Experimental Investigation of the Stress–Strain Behavior and Strength Characterization of Rubberized Reinforced Concrete

Abstract

1. Introduction

2. Methodology

3. Experimental Program

3.1. Standard Concrete Cylinder and Test Specimen

3.2. Materials

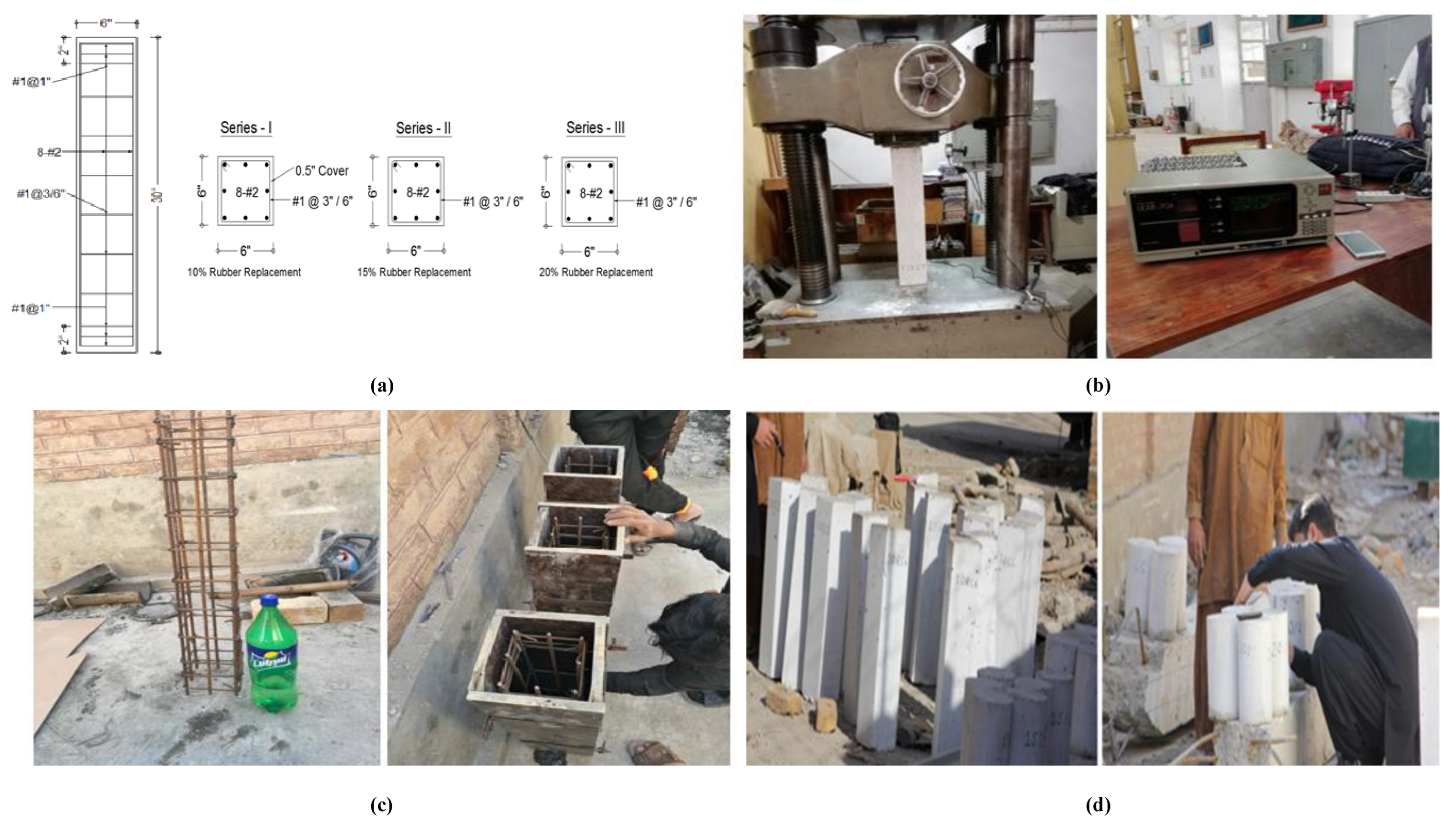

3.3. Fabrication Phase

3.4. Test Specimens

3.5. Experimental Investigation

3.6. Testing Setup

4. Results and Discussion

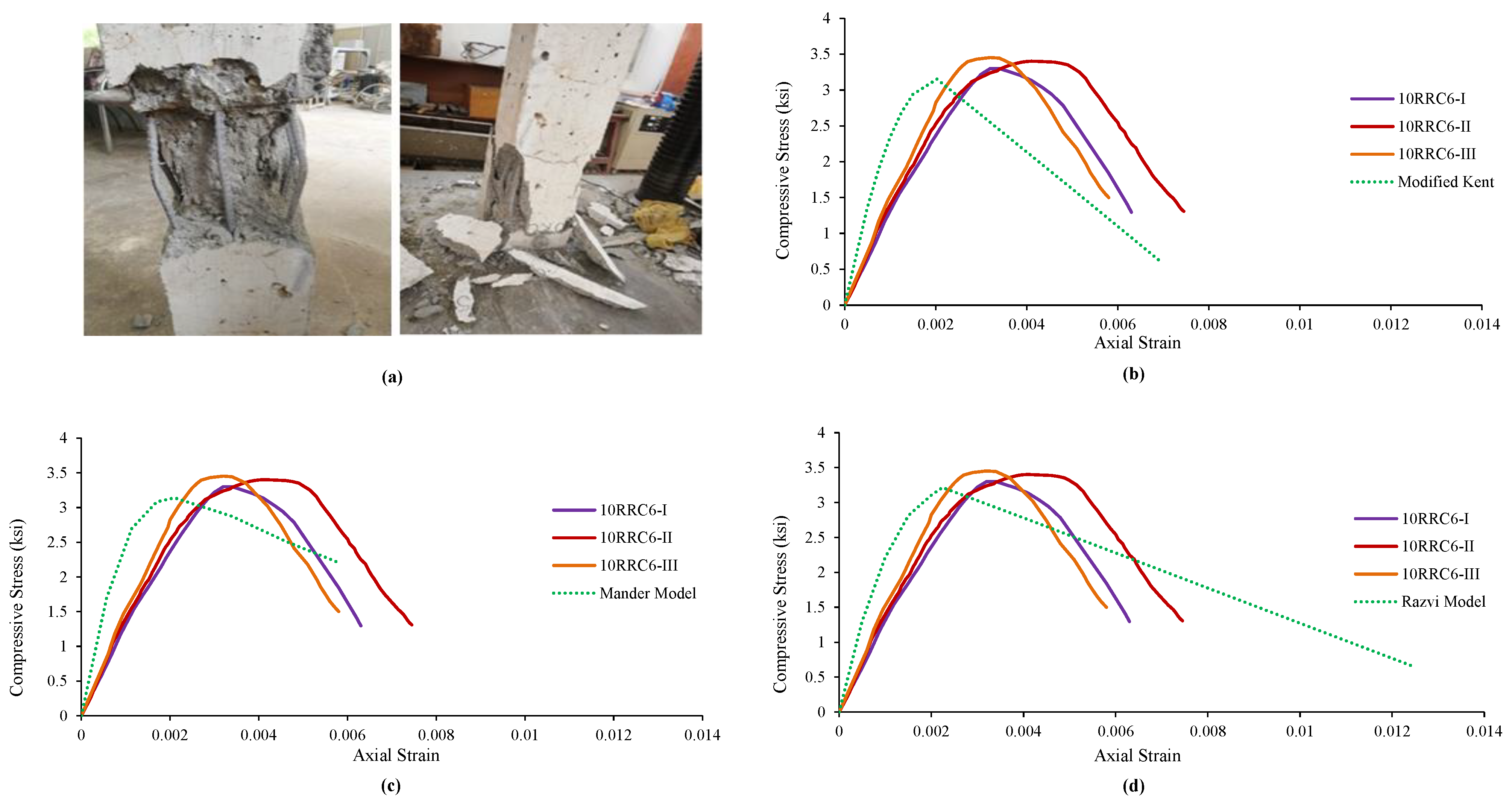

4.1. Observed Behavior and Comparison of 10RRC6 Models

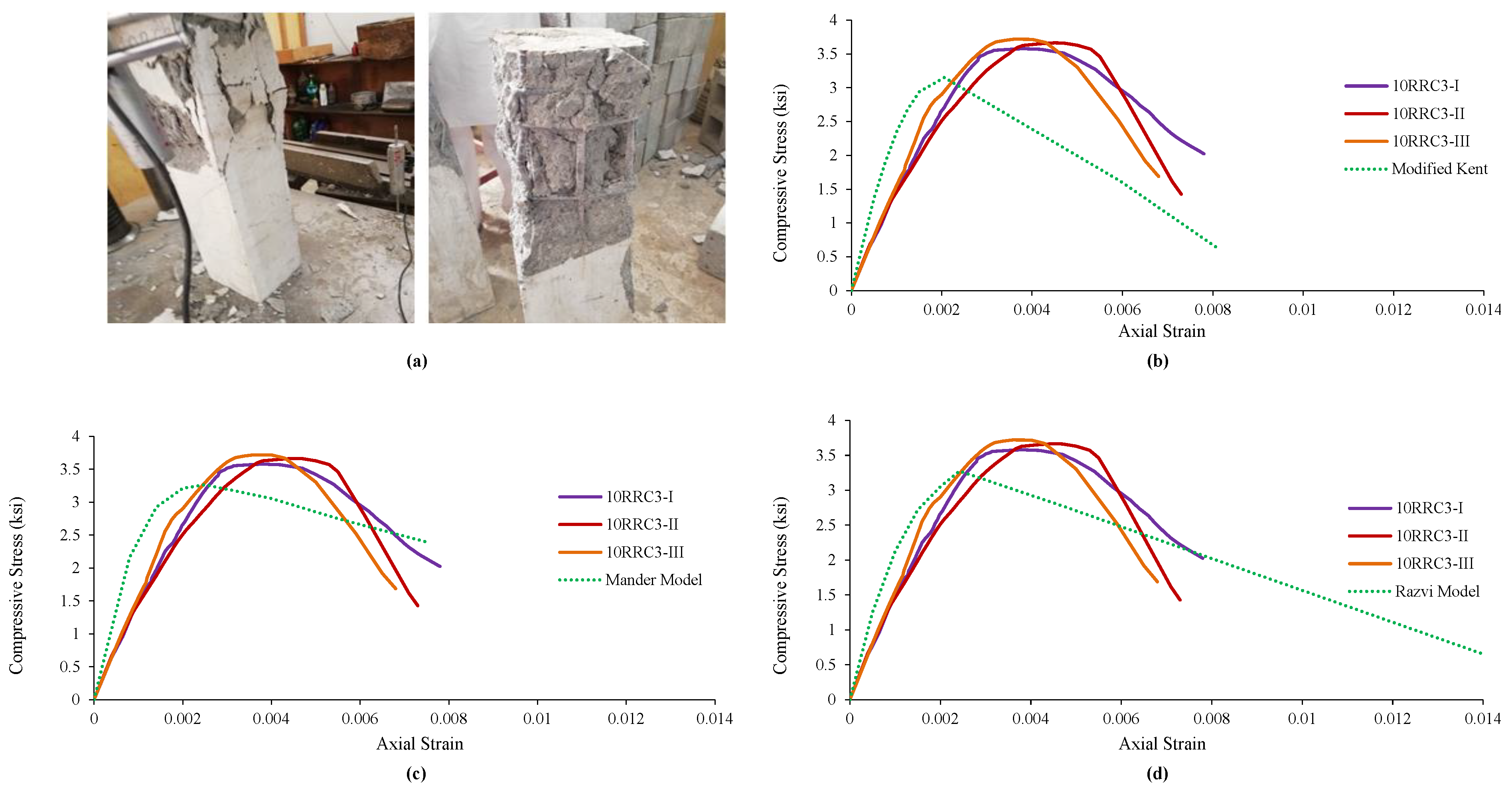

4.2. Observed Behavior and Comparison of 10RRC3 Models

Comparison of 10RRC6 and 10RRC3 Specimens

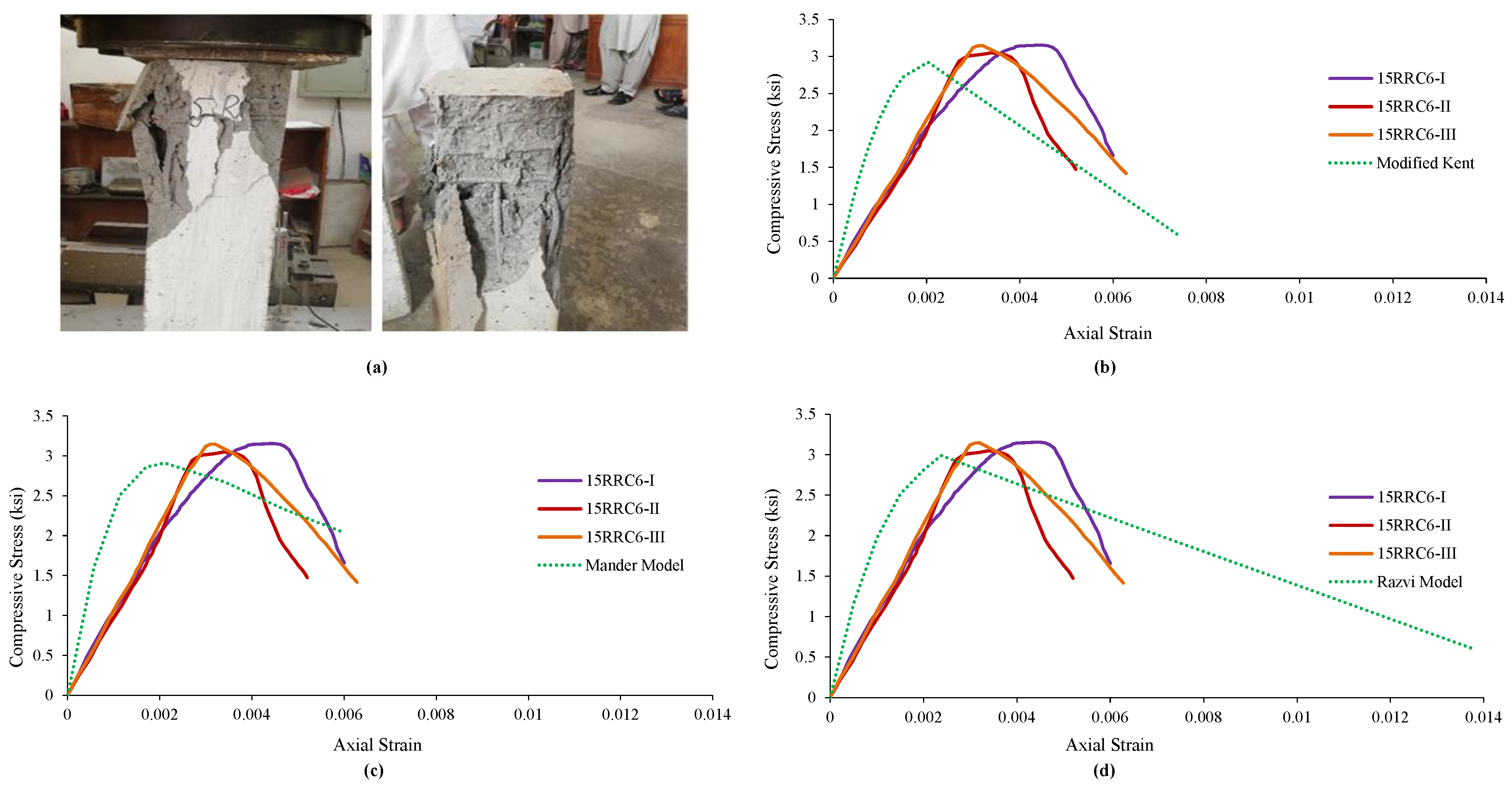

4.3. Observed Behavior and Comparison of 15RRC6 Models

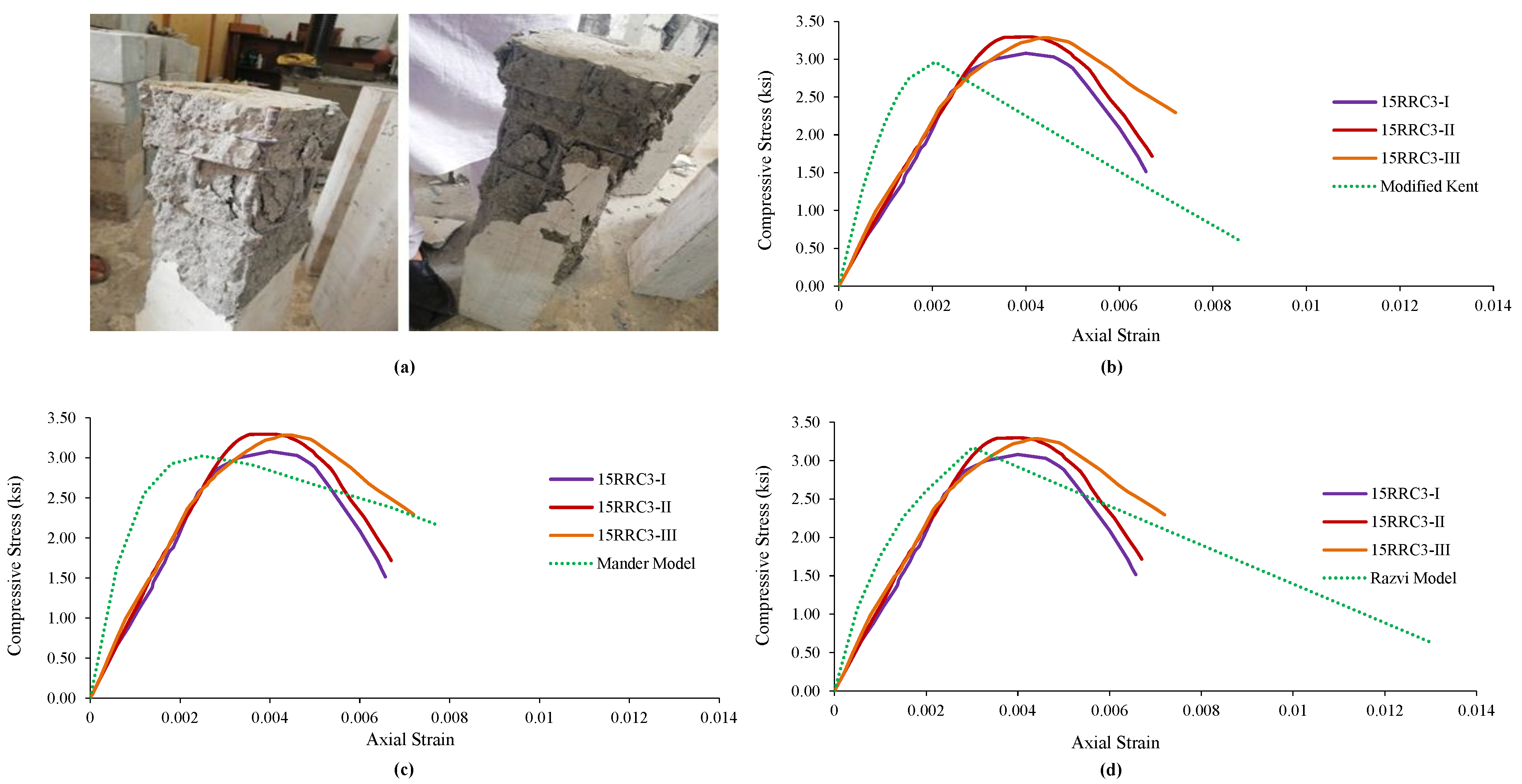

4.4. Observed Behavior and Comparison of 15RRC3 Models

Comparison of the Behavior of 15RRC6 and 15RCC3

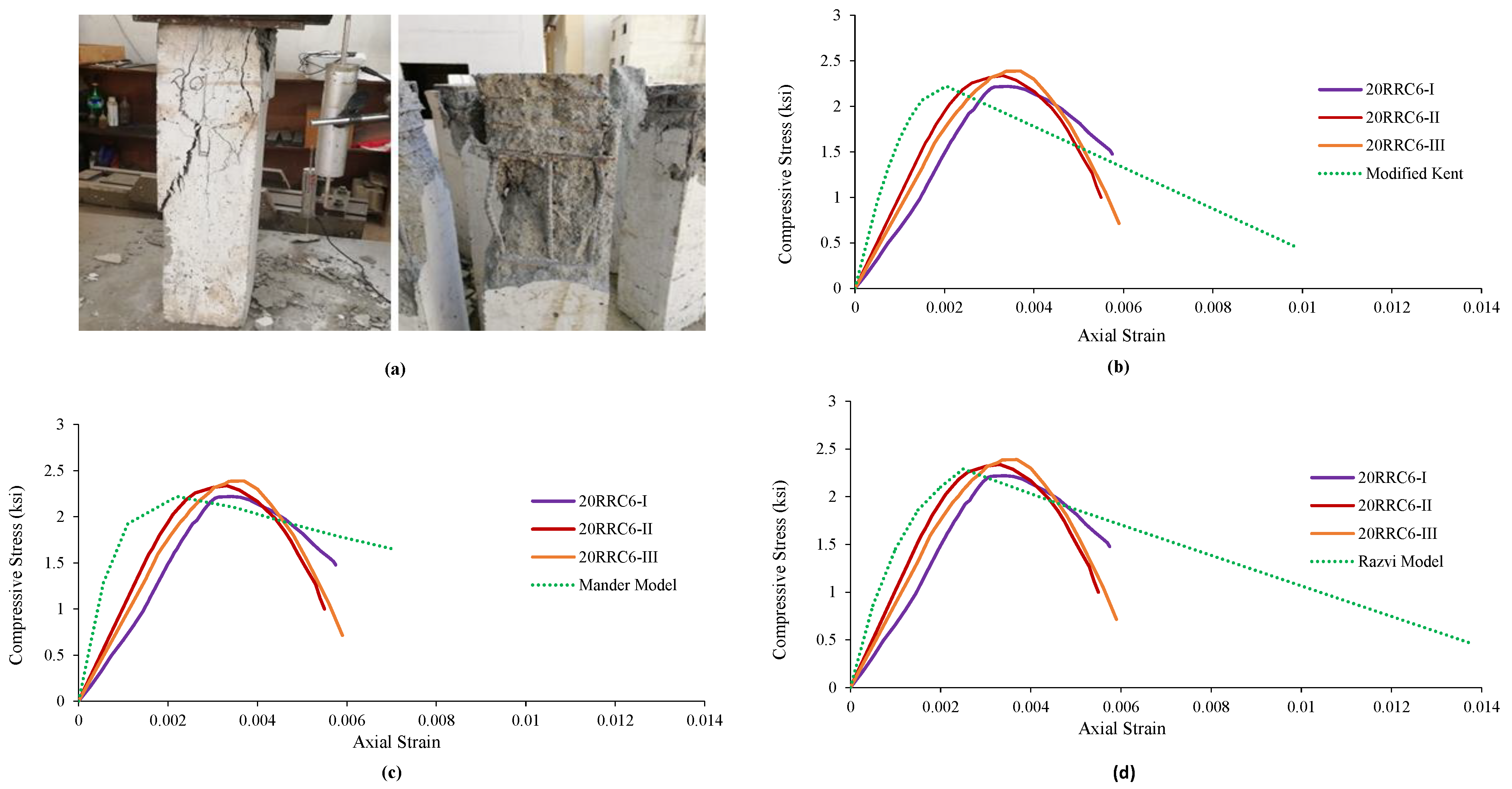

4.5. Observed Behavior and Comparison of 20RRC6 Models

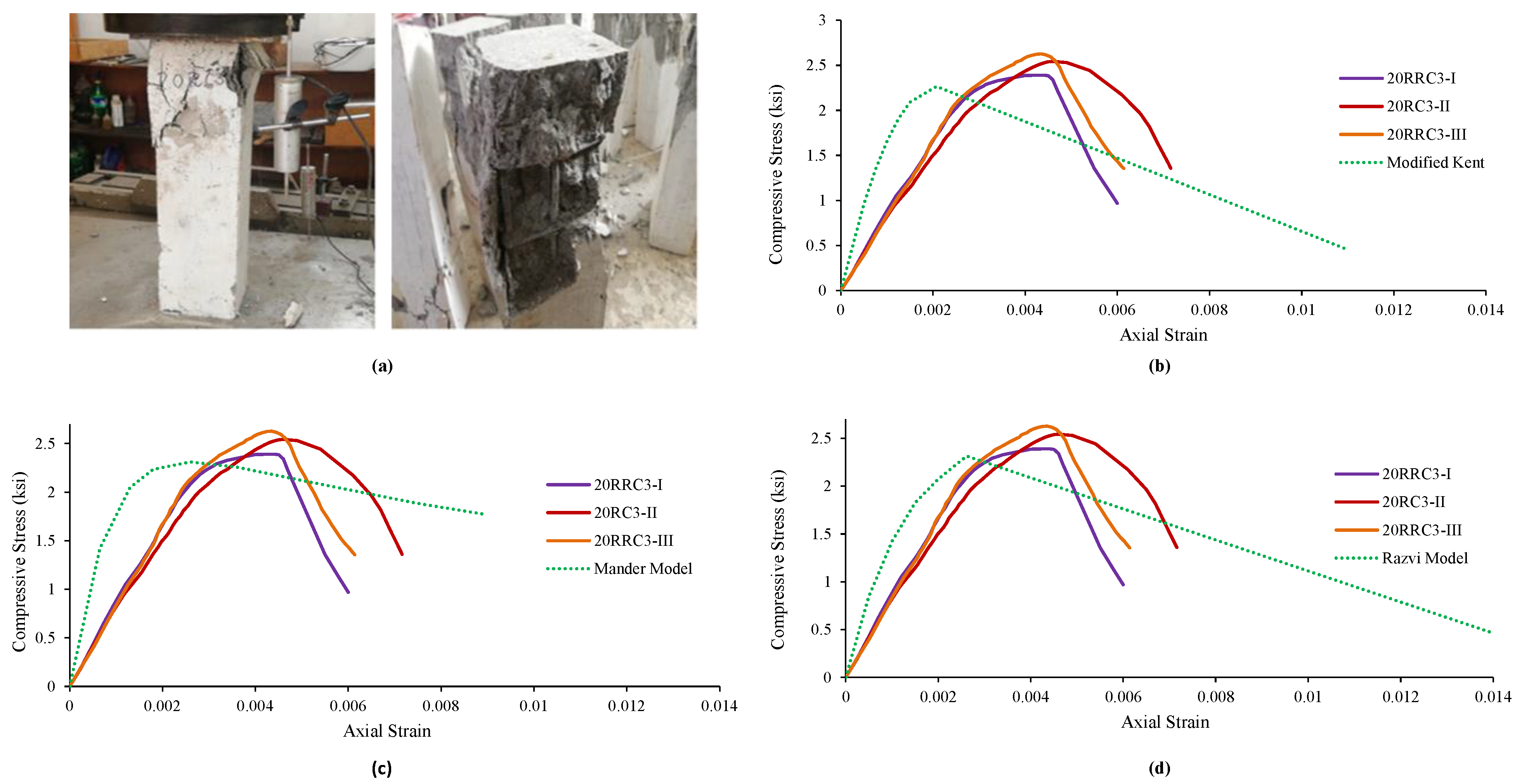

4.6. Observed Behavior and Comparison of 20RRC3 Models

Comparison of 20RRC6 and 20RRC3

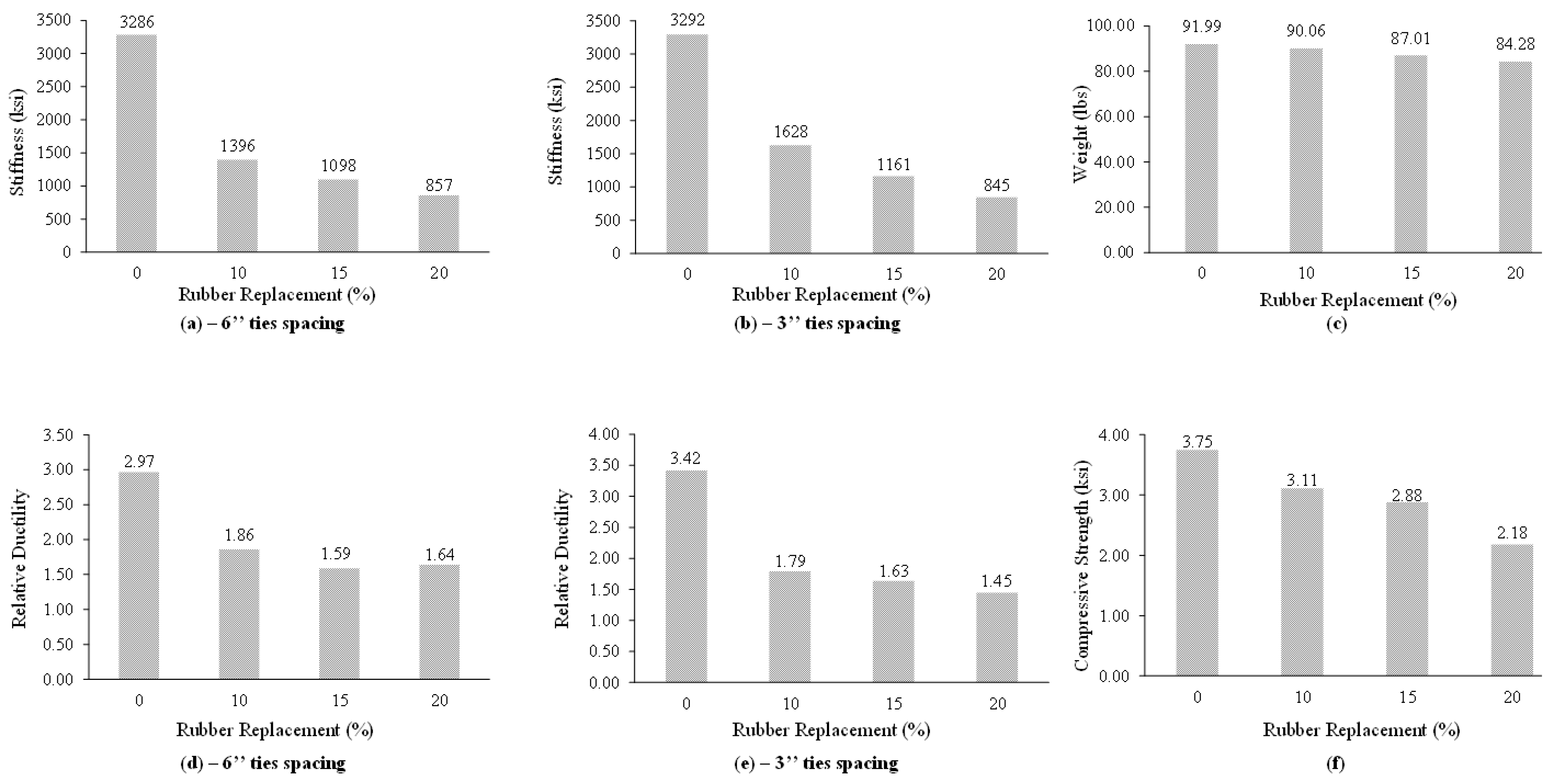

4.7. Stiffness Degradation

4.8. Reduction in Weight

4.9. Relative Ductility

4.10. Compressive Strength

5. Conclusions

- The experimental data recorded during testing of the concrete cylinders and reinforced test specimens shows that 20% rubber replacement via fine aggregates causes an 8.4% reduction in weight and 41.86% in compressive strength compared to normal concrete. The peak strength has increased from 7% to 14% concerning the Modified Kent and Park Model. The reinforced rubberized concrete stiffness decreased while the strain at peak increased.

- Likewise, the ultimate strain was decreased in each series, and the degradation of stiffness occurs at 50.53%, 64.72%, and 74.34% concerning normal concrete. Similarly, employing scrap rubber crumbs in concrete causes the relative ductility to decrease by 39.60%, 44.93%, and 51.27% compared with Modified Kent and Park Model, for 10%, 15%, and 20% volume replacement (3 inches spacing). It was also found that the relative ductility is reduced for specimens having 3 in (76 mm) c/c tie spacing in contrast to specimens having 6 in (152 mm) c/c tie spacing by using rubberized concrete due to confinement of lateral ties.

- The plain and reinforced concrete employing crumb rubber is under investigation worldwide at different sections and full-frame structure levels. The Poison’s ratio of rubberized aggregate concrete and its variation with percentage replacement of rubber is under exploration. It is recommended to build frame structures and various sections of structural members, i.e., beam and column of plain and reinforced concrete, and be tested under static and dynamic loading to know the performance parameters and behavior so that scrap rubber can be confidently used as building materials. This will serve as a guideline of reusability of rubber in construction industries and will minimize the associated problems like contamination of the environment and dumping site availability.

- With the advancement in artificial intelligence (AI), wide variety of civil engineering problems are solved using AI [38,39,40,41,42,43,44,45]. AI models shall be developed that can product the mechanical and durability properties of rubberized concrete. This way, cost, time, and economy of the project can be effectively increased.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Silvestravičiūtė, I.; Šleinotaitė-Budrienė, L. Possibility to use scrap tyres as an alternative fuel in cement industry. Environ. Res. Eng. Manag. 2002, 3, 38–48. [Google Scholar]

- Stutz, J.; Donahue, S.; Mintzer, E.; Cotter, A. Recycled Rubber Products in Landscaping Applications; Tellus Institute, Resource and Environmental Strategies: Boston, MA, USA, 2003. [Google Scholar]

- Mohd Mustafa Al Bakri, A.; Adam, S.N.F.S.; Bakar, M.A.; Leong, K. Comparison of Rubber as Aggregate and Rubber as Filler in Concrete. In Proceedings of the 1st International Conference on Sustainable Material (ICOMS), Bangalore, India, 14–18 November 2007. [Google Scholar]

- Shah, S.; Naseer, A.; Shah, A.; Ashraf, M. Evaluation of thermal and structural behavior of concrete containing rubber aggregate. Arab. J. Sci. Eng. 2014, 39, 6919–6926. [Google Scholar] [CrossRef]

- Aniruddh, M.; Kumar, A.; Khan, M.A. Effect on compressive strength of concrete by using waste rubber as partial replacement of fine aggregate: A review. Int. Res. J. Eng. Technol. 2016, 3, 86–89. [Google Scholar]

- Savas, B.Z.; Ahmad, S.; Fedroff, D. Freeze-thaw durability of concrete with ground waste tire rubber. Transp. Res. Rec. 1997, 1574, 80–88. [Google Scholar] [CrossRef]

- Naik, T.R.; Seddiquie, R. Properties of concrete containing scrap tyre rubber—An overview. Waste Manag. 2004, 24, 563–569. [Google Scholar]

- Eldin, N.N.; Senouci, A.B. Measurement and prediction of the strength of rubberized concrete. Cem. Concr. Compos. 1994, 16, 287–298. [Google Scholar] [CrossRef]

- Xue, J.; Shinozuka, M. Rubberized concrete: A green structural material with enhanced energy-dissipation capability. Constr. Build. Mater. 2013, 42, 196–204. [Google Scholar] [CrossRef]

- Sharma, U.; Kansal, R. Study in beneficial point of rubber aggregate for using in concrete mix: A review. Int. J. Recent Res. Civ. Mech. Eng. 2017, 3, 94–97. [Google Scholar]

- Thomas, B.S.; Gupta, R.C.; Mehra, P.; Kumar, S. Performance of high strength rubberized concrete in aggressive environment. Constr. Build. Mater. 2015, 83, 320–326. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Rubber-tire particles as concrete aggregate. J. Mater. Civ. Eng. 1993, 5, 478–496. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Baghban, M.H.; Faridmehr, I.; Huseien, G.F.; Abidin, A.R.Z.; Ismail, M. Performance Evaluation of Modified Rubberized Concrete Exposed to Aggressive Environments. Materials 2021, 14, 1900. [Google Scholar] [CrossRef] [PubMed]

- Saberian, M.; Li, J. Effect of freeze–thaw cycles on the resilient moduli and unconfined compressive strength of rubberized recycled concrete aggregate as pavement base/subbase. Transp. Geotech. 2021, 27, 100477. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F.; Dai, K. Effect of age and waste crumb rubber aggregate proportions on flexural characteristics of self-compacting rubberized concrete. Struct. Concr. 2021, in press. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F. Application of waste tire rubber and recycled aggregates in concrete products: A new compression casting approach. Resour. Conserv. Recycl. 2021, 167, 105353. [Google Scholar] [CrossRef]

- Romanazzi, V.; Leone, M.; Tondolo, F.; Fantilli, A.P.; Aiello, M.A. Bond strength of rubberized concrete with deformed steel bar. Constr. Build. Mater. 2021, 272, 121730. [Google Scholar] [CrossRef]

- Feng, W.; Chen, B.; Yang, F.; Liu, F.; Li, L.; Jing, L.; Li, H. Numerical study on blast responses of rubberized concrete slabs using the Karagozian and Case concrete model. J. Build. Eng. 2021, 33, 101610. [Google Scholar] [CrossRef]

- More, T.R.; Jadhao, P.D.; Dumne, S. Strength appraisal of concrete containing waste tyre crumb rubber. Int. J. Struct. Civ. Eng. Res. 2015, 4, 88–99. [Google Scholar]

- Liu, H.; Wang, X.; Jiao, Y.; Sha, T. Experimental investigation of the mechanical and durability properties of crumb rubber concrete. Materials 2016, 9, 172. [Google Scholar] [CrossRef]

- Copetti, C.M.; Borges, P.M.; Squiavon, J.Z.; da Silva, S.R.; de Oliveira Andrade, J.J. Evaluation of tire rubber surface pre-treatment and silica fume on physical-mechanical behavior and microstructural properties of concrete. J. Clean. Prod. 2020, 256, 120670. [Google Scholar] [CrossRef]

- Abd-Elaal, E.-S.; Araby, S.; Mills, J.E.; Youssf, O.; Roychand, R.; Ma, X.; Zhuge, Y.; Gravina, R.J. Novel approach to improve crumb rubber concrete strength using thermal treatment. Constr. Build. Mater. 2019, 229, 116901. [Google Scholar] [CrossRef]

- Najim, K.B.; Hall, M.R. Crumb rubber aggregate coatings/pre-treatments and their effects on interfacial bonding, air entrapment and fracture toughness in self-compacting rubberised concrete (SCRC). Mater. Struct. 2013, 46, 2029–2043. [Google Scholar] [CrossRef]

- Onuaguluchi, O. Effects of surface pre-coating and silica fume on crumb rubber-cement matrix interface and cement mortar properties. J. Clean. Prod. 2015, 104, 339–345. [Google Scholar] [CrossRef]

- KIST, B.; Kigali, R. A review on construction technologies that enables environmental protection: Rubberized concrete. Am. J. Eng. Appl. Sci. 2008, 1, 40–44. [Google Scholar]

- AbdelAleem, B.H.; Hassan, A.A. Influence of rubber content on enhancing the structural behaviour of beam–column joints. Mag. Concr. Res. 2018, 70, 984–996. [Google Scholar] [CrossRef]

- Youssf, O.; Mills, J.E.; Benn, T.; Zhuge, Y.; Ma, X.; Roychand, R.; Gravina, R. Development of Crumb Rubber Concrete for Practical Application in the Residential Construction Sector–Design and Processing. Constr. Build. Mater. 2020, 260, 119813. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Lokuge, W.P.; Sanjayan, J.G.; Setunge, S. Stress–strain model for laterally confined concrete. J. Mater. Civ. Eng. 2005, 17, 607–616. [Google Scholar] [CrossRef]

- Sakai, J.; Kawashima, K. Unloading and reloading stress–strain model for confined concrete. J. Struct. Eng. 2006, 132, 112–122. [Google Scholar] [CrossRef]

- Campione, G.; Cavaleri, L.; Ferrotto, M.; Macaluso, G.; Papia, M. Efficiency of stress-strain models of confined concrete with and without steel jacketing to reproduce experimental results. Open Constr. Build. Technol. J. 2016, 10, 65–86. [Google Scholar] [CrossRef][Green Version]

- Feng, D.-C.; Ding, Z.-D. A new confined concrete model considering the strain gradient effect for RC columns under eccentric loading. Mag. Concr. Res. 2018, 70, 1189–1204. [Google Scholar] [CrossRef]

- Martínez-Rueda, J.E.; Elnashai, A. Confined concrete model under cyclic load. Mater. Struct. 1997, 30, 139–147. [Google Scholar] [CrossRef]

- Teng, J.; Huang, Y.; Lam, L.; Ye, L. Theoretical model for fiber-reinforced polymer-confined concrete. J. Compos. Constr. 2007, 11, 201–210. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, M.; Tang, Y.; Zhang, X.; Ding, X. Behaviour of high-strength concrete columns confined by spiral reinforcement under uniaxial compression. Constr. Build. Mater. 2017, 154, 496–503. [Google Scholar] [CrossRef]

- Marques, S.P.C.; Marques, D.C.d.S.C.; Lins da Silva, J.; Cavalcante, M.A.A. Model for analysis of short columns of concrete confined by fiber-reinforced polymer. J. Compos. Constr. 2004, 8, 332–340. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C.; Vincent, T. FRP-confined concrete in circular sections: Review and assessment of stress–strain models. Eng. Struct. 2013, 49, 1068–1088. [Google Scholar] [CrossRef]

- Iqbal, M.; Zhang, D.; Jalal, F.E. Durability evaluation of GFRP rebars in harsh alkaline environment using optimized tree-based random forest model. J. Ocean. Eng. Sci. 2021, in press. [Google Scholar] [CrossRef]

- Iqbal, M.; Zhao, Q.; Zhang, D.; Jalal, F.E.; Jamal, A. Evaluation of tensile strength degradation of GFRP rebars in harsh alkaline conditions using non-linear genetic-based models. Mater. Struct. 2021, 54, 1–20. [Google Scholar] [CrossRef]

- Jalal, F.E.; Xu, Y.; Li, X.; Jamhiri, B.; Iqbal, M. Fractal approach in expansive clay-based materials with special focus on compacted GMZ bentonite in nuclear waste disposal: A systematic review. Environ. Sci. Pollut. Res. 2021, 28, 43287–43314. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.-H.; Dam, N.D.; Jalal, F.E.; Al-Ansari, N.; Ho, L.S.; Phong, T.V.; Iqbal, M.; Le, H.V.; Nguyen, H.B.T.; Prakash, I.; et al. GIS-Based Soft Computing Models for Landslide Susceptibility Mapping: A Case Study of Pithoragarh District, Uttarakhand State, India. Math. Probl. Eng. 2021, 2021, 9914650. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Jalal, F.E.; Iqbal, M.; Rehman, Z.U.; Ibe, K. Intelligent modeling of unconfined compressive strength (UCS) of hybrid cement-modified unsaturated soil with nanostructured quarry fines inclusion. Innov. Infrastruct. Solut. 2021, 7, 98. [Google Scholar] [CrossRef]

- Jamal, A.; Al-Ahmadi, H.M.; Butt, F.M.; Iqbal, M.; Almoshaogeh, M.; Ali, S. Metaheuristics for Traffic Control and Optimization: Current Challenges and Prospects; IntechOpen: London, UK, 2021. [Google Scholar]

- Trong, D.K.; Pham, B.T.; Jalal, F.E.; Iqbal, M.; Roussis, P.C.; Mamou, A.; Ferentinou, M.; Vu, D.Q.; Duc Dam, N.; Tran, Q.A. On Random Subspace Optimization-Based Hybrid Computing Models Predicting the California Bearing Ratio of Soils. Materials 2021, 14, 6516. [Google Scholar] [CrossRef] [PubMed]

- Jalal, F.E.; Xu, Y.; Iqbal, M.; Jamhiri, B.; Javed, M.F. Predicting the compaction characteristics of expansive soils using two genetic programming-based algorithms. Transp. Geotech. 2021, 30, 100608. [Google Scholar] [CrossRef]

| Class | Specimen ID | Ties Spacing | Reinforcement (Longitudinal) | Rubber (%) by Volume | Cross-Section (in2) |

|---|---|---|---|---|---|

| A1 | 10RRC6 | #1@ 6 in c/c | 8 # 2 | 10 | 6 × 6 |

| A2 | 10RRC3 | #1@ 3 in c/c | |||

| B1 | 15RRC6 | #1@ 6 in c/c | 15 | 6 × 6 | |

| B2 | 15RRC3 | #1@ 3 in c/c | |||

| C1 | 20RRC6 | #1@ 6 in c/c | 20 | 6 × 6 | |

| C2 | 20RRC3 | #1@ 3 in c/c |

| Sieve No | Sieve Size (mm) | Retained Weight (gm) | Passing Weight (gm) | Cumulative Weight (gm) | %Age Passing |

|---|---|---|---|---|---|

| 3/4” | 19 | 0 | 3998 | 0 | 100 |

| 1/2” | 12.5 | 61 | 3937 | 61 | 98.5 |

| 3/8” | 9.5 | 1242 | 2695 | 1303 | 67.4 |

| 4 | 4.75 | 1708 | 987 | 3011 | 24.7 |

| Pan | 987 | 0 | 3998 | 0.0 |

| Sieve No | Sieve Size (mm) | Retained Weight (gm) | Passing Weight (gm) | Cumulative Weight (gm) | %Age Passing |

|---|---|---|---|---|---|

| 4 | 4.75 | 0 | 1008 | 0 | 100.0 |

| 8 | 2.35 | 0 | 1008 | 0 | 100.0 |

| 16 | 1.18 | 1 | 1007 | 1 | 99.9 |

| 30 | 0.6 | 4 | 1003 | 5 | 99.5 |

| 50 | 0.3 | 34 | 969 | 39 | 96.1 |

| 100 | 0.15 | 856 | 113 | 895 | 11.2 |

| 200 | 0.075 | 103 | 10 | 998 | 1.0 |

| Pan | 10 | 0 | 1008 | 0.0 |

| Parameter | 10RRC6 (Average) | MKM | % Difference w.r.t MKM | MM | % Difference w.r.t MM | RM | % Difference w.r.t RM |

|---|---|---|---|---|---|---|---|

| Peak Strength (ksi) | 3.38 | 3.15 | (+) 07.30 | 3.14 | (+) 07.64 | 3.19 | (+) 05.95 |

| Ultimate Strain (in/in) | 0.0065 | 0.0069 | (−) 05.79 | 0.0058 | (+) 12.06 | 0.0125 | (−) 48.00 |

| Strain at Peak (in/in) | 0.0035 | 0.002 | (+) 75.00 | 0.0021 | (+) 66.66 | 0.0022 | (+) 59.09 |

| Relative Ductility | 1.86 | 3.4 | (−) 45.29 | 2.76 | (−) 32.60 | 5.58 | (−) 66.66 |

| Stiffness (ksi) | 1396 | 3108 | (−) 55.08 | 3139 | (−) 55.52 | 3160 | (−) 55.82 |

| Parameter. | 10RRC3 (Average) | MKM | % Difference w.r.t MKM | MM | % Difference w.r.t MM | RM | % Difference w.r.t RM |

|---|---|---|---|---|---|---|---|

| Peak Strength (ksi) | 3.65 | 3.2 | (+) 14.06 | 3.27 | (+) 11.62 | 3.24 | (+) 12.65 |

| Ultimate Strain (in/in) | 0.0073 | 0.0081 | (−) 09.87 | 0.0075 | (−) 02.14 | 0.014 | (−) 47.85 |

| Strain at Peak (in/in) | 0.0045 | 0.0021 | (+) 114.28 | 0.0025 | (+) 80.00 | 0.002 | (+) 87.50 |

| Relative Ductility | 1.79 | 3.94 | (−) 54.56 | 2.98 | (−) 39.93 | 5.76 | (−) 68.92 |

| Stiffness (ksi) | 1628 | 3292 | (−) 50.54 | 3150 | (−) 48.31 | 3171 | (−) 48.65 |

| Parameter | 10RRC6 Average | 10RRC3 Average | % Difference w.r.t 10RRC3 |

|---|---|---|---|

| Peak Strength (ksi) | 3.38 | 3.65 | (+) 07.39 |

| Ultimate Strain (in/in) | 0.0058 | 0.0073 | (+) 20.54 |

| Strain at Peak (in/in) | 0.0037 | 0.0045 | (+) 17.77 |

| Relative Ductility | 1.86 | 1.79 | (−) 03.91 |

| Stiffness (ksi) | 1396 | 1628 | (+) 14.25 |

| Parameter | 15RRC6 (Average) | MKM | % Variation w.r.t MKM | MM | % Variation w.r.t MM | RM | % Variation w.r.t RM |

|---|---|---|---|---|---|---|---|

| Peak Strength (ksi) | 3.12 | 2.92 | (+) 06.84 | 2.92 | (+) 04.45 | 2.92 | (+) 07.87 |

| Ultimate Strain (in/in) | 0.0058 | 0.0074 | (−) 21.62 | 0.0074 | (−) 29.72 | 0.0074 | (−) 14.86 |

| Strain at Peak (in/in) | 0.0037 | 0.002 | (+) 85.00 | 0.002 | (+) 70.00 | 0.002 | (+) 60.00 |

| Relative Ductility | 1.59 | 3.65 | (−) 56.43 | 3.65 | (−) 58.08 | 3.65 | (−) 46.30 |

| Stiffness (ksi) | 1098 | 2874 | (−) 61.79 | 2874 | (−) 64.40 | 2874 | (−) 61.16 |

| Parameter | 15RRC3 (Average) | MKM | % Variation w.r.t MKM | MM | % Variation w.r.t MM | RM | % Variation w.r.t RM |

|---|---|---|---|---|---|---|---|

| Peak Strength (ksi) | 3.22 | 2.96 | (+) 08.78 | 3.02 | (+) 06.62 | 3.17 | (+) 01.57 |

| Ultimate Strain (in/in) | 0.0068 | 0.0086 | (−) 20.93 | 0.0074 | (−) 08.10 | 0.013 | (−) 47.69 |

| Strain at Peak (in/in) | 0.0042 | 0.0021 | (+) 100.00 | 0.0025 | (+) 68.00 | 0.003 | (+) 40.00 |

| Relative Ductility | 1.63 | 4.18 | (−) 61.00 | 2.96 | (−) 44.93 | 4.32 | (−) 62.26 |

| Stiffness (ksi) | 1161 | 2877 | (−) 59.64 | 3023 | (−) 61.59 | 2891 | (−) 59.84 |

| Parameter | 15RRC6 (Average) | 15RRC3 (Average) | % Variation w.r.t 15RRC3 |

|---|---|---|---|

| Peak Strength (ksi) | 3.12 | 3.22 | (+) 03.10 |

| Ultimate Strain (in/in) | 0.0058 | 0.0068 | (+) 14.70 |

| Strain at Peak (in/in) | 0.0037 | 0.0042 | (+) 11.90 |

| Relative Ductility | 1.59 | 1.63 | (+) 02.45 |

| Stiffness (ksi) | 1098 | 1161 | (+) 05.42 |

| Parameter | 20RRC6 (Average) | MKM | % Variation w.r.t MKM | MM | % Variation w.r.t MM | RM | % Variation w.r.t RM |

|---|---|---|---|---|---|---|---|

| Peak Strength (ksi) | 2.32 | 2.22 | (+) 04.50 | 2.22 | (+) 04.50 | 2.29 | (+) 01.31 |

| Ultimate Strain (in/in) | 0.0057 | 0.0099 | (−) 42.42 | 0.007 | (−) 18.57 | 0.0138 | (−) 58.69 |

| Strain at Peak (in/in) | 0.0035 | 0.002 | (+) 75.00 | 0.0022 | (+) 59.09 | 0.0025 | (+) 40.00 |

| Relative Ductility | 1.64 | 4.86 | (−) 66.25 | 3.18 | (−) 48.42 | 5.52 | (−) 70.28 |

| Stiffness (ksi) | 857 | 2171 | (−) 60.25 | 2612 | (−) 67.18 | 2234 | (−) 61.63 |

| Parameter | 20RRC3 (Average) | MKM | % Variation w.r.t MKM | MM | % Variation w.r.t MM | RM | % Variation w.r.t RM |

|---|---|---|---|---|---|---|---|

| Peak Strength (ksi) | 2.52 | 2.26 | (+) 11.50 | 2.31 | (+) 09.09 | 2.31 | (+) 09.09 |

| Ultimate Strain (in/in) | 0.0064 | 0.011 | (−) 41.81 | 0.00889 | (−) 28.00 | 0.014 | (−) 54.28 |

| Strain at Peak (in/in) | 0.0045 | 0.0021 | (+) 114.28 | 0.0026 | (+) 73.07 | 0.0026 | (+) 73.07 |

| Relative Ductility | 1.44 | 5.29 | (−) 72.77 | 3.42 | (−) 57.89 | 5.38 | (−) 73.23 |

| Stiffness (ksi) | 845 | 2171 | (−) 61.07 | 2566 | (−) 67.06 | 2261 | (−) 62.54 |

| Parameter | 20RRC6 (Average) | 20RRC3 (Average) | % Variation w.r.t 20RRC3 |

|---|---|---|---|

| Peak Strength (ksi) | 2.32 | 2.52 | (+) 07.93 |

| Ultimate Strain (in/in) | 0.0057 | 0.0064 | (+) 10.93 |

| Strain at Peak (in/in) | 0.0035 | 0.0045 | (+) 22.22 |

| Relative Ductility | 1.64 | 1.44 | (−) 13.88 |

| Stiffness (ksi) | 857 | 845 | (−) 01.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, H.; Iqbal, M.; Khan, K.; Jamal, A.; Nawaz, A.; Khan, N.; Jalal, F.E.; Almaliki, A.H.; Hussein, E.E. Experimental Investigation of the Stress–Strain Behavior and Strength Characterization of Rubberized Reinforced Concrete. Materials 2022, 15, 730. https://doi.org/10.3390/ma15030730

Ullah H, Iqbal M, Khan K, Jamal A, Nawaz A, Khan N, Jalal FE, Almaliki AH, Hussein EE. Experimental Investigation of the Stress–Strain Behavior and Strength Characterization of Rubberized Reinforced Concrete. Materials. 2022; 15(3):730. https://doi.org/10.3390/ma15030730

Chicago/Turabian StyleUllah, Hanif, Mudassir Iqbal, Kaffayatullah Khan, Arshad Jamal, Adnan Nawaz, Nayab Khan, Fazal E. Jalal, Abdulrazak H. Almaliki, and Enas E. Hussein. 2022. "Experimental Investigation of the Stress–Strain Behavior and Strength Characterization of Rubberized Reinforced Concrete" Materials 15, no. 3: 730. https://doi.org/10.3390/ma15030730

APA StyleUllah, H., Iqbal, M., Khan, K., Jamal, A., Nawaz, A., Khan, N., Jalal, F. E., Almaliki, A. H., & Hussein, E. E. (2022). Experimental Investigation of the Stress–Strain Behavior and Strength Characterization of Rubberized Reinforced Concrete. Materials, 15(3), 730. https://doi.org/10.3390/ma15030730