The Use of Modal Analysis in Addition Percentage Differentiation, and Mechanical Properties of Ordinary Concretes with the Addition of Fly Ash from Sewage Sludge

Abstract

:1. Introduction

2. Materials and Methods

2.1. Types of Modal Analysis

- -

- Enables the analysis of large-sized objects for which laboratory tests are difficult;

- -

- Models objects more correctly because the inputs correspond to real loads;

- -

- Enables the identification of nonlinear models.

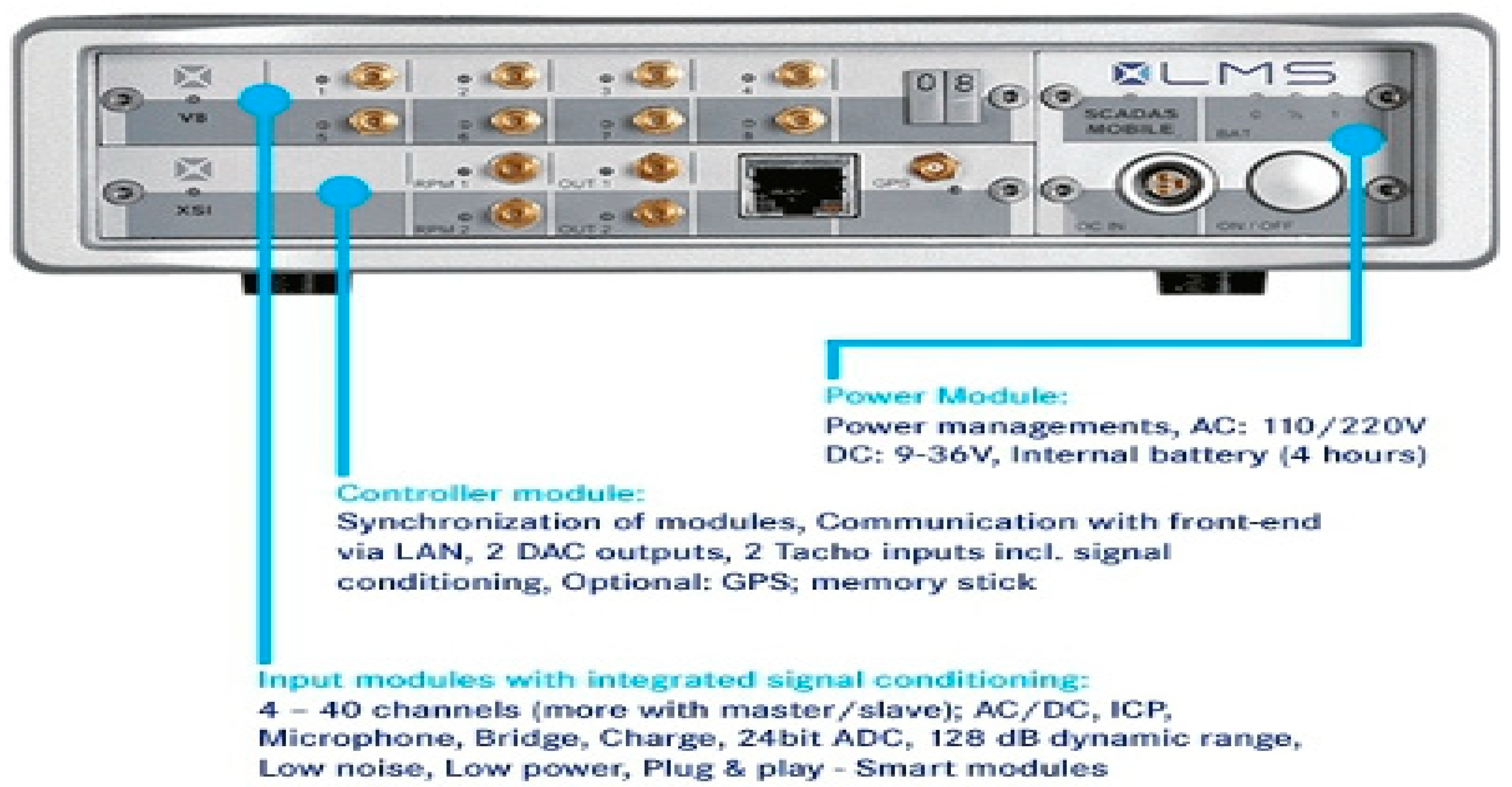

2.2. Measurement Systems

3. Results and Discussion

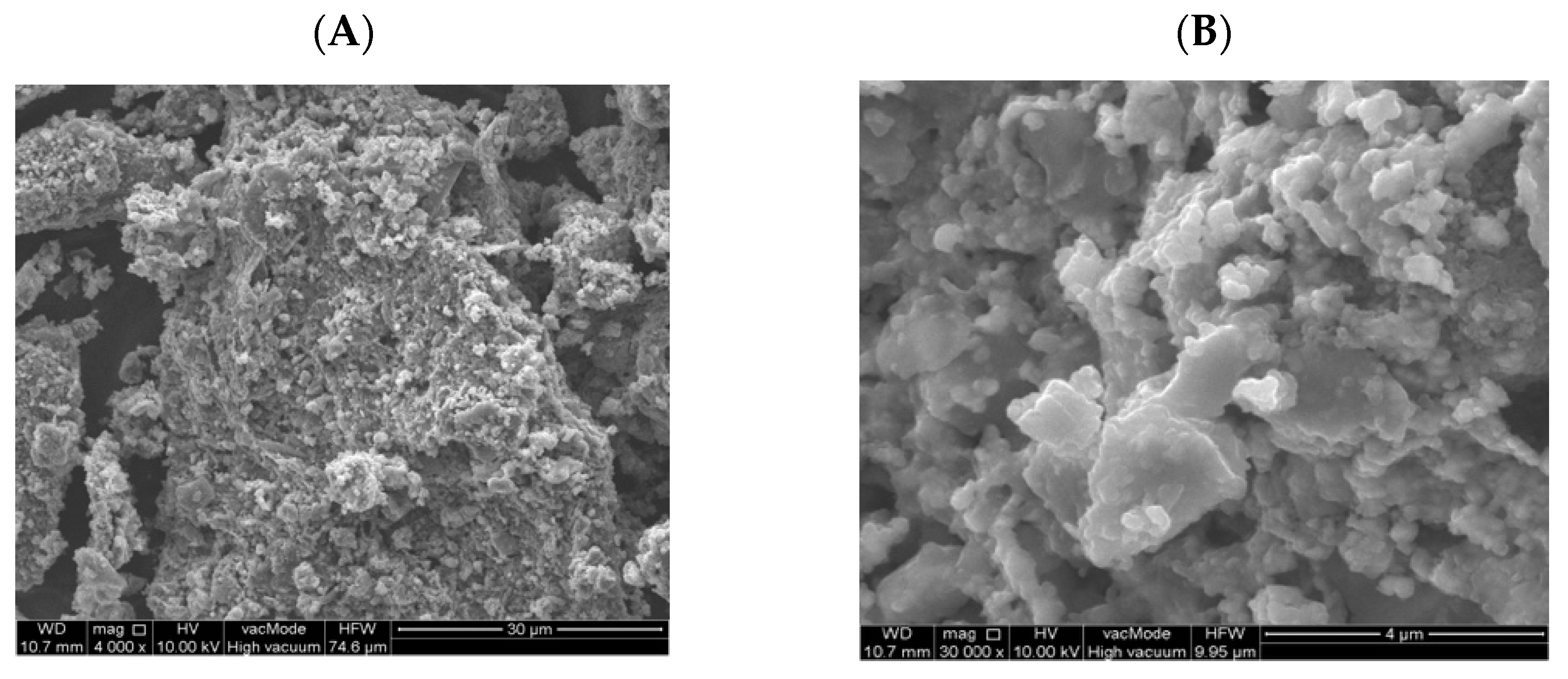

3.1. Properties of the Fly Ash

3.2. Properties of the Concrete Mix

3.3. Compressive Strength

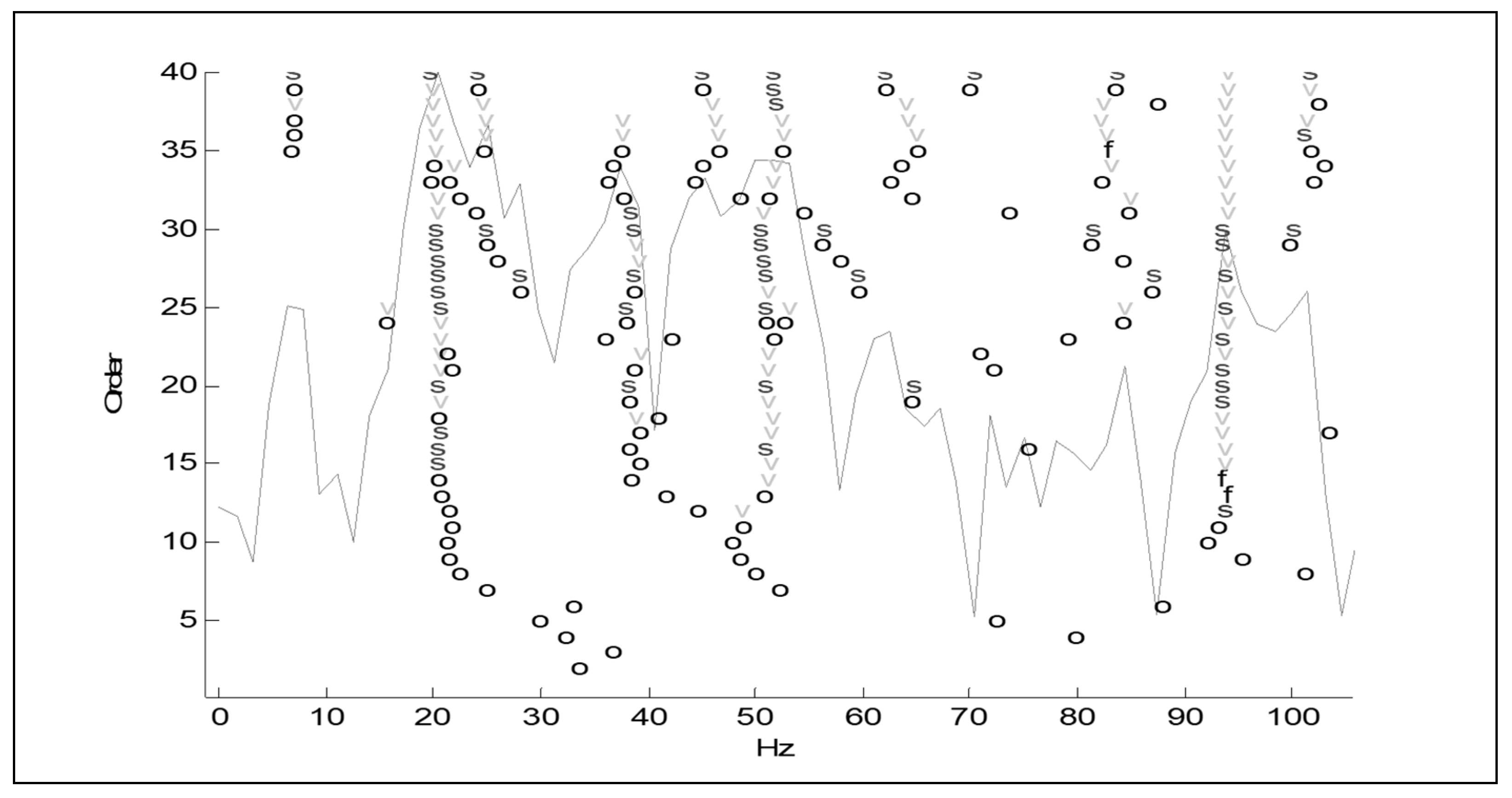

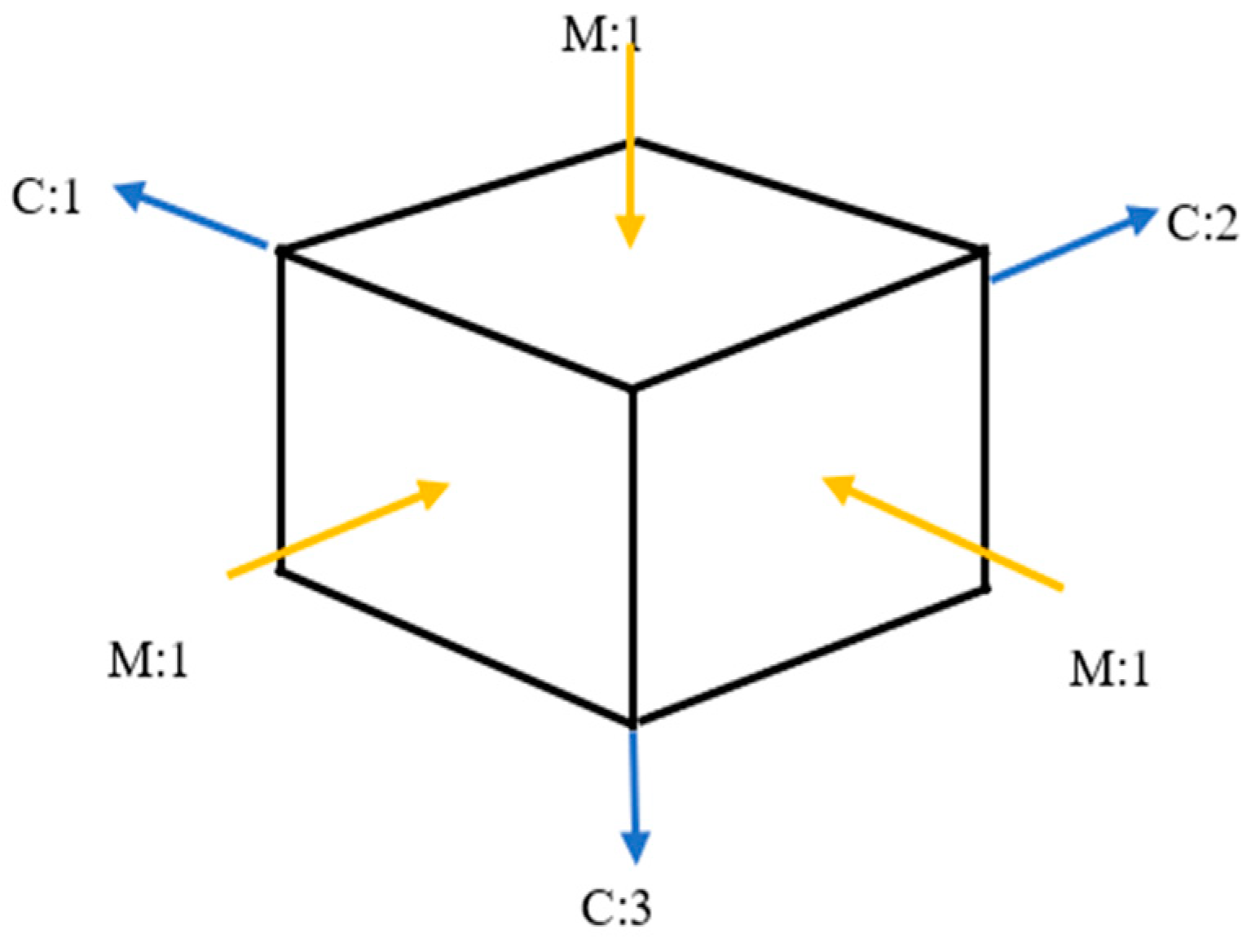

3.4. Modal Analysis Results of Ordinary Concretes with the Addition of Fly Ash from Sewage Sludge

4. Conclusions

- There is no typical quality and typical composition of municipal wastewater supplied to the treatment plant; thus, there is no typical physico-chemical composition formed during the thermal treatment of sewage sludge—fly ash;

- Waste-generated fly ash from the thermal transformation of sewage sludge used to produce concrete has a positive effect on its compressive strength;

- Fly ash from the thermal transformation of sewage sludge does not meet the requirements of PN-EN 450-1: 2012. It has a different physico-chemical composition compared to the fly ash from coal combustion used in concrete technology. The highest percentage of the collected fly ash samples were oxides of silicon, calcium, phosphorus, and aluminum;

- Concrete containing fly ash from the incineration of sewage sludge in its composition was characterized by a compressive strength comparable to that of the reference concrete without the additive. With an ash content up to 20%, they can be used as a cement substitute. The average compressive strength of concrete containing 20% fly ash from the thermal transformation of sewage sludge was after 28, 56, and 365 days of maturation was 50.1 MPa, 50.8 MPa, and 61.9 MPa, respectively;

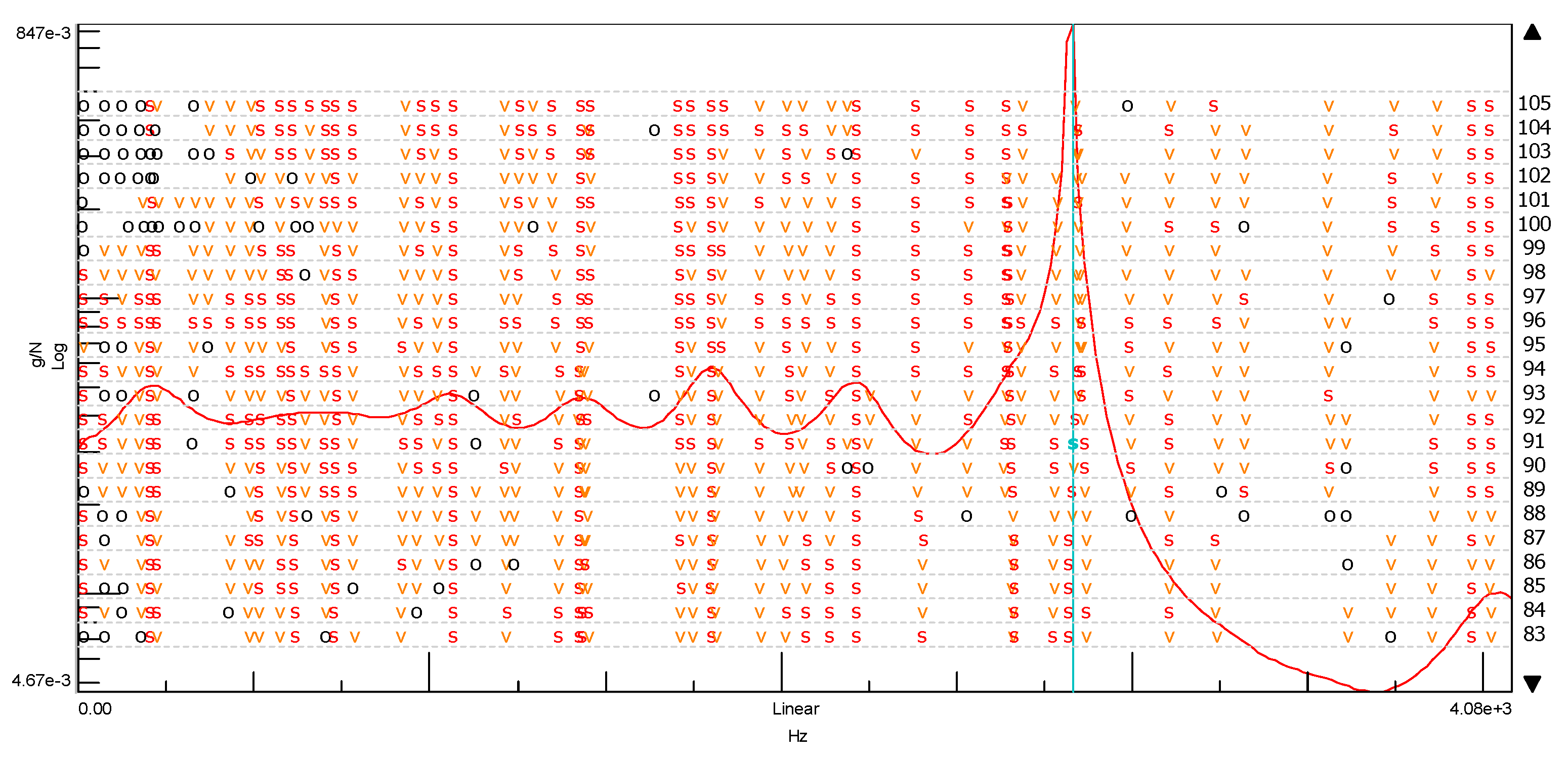

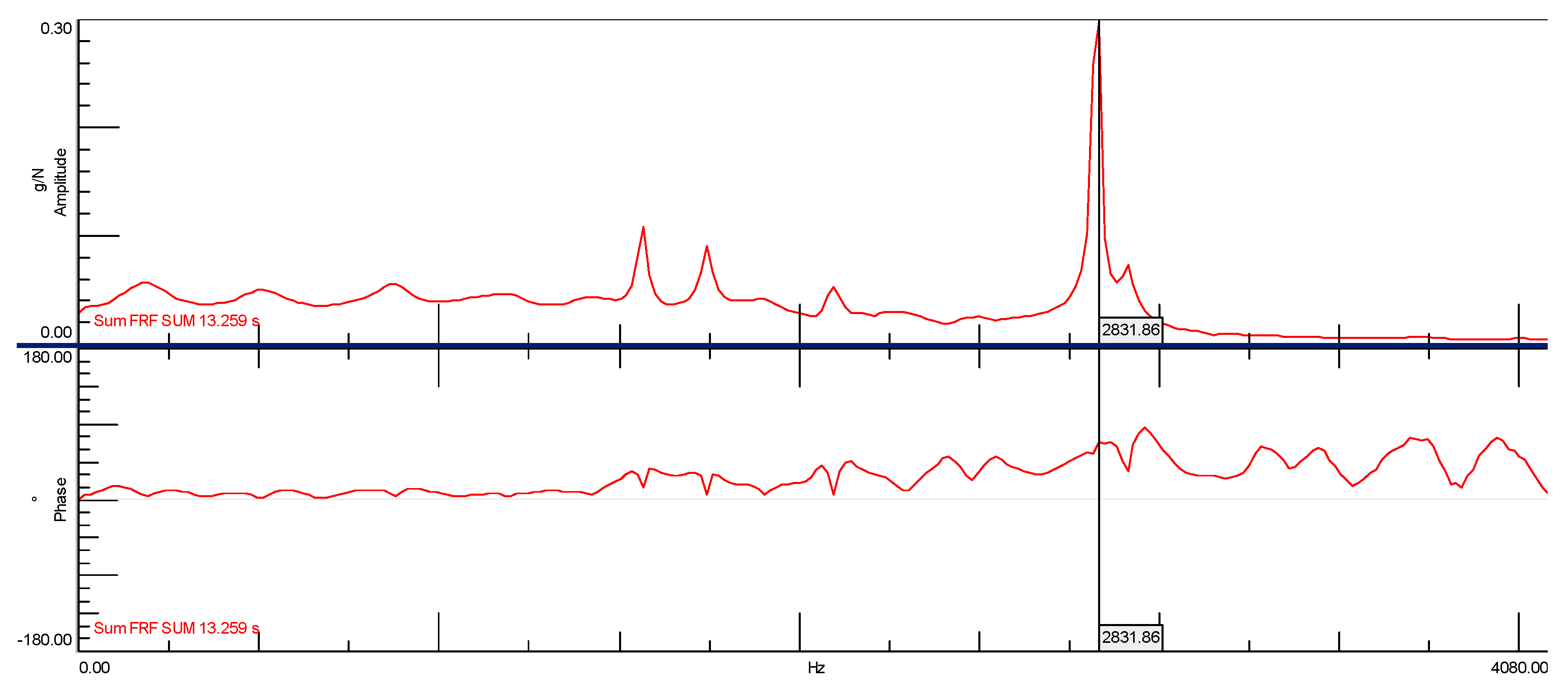

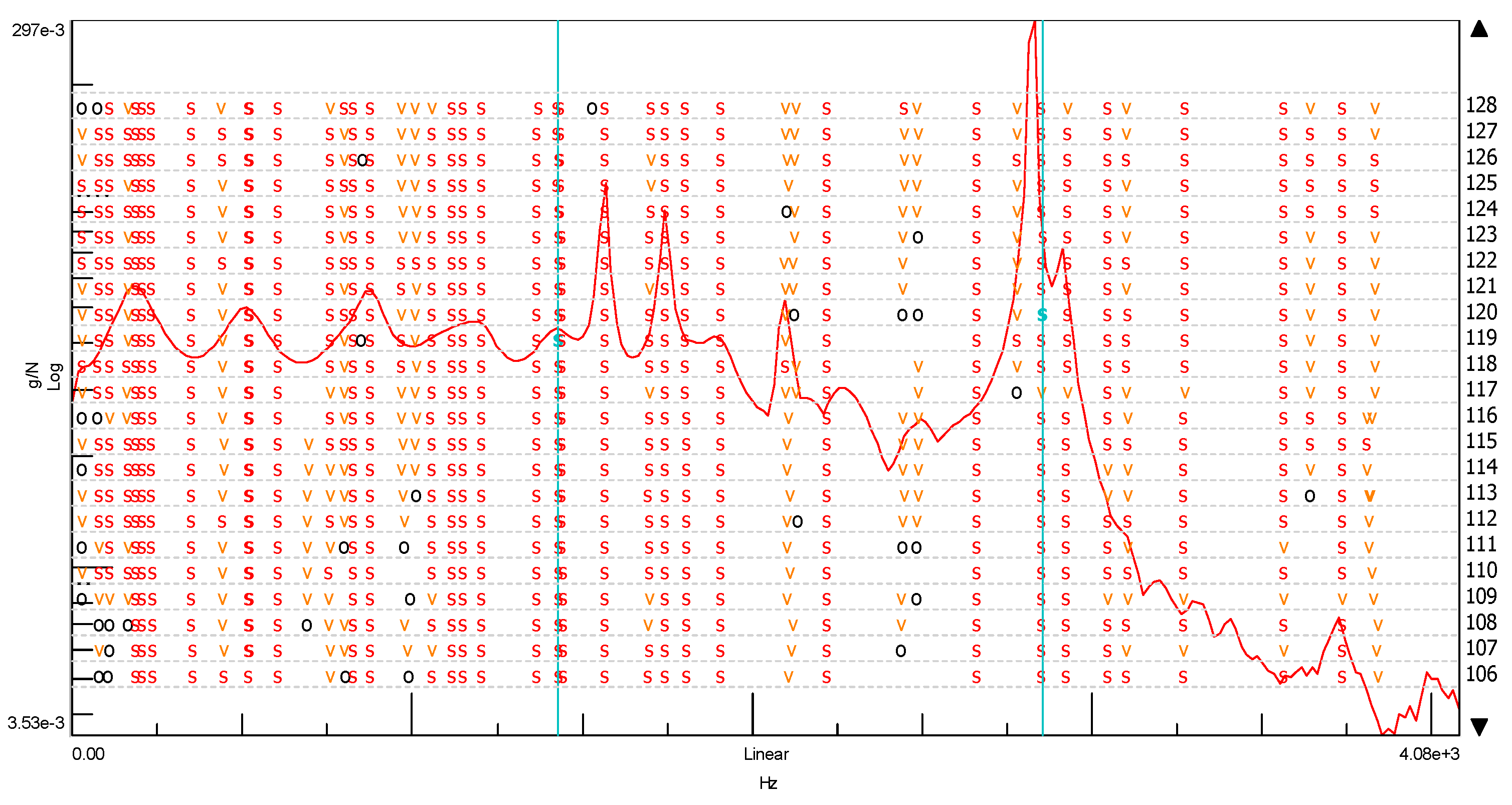

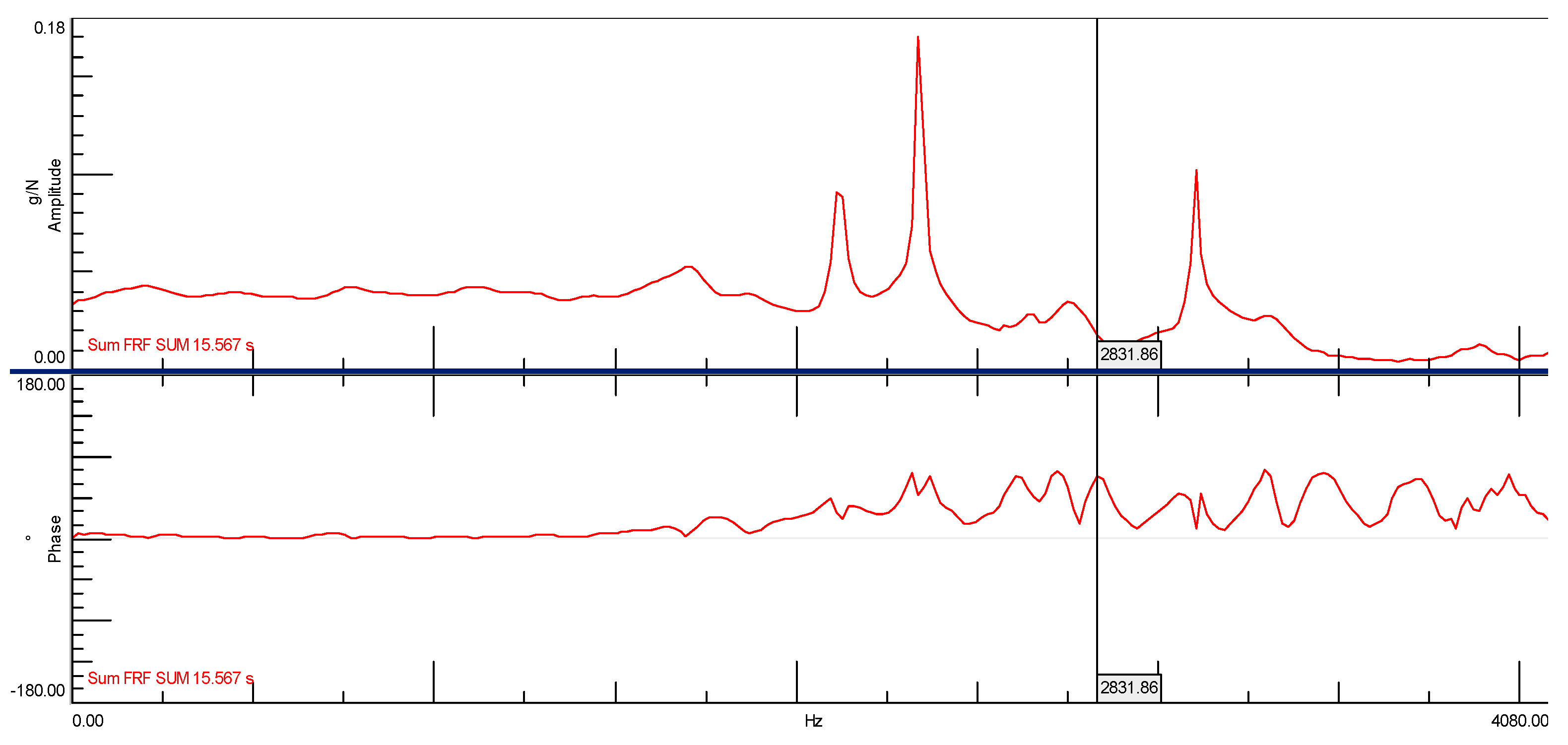

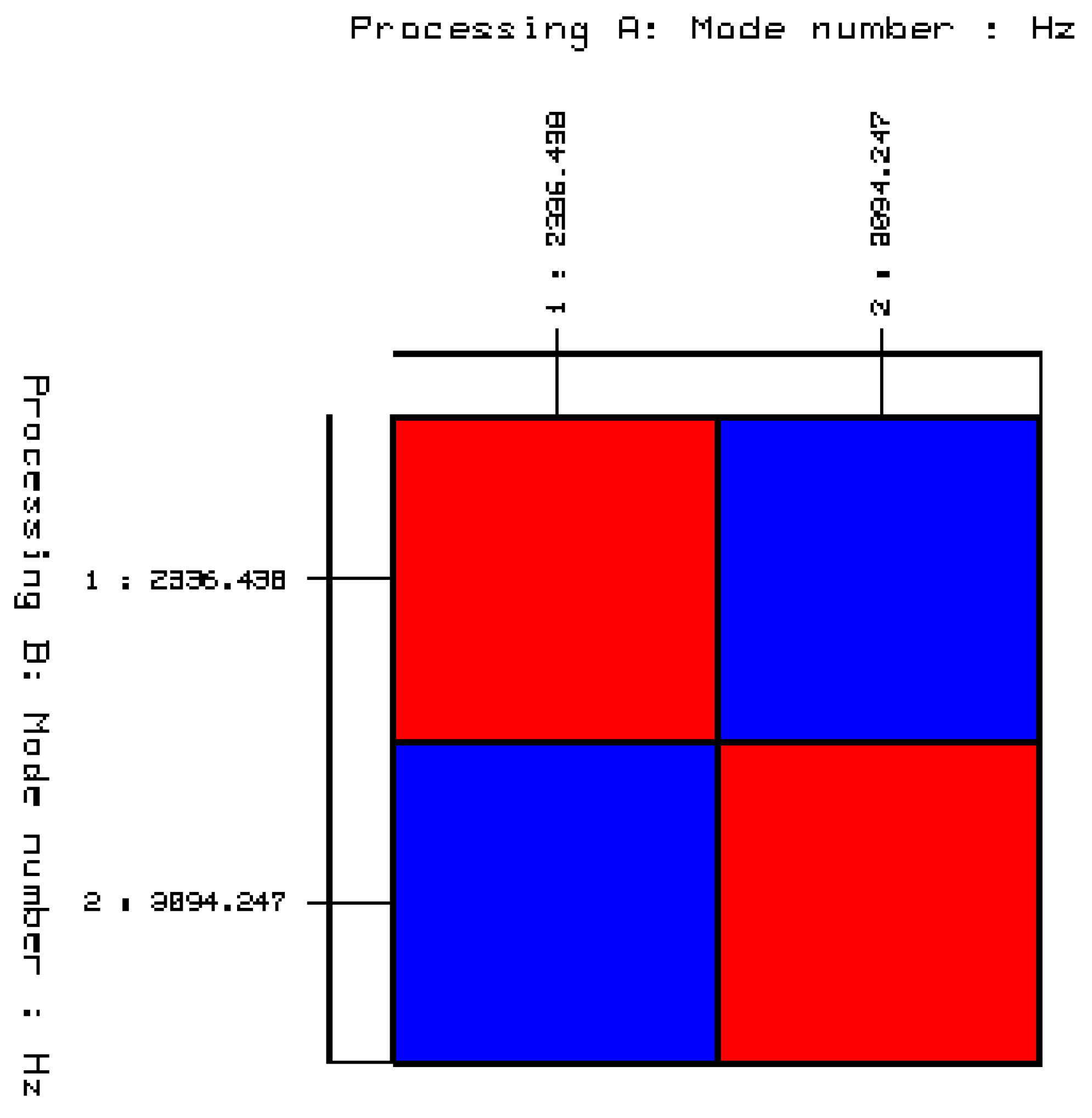

- The results of the conducted modal tests of cubes without and with the addition of ash showed that it is possible to distinguish both products using the method of experimental modal analysis. For the cube without the addition of ash, one natural frequency was determined at the level of 2831.86 (Hz), while for the cube with the ash addition, two natural frequencies were established at level I—2336.44 (Hz) and II—3094.25 (Hz). The obtained results of the analysis clearly indicate that the dynamic state in the case of the cube without the addition of ash and the cube with the 20% ash addition is different. This is part of an additional research study that will be continued in the future. The results of these studies are assumed to result in the development of a model for the non-invasive diagnosis of the mechanical properties of concrete containing fly ash from the incineration of sewage sludge.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Statistics Yearbook. Available online: https://stat.gov.pl/en/topics/statisticalyearbooks/statistical-yearbooks/concise-statistical-yearbook-of-poland-2020,1,21.html (accessed on 12 February 2021).

- IEA—Shaping a Secure and Sustainable Energy Future for All. Available online: www.iea.org (accessed on 12 February 2021).

- Kuzielová, E.; Slaný, M.; Žemlička, M.; Masilko, J.; Palou, T.M. Composition of Silica Fume—Portland Cement Systems Formed under Hydrothermal Curing Evaluated by FTIR, XRD, and TGA. Materials 2021, 14, 2786. [Google Scholar] [CrossRef]

- Jones, R.; McCarthy, M.; Newlands, M. Fly ash route to low embodied CO2 and implications for concrete construction. In Proceedings of the 2011 World of Coal Ash Conference, Denver, CO, USA, 9–12 May 2011; pp. 1–14. [Google Scholar]

- Gupta, S.M. Support vector machines-based modelling of concrete strength. Int. J. Intel. Technol. 2007, 3, 12–18. [Google Scholar]

- Kim, J.I.; Kim, D.K. Application of neural networks for estimation of concrete strength. KSCE J. Civ. Eng. 2002, 6, 4. [Google Scholar] [CrossRef] [Green Version]

- PN-EN 450-1:2012 Fly Ash for Concrete. Part 1: Definition, Specifications and Conformity Criteria; Polish Standardization Committee: Warsaw, Poland, 2012.

- Strategy for Dealing with Municipal Sewage Sludge for 2019–2022; Ministry of the Environment: Warsaw, Poland, 2018.

- Ordinance of the Minister of Economy of 16 July 2015 on Admitting Waste for Storage in Landfills (Dz.U. 2015 poz. 1277). Warsaw, Poland. Available online: https://www.gov.pl (accessed on 10 July 2021).

- Sadecka, Z.; Myszograj, S.; Suchowska-Kisielewicz, M. Legal aspects of natural use of sewage sludge. Zesz. Nauk. Inż. Śr. Univ. Ziel. Góra 2011, 144, 5–17. [Google Scholar]

- Bień, J.; Wystalska, K. Sludge management—The need to change strategic decisions. Environ. Eng. Prot. 2014, 17, 357–361. [Google Scholar]

- Bień, J.; Neczaj, E.; Neczaj, M.; Worwąg, A.; Grosser, D.; Nowak, M.; Milczarek, M.; Janik, S. Directions of sediment management in Poland after 2013. Environ. Eng. Prot. 2011, 14, 378. [Google Scholar]

- Borowski, G.; Gajewska, M.; Haustein, E. Possibilities of utilization of ashes from thermal transformation of sewage sludge in fluidized bed boilers. Eng. Environ. Prot. 2014, 17, 393–402. [Google Scholar]

- Pająk, T. Thermal treatment of sewage sludge in the face of the challenges of 2016. Inż. Ochr. Śr. 2014, 17, 363–376. [Google Scholar]

- Circular Economy, i.e., a Circular Economy. Available online: https://www.euractiv.pl/section/energia-i-srodowisko/news/circular-economy-czyli-ekonomia-zrownowazonego-rozwoju (accessed on 22 July 2021).

- Park, Y.J.; Park, S.; Moon, O.; Heo, J. Crystalline phase control of glass ceramics obtained from sewage sludge fly ash. Ceram. Int. 2003, 29, 223–227. [Google Scholar] [CrossRef]

- Merino, I.; Arévalo, L.F.; Romero, F. Preparation, and characterization of ceramic products by thermal treatment of sewage sludge ashes mixed with different additives. Waste Manag. 2007, 27, 1829–1844. [Google Scholar] [CrossRef]

- Lin, D.F.; Luo, H.L.; Cheng, J.F.; Zhuang, M.L. Strengthening tiles manufactured with sewage sludge ash replacement by adding micro carbon powder. Mater. Struct. 2016, 49, 3559–3567. [Google Scholar] [CrossRef]

- Lin, D.F.; Luo, H.L.; Lin, K.L.; Liu, Z.K. Effects of waste glass and waste foundry sand additions on reclaimed tiles containing sewage sludge ash. Environ. Technol. 2017, 38, 1679–1688. [Google Scholar] [CrossRef] [PubMed]

- Piasta, W.; Lukawska, M. The effect of sewage sludge ash on properties of cement composites. Proc. Eng. 2016, 161, 1018–1024. [Google Scholar] [CrossRef] [Green Version]

- Vouk, D.; Nakic, D.; Stirmer, N.; Cheeseman, C.R. Use of sewage sludge ash in cementitious materials. Rev. Adv. Mater. Sci. 2017, 49, 158–170. [Google Scholar]

- Ordinance of the Minister of Development of 21 January 2016, on the Requirements for the Thermal Waste Treatment Process and the Methods of Handling Waste Resulting from this Process. (Dz.U. 2016 poz. 108). Available online: http://isap.sejm.gov.pl (accessed on 22 July 2021).

- UE/75/2010 Directive of the European Parliament and the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control). Available online: http://isap.sejm.gov.pl (accessed on 10 July 2021).

- Rutkowska, G.; Fronczyk, J.; Filipczuk, S. Influence of flight ash properties from thermal transformation of sewage sludge on ordinary concrete parameters. Acta Sci. Pol. Archit. 2020, 19, 43–54. [Google Scholar]

- Rutkowska, G.; Wichowski, P.; Franus, M.; Mendryk, M.; Fronczyk, J. Modification of Ordinary Concrete Using Fly Ash from combustion of Municipal Sewage Sludge. Materials 2020, 13, 487. [Google Scholar] [CrossRef] [Green Version]

- Rutkowska, G.; Wichowski, P.; Fronczyk, J.; Franus, M.; Chalecki, M. Use of fly ashes from municipal sewage sludge combustion in production of ash concretes. Constr. Build. Mater. 2018, 188, 874–883. [Google Scholar] [CrossRef]

- Rutkowska, G.; Ogrodnik, P.; Fronczyk, J.; Bilgin, A. Temperature influence on ordinary concrete modified with fly ash from thermally conversed municipal sewage sludge strength parameters. Materials 2020, 13, 5259. [Google Scholar] [CrossRef]

- Monzó, J.; Paya, J.; Borrachero, M.V.; Peris-Mora, E. Mechanical behavior of mortars containing sewage sludge ash (SSA) and Portland cements with different tricalcium aluminate content. Cem. Concr. Res. 1999, 29, 87–94. [Google Scholar] [CrossRef]

- Ing, D.S.; Chin, S.C.; Guan, T.K.; Suil, A. The use of sewage sludge ash (SSA) as partial replacement of cement in concrete. ARPN J. Eng. Appl. Sci. 2016, 11, 3771–3775. [Google Scholar]

- Cyr, M.; Coutand, M.; Clastres, P. Technological and environmental behavior of sewage sludge ash (SSA) in cement-based materials. Cem. Concr. Res. 2007, 37, 1278–1289. [Google Scholar] [CrossRef]

- Lin, K.L.; Chang, W.C.; Lin, D.F.; Luo, H.L.; Tsai, M.C. Effects of nano-SiO2 and different ash particle sizes on sludge ash-cement mortar. J. Environ. Manag. 2008, 88, 708–714. [Google Scholar] [CrossRef]

- Baeza-Broton, F.; Garces, P.; Paya, J.; Saval, J.M. Portland cement systems with addition of sewage sludge ash. Application in concretes for the manufacture of blocks. J. Clean. Prod. 2014, 82, 112–124. [Google Scholar]

- Lin, K.-L.; Lin, C.-Y. Hydration characteristics of waste sludge ash utilized as raw cement material. Cem. Concr. Res. 2005, 35, 1999–2007. [Google Scholar] [CrossRef]

- Yen, C.L.; Tseng, D.H.; Lin, T.T. Characterization of eco-cement paste produced from waste sludges. Chemosphere 2011, 84, 220–226. [Google Scholar] [CrossRef]

- Ferreira, C.; Ribeiro, A.; Ottosen, L. Possible applications for municipal solid waste fly ash. J. Hazard. Mater. 2003, 96, 201–216. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.S.; Poon, C.S. Combined use of sewage sludge ash and recycled glass cullet for the production of concrete blocks. J. Clean. Prod. 2018, 171, 1447–1459. [Google Scholar] [CrossRef]

- Uhl, T. Computer-aided identification of mechanical structure models. WNT Sci. Tech. Publ. 1997, 3, 45–57. [Google Scholar]

- Roberts, G.W.; Meng, X.; Dodson, A.H. Integrating a Global Positioning System and Accelerometers to Monitor the Deflection of Bridges. J. Surv. Eng. 2004, 130, 65–72. [Google Scholar] [CrossRef]

- Li, B.; Cai, H.; Mao, X.; Huang, J.; Luo, B. Estimation of CNC Machine-tool Dynamic Parameters Based on Random Cutting Excitation Through Operational Modal Analysis. Int. J. Mach. Tools Manuf. 2013, 71, 26–40. [Google Scholar] [CrossRef]

- Żółtowski, M.; Liss, M. The use of modal analysis in the evaluation of welded steel structures. Stud. Proc. Pol. Assoc. Knowl. Manag. 2016, 79, 233–248. [Google Scholar]

- PN-EN 206+A1:2016-12 Concrete. Part 1. Requirements, Properties, Manufacturing and Conformity. Available online: https://sklep.pkn.pl (accessed on 10 April 2021).

- Jamroży, Z. Concrete and Its Technologirs, 3rd ed.; PWN: Warsaw, Poland, 2015. (In Polish) [Google Scholar]

- PN-EN 197-1: 2012 Cement—Part 1: Composition, Requirements, and Compliance Criteria for Common Cements. Available online: http://www.puntofocal.gov.ar/notific_otros_miembros/mwi40_t.pdf (accessed on 10 April 2021).

- PN-EN 12350-6:2011 Testing of Fresh Concrete. Part 6: Density. Available online: https://sklep.pkn.pl (accessed on 10 March 2021).

- PN-EN 12350-7:2019 Testing of Fresh Concrete. Part 7: Air Content—Pressure Method. Available online: https://standards.iteh.ai/catalog/standards/cen/444b4a93-2e0f-41e7-96e9-7d25505d78bd/en-12350-7-2019 (accessed on 10 March 2021).

- PN-EN 12350-2:2011 Testing of Fresh Concrete. Part 2. Slump Test. Available online: https://sklep.pkn.pl (accessed on 10 April 2021).

- PN-EN 12390-3: 2019-07. Testing of Hardened Concrete. Part 3: Compressive Strength of Test Specimens. Available online: https://standards.iteh.ai/catalog/standards/cen/7eb738ef-44af-436c-ab8e-e6561571302c/en-12390-3-2019 (accessed on 10 March 2021).

- PN-B-06265:2004 Plain Concrete. Available online: https://sklep.pkn.pl (accessed on 10 April 2021).

- ASTM C379-65T Specification for Fly Ash for Use as a Pozzolanic Material with Lime. Available online: https://www.astm.org/Standards/C379.htm (accessed on 12 February 2021).

- Jain, H.; Rawat, A.; Sachan, A.K. A Review on Advancement in Sensor Technology in Structural Health Monitoring System. J. Struct. Eng. Manag. 2015, 2, 1–7. [Google Scholar]

- Żółtowski, B.; Żółtowski, M. Vibration Signals in Mechanical Engineering and Construction; ITE—PIB: Radom, Poland, 2015. [Google Scholar]

- He, C.; Xing, J.C.; Zhang, X. A New Method for Modal Parameter Identification Based on Natural Excitation Technique and ARMA Model in Ambient Excitation. Adv. Mater. Res. 2015, 1065, 1016–1019. [Google Scholar] [CrossRef]

- Żółtowski, M. Investigations of harbour brick structures by using operational modal analysis. Pol. Marit. Res. 2014, 21, 42–53. [Google Scholar] [CrossRef] [Green Version]

- Le, T.P.; Paultre, P. Modal identification based on the time-frequency domain decomposition of unknown-input dynamic tests. Int. J. Mech. Sci. 2013, 71, 41–50. [Google Scholar] [CrossRef]

- Kosior-Kazberuk, M. Application of SSA as partial replacement of aggregate in concrete. Pol. J. Environ. Stud. 2011, 20, 365–370. [Google Scholar]

- Joshi, R.C.; Lohtia, R.P. Fly ash in concrete: Production properties and uses. In Advances and Concrete Technology; Malhot, V.M., Ed.; Gordon and Breach Science Publishers: Ottawa, ON, Canada, 1997; Volume 2, p. 269. [Google Scholar]

- PN-EN 451-2:2017-06 Fly Ash Test Method—Determination of Fineness by Wet Sieving. Available online: https://standards.iteh.ai/catalog/standards/cen/39f1ef7f-e230-41c3-8335-b3a377bab125/en-451-2-2017 (accessed on 10 March 2021).

- PN-EN 1097-07:2008 Determination of the Filler Density. Available online: https://sklep.pkn.pl (accessed on 10 April 2021).

- Alonso, J.L.; Wesche, K. Characterization of fly ash. Fly ash in concrete properties and performance. In Report of Technical Committee 67-FAB—Use Fly Ash in Building; Wesche, K., Ed.; RILEM. E&FN SPON: London, UK, 1991. [Google Scholar]

- Malhotra, V.M.; Ramezanianpour, A.A. Fly Ash in Concrete, 2nd ed.; CANMT—Canada Centre for Mineral and Energy Technology: Ottawa, ON, Canada, 1994. [Google Scholar]

- Williams, P.T. Waste Treatment and Disposal, 2nd ed.; John Wiley & Sons: London, UK, 2005. [Google Scholar]

- Małolepszy, J.; Tkaczewska, E. Influence of fly ashes from the co-combustion of coal and biomass on the hydration process and properties of cement. Concr. Days 2006, 23, 591–601. (In Polish) [Google Scholar]

- Yusur, R.O.; Noor, Z.Z.; Din, M.D.F.M.D.; Abba, A.H. Use of sewage sludge ash (SSA) in the production of cement and concrete-a review. Int. J. Glob. Environ. Issues 2012, 12, 214–228. [Google Scholar]

- Chang, F.; Lin, J.; Tsail, C.; Wang, K. Study on cement mortar and concrete made with sewage sludge ash. Water Sci. Technol. 2010, 62, 1689–1693. [Google Scholar] [CrossRef]

- Chen, M.; Blanc, D.; Gautier, M.; Mehu, J.; Gourdon, R. Environmental and technical assessments of the potential utilization of sewage sludge ashes (SSAs) as secondary raw materials in construction. Waste Manag. 2013, 33, 1268–1275. [Google Scholar] [CrossRef]

- Kosior-Kazberuk, M. New mineral additives foe concreto. Civil Environ. Eng. 2011, 2, 47–55. [Google Scholar]

spectral transition function FRF (Side A),

spectral transition function FRF (Side A),  spectral transition function FRF (Side B),

spectral transition function FRF (Side B),  spectral transition function FRF (Page C).

spectral transition function FRF (Page C).

spectral transition function FRF (Side A),

spectral transition function FRF (Side A),  spectral transition function FRF (Side B),

spectral transition function FRF (Side B),  spectral transition function FRF (Page C).

spectral transition function FRF (Page C).

spectral transition function FRF (Side A),

spectral transition function FRF (Side A),  spectral transition function FRF (Side B),

spectral transition function FRF (Side B),  spectral transition function FRF (page C).

spectral transition function FRF (page C).

spectral transition function FRF (Side A),

spectral transition function FRF (Side A),  spectral transition function FRF (Side B),

spectral transition function FRF (Side B),  spectral transition function FRF (page C).

spectral transition function FRF (page C).

| Fraction | Fraction Mixing Percentage Ratio (for Sand and Gravel) | Grain Composition of (%) | |||

|---|---|---|---|---|---|

| I Stage | II Stage | III Stage | Sand | Gravel | |

| 0.0–0.125 | 30 | 1.26 | 0.38 | ||

| 0.0125–0.25 | 12.33 | 3.70 | |||

| 0.25–0.50 | 36.35 | 10.91 | |||

| 0.50–1.0 | 33.12 | 9.94 | |||

| 1.0–2.0 | 16.94 | 5.07 | |||

| 2.0–4.0 | 35 | 70 | 24.50 | ||

| 4.0–8.0 | 49 | 65 | 22.29 | ||

| 8.0–16.0 | 51 | 23.21 | |||

| Beginning of Binding Time (min) | Compressive Strength after 2 Days (MPa) | Compressive Strength after 28 Days (MPa) | Blaine’s Specific Surface Area (cm2/g) |

|---|---|---|---|

| 218 | 22 | 49.8 | 3330 |

| The share of mineral phases CEM I (5 mass) | |||

| C3S—61.8 | C2S—12.3 | C3A—7.6 | C4AF—4.1 |

| SiO2 (%) | Sulfate Content SO3 (%) | Roasting Loss (%) | Chloride Content Cl (%) | Alkali Content Na2Oeq (%) |

|---|---|---|---|---|

| 20.20 | 3.20 | 3.20 | 0.06 | 0.73 |

| CaO | Al2O3 | Fe2O3 | MgO | CaOw |

| 65.21 | 4.34 | 2.37 | 1.51 | 1.76 |

| Specification | Mass of Concrete Ingredients (kg/m3) | |||

|---|---|---|---|---|

| Aggregate | Water | Cement | Fly Ash | |

| Concrete CO | 1812.15 | 193.55 | 380.12 | - |

| FA 2.5% Concrete with quantity 5% of fly ash | 1812.15 | 193.55 | 370.62 | 9.50 |

| FA 5% Concrete with quantity 5% of fly ash | 1812.15 | 193.55 | 361.11 | 19.01 |

| FA 7.5% Concrete with quantity 5% of fly ash | 1812.15 | 193.55 | 351.61 | 28.51 |

| FA 10% Concrete with quantity 10% of fly ash | 1812.15 | 193.55 | 342.11 | 38.01 |

| FA12. 5% Concrete with quantity 5% of fly ash | 1812.15 | 193.55 | 332.60 | 47.52 |

| FA 15% Concrete with quantity 15% of fly ash | 1812.15 | 193.55 | 323.10 | 57.02 |

| FA 17.5% Concrete with quantity 5% of fly ash | 1812.15 | 193.55 | 313.60 | 66.52 |

| FA 20 % Concrete with quantity 20% of fly ash | 1812.15 | 193.55 | 308.10 | 72.02 |

| Ordinary Concrete Cube with 20% Addition of Fly Ash from Sewage Sludge | Mode 1 | Mode 2 | Mode 3 | |

|---|---|---|---|---|

| 2119.214 | 2336.438 | 3094.247 | ||

| Mode 1 | 2119.214 | 100 | 27.697 | 61.491 |

| Mode 2 | 2336.438 | 27.697 | 100 | 1.322 |

| Mode 3 | 3094.247 | 61.491 | 1.322 | 100 |

| Ordinary Concrete Cube with 20% Addition of Fly Ash from Sewage Sludge | Mod | Mod | |

|---|---|---|---|

| 2336.438 | 3094.247 | ||

| Mode 2 | 2336.438 | 100 | 1.464 |

| Mode 3 | 3094.247 | 1.464 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rutkowska, G.; Żółtowski, M.; Liss, M. The Use of Modal Analysis in Addition Percentage Differentiation, and Mechanical Properties of Ordinary Concretes with the Addition of Fly Ash from Sewage Sludge. Materials 2021, 14, 5039. https://doi.org/10.3390/ma14175039

Rutkowska G, Żółtowski M, Liss M. The Use of Modal Analysis in Addition Percentage Differentiation, and Mechanical Properties of Ordinary Concretes with the Addition of Fly Ash from Sewage Sludge. Materials. 2021; 14(17):5039. https://doi.org/10.3390/ma14175039

Chicago/Turabian StyleRutkowska, Gabriela, Mariusz Żółtowski, and Michał Liss. 2021. "The Use of Modal Analysis in Addition Percentage Differentiation, and Mechanical Properties of Ordinary Concretes with the Addition of Fly Ash from Sewage Sludge" Materials 14, no. 17: 5039. https://doi.org/10.3390/ma14175039

APA StyleRutkowska, G., Żółtowski, M., & Liss, M. (2021). The Use of Modal Analysis in Addition Percentage Differentiation, and Mechanical Properties of Ordinary Concretes with the Addition of Fly Ash from Sewage Sludge. Materials, 14(17), 5039. https://doi.org/10.3390/ma14175039