A Pilot Study on Machining Difficult-to-Cut Materials with the Use of Tools Fabricated by SLS Technology

Abstract

:1. Introduction

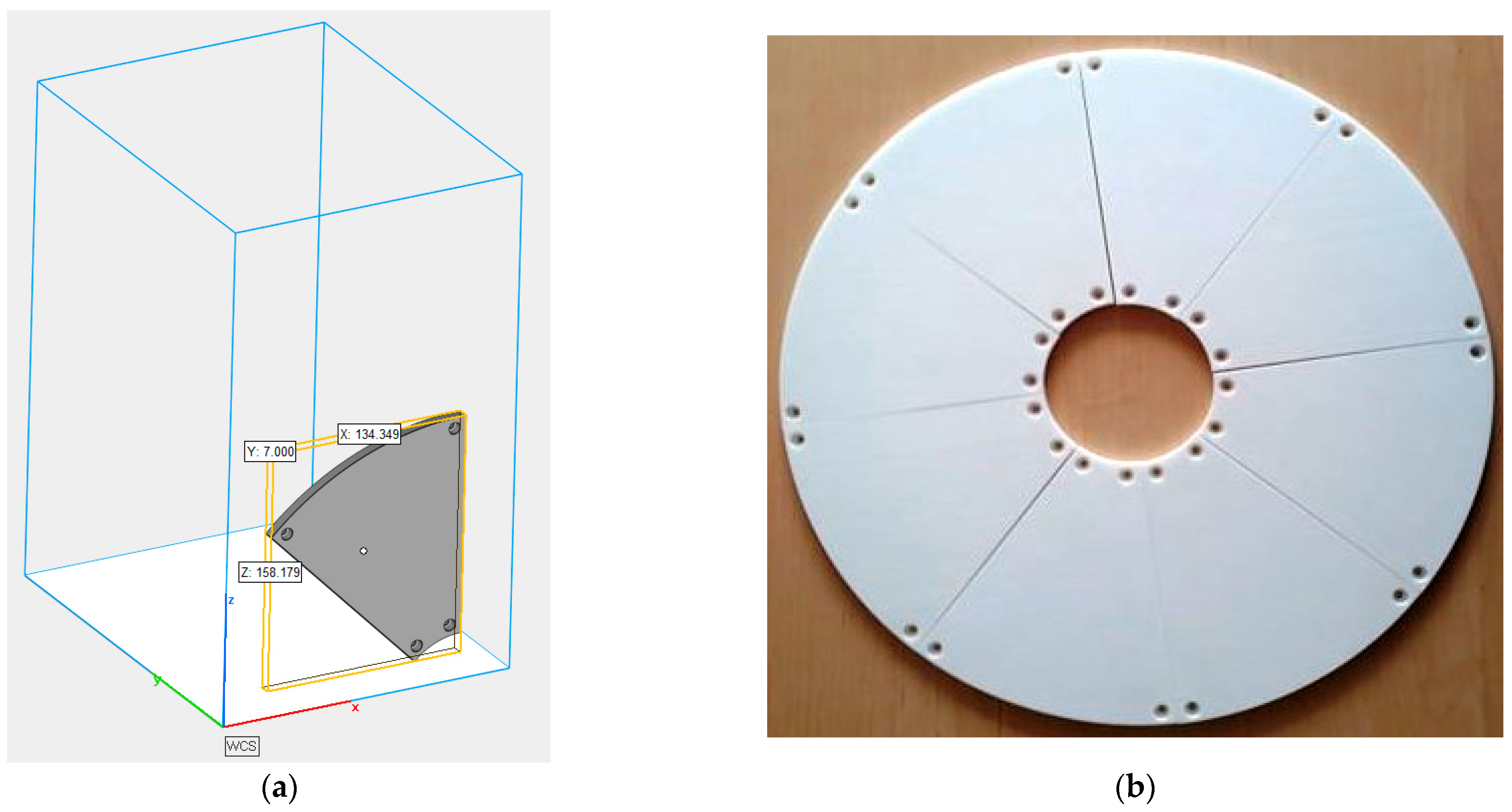

2. Materials and Methods

3. Experimental Results

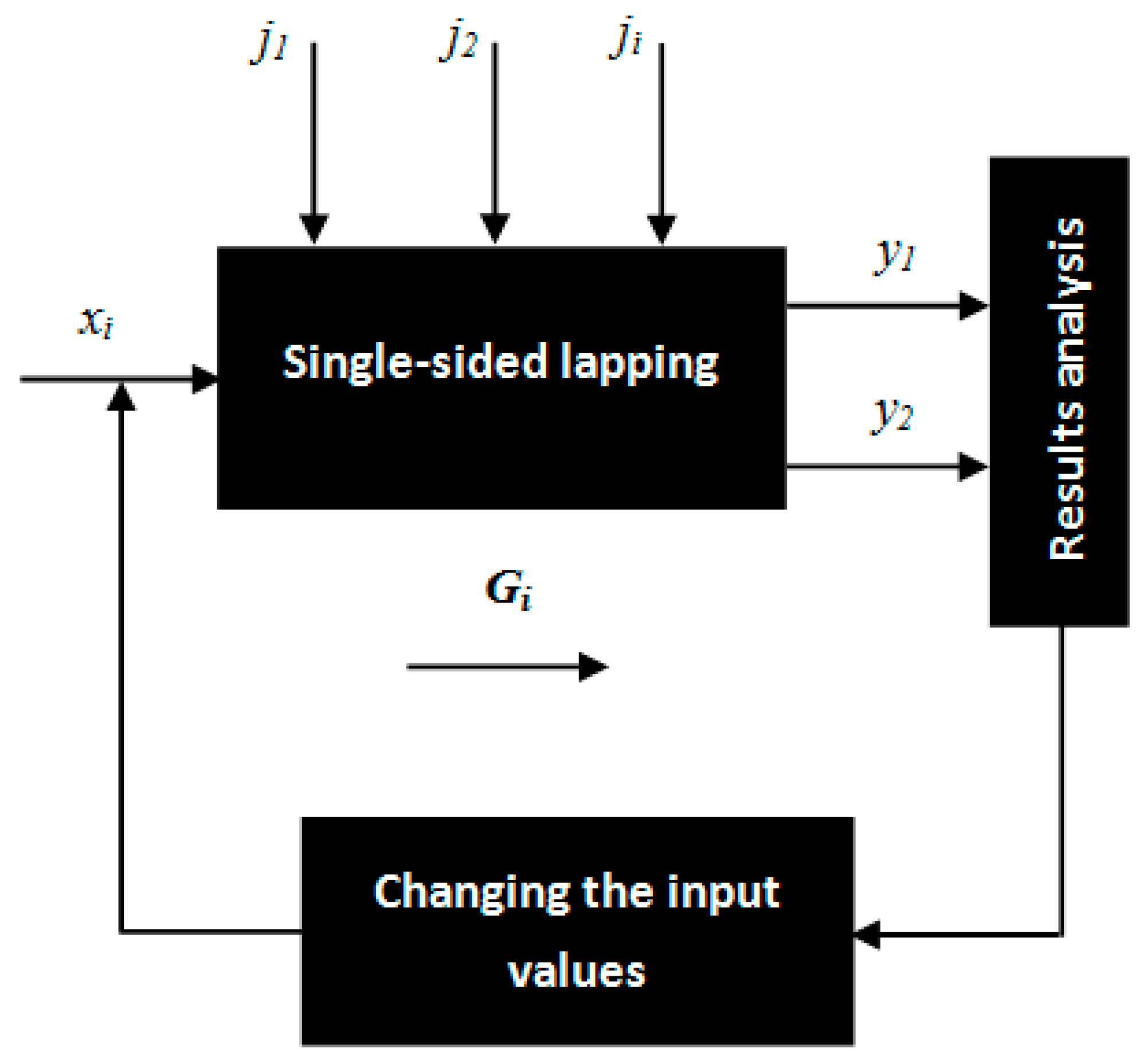

3.1. Scheme of Experimental Tests and Process Factors

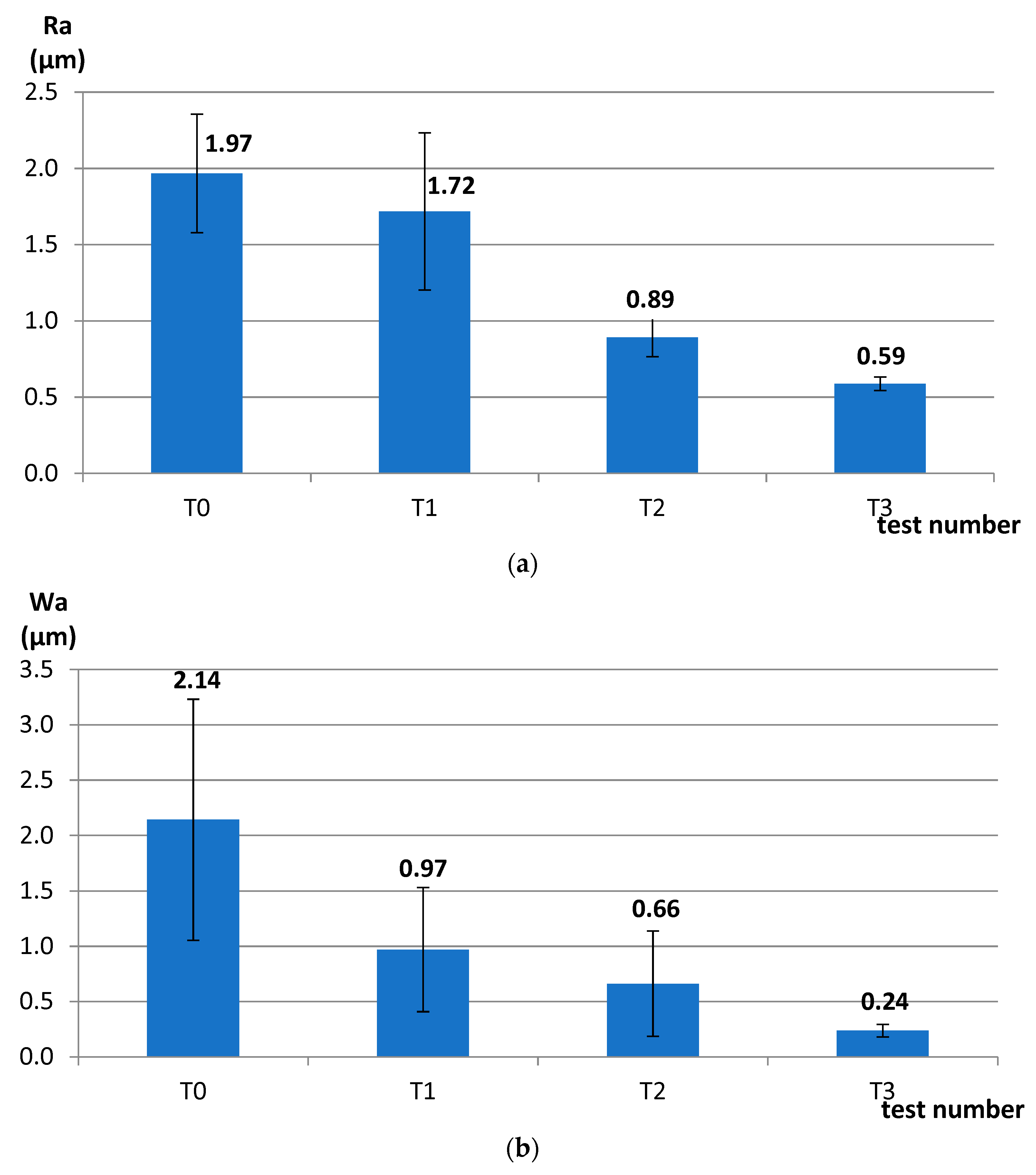

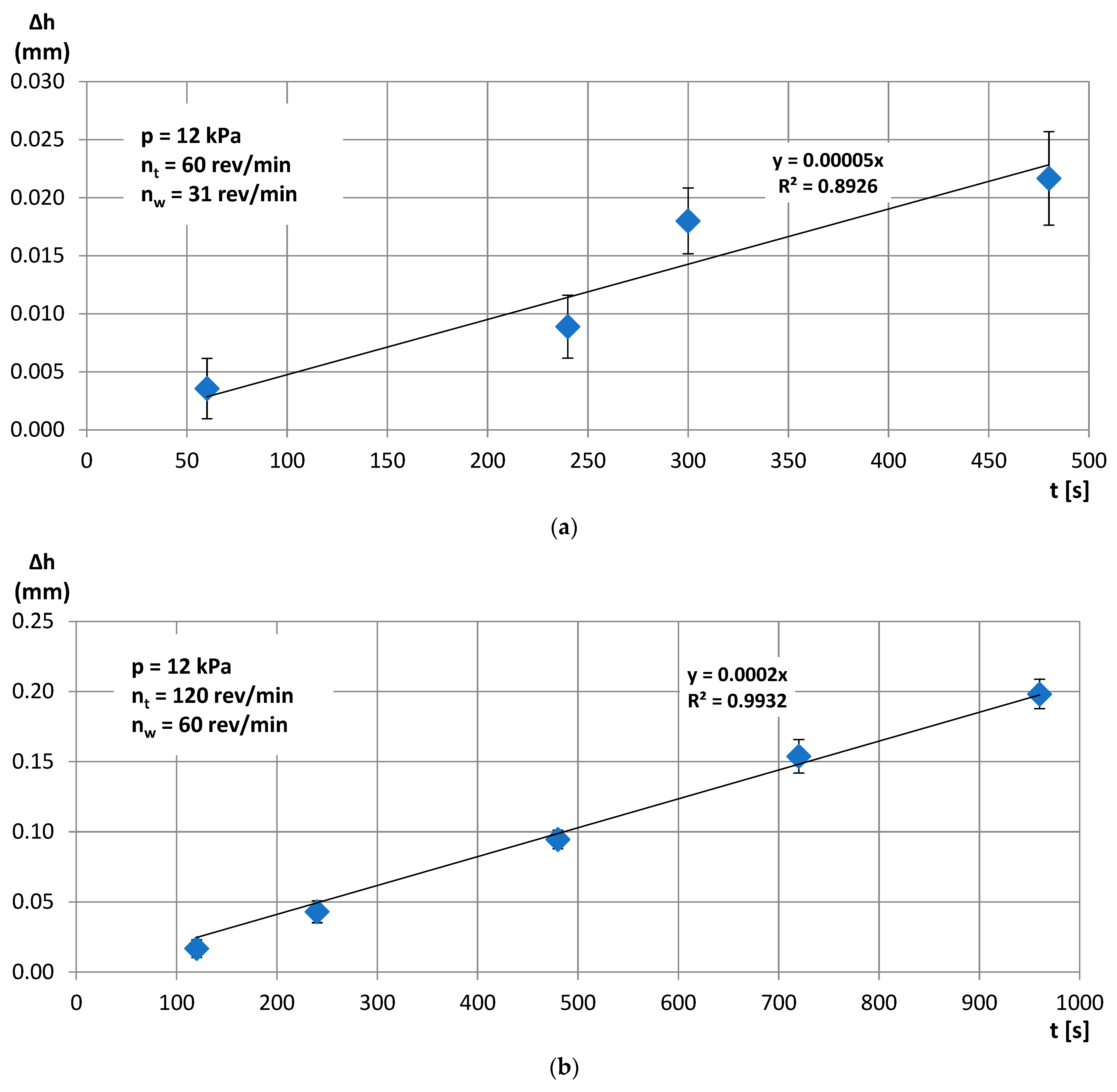

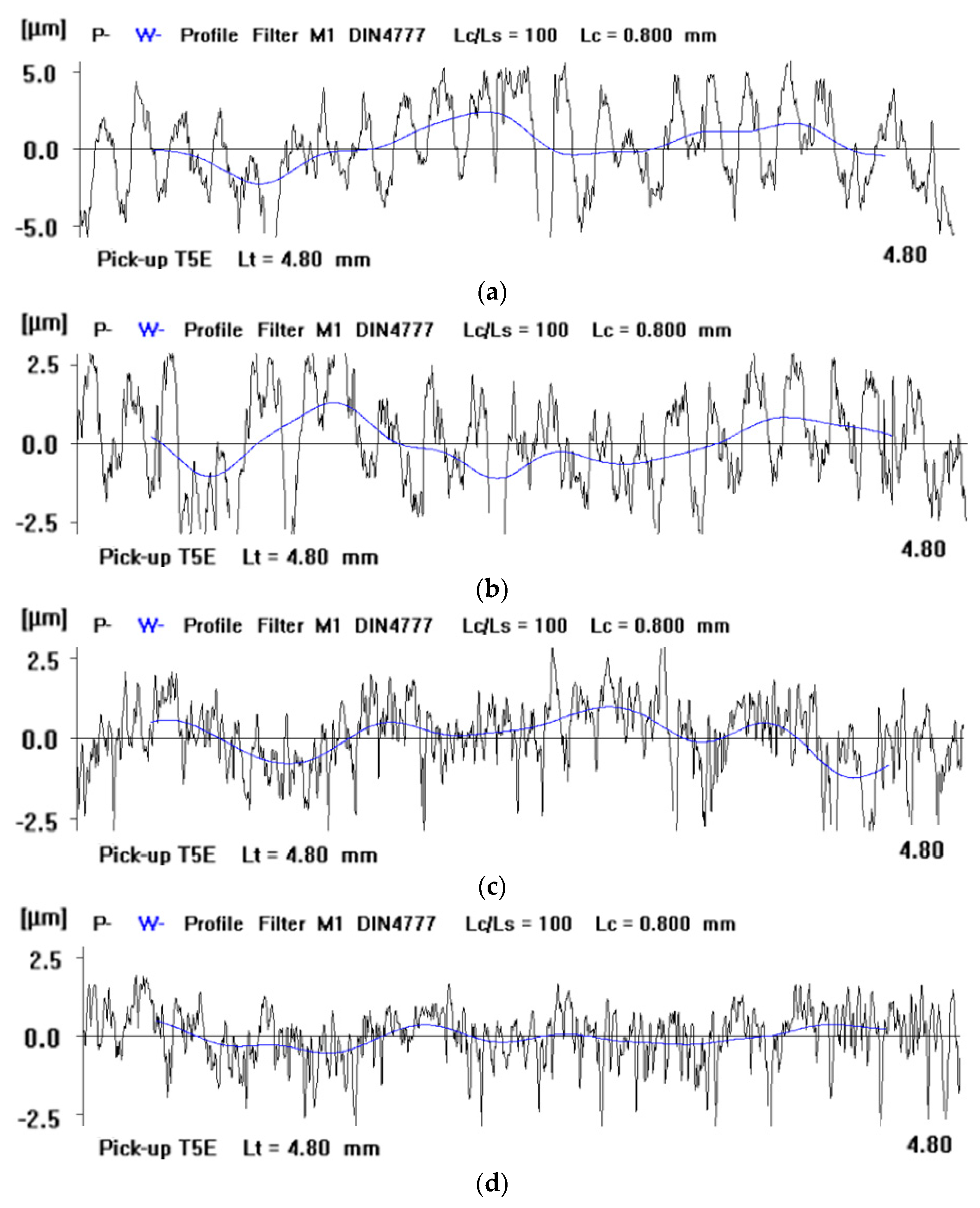

3.2. Experimental Tests of Single-Sided Lapping of Al2O3 Ceramics

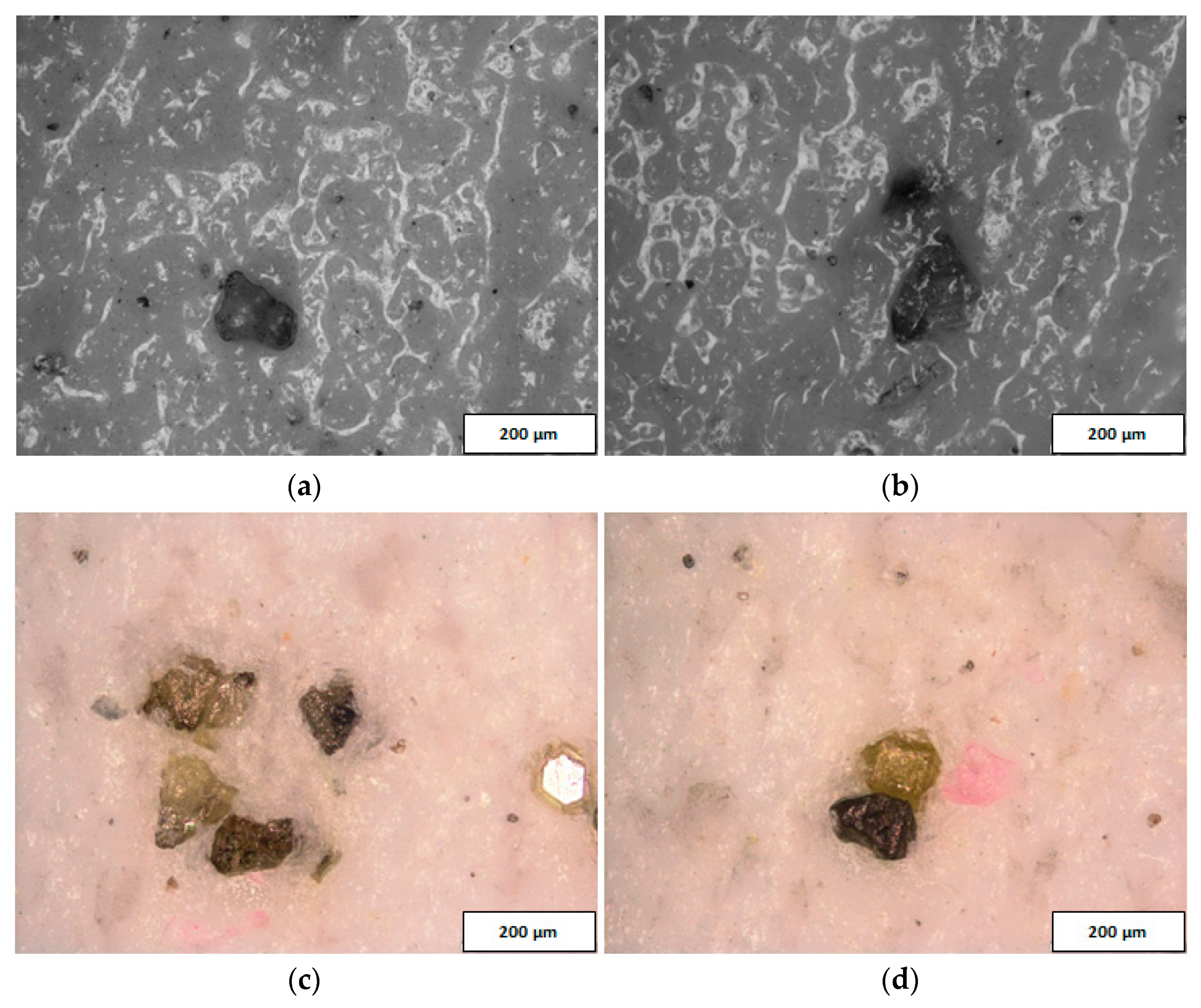

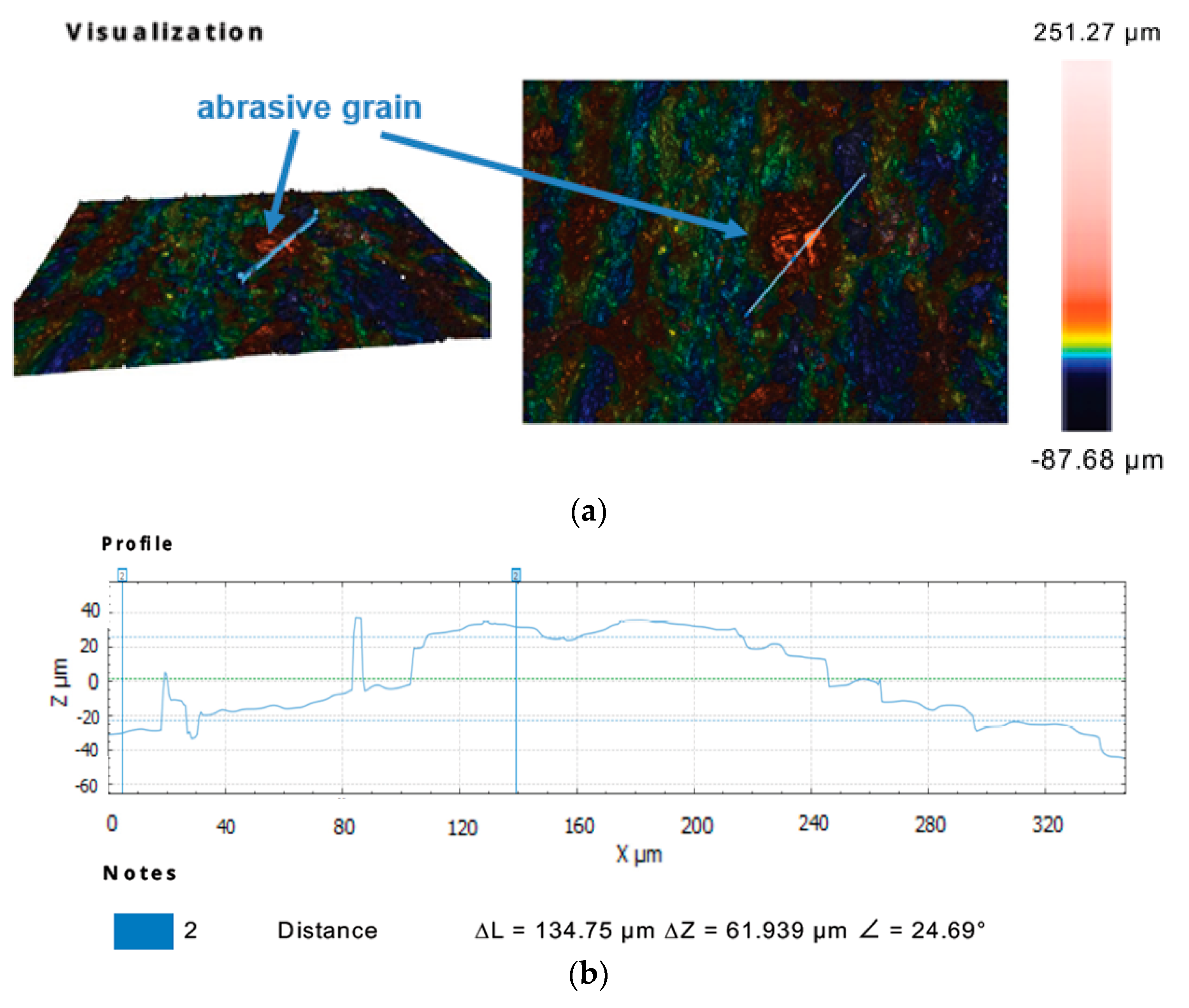

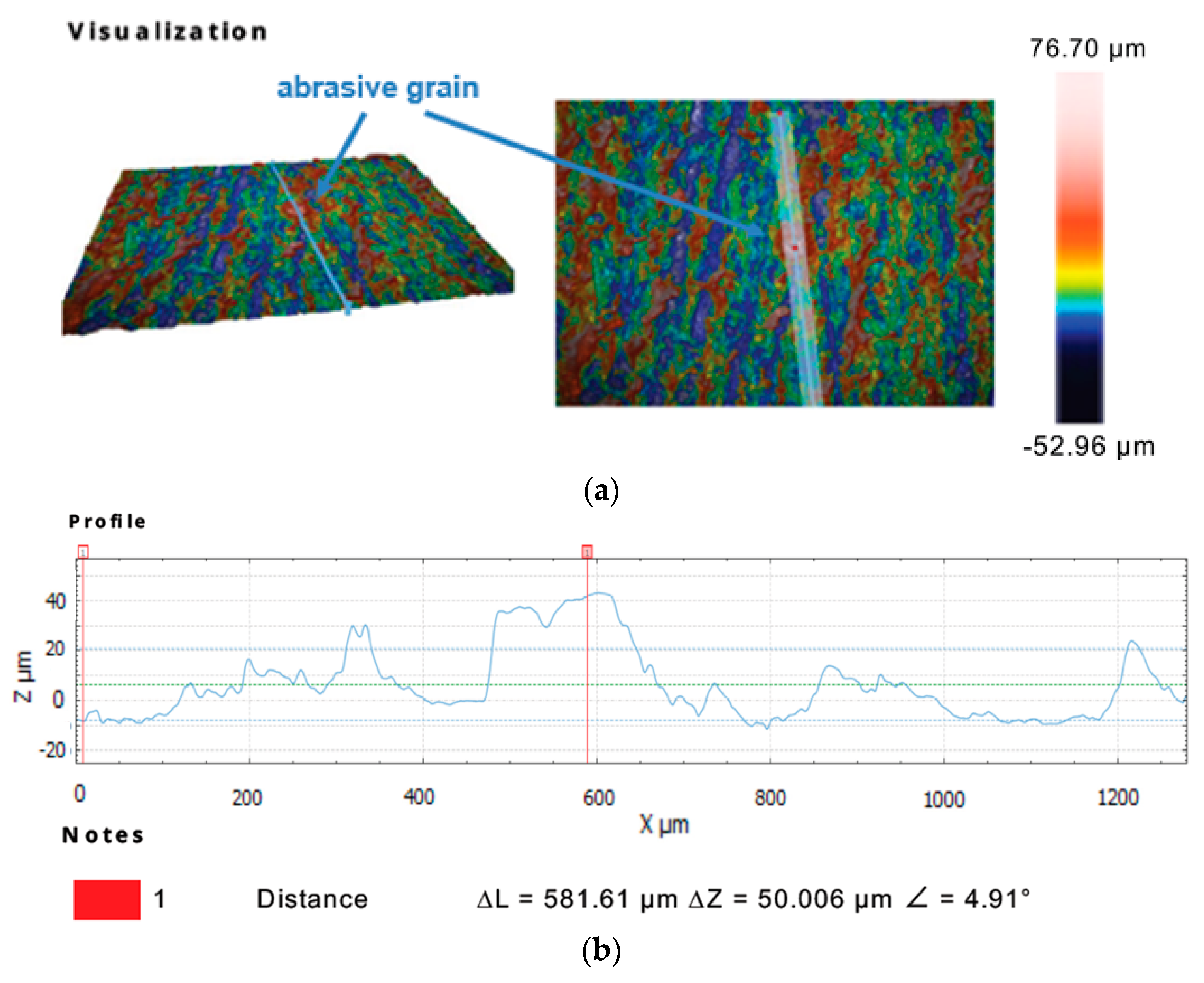

3.3. Microscopic Observations of the Tool’s Active Surface

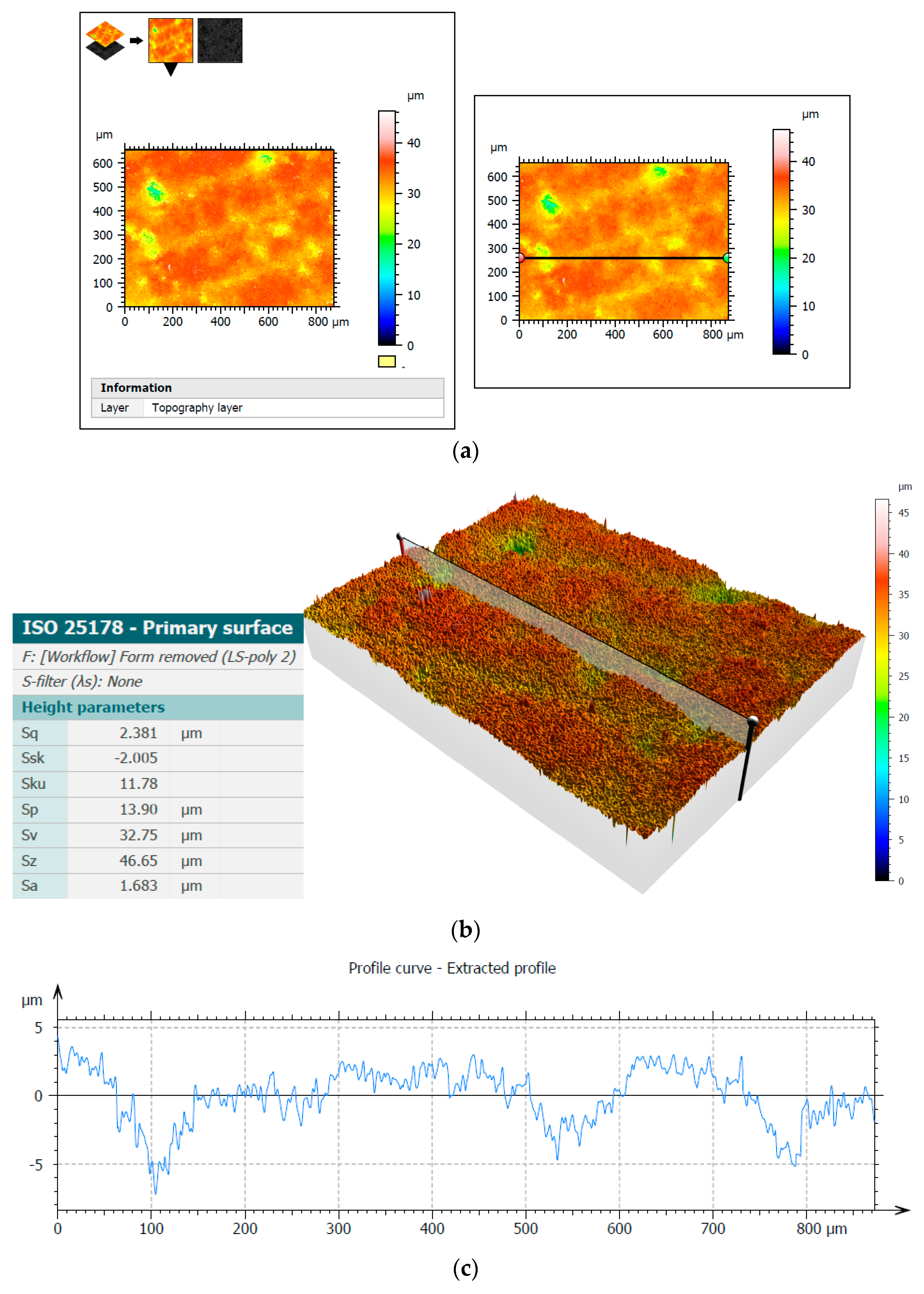

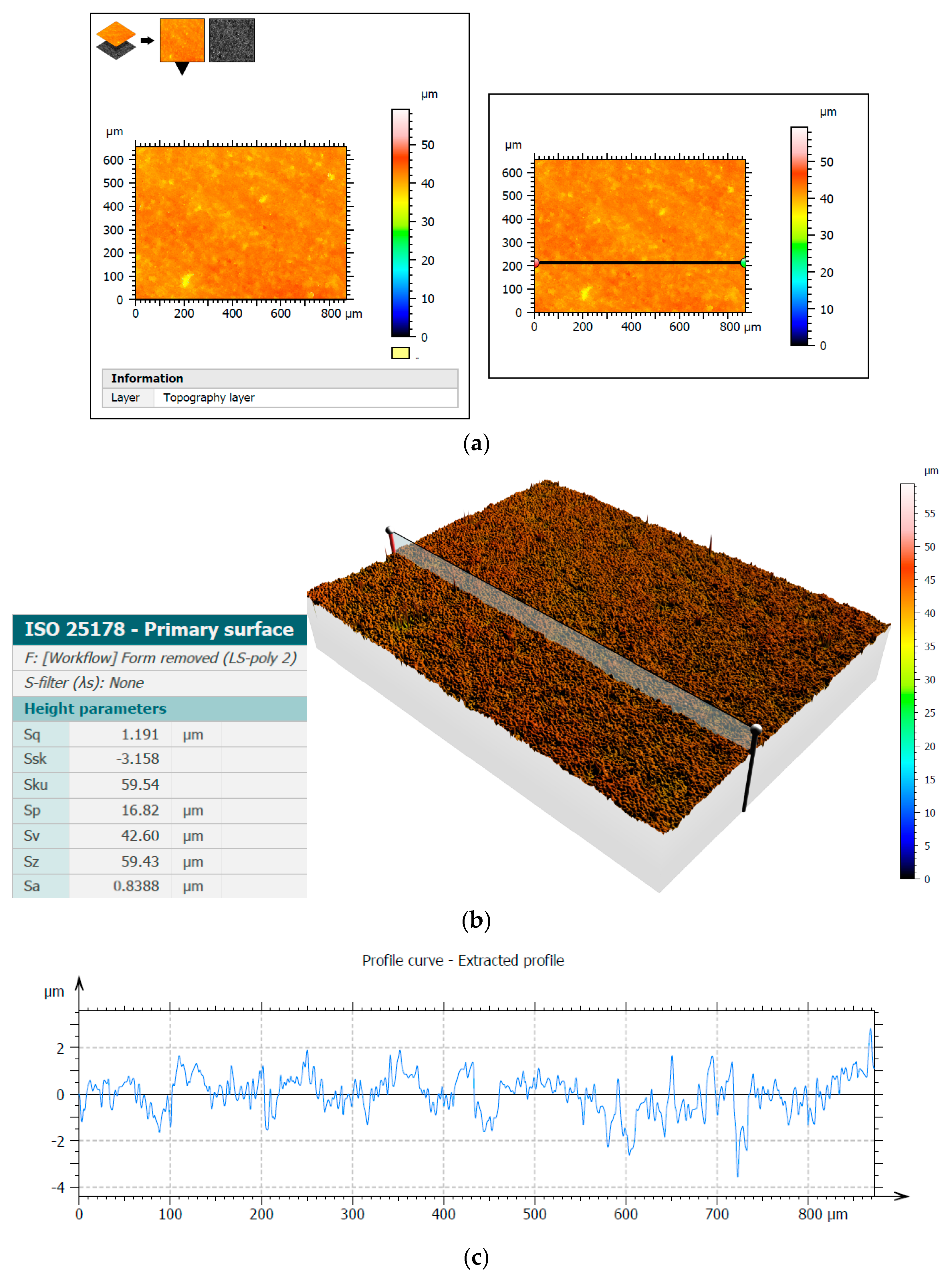

3.4. Microscopic Observations of the Machined Surfaces of Al2O3 Technical Ceramics

4. Discussion

5. Conclusions

- The use of low kinematic parameters, unit pressure, as well as a short machining time and small abrasive grains did not allow for effective material removal and significant improvement in the surface quality of the samples made of Al2O3 technical ceramics, except for their waviness;

- An increase in the kinematic parameters, unit pressure, and machining time, as well as adding free large D107 abrasive grains significantly improved the amount of removed material, as well as the surface roughness and waviness parameters measured on the machined surfaces of the Al2O3 samples;

- A soft and resilient polyamide PA 2200 with flexural modulus 1500 MPa [28] induced the easy embedding of hard diamond grains. Microscopic observations conducted after the experimental tests confirmed the equipment of the tool’s active surface with diamond grains. Their permanent embedding in the lapping tool allowed for effective material removal along with the reduction in surface roughness and waviness. Microscopic observations and the obtained technological effects suggested the process transition from conventional lapping treated as three-body abrasion to grinding or lap-grinding treated as two-body abrasion;

- After all tests, no visible signs of damage or excessive wear of the prototype lapping plate were observed. After cleaning the remains of the applied abrasive suspension, the SLS-printed tool was effectively used in the next experimental tests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deja, M. Wear of Electroplated Tools Used for Flat Grinding of Ceramics. In Solid State Phenomena; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2013; Volume 199, pp. 633–638. [Google Scholar]

- Barylski, A.; Deja, M. Finishing of ceramics in a single-disk lapping machine configuration. In Solid State Phenomena; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2010; Volume 165, pp. 237–243. [Google Scholar]

- Deja, M.; List, M.; Lichtschlag, L.D.; Uhlmann, E. Thermal and technological aspects of double face grinding of Al2O3 ceramic materials. Ceram. Int. 2019, 45, 19489–19495. [Google Scholar] [CrossRef]

- Deja, M.; Lichtschlag, L.; Uhlmann, E. Thermal and technological aspects of double face grinding of C45 carbon steel. J. Manuf. Process. 2021, 64, 1036–1046. [Google Scholar] [CrossRef]

- Barylski, A.; Deja, M. Influence of Flat Lapping Kinematics on Machinability of Ceramics. In Solid State Phenomena; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2013; Volume 199, pp. 615–620. [Google Scholar] [CrossRef]

- Deja, M. Correlation between shape errors in flat grinding. J. Vibroengineering 2012, 14, 520–527. [Google Scholar]

- Deja, M.; Zieliński, D. Wear of electroplated diamond tools in lap-grinding of Al2O3 ceramic materials. Wear 2020, 460–461, 203461. [Google Scholar] [CrossRef]

- Barylski, A.; Deja, M. Microgrinding of flat surfaces on single-disc lapping machine. Int. J. Mach. Mach. Mater. 2009, 5, 245. [Google Scholar] [CrossRef]

- Park, C.; Kim, H.; Lee, S.; Jeong, H. The influence of abrasive size on high-pressure chemical mechanical polishing of sapphire wafer. Int. J. Precis. Eng. Manuf. Technol. 2015, 2, 157–162. [Google Scholar] [CrossRef] [Green Version]

- Kim, U.S.; Park, J.W. High-Quality Surface Finishing of Industrial Three-Dimensional Metal Additive Manufacturing Using Electrochemical Polishing. Int. J. Precis. Eng. Manuf. Technol. 2019, 6, 11–21. [Google Scholar] [CrossRef]

- Tan, K.; Yeo, S. Surface finishing on IN625 additively manufactured surfaces by combined ultrasonic cavitation and abrasion. Addit. Manuf. 2020, 31, 100938. [Google Scholar] [CrossRef]

- Liang, Y.; Dutta, S.P. Application trend in advanced ceramic technologies. Technovation 2001, 21, 61–65. [Google Scholar] [CrossRef]

- Molaiekiya, F.; Aramesh, M.; Veldhuis, S. Chip formation and tribological behavior in high-speed milling of IN718 with ceramic tools. Wear 2020, 446–447, 203191. [Google Scholar] [CrossRef]

- Chang, C.-W.; Kuo, C.-P. Evaluation of surface roughness in laser-assisted machining of aluminum oxide ceramics with Taguchi method. Int. J. Mach. Tools Manuf. 2007, 47, 141–147. [Google Scholar] [CrossRef]

- Lee, T.; Jeong, H.; Kim, H.; Lee, S.; Kim, D. Effect of platen shape on evolution of total thickness variation in single-sided lapping of sapphire wafer. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 225–229. [Google Scholar] [CrossRef]

- Pawar, P.; Ballav, R.; Kumar, A. An Overview of Machining Process of Alumina and Alumina Ceramic Composites. Manuf. Sci. Technol. 2015, 3, 10–15. [Google Scholar] [CrossRef] [Green Version]

- Deja, M.; Zieliński, D.; Kadir, A.; Humaira, S. Applications of Additively Manufactured Tools in Abrasive Machining—A Literature Review. Materials 2021, 14, 1318. [Google Scholar] [CrossRef]

- Deja, M.; Zielinski, D. A pilot study to assess an in-process inspection method for small diameter holes produced by direct metal laser sintering. Rapid Prototyp. J. 2019, 26, 418–436. [Google Scholar] [CrossRef]

- Deja, M.; Dobrzyński, M.; Flaszyński, P.; Haras, J.; Zieliński, D. Application of Rapid Prototyping Technology in the Manufacturing of Turbine Blade with Small Diameter Holes. Pol. Marit. Res. 2018, 25, 119–123. [Google Scholar] [CrossRef] [Green Version]

- Deja, M.; Siemiątkowski, M.S.; Zieliński, D. Multi-Criteria Comparative Analysis of the Use of Subtractive and Additive Technologies in the Manufacturing of Offshore Machinery Components. Pol. Marit. Res. 2020, 27, 71–81. [Google Scholar] [CrossRef]

- Tian, C.; Li, X.; Zhang, S.; Guo, G.; Wang, L.; Rong, Y. Study on design and performance of metal-bonded diamond grinding wheels fabricated by selective laser melting (SLM). Mater. Des. 2018, 156, 52–61. [Google Scholar] [CrossRef]

- Tian, C.; Li, X.; Zhang, S.; Guo, G.; Ziegler, S.; Schleifenbaum, J.H.; Wang, L.; Rong, Y. Porous structure design and fabrication of metal-bonded diamond grinding wheel based on selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2018, 100, 1451–1462. [Google Scholar] [CrossRef]

- Tian, C.; Li, X.; Li, H.; Guo, G.; Wang, L.; Rong, Y. The effect of porosity on the mechanical property of metal-bonded diamond grinding wheel fabricated by selective laser melting (SLM). Mater. Sci. Eng. A 2019, 743, 697–706. [Google Scholar] [CrossRef]

- Tian, C.; Li, X.; Li, H.; Guo, G.; Wang, L.; Rong, Y. Study on process and manufacturability of metal-bonded diamond grinding wheel fabricated by selective laser melting (SLM). J. Phys. Conf. Ser. 2019, 1303, 012144. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, X.; Chen, S.; Hui, J. An Experimental Study on the Precision Abrasive Machining Process of Hard and Brittle Materials with Ultraviolet-Resin Bond Diamond Abrasive Tools. Materials 2019, 12, 125. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, L.; Zhang, X.; Lee, C.-H.; Marinescu, I.D.; Zhang, Y.; Hui, J. An Experimental Study on the Abrasive Machining Process of Electronic Substrate Material with A Novel Ultraviolet-Curable Resin Bond Diamond Lapping Plate. IEEE Access 2019, 7, 64375–64385. [Google Scholar] [CrossRef]

- Du, Z.-J.; Zhang, F.-L.; Xu, Q.-S.; Huang, Y.-J.; Li, M.-C.; Huang, H.-P.; Wang, C.-Y.; Zhou, Y.-M.; Tang, H.-Q. Selective laser sintering and grinding performance of resin bond diamond grinding wheels with arrayed internal cooling holes. Ceram. Int. 2019, 45, 20873–20881. [Google Scholar] [CrossRef]

- EOS GmbH. PA 200 Balance 1.0. 2010. Available online: https://drukarki3d.pl/wp-content/uploads/2015/09/karta-materiałowa-PA-2200-ENG.pdf (accessed on 20 March 2019).

| Lapping Plate | |

| Outer tool diameter | do = 380 mm |

| Inner tool diameter | di = 90 mm |

| Raw material | polyamide powder PA 2200 |

| SLS Process Parameter | |

| Thickness of a single layer | 100 µm |

| Laser type | CO2 |

| Power of laser | 30 W |

| Length of laser beam | 10.6 µm |

| Printing speed | 10 mm/s |

| Printing resolution | 0.005 mm |

| Postprocessing | |

| Sandblasting and cleaning of unsintered powder particles using compressed air | |

| X—Independent Variables | |||||

|---|---|---|---|---|---|

| Test Number | Unit Pressure p (kPa) | Rotational Speed (rev/min) | Type of Abrasive Suspension (mL) | Lapping Time Δt (s) | |

| Lapping Tool nt | Leading Ring nw | ||||

| T1 | 6 | 60 | 31 | 4 mL diamond paste SD 28/20 | 60; 120 |

| T2 | 12 | 60 | 31 | 0.5 mL of abrasive grains D107 | 60; 240; 300; 480 |

| T3 | 12 | 120 | 60 | 0.5 mL of abrasive grains D107 | 120; 240; 480; 720; 940 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deja, M.; Zieliński, D. A Pilot Study on Machining Difficult-to-Cut Materials with the Use of Tools Fabricated by SLS Technology. Materials 2021, 14, 5306. https://doi.org/10.3390/ma14185306

Deja M, Zieliński D. A Pilot Study on Machining Difficult-to-Cut Materials with the Use of Tools Fabricated by SLS Technology. Materials. 2021; 14(18):5306. https://doi.org/10.3390/ma14185306

Chicago/Turabian StyleDeja, Mariusz, and Dawid Zieliński. 2021. "A Pilot Study on Machining Difficult-to-Cut Materials with the Use of Tools Fabricated by SLS Technology" Materials 14, no. 18: 5306. https://doi.org/10.3390/ma14185306

APA StyleDeja, M., & Zieliński, D. (2021). A Pilot Study on Machining Difficult-to-Cut Materials with the Use of Tools Fabricated by SLS Technology. Materials, 14(18), 5306. https://doi.org/10.3390/ma14185306