Experimental Study on Consolidation-Creep Behavior of Subgrade Modified Soil in Seasonally Frozen Areas

Abstract

:1. Introduction

2. Materials and Methods

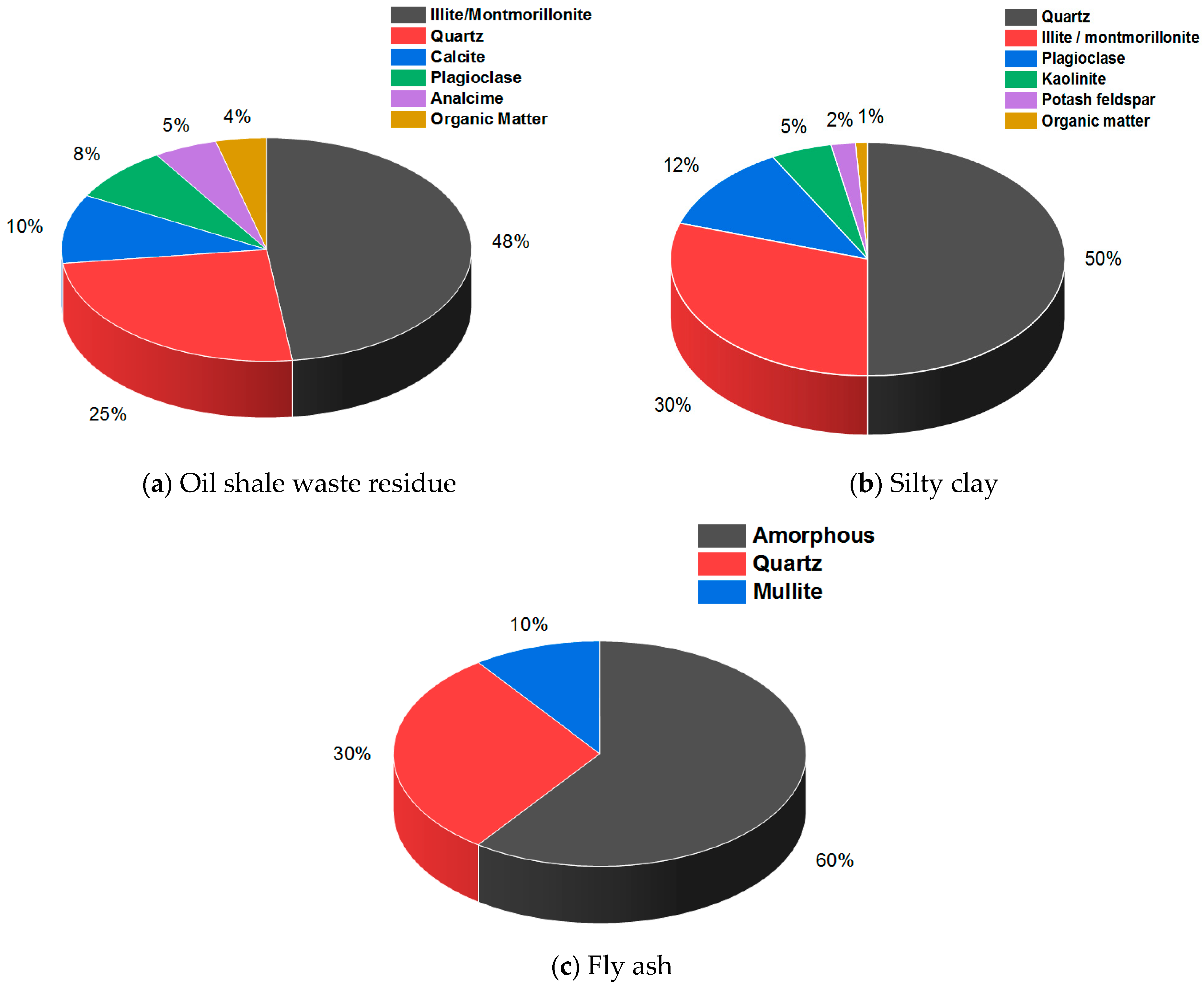

2.1. Raw Materials

2.2. Composition Analysis

2.3. Preparation of the Modified Soil

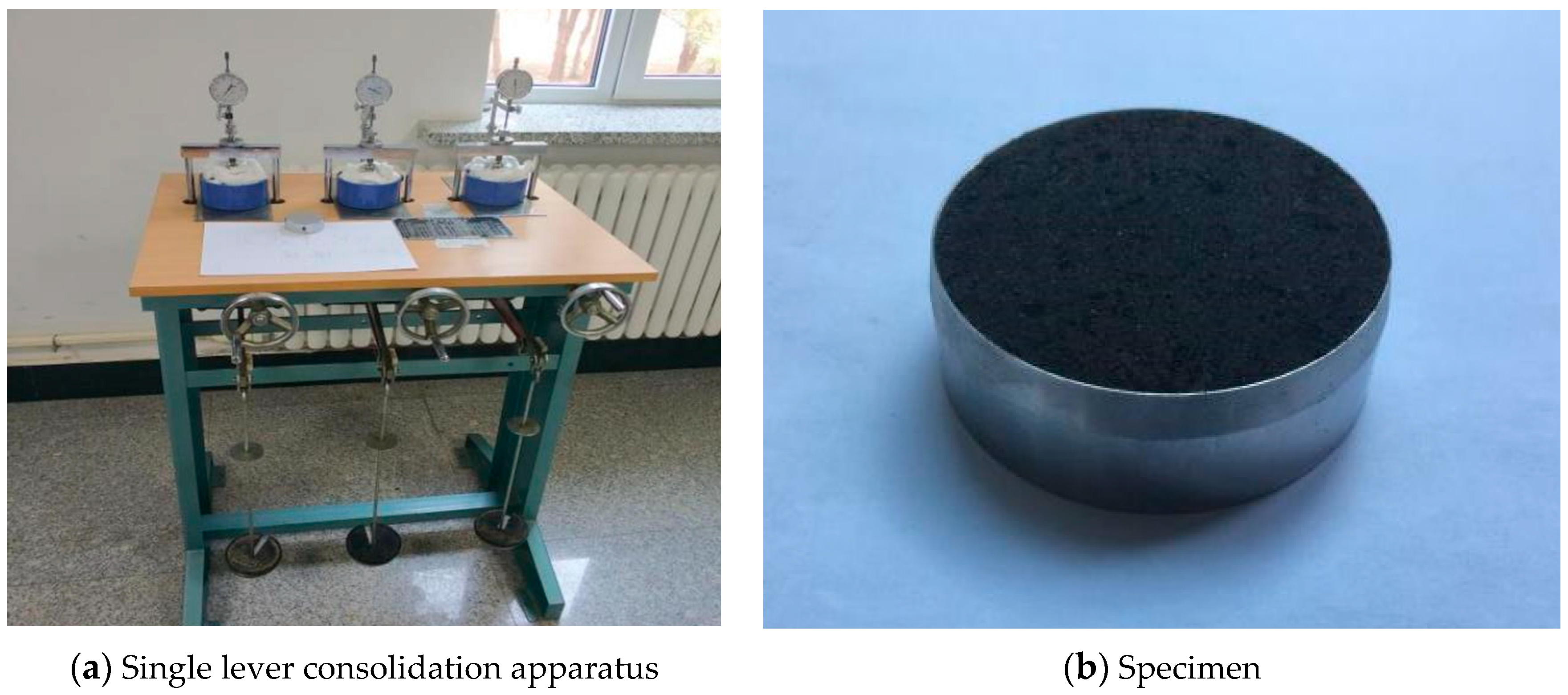

2.4. Test Scheme

- Sample installation. The sample is loaded into the protective ring and placed on the pervious stone. The top surface of the sample is placed on the pervious stone and the pressure transmission plate and placed in the middle of the pressure frame. Directions are as follows. Turn the hand wheel clockwise until the lever reaches the top, then turn it counterclockwise 1 or 2 times. Make the pressure head face to face with the pressure plate and adjust the screws on the beam so that the container can be freely taken and put. Before starting the test, apply a 1 kPa preload (25.5 g) and adjust the dial gauge to zero. After preloading, the load can be applied step by step.

- Loading scheme. The loading method adopted in this paper is hierarchical loading, and the instrument leverage ratio is 1:12. The loading sequence is 25-50-100-200-400-800 kPa, that is, the loading ratio is 1. During the experiment, wet cotton was used to surround the upper and lower permeable water surfaces to avoid moisture evaporation. The reading time points are 0 s, 15 s, 1 min, 2 min, 4 min, 6 min, 9 min, 12 min, 16 min, 20 min, 25 min, 35 min, 45 min, 60 min, 90 min, 2 h, 4 h, 10 h, 23 h, 24 h at the beginning of the test. The data were then recorded every 24 h. When the deformation of the specimen is less than 0.005 mm/d, that is, the deformation in two days is less than 0.01 mm, it can be considered that the deformation is stable, and the next level of load can be applied.

- Test data processing and analysis.

3. Results and Discussion

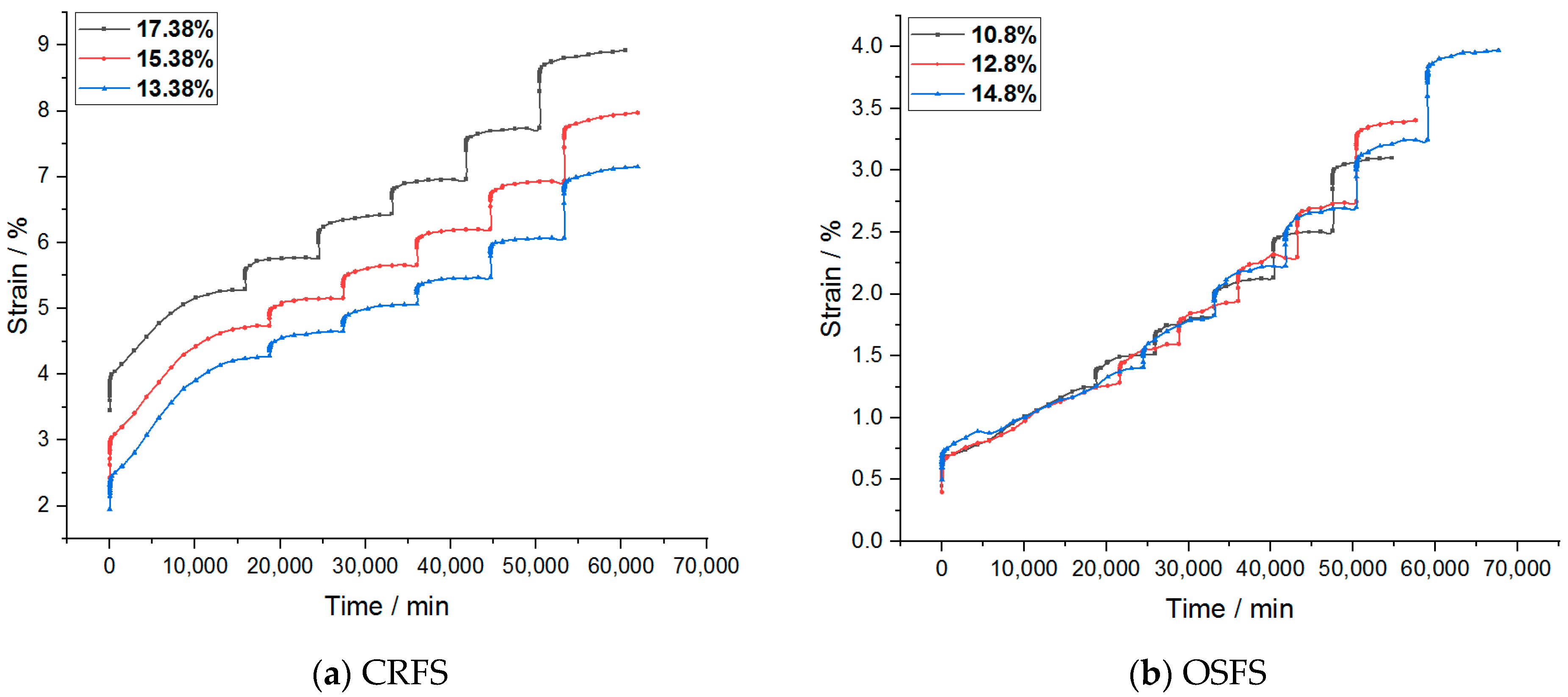

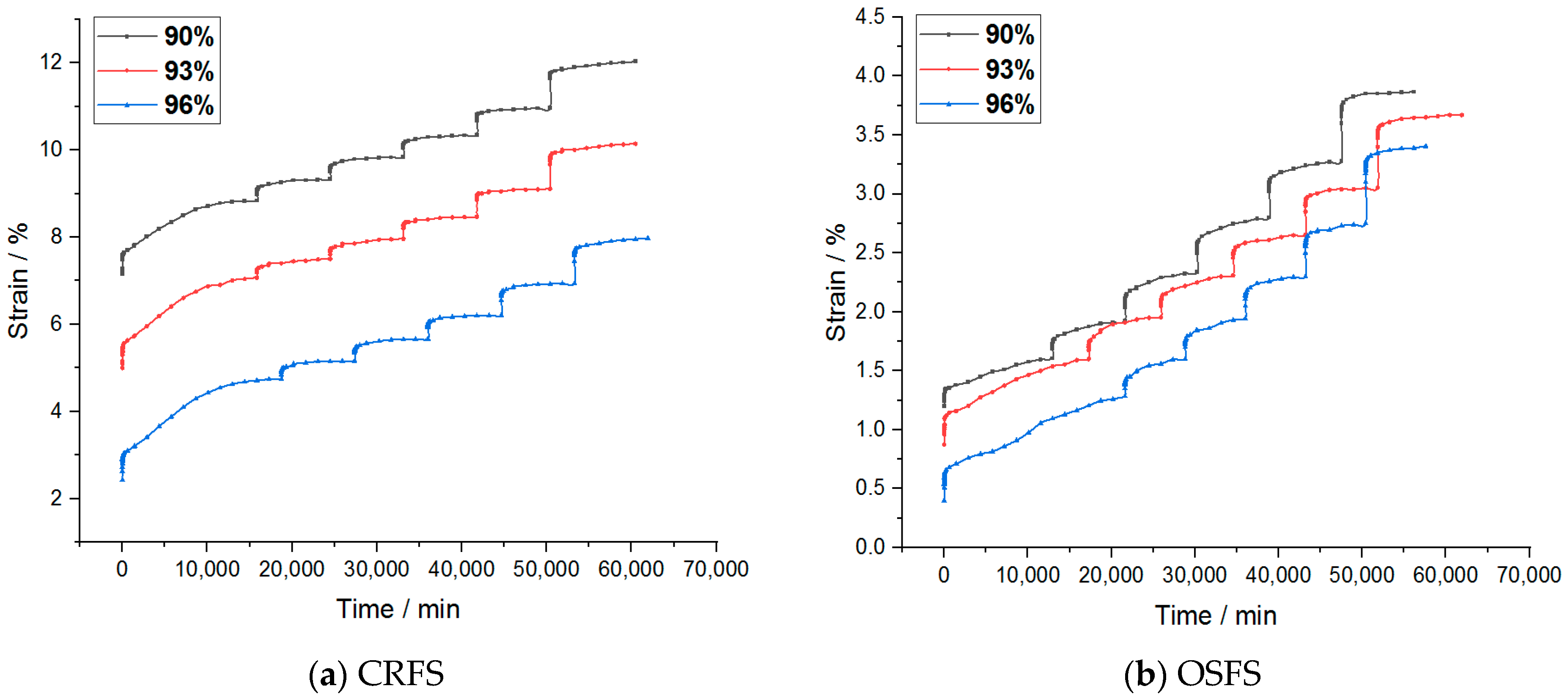

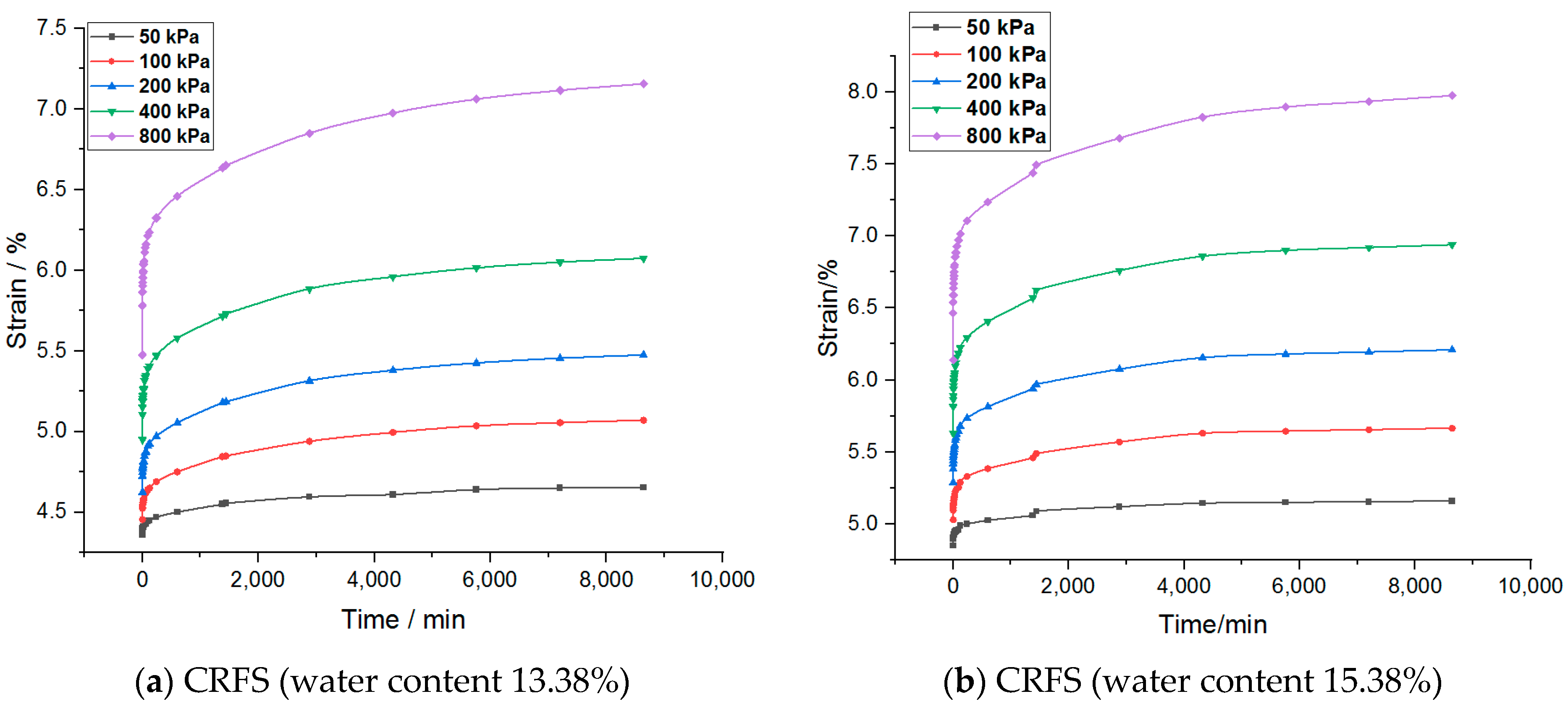

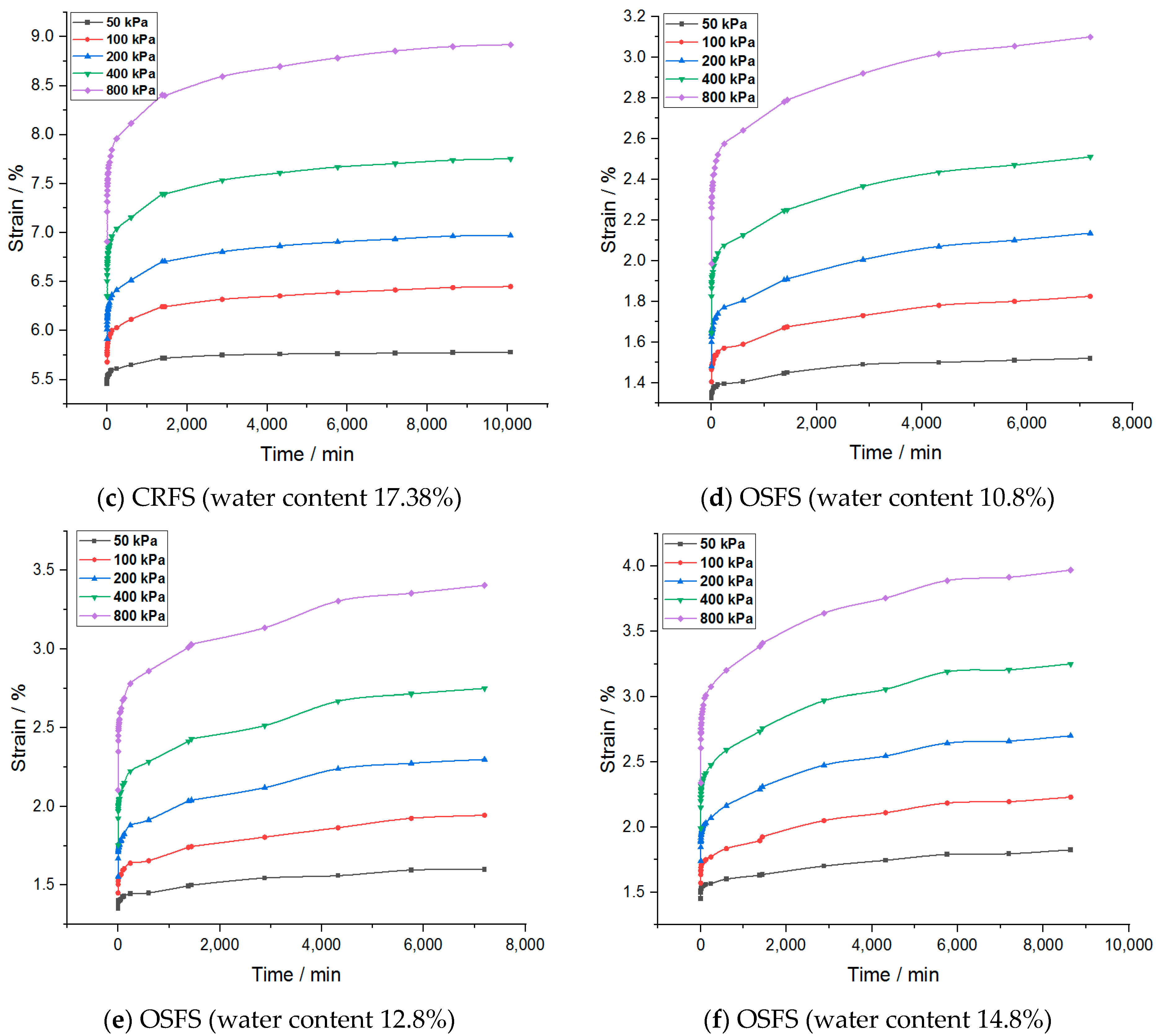

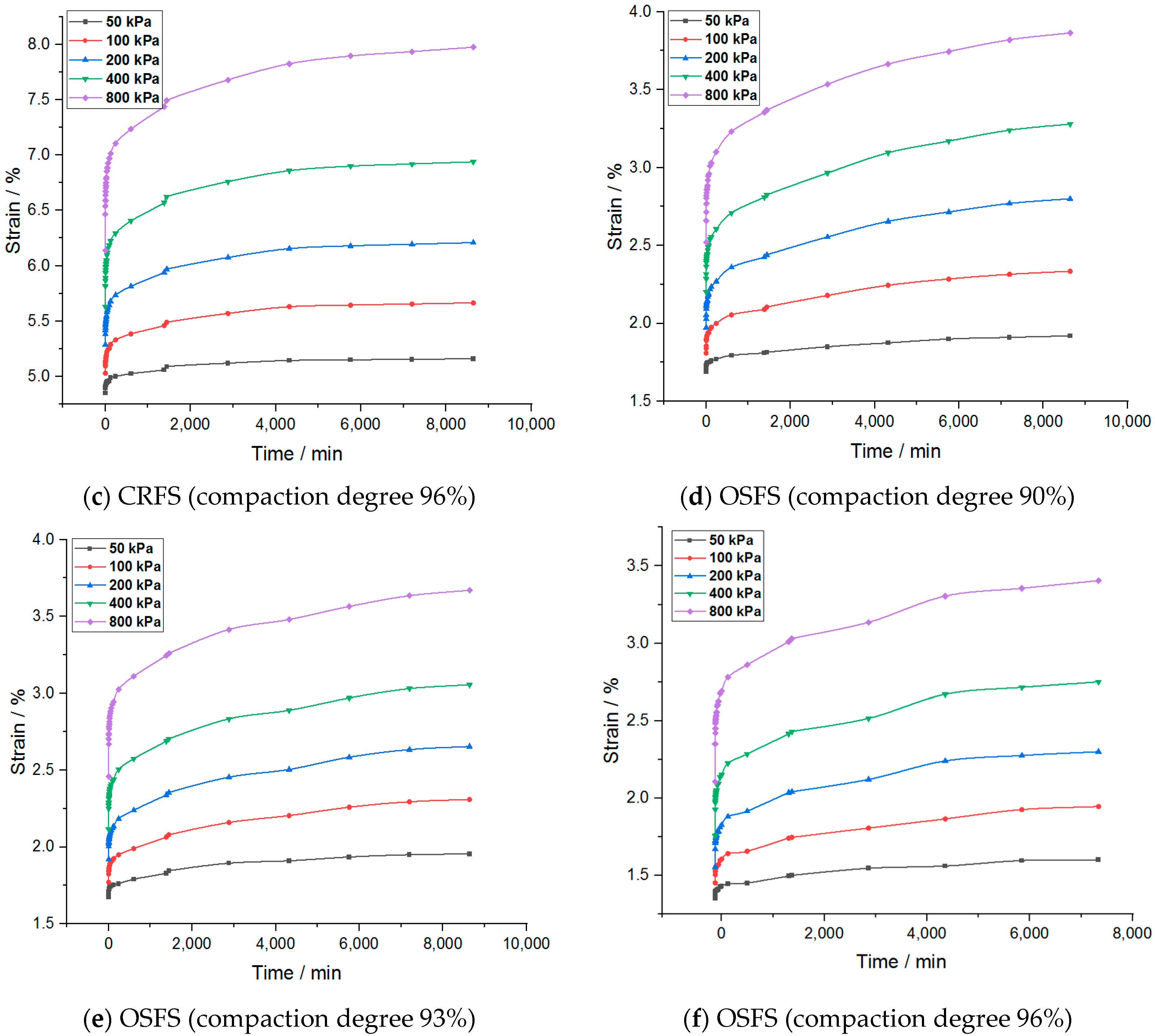

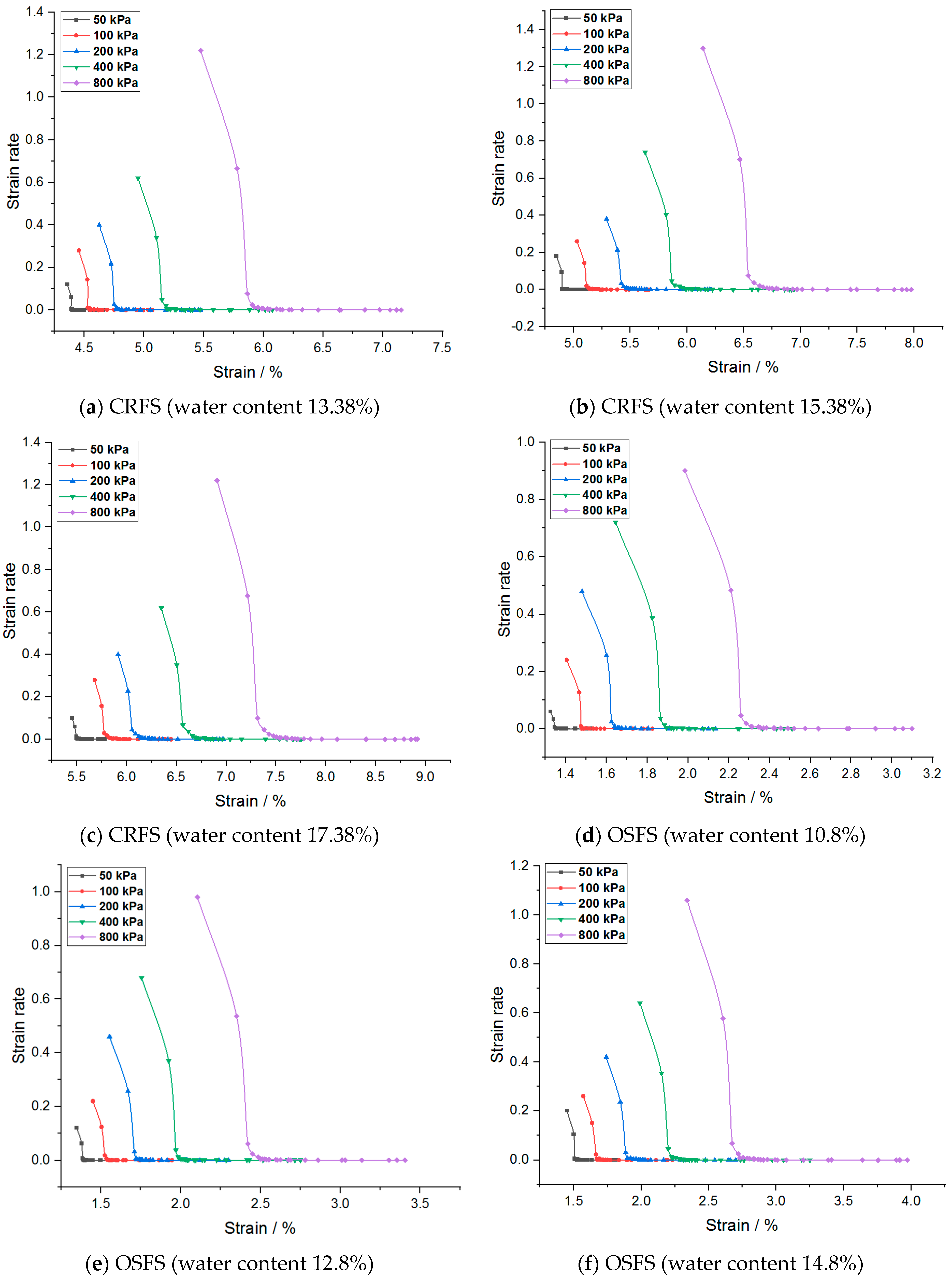

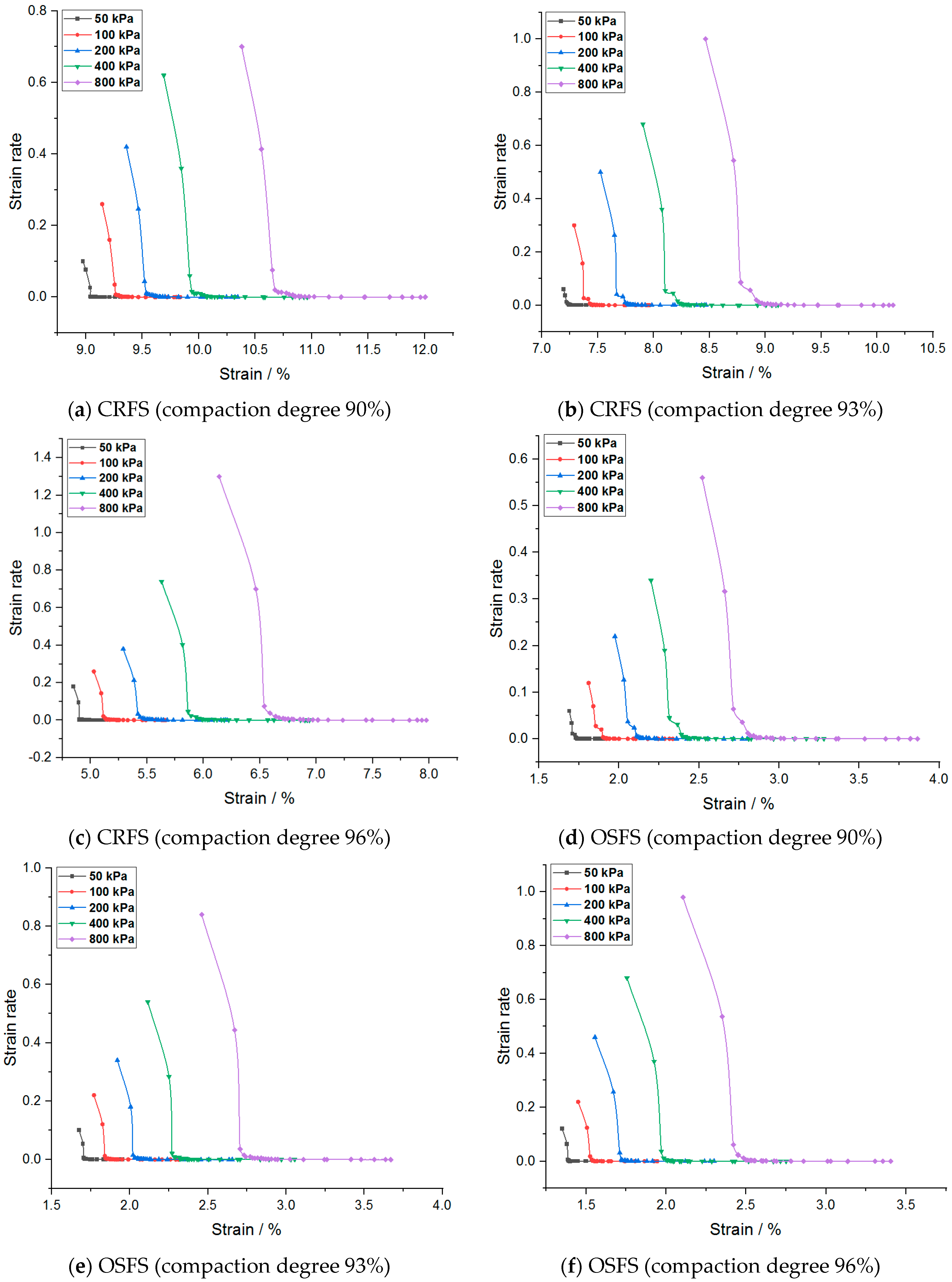

3.1. Strain–Time Curve Analysis

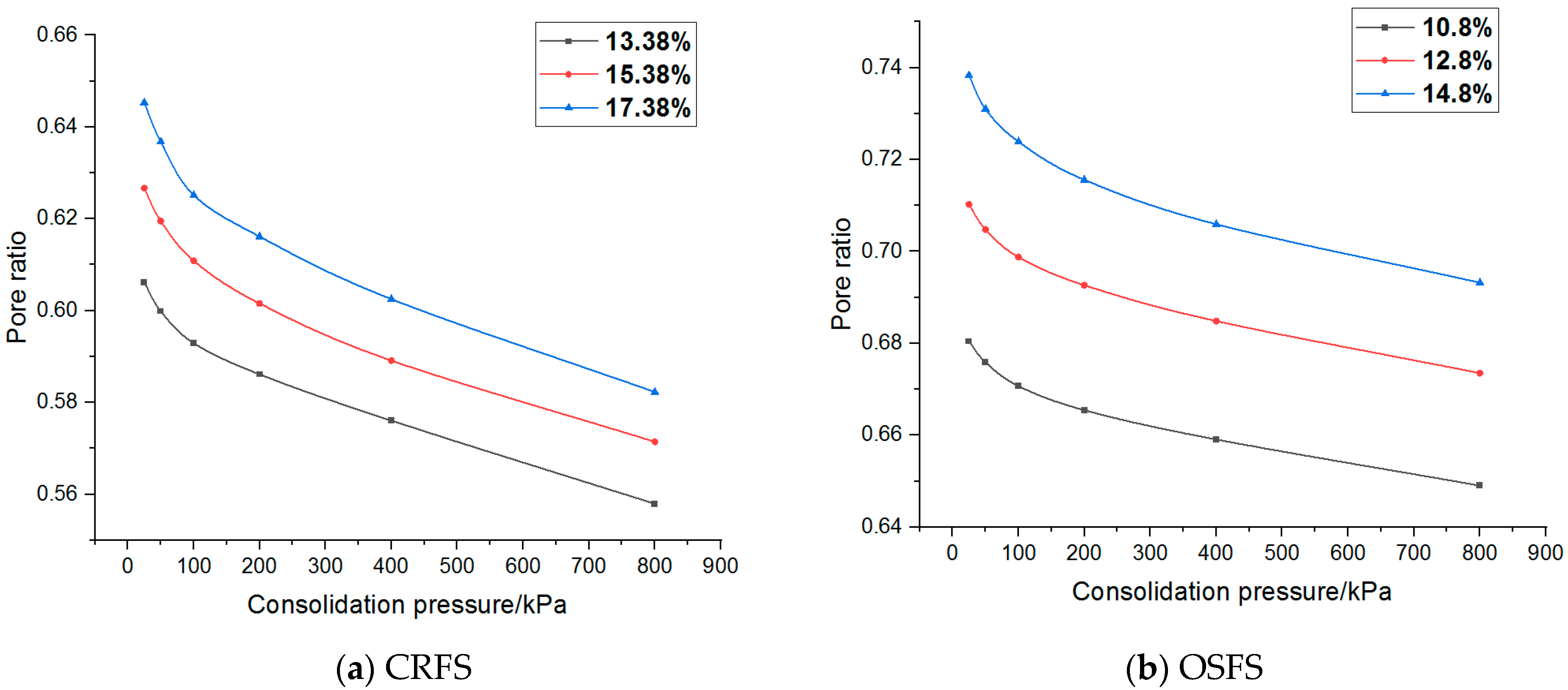

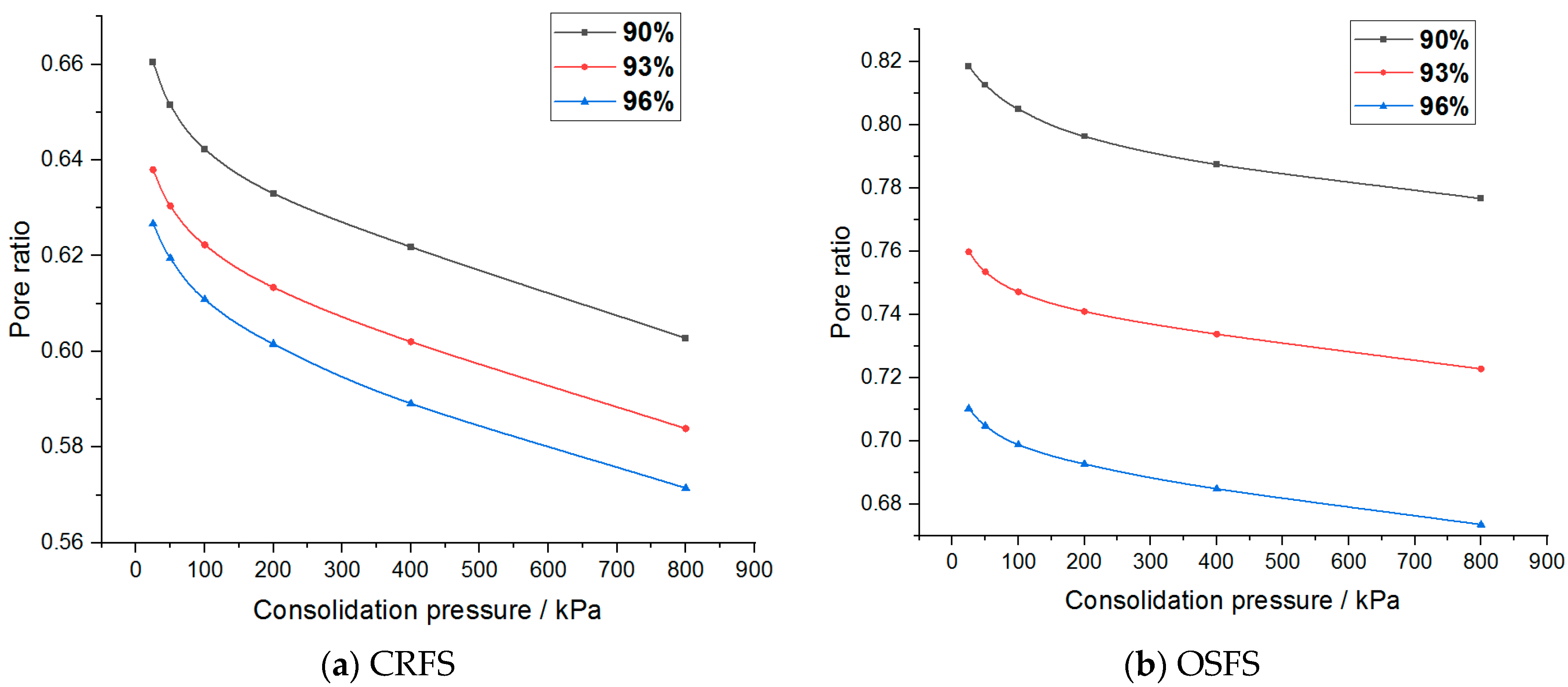

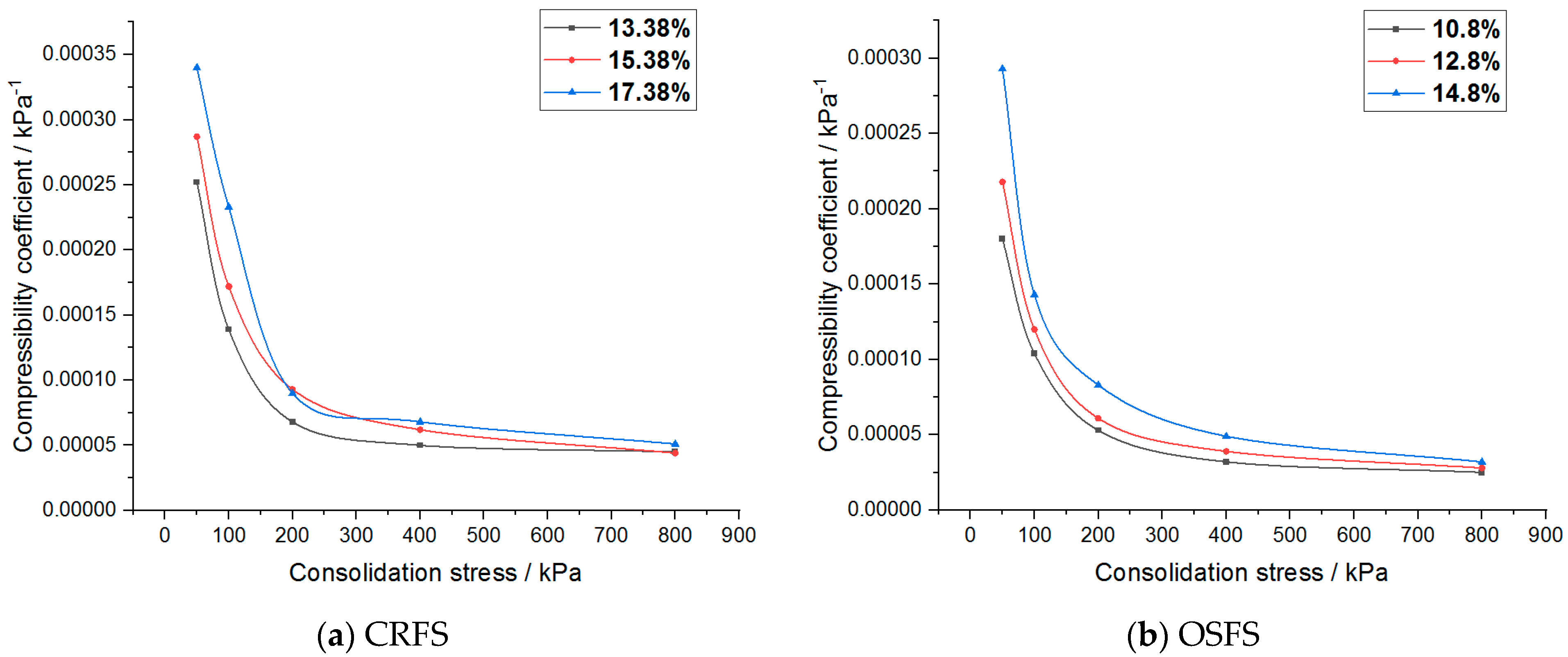

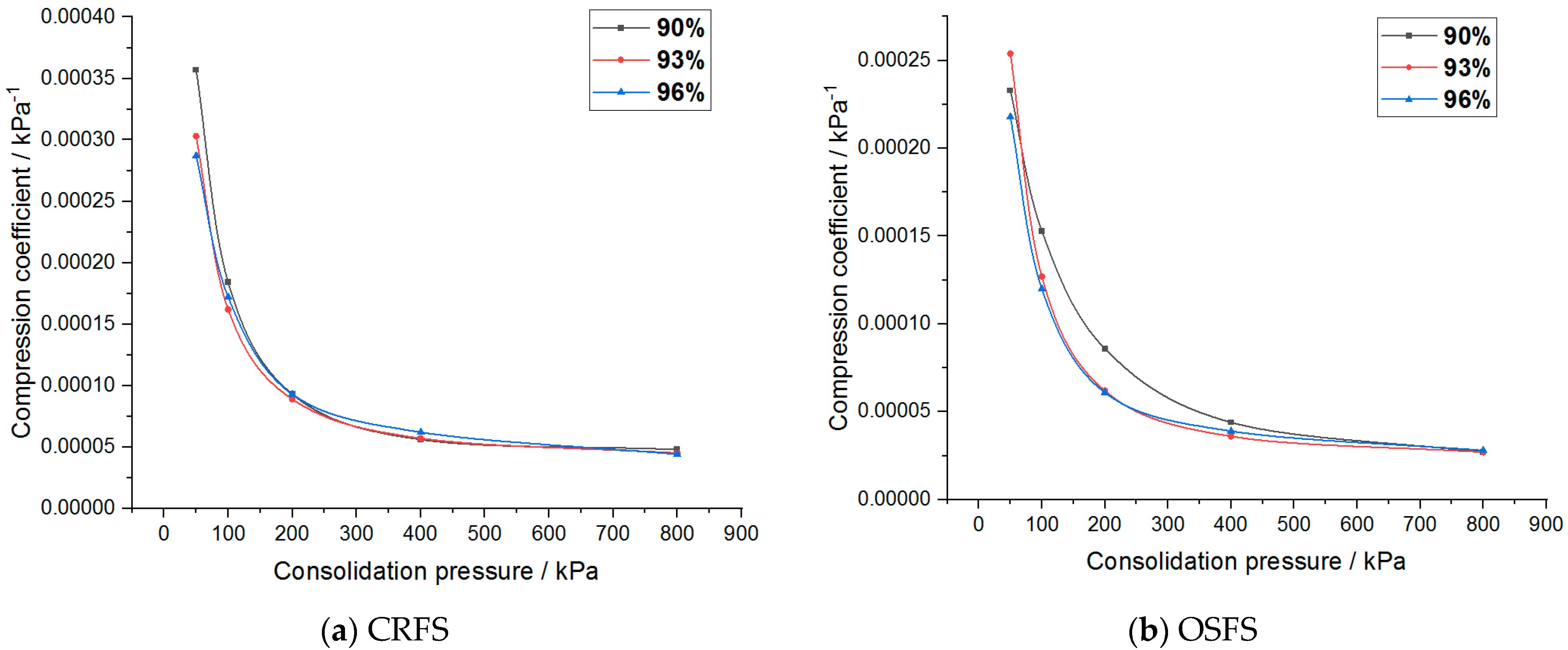

3.2. Analysis of Pore Ratio–Stress Curve

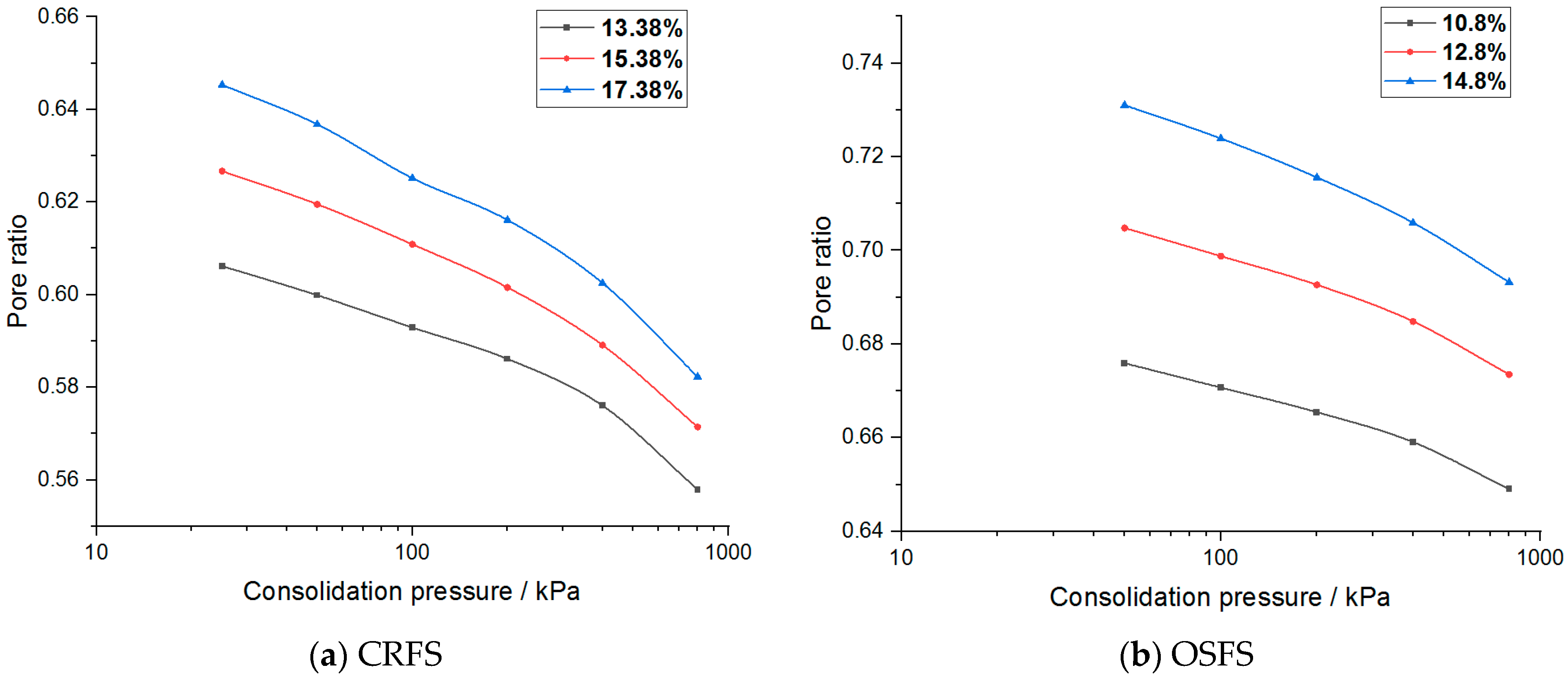

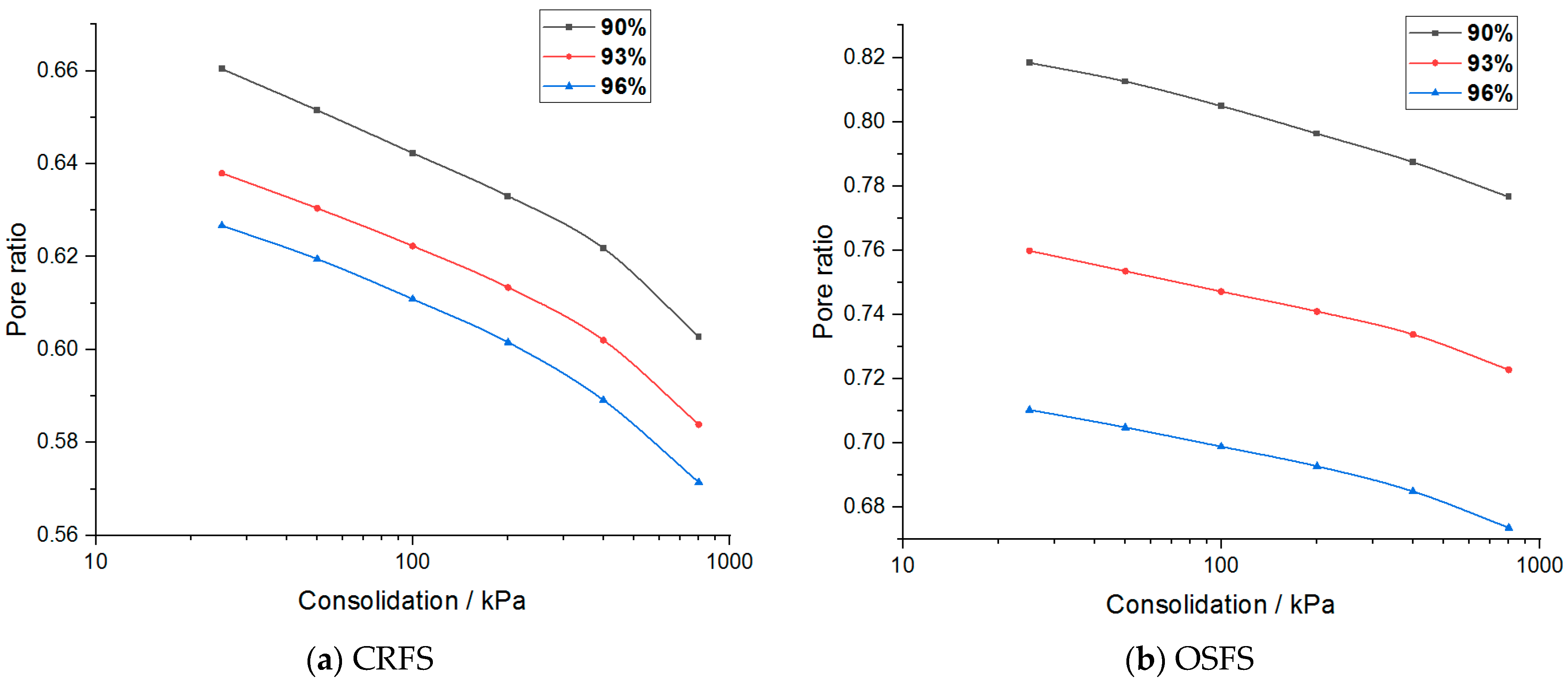

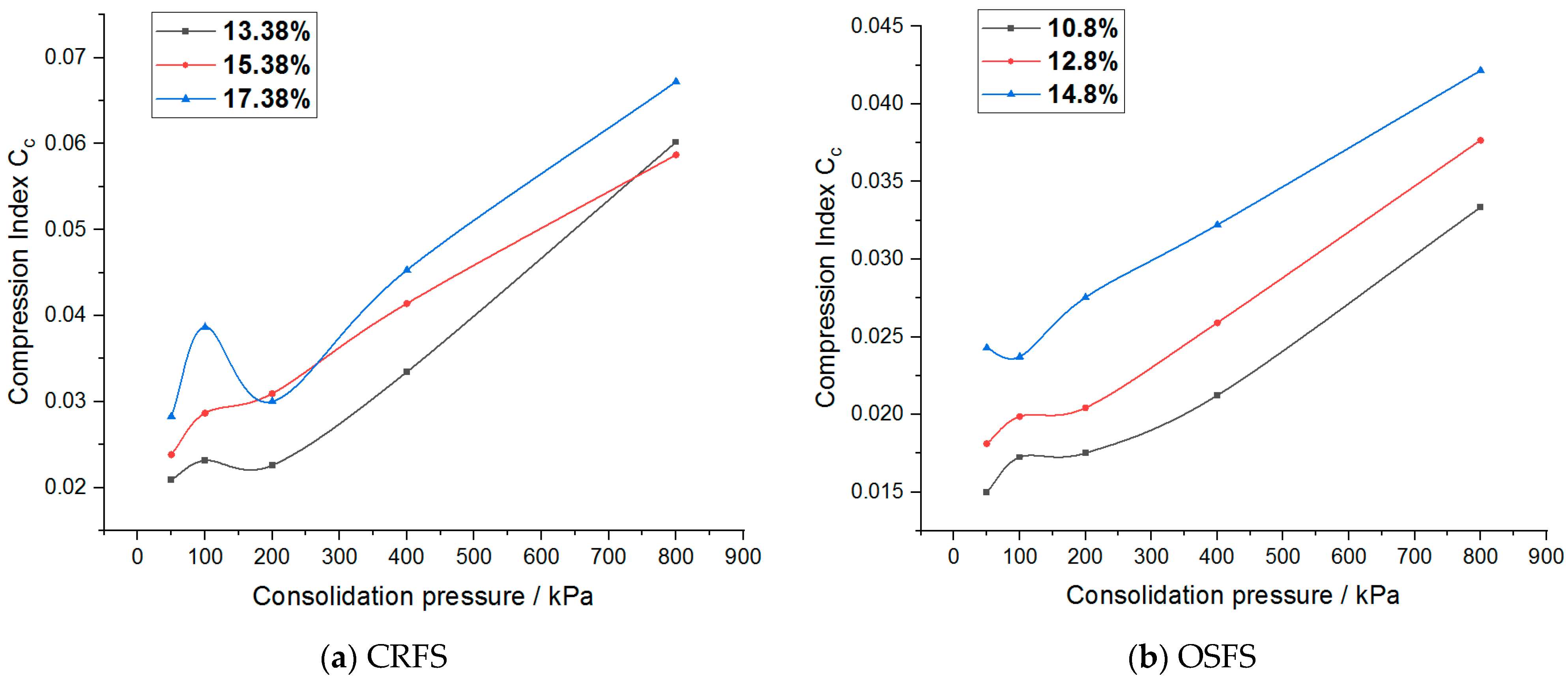

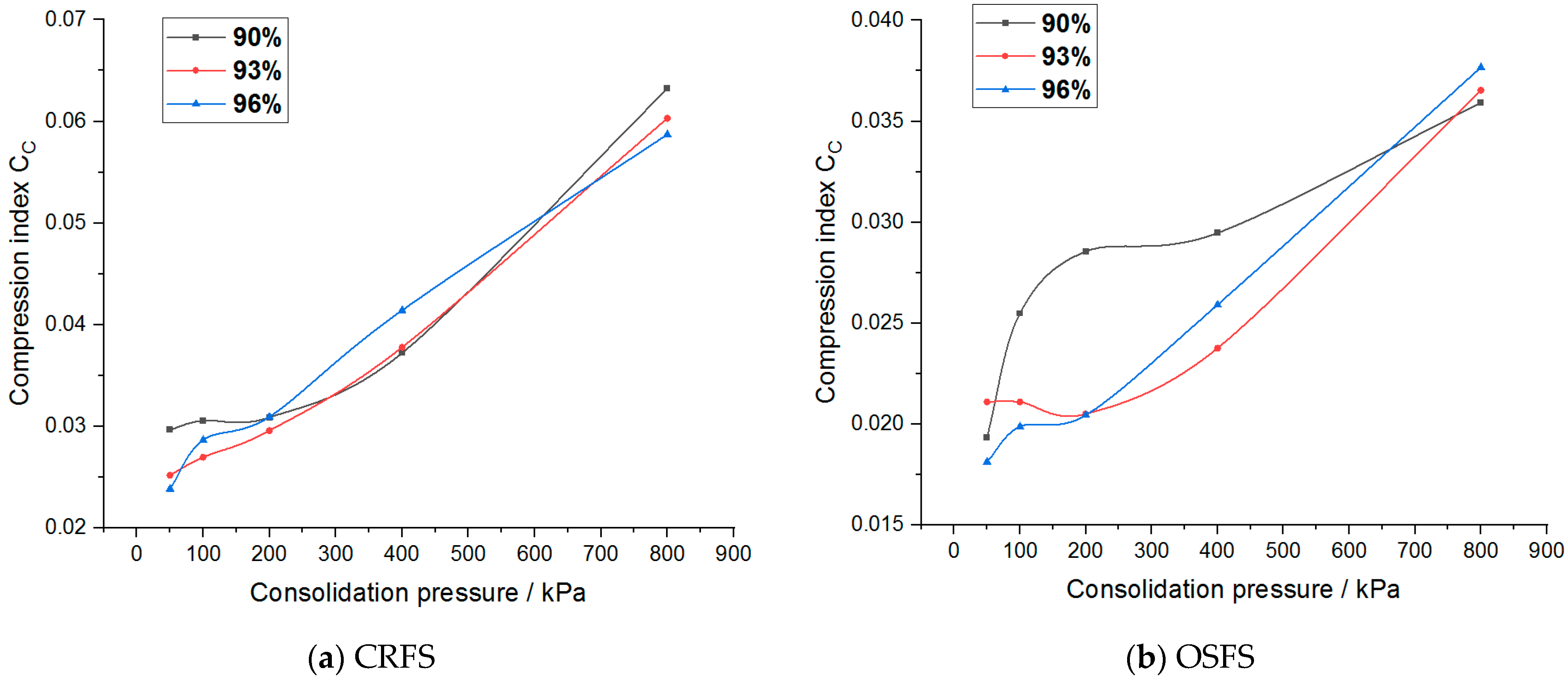

3.3. Pore Ratio–Stress Logarithmic Curve Analysis

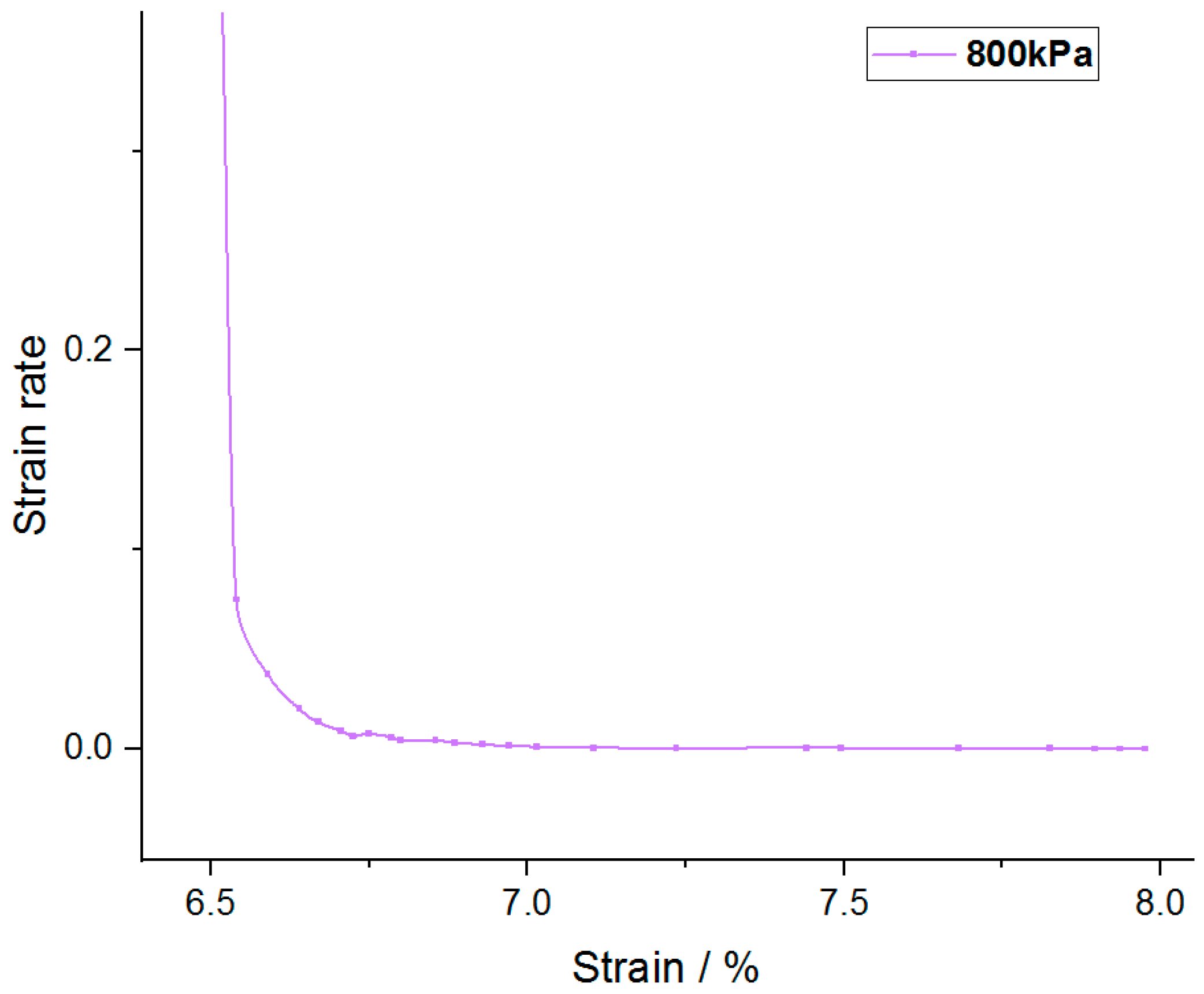

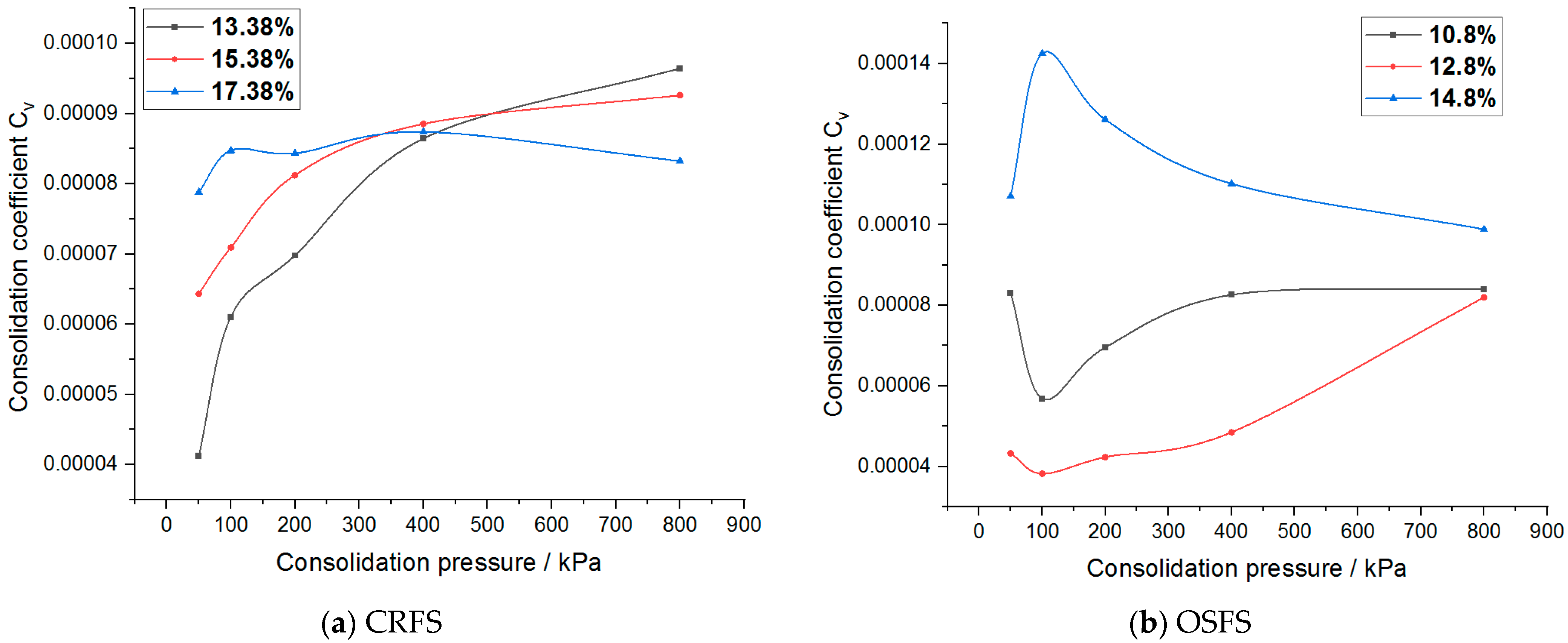

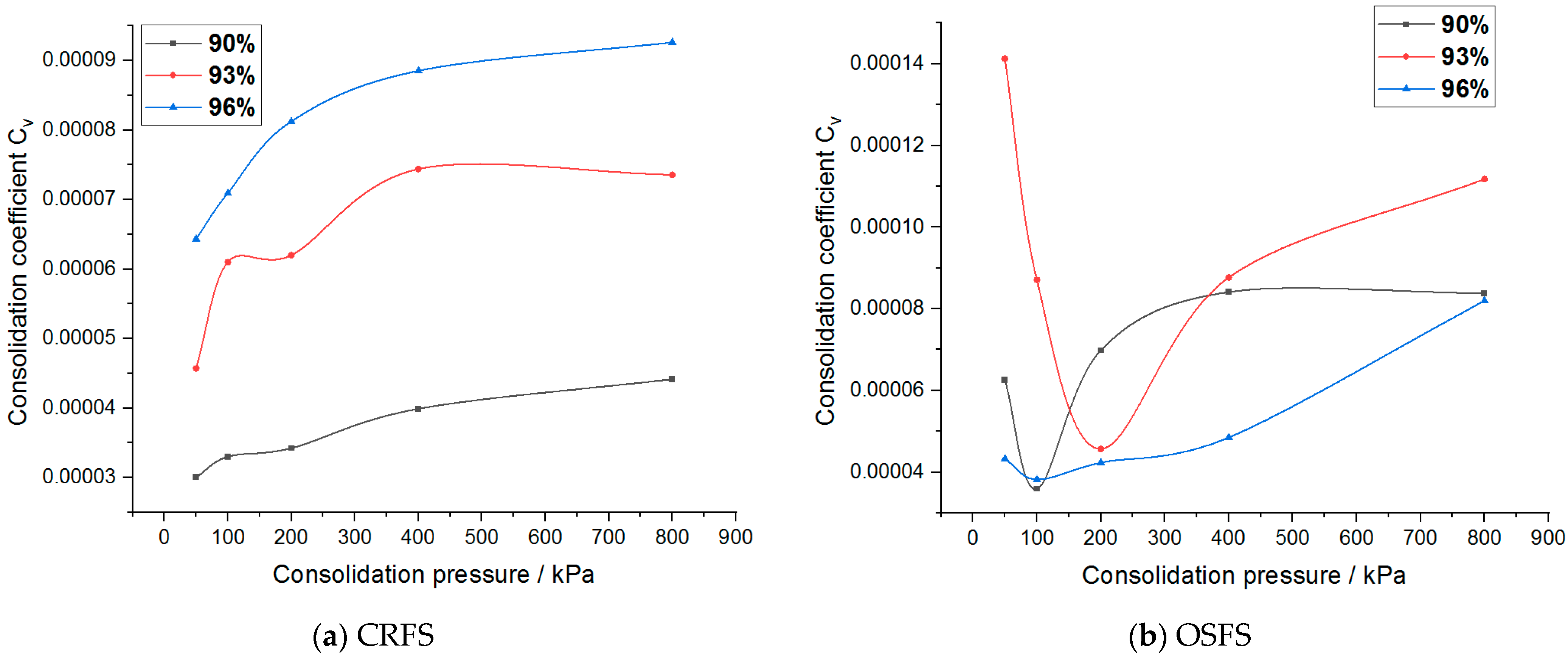

3.4. Data of Dial Indicator–Time Square Root Curve Analysis

4. Conclusions

- The higher the water content and the lower the compaction degree, the greater the creep deformation of the modified soil. The creep deformation of OSFS is relatively small, which is about 40% of that of CRFS, and it is also less affected by water content and compaction degree;

- The secondary consolidation coefficient of the two modified soils increases with the increase of water content, decreases with the increase of compaction degree, and increases in attenuation with the increase of consolidation pressure. The secondary consolidation coefficient of OSFS is slightly larger, which is about 1.2 times that of CRFS;

- The compressibility coefficient of the two modified soils increases with the increase of water content, decreases with the increase of compaction degree, decreases exponentially with the increase of consolidation pressure, and finally tends to a constant value. The compressibility coefficient of OSFS is about 73% of that of CRFS;

- The consolidation coefficient of CRFS increases with the increase of compaction degree, while the consolidation coefficient of OSFS improves with the increase of compaction degree without an obvious rule.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, X.; Wang, J.; Zhang, L. Physics of Frozen Soil, 2nd ed.; Science Press: Beijing, China, 2010; pp. 1–2. [Google Scholar]

- Wang, S.J.; Chen, Z.G.; Qin, W.J.; Yu, L.M. Mechanism analysis on subgrade frost heaving in seasonal frozen region. J. Highw. Transp. Res. Dev. 2013, 7, 28–33. [Google Scholar]

- Xu, J. Study on Solutions of Subgrade Disease of Expressway and Establishment of PMS System. Ph.D. Thesis, Jilin University, Jilin, China, 2010. [Google Scholar]

- Wang, F.; Ping, X.; Zhou, J.; Kang, T. Effects of crumb rubber on the frost resistance of cement-soil. Constr. Build. Mater. 2019, 223, 120–132. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J. Long-term permanent deformation behaviour of recycled concrete aggregate with addition of crumb rubber in base and sub-base applications. Soil Dyn. Earthq. Eng. 2019, 121, 436–441. [Google Scholar] [CrossRef]

- Kang, X.; Ge, L.; Kang, G.C.; Mathews, C. Laboratory investigation of the strength, stiffness, and thermal conductivity of fly ash and lime kiln dust stabilised clay subgrade materials. Road Mater. Pavement. 2015, 16, 928–945. [Google Scholar] [CrossRef]

- Renjith, R.; Robert, D.; Setunge, S.; Costa, S.; Mohajerani, A. Optimization of fly ash based soil stabilization using secondary admixtures for sustainable road construction. J. Clean Prod. 2021, 294, 126264. [Google Scholar] [CrossRef]

- Wei, H.; Li, Z.; Jiao, Y. Effects of Diatomite and SBS on Freeze-Thaw Resistance of Crumb Rubber Modified Asphalt Mixture. Adv. Mater. Sci. Eng. 2017, 2017, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Li, C. Experimental Study on Mechanics Effects of Fly Ash Soil Improved by Rubber Particles under Freeze-Thaw Cycle. Ph.D. Thesis, Jilin University, Jilin, China, 2012. [Google Scholar]

- Cui, J. Research on Stability of Subgrade Soil Modified by Oil Shale Waste Residue and Fly Ash. Master’s Thesis, Jilin University, Jilin, China, 2018. [Google Scholar]

- Wei, H.; Zhang, Y.; Cui, J.; Han, L.; Li, Z. Engineering and environmental evaluation of silty clay modified by waste fly ash and oil shale ash as a road subgrade material. Constr. Build. Mater. 2019, 196, 204–213. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, X. Review of research on creep-consolidation coupling effects in soft soil. J. Jinan. Univ. (Nat. Sci. Med. Ed.) 2004, 3, 315–321. [Google Scholar]

- Ho, L.; Fatahi, B.; Khabbaz, H. Analytical Solution for One-Dimensional Consolidation of Unsaturated Soils using Eigenfunction Expansion Method. Int. J. Numer. Anal. Methods Geomech. 2014, 38, 1058–1077. [Google Scholar] [CrossRef]

- Chen, Z. One dimensional problems of consolidation and secondary time effects. Chin. J. Civil Eng. 1958, 01, 1–10. [Google Scholar]

- Zhou, F.; Wang, L.; Liu, H. A fractional elasto-viscoplastic model for describing creep behavior of soft soil. Acta Geotech. 2021, 16, 67–76. [Google Scholar] [CrossRef]

- Tan, F.; Zhou, W.; Yuen, K.V. Effect of loading duration on uncertainty in creep analysis of clay. Int. J. Numer. Anal. Methods Geomech. 2018, 42, 1235–1254. [Google Scholar] [CrossRef]

- Yu, Z.; Zhao, W.; Gu, J. 3-D FEM analysis of soft viscoelastic/viscoplastic foundation with drainage preloading. J. Hehai Univ. 1995, 5, 1–7. [Google Scholar]

- Wang, L.; Wang, L. Semianalytical analysis of creep and thermal consolidation behaviors in layered saturated clays. Int. J. Geomech. 2020, 20, 06020001. [Google Scholar] [CrossRef]

- Wong, C.K.; Wan, R.G.; Wong, R.C.K. Methodology for estimating creep deformation from consolidation deformation in 1D compression. Int. J. Geomech. 2018, 18, 04018042. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, P.; Lyu, W.; Yu, G.; Yang, C. Study of the backfill confined consolidation law and creep constitutive model under high stress. Geotech. Test. J. 2018, 41, 390–402. [Google Scholar] [CrossRef]

- Yin, J.; Feng, W. A new simplified method and its verification for calculation of consolidation settlement of a clayey soil with creep. Can. Geotech. J. 2017, 54, 333–347. [Google Scholar] [CrossRef] [Green Version]

- Bezvolev, S.G. Precision of the creep coefficient and secondary consolidation of water-saturated viscous soil. Soil. Mech. Found. Eng. 2019, 56, 309–313. [Google Scholar] [CrossRef]

- Rezania, M.; Bagheri, M.; Nezhad, M.M. Creep and consolidation of a stiff clay under saturated and unsaturated conditions. Can. Geotech. J. 2020, 57, 728–741. [Google Scholar] [CrossRef]

- Ran, Q.; Gu, X. A Coupled Model for Land Subsidence Computation with Consideration of Rheological Property. Chin. J. Geol. Hazard Control 1998, 2, 99–103. [Google Scholar]

- Chen, X.; Bai, S. Research on Creep-Consolidation Characteristics and Calculating Model of Soft Soil. Chin. J. Rock Mech. Eng. 2003, 5, 728–734. [Google Scholar]

- Yu, F.; Zhao, W.; Li, R. Creep-consolidation finite element analysis of soft ground settlement and its engineering application. J. Hehai Univ. (Nat. Sci. Ed.) 2006, 2, 180–184. [Google Scholar]

- Tang, B.; Wang, L. Model of coupled behaviors of consolidation and creep of soft clay. J. Wuhan Univ. Sci. Technol. 2009, 32, 94–97. [Google Scholar] [CrossRef]

- Sun, M.; Wang, Q.; Niu, C.; Sun, T. Consolidation and creep theory based on terzaghi consolidation theory and empirical creep model. J. Northeast. Univ. (Nat. Sci. Ed.) 2016, 37, 1188–1192. [Google Scholar]

- Liu, X.; Wu, W.; Wang, J.; Cao, P.; Zhou, J. Creep analysis of composite soil in clay dam foundation based on consolidation effect. Water Power 2019, 45, 51–54. [Google Scholar]

- Jia, J.; Wang, Y.; Leng, Y. Unloading creep characteristics of frozen clay subjected to long-term high-pressure K0 consolidation before freezing. Adv. Civ. Eng. 2019, 2019, 7192845. [Google Scholar] [CrossRef] [Green Version]

- Ghezal, A.F.; Assaf, G. Time-dependent behavior of self-consolidating concrete loaded at early age: Influence of chemical admixtures. J. Mater. Civil. Eng. 2016, 28, 04015066. [Google Scholar] [CrossRef]

- Kamoun, J.; Bouassida, M. Creep behavior of unsaturated cohesive soils subjected to various stress levels. Arab. J. Geosci. 2018, 11, 1–7. [Google Scholar] [CrossRef]

- Jarad, N.; Cuisinier, O.; Masrouri, F. Effect of temperature and strain rate on the consolidation behaviour of compacted clayey soils. Eur. J. Environ. Civ. Eng. 2019, 23, 789–806. [Google Scholar] [CrossRef]

- Ghio, A.P.; Carlos, O.; Antonio, B. Compressibility and creep of a diatomaceous soil. Eng. Geol. 2019, 258, 105145. [Google Scholar]

- Rezania, M.; Nezhad, M.M.; Zanganeh, H.; Castro, J.; Sivasithamparam, N. Modeling pile setup in natural clay deposit considering soil anisotropy, structure, and creep effects: Case study. Int. J. Geomech. 2017, 17, 04016075. [Google Scholar] [CrossRef] [Green Version]

- Ter-Martirosyan, Z.G.; Bakhmisov, V.V. To the question of concrete creep in the soil environment. Vestnik MGSU 2020, 15, 1285–1296. [Google Scholar] [CrossRef]

- Wang, S.; Luo, Y.; Yang, J. Experimental study on creep consolidation behavior of intact loess. Hydrogeol. Eng. Geol. 2009, 36, 72–75. [Google Scholar]

- Zhang, X.; Wang, C.; Li, J. Experimental study of coupling behaviors of consolidation-creep of soft clay and its mechanism. Rock Soil Mech. 2011, 32, 3584–3590. [Google Scholar]

- Li, C.; Liu, H.; Wei, H. Experimental research on dynamic characteristics of fly ash soil improved by rubber particles. Rock Soil Mech 2011, 32, 2025–2028. [Google Scholar]

- (JTG D30-2015). Design of Highway Subgrades; Renmin Communication Press: Beijing, China, 2015. [Google Scholar]

- (JTG E40-2007). Test. Methods of Soils for Highway Engineering; Renmin Communication Press: Beijing, China, 2007. [Google Scholar]

| Index | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index | Optimum Moisture Content (%) | Maximum Dry Density (g/cm3) |

|---|---|---|---|---|---|

| CRFS | 38.3 | 24.9 | 13.4 | 15.38 | 1.73 |

| OSFS | 39.4 | 26.9 | 12.5 | 12.8 | 1.67 |

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | TiO2 | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|---|

| Oil Shale Residue | 56.28 | 13.44 | 7.22 | 6.42 | 2.49 | 2.31 | 1.84 | 0.59 | 8.56 |

| Fly Ash | 63.55 | 22.00 | 3.09 | 0.92 | 1.08 | 0.75 | 3.08 | 1.10 | 3.19 |

| Silty Clay | 68.76 | 14.53 | 4.13 | 1.25 | 1.32 | 1.99 | 3.07 | 0.73 | 3.56 |

| Modified Soil | Control Indicators | |

|---|---|---|

| Moisture Content | Dry Density | |

| CRFS | 13.38% | 1.6608 g/cm3 |

| 15.38% | 1.6608 g/cm3 | |

| 17.38% | 1.6608 g/cm3 | |

| 15.38% | 1.5570 g/cm3 | |

| 15.38% | 1.6089 g/cm3 | |

| OSFS | 10.80% | 1.5984 g/cm3 |

| 12.80% | 1.5984 g/cm3 | |

| 14.80% | 1.5984 g/cm3 | |

| 12.80% | 1.4985 g/cm3 | |

| 12.80% | 1.5484 g/cm3 | |

| Consolidation Pressure | CRFS | OSFS | ||||

|---|---|---|---|---|---|---|

| 13.38% | 15.38% | 17.38% | 10.8% | 12.8% | 14.8% | |

| 50 kPa | 0.00186 | 0.00175 | 0.00174 | 0.00157 | 0.00246 | 0.00366 |

| 100 kPa | 0.00382 | 0.00367 | 0.00421 | 0.00312 | 0.00468 | 0.00649 |

| 200 kPa | 0.00504 | 0.00513 | 0.00573 | 0.00448 | 0.00638 | 0.00855 |

| 400 kPa | 0.00609 | 0.0069 | 0.00744 | 0.00531 | 0.00772 | 0.01069 |

| 800 kPa | 0.00823 | 0.00901 | 0.00999 | 0.00641 | 0.00898 | 0.01231 |

| Consolidation Pressure | CRFS | OSFS | ||||

|---|---|---|---|---|---|---|

| 90% | 93% | 96% | 90% | 93% | 96% | |

| 50 kPa | 0.00239 | 0.00217 | 0.00175 | 0.00218 | 0.00266 | 0.00246 |

| 100 kPa | 0.00465 | 0.00448 | 0.00367 | 0.00486 | 0.00512 | 0.00468 |

| 200 kPa | 0.00659 | 0.00595 | 0.00513 | 0.00755 | 0.00657 | 0.00638 |

| 400 kPa | 0.00806 | 0.00723 | 0.0069 | 0.00964 | 0.00761 | 0.00772 |

| 800 kPa | 0.01064 | 0.00962 | 0.00901 | 0.01064 | 0.00882 | 0.00898 |

| Modified Soil | CRFS | OSFS | ||||

|---|---|---|---|---|---|---|

| Water Content | 13.38% | 15.38% | 17.38% | 10.8% | 12.8% | 14.8% |

| Consolidated Yield Stresses | 191 | 173 | 180 | 171 | 168 | 155 |

| Modified Soil | CRFS | OSFS | ||||

|---|---|---|---|---|---|---|

| Compaction Degrees | 90% | 93% | 96% | 90% | 93% | 96% |

| Consolidated Yield Stresses | 179 | 177 | 173 | 123 | 149 | 168 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Pang, W.; Li, Z.; Wei, H.; Han, L. Experimental Study on Consolidation-Creep Behavior of Subgrade Modified Soil in Seasonally Frozen Areas. Materials 2021, 14, 5138. https://doi.org/10.3390/ma14185138

Wang F, Pang W, Li Z, Wei H, Han L. Experimental Study on Consolidation-Creep Behavior of Subgrade Modified Soil in Seasonally Frozen Areas. Materials. 2021; 14(18):5138. https://doi.org/10.3390/ma14185138

Chicago/Turabian StyleWang, Fuyu, Weichen Pang, Ziqi Li, Haibin Wei, and Leilei Han. 2021. "Experimental Study on Consolidation-Creep Behavior of Subgrade Modified Soil in Seasonally Frozen Areas" Materials 14, no. 18: 5138. https://doi.org/10.3390/ma14185138

APA StyleWang, F., Pang, W., Li, Z., Wei, H., & Han, L. (2021). Experimental Study on Consolidation-Creep Behavior of Subgrade Modified Soil in Seasonally Frozen Areas. Materials, 14(18), 5138. https://doi.org/10.3390/ma14185138