Influence of Polypropylene and Steel Fibers on the Performance and Crack Repair of Self-Compacting Concrete

Abstract

:1. Introduction

2. Methods

2.1. Materials

2.2. Mixing and Proportions

2.3. Testing

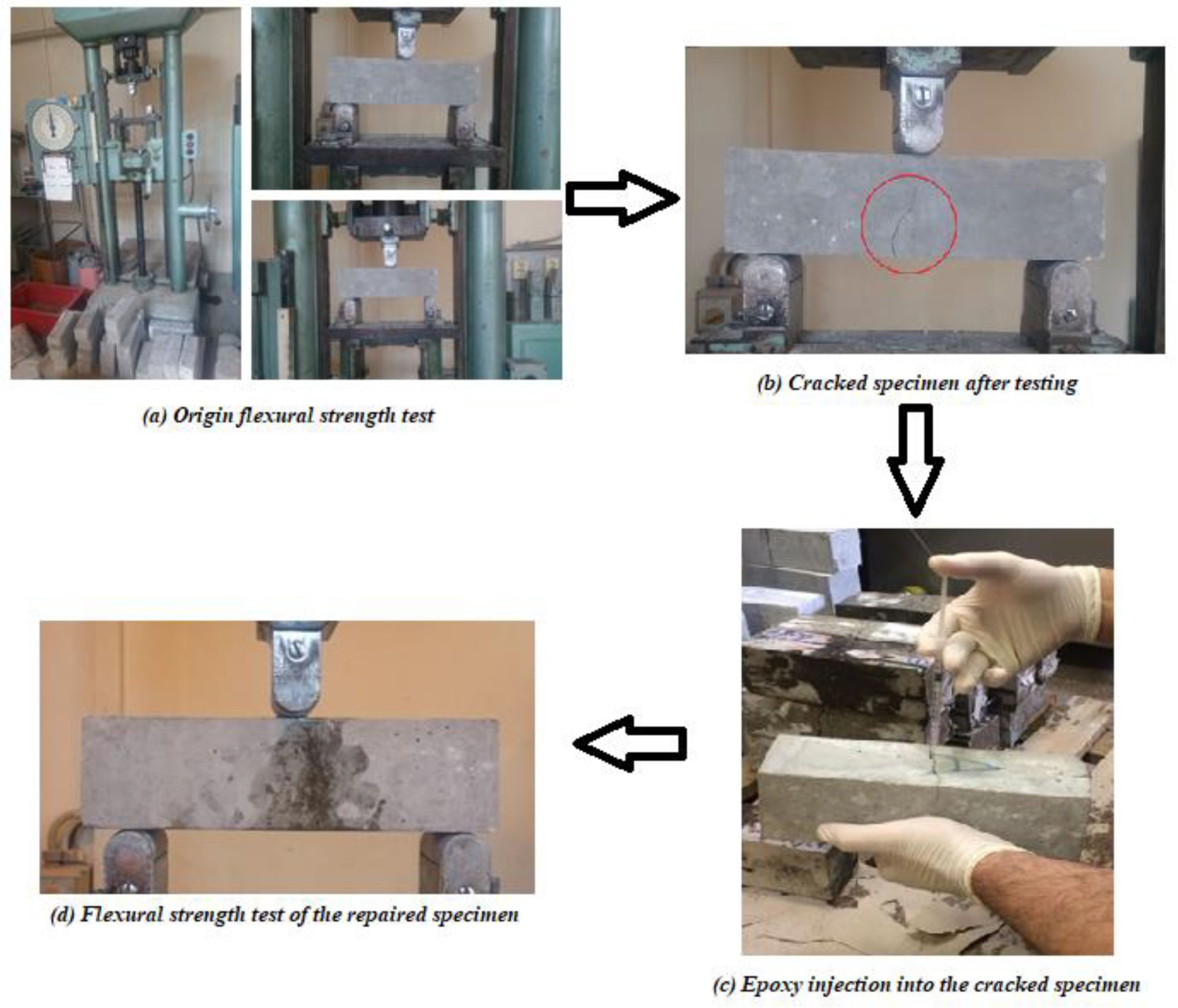

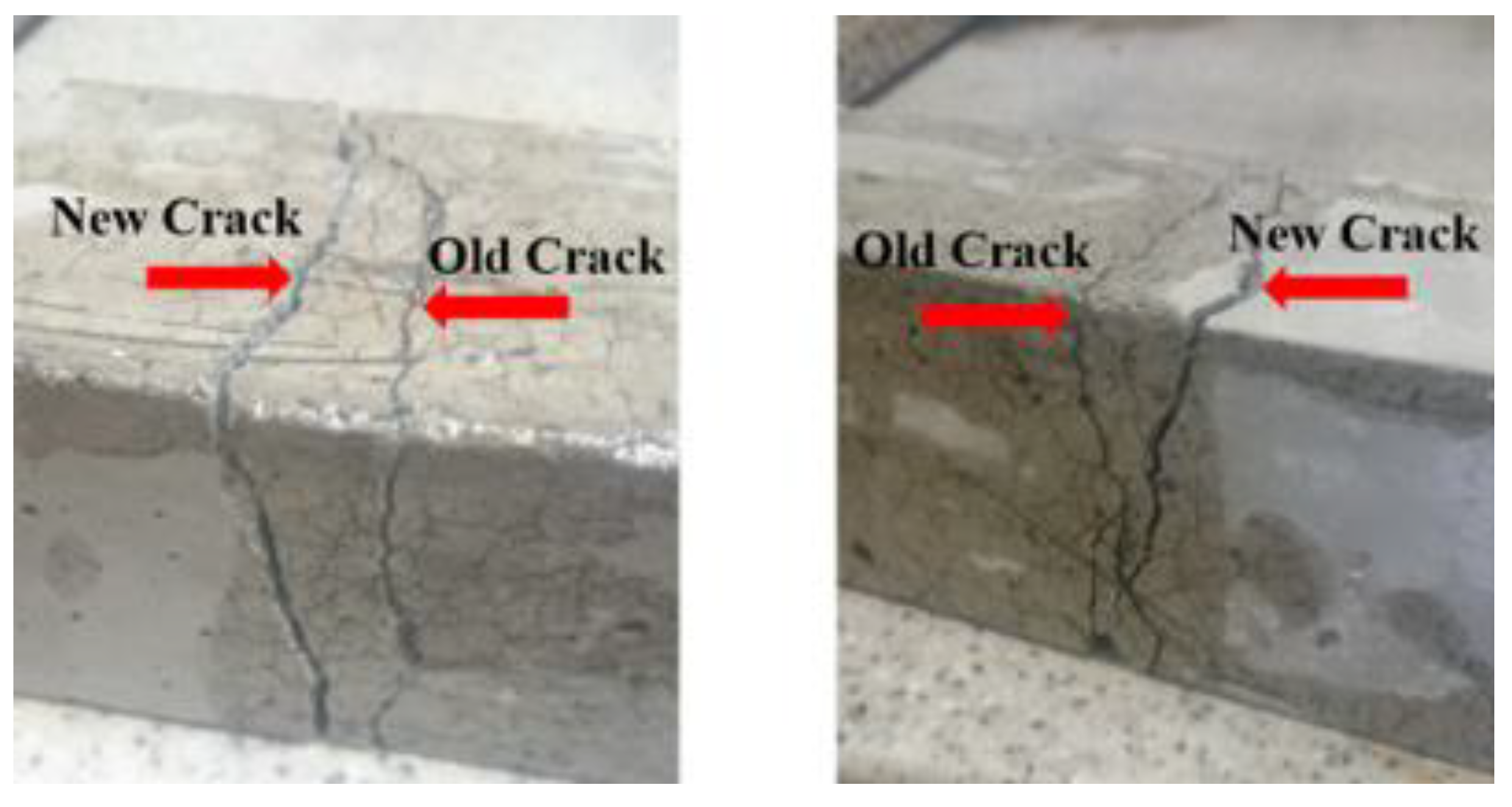

- The crack was cleaned using compressed air.

- The epoxy resin was prepared.

- The crack was filled with the epoxy resin by injecting it using a syringe (Figure 4c).

- After epoxy injection, the outer edges of the crack were painted using epoxy.

- The specimen was left for 24 h, then the flexural test was carried out on the repaired specimen (Figure 4d).

3. Results

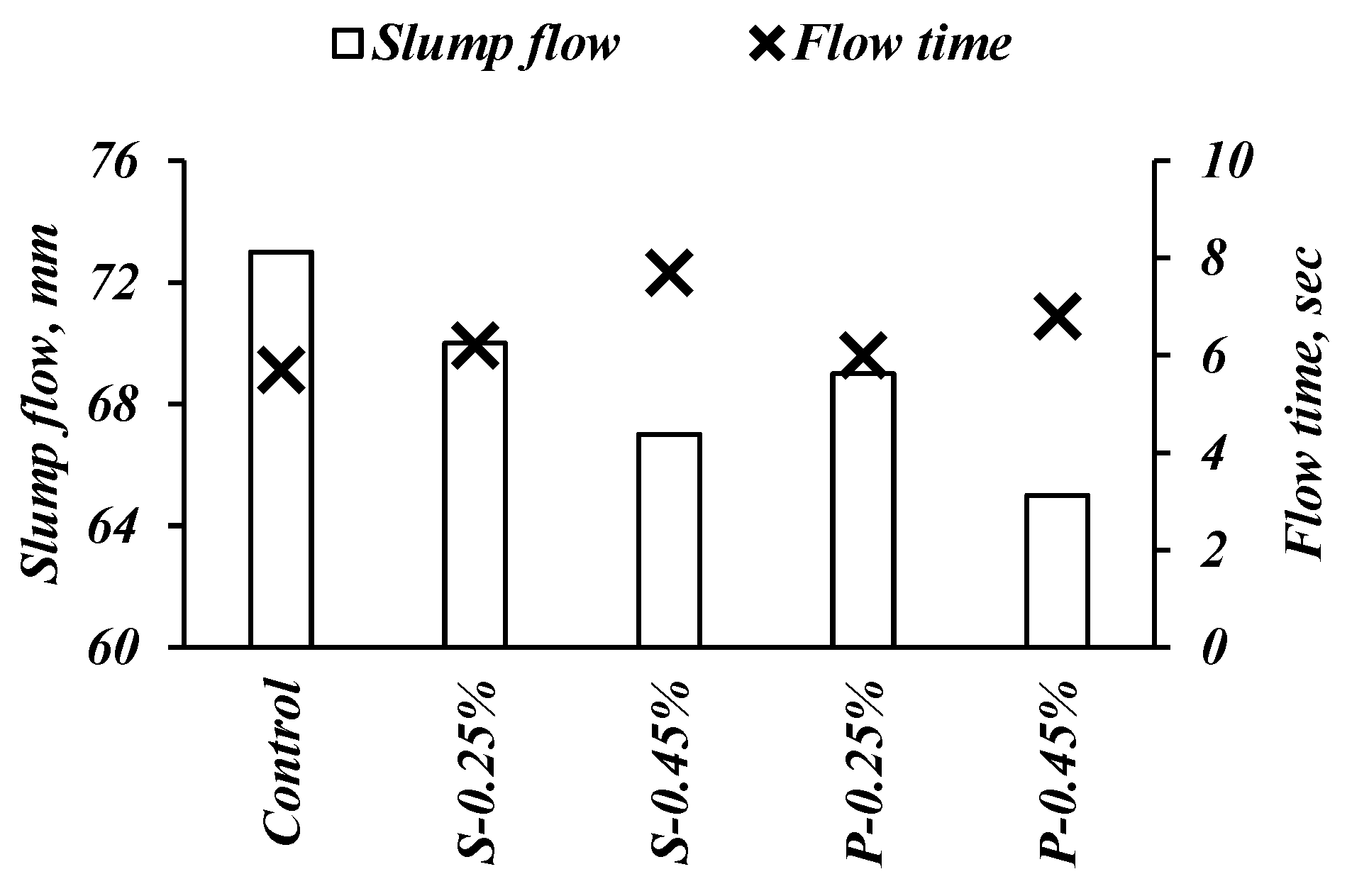

3.1. Fresh Properties

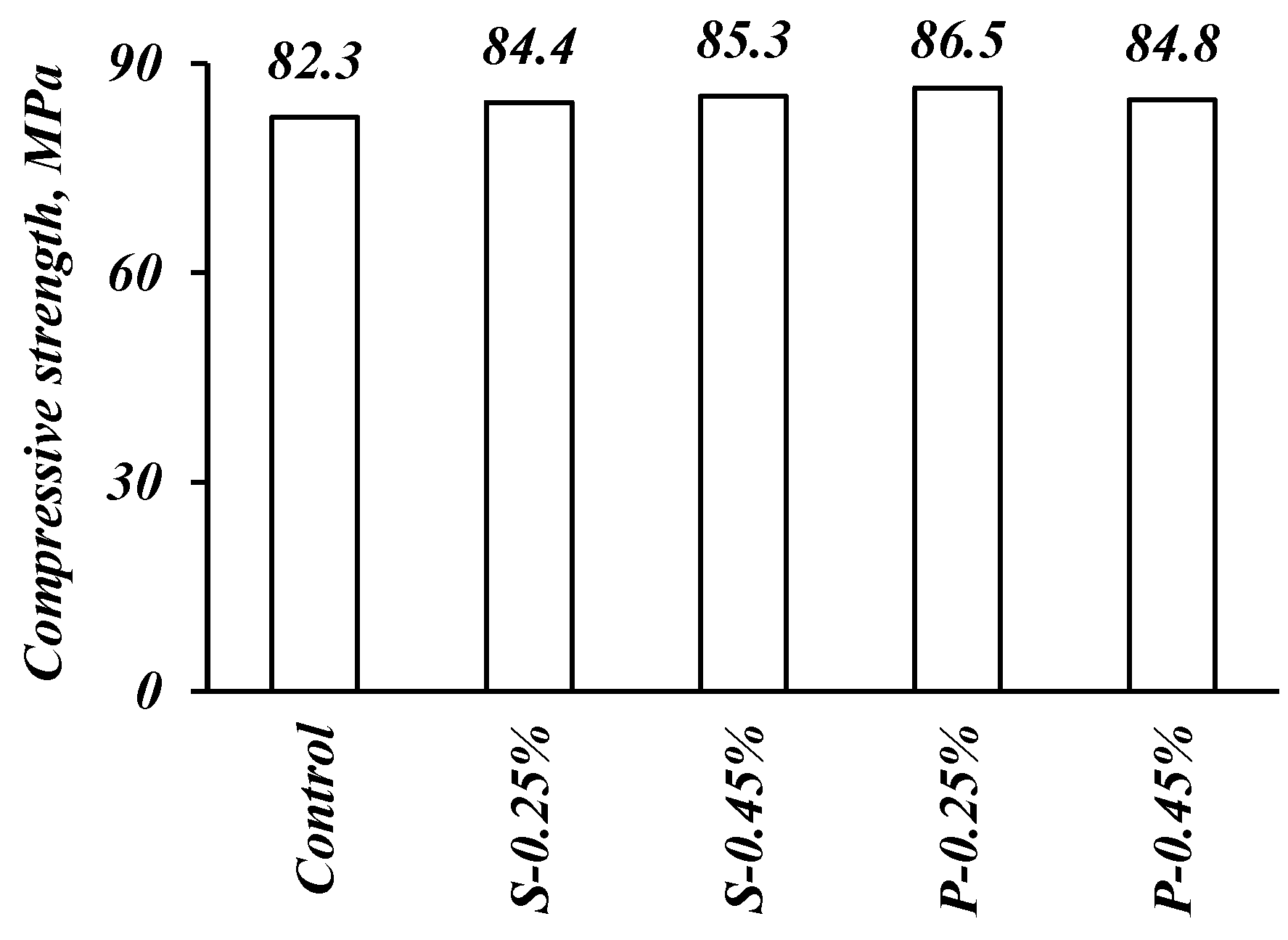

3.2. Compressive Strength

3.3. Splitting Tensile Strength

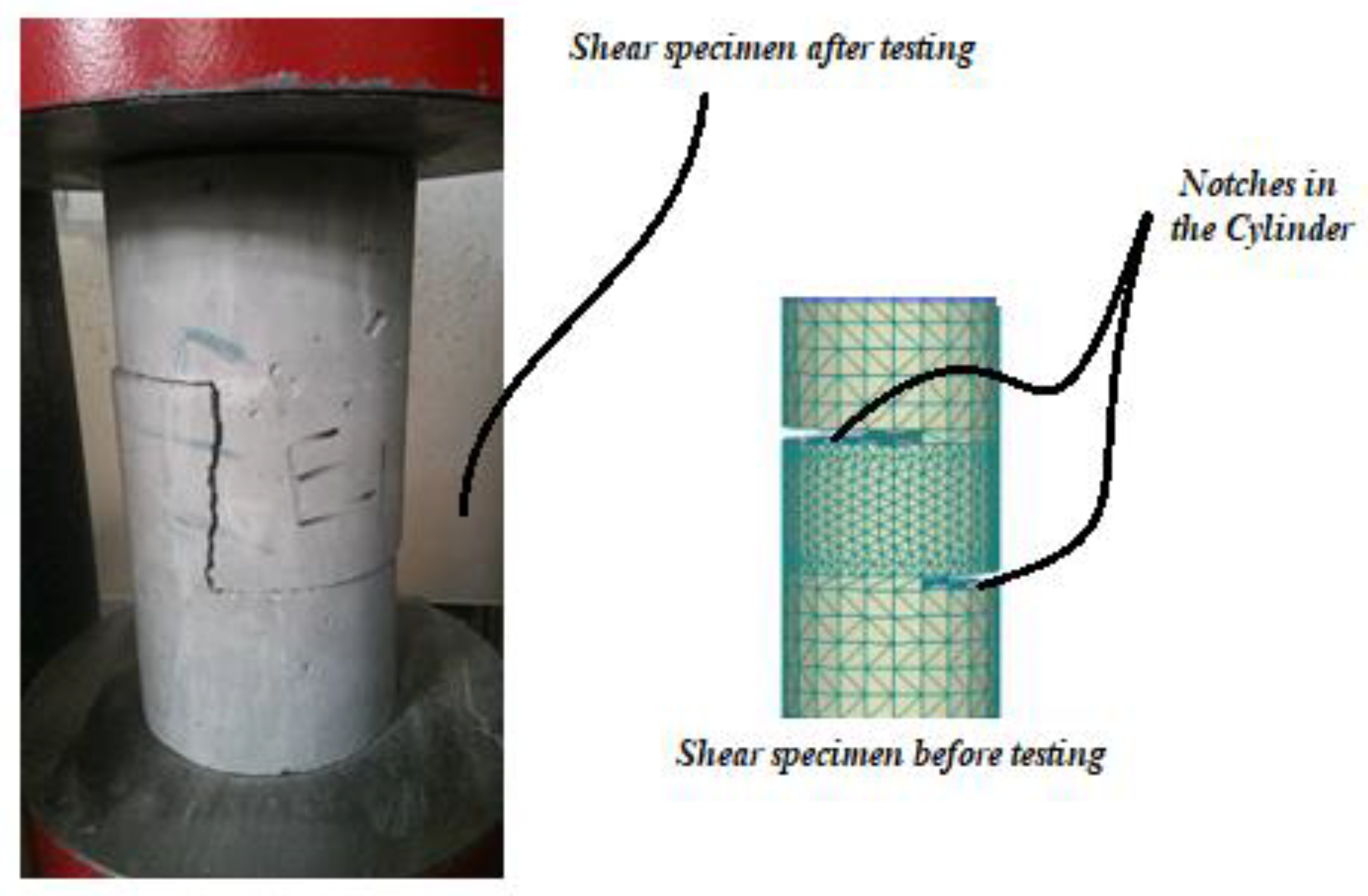

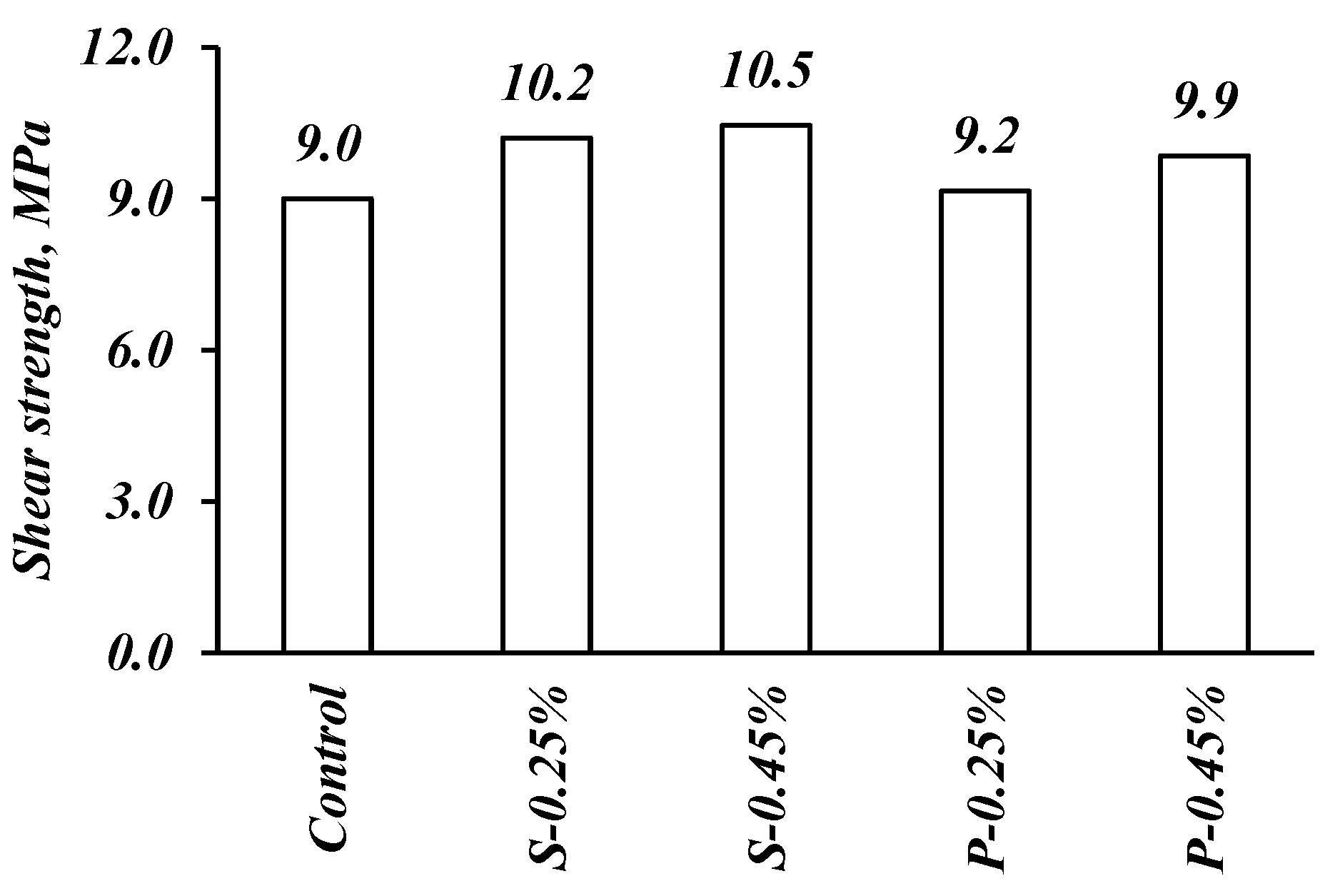

3.4. Shear Strength

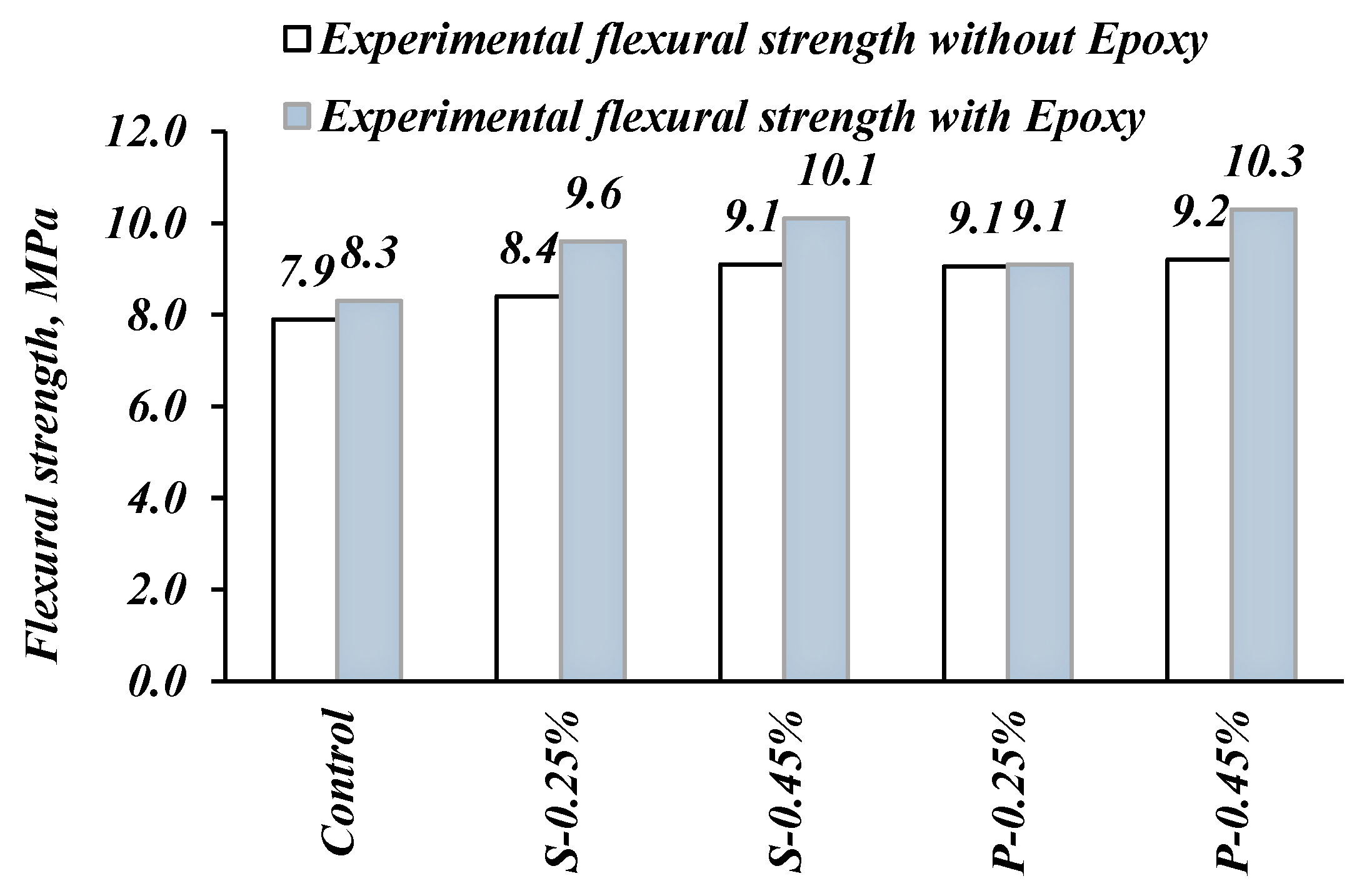

3.5. Flexural Strength (Before and After Epoxy)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liao, W.-C.; Perceka, W.; Liu, E.-J. Compressive Stress-Strain Relationship of High Strength Steel Fiber Reinforced Concrete. J. Adv. Concr. Technol. 2015, 13, 379–392. [Google Scholar] [CrossRef] [Green Version]

- Amin, M.; Tayeh, B.A.; Saad Agwa, I. Investigating the mechanical and microstructure properties of fibre-reinforced lightweight concrete under elevated temperatures. Case Stud. Constr. Mater. 2020, 13, e00459. [Google Scholar] [CrossRef]

- Matar, P.; Assaad, J.J. Concurrent effects of recycled aggregates and polypropylene fibers on workability and key strength properties of self-consolidating concrete. Constr. Build. Mater. 2019, 199, 492–500. [Google Scholar] [CrossRef]

- da Silva, G.C.S.; Christ, R.; Pacheco, F.; de Souza, C.F.N.; Gil, A.M.; Tutikian, B.F. Evaluating steel fiber-reinforced self-consolidating concrete performance. Struct. Concr. 2020, 21, 448–457. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical properties of steel fiber-reinforced Concrete. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- American Concrete Institute. An ACI Standard and Report. Building Code Requirements for Structural Concrete (ACI 318-14). Commentary on Building Code Requirements for Structural Concrete (ACI 318R-14); American Concrete Institute: Farmington Hills, MI, USA, 2014; Available online: https://www.concrete.org/store/productdetail.aspx?ItemID=318U14&Language=English (accessed on 1 September 2021).

- Fédération Internationale du Béton. Model Code for Concrete Structures 2010; Fédération Internationale du Béton: Lausanne, Switzerland, 2010. [Google Scholar]

- Khaloo, A.; Raisi, E.M.; Hosseini, P.; Tahsiri, H. Mechanical performance of self-compacting concrete reinforced with steel fibers. Constr. Build. Mater. 2014, 51, 179–186. [Google Scholar] [CrossRef]

- Dawood, E.T.; Ramli, M. Mechanical properties of high strength flowing concrete with hybrid fibers. Constr. Build. Mater. 2012, 28, 193–200. [Google Scholar] [CrossRef]

- Marcos-Meson, V.; Michel, A.; Solgaard, A.; Fischer, G.; Edvardsen, C.; Skovhus, T.L. Corrosion resistance of steel fibre reinforced concrete—A literature review. Cem. Concr. Res. 2018, 103, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Bolat, H.; Simşek, O.; Çullu, M.; Durmuş, G.; Can, Ö. The effects of macro synthetic fiber reinforcement use on physical and mechanical properties of concrete. Compos. Part B Eng. 2014, 61, 191–198. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Han, B.; Sun, S.; Ding, S.; Zhang, L.; Yu, X.; Ou, J. Review of nanocarbon-engineered multifunctional cementitious composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Sun, Z.; Xu, Q. Microscopic, physical and mechanical analysis of polypropylene fiber reinforced concrete. Mater. Sci. Eng. A 2019, 527, 198–204. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Khayat, K.H.; Roussel, Y. Testing and performance of fiber-reinforced, self-consolidating concrete. Mater. Struct. 2000, 33, 391–397. [Google Scholar] [CrossRef]

- Khayat, K.H.; Kassimi, F.; Ghoddousi, P. Mixture design and testing of fiber-reinforced self-consolidating concrete. ACI Mater. J. 2014, 111, 143–152. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI Committee 54. Concrete Repair Guide (ACI 546R-04); American Concrete Institute: Farmington Hills, MI, USA, 2004; Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/13543 (accessed on 1 September 2021).

- Issa, C.A.; Debs, P. Experimental study of epoxy repairing of cracks in concrete. Constr. Build. Mater. 2007, 21, 157–163. [Google Scholar] [CrossRef]

- Ekenel, M.; Myers, J.J. Durability performance of RC beams strengthened with epoxy injection and CFRP fabrics. Constr. Build. Mater. 2007, 21, 1182–1190. [Google Scholar] [CrossRef]

- French, C.W.; Thorp, G.A.; Tsai, W.J. Epoxy repair techniques for moderate earthquake damage. ACI Struc. J. 1990, 87, 416–424. [Google Scholar]

- Nikopour, H.; Nehdi, M. Shear repair of RC beams using epoxy injection and hybrid external FRP. Mater. Struct. Constr. 2011, 44, 1865–1877. [Google Scholar] [CrossRef]

- Ahmad, S.; Elahi, A.; Barbhuiya, S.; Farooqi, Y. Repair of cracks in simply supported beams using epoxy injection technique. Mater. Struct. Constr. 2013, 46, 1547–1559. [Google Scholar] [CrossRef]

- Kim, T.K.; Park, J.S. Performance Evaluation of Concrete Structures Using Crack Repair Methods. Sustainability 2021, 13, 3217. [Google Scholar] [CrossRef]

- European Committee for Standardization. ISO 196-2:2013. Cement Testing Methods. Part 2: Chemical Analysis of Cement; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- The European Federation of Specialist Construction Chemicals and Concrete Systems (EFNARC). The European Guidelines for Self-Compacting Concrete. Specification, Production and Use. 2005. Available online: https://wwwp.feb.unesp.br/pbastos/c.especiais/Efnarc.pdf (accessed on 1 September 2021).

- Hambach, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. Cem. Concr. Compos. 2017, 79, 62–70. [Google Scholar] [CrossRef]

- Liu, G.M.; Cheng, W.M.; Chen, L.J.; Pan, G.; Liu, Z.X. Rheological properties of fresh concrete and its application on shotcrete. Constr. Build. Mater. 2020, 243, 118180. [Google Scholar] [CrossRef]

- Abed, M. Self-compacting high-performance concrete in terms of mixing proportions and procedure. Concr. Struct. 2018, 19, 22–27. [Google Scholar] [CrossRef]

- Abed, M.A. Green Self-Compacting High-Performance Concrete. Ph.D. Thesis, Budapest University of Technology and Economics, Budapest, Hungary, 2019. Available online: https://repozitorium.omikk.bme.hu/handle/10890/13162 (accessed on 1 September 2021).

- British Standards Institution. BSI EN 12390-3 (2009). Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens; British Standards Institution: London, UK, 2009. [Google Scholar]

- British Standards Institution. BSI EN 12390-5 (2009). Testing Hardened Concrete. Part 5: Flexural Strength of Test Specimens; British Standards Institution: London, UK, 2009. [Google Scholar]

- British Standards Institution. BSI EN 12697-23 (2004) Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens; British Standards Institution: London, UK, 2004. [Google Scholar]

- Mastali, M.; Dalvand, A. Fresh and hardened properties of self-compacting concrete reinforced with hybrid recycled steel-polypropylene fiber. J. Mater. Civ. Eng. 2017, 29, 1–15. [Google Scholar] [CrossRef]

- Mehdipour, I.; Vahdani, M.; Libre, N.A.; Shekarchi, M. Relationship between workability and mechanical properties of fibre-reinforced self-consolidating mortar. Mag. Concr. Res. 2013, 65, 1011–1022. [Google Scholar] [CrossRef]

- Dhonde, H.B.; Mo, Y.L.; Hsu, T.C.; Vogel, J. Fresh and hardened properties of self-consolidating fiber-reinforced concrete. ACI Mater. J. 2007, 5, 491–500. [Google Scholar]

- Yap, S.P.; Alengaram, U.J.; Jumaat, M.Z. Enhancement of mechanical properties in polypropylene- and nylon-fibre reinforced oil palm shell concrete. Mater. Des. 2013, 49, 1034–1041. [Google Scholar] [CrossRef]

- Lee, J.H.; Cho, B.; Choi, E. Flexural capacity of fiber reinforced concrete with a consideration of concrete strength and fiber content. Constr. Build. Mater. 2017, 138, 222–231. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. The long-term compressive strength and durability properties of silica fume fiber-reinforced concrete. Mater. Sci. Eng. A 2012, 531, 107–111. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. On the mechanical properties and fracture behavior of polyolefin fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2014, 55, 274–288. [Google Scholar] [CrossRef]

- Mydin, A.O.; Soleimanzadeh, S. Effect of polypropylene fiber content on flexural strength of lightweight foamed concrete at ambient and elevated temperatures. Adv. Appl. Sci. Res. 2012, 3, 2837–2846. [Google Scholar]

- Sadrinejad, I.; Madandoust, R.; Ranjbar, M.M. The mechanical and durability properties of concrete containing hybrid synthetic fibers. Constr. Build. Mater. 2018, 178, 72–82. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R. The impact resistance and mechanical properties of reinforced self-compacting concrete with recycled glass fibre reinforced polymers. J. Clean. Prod. 2016, 124, 312–324. [Google Scholar] [CrossRef]

- Gali, S.; Subramaniam, K.V.L. Improvements in fracture behavior and shear capacity of fiber reinforced normal and self consolidating concrete: A comparative study. Constr. Build. Mater. 2018, 189, 205–217. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Yoon, Y.-S.; Banthia, N. Flexural response of steel-fiber-reinforced concrete beams: Effects of strength, fiber content, and strain-rate. Cem. Concr. Compos. 2015, 64, 84–92. [Google Scholar] [CrossRef]

- Šušteršič, J.; Zajc, J.; Jure, K.; Korla, J.; Leskovar, I. Efficient Repair of Crack in SFRC with Low-Viscosity Epoxy Adhesive. Adv. Mater. Res. 2015, 1129, 453–459. [Google Scholar] [CrossRef]

- Feng, J.; Gao, X.; Li, J.; Dong, H.; Hec, Q.; Liang, J.; Sun, W. Penetration resistance of hybrid-fiber-reinforced high-strength concrete under projectile multi-impact. Const. Build. Mater. 2019, 202, 341–352. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI 363R-92 State of the Art Report on High Strength Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1992; Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/5194 (accessed on 1 September 2021).

- Comité Euro-International du Béton. CEB-FIP Model Code 1990: Design Code; Thomas Telford Ltd.: London, UK, 1990. [Google Scholar]

- Standards Association of Australia. Australian Standard for Concrete Structures; Standards Association of Australia: Sydney, Australia, 2001; Available online: https://www.icevirtuallibrary.com/doi/book/10.1680/ceb-fipmc1990.35430 (accessed on 1 September 2021).

| Measured Property | CEM I |

|---|---|

| Density (g/cm3) | 3.02 |

| Specific surface area (cm2/g) | 3326 |

| Loss on ignition | 3.0 |

| SiO2 | 19.33 |

| CaO | 63.43 |

| MgO | 1.45 |

| Fe2O3 | 3.42 |

| Al2O3 | 4.67 |

| SO3 | 2.6 |

| Chloride content | 0.04 |

| Free CaO | 0.71 |

| K2O | 0.78 |

| Na2O | 0.33 |

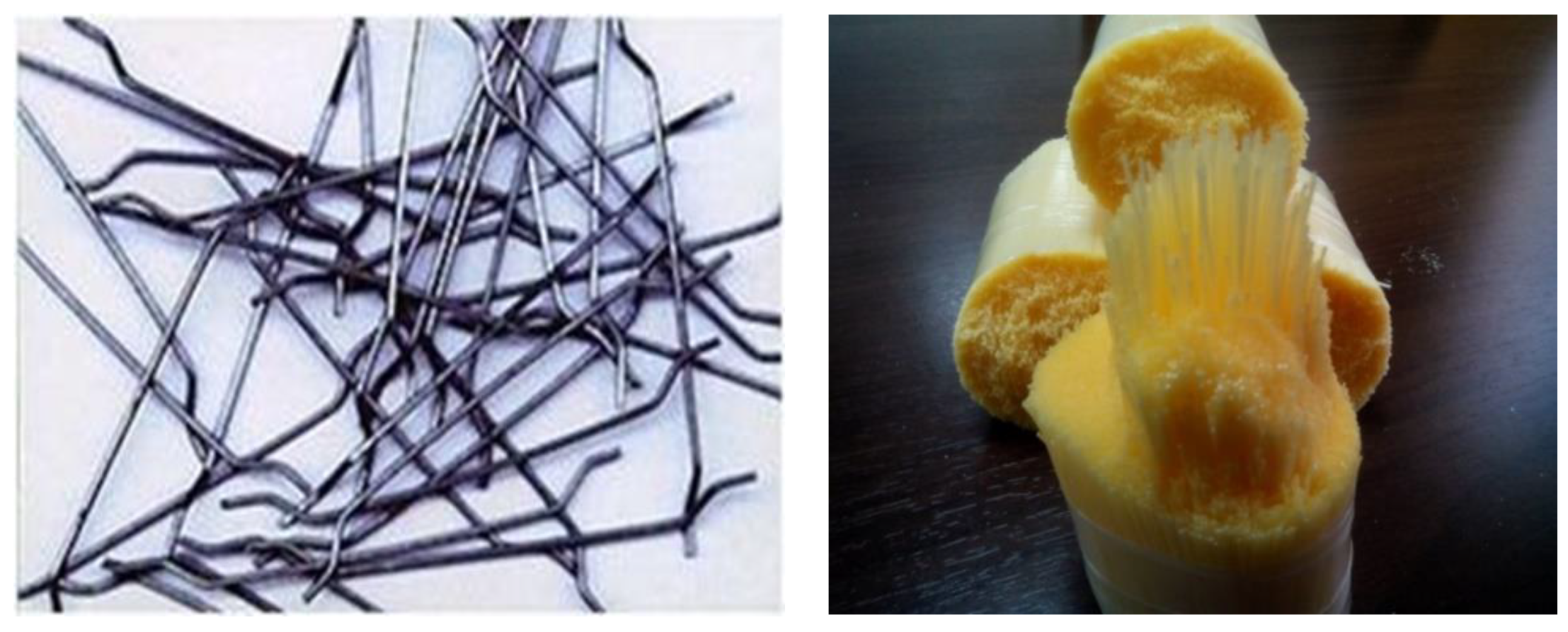

| Type | Steel Fiber 3D 65/60 BG Dramix® | Synthetic Fiber Macro Fiber Concrix |

|---|---|---|

| Material | Steel | Polyolefin |

| Density (g/cm2) | 7.85 | 0.91 |

| Length (mm) | 60 mm | 50 mm |

| Diameter (µm) | 900 µm | 500 µm |

| Colour | gray | yellow |

| Number of fibers by kg | 3200 | 150,000 |

| Tensile strength (MPa) | 1160 | 590 |

| Modulus of elasticity (GPa) | >210 | >11 |

| Mix | Fiber Type | Fiber Volume (%) | Cement (kg/m3) | Fine Aggregates (kg/m3) | Coarse Aggregates (kg/m3) | Admixture (kg/m3) | Water (kg/m3) |

|---|---|---|---|---|---|---|---|

| Control | - | 0 | 500 | 783 | 939 | 1.5 | 175 |

| S–0.25% | Steel | 0.25 | 500 | 780 | 935 | 1.5 | 175 |

| S–0.45% | Steel | 0.45 | 500 | 778 | 933 | 1.5 | 175 |

| P–0.25% | Polypropene | 0.25 | 500 | 781 | 936 | 1.5 | 175 |

| P–0.45% | Polypropene | 0.45 | 500 | 779 | 934 | 1.5 | 175 |

| Test | Formula | Notations |

|---|---|---|

| Compressive strength | P = load at failure (KN) AC = compression area (mm2) LT = length of the cylinder (mm) D = diameter of the cylinder(mm) b = width of the prism (mm) d = depth of the prism (mm) LF = length between supports of the prism (mm) AS = shear area (mm2) | |

| Splitting tensile strength | ||

| Flexural strength | ||

| Shear strength |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abed, M.A.; Fořt, J.; Naoulo, A.; Essa, A. Influence of Polypropylene and Steel Fibers on the Performance and Crack Repair of Self-Compacting Concrete. Materials 2021, 14, 5506. https://doi.org/10.3390/ma14195506

Abed MA, Fořt J, Naoulo A, Essa A. Influence of Polypropylene and Steel Fibers on the Performance and Crack Repair of Self-Compacting Concrete. Materials. 2021; 14(19):5506. https://doi.org/10.3390/ma14195506

Chicago/Turabian StyleAbed, Mohammed A., Jan Fořt, Abdulkarim Naoulo, and Amr Essa. 2021. "Influence of Polypropylene and Steel Fibers on the Performance and Crack Repair of Self-Compacting Concrete" Materials 14, no. 19: 5506. https://doi.org/10.3390/ma14195506

APA StyleAbed, M. A., Fořt, J., Naoulo, A., & Essa, A. (2021). Influence of Polypropylene and Steel Fibers on the Performance and Crack Repair of Self-Compacting Concrete. Materials, 14(19), 5506. https://doi.org/10.3390/ma14195506