Strength and Durability Properties of Antimony Tailing Coarse Aggregate (ATCA) Concrete

Abstract

:1. Introduction

2. Materials and Mix Ratio of Concrete

2.1. Materials

2.1.1. Cement

2.1.2. Aggregate

2.2. Mix Ratio of Concrete

3. The Workability of Fresh Concrete

3.1. Experiment Methodology

3.2. Results and Discussion

4. Mechanical Property Experiments

4.1. Specimen Design

4.2. Results and Discussion

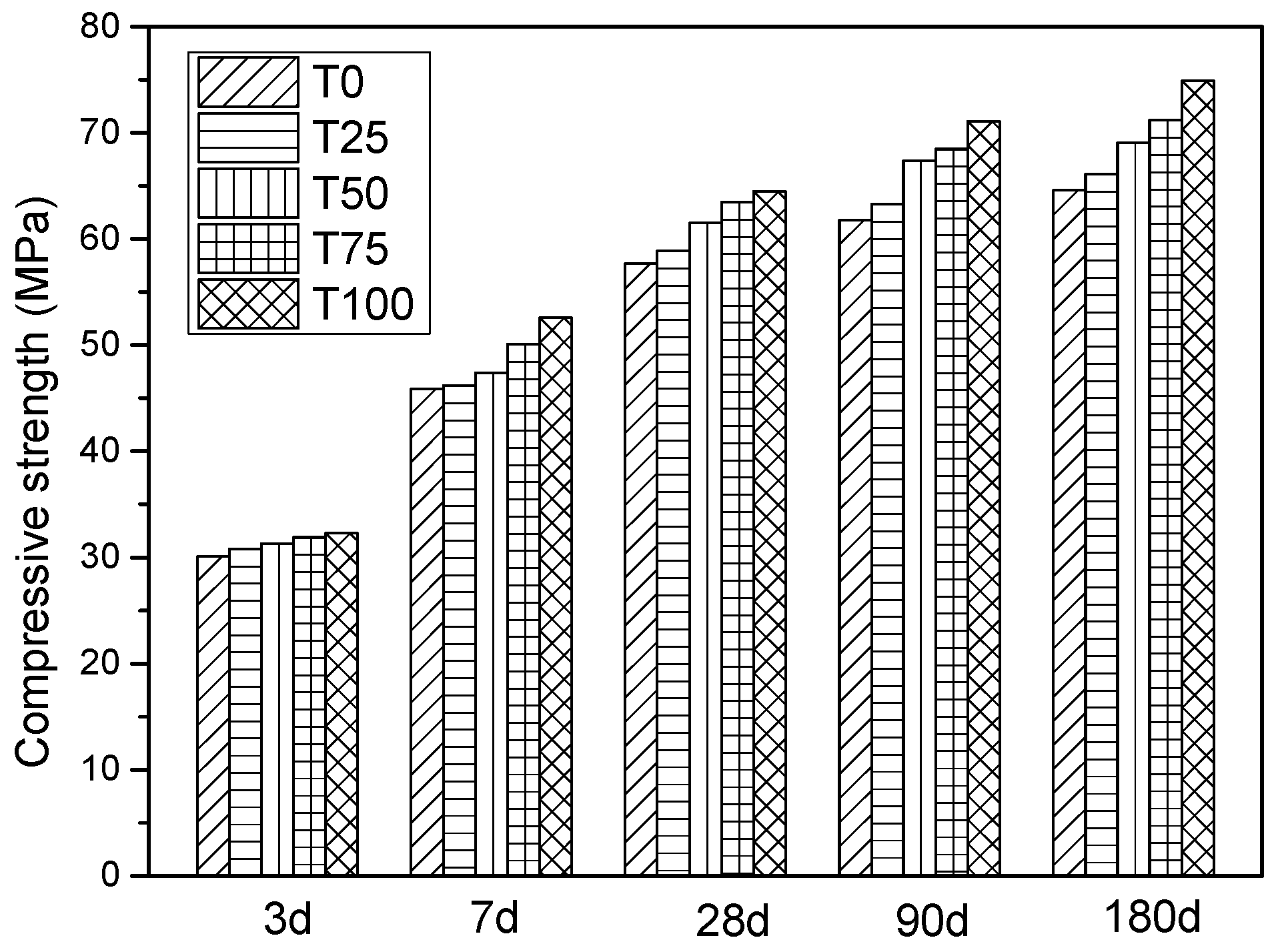

4.2.1. Compressive Strength of Cubic Sample

4.2.2. Splitting Tensile Strength of Cubic Sample

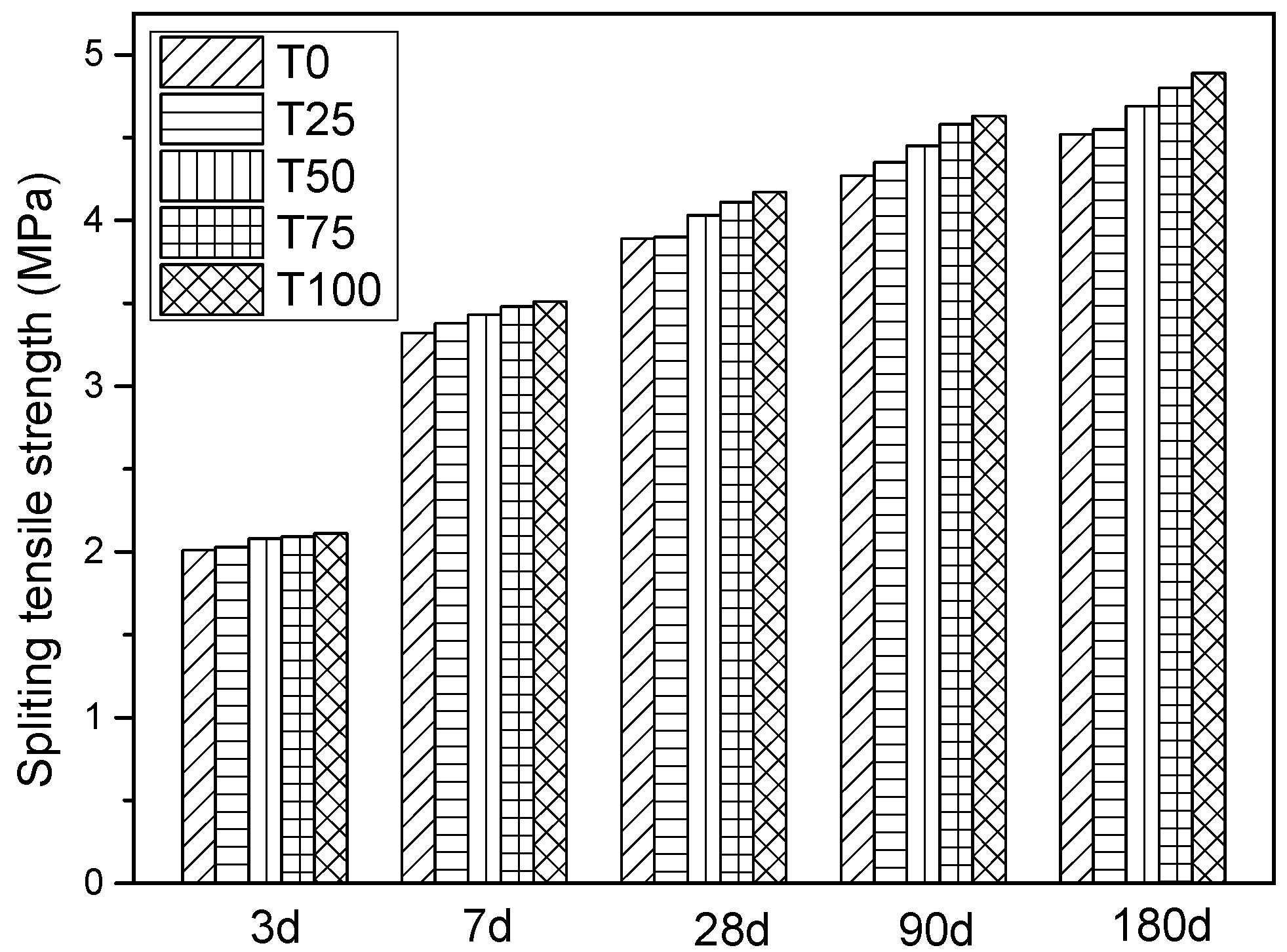

4.2.3. Compressive Strength and Compressive Elastic Modulus of Prism Specimens

5. Long-Term Behavior Experiments

5.1. Specimen Design

5.2. Results and Discussion

5.2.1. Drying Shrinkage

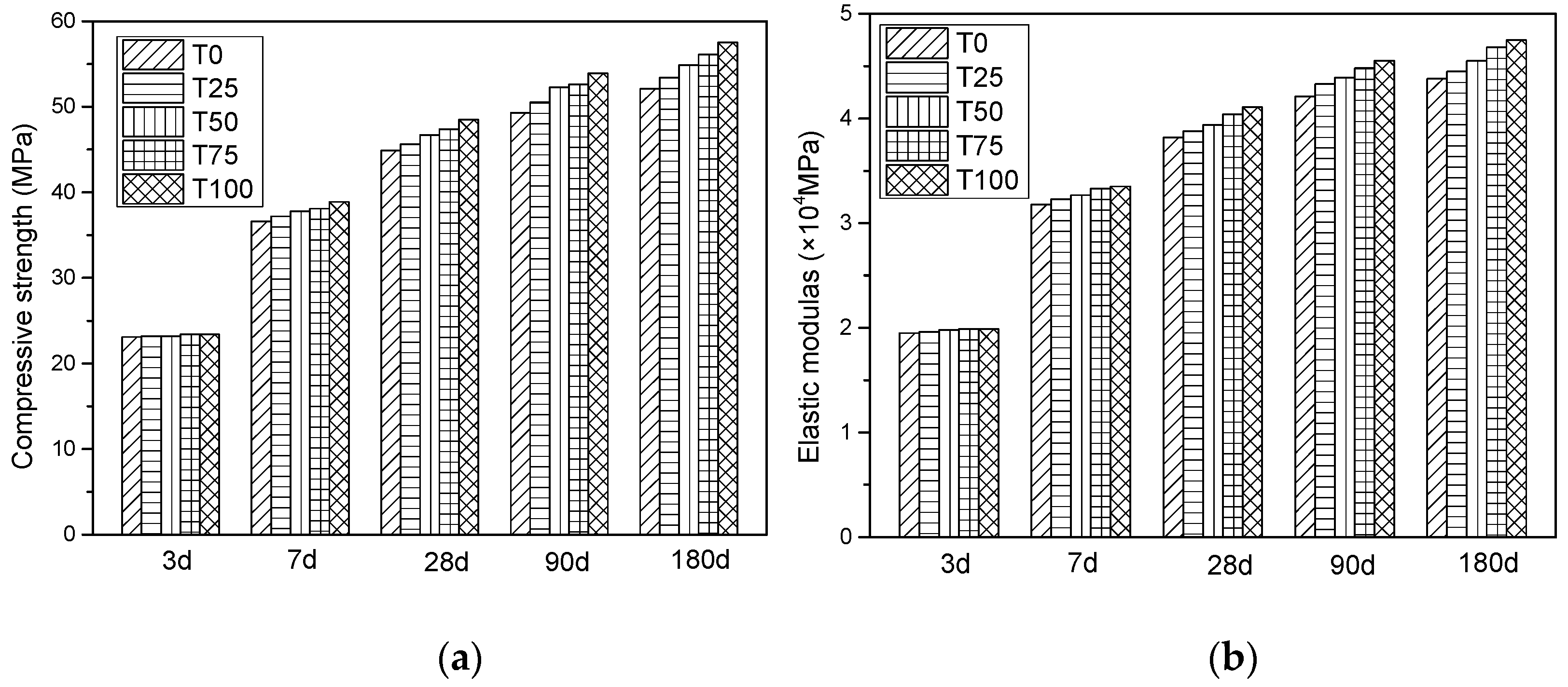

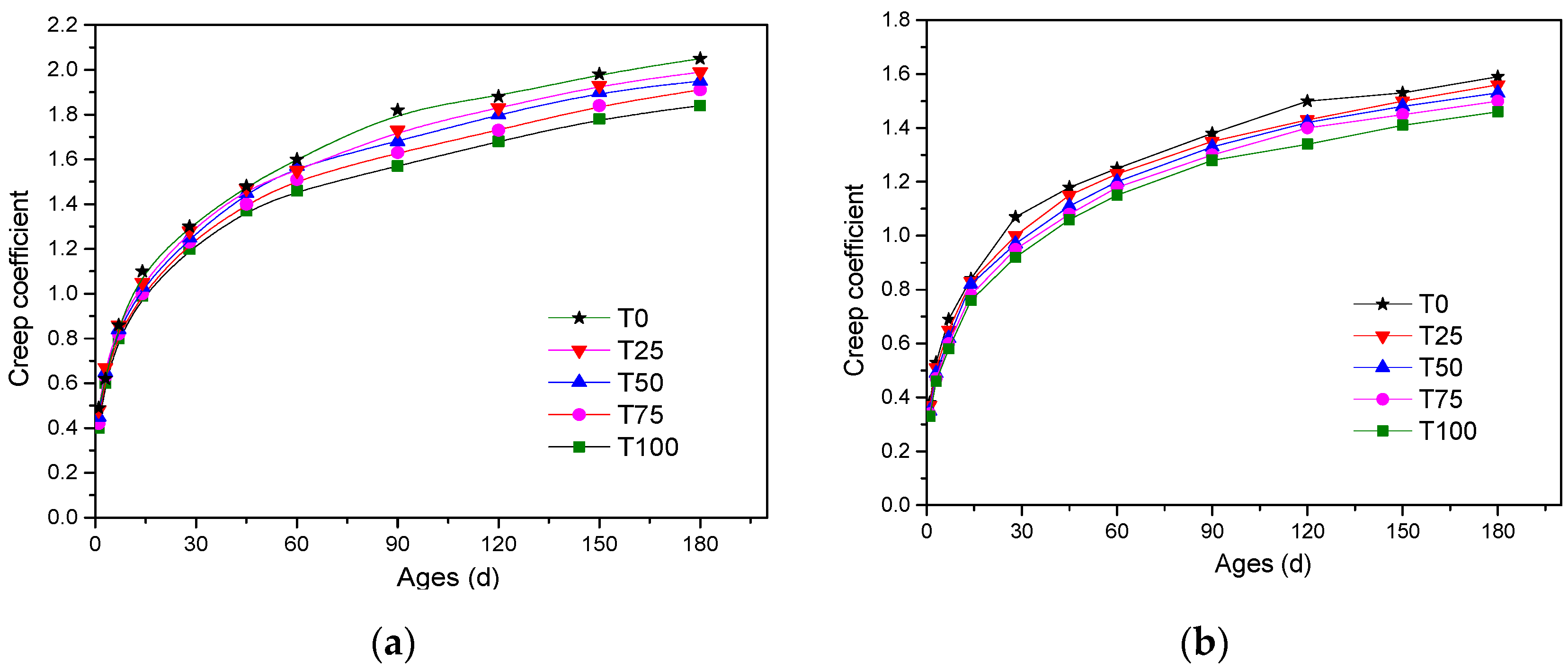

5.2.2. Creep

6. Durability Performance Experiments

6.1. Specimen Design

6.2. Results and Discussion

6.2.1. Frost-Resistant Performance

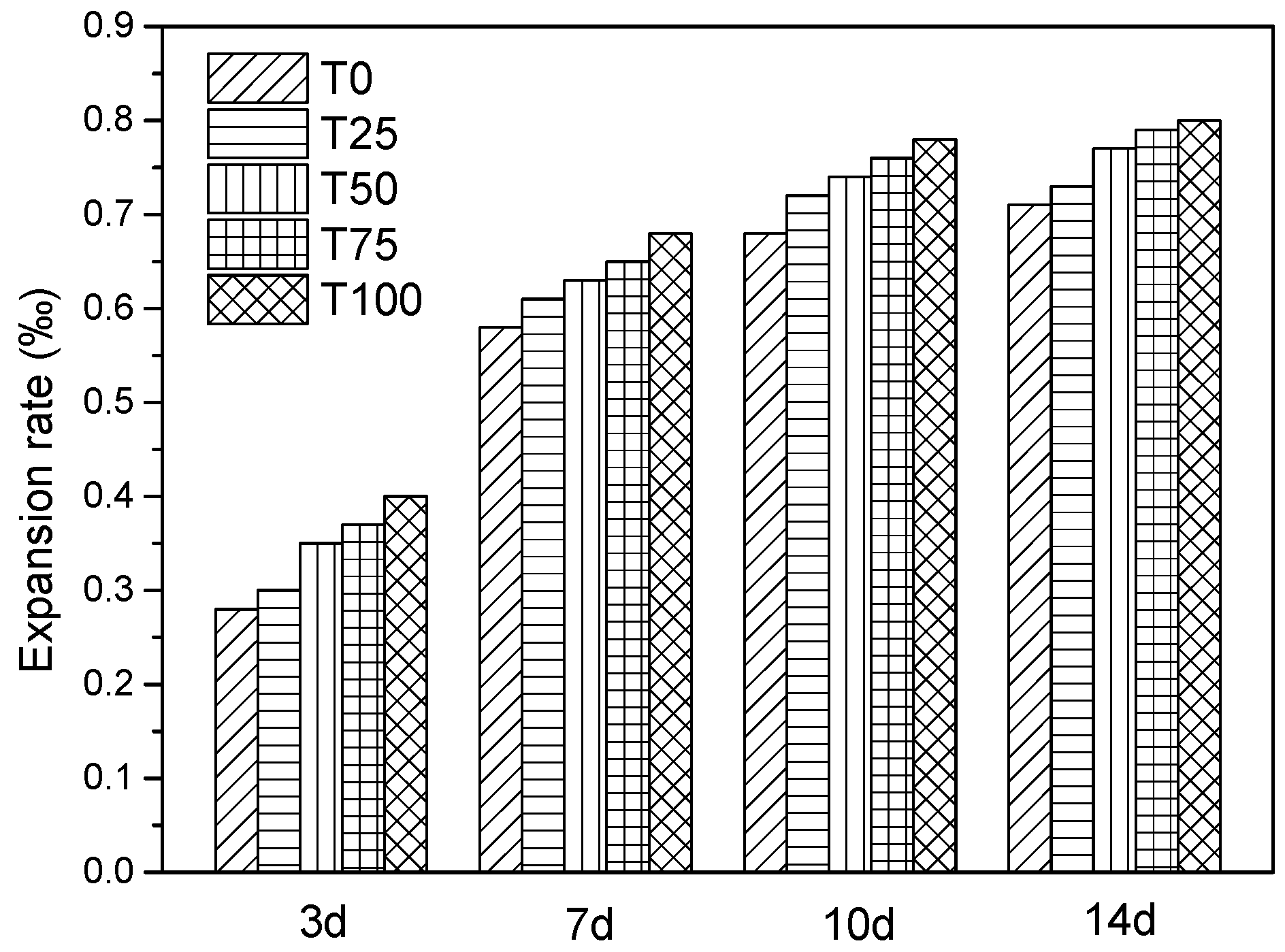

6.2.2. Alkali Activity

6.2.3. Chloride Permeability

6.2.4. Cracking Sensitivity

6.2.5. Carbonation Depth

7. Conclusions

- (1)

- ATCA as a complete substitution for NCA in concrete possesses good workability, which is nearly the same as NCA concrete.

- (2)

- ATCA as a complete substitution for NCA in concrete possesses perfect physical and mechanical properties. The cubic compressive strength, cubic splitting tensile strength, prism compressive strength, and elastic modulus of ATCA concrete with all replacement levels is superior to that of NCA concrete.

- (3)

- The drying shrinkage and creep of ATCA concrete decrease with the increased replacement level of ATCA. Furthermore, the drying shrinkage and creep of ATCA concrete with all replacement levels are superior to the controlled sample.

- (4)

- The ability of resistance to carbonation, the frost-resistant, and the chloride permeability performance of ATCA concrete are enhanced. While the alkali activity and cracking sensitivity behavior of the samples with ATCA seem to be decreased. Nevertheless, the difference is not significant and can be neglected.

- (5)

- It is found that all of the control indices meet the requirements of the current industry standards of China. The utilization of ATCA as a complete substitute for NCA in high-strength concrete has very important environmental and economic benefits.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thomas, C.; Sosa, I.; Setién, J.; Polanco, J.A.; Cimentada, A.I. Evaluation of the fatigue behavior of recycled aggregate concrete. J. Clean. Prod. 2014, 65, 397–405. [Google Scholar] [CrossRef]

- Sun, J.; Lin, S.; Zhang, G.; Sun, Y.; Wang, X. The effect of graphite and slag on electrical and mechanical properties of electrically conductive cementitious composites. Constr. Build. Mater. 2021, 281, 122606. [Google Scholar] [CrossRef]

- Wang, J.; Tang, S.; Zheng, H.; Zhu, M. Flexural behavior of a 30-meter full-scale simply supported prestressed concrete box girder. Appl. Sci. 2020, 10, 3076. [Google Scholar] [CrossRef]

- Ma, G.; Sun, J.; Aslani, F.; Huang, Y.; Jiao, F. Review on electromagnetic wave absorbing capacity improvement of cementitious material. Constr. Build. Mater. 2020, 262, 120907. [Google Scholar] [CrossRef]

- Hendi, A.; Behravan, A.; Mostofinejad, D.; Sedaghatdoost, A.; Amini, M. A step towards green concrete: Effect of waste silica powder usage under HCl attack. J. Clean. Prod. 2018, 188, 278–289. [Google Scholar] [CrossRef]

- Alfayez, S.; Ali, M.A.E.M.; Nehdi, M.L. Eco-efficient fiber-reinforced replaced recycled aggregate concrete under impact loading. Infrastructures 2019, 4, 37. [Google Scholar] [CrossRef] [Green Version]

- Hou, S.; Kong, Z.; Wu, B.; Liu, L. Compactness monitoring of compound concrete filled with demolished concrete lumps using PZT-based smart aggregates. J. Aerosp. Eng. 2018, 31, 04018064. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Yao, X.; Ren, Z.; Zhang, G.; Zhang, C.; Chen, X.; Ma, W.; Wang, X. Machine-learning-aided prediction of flexural strength and ASR expansion for waste glass cementitious composite. Appl. Sci. 2021, 11, 6686. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Liu, S.; Dehghani, A.; Wang, X. Mechanical, chemical and hydrothermal activation for waste glass reinforced cement. Constr. Build. Mater. 2021, 301, 124361. [Google Scholar] [CrossRef]

- Qi, C.; Wu, F.; Deng, Q.; Liu, G.; Mo, C.; Liu, B.; Zhu, J. Distribution and accumulation of antimony in plants in the super-large Sb deposit areas. Microchem. J. 2011, 97, 44–51. [Google Scholar] [CrossRef]

- Rout, S.K.; Sahoo, T.; Das, S.K. Design of tailing dam using red mud. Open Eng. 2013, 3, 316–328. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr. Build. Mater. 2012, 29, 323–331. [Google Scholar] [CrossRef]

- Paivo, K.; Ismailovc, A.; Solismaa, S.; Sreenivasan, H.; Risnen, M.L.; Levnen, E.; Illikainen, M. Recycling mine tailings in chemically bonded ceramics—A review. J. Clean. Prod. 2018, 174, 634–649. [Google Scholar]

- Hou, B.; Kuang, Y.; Han, H.; Ye, L.; Ren, B.; Deng, R.; Hursthouse, A. Enhanced performance and hindered membrane fouling for the treatment of coal chemical industry wastewater using a novel membrane electro-bioreactor with intermittent direct current. Bioresour. Technol. 2018, 271, 332–339. [Google Scholar] [CrossRef] [Green Version]

- Ramakokovhu, M.M.; Kasaini, H.; Mbaya, R.K.K. Leaching characteristics of upgraded copper otation tailings. World Acad. Sci. 2012, 6, 853–857. [Google Scholar]

- Shamsai, A.; Pak, A.; Bateni, S.M.; Ayatollahi, S.A.H. Geotechnical characteristics of copper mine tailings: A case study. Geotech. Geol. Eng. 2007, 25, 591–602. [Google Scholar] [CrossRef]

- Thomas, B.S.; Anoop, S.; Kumar, V.S. Utilisation of solid waste particles as aggregates in concrete. Procedia Eng. 2012, 38, 3789–3796. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Duan, X.; Chen, T.; Yan, B.; Li, L. Mechanical properties and toxicity risks of lead-zinc sulfide tailing-based construction materials. Materials 2021, 14, 2940. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Eren, O. Recycling of copper tailings as an additive in cement mortars. Constr. Build. Mater. 2012, 37, 723–727. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Özgür, E. Rheology, strength and durability properties of mortars containing copper tailings as a cement replacement material. Eur. J. Environ. Civ. Eng. 2013, 17, 19–31. [Google Scholar] [CrossRef]

- Thomas, B.S.; Damare, A.; Gupta, R.C. Strength and durability characteristics of copper tailing concrete. Constr. Build. Mater. 2013, 48, 894–900. [Google Scholar] [CrossRef]

- Sharma, R.; Khan, R.A. Sustainable use of copper slag in self compacting concrete containing supplementary cementitious materials. J. Clean. Prod. 2017, 151, 179–192. [Google Scholar] [CrossRef]

- Huang, X.; Ni, W.; Cui, W.; Wang, Z.; Zhu, L. Preparation of autoclaved aerated concrete using copper tailings and blast furnace slag. Constr. Build. Mater. 2012, 27, 1–5. [Google Scholar] [CrossRef]

- Zhao, S.; Fan, J.; Sun, W. Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr. Build. Mater. 2014, 50, 540–548. [Google Scholar] [CrossRef]

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Mirza, J. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Lv, X.; Shen, W.; Wang, L.; Dong, Y.; Zhang, J.; Xie, Z. A comparative study on the practical utilization of iron tailings as a complete replacement of normal aggregates in dam concrete with different gradation. J. Clean. Prod. 2019, 211, 704–715. [Google Scholar] [CrossRef]

- Liu, W.; Xu, X.; An, Y. Study on the sprayed concrete with iron tailings. Adv. Mater. Res. 2012, 347–353, 1939–1943. [Google Scholar] [CrossRef]

- Huang, X.; Ranade, R.; Li, V.C. Feasibility study of developing green ECC using iron ore tailings powder as cement replacement. J. Mater. Civ. Eng. 2013, 25, 923–931. [Google Scholar] [CrossRef]

- Li, H.; Liu, P.; Li, C.; Li, G.; Zhang, H. Experimental research on dynamic mechanical properties of metal tailings porous concrete. Constr. Build. Mater. 2019, 213, 20–31. [Google Scholar] [CrossRef]

- Han, F.; Song, S.; Liu, J.; Huang, S. Properties of steam-cured precast concrete containing iron tailing powder. Powder Technol. 2019, 345, 292–299. [Google Scholar] [CrossRef]

- Choi, Y.W.; Kim, Y.J.; Choi, O.; Lee, K.M.; Lachemi, M. Utilization of tailings from tungsten mine waste as a substitution material for cement. Constr. Build. Mater. 2009, 23, 2481–2486. [Google Scholar] [CrossRef]

- Amaratunga, L.M.; Yaschyshyn, D.N. Development of a high modulus paste fill using fine gold mill tailings. Geotech. Geol. Eng. 1997, 15, 205–219. [Google Scholar] [CrossRef]

- Barna, R.; Moszkowicz, P.; Gervais, C. Leaching assessment of road materials containing primary lead and zinc slags. Waste Manag. 2004, 24, 945–955. [Google Scholar] [CrossRef] [PubMed]

- Gao, S.; Kang, S. Sustainable applications for utilizing molybdenum tailings in concrete. J. Clean. Prod. 2020, 266, 122020. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Zhang, L.; Li, B.; Deng, R.; Shi, D. Sustainable applications for utilizing antimony tailing coarse aggregate (ATCA) in concrete: Characteristic of ATCA and toxicity risks of concrete. Materials 2021, 14, 5480. [Google Scholar] [CrossRef]

- CNSMC. Common Portland Cement (GB 175-2007); China National Standardization Management Committee: Beijing, China, 2007. [Google Scholar]

- Zhou, S.; Andrew, H.; Chen, T. Pollution characteristics of Sb, As, Hg, Pb, Cd and Zn in soils from different zones of Xikuangshan antimony mine. J. Anal. Methods Chem. 2019, 2019, 2754385. [Google Scholar] [CrossRef]

- Deng, R.; Tang, Z.; Hou, B.; Ren, B.; Hursthouse, A. Microbial diversity in soils from antimony mining sites: Geochemicalcontrol promotes species enrichment. Environ. Chem. Lett. 2020, 18, 911–922. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Deng, R.; Ren, B.; Yaseen, M.; Hursthouse, A. Enhancing the removal of Sb (III) from water: A Fe3O4@HCO composite adsorbent caged in sodium alginate microbeads. Processes 2020, 8, 44. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.; Hursthouse, A. The impact of physical properties on the leaching of potentially toxic elements from antimony ore processing wastes. Int. J. Environ. Res. Public Health 2019, 16, 2355. [Google Scholar] [CrossRef] [Green Version]

- Jiada, W. Antimony vein deposits of China. Ore Geol. Rev. 1993, 8, 213–232. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Z.; Wu, J.; Mo, P. Efficiency and mechanisms of antimony removal from wastewater using mixed cultures of iron-oxidizing bacteria and sulfate-reducing bacteria based on scrap iron. Sep. Purif. Technol. 2020, 246, 116756. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, R.; Ren, B.; Hou, B.; Hursthouse, A. Preparation of a novel Fe3O4/HCO composite adsorbent and the mechanism for the removal of antimony (III) from aqueous solution. Sci. Rep. 2019, 9, 13021. [Google Scholar] [CrossRef]

- MHUDPRC. Standard for Test Method of Performance on Ordinary Fresh Concrete (GB/T 50080-2016); Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- ACI 301M-10. Specifications for Structural Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2010. [Google Scholar]

- BS EN 12350-5:2009. Testing Fresh Concrete; The Authority of the Standards Policy and Strategy Committee: Brussels, Belgium, 2009. [Google Scholar]

- Feng, Q.; Liang, Y.; Song, G. Real-time monitoring of early-age concrete strength using piezoceramic-based smart aggregates. J. Aerosp. Eng. 2019, 32, 04018115. [Google Scholar] [CrossRef]

- Kong, Q.; Hou, S.; Ji, Q.; Mo, Y.; Song, G. Very early age concrete hydration characterization monitoring using piezoceramic based smart aggregates. Smart Mater. Struct. 2013, 22, 085025. [Google Scholar] [CrossRef]

- MHUDPRC. Standard for Test Methods of Concrete Physical and Mechanical Properties (GB/T 50081-2019); Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Zhou, C.; Li, L.; Wang, J. Modified bar simulation method for shear lag analysis of non-prismatic composite box girders with corrugated steel webs. Thin-Walled Struct. 2020, 155, 106957. [Google Scholar] [CrossRef]

- Fujiwara, T. Effect of aggregate on drying shrinkage of concrete. J. Adv. Concr. Technol. 2008, 6, 31–44. [Google Scholar] [CrossRef] [Green Version]

- Zhu, W.; Wei, J.; Li, F.; Zhang, T.; Chen, Y.; Hu, J.; Yu, Q. Understanding restraint effect of coarse aggregate on the drying shrinkage of self-compacting concrete. Constr. Build. Mater. 2016, 114, 458–463. [Google Scholar] [CrossRef]

- Shen, D.; Wen, C.; Zhu, P.; Wu, Y.; Yuan, J. Influence of barchip fiber on early-age autogenous shrinkage of high strength concrete. Constr. Build. Mater. 2020, 256, 119223. [Google Scholar] [CrossRef]

- MHUDPRC. Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete (GB/T 50082-2009); Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- Kong, Q.; Wang, R.; Song, G.; Yang, Z.; Still, B. Monitoring the soil freeze-thaw process using piezoceramic-based smart aggregate. J. Cold Reg. Eng. 2014, 28, 06014001. [Google Scholar] [CrossRef]

- Peng, J.; Hu, S.; Zhang, J.; Cai, C.S.; Li, L. Influence of cracks on chloride diffusivity in concrete: A five-phase mesoscale model approach. Constr. Build. Mater. 2019, 197, 587–596. [Google Scholar] [CrossRef]

- Zheng, L.; Cheng, H.; Huo, L.; Song, G. Monitor concrete moisture level using percussion and machine learning. Constr. Build. Mater. 2019, 229, 117077. [Google Scholar] [CrossRef]

- Liu, T.; Huang, Y.; Zou, D.; Teng, J.; Li, B. Exploratory study on water seepage monitoring of concrete structures using piezoceramic based smart aggregates. Smart Mater. Struct. 2013, 22, 065002. [Google Scholar] [CrossRef]

- Zou, D.; Li, W.; Liu, T.; Teng, J. Two-dimensional water seepage monitoring in concrete structures using smart aggregates. Struct. Monitor. Maint. 2018, 5, 313–323. [Google Scholar]

- Khan, I.; Castel, A.; Gilbert, R.I. Tensile creep and early-age concrete cracking due to restrained shrinkage. Constr. Build. Mater. 2017, 149, 705–715. [Google Scholar] [CrossRef]

- Wang, J.; Fan, Z. Detecting of the crack and leakage in the joint of precast concrete segmental bridge using piezoceramic based smart aggregate. Sensors 2020, 20, 5398. [Google Scholar] [CrossRef] [PubMed]

- Song, G.; Mo, Y.L.; Otero, K.; Gu, H. Health monitoring and rehabilitation of a concrete structure using intelligent materials. Smart Mater. Struct. 2006, 15, 309. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Zheng, Y.; Song, G.; Chen, D.; Ye, Y. Identification of the structural damage mechanism of BFRP bars reinforced concrete beams using smart transducers based on time reversal method. Constr. Build. Mater. 2019, 220, 615–627. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Cl− | Loss |

|---|---|---|---|---|---|---|---|

| 56.1 | 34.6 | 0.8 | 1.1 | 3.25 | 2.3 | 0.024 | 4.35 |

| Description | ATCA Proportion | ||||

|---|---|---|---|---|---|

| T0 | T25 | T50 | T75 | T100 | |

| Cement | 485 | 485 | 485 | 485 | 485 |

| NCA | 1047 | 785.3 | 523.5 | 261.8 | 0 |

| ATCA | 0 | 261.8 | 523.5 | 785.3 | 1047 |

| Manufactured sand | 758 | 758 | 758 | 758 | 758 |

| Water | 160 | 160 | 160 | 160 | 160 |

| Superplasticizer | 5.8 | 5.8 | 5.8 | 5.8 | 5.8 |

| Series | Slump (mm) | Air Content (%) | Setting Time (min) | Apparent Density (kg/m3) | |||

|---|---|---|---|---|---|---|---|

| 0 h | 1 h | 0 h | 1 h | Initial | Final | ||

| T0 | 198 | 187 | 3.8 | 2.9 | 398 | 570 | 2445 |

| T25 | 195 | 183 | 3.7 | 2.8 | 389 | 565 | 2451 |

| T50 | 192 | 182 | 3.7 | 2.7 | 380 | 556 | 2461 |

| T75 | 188 | 179 | 3.4 | 2.7 | 372 | 547 | 2468 |

| T100 | 185 | 175 | 3.3 | 2.6 | 365 | 540 | 2475 |

| No. | Experiments | Sample Shape | Sample Size (mm) |

|---|---|---|---|

| 1 | Cubic compressive strength | Cube | 150 × 150 × 150 |

| 2 | Splitting tensile strength | Cube | 150 × 150 × 150 |

| 3 | Prism compressive strength | Prism | 150 × 150 × 300 |

| 4 | Elasticity modulus | Prism | 150 × 150 × 300 |

| No. | Experiments | Sample Shape | Sample Size (mm) |

|---|---|---|---|

| 1 | Shrinkage | Prism | 100 × 100 × 515 |

| 2 | Creep | Prism | 100 × 100 × 400 |

| No. | Experiments | Sample Shape | Sample Size (mm) |

|---|---|---|---|

| 1 | Frost-resistant performance | Prism | 100 × 100 × 400 |

| 2 | Alkali activity | Prism | 25 × 25 × 280 |

| 3 | Chloride permeability | Cylinder | Ø100 × 50 |

| 4 | Cracking sensitivity | Plate | 800 × 600 × 100 |

| 5 | Carbonation | Cube | 100 × 100 × 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Wang, J.; Zhang, L.; Deng, R.; Zhou, S.; Wang, G. Strength and Durability Properties of Antimony Tailing Coarse Aggregate (ATCA) Concrete. Materials 2021, 14, 5606. https://doi.org/10.3390/ma14195606

Li L, Wang J, Zhang L, Deng R, Zhou S, Wang G. Strength and Durability Properties of Antimony Tailing Coarse Aggregate (ATCA) Concrete. Materials. 2021; 14(19):5606. https://doi.org/10.3390/ma14195606

Chicago/Turabian StyleLi, Long, Jianqun Wang, Longwei Zhang, Renjian Deng, Saijun Zhou, and Gongxun Wang. 2021. "Strength and Durability Properties of Antimony Tailing Coarse Aggregate (ATCA) Concrete" Materials 14, no. 19: 5606. https://doi.org/10.3390/ma14195606

APA StyleLi, L., Wang, J., Zhang, L., Deng, R., Zhou, S., & Wang, G. (2021). Strength and Durability Properties of Antimony Tailing Coarse Aggregate (ATCA) Concrete. Materials, 14(19), 5606. https://doi.org/10.3390/ma14195606