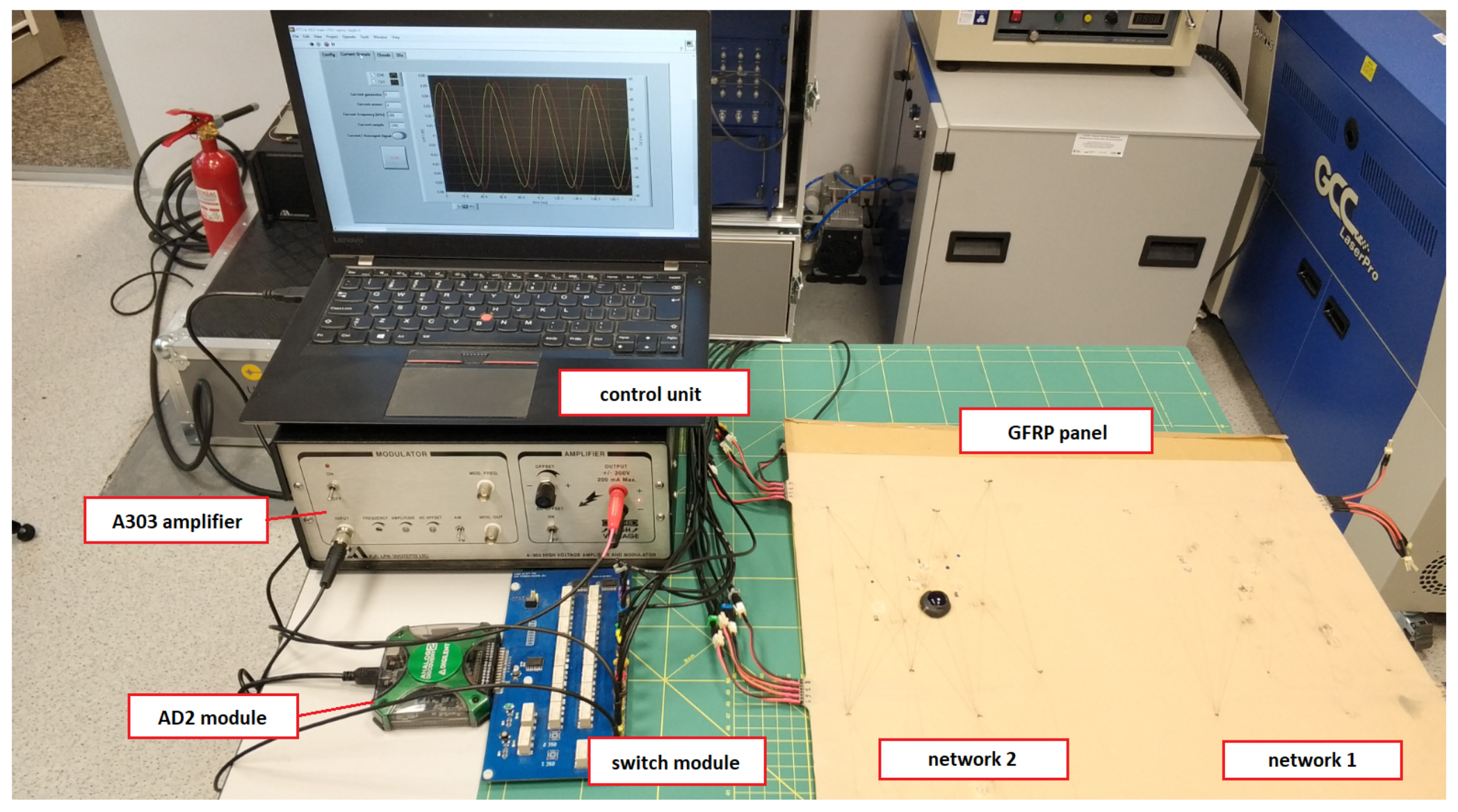

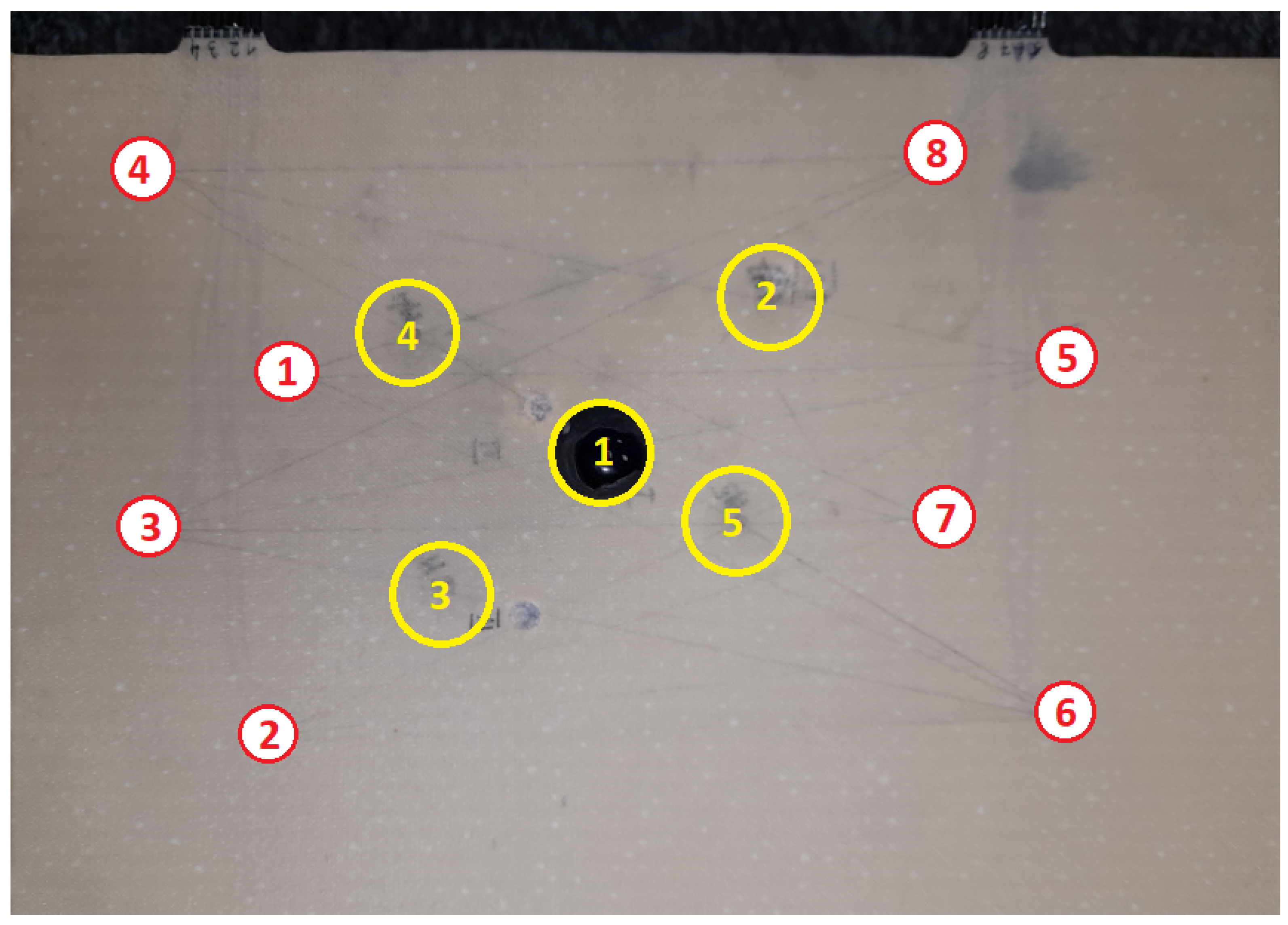

For the experiment, a GFRP composite panel equipped with two networks containing 8 PZT sensors each was used (

Figure 5). Sensor localization was the same for both networks (

Figure 6). Single layered PZT transducers produced by STEMINC (mod. SMD05T04R111WL), with a diameter equal to 5 mm, and thickness of 0.4 mm, made of SM111 material and of 450 ± 10 kHz resonant frequency [

71] were used in the experiment. The sensors were embedded into the internal structure of the composite panel in its symmetry plane. For sensors excitation and signal acquisition, a dedicated system based on Analog Discovery 2 (AD2) module by DIGILENT [

72] connected with eight channels relay switch module designed in the experiment hosting institution (ITWL) has been used (

Figure 5). The signal generator was connected to A303 high voltage amplifier [

73] to obtain a 100 Vpp (symmetric) harmonic excitation signal in the frequency range of 200–350 kHz.

4.1. Application of Voltage Transfer Ratio Approach to Artificial Damage Detection

Artificial damage was simulated for both networks by attaching a small mass to the surface of the panel at five predefined locations with the use of bitumen type paste (

Figure 6). Excitation and response signals were collected for every pair of PZT transducers for the pristine state of the structure and with artificial damage introduced at predefined locations, which allowed for DIs calculation in accordance with Equation (

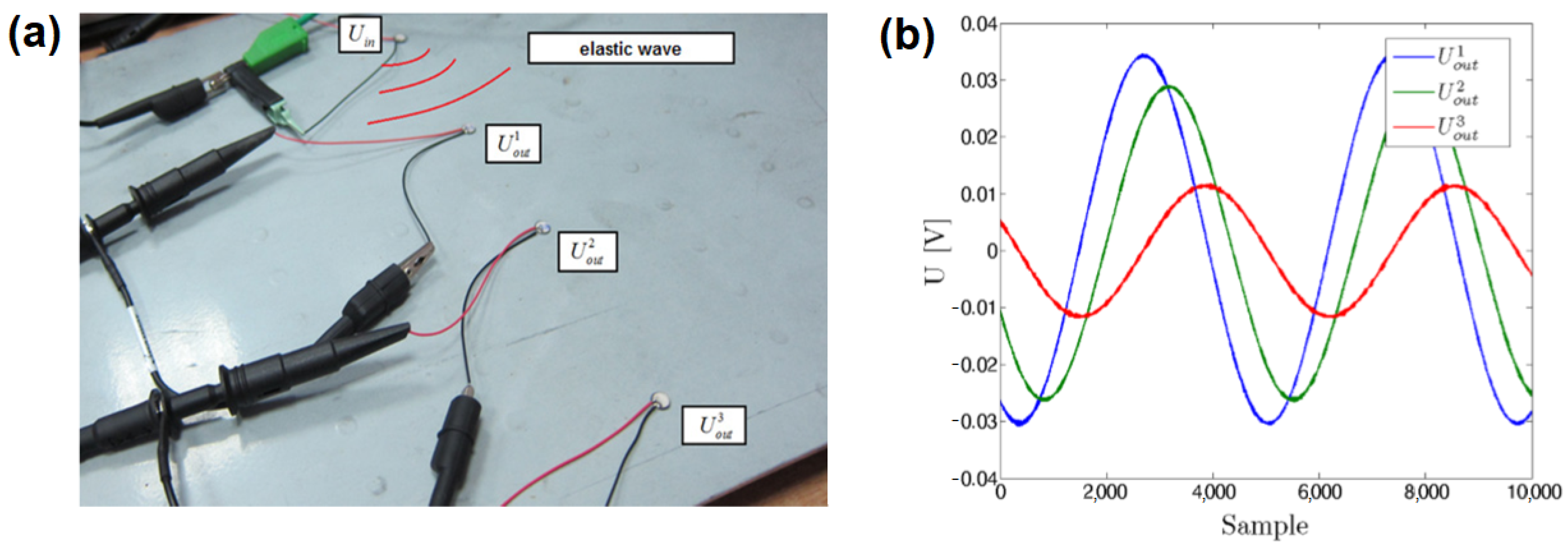

3). The sensor used for elastic wave excitation was electrically isolated from the receiver, for measurement of the excitation

as well as induced voltages

standard oscilloscope probes were used. To diminish the noise, for a given frequency sinusoidal excitation was applied to PZT actuator and sinusoidal induced voltage was acquired on PZT receiver. Then the obtained input and output signals were averaged and FVTR coefficients were calculated on averaged signals. For every series of measurements and every sensing path of the network, only 50% of data closest to the point defined by median values of DIs obtained for the series were considered for analysis.

For both PZT networks, the following distinction of sensing paths with respect to introduced artificial damage has been introduced:

Type I sensing paths which runs transversally through artificial damage and are sensitive to transmission mode of elastic waves interaction with damage;

Type II sensing paths which are tangential to artificial damage or runs it its proximity and can be affected by transmission mode (to some extent) and reflection mode of wave interaction with damage;

Type III sensing paths which are separated from artificial damage but are affected by waves reflected from damage;

Type IV sensing paths which are well separated from damage and are not influenced by its presence.

Therefore, in terms of Bayesian framework defined in

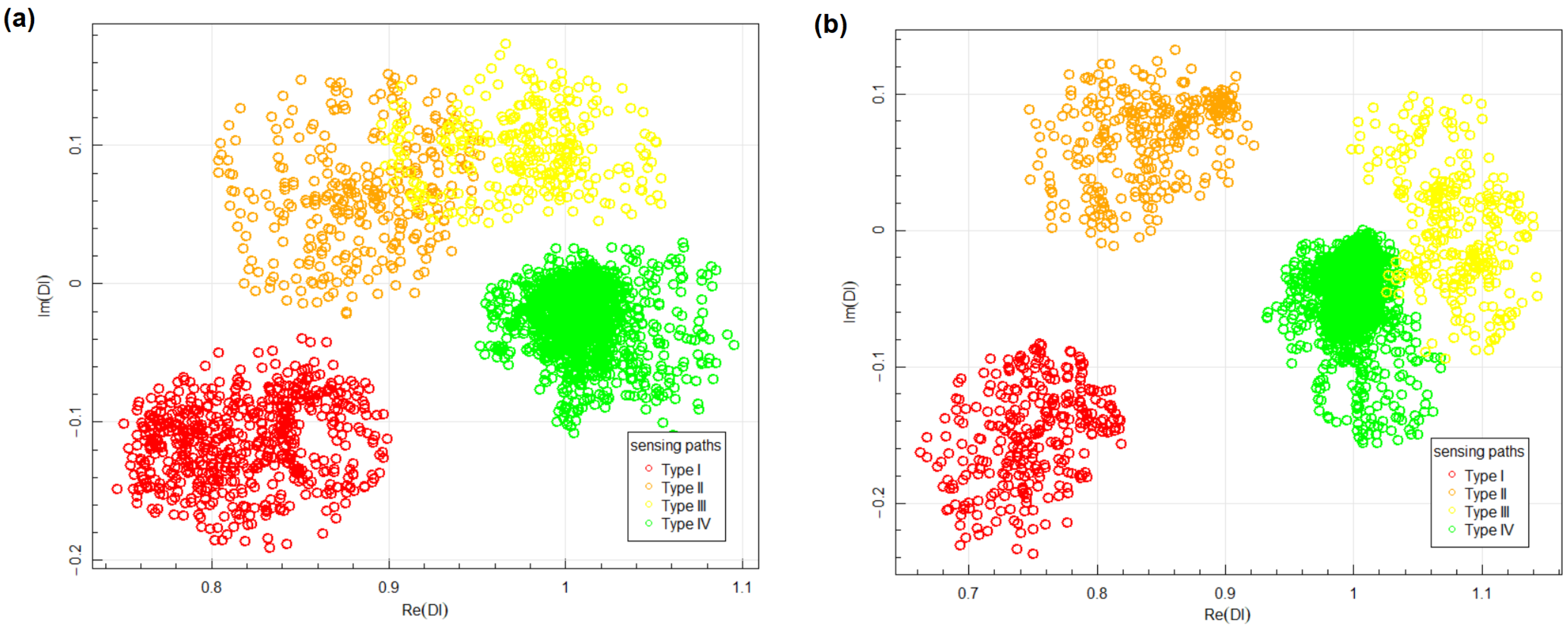

Section 3, equivalents of four structural states were defined for every sensing path. In

Figure 7 examples of Damage Indices obtained for two locations within the first PZT network, i.e., location no. 1 and location no. 3 (as shown in

Figure 6), are presented. The following classification of sensing paths has been made in those examples:

Type I sensing paths are defined by the following pair of PZT transducers:

- -

for location no. 1: 3–5, 1–7, 2–8, 4–6;

- -

for location no. 3: 2–8, 3–6.

Type II sensing paths are defined by the following pair of PZT transducers:

- -

for location no. 1: 1–6, 4–7;

- -

for location no. 3: 3–7, 2–5.

Type III sensing paths are defined by the following pair of PZT transducers:

- -

for location no. 1: 3–7, 1–5;

- -

for location no. 3: 2–7, 3–5.

The rest of the sensing paths of the network were not significantly influenced by damage presence, so these were classified as Type IV sensing paths. The rest of the data obtained for other artificial damage locations for both PZT networks were labeled in a similar manner.

Data obtained under seemingly identical conditions for undamaged state of the structure, i.e., Type IV sensing paths, can be used to assess the measurement noise. Absolute values of Type IV data obtained for damage location no. 1 (

Figure 7a) are in the interval

and arguments are contained in

. The variability of forward voltage transfer ratio, i.e., FVTR as defined in Equation (

1) is mainly due to noise of the voltage

induced on PZT receiver, as being orders of magnitude smaller than the input voltage

. Additionally, since the voltage measurement is triggered on the raising slope of the input voltage

, it should not contribute to the phase variability of FVTR. Based on presented limiting values of the Damage Indices it can be assessed that the measurement noise in the amplitude of the output signals under seemingly identical conditions does not exceed 10% and variation of phase is less than

. If the dimensions of the network or attenuation properties of the medium are changed, these values could change as well since it could have significant impact on the output amplitudes.

Hotelling’s

test was performed to assess statistical significance of difference between data corresponding to different type of sensing paths. The test was performed with use of Hotelling package in R environment [

74]. The value of

statistics obtained for data corresponding to damage location no. 1 between Type II and Type III sensing paths was 1038 with corresponding

p-value equal to 0. Since these are groups of data least separated from each other (

Figure 7a), this means very strong statistical significance between data obtained for different type of sensing paths under similar measurement conditions.

The results of measurement depend on relative location of damage and sensing path considered. The data corresponding to different types of sensing paths are in separated regions of the complex plane (

Figure 7). This can be used for sensor location placement optimization algorithms [

75] or modification of structure imaging algorithms, e.g., RAPID imaging algorithm [

76,

77,

78] by introduction of additional sensing path geometrical mappings, depending on their type. Repeatability of indications was noticed for different sensing paths belonging to the same group. There are many factors which can impact results of structure assessment or working condition of monitored structure identification, e.g., in terms of loads [

79]. Some of them, e.g., external measurement conditions such as temperature or stress level of the structure during measurement, can be either controlled or their influence can be diminished by proper definition of baseline signals data set, which can be acquired in broad variability range of such parameters. However, there are also hard to be controlled parameters which can also influence signals acquired by PZT sensors, e.g., strength of adhesive layer between sensor and monitored structure. Therefore, repeatability of a given Damage Index under similar structure conditions, but for different sensing paths is not always granted. In particular, proper normalization factors need to be used to take into account influence of length or the orientation of sensing path on values of Damage Index. In the presented study, Damage Indices obtained for different sensing paths but belonging to the same type of sensing paths influenced by damage, especially Type I and Type II are located in similar regions of the complex plane. In particular, Type I data are in the region contained in the domain

of the complex plane for damage in location no. 1 and in location no. 3 (

Figure 7). This result was obtained for sensing paths with different lengths and orientation for anisotropic GFRP medium, which indicates that Damage Index based on voltage transfer ratio (Equation (

3)) allows for compensation of factors related to manufacturing of sensor network and anisotropies of monitored structure as well as anisotropies of piezoelectric properties of PZT sensors. This property is of significant importance for proper structure assessment based on the voltage transfer ratio approach to SHM, since it opens a possibility for proper SHM system calibration as well as application of data classification methods, Bayesian classifier in particular.

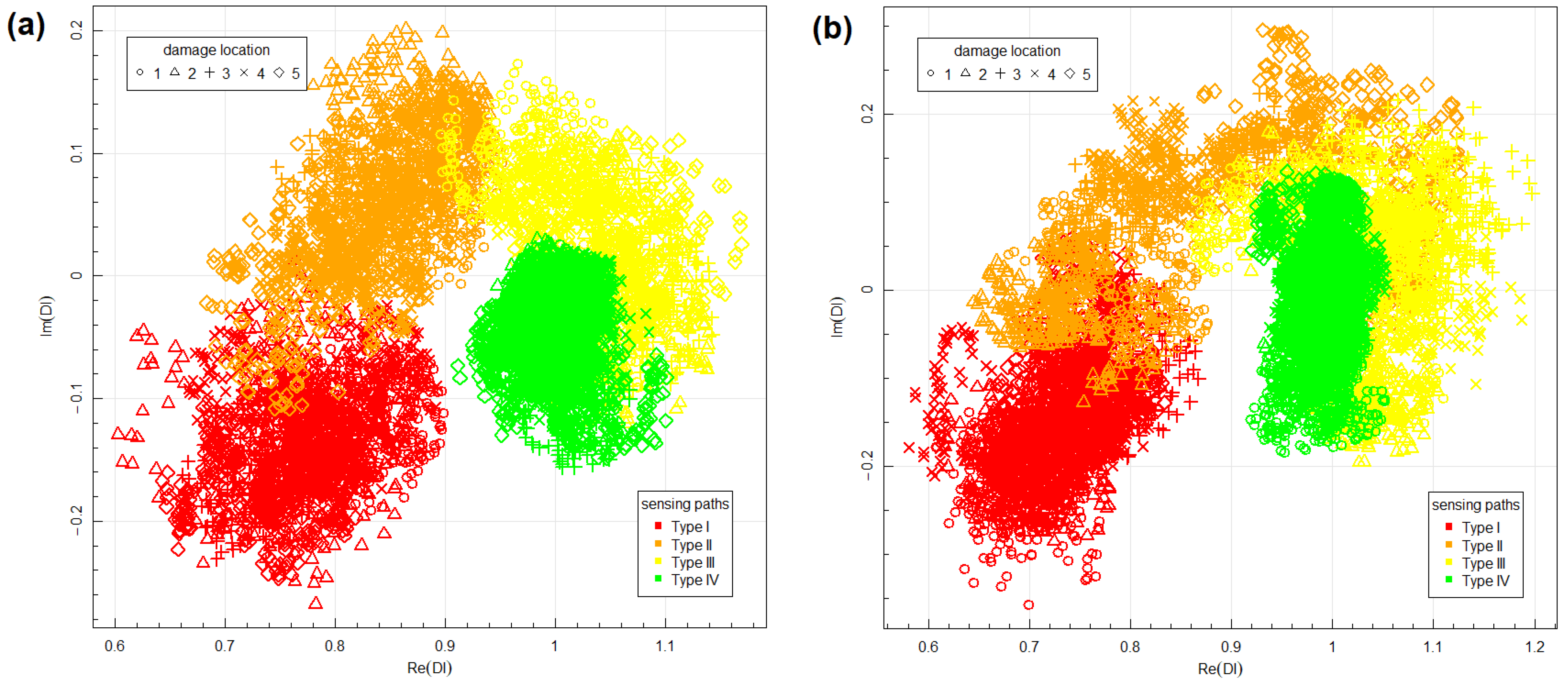

Aggregated data for both networks are presented in

Figure 8. The data corresponding to Type I and Type II sensing paths, which were sensitive on the transmission mode of elastic waves interaction with artificial damage, are well separated from DIs obtained for sensing paths not sensitive to damage (Type IV). For Type III sensing paths, the obtained data sets can intersect both with data acquired for sensing paths influenced by damage (Type II) as in location no. 1 (

Figure 7a) as well as data corresponding to an undamaged state of the structure (Type IV) as in location no. 3 (

Figure 7b), therefore it was observed that transmission mode of elastic wave interaction with damage has a stronger effect on DIs than reflection mode of interaction. Additionally, it can be noticed that the variance of data is higher for Type II and Type III sensing paths, which are sensitive to the reflection mode of wave interaction with damage. This can be related to the influence of damage presence on phase change of received signal for such sensing paths. Phase change can depend on damage-respective localization of damage and sensing path, which can cause higher variation of data in those groups.

Based on the obtained data, the efficiency and properties of the proposed Bayesian classifier have been studied. For that purpose, the bootstrap data resampling method was applied [

80] in accordance with the following procedure implemented using boot library available in the R environment. Data acquired for network one corresponding to different groups and obtained for randomly selected sensing path and measurement series were used for Bayesian model definition. Then training data set was removed from the bootstrap sample, and 100 data points of the remaining set were randomly selected and classified using the obtained model for model validation, both using the data obtained for network one and network two. The percentage of correct and misclassified results was determined, and the next step of the bootstrap resampling procedure was initiated. Similarly, the nearest-neighbor classifier performance was verified. For this algorithm, the majority class of 20 nearest neighbors to a given data point was used as a basis for classification. In the

Table 1,

Table 2,

Table 3 and

Table 4 below, confusion matrices of Bayesian and nearest-neighbor classifiers are presented, which were calculated based on mean values of classification rates obtained for different groups of data after 300 steps of the bootstrap procedure in both cases.

It can be noticed that the Bayesian classifier is characterized by a very low percentage of false-positive indications and reduced sensitivity to small disturbances of signal due to damage (which is the case for Type III sensing paths). For sensing paths not influenced by damage (Type IV), the probability of DIs misclassification is less than 3%, and the probability of detection of Type III data is 2–23%. As mentioned above, for sensing paths not sensitive to the reflection mode of wave interaction with damage, data variance is smaller. Therefore, ML estimators used in the proposed method tend to be more accurate for those groups of data, which after integration over hyperparameter space (

6) results in more compact classification domains than for Type II and Type III groups of data (

Figure 9). In those regions, a posteriori probability of class correspondence is higher for Type IV data, even if a significant number of other types of data are contained there, which is not the case for the nearest-neighbor model. A reduced ratio of false-positive indications can be of significant importance for particular applications, e.g., in aerospace, where costs of unplanned maintenance procedures can be very high. In such cases, reduction of false calls ratio can be critical to the practical application of the system.

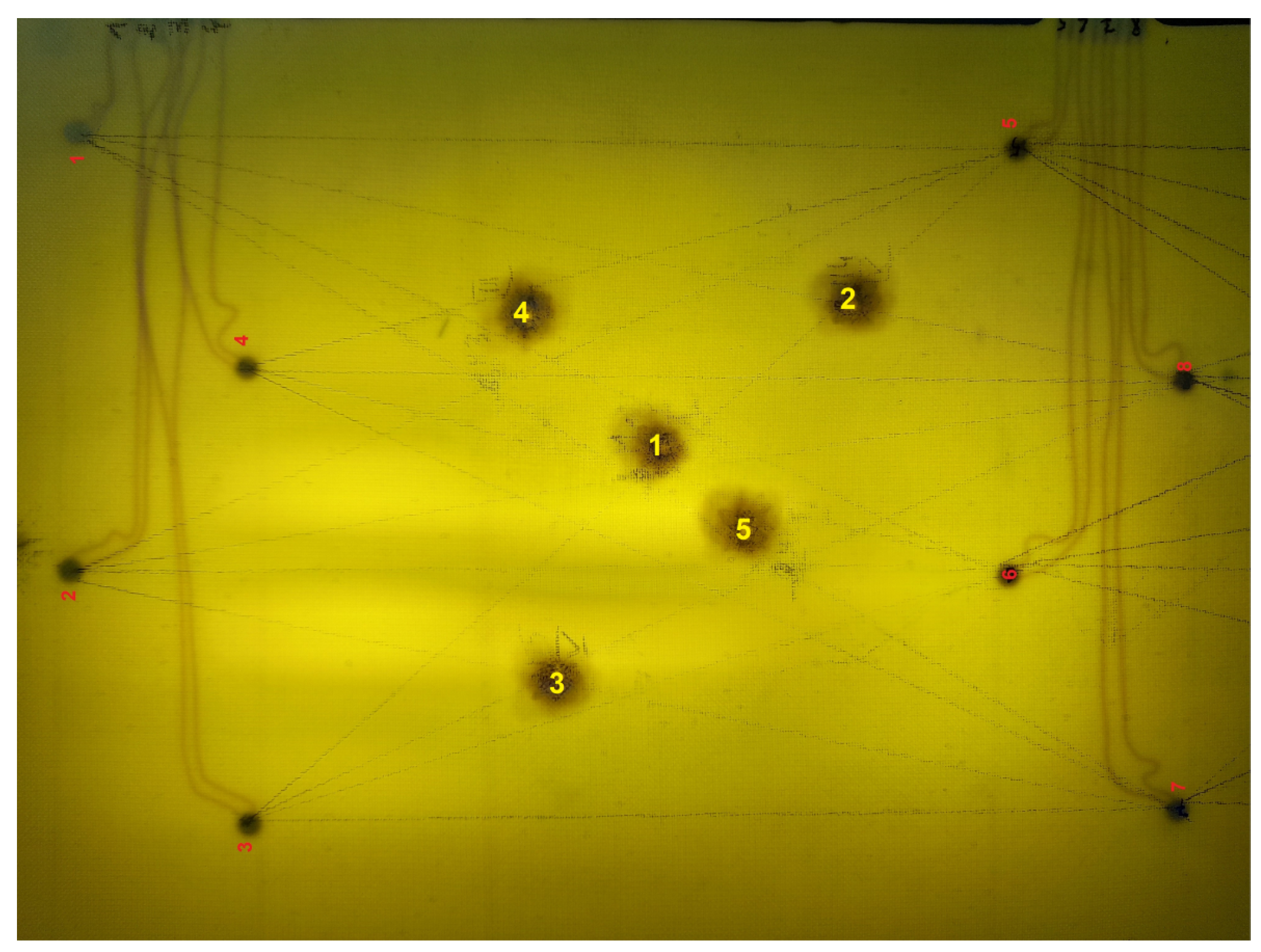

4.2. Application of Voltage Transfer Ratio Approach to Impact Damage Detection

For additional, practical verification of the method, damage caused by impacts of low energies were introduced within network no. 2. For that purpose, an air gun able to provide not more than 17 J of kinetic energy to the pellet with an initial speed not higher than 300 m/s was used (

Figure 10). The specimen was subjected to five shoots which caused Barely Visible Impact Damage (BVID) in the proximity of artificial damage locations (

Figure 11).

Measurements were conducted for the pristine state of the structure and after each subsequent impact. In the case of BVID damage, the data were divided into three groups:

Type I sensing paths which runs transversally through BVID;

Type II sensing paths which runs in close proximity of impact damage;

Type III sensing paths which are separated from impact damage and are barely influenced by its presence.

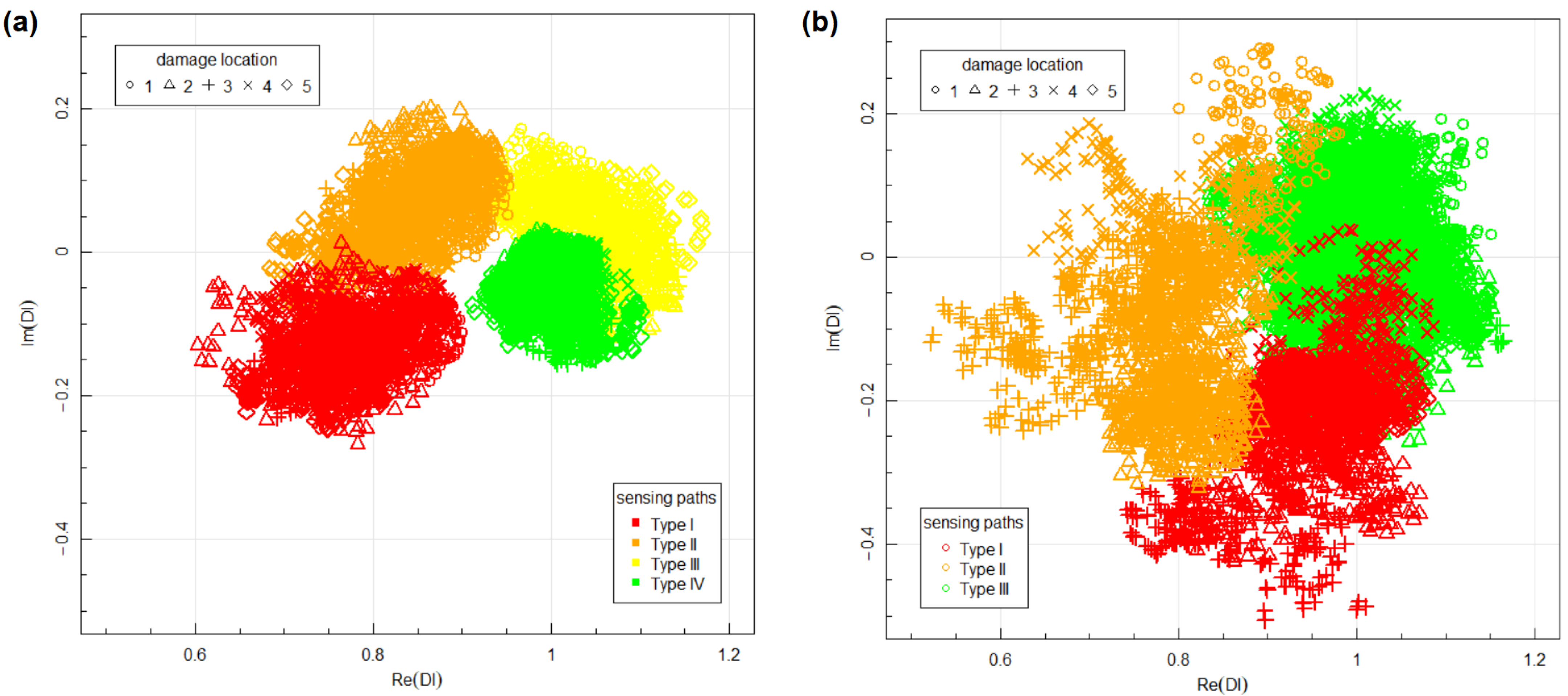

The DIs obtained for BVID damage on network two are presented in

Figure 12. Impact damage affects acquired signals more significantly than artificial damage, resulting in a higher variance of data corresponding to different groups. Therefore, differentiation between sensing paths running in the proximity of damage to two groups, as in the case of artificial damage experiment, was not possible. Data obtained for Type II sensing paths for BVID damage are in region of complex plane similar to Type I and Type II data obtained for artificial damage and data for Type III sensing paths least influenced by BVID damage (

Figure 12b) covers the domain occupied by data corresponding to Type III and Type IV sensing paths in the case of artificial damage. As indicated in

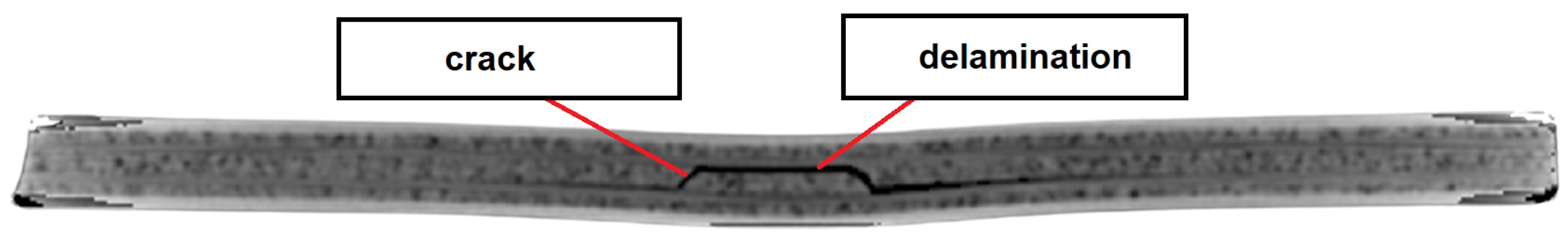

Figure 1 BVID damage can introduce severe change of local mechanical properties of the structure, therefore its impact on signal acquired by PZT receiver can be more significant.

Signals acquired for network 1 in the presence of artificial damage were used as training data for Bayesian and nearest-neighbor model definition and data classification in the presence of BVID damage within network 2. The confusion matrix for Bayesian classifier is provided in

Table 5 and in

Table 6 for nearest-neighbor classifier.

Bayesian classifier trained on artificial damage resulted in a very low false-positive ratio for BVID damage—4% compared to 16% of false calls obtained for the nearest-neighbor classifier. Signals acquired for sensing paths running in the proximity of BVID damage but not intersecting them were more heavily influenced by structural damage than by artificial mass. A significant fraction of data for Type II sensing paths, i.e., 78% for Bayesian and 54% for the nearest-neighbor classifier, were classified as Type I sensing paths. Additionally, in the case of Type I sensing paths, more significant shift in the phase of received signals and spread of data were observed (

Figure 12) which caused a significant fraction of those data being classified as undamaged type (Type IV), i.e., 34% for Bayesian and 29% for nearest-neighbor classifier.