The Viscoelastic Behaviour of Waterlogged Archaeological Wood Treated with Methyltrimethoxysilane

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

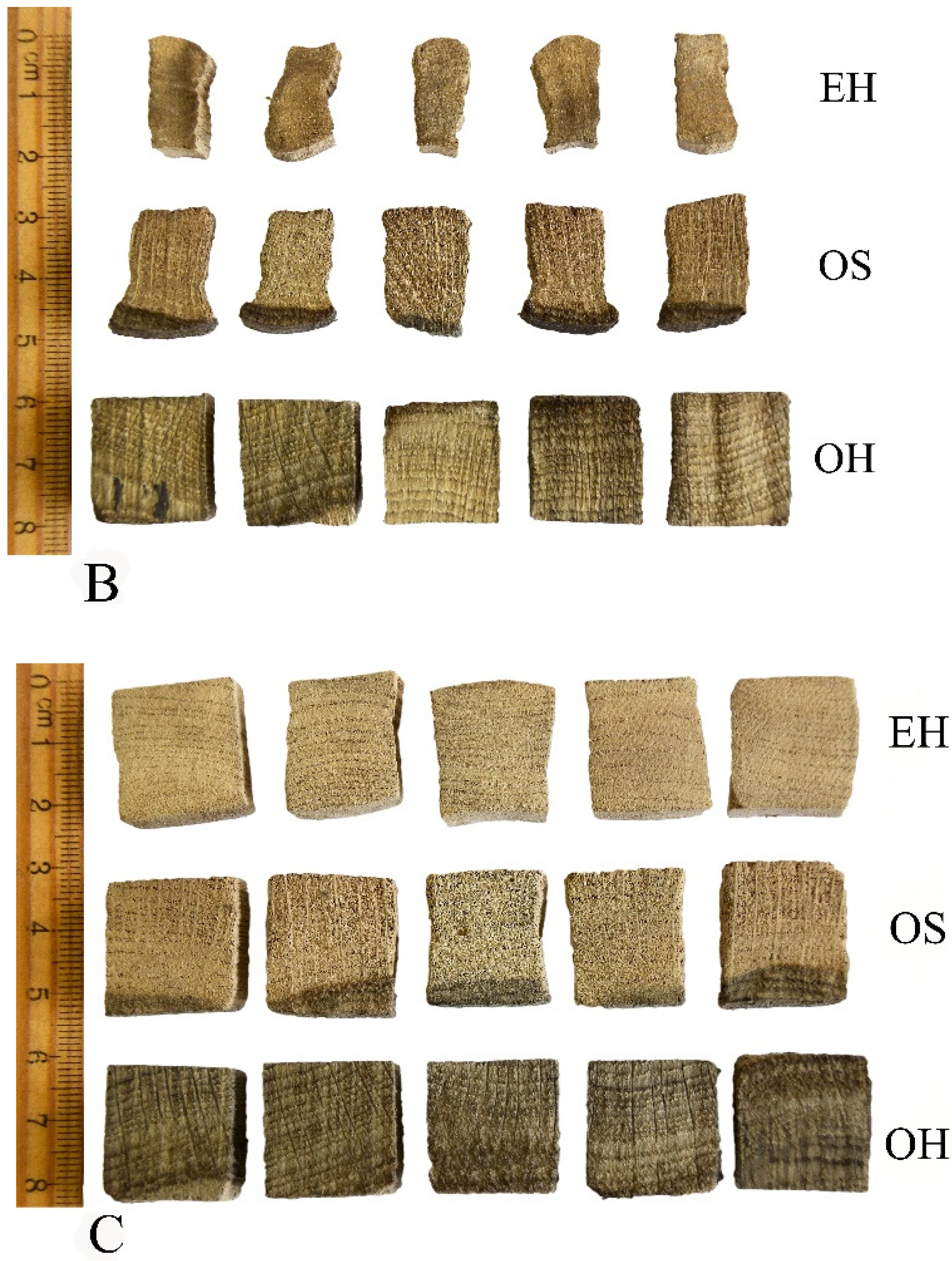

2.2.1. Sample Preparation

2.2.2. Effectiveness of the Treatment Calculations

2.2.3. Dynamic Mechanical Analysis Measurements

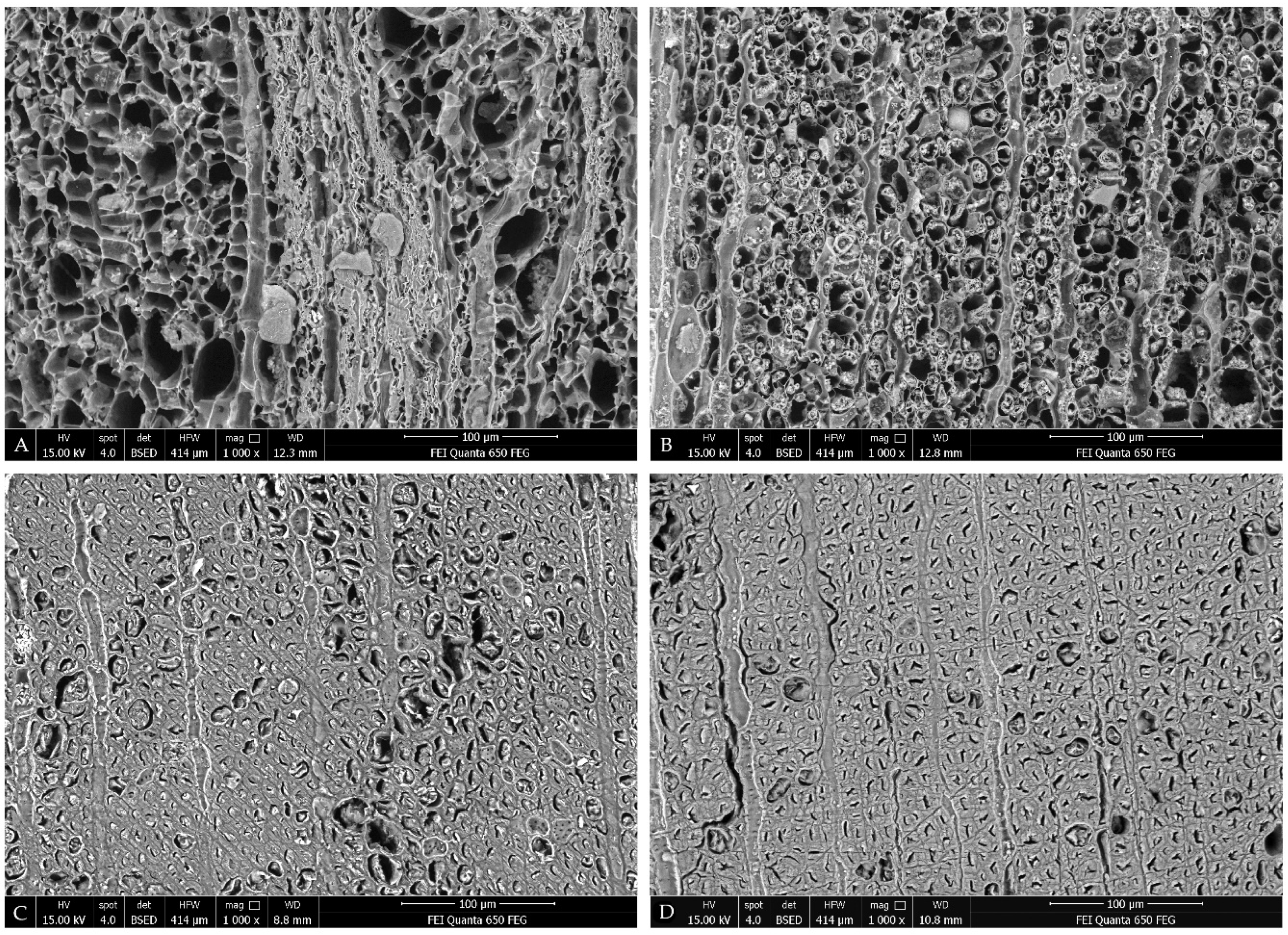

2.2.4. Scanning Electron Microscopy Imaging

2.2.5. Surface Area and Pore Volume Measurements

2.2.6. Moisture Sorption Analyses

3. Results and Discussion

3.1. Effectiveness of the Treatment and Its Impact on the Wood Structure

3.2. The Effect of the Treatment on the Moisture Properties of Archaeological Wood

3.3. Viscoelastic Behaviour of Untreated and MTMS-Treated Archaeological Wood

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Florian, M.-L.E. Scope and History of Archaeological Wood; Advances in Chemistry; American Chemical Society: Washington, DC, USA, 1989; Volume 225, pp. 3–32. ISBN 978-0-8412-1623-5. [Google Scholar]

- Blanchette, R.A. Microbial Degradation of Wood from Aquatic and Terrestrial Environments. Cult. Herit. Microbiol. Fundam. Stud. Conserv. Sci. 2010, 54, 179–218. [Google Scholar]

- Björdal, C.G. Microbial Degradation of Waterlogged Archaeological Wood. J. Cult. Herit. 2012, 13, S118–S122. [Google Scholar] [CrossRef]

- Hoffmann, P. On the Stabilization of Waterlogged Oakwood with PEG. II. Designing a Two-Step Treatment for Multi-Quality Timbers. Stud. Conserv. 1986, 31, 103–113. [Google Scholar] [CrossRef]

- Unger, A.; Schniewind, A.; Unger, W. Conservation of Wood Artifacts: A Handbook; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Jensen, P.; Schnell, U. The Implications of Using Low Molecular Weight PEG for Impregnation of Waterlogged Archaeological Wood Prior to Freeze Drying. In Proceedings of the 9th ICOM Group on Wet Organic Archaeological Materials Conference, Copenhagen, Denmark, 7–11 June 2004; pp. 279–308. [Google Scholar]

- Bjurhager, I.; Ljungdahl, J.; Wallström, L.; Gamstedt, E.K.; Berglund, L.A. Towards Improved Understanding of PEG-Impregnated Waterlogged Archaeological Wood: A Model Study on Recent Oak. Holzforschung 2010, 64, 243–250. [Google Scholar] [CrossRef]

- Almkvist, G.; Hocker, E.; Sahlstedt, M.; Museums, S.M. Iron Removal from Waterlogged Wood; SLU Repro: Uppsala, Sweden, 2013. [Google Scholar]

- Almkvist, G.; Persson, I. Degradation of Polyethylene Glycol and Hemicellulose in the Vasa. Holzforschung 2008, 62, 64–70. [Google Scholar] [CrossRef]

- Hocker, E.; Almkvist, G.; Sahlstedt, M. The Vasa Experience with Polyethylene Glycol: A Conservator’s Perspective. J. Cult. Herit. 2012, 13, S175–S182. [Google Scholar] [CrossRef]

- Wagner, L.; Almkvist, G.; Bader, T.K.; Bjurhager, I.; Rautkari, L.; Gamstedt, E.K. The Influence of Chemical Degradation and Polyethylene Glycol on Moisture-Dependent Cell Wall Properties of Archeological Wooden Objects: A Case Study of the Vasa Shipwreck. Wood Sci. Technol. 2016, 50, 1103–1123. [Google Scholar] [CrossRef]

- Kaye, B. Conservation of Waterlogged Archaeological Wood. Chem. Soc. Rev. 1995, 24, 35–43. [Google Scholar] [CrossRef]

- Grattan, D.W. A Practical Comparative Study of Several Treatments for Waterlogged Wood. Stud. Conserv. 1982, 27, 124–136. [Google Scholar] [CrossRef]

- Hoffmann, P. Sucrose for Waterlogged Wood: Not so Simple at All. In Proceedings of the ICOM Committee for Conservation, 11th Triennial Meeting, Edinburgh, UK, 1–6 September 1996; Preprints. pp. 657–662. [Google Scholar]

- Endo, R.; Kamei, K.; Iida, I.; Kawahara, Y. Dimensional Stability of Waterlogged Wood Treated with Hydrolyzed Feather Keratin. J. Archaeol. Sci. 2008, 35, 1240–1246. [Google Scholar] [CrossRef]

- Kennedy, A.; Pennington, E.R. Conservation of Chemically Degraded Waterlogged Wood with Sugars. Stud. Conserv. 2014, 59, 194–201. [Google Scholar] [CrossRef]

- McQueen, C.M.; Tamburini, D.; Lucejko, J.J.; Braovac, S.; Gambineri, F.; Modugno, F.; Colombini, M.P.; Kutzke, H. New Insights into the Degradation Processes and Influence of the Conservation Treatment in Alum-Treated Wood from the Oseberg Collection. Microchem. J. 2017, 132, 119–129. [Google Scholar] [CrossRef]

- Giachi, G.; Capretti, C.; Donato, I.D.; Macchioni, N.; Pizzo, B. New Trials in the Consolidation of Waterlogged Archaeological Wood with Different Acetone-Carried Products. J. Archaeol. Sci. 2011, 38, 2957–2967. [Google Scholar] [CrossRef]

- Broda, M.; Hill, C.A.S. Conservation of Waterlogged Wood—Past, Present and Future Perspectives. Forests 2021, 12, 1193. [Google Scholar] [CrossRef]

- Antonelli, F.; Galotta, G.; Sidoti, G.; Zikeli, F.; Nisi, R.; Petriaggi, B.D.; Romagnoli, M. Cellulose and Lignin Nano-Scale Consolidants for Waterlogged Archaeological Wood. Front. Chem. 2020, 8, 32. [Google Scholar] [CrossRef] [PubMed]

- Andriulo, F.; Giorgi, R.; Steindal, C.C.; Kutzke, H.; Braovac, S.; Baglioni, P. Hybrid Nanocomposites Made of Diol-Modified Silanes and Nanostructured Calcium Hydroxide. Applications to Alum-Treated Wood. Pure Appl. Chem. 2017, 89, 29–39. [Google Scholar] [CrossRef]

- Cavallaro, G.; Lazzara, G.; Milioto, S.; Parisi, F.; Ruisi, F. Nanocomposites Based on Esterified Colophony and Halloysite Clay Nanotubes as Consolidants for Waterlogged Archaeological Woods. Cellulose 2017, 24, 3367–3376. [Google Scholar] [CrossRef]

- Cavallaro, G.; Milioto, S.; Parisi, F.; Lazzara, G. Halloysite Nanotubes Loaded with Calcium Hydroxide: Alkaline Fillers for the Deacidification of Waterlogged Archeological Woods. ACS Appl. Mater. Interfaces 2018, 10, 27355–27364. [Google Scholar] [CrossRef]

- Cipriani, G.; Salvini, A.; Baglioni, P.; Bucciarelli, E. Cellulose as a Renewable Resource for the Synthesis of Wood Consolidants. J. Appl. Polym. Sci. 2010, 118, 2939–2950. [Google Scholar] [CrossRef]

- McHale, E.; Steindal, C.C.; Kutzke, H.; Benneche, T.; Harding, S.E. In Situ Polymerisation of Isoeugenol as a Green Consolidation Method for Waterlogged Archaeological Wood. Sci. Rep. 2017, 7, 46481. [Google Scholar] [CrossRef]

- Salanti, A.; Zoia, L.; Zanini, S.; Orlandi, M. Synthesis and Characterization of Lignin–Silicone Hybrid Polymers as Possible Consolidants for Decayed Wood. Wood Sci. Technol. 2016, 50, 117–134. [Google Scholar] [CrossRef]

- Walsh, Z.; Janeček, E.-R.; Jones, M.; Scherman, O.A. Natural Polymers as Alternative Consolidants for the Preservation of Waterlogged Archaeological Wood. Stud. Conserv. 2017, 62, 173–183. [Google Scholar] [CrossRef]

- Walsh, Z.; Janeček, E.-R.; Hodgkinson, J.T.; Sedlmair, J.; Koutsioubas, A.; Spring, D.R.; Welch, M.; Hirschmugl, C.J.; Toprakcioglu, C.; Nitschke, J.R. Multifunctional Supramolecular Polymer Networks as Next-Generation Consolidants for Archaeological Wood Conservation. Proc. Natl. Acad. Sci. USA 2014, 111, 17743–17748. [Google Scholar] [CrossRef]

- Walsh-Korb, Z.; Avérous, L. Recent Developments in the Conservation of Materials Properties of Historical Wood. Prog. Mater. Sci. 2019, 102, 167–221. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, K.; Hu, D. High Retreatability and Dimensional Stability of Polymer Grafted Waterlogged Archaeological Wood Achieved by ARGET ATRP. Sci. Rep. 2019, 9, 9879. [Google Scholar] [CrossRef]

- Cavallaro, G.; Milioto, S.; Lazzara, G. Halloysite Nanotubes: Interfacial Properties and Applications in Cultural Heritage. Langmuir 2020, 36, 3677–3689. [Google Scholar] [CrossRef] [PubMed]

- Lisuzzo, L.; Hueckel, T.; Cavallaro, G.; Sacanna, S.; Lazzara, G. Pickering Emulsions Based on Wax and Halloysite Nanotubes: An Ecofriendly Protocol for the Treatment of Archeological Woods. ACS Appl. Mater. Interfaces 2020, 13, 1651–1661. [Google Scholar] [CrossRef] [PubMed]

- Parisi, F.; Bernardini, F.; Cavallaro, G.; Mancini, L.; Milioto, S.; Prokop, D.; Lazzara, G. Halloysite Nanotubes/Pluronic Nanocomposites for Waterlogged Archeological Wood: Thermal Stability and X-ray Microtomography. J. Therm. Anal. Calorim. 2020, 141, 981–989. [Google Scholar] [CrossRef]

- DeWolf, H. Conservation Research Laboratory Instructions: Polymer Passivation (Silicone Oil) Conservation Treatment Based on Report by Helen Dewolf, 26 May 2004 and Modified by Donny L. Hamilton. Personal communication, 2007. [Google Scholar]

- Klosowski, J.M.; Smith, C.W. Method of Conserving Waterlogged Materials. Patent US5789087A, 1 February 2000. [Google Scholar]

- Smith, C.W.; Hamilton, D.L. Treatment of Waterlogged Wood Using Hydrolyzable, Multi-Functional Alkoxysilane Polymers. In Proceedings of the 8th ICOM Group on Wet Organic Archaeological Materials Conference, Stockholm, Sweden, 11–15 June 2001; pp. 614–615. [Google Scholar]

- Broda, M.; Dąbek, I.; Dutkiewicz, A.; Dutkiewicz, M.; Popescu, C.-M.; Mazela, B.; Maciejewski, H. Organosilicons of Different Molecular Size and Chemical Structure as Consolidants for Waterlogged Archaeological Wood—A New Reversible and Retreatable Method. Sci. Rep. 2020, 10, 2188. [Google Scholar] [CrossRef]

- Broda, M. Biological Effectiveness of Archaeological Oak Wood Treated with Methyltrimethoxysilane and PEG against Brown-Rot Fungi and Moulds. Int. Biodeterior. Biodegrad. 2018, 134, 110–116. [Google Scholar] [CrossRef]

- Broda, M.; Curling, S.F.; Spear, M.J.; Hill, C.A. Effect of Methyltrimethoxysilane Impregnation on the Cell Wall Porosity and Water Vapour Sorption of Archaeological Waterlogged Oak. Wood Sci. Technol. 2019, 53, 703–726. [Google Scholar] [CrossRef]

- Eder, M.; Arnould, O.; Dunlop, J.W.; Hornatowska, J.; Salmén, L. Experimental Micromechanical Characterisation of Wood Cell Walls. Wood Sci. Technol. 2013, 47, 163–182. [Google Scholar] [CrossRef]

- Green, D.W.; Winandy, J.E.; Kretschmann, D.E. Mechanical Properties of Wood, Forest Products Laboratory. In Wood Handbook—Wood as an Engineering Material; General Technical Report FPL-GTR-113; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999. [Google Scholar]

- Hamdan, S.; Dwianto, W.; Morooka, T.; Norimoto, M. Softening Characteristics of Wet Wood under Quasi Static Loading. Holzforschung 2000, 54, 557–560. [Google Scholar] [CrossRef]

- Hofstetter, K.; Gamstedt, E.K. Hierarchical Modelling of Microstructural Effects on Mechanical Properties of Wood. A Review COST Action E35 2004–2008: Wood Machining–Micromechanics and Fracture. Holzforschung 2009, 63, 130–138. [Google Scholar] [CrossRef]

- Lenth, C.A.; Kamke, F.A. Moisture Dependent Softening Behavior of Wood. Wood Fiber Sci. 2007, 33, 492–507. [Google Scholar]

- Lichtenegger, H.; Reiterer, A.; Stanzl-Tschegg, S.E.; Fratzl, P. Variation of Cellulose Microfibril Angles in Softwoods and Hardwoods—A Possible Strategy of Mechanical Optimization. J. Struct. Biol. 1999, 128, 257–269. [Google Scholar] [CrossRef]

- Mark, R.E. Cell Wall Mechanics of Tracheids. In Cell Wall Mechanics of Tracheids; Yale University Press: New Haven, CT, USA; London, UK, 1967. [Google Scholar]

- Sheng-Zuo, F.; Wen-Zhong, Y.; Xiang-Xiang, F.U. Variation of Microfibril Angle and Its Correlation to Wood Properties in Poplars. J. For. Res. 2004, 15, 261–267. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Xiao, Z.; Che, W.; Trinh, H.M.; Xie, Y. Effects of Modification with a Combination of Styrene-Acrylic Copolymer Dispersion and Sodium Silicate on the Mechanical Properties of Wood. J. Wood Sci. 2019, 65, 2. [Google Scholar] [CrossRef]

- Vorobyev, A. Static and Time-Dependent Mechanical Behaviour of Preserved Archaeological Wood: Case Studies of the Seventeenth Century Warship Vasa. Ph.D. Thesis, Acta Universitatis Upsaliensis, Uppsala, Sweden, 2017. [Google Scholar]

- Xie, Y.; Fu, Q.; Wang, Q.; Xiao, Z.; Militz, H. Effects of Chemical Modification on the Mechanical Properties of Wood. Eur. J. Wood Wood Prod. 2013, 71, 401–416. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, Z.; Sèbe, G.; Wu, R.; Virtudazo, R.V.R.; Tingaut, P.; Koebel, M.M. Multiscale Assembly of Superinsulating Silica Aerogels Within Silylated Nanocellulosic Scaffolds: Improved Mechanical Properties Promoted by Nanoscale Chemical Compatibilization. Adv. Funct. Mater. 2015, 25, 2326–2334. [Google Scholar] [CrossRef]

- Sun, X.; Jia, X.; Li, F.; Li, J.; Li, J.; Zhang, C.; Chen, S.; Cui, J.; Sun, K.; Zhang, S. Effect of Poly-Methyltriethoxysilane on the Waterproof Property of Starch/Fiber Composites with Open Cell Structures. RSC Adv. 2019, 9, 19508–19517. [Google Scholar] [CrossRef]

- Sun, Z.; Mingming, W. Effects of Sol-Gel Modification on the Interfacial and Mechanical Properties of Sisal Fiber Reinforced Polypropylene Composites. Ind. Crops. Prod. 2019, 137, 89–97. [Google Scholar] [CrossRef]

- Calabia, B.P.; Ninomiya, F.; Yagi, H.; Oishi, A.; Taguchi, K.; Kunioka, M.; Funabashi, M. Biodegradable Poly(Butylene Succinate) Composites Reinforced by Cotton Fiber with Silane Coupling Agent. Polymers 2013, 5, 128–141. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.; Xiao, Z.; Militz, H.; Mai, C. Silane Coupling Agents Used for Natural Fiber/Polymer Composites: A Review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Olsson, A.-M.; Salmén, L. The Effect of Lignin Composition on the Viscoelastic Properties of Wood. Nord. Pulp. Pap. Res. J. 1997, 12, 140–144. [Google Scholar] [CrossRef]

- Placet, V.; Passard, J.; Perre, P. Viscoelastic Properties of Green Wood across the Grain Measured by Harmonic Tests in the Range 0–95 C: Hardwood vs. Softwood and Normal Wood vs. Reaction Wood. Holzforschung 2007, 61, 458–557. [Google Scholar] [CrossRef]

- Sun, N.; Das, S.; Frazier, C.E. Dynamic Mechanical Analysis of Dry Wood: Linear Viscoelastic Response Region and Effects of Minor Moisture Changes. Holzforschung 2007, 61, 28–33. [Google Scholar] [CrossRef]

- Kelley, S.S.; Rials, T.G.; Glasser, W.G. Relaxation Behaviour of the Amorphous Components of Wood. J. Mater. Sci. 1987, 22, 617–624. [Google Scholar] [CrossRef]

- Obataya, E.; Norimoto, M.; Tomita, B. Mechanical Relaxation Processes of Wood in the Low-Temperature Range. J. Appl. Polym. Sci. 2001, 81, 3338–3347. [Google Scholar] [CrossRef]

- Bjørkmann, A.; Salmén, L. Studies on Solid Wood. II. The Influence of Chemical Modifications on Viscoelastic Properties. Cell. Chem. Technol. 2000, 34, 7–20. [Google Scholar]

- Salmén, L.; Stevanic, J.S.; Olsson, A.-M. Contribution of Lignin to the Strength Properties in Wood Fibres Studied by Dynamic FTIR Spectroscopy and Dynamic Mechanical Analysis (DMA). Holzforschung 2016, 70, 1155–1163. [Google Scholar] [CrossRef]

- Stevanic, J.S.; Salmén, L. Molecular Origin of Mechano-Sorptive Creep in Cellulosic Fibres. Carbohydr. Polym. 2020, 230, 115615. [Google Scholar] [CrossRef]

- Startsev, O.V.; Makhonkov, A.; Erofeev, V.; Gudojnikov, S. Impact of Moisture Content on Dynamic Mechanical Properties and Transition Temperatures of Wood. Wood Mater. Sci. Eng. 2017, 12, 55–62. [Google Scholar] [CrossRef]

- Gerhards, C.C. Effect of Moisture Content and Temperature on the Mechanical Properties of Wood: An Analysis of Immediate Effects. Wood Fiber Sci. 2007, 14, 4–36. [Google Scholar]

- McCarthy, C.J.; Birkinshaw, C.; Pembroke, J.T.; Hale, M. Dynamic Mechanical Analysis as a Technique for the Study of Fungal Degradation of Wood. Biotechnol. Tech. 1991, 5, 493–496. [Google Scholar] [CrossRef]

- Curling, S.F.; Clausen, C.A.; Winandy, J.E. Relationships between Mechanical Properties, Weight Loss, and Chemical Composition of Wood during Incipient Brown-Rot Decay. For. Prod. J. 2002, 52, 34–39. [Google Scholar]

- Ormondroyd, G.A.; Alfredsen, G.; Prabhakaran, R.D.; Curling, S.F.; Stefanowski, B.K.; Spear, M.J.; Gobakken, L.R. Assessment of the Use of Dynamic Mechanical Analysis to Investigate Initial Onset of Brown Rot Decay of Scots Pine (Pinus Sylvestris L.). Int. Biodeter. Biodegr. 2017, 120, 1–5. [Google Scholar] [CrossRef][Green Version]

- Bledzki, A.K.; Faruk, O.; Huque, M. Physico-Mechanical Studies of Wood Fiber Reinforced Composites. Polym. Plast. Technol. Eng. 2002, 41, 435–451. [Google Scholar] [CrossRef]

- Sewda, K.; Maiti, S.N. Dynamic Mechanical Properties of High Density Polyethylene and Teak Wood Flour Composites. Polym. Bull. 2013, 70, 2657–2674. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, M.; Lin, L. Investigation of Bulk and In Situ Mechanical Properties of Coupling Agents Treated Wood Plastic Composites. Polym. Test. 2017, 58, 292–299. [Google Scholar] [CrossRef]

- Hristov, V.; Vasileva, S. Dynamic Mechanical and Thermal Properties of Modified Poly (Propylene) Wood Fiber Composites. Macromol. Mater. Eng. 2003, 288, 798–806. [Google Scholar] [CrossRef]

- Nkeuwa, W.N.; Riedl, B.; Landry, V. UV-Cured Clay/Based Nanocomposite Topcoats for Wood Furniture. Part II: Dynamic Viscoelastic Behavior and Effect of Relative Humidity on the Mechanical Properties. Prog. Org. Coat. 2014, 77, 12–23. [Google Scholar] [CrossRef]

- Fang, L.; Chang, L.; Guo, W.; Chen, Y.; Wang, Z. Influence of Silane Surface Modification of Veneer on Interfacial Adhesion of Wood–Plastic Plywood. Appl. Surf. Sci. 2014, 288, 682–689. [Google Scholar] [CrossRef]

- Broda, M.; Mazela, B. Application of Methyltrimethoxysilane to Increase Dimensional Stability of Waterlogged Wood. J. Cult. Herit. 2017, 25, 149–156. [Google Scholar] [CrossRef]

- Broda, M.; Frankowski, M. Determination of the Content of Selected Elements in Medieval Waterlogged Oak Wood from the Lednica Lake—A Case Study. Environ. Sci. Pollut. R 2017, 24, 23401–23410. [Google Scholar] [CrossRef]

- Spear, M.J.; Broda, M. Comparison of Contemporary Elm (Ulmus spp.) and Degraded Archaeological Elm: The Use of Dynamic Mechanical Analysis under Ambient Moisture Conditions. Materials 2020, 13, 5026. [Google Scholar] [CrossRef]

- Rowell, R.M.; Ellis, W.D. Determination of Dimensional Stabilization of Wood Using the Water-Soak Method. Wood Fiber Sci. 1978, 10, 104–111. [Google Scholar]

- Hill, C.; Altgen, M.; Rautkari, L. Thermal Modification of Wood—A Review: Chemical Changes and Hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The Determination of Pore Volume and Area Distributions in Porous Substances. I. Computations from Nitrogen Isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Broda, M.; Curling, S.F.; Frankowski, M. The Effect of the Drying Method on the Cell Wall Structure and Sorption Properties of Waterlogged Archaeological Wood. Wood Sci. Technol. 2021, 55, 971–989. [Google Scholar] [CrossRef]

- Glass, S.V.; Boardman, C.R.; Zelinka, S.L. Short Hold Times in Dynamic Vapor Sorption Measurements Mischaracterize the Equilibrium Moisture Content of Wood. Wood Sci. Technol. 2017, 51, 243–260. [Google Scholar] [CrossRef]

- Broda, M.; Mazela, B.; Radka, K. Methyltrimethoxysilane as a Stabilising Agent for Archaeological Waterlogged Wood Differing in the Degree of Degradation. J. Cult. Herit. 2019, 35, 129–139. [Google Scholar] [CrossRef]

- Popescu, C.-M.; Broda, M. Interactions between Different Organosilicons and Archaeological Waterlogged Wood Evaluated by Infrared Spectroscopy. Forests 2021, 12, 268. [Google Scholar] [CrossRef]

- Schuerch, C. Plasticizing Wood with Liquid Ammonia. Ind. Eng. Chem. 1963, 55, 39. [Google Scholar] [CrossRef]

- Timar, M.C.; Mihai, M.D.; Maher, K.; Irle, M. Preparation of Wood with Thermoplastic Properties, Part 1. Classical Synthesis. Holzforschung 2000, 54, 71–76. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, J.; Lyu, J. Moisture-Dependent Orthotropic Viscoelastic Properties of Chinese Fir Wood during Quenching in the Temperature Range of 20 to −120 °C. Holzforschung 2020, 74, 10–19. [Google Scholar] [CrossRef]

- Back, E.L.; Salmén, N.L. Glass Transitions of Wood Components Hold Implications for Molding and Pulping Processes [Wood and Paper Materials]. TAPPI J. Tech. Assoc. Pulp Pap. Ind. 1982, 65, 107–110. [Google Scholar]

- Heijboer, J. Secondary Loss Peaks in Glassy Amorphous Polymers. Int. J. Polym. Mater. 1977, 6, 11–37. [Google Scholar] [CrossRef]

- Montes, H.; Mazeau, K.; Cavaillé, J.Y. Secondary Mechanical Relaxations in Amorphous Cellulose. Macromolecules 1997, 30, 6977–6984. [Google Scholar] [CrossRef]

- Kim, K.Y.; Kim, N.H.; Nishinari, K. Dielectric and Viscoelastic Properties of Cellulose Derivatives. Carbohydr. Polym. 1991, 16, 189–198. [Google Scholar] [CrossRef]

- Ebringerová, A.; Heinze, T. Xylan and Xylan Derivatives–Biopolymers with Valuable Properties, 1. Naturally Occurring Xylans Structures, Isolation Procedures and Properties. Macromol. Rapid Commun. 2000, 21, 542–556. [Google Scholar] [CrossRef]

- Obataya, E. Mechanical and Dielectric Relaxations of Wood in a Low Temperature Range. I. Relaxations Due to Methylol Groups and Adsorbed Water. Mokuzai Gakkaishi 1996, 42, 243–249. [Google Scholar]

- Backman, A.C.; Lindberg, K.A.H. Differences in Wood Material Responses for Radial and Tangential Direction as Measured by Dynamic Mechanical Thermal Analysis. J. Mater. Sci. 2001, 36, 3777–3783. [Google Scholar] [CrossRef]

- Havimo, M. A Literature-Based Study on the Loss Tangent of Wood in Connection with Mechanical Pulping. Wood Sci. Technol. 2009, 43, 627. [Google Scholar] [CrossRef]

- Ashaduzzaman, M.; Hale, M.D.; Ormondroyd, G.A.; Spear, M.J. Dynamic Mechanical Analysis of Scots Pine and Three Tropical Hardwoods. Int. Wood Prod. J. 2020, 11, 189–203. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, J.; Yan, H. Dynamic Viscoelastic Properties of Wood Treated by Three Drying Methods Measured at High-Temperature Range. Wood Fiber Sci. 2008, 40, 72–79. [Google Scholar]

- Einfeldt, J.; Meißner, D.; Kwasniewski, A. Polymerdynamics of Cellulose and Other Polysaccharides in Solid State-Secondary Dielectric Relaxation Processes. Prog. Polym. Sci. 2001, 26, 1419–1472. [Google Scholar] [CrossRef]

- Sugiyama, M.; Obataya, E.; Norimoto, M. Viscoelastic Properties of the Matrix Substance of Chemically Treated Wood. J. Mater. Sci. 1998, 33, 3505–3510. [Google Scholar] [CrossRef]

- Goring, D.A. Thermal Softening of Lignin, Hemicelluolose and Cellulose. Pulp Pap. 1963, 64, T517–T527. [Google Scholar]

- Lin, S.Y.; Dence, C.W. Methods in Lignin Chemistry; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Olsson, A.M.; Salmén, L. Viscoelasticity of in Situ Lignin as Affected by Structure: Softwood vs. Hardwood. ACS Symp. Ser. USA 1992, 133–149. [Google Scholar] [CrossRef]

- Laborie, M.-P.; Salmén, L.; Frazier, C.E. Cooperativity Analysis of the in Situ Lignin Glass Transition. Holzforschung 2004, 58, 129–133. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; Ogunleye, B.M. Mid-Infrared Spectroscopy and Dynamic Mechanical Analysis of Heat-Treated Obeche (Triplochiton Scleroxylon) Wood. Maderas Cienc. Technol. 2015, 17, 5–16. [Google Scholar] [CrossRef]

- Jebrane, M.; Harper, D.; Labbé, N.; Sèbe, G. Comparative Determination of the Grafting Distribution and Viscoelastic Properties of Wood Blocks Acetylated by Vinyl Acetate or Acetic Anhydride. Carbohydr. Polym. 2011, 84, 1314–1320. [Google Scholar] [CrossRef]

- Pizzo, B.; Pecoraro, E.; Lazzeri, S. Dynamic Mechanical Analysis (DMA) of Waterlogged Archaeological Wood at Room Temperature. Holzforschung 2018, 72, 421–431. [Google Scholar] [CrossRef]

- Boyd, R.H. Relaxation Processes in Crystalline Polymers: Experimental Behaviour—A Review. Polymer 1985, 26, 323–347. [Google Scholar] [CrossRef]

| Wood Type | Treatment | MC (%) | WPG (%) | S (%) | ASE (%) |

|---|---|---|---|---|---|

| AE | untreated | 9.2 | - | 68.7 ± 1.2 | - |

| MTMS | 6.5 | 172.8 ± 4.16 | 16.3 ± 3.8 | 76.2 ± 5.5 | |

| AOS | untreated | 9.0 | - | 43.4 ± 1.8 | - |

| MTMS | 5.5 | 203.2 ± 15.04 | 6.0 ± 4.1 | 86.2 ± 9.4 | |

| AOH | untreated | 9.7 | - | 23.2 ± 2.7 | - |

| MTMS | 7.4 | 50.07 ± 1.64 | 1.7 ± 0.5 | 92.8 ± 1.5 |

| Wood Species | Wood ID | Surface Area (m2 g–1) | Total Pore Volume (cm3 g–1) | Bulk Density (g cm–3) |

|---|---|---|---|---|

| Elm heartwood | AE | 1.60 ± 0.06 | 0.0038 | 0.53 ± 0.09 |

| AET | 1.68 ± 0.03 | 0.0048 | 0.48 ± 0.01 | |

| CE | 0.53 ± 0.01 | 0.0016 | 0.71 ± 0.01 | |

| Oak sapwood | AOS | 4.14 ± 0.10 | 0.0146 [39] | 0.27 ± 0.03 |

| AOST | 1.09 ± 0.07 | 0.0020 [39] | 0.47 ± 0.01 | |

| COS | 0.60 ± 0.06 | 0.0012 | 0.67 ± 0.00 | |

| Oak heartwood | AOH | 0.64 ± 0.01 | 0.0019 | 0.70 ± 0.01 |

| AOHT | 0.30 ± 0.02 | 0.0014 [39] | 0.73 ± 0.03 | |

| COH | 0.35 ± 0.02 | 0.0011 [39] | 0.60 ± 0.01 |

| Wood ID | MC (%) | ρ (g cm−3) | Tan δ Response (°C) | E′ at 25 °C (MPa) | E″ at 25 °C (MPa) | Tan δ at 25 °C | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| γ | MTMS | βwet | β2 | β1 | α | ||||||

| CE | 8.3 ± 0.3 | 0.71 ± 0.01 b | −97 ± 2 | - | −41 ± 15 | - | 97 ± 3b | - | 394.0 ± 64.9 b | 15.3 ± 1.5 b | 0.039 ± 0.003 a |

| AE | 8.0 ± 0.4 | 0.53 ± 0.09 a(a) | −86 ± 3 | - | - | - | 95 ± 2b | 114 ± 2b | 61.6 ± 5.5 a(a) | 2.8 ± 0.5 a(a) | 0.045 ± 0.005 ab(a) |

| AET | 4.2 ± 0.2 | 0.48 ± 0.01 a(a) | −89 ± 3 | −5 ± 8 | - | - | 109 ± 8 | incr. | 87.9 ± 4.1 a(b) | 4.8 ± 0.5 a(b) | 0.055 ± 0.006 b(a) |

| COS | 7.8 ± 0.2 | 0.67 ± 0.00 c | −99 ± 0 | - | −43 ± 5 | 98 ± 2b | 110 ± 5b | incr. | 439.2 ± 18.4 c | 15.8 ± 1.5 b | 0.036 ± 0.002 a |

| AOS | 8.4 ± 0.4 | 0.27 ± 0.03 a(a) | −75 ± 4 | - | - | 93 ± 6 | 117 ± 0b | - | 52.8 ± 8.2 a(a) | 2.6 ± 0.5 a(a) | 0.050 ± 0.006 b(a) |

| AOST | 3.9 ± 0.2 | 0.47 ± 0.01 b(b) | −77 ± 5 | 70 ± 7 | −3 ± 1 | - | 132 ± 5 | incr. | 108.4 ± 13.4 b(b) | 4.6 ± 0.4 a(b) | 0.043 ± 0.002 ab(a) |

| COH | 6.8 ± 0.1 | 0.60 ± 0.01 a | −87 ± 4b | - | - | 66 ± 0 | 99 ± 1b | incr. | 278.4 ± 52.5 a | 11.0 ± 2.8 a | 0.039 ± 0.003 a |

| AOH | 7.7 ± 0.1 | 0.70 ± 0.01 b(a) | −105 ± 3b | - | −90 ± 3b | 17 ± 0 54 ± 3 | 107 ± 5 | incr. | 300.3 ± 57.3 a(a) | 9.9 ± 2.0 a(a) | 0.033 ± 0.003 a(a) |

| AOHT | 5.2 ± 0.2 | 0.78 ± 0.01 b(a) | −91 ± 5b | 58 ± 6 | −55 ± 4 | 100 ± 1 | 131 ± 9 | incr. | 213.6 ± 21.2 a(a) | 8.0 ± 0.9 a(a) | 0.038 ± 0.003 a(a) |

| Wood ID | MC (%) | Tan δ at Each Frequency | Activation Energy (kJ·mol−1) | |||

|---|---|---|---|---|---|---|

| 1 Hz | 5 Hz | 10 Hz | γ Peak | MTMS | ||

| CE | 8.3 ± 0.3 | −100.7 | −89.5 | −86.2 | 39.2 | - |

| AE | 8.0 ± 0.4 | −74.6 | −66.6 | −62.3 | 62.4 | - |

| AET | 4.2 ± 0.2 | −86.2 | −78.1 | −73.8 | 55.1 | 152.2 |

| COS | 7.8 ± 0.2 | −99.3 | −85.8 | −79.6 | 31.0 | - |

| AOS | 8.4 ± 0.4 | −58.9 | −54.1 | −50.0 | 98.7 | - |

| AOST | 3.9 ± 0.2 | −80.1 | −67.7 | −65.1 | 46.1 | 980.5 |

| COH | 6.7 ± 0.2 | −84.9 | −76.9 | −66.7 | 38.4 | - |

| AOH | 7.7 ± 0.1 | −98.3 | −87.2 | −75.8 | 28.1 | - |

| AOHT | 5.2 ± 0.2 | −77.6 | −63.7 | −67.2 | 45.5 | 221.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Broda, M.; Spear, M.J.; Curling, S.F.; Ormondroyd, G.A. The Viscoelastic Behaviour of Waterlogged Archaeological Wood Treated with Methyltrimethoxysilane. Materials 2021, 14, 5150. https://doi.org/10.3390/ma14185150

Broda M, Spear MJ, Curling SF, Ormondroyd GA. The Viscoelastic Behaviour of Waterlogged Archaeological Wood Treated with Methyltrimethoxysilane. Materials. 2021; 14(18):5150. https://doi.org/10.3390/ma14185150

Chicago/Turabian StyleBroda, Magdalena, Morwenna J. Spear, Simon F. Curling, and Graham A. Ormondroyd. 2021. "The Viscoelastic Behaviour of Waterlogged Archaeological Wood Treated with Methyltrimethoxysilane" Materials 14, no. 18: 5150. https://doi.org/10.3390/ma14185150

APA StyleBroda, M., Spear, M. J., Curling, S. F., & Ormondroyd, G. A. (2021). The Viscoelastic Behaviour of Waterlogged Archaeological Wood Treated with Methyltrimethoxysilane. Materials, 14(18), 5150. https://doi.org/10.3390/ma14185150