Analysis of the Accuracy of Mass Difference-Based Measurement of Dry Clutch Friction Material Wear

Abstract

:1. Introduction

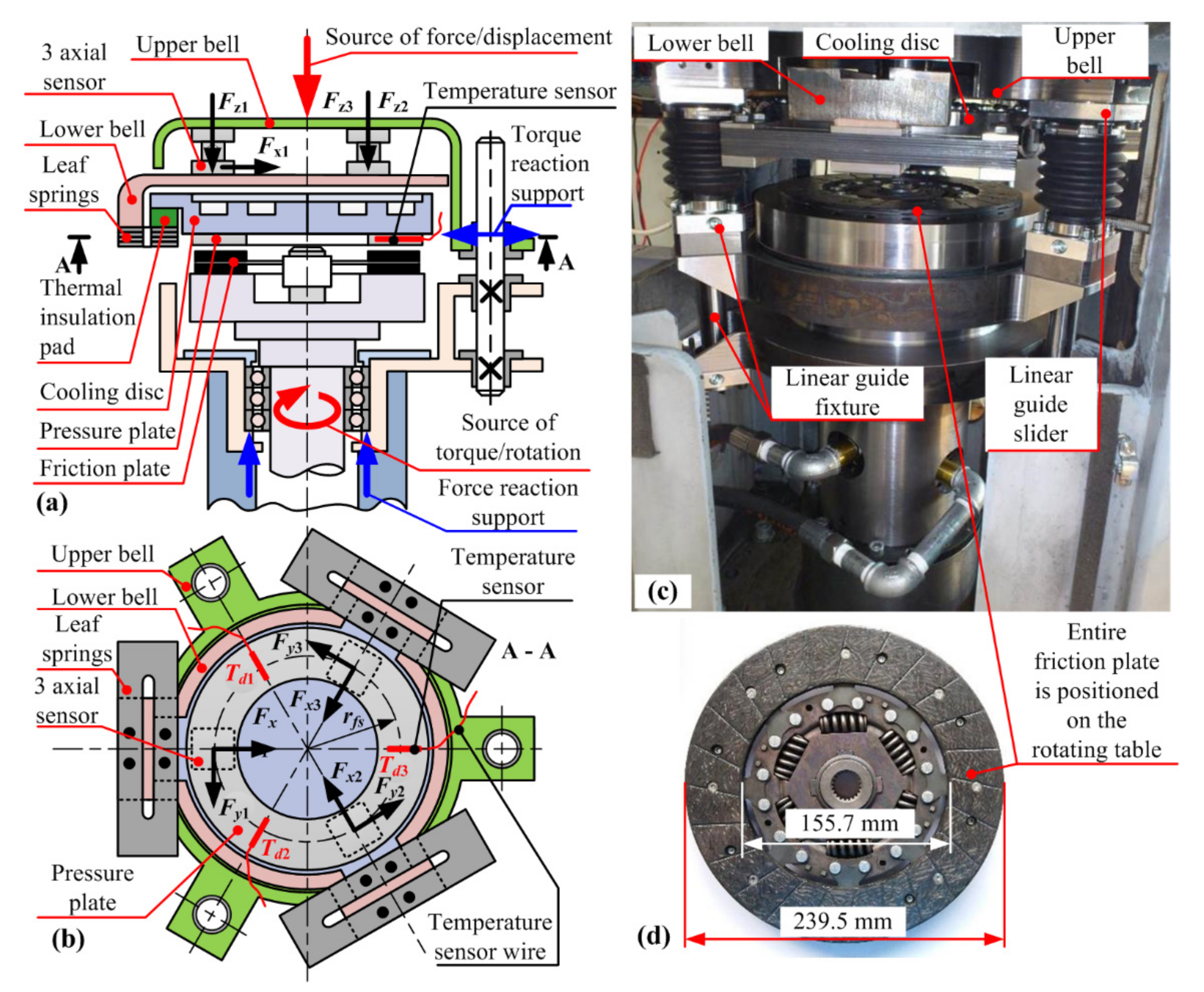

2. Disc-on-Disc Tribometer

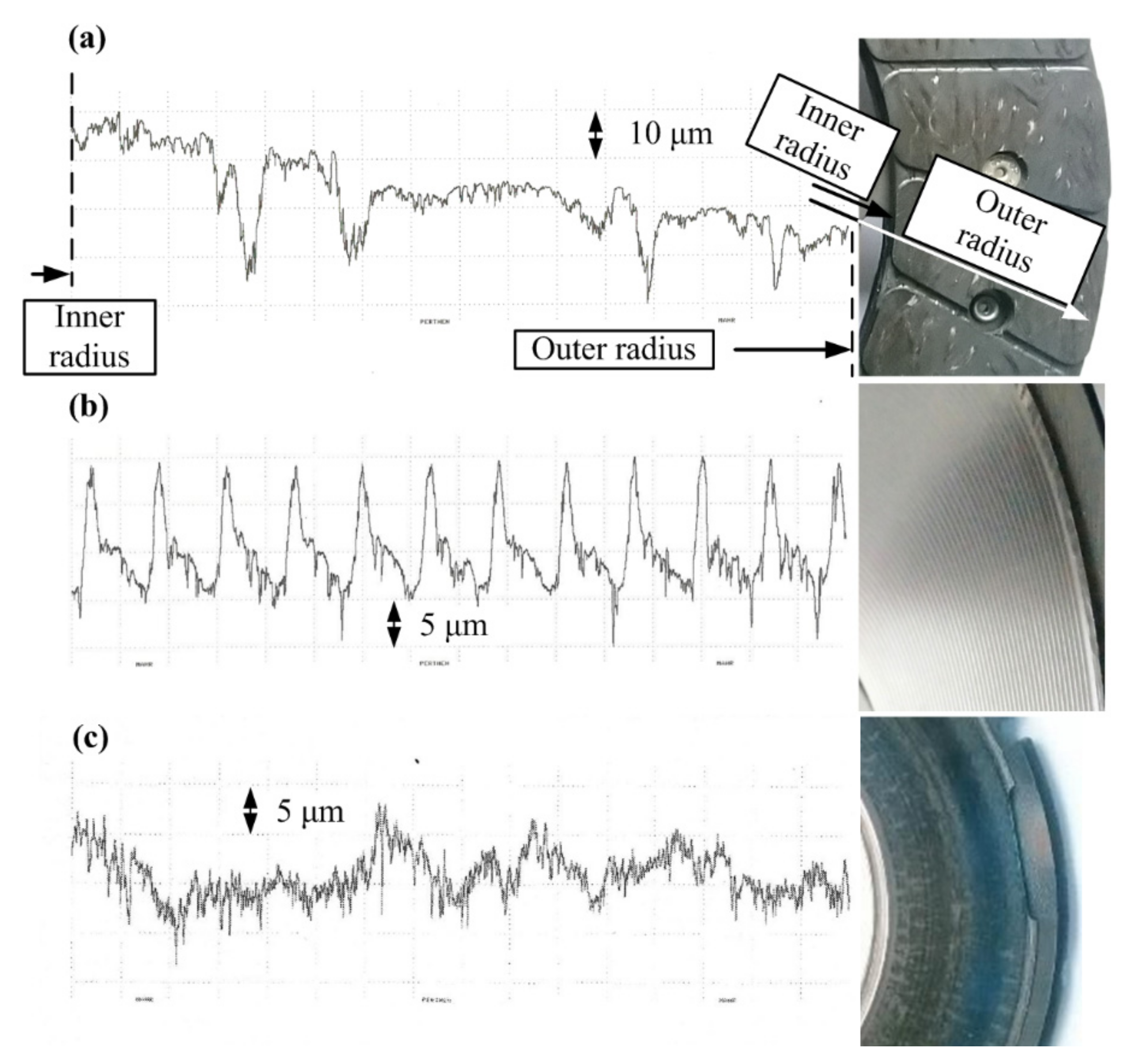

3. Basic Specifics of Friction Pair Materials

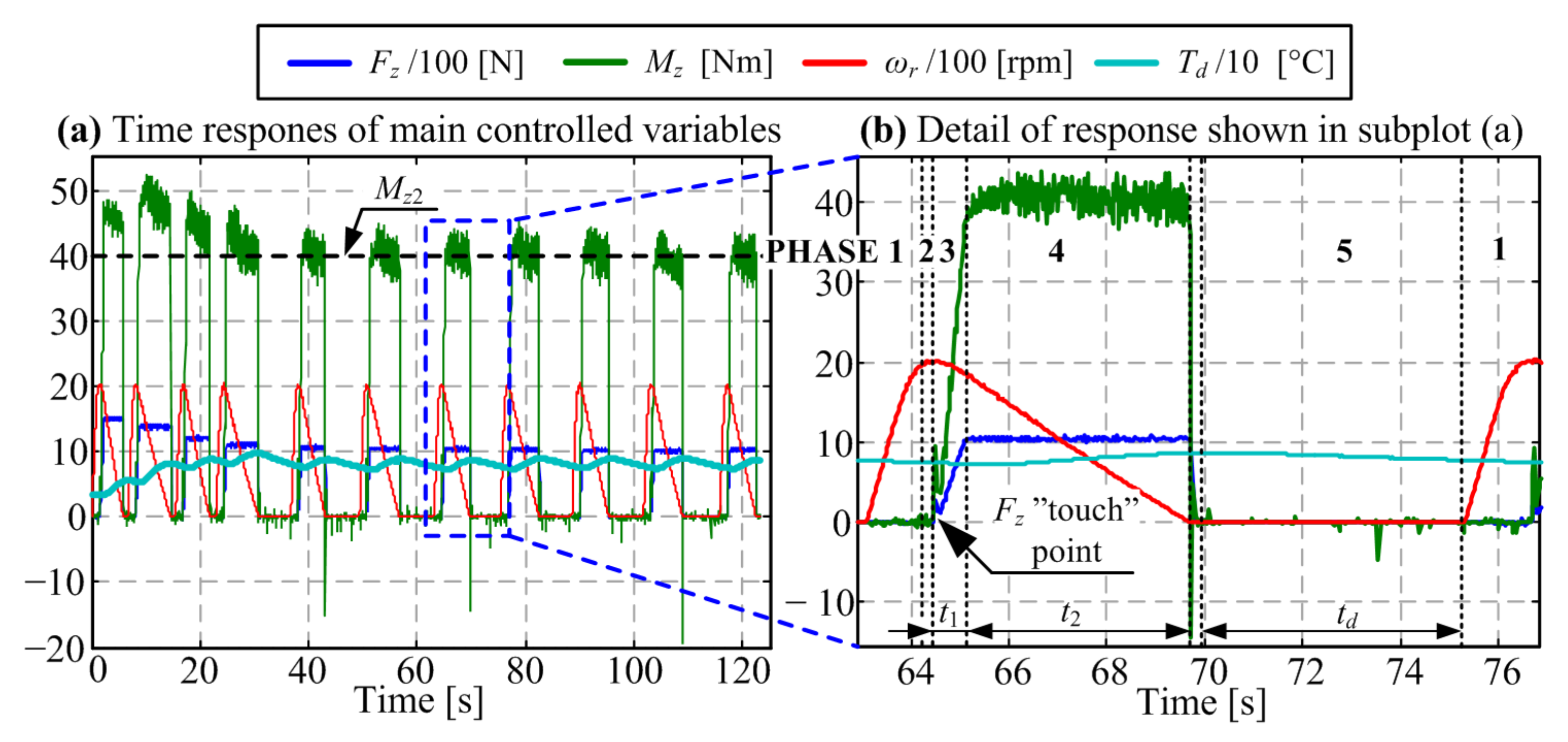

4. Organization of Experiments

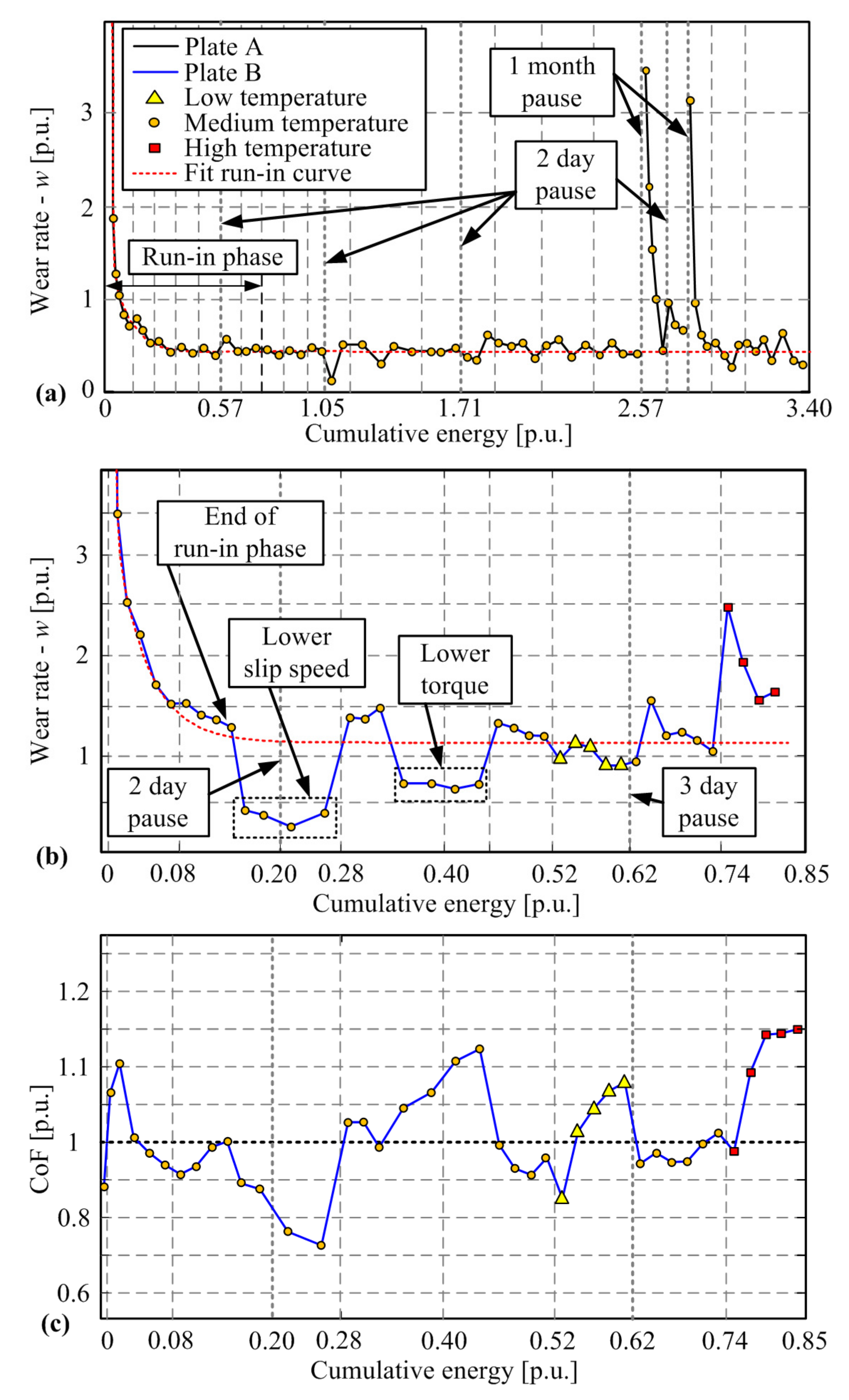

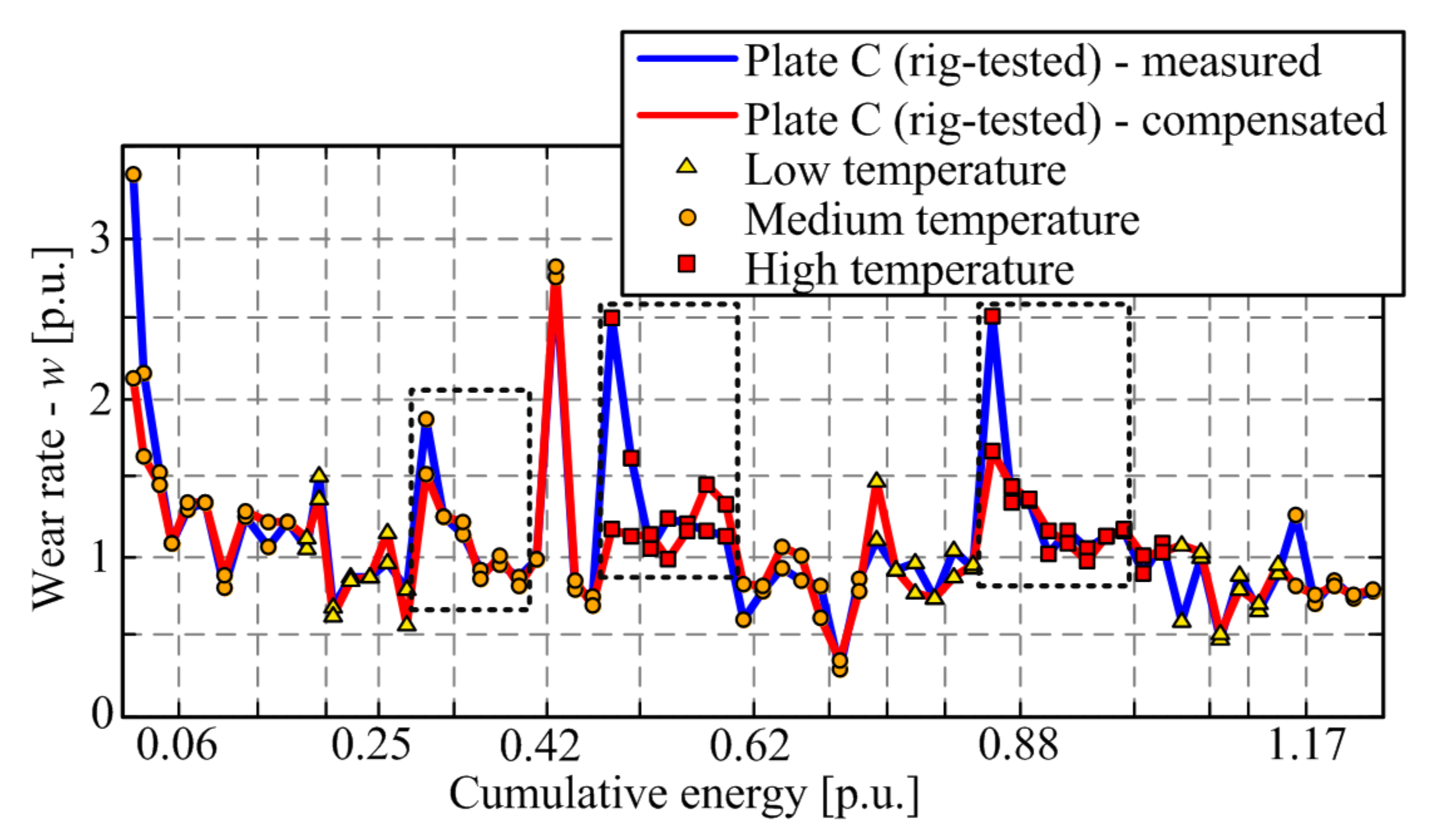

5. Wear Rate Behavior with Respect to Change of Operating Point

6. Detailed Characterization of Moisture Influence on Wear Rate Measurement

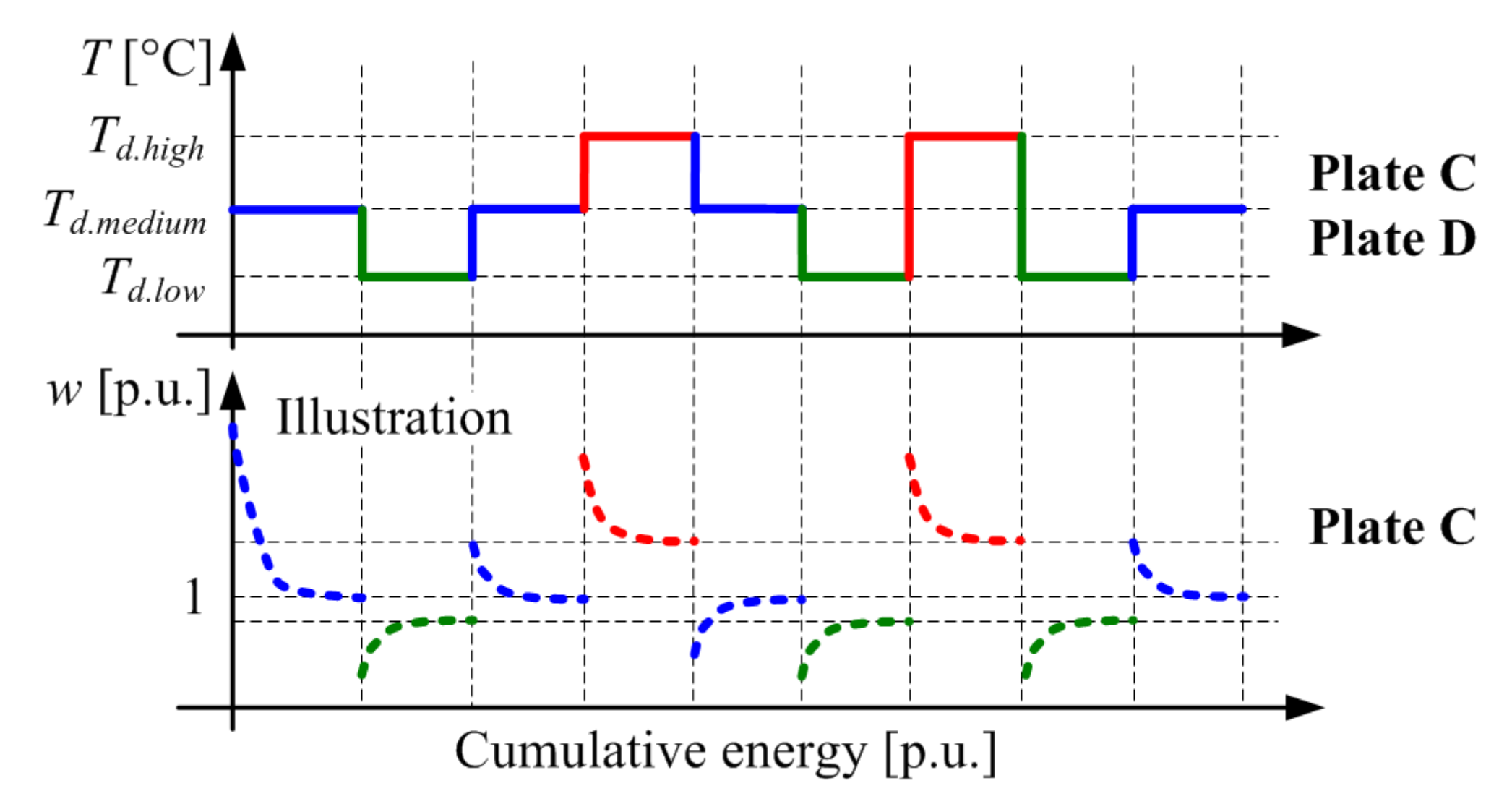

6.1. Plan of Experiments

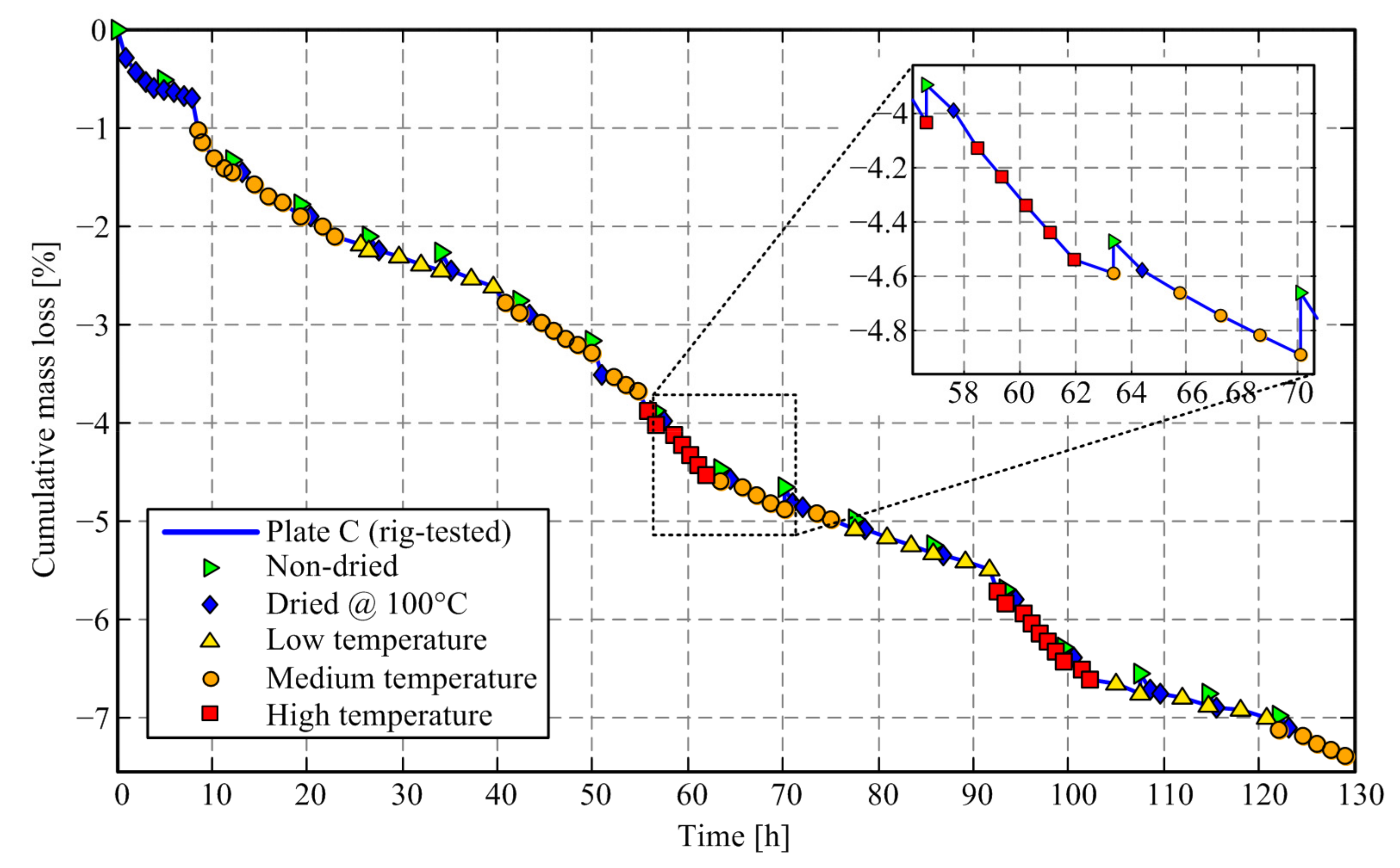

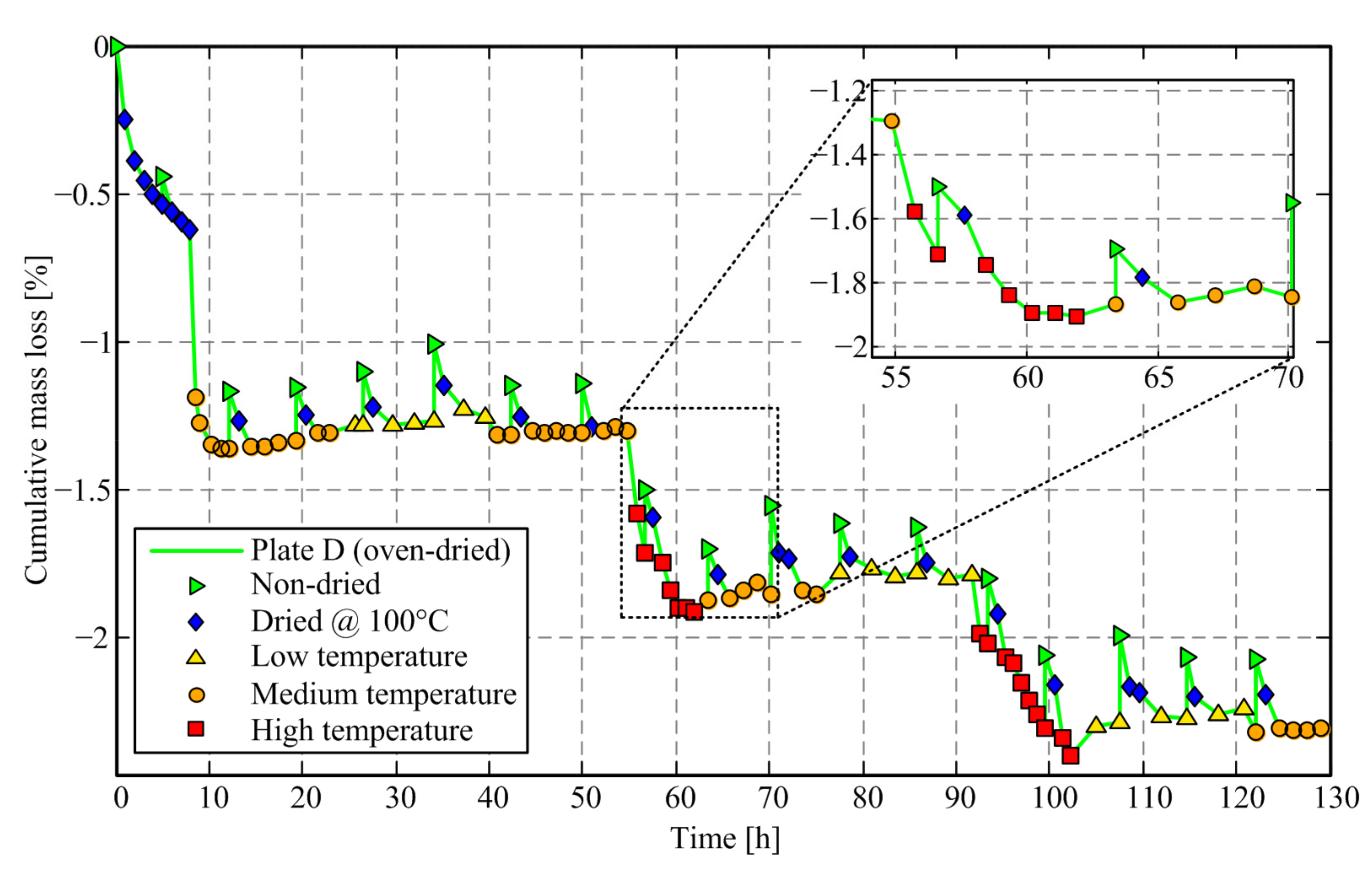

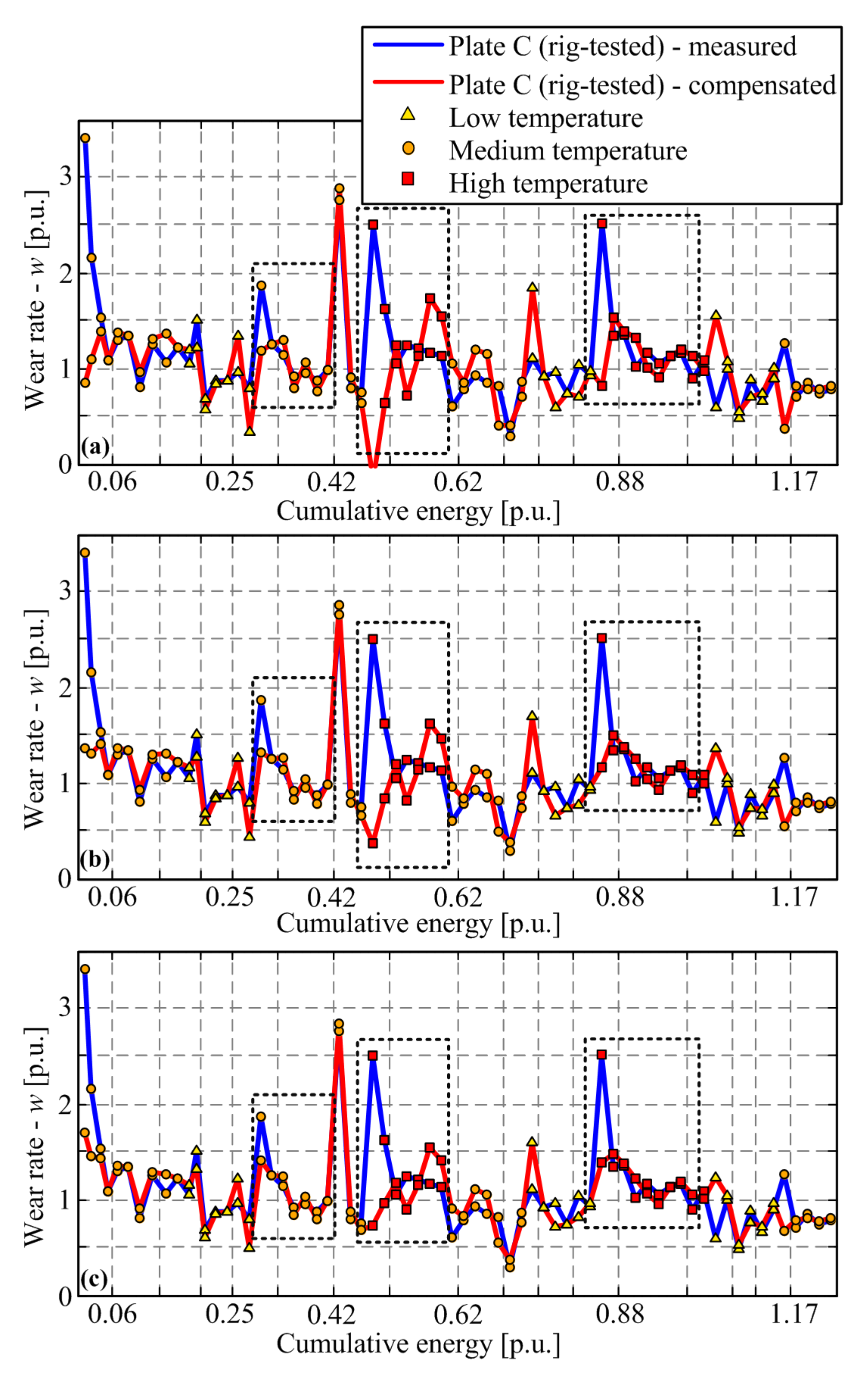

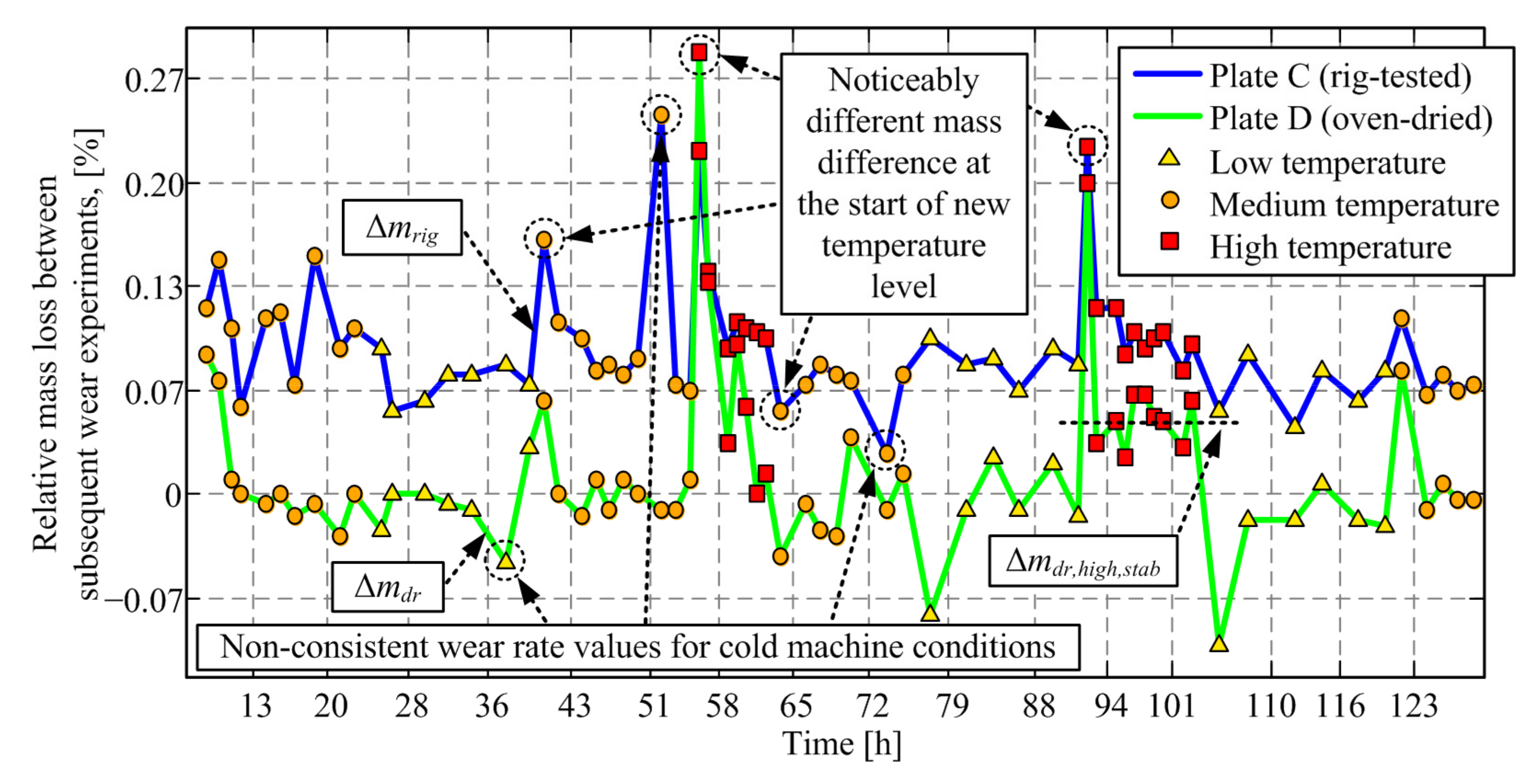

6.2. Analysis of the Weight Measurement Results

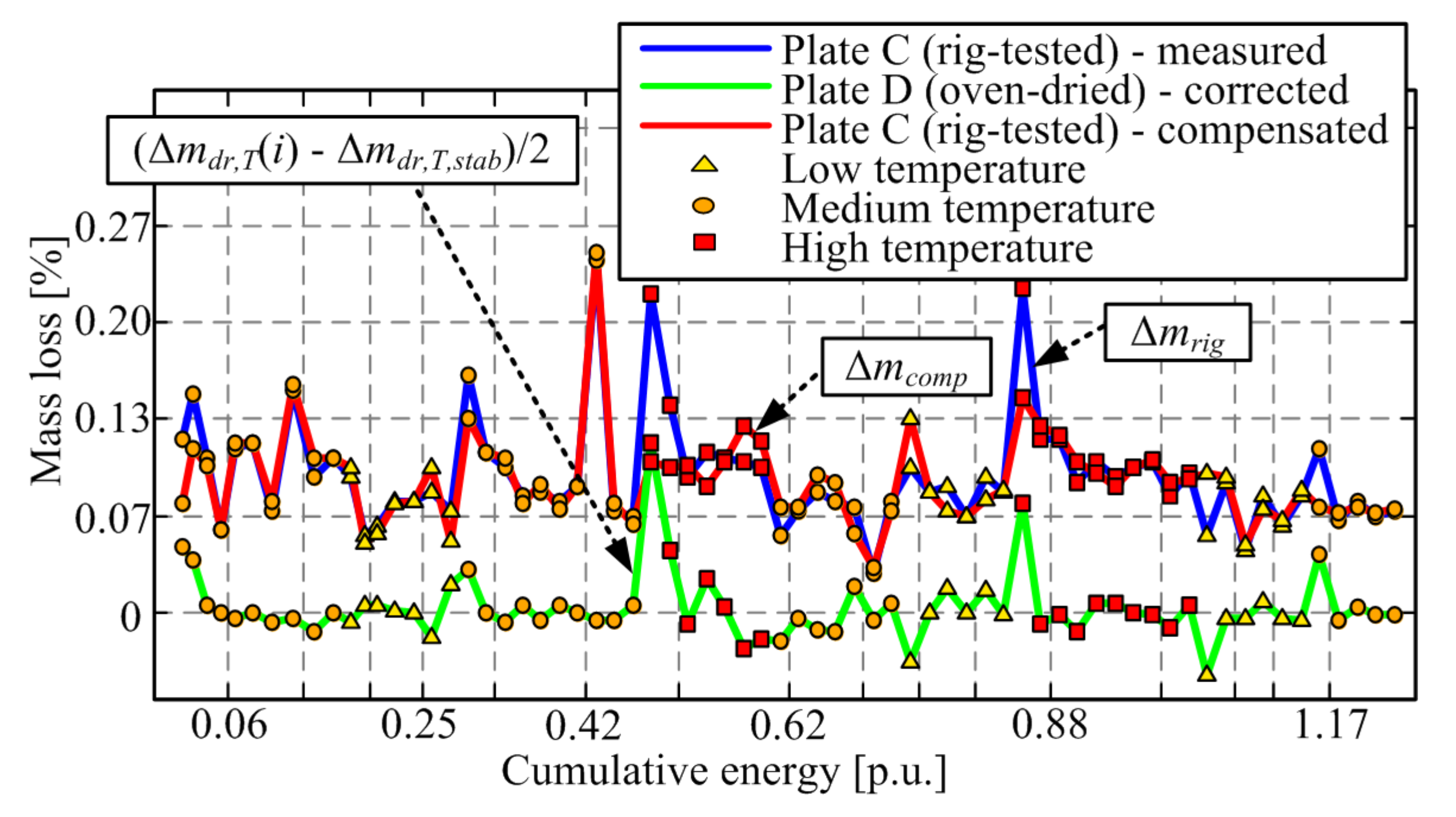

6.3. Moisture Content Compensation Procedure

7. Conclusions

- (i)

- design the experiments in the way that the operating points to be considered are grouped in sets of equal target temperature (other operating parameters should be randomized);

- (ii)

- record a run-in set of experiments after a long pause or after the temperature operating point change, which would last until the transient wear effect ceases; and

- (iii)

- introduce a ‘blind’ wear rate experiment at the beginning of each workday and set its target temperature to the level of the next, real test to heat up the pressure and friction plates and further mitigate the moisture effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sim, K.; Oh, S.M.; Namkoong, C.; Lee, J.S.; Han, K.S.; Hwang, S.H. Control strategy for clutch engagement during mode change of plug-in hybrid electric vehicle. Int. J. Automot. Technol. 2017, 18, 901–909. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, C.; Zhang, Q.; He, X. Torque Coordination Control during Braking Mode Switch for a Plug-in Hybrid Electric Vehicle. Energies 2017, 10, 1684. [Google Scholar] [CrossRef] [Green Version]

- Liauw, Y.D.S.; Roozegar, M.; Zou, T.; Morozov, A.; Angeles, J. A topology-change model of multi-speed transmissions in electric vehicles during gear-shifting. Mechatronics 2018, 55, 151–161. [Google Scholar] [CrossRef]

- Wheals, J.C.; Turner, A.; Ramsay, K.; O’Neil, A.; Bennett, C.J.; Fang, H. Double Clutch Transmission (DCT) Using Multi-Plexed Linear Actuation Technology and Dry Clutches for High Efficiency and Low Cost, SAE2007, 2007-01-1096. Available online: https://www.sae.org/publications/technical-papers/content/2007-01-1096/ (accessed on 22 October 2011).

- Faust, H. The Transmission—Now and in Future the Most Efficient Connection Between the Powertrain and the Road. In Proceedings of the Schaeffler Symposium 2018, Baden-Baden, Germany, 11–13 April 2018. [Google Scholar]

- Hoić, M.; Hrgetić, M.; Deur, J.; Tissot, A. Design of a test rig in support of E-clutch dynamics characterization, modelling, and control. In Proceedings of the Powertrain Modelling and Control Conference PMC 2018, Loughborough, UK, 10–11 September 2018. [Google Scholar]

- Foulard, S.; Rinderknecht, S.; Ichchou, M.; Perret-Liaudet, J. Automotive drivetrain model for transmission damage prediction. Mechatronics 2015, 30, 27–54. [Google Scholar] [CrossRef]

- Bachinger, M.; Stolz, M.; Horn, M. A novel drive train modelling approach for real-time simulation. Mechatronics 2015, 32, 67–78. [Google Scholar] [CrossRef]

- Deur, J.; Ivanović, V. Clutch actuation. In Encyclopedia of Automotive Engineering; Crolla, D., Foster, D.E., Kobayashi, T., Vaughan, N., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Rabinowicz, E.; Tanner, R.I. Friction and Wear of Materials. J. Appl. Mech. 1966, 33, 479. [Google Scholar] [CrossRef]

- Findik, F. Latest progress on tribological properties of industrial materials. Mater. Des. 2014, 57, 218–244. [Google Scholar] [CrossRef]

- Varenberg, M. Towards a unified classification of wear. Friction 2013, 1, 333–340. [Google Scholar] [CrossRef] [Green Version]

- Ramalhoa, A.; Miranda, J.C. The relationship between wear and dissipated energy in sliding systems. Wear 2006, 260, 361–367. [Google Scholar] [CrossRef] [Green Version]

- Kapoor, S.G. Clutch wear prediction via a deterministic stochastic modeling approach. Wear 1984, 93, 181–192. [Google Scholar] [CrossRef]

- Hoić, M.; Hrgetić, M.; Deur, J. Design of a pin-on-disc-type CNC tribometer including an automotive dry clutch application. Mechatronics 2016, 40, 220–232. [Google Scholar] [CrossRef]

- Satapathy, B.K.; Bijwe, J. Comparison of Friction and Wear Behavior Between C/C, C/C-SiC and Metallic Composite Materials, Part II. Optimisation by balancing and ranking using multiple criteria decision model (MCDM). Tribol. Lett. 2015, 60, 15. [Google Scholar]

- Hoić, M.; Škugor, B.; Deur, J.; Tissot, A. Experimental characterization and modeling of automotive dry clutch friction lining wear. In Proceedings of the VDI-Fachtagung Kupplungen und Kupplungssysteme in Antrieben 2019, Ettlingen bei Karlsruhe, Germany, 26–27 March 2019. [Google Scholar]

- Jahangiri, M.; Hashempour, M.; Razavizadeh, H.; Rezaie, H.R. A new method to investigate the sliding wear behaviour of ma-terials based on energy dissipation: W–25 wt%Cu composite. Wear 2012, 274–275, 175–182. [Google Scholar] [CrossRef]

- Della Gatta, A.; Iannelli, L.; Pisaturo, M.; Senatore, A.; Vasca, F.A. survey on modeling and engagement control for automotive dry clutch. Mechatronics 2018, 55, 63–75. [Google Scholar] [CrossRef]

- Chestney, A.W.; Crolla, D.A. The effect of grooves on the performance of friction materials in overload clutches. Wear 1979, 53, 143–163. [Google Scholar] [CrossRef]

- Nilov, S.; Kulik, V.I.; Garshin, A.P. Analysis of friction materials and technologies developed to make brake shoes for heavily loaded brake systems with disks made of a ceramic composite. Refract. Ind. Ceram. 2015, 56, 402–412. [Google Scholar] [CrossRef]

- Eriksson, M.; Bergman, F.; Jacobson, S. On the nature of tribological contact in automotive brakes. Wear 2002, 252, 26–36. [Google Scholar] [CrossRef]

- Hoić, M.; Hrgetić, M.; Kranjčević, N.; Kostelac, M.; Deur, J.; Tissot, A. Design of a disc-on-disc-type CNC tribometer targeted at dry clutch friction plate wear characterization. Int. J. Automot. Technol. accepted.

- Vivek, S.; Jayakumari, L.J.; Stephen Bernard, S.; Suresh, G.; Javeed Ahmed, M.; Arulmurugan, S. Tribological and mechanical properties of biobased reinforcement in a friction composite material. Matéria 2020, 25, 3. [Google Scholar] [CrossRef]

- Tavangar, R.; Ansari Moghadam, H.; Khavandi, A.; Banaeifar, S. Comparison of dry sliding behavior and wear mechanism of low metallic and copper-free brake pads. Tribol. Int. 2020, 151, 106416. [Google Scholar] [CrossRef]

- Majeed, B.; Basturk, S. Analysis of polymeric composite materials for frictional wear resistance purposes. Polym. Polym. Compos. 2021, 29, 127–137. [Google Scholar] [CrossRef]

- Xiang, Z.Y.; Chen, W.; Mo, J.L.; Liu, Q.A.; Fan, Z.Y.; Zhou, Z.R. The effects of the friction block shape on the tribological and dynamical behaviours of high-speed train brakes. Int. J. Mech. Sci. 2021, 194, 106184. [Google Scholar] [CrossRef]

- Wei, L.; Choy, Y.S.; Cheung, C.S.; Chu, H.K. Comparison of tribology performance, particle emissions and brake squeal noise between Cu-containing and Cu-free brake materials. Wear 2021, 466–467, 203577. [Google Scholar] [CrossRef]

- Satheesan, B.; Mohammed, A.S. Tribological characterization of epoxy hybrid nanocomposite coatings reinforced with gra-phene oxide and titania. Wear 2021, 466–467, 466–467. [Google Scholar]

- Borawski, A. Impact of Operating Time on Selected Tribological Properties of the Friction Material in the Brake Pads of Pas-senger Cars. Materials 2021, 14, 884. [Google Scholar] [CrossRef]

- Pelto, J.; Heino, V.; Karttunen, M.; Rytöluoto, I.; Ronkainen, H. Tribological performance of high density polyethylene (HDPE) composites with low nanofiller loading. Wear 2020, 460–461, 203451. [Google Scholar] [CrossRef]

- Sekunowo, O.I.; Durowaye, S.I.; Lawal, G.I. Synthesis and characterisation of iron millscale particles reinforced ceramic matrix composite. J. King Saud Univ.-Eng. Sci. 2019, 31, 78–85. [Google Scholar] [CrossRef]

- Ravikumar, K.; Pridhar, T. Evaluation on properties and characterization of asbestos free palm kernel shell fibre (PKSF)/polymer composites for brake pads. Mater. Res. Express 2019, 6, 1165d2. [Google Scholar] [CrossRef]

- Wongpayakyotin, A.; Jubsilp, C.; Tiptipakorn, S.; Mora, P.; Bielawski, C.W.; Rimdusit, S. Effects of Alkyl-Substituted Polybenzoxazines on Tribological Properties of Non-Asbestos Composite Friction Materials. Polymers 2021, 13, 567. [Google Scholar] [CrossRef]

- Li, J.; Chen, P.; Wang, Y. Tribological and corrosion performance of epoxy resin composite coatings reinforced with graphene oxide and fly ash cenospheres. J. Appl. Polym. Sci. 2021, 138, 50042. [Google Scholar] [CrossRef]

- Hoić, M.; Škugor, B.; Miklik, A.; Deur, J.; Tissot, A. Experimental characterization and modeling of dry clutch wear with em-phasis on fading effect. VDI-Fachtagung Kupplungen und Kupplungssysteme in Antrieben 2021. submitted. [Google Scholar]

- SAE International Surface Vehicle Recommended Practice. SAE No. 2 Clutch Friction Test Machine Guidelines. SAE Standard J286, Stabilized March 2012. Available online: https://www.sae.org/standards/content/j286_201203/ (accessed on 20 June 2021).

- Bezzazi, M.; Khamlichi, A.; Jabbouri, A.; Reis, P.; Davim, J.P. Experimental characterization of frictional behaviour of clutch facings using Pin-on-disk machine. Mater. Des. 2007, 28, 2148–2153. [Google Scholar] [CrossRef]

- Fidlin, A.; Bäuerle, S.; Boy, F. Modelling of the gas induced fading of organic linings in dry clutches. Tribol. Int. 2015, 92, 559–566. [Google Scholar] [CrossRef]

- Clausnizer, H.; Fidlin, A.; Figuli, R.; Jehle, G.; Wilhelm, M.; Keller, J.S. Experimental investigation of the permeability of a tribo-contact in dry friction clutches. Tribol. Int. 2018, 118, 157–162. [Google Scholar] [CrossRef]

- Senatore, A.; D’Auria, C.; Pisaturo, M. Frictional Behaviour and Engagement Control in Dry Clutch Based Automotive Transmissions. Veh. Eng. 2017, 4, 1–12. [Google Scholar] [CrossRef]

- Klotz, T.; Ott, S.; Albers, A. Analyse des Schaedigunngs- und Erholungverhaltens trockenlaufender Friktionspaarungen. In Proceedings of the VDI-Fachtagung Kupplungen und Kupplungssysteme in Antrieben 2019, Ettlingen bei Karlsruhe, Germany, 26–27 March 2019. [Google Scholar]

- Satapathy, B.K.; Bijwe, J. Performance of friction materials based on variation in nature of organic fibres Part I. Fade and re-covery bahviour. Wear 2004, 257, 573–584. [Google Scholar] [CrossRef]

- Hoić, M.; Deur, J.; Herold, Z.; Ivanović, V. Modeling of Dual Dry Clutch Thermal Dynamics. In Proceedings of the International Conference on Powertrain Modelling and Control, University of Bradford, West Yokshire, UK, 4–9 September 2012. [Google Scholar]

| Nb. | Temp. | C | D | Nb. | Temp. | C | D | Nb. | Temp. | C | D |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 20 | 0.00% | 0.00% | 39 | 20 | −2.75% | −1.14% | 77 | Low | −5.32% | −1.78% |

| 2 | 100 | −0.29% | −0.25% | 40 | 100 | −2.90% | −1.26% | 78 | 20 | −5.25% | −1.62% |

| 3 | 100 | −0.45% | −0.39% | 41 | Medium | −2.98% | −1.30% | 79 | 100 | −5.36% | −1.75% |

| 4 | 100 | −0.53% | −0.46% | 42 | Medium | −3.06% | −1.31% | 80 | Low | −5.41% | −1.80% |

| 5 | 100 | −0.59% | −0.50% | 43 | Medium | −3.14% | −1.30% | 81 | Low | −5.50% | −1.79% |

| 6 | 100 | −0.63% | −0.54% | 44 | Medium | −3.22% | −1.31% | 82 | High | −5.71% | −1.98% |

| 7 | 20 | −0.51% | −0.44% | 45 | Medium | −3.30% | −1.31% | 83 | High | −5.83% | −2.02% |

| 8 | 100 | −0.64% | −0.56% | 46 | 20 | −3.16% | −1.14% | 84 | 20 | −5.70% | −1.80% |

| 9 | 100 | −0.69% | −0.59% | 47 | 100 | −3.52% | −1.29% | 85 | 100 | −5.79% | −1.91% |

| 10 | 100 | −0.71% | −0.62% | 48 | Medium | −3.54% | −1.30% | 86 | High | −5.95% | −2.06% |

| 11 | Medium | −1.04% | −1.19% | 49 | Medium | −3.61% | −1.29% | 87 | High | −6.04% | −2.09% |

| 12 | Medium | −1.16% | −1.28% | 50 | Medium | −3.68% | −1.30% | 88 | High | −6.14% | −2.15% |

| 13 | Medium | −1.30% | −1.35% | 51 | High | −3.89% | −1.58% | 89 | High | −6.23% | −2.21% |

| 14 | Medium | −1.41% | −1.36% | 52 | High | −4.03% | −1.71% | 90 | High | −6.33% | −2.26% |

| 15 | Medium | −1.47% | −1.36% | 53 | 20 | −3.89% | −1.50% | 91 | High | −6.43% | −2.30% |

| 16 | 20 | −1.34% | −1.16% | 54 | 100 | −3.99% | −1.59% | 92 | 20 | −6.28% | −2.06% |

| 17 | 100 | −1.47% | −1.27% | 55 | High | −4.12% | −1.74% | 93 | 100 | −6.38% | −2.16% |

| 18 | Medium | −1.58% | −1.35% | 56 | High | −4.23% | −1.84% | 94 | High | −6.51% | −2.33% |

| 19 | Medium | −1.69% | −1.35% | 57 | High | −4.34% | −1.90% | 95 | High | −6.61% | −2.39% |

| 20 | Medium | −1.76% | −1.34% | 58 | High | −4.44% | −1.90% | 96 | Low | −6.66% | −2.30% |

| 21 | Medium | −1.91% | −1.33% | 59 | High | −4.54% | −1.91% | 97 | Low | −6.75% | −2.28% |

| 22 | 20 | −1.79% | −1.15% | 60 | Medium | −4.59% | −1.87% | 98 | 20 | −6.54% | −1.99% |

| 23 | 100 | −1.91% | −1.25% | 61 | 20 | −4.47% | −1.70% | 99 | 100 | −6.72% | −2.16% |

| 24 | Medium | −2.00% | −1.30% | 62 | 100 | −4.57% | −1.78% | 100 | 100 | −6.75% | −2.18% |

| 25 | Medium | −2.11% | −1.30% | 63 | Medium | −4.66% | −1.86% | 101 | Low | −6.79% | −2.27% |

| 26 | Low | −2.20% | −1.28% | 64 | Medium | −4.74% | −1.84% | 102 | Low | −6.87% | −2.27% |

| 27 | Low | −2.25% | −1.28% | 65 | Medium | −4.82% | −1.81% | 103 | 20 | −6.75% | −2.06% |

| 28 | 20 | −2.12% | −1.10% | 66 | Medium | −4.89% | −1.85% | 104 | 100 | −6.89% | −2.19% |

| 29 | 100 | −2.26% | −1.22% | 67 | 20 | −4.66% | −1.55% | 105 | Low | −6.93% | −2.26% |

| 30 | Low | −2.31% | −1.28% | 68 | 100 | −4.83% | −1.71% | 106 | Low | −7.01% | −2.24% |

| 31 | Low | −2.39% | −1.28% | 69 | 100 | −4.85% | −1.73% | 107 | Medium | −7.12% | −2.31% |

| 32 | Low | −2.46% | −1.27% | 70 | Medium | −4.91% | −1.84% | 108 | 20 | −6.97% | −2.07% |

| 33 | 20 | −2.28% | −1.01% | 71 | Medium | −4.99% | −1.85% | 109 | 100 | −7.10% | −2.19% |

| 34 | 100 | −2.46% | −1.14% | 72 | Low | −5.09% | −1.78% | 110 | Medium | −7.18% | −2.30% |

| 35 | Low | −2.54% | −1.22% | 73 | 20 | −4.97% | −1.61% | 111 | Medium | −7.26% | −2.31% |

| 36 | Low | −2.61% | −1.25% | 74 | 100 | −5.10% | −1.72% | 112 | Medium | −7.32% | −2.31% |

| 37 | Medium | −2.77% | −1.31% | 75 | Low | −5.17% | −1.77% | 113 | Medium | −7.39% | −2.30% |

| 38 | Medium | −2.88% | −1.31% | 76 | Low | −5.26% | −1.79% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoić, M.; Miklik, A.; Kostelac, M.; Deur, J.; Tissot, A. Analysis of the Accuracy of Mass Difference-Based Measurement of Dry Clutch Friction Material Wear. Materials 2021, 14, 5356. https://doi.org/10.3390/ma14185356

Hoić M, Miklik A, Kostelac M, Deur J, Tissot A. Analysis of the Accuracy of Mass Difference-Based Measurement of Dry Clutch Friction Material Wear. Materials. 2021; 14(18):5356. https://doi.org/10.3390/ma14185356

Chicago/Turabian StyleHoić, Matija, Alen Miklik, Milan Kostelac, Joško Deur, and Andreas Tissot. 2021. "Analysis of the Accuracy of Mass Difference-Based Measurement of Dry Clutch Friction Material Wear" Materials 14, no. 18: 5356. https://doi.org/10.3390/ma14185356

APA StyleHoić, M., Miklik, A., Kostelac, M., Deur, J., & Tissot, A. (2021). Analysis of the Accuracy of Mass Difference-Based Measurement of Dry Clutch Friction Material Wear. Materials, 14(18), 5356. https://doi.org/10.3390/ma14185356