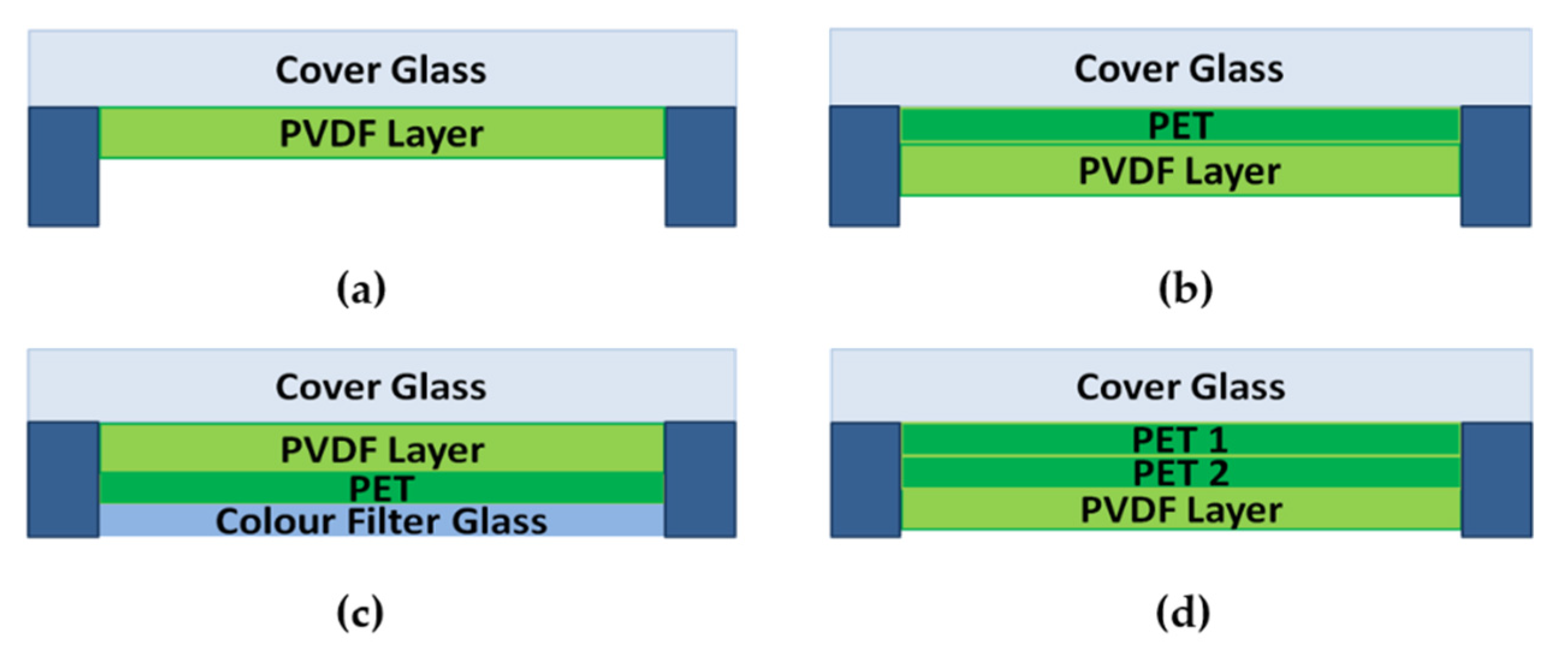

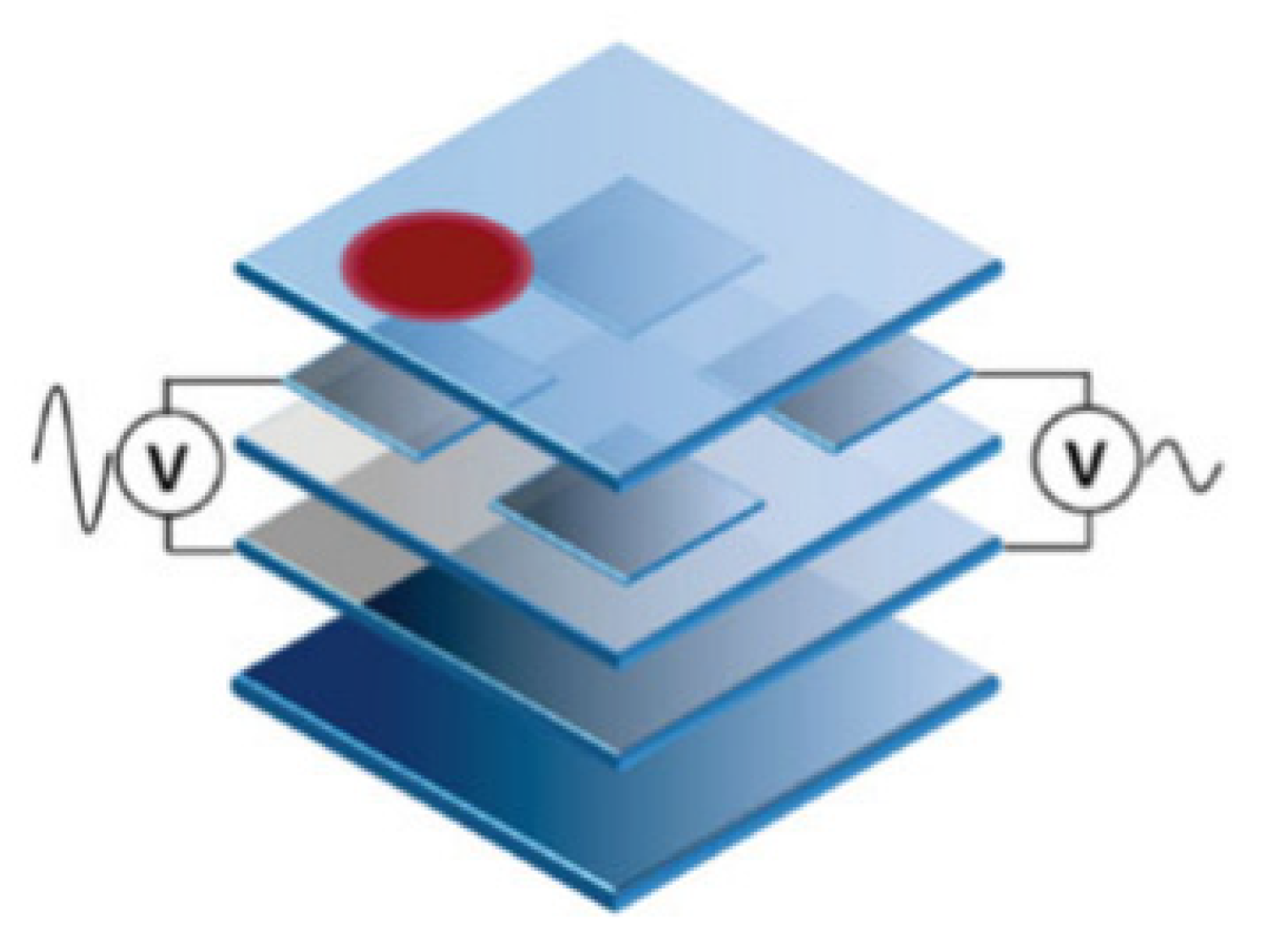

3.1. Typical Architecture

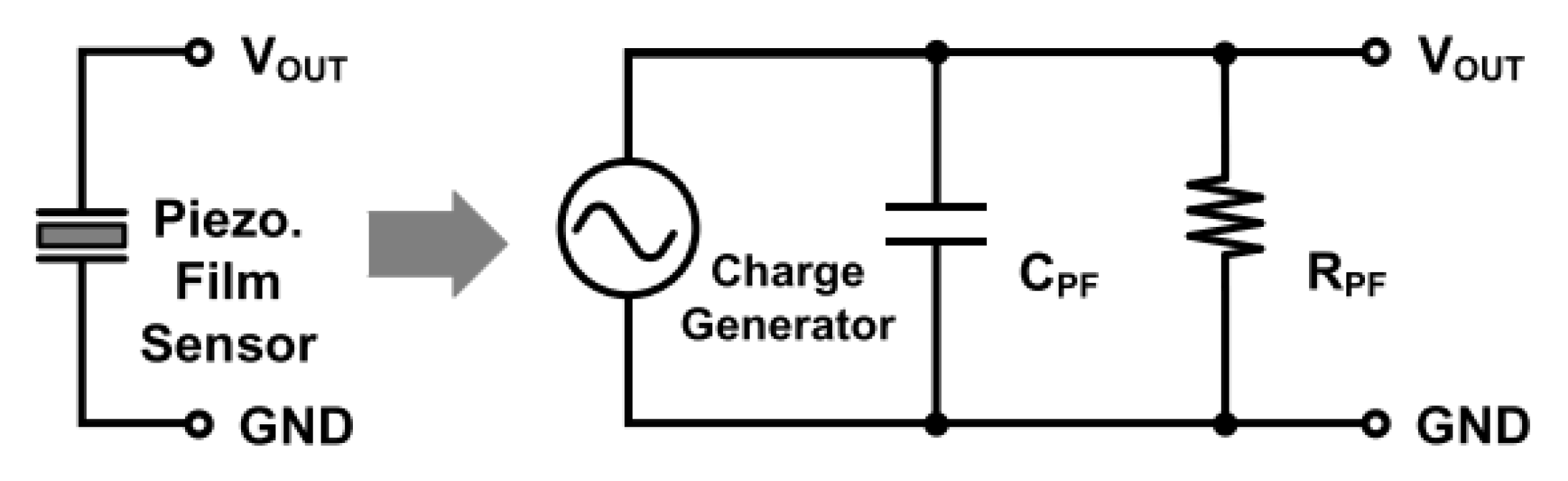

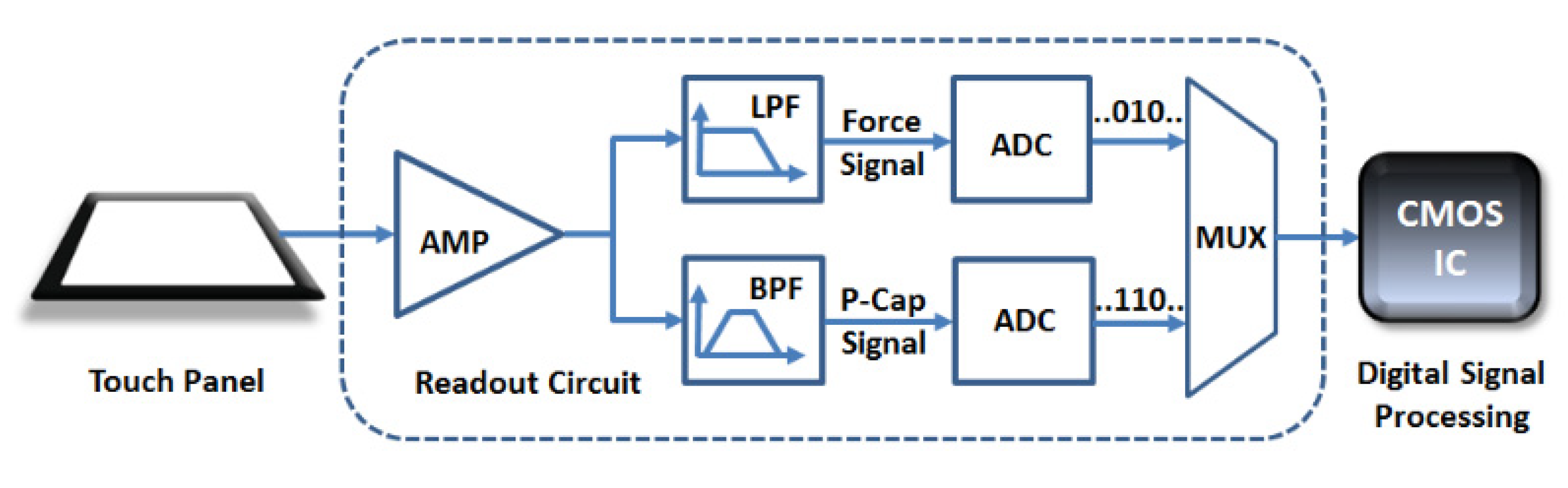

3.2. Typical Readout Circuity

4. Conventional Applications and Discussions

4.1. Conventional Piezoelectric-Based Touch Panels

4.2. Drawbacks and State of the Art Solutions

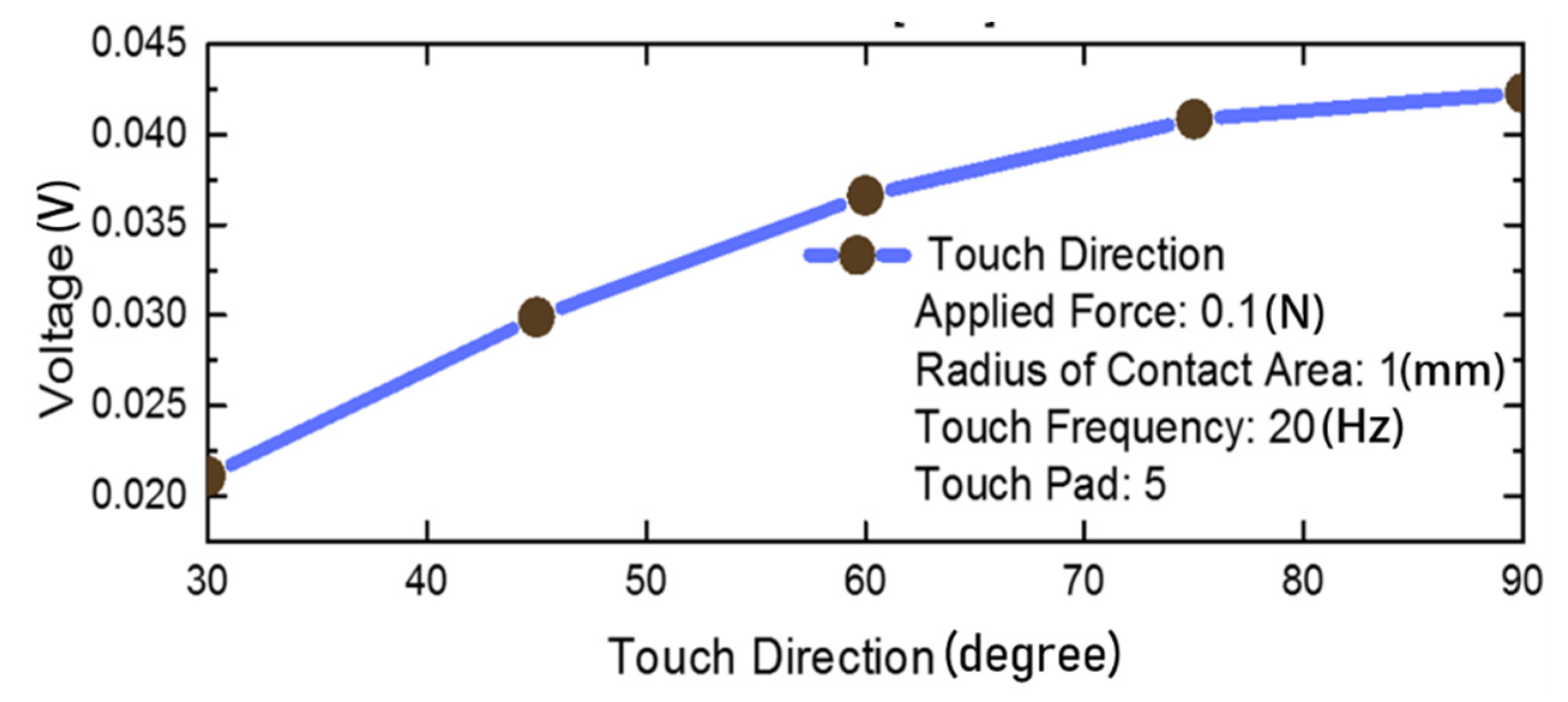

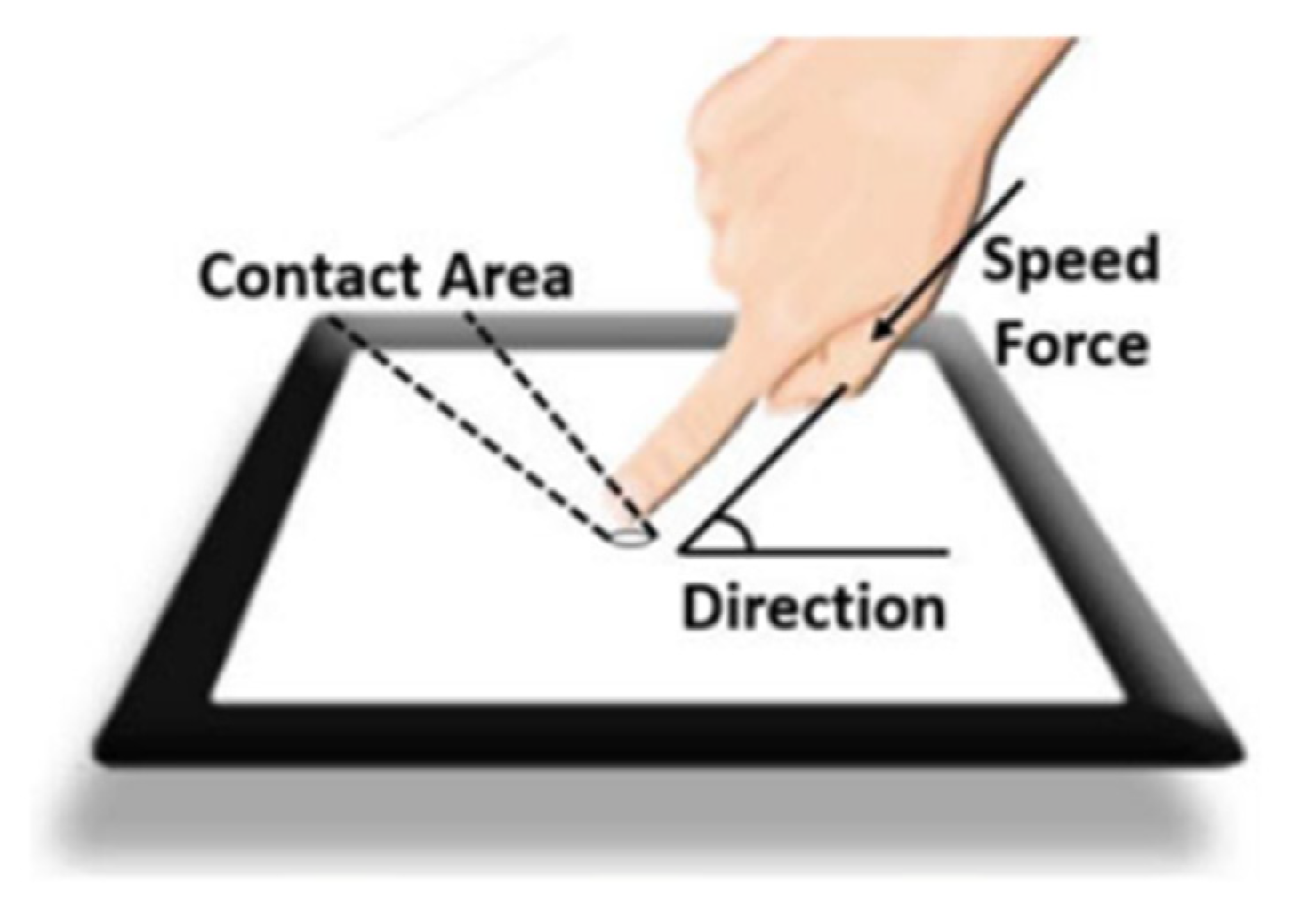

4.2.1. Contact Area and Touch Direction

4.2.2. Touch Speed

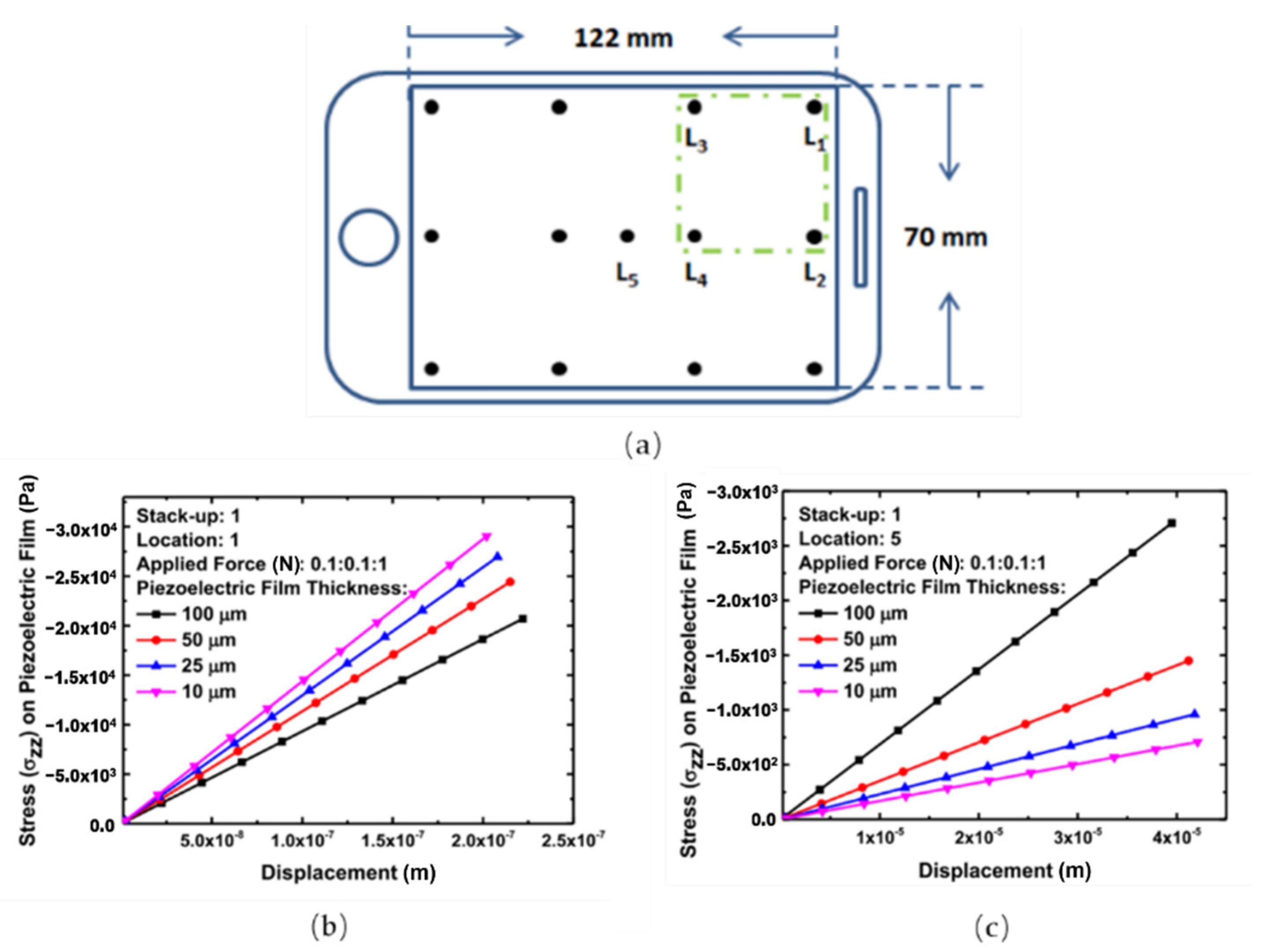

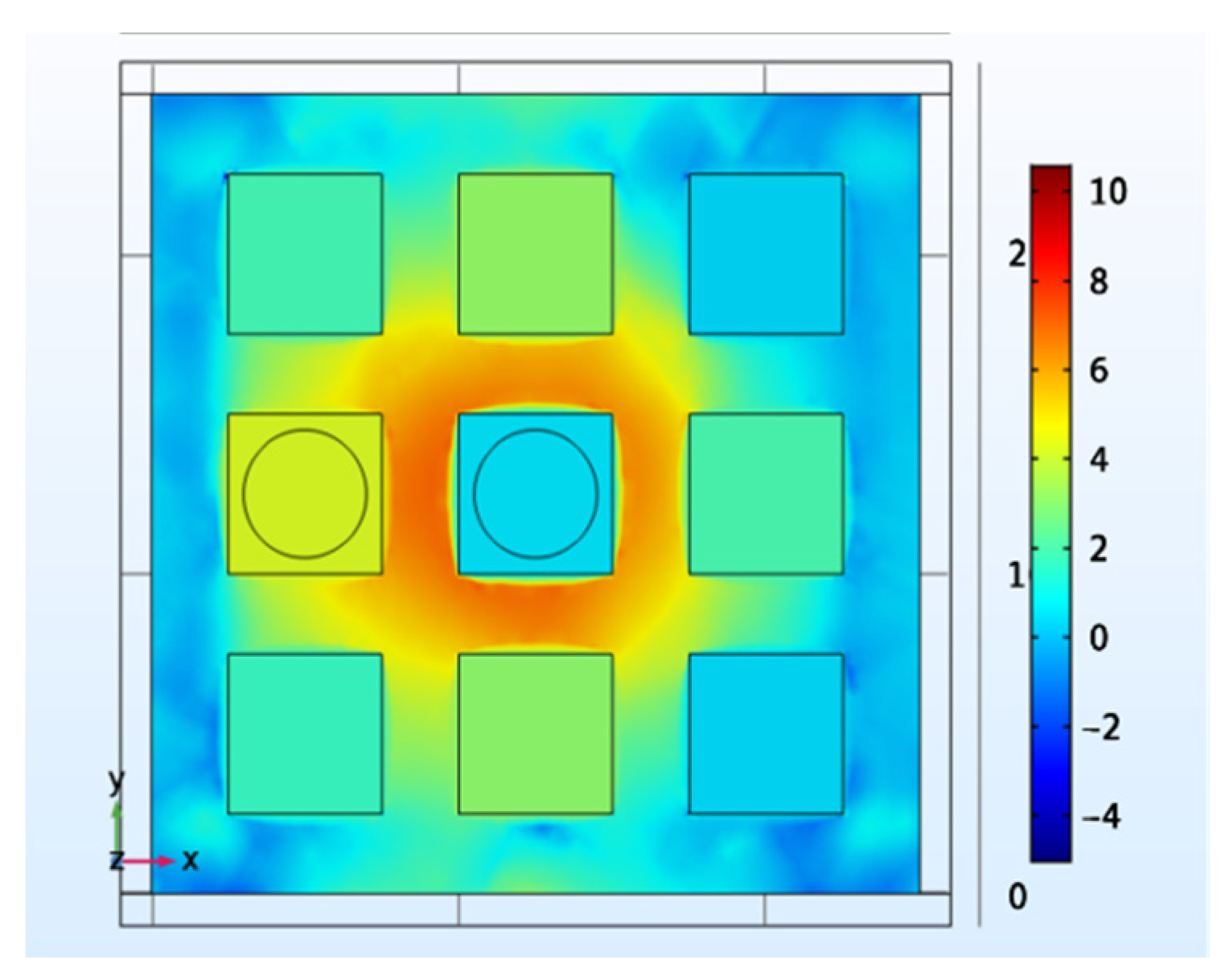

4.2.3. Propagated Stress

4.2.4. Preload Effect

4.2.5. Boundary Condition

5. Emerging Applications

5.1. Authentication

5.2. Underwater Application

5.3. Mood Detection

5.4. Multi-Touch

5.5. Robotic Skin

5.6. Gait Analysis

6. Challenges

6.1. Pyroelectric Effect Interference

6.2. Triboelectric Effect Interference

6.3. Sensitivity to Temperature Change

6.4. Multi Touch Interference

7. Conclusions and Perspective

Author Contributions

Funding

Conflicts of Interest

References

- Nathan, A.; Gao, S. Interactive displays: The next omnipresent technology [point of view]. Proc. IEEE 2016, 104, 1503–1507. [Google Scholar] [CrossRef]

- Geelhaar, T. Liquid crystals for display applications. Liq. Cryst. 1998, 24, 91–98. [Google Scholar] [CrossRef]

- Gao, H.-Y.; Yao, Q.-X.; Liu, P.; Zheng, Z.-Q.; Liu, J.-C.; Zheng, H.-D.; Zeng, C.; Yu, Y.-J.; Sun, T.; Zeng, Z.-X. Latest development of display technologies. Chin. Phys. B 2016, 25, 094203. [Google Scholar] [CrossRef]

- Anderson, P. Advanced Display Technologies; JISC: Bristol, UK, 2005. [Google Scholar]

- Lowe, J. Computer creates custom control panel. Des. News 1974, 29, 54–55. [Google Scholar]

- Barrett, G.; Omote, R. Projected-capacitive touch technology. Inf. Disp. 2010, 26, 16–21. [Google Scholar] [CrossRef]

- Walker, G. A review of technologies for sensing contact location on the surface of a display. J. Soc. Inf. Disp. 2012, 20, 413–440. [Google Scholar] [CrossRef]

- Gao, S.; Arcos, V.; Nathan, A. Piezoelectric vs. Capacitive Based Force Sensing in Capacitive Touch Panels. IEEE Access 2016, 4, 3769–3774. [Google Scholar] [CrossRef]

- Gao, S.; Wu, L. Why Piezoelectric Material is Unsuccessful in Interactive Displays: Challenges in High Detection Accuracy. IEEE Consum. Electron. Mag. 2019, 8, 28–31. [Google Scholar] [CrossRef]

- Gao, S.; Huang, C.-y.; Wu, L. Piezoelectric material based technique for concurrent force sensing and energy harvesting for interactive displays. In Proceedings of the 2017 IEEE Sensors, Glasgow, Scotland, 29 October–1 November 2017; pp. 1–3. [Google Scholar]

- Goldacker, T.; Abetz, V.; Stadler, R.; Erukhimovich, I.; Leibler, L.J.N. Non-centrosymmetric superlattices in block copolymer blends. Nature 1999, 398, 137–139. [Google Scholar] [CrossRef]

- Briscoe, J.; Jalali, N.; Woolliams, P.; Stewart, M.; Weaver, P.M.; Cain, M.; Dunn, S. Measurement techniques for piezoelectric nanogenerators. Energy Environ. Sci. 2013, 6. [Google Scholar] [CrossRef]

- Gao, S. A Multi-Functional Touch Panel for Multi-Dimensional Sensing in Interactive Displays; University of Cambridge: Cambridge, UK, 2017. [Google Scholar]

- Berlincourt, D.; Jaffe, H.; Shiozawa, L.R. Electroelastic Properties of the Sulfides, Selenides, and Tellurides of Zinc and Cadmium. Phys. Rev. 1963, 129, 1009–1017. [Google Scholar] [CrossRef]

- Piliposian, G.; Hasanyan, A.; Piliposyan, G.; Jilavyan, H. On the sensing, actuating and energy harvesting properties of a composite plate with piezoelectric patches. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 657–668. [Google Scholar] [CrossRef]

- Rödel, J.; Webber, K.G.; Dittmer, R.; Jo, W.; Kimura, M.; Damjanovic, D. Transferring lead-free piezoelectric ceramics into application. J. Eur. Ceram. Soc. 2015, 35, 1659–1681. [Google Scholar] [CrossRef]

- Trolier-McKinstry, S.; Zhang, S.; Bell, A.J.; Tan, X. High-Performance Piezoelectric Crystals, Ceramics, and Films. Annu. Rev. Mater. Res. 2018, 48, 191–217. [Google Scholar] [CrossRef] [Green Version]

- Zu, H.; Wu, H.; Wang, Q.M. High-Temperature Piezoelectric Crystals for Acoustic Wave Sensor Applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 486–505. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, F.; Green, D.J. Piezoelectric Materials for High Temperature Sensors. J. Am. Ceram. Soc. 2011, 94, 3153–3170. [Google Scholar] [CrossRef]

- Kawai, H. The piezoelectricity of poly (vinylidene fluoride). Jpn. J. Appl. Phys. 1969, 8, 975. [Google Scholar] [CrossRef]

- Crossley, S.; Whiter, R.; Kar-Narayan, S. Polymer-based nanopiezoelectric generators for energy harvesting applications. Mater. Sci. Technol. 2014, 30, 1613–1624. [Google Scholar] [CrossRef]

- Covaci, C.; Gontean, A. Piezoelectric Energy Harvesting Solutions: A Review. Sensors 2020, 20, 3512. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Unnikrishnan, L.; Nayak, S.K.; Mohanty, S. Advances in Piezoelectric Polymer Composites for Energy Harvesting Applications: A Systematic Review. Macromol. Mater. Eng. 2019, 304. [Google Scholar] [CrossRef] [Green Version]

- Vu, C.C.; Kim, S.J.; Kim, J. Flexible wearable sensors-an update in view of touch-sensing. Sci. Technol. Adv. Mater. 2021, 22, 26–36. [Google Scholar] [CrossRef]

- Sappati, K.K.; Bhadra, S.J.S. Piezoelectric polymer and paper substrates: A review. Sensors 2018, 18, 3605. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, J.; Xiong, C.; Dong, L.; Chen, C.; Lei, Y.; Chen, L.; Li, R.; Zhu, Q.; Liu, X. Enhancement of dielectric constant and piezoelectric coefficient of ceramic-polymer composites by interface chelation. J. Mater. Chem. 2009, 19, 2817–2821. [Google Scholar] [CrossRef]

- Hu, D.; Yao, M.; Fan, Y.; Ma, C.; Fan, M.; Liu, M.J.N.E. Strategies to achieve high performance piezoelectric nanogenerators. Nano Energy 2019, 55, 288–304. [Google Scholar] [CrossRef]

- Choi, Y.J.; Yoo, M.-J.; Kang, H.-W.; Lee, H.-G.; Han, S.H.; Nahm, S. Dielectric and piezoelectric properties of ceramic-polymer composites with 0–3 connectivity type. J. Electroceram. 2013, 30, 30–35. [Google Scholar] [CrossRef]

- Zaarour, B.; Zhu, L.; Huang, C.; Jin, X.; Alghafari, H.; Fang, J.; Lin, T. A review on piezoelectric fibers and nanowires for energy harvesting. J. Ind. Text. 2019, 51. [Google Scholar] [CrossRef]

- Mokhtari, F.; Cheng, Z.; Raad, R.; Xi, J.; Foroughi, J. Piezofibers to smart textiles: A review on recent advances and future outlook for wearable technology. J. Mater. Chem. A 2020, 8, 9496–9522. [Google Scholar] [CrossRef]

- Matsouka, D.; Vassiliadis, S. Piezoelectric melt-spun textile fibers: Technological overview. In Piezoelectricity—Organic and Inorganic Materials and Applications; BoD–Books on Demand: Norderstedt, Germany, 2018. [Google Scholar]

- Racles, C.; Dascalu, M.; Bele, A.; Tiron, V.; Asandulesa, M.; Tugui, C.; Vasiliu, A.-L.; Cazacu, M. All-silicone elastic composites with counter-intuitive piezoelectric response, designed for electromechanical applications. J. Mater. Chem. C 2017, 5, 6997–7010. [Google Scholar] [CrossRef]

- Singh, A.; Das, S.; Bharathkumar, M.; Revanth, D.; Karthik, A.; Sastry, B.S.; Rao, V.R. Low cost fabrication of polymer composite (h-ZnO+ PDMS) material for piezoelectric device application. Mater. Res. Express 2016, 3, 075702. [Google Scholar] [CrossRef]

- Babu, I.; de With, G.J. Highly flexible piezoelectric 0–3 PZT–PDMS composites with high filler content. Compos. Sci. Technol. 2014, 91, 91–97. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Yu, F.; Jiang, X.; Lee, H.-Y.; Luo, J.; Shrout, T.R. Recent Developments in Piezoelectric Crystals. J. Korean Ceram. Soc. 2018, 55, 419–439. [Google Scholar] [CrossRef] [Green Version]

- Uchino, K. Advanced Piezoelectric Materials: Science and Technology; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Acosta, M.; Novak, N.; Rojas, V.; Patel, S.; Vaish, R.; Koruza, J.; Rossetti, G., Jr.; Rödel, J. BaTiO3-based piezoelectrics: Fundamentals, current status, and perspectives. Appl. Phys. Rev. 2017, 4, 041305. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Miao, L.; Zhang, Z.; Pu, X.; Feng, Q.; Yanagisawa, K.; Fan, Y.; Fan, M.; Wen, P.; Hu, D. Recent progress in piezoelectric thin film fabrication via the solvothermal process. J. Mater. Chem. A 2019, 7, 16046–16067. [Google Scholar] [CrossRef]

- Lee, B.; Zhang, J. Preparation, structure evolution and dielectric properties of BaTiO3 thin films and powders by an aqueous sol-gel process. Thin Solid Films 2001, 388, 107–113. [Google Scholar] [CrossRef]

- Maneeshya, L.; Thomas, P.; Joy, K. Effects of site substitutions and concentration on the structural, optical and visible photoluminescence properties of Er doped BaTiO3 thin films prepared by RF magnetron sputtering. Opt. Mater. 2015, 46, 304–309. [Google Scholar] [CrossRef]

- Wills, L.; Wessels, B.W.; Richeson, D.; Marks, T.J. Epitaxial growth of BaTiO3 thin films by organometallic chemical vapor deposition. Appl. Phys. Lett. 1992, 60, 41–43. [Google Scholar] [CrossRef]

- Gao, S.; Yan, S.; Zhao, H.; Nathan, A. Touch-Based Human-Machine Interaction: Principles and Applications; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Gao, S.; Shi, Y.; Liu, Q.; Xu, L.; Fu, B.; Yang, Z. 4-dimensional sensing in interactive displays enabled by both capacitive and piezoelectric based touch panel. IEEE Access 2019, 7, 33787–33794. [Google Scholar] [CrossRef]

- Vuorinen, T.; Zakrzewski, M.; Rajala, S.; Lupo, D.; Vanhala, J.; Palovuori, K.; Tuukkanen, S. Printable, Transparent, and Flexible Touch Panels Working in Sunlight and Moist Environments. Adv. Funct. Mater. 2014, 24, 6340–6347. [Google Scholar] [CrossRef]

- Gao, S.; Guo, R.; Shao, M.; Xu, L. A Touch Orientation Classification-Based Force-Voltage Responsivity Stabilization Method for Piezoelectric Force Sensing in Interactive Displays. IEEE Sens. J. 2020, 20, 8147–8154. [Google Scholar] [CrossRef]

- Huang, A.; Gao, S.; Dai, Y.; Kitsos, V.; Tian, W.; Xu, L. A capacitive information-based force-voltage responsivity stabilization method for piezoelectric touch panels. IEEE J. Electron Devices Soc. 2019, 7, 1018–1025. [Google Scholar] [CrossRef]

- Lu, Y.; Cui, Z.; Guo, R.; Xu, L.; Gao, S. A Machine-Learning-Based Touch Orientation Detection Method for Piezoelectric Touch Sensing in Noisy Environment. IEEE Sens. J. 2021, 1. [Google Scholar] [CrossRef]

- Fu, J.Y.; Liu, P.Y.; Cheng, J.; Bhalla, A.S.; Guo, R. Optical measurement of the converse piezoelectric d 33 coefficients of bulk and microtubular zinc oxide crystals. Appl. Phys. Lett. 2007, 90, 212907. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, M.; Dai, Y.; Xie, Y.; Tian, W.; Xu, L.; Gao, S. A force-voltage responsivity stabilization method for piezoelectric-based insole gait analysis for high detection accuracy in health monitoring. Int. J. Distrib. Sens. Netw. 2020, 16. [Google Scholar] [CrossRef]

- Gao, S.; Wu, X.; Ma, H.; Robertson, J.; Nathan, A. Ultrathin multifunctional graphene-PVDF layers for multidimensional touch interactivity for flexible displays. ACS Appl. Mater. Interfaces 2017, 9, 18410–18416. [Google Scholar] [CrossRef]

- Shi, J.; Chen, J.; Lin, J.; Gao, S. Preload Effect Elimination Technique for Piezoelectric Force Touch Sensing in Human-Machine Interactivities. TechRxiv 2020. [Google Scholar] [CrossRef]

- Gao, S.; Duan, J.; Wei, Z.; Nathan, A. P-193: High force sensing accuracy in piezoelectric based interactive displays by artificial neural networks. Dig. Tech. Pap. SID Int. Symp. 2018, 52, 1893–1896. [Google Scholar] [CrossRef]

- Dai, Y.; Chen, J.; Tian, W.; Xu, L.; Gao, S. A PVDF/Au/PEN Multifunctional Flexible Human-Machine Interface for Multidimensional Sensing and Energy Harvesting for the Internet of Things. IEEE Sens. J. 2020, 20, 7556–7568. [Google Scholar] [CrossRef]

- Hennebert, C.; dos Santos, J. Security protocols and privacy issues into 6LoWPAN stack: A synthesis. IEEE Internet Things J. 2014, 1, 384–398. [Google Scholar] [CrossRef]

- Huang, A.; Gao, S.; Chen, J.; Xu, L.; Nathan, A. High Security User Authentication Enabled by Piezoelectric Keystroke Dynamics and Machine Learning. IEEE Sens. J. 2020, 20, 13037–13046. [Google Scholar] [CrossRef]

- Cui, Z.; Huang, A.; Chen, J.; Gao, S. Piezoelectric Touch Sensing Based Keystroke Dynamic Technique for Multi-User Authentication. IEEE Sens. J. 2021, 1. [Google Scholar] [CrossRef]

- Heraz, A.; Clynes, M. Recognition of Emotions Conveyed by Touch through Force-Sensitive Screens: Observational Study of Humans and Machine Learning Techniques. JMIR Ment. Health 2018, 5, e10104. [Google Scholar] [CrossRef]

- Nam, C.; Shin, D. Force-touch measurement methodology based on user experience. Int. J. Distrib. Sens. Netw. 2018, 14. [Google Scholar] [CrossRef] [Green Version]

- Qi, Y.; Jia, W.; Gao, S. Emotion recognition based on piezoelectric keystroke dynamics and machine learning. In Proceedings of the 2021 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Virtual Conference, 20–23 June 2021; pp. 1–4. [Google Scholar]

- Singla, R.; Malhotra, M.; Agarwal, D.; Chopra, D. Multi Touch: An Optical Approach (Comparison of various techniques). Int. J. Sci. Res. Publ. 2013, 3, 1–6. [Google Scholar]

- Zhang, S.; Tu, S.; Sui, Z.; Gao, S. Piezoelectric and machine learning-based technique for classifying force levels and locations of multiple force touch events. In Proceedings of the 2021 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Virtual Conference, 20–23 June 2021; pp. 1–4. [Google Scholar]

- Kang, M.; Park, J.H.; Lee, K.I.; Cho, J.W.; Bae, J.; Ju, B.K.; Lee, C.S. Fully flexible and transparent piezoelectric touch sensors based on ZnO nanowires and BaTiO3-added SiO2 capping layers. Phys. Status Solidi 2015, 212, 2005–2011. [Google Scholar] [CrossRef]

- Seminara, L.; Pinna, L.; Ibrahim, A.; Noli, L.; Capurro, M.; Caviglia, S.; Gastaldo, P.; Valle, M. Electronic Skin: Achievements, Issues and Trends. Procedia Technol. 2014, 15, 549–558. [Google Scholar] [CrossRef]

- Seminara, L.; Pinna, L.; Valle, M.; Basiricò, L.; Loi, A.; Cosseddu, P.; Bonfiglio, A.; Ascia, A.; Biso, M.; Ansaldo, A. Piezoelectric polymer transducer arrays for flexible tactile sensors. IEEE Sens. J. 2013, 13, 4022–4029. [Google Scholar] [CrossRef]

- Dai, Y.; Gao, S. A Flexible Multi-Functional Smart Skin for Force, Touch Position, Proximity, and Humidity Sensing for Humanoid Robots. IEEE Sens. J. 2021, 1. [Google Scholar] [CrossRef]

- Gao, S.; Chen, J.-L.; Dai, Y.-N.; Wang, R.; Kang, S.-B.; Xu, L.-J. Piezoelectric-Based Insole Force Sensing for Gait Analysis in the Internet of Health Things. IEEE Consum. Electron. Mag. 2020, 10, 39–44. [Google Scholar] [CrossRef]

- Cha, Y.; Song, K.; Shin, J.; Kim, D. Gait analysis system based on slippers with flexible piezoelectric sensors. In Proceedings of the 2018 IEEE International Conference on Robotics and Biomimetics (ROBIO), Kuala Lumpur, Malaysia, 12–15 December 2018; pp. 2479–2484. [Google Scholar]

- Dai, Y.; Xie, Y.; Chen, J.; Kang, S.; Xu, L.; Gao, S. A lamination-based piezoelectric insole gait analysis system for massive production for Internet-of-health things. Int. J. Distrib. Sens. Netw. 2020, 16, 1550147720905431. [Google Scholar] [CrossRef]

- Bune, A.; Zhu, C.; Ducharme, S.; Blinov, L.M.; Fridkin, V.M.; Palto, S.P.; Petukhova, N.; Yudin, S.G. Piezoelectric and pyroelectric properties of ferroelectric Langmuir-Blodgett polymer films. J. Appl. Phys. 1999, 85, 7869–7873. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.-W.; Kim, D.-K.; Kodani, T.; Kanemura, T.; Gwon, H.-D.; Cho, G.-H.; Han, K.-Y.; Kim, H.-S. Thermal-Variation Insensitive Force-Touch Sensing System Using Transparent Piezoelectric Thin-Film. IEEE Sens. J. 2018, 18, 5863–5875. [Google Scholar] [CrossRef]

- Rendl, C.; Greindl, P.; Haller, M.; Zirkl, M.; Stadlober, B.; Hartmann, P. PyzoFlex: Printed piezoelectric pressure sensing foil. In Proceedings of the 25th Annual ACM Symposium on User Interface Software and Technology, New York, NY, USA, 7–10 October 2012; pp. 509–518. [Google Scholar]

- Wang, S.; Lin, L.; Wang, Z.L. Triboelectric nanogenerators as self-powered active sensors. Nano Energy 2015, 11, 436–462. [Google Scholar] [CrossRef] [Green Version]

- Hafner, J.; Teuschel, M.; Schneider, M.; Schmid, U. Origin of the strong temperature effect on the piezoelectric response of the ferroelectric (co-)polymer P(VDF70-TrFE30). Polymer 2019, 170, 1–6. [Google Scholar] [CrossRef]

- Surbhi; Sukesha. Response of piezoelectric materials to the external temperature, electric field and humidity. Mater. Today Proc. 2020, 28, 1951–1954. [Google Scholar] [CrossRef]

- Rafique, S.; Kasi, A.K.; Kasi, J.K.; Bokhari, M.; Shakoor, Z. Fabrication of Br doped ZnO nanosheets piezoelectric nanogenerator for pressure and position sensing applications. Curr. Appl. Phys. 2021, 21, 72–79. [Google Scholar] [CrossRef]

| Piezoelectric Materials | Piezoelectric Strain Constant (pC/N) | Piezoelectric Stress Constant (Vm/N) | Relative Permittivity | Electromechanical Coupling Factor (%) | Density (103 kg/m3) | Curie Point (°C) | Flexibility | Advantage | Disadvantage |

|---|---|---|---|---|---|---|---|---|---|

| Crystals (Quartz) | = 2.3 | = 0.06 | 4.65 | 1 | 2.65 | 573 | Poor | High , low temperature coefficient | Low dielectric constant and piezoelectric coefficient |

| Crystals (LN) | = 6.0 | = 0.01~0.02 | 28–85 | 60 | 4.65 | 1140 | Poor | Low acoustic losses, colorless, insoluble in water and organic solvents | Phase transition prior to the melting point |

| Crystals (LT) | = 5.7 | = 0.01 | 43–54 | 30 | 7.46 | 605 | Poor | ||

| Ceramics (PZT) | = 110 = 225~590 | = 0.01 = 0.021~0.056 | 1200 | 30 | 7.5 | 386 | Poor | High piezoelectric coefficient | Brittleness, lead contained, high density |

| Ceramics (BaTiO3) | = 190 | = 0.01 | 1700 | 35 | 6 | 130 | Poor | High piezoelectric coefficient and high electromechanical coupling factor, lead-free | Low Curie point |

| Polymers (PVDF) | 23 | 0.22 −0.31 | 12 | 12 | 1.78 | 80 | Outstanding | Flexible, light-weight | Low Curie point, small dielectric constant |

| Ceramic-polymer composite (PZT embedded in an inactive epoxy resin matrix) | = 25 | = 0.09 | 32 | 0.5–0.7 | 4500 | - | Good | Flexible, low density compared with ceramics | Low dielectric constant |

| Method | Growth Temperature (°C) | Pressure (Pa) | Substrate | Advantage | Disadvantage |

|---|---|---|---|---|---|

| Magnetron sputtering | Room temperature | 1 | Quartz | Good uniformity; large area | High manufacturing cost |

| Chemical vapor deposition | 600–800 | 533–667 | LaAlO3 | High purity and density | Requirement for different cavities |

| Sol-gel method | 100 °C for generating the sol; 800 °C for crystallization | Atmospheric pressure | Pt-coated Si wafer | Simple process | Easy to crack |

| Solvothermal process | 140 | High pressure | Si (100) deposited with Ti (1000 Å) | Simple operation; low temperature | Danger of high pressure |

| Drawbacks | Solutions | Performance | Refs |

|---|---|---|---|

| Unstable responsivity introduced by different touch area and direction | Estimating touch area and direction using capacitance information | An improvement in stability of force voltage responsivity of 85% | [46] |

| Classifying touch directions using an artificial network | Force detection accuracy of 90% | [45] | |

| frequency dependence | Calibrating using the frequency information | Improving detection accuracy by 2.5% | [49] |

| Propagated stress | Eliminating the propagated stress using capacitive information | Eliminating the propagated stress successfully | [50] |

| Preload effect | Obtaining the prestress using the resonant characteristics and calibrating | Improving the detection accuracy by 15.17% | [51] |

| Boundary condition | Estimating touch position and force amplitude using an artificial network | 0.56 mm shift of the touch position Force detection accuracy of 94.2% | [52] |

| Measuring the curvature radius using the capacitive information and calibrating the response | 1.7% change in the force responsivity with 3 cm change in the curvature radius | [53] |

| Emerging Applications | Principles of the Work | Advantages | Disadvantages | Performance of Typical Design | Refs |

|---|---|---|---|---|---|

| Authentication | Extract touch features using piezoelectric touch panel for authentication | Simplicity of use High sensitivity | Decreasing accuracy with the variation of keystroke habit | The EER of 0.720% | [55] |

| The accuracy of 97% Multi-user support | [56] | ||||

| Mood detection | Extract touch behaviors using piezoelectric touch panel for emotion classification | Cost-effective Non-intrusive High sensitivity | Individual difference when experiencing the same emotion | The classification accuracy of 78.31% Short text input | [59] |

| Underwater | Sensitive to the mechanical displacement Not affected by small amounts of water | No limitations in moist environment | Affected by the temperature of the water | Excellent properties when using in the water | [44] |

| Humanoid skin | Detect force based on the flexible piezoelectric techniques | Low cost The coupling ability with capacitive techniques | Temperature effect | The force sensitivity of 0.05 N The spatial resolution of 0.29 mm | [65] |

| Gait analysis | Detect the plantar pressure for gait analysis | Passive detection Low power consumption | The frequency dependency of | The responsivity of 693.1 mV/N The sensitivity of 0.056 N | [68] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Fu, Z. Piezoelectric Based Touch Sensing for Interactive Displays—A Short Review. Materials 2021, 14, 5698. https://doi.org/10.3390/ma14195698

Liu Z, Fu Z. Piezoelectric Based Touch Sensing for Interactive Displays—A Short Review. Materials. 2021; 14(19):5698. https://doi.org/10.3390/ma14195698

Chicago/Turabian StyleLiu, Ziting, and Zhe Fu. 2021. "Piezoelectric Based Touch Sensing for Interactive Displays—A Short Review" Materials 14, no. 19: 5698. https://doi.org/10.3390/ma14195698

APA StyleLiu, Z., & Fu, Z. (2021). Piezoelectric Based Touch Sensing for Interactive Displays—A Short Review. Materials, 14(19), 5698. https://doi.org/10.3390/ma14195698