1. Introduction

Over the past few years, several studies were carried out to investigate the relationship between the percentage of mixing pozzolanic materials with cement and water for obtaining the optimum water-to-cement ratio in different types of concrete. Many researchers have worked on the application of cement replacements, such as fly ash, silica fume and slag, in concrete mixes [

1,

2,

3,

4,

5]. The effect of natural powders, such as pumice, rice husk ash (RHA) and perlite on concrete properties, have been also investigated [

6,

7,

8,

9]. Incorporating concrete with pumice led to a higher strength-to-weight ratio in comparison with concrete with cement [

10,

11,

12,

13,

14,

15]. Slag is another most used cement replacement powder, which can provide some benefits such as low heat in hydration, proper performance, resistance to sulfate attack, acid, abrasion and corrosion [

16].

Self-consolidating concrete (SCC) is one of the common types of concrete, which has been used in structural applications due to suitable workability and the spreading ability without the need for mechanical vibration [

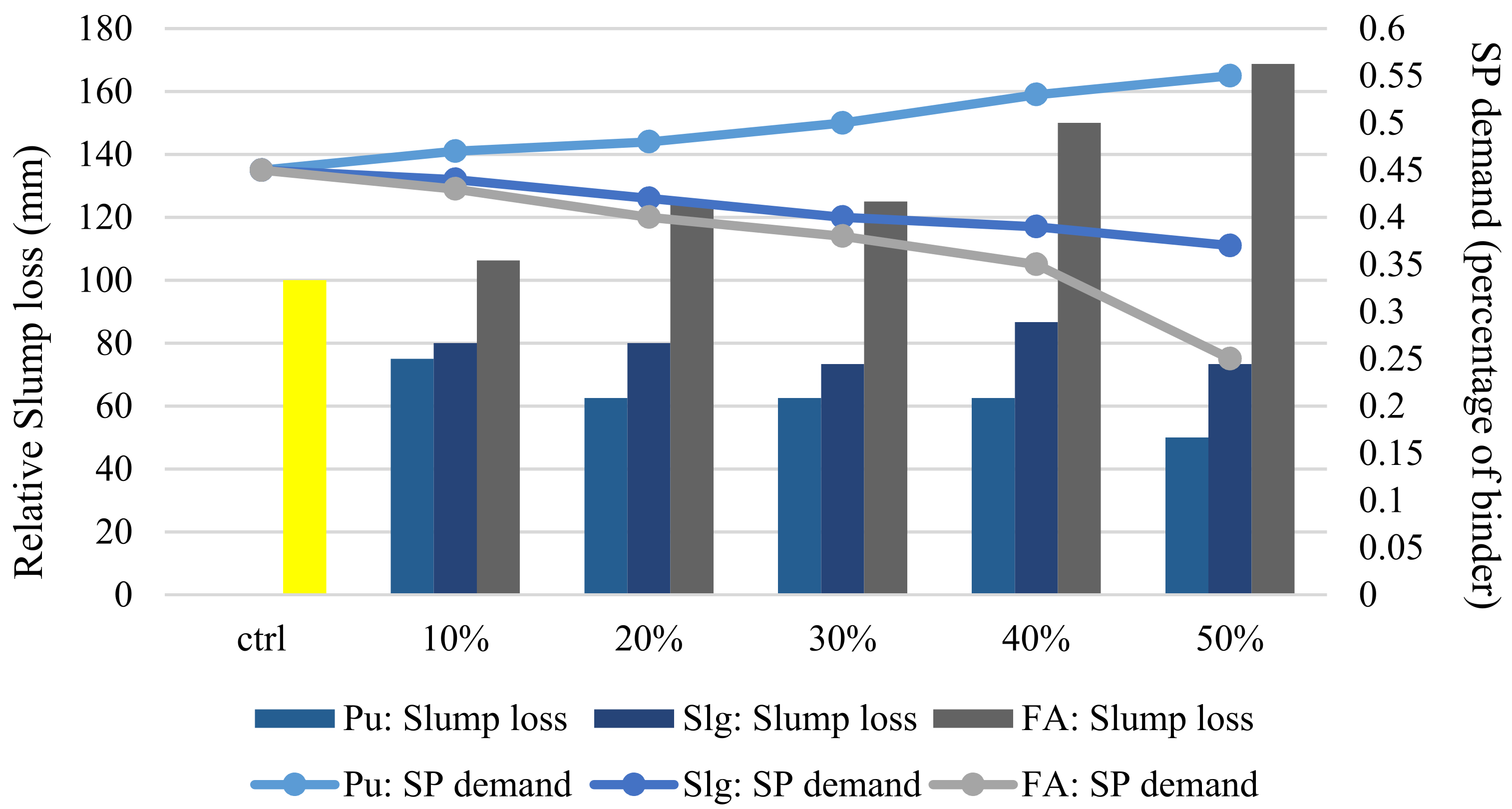

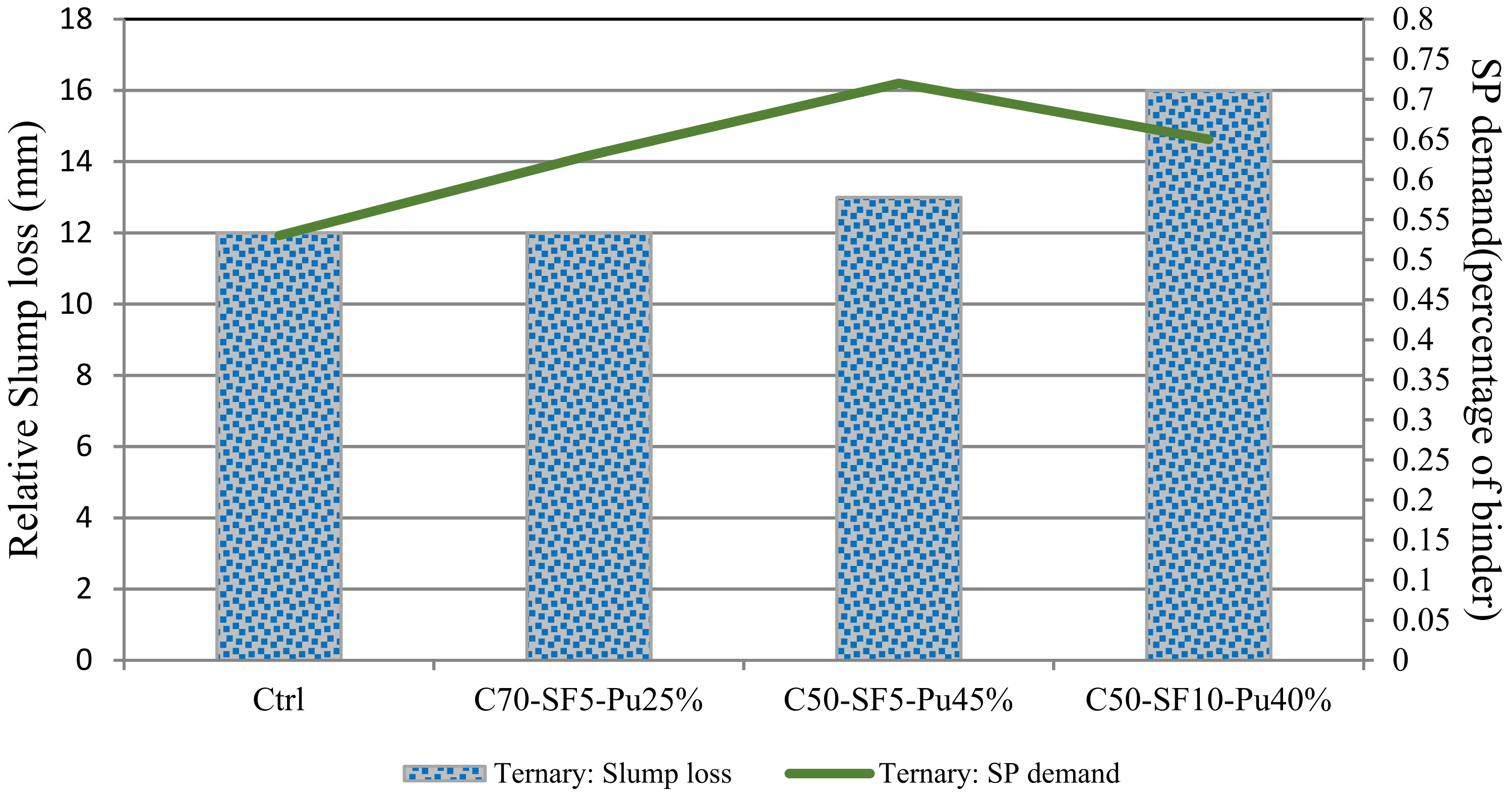

17]. Using a lower value of coarse aggregates in comparison to fine aggregates and higher cement content leads to better compactability and lower segregation and enhances the workability of concrete. Compactability can be enhanced by working on SCC mix design. In order to obtain a sustainable SCC, a reliable mix design is required. Slump retention is a critical parameter in SCC mix design, which has been widely investigated in recent years. One of the governing parameters in controlling slump retention is superplasticizer (SP) demand. Slump loss is the difference between measured slumps at various times of concrete production. The required amount of SP in SCC is directly related to the slump loss so that by increasing slump loss, more SP demand is required. Bani Ardalan et al. [

18] studied the workability and compressive strength of SCC incorporating pumice, slag and fly ash as supplementary cementitious materials. The cement replacements proportions included 10% to 50% as binary mix designs. Silica fume was also used along with pumice in some mixes as ternary mix designs. It was found that the properties of mixtures were improved with silica fume incorporation. Shariati et al. [

19] showed that using pumice powder and slag as cement replacements in SCC leads to promising results. However, more explorations on the amount of SP are still required to produce concrete with higher workability and placeability. There are limited non-destructive tests available for concrete, which are mostly related to fresh properties. Five key design parameters of SCC, including J-ring, U-box, V-funnel, 3 min slump and 50 min slump (T50), have a non-destructive nature.

Partial replacement of cement in SCC with other materials changes the fresh and mechanical properties. Although these changes can be observed by experiments, it is not simple to identify the most influential parameters on fresh properties and predict the design parameters. To address this problem, artificial intelligence (AI) models can be employed, which are able to produce accurate results by simulating human intelligence [

20,

21,

22,

23,

24]. Uysal and Tanyildizi [

25] used an artificial neural network (ANN) to predict the compressive strength of SCC with mineral additives. They found that the ANN model can be an appropriate alternative for experimental methods. Asteris et al. [

26] applied ANN models to evaluate the mechanical properties of SCC based on the experimental data. It was reported that the back propagation neural networks are able to provide reliable results for predicting the compressive strength of SCC. Nguyen et al. [

27] employed two AI algorithms to predict the compressive strength of fiber-reinforced high-strength SCC. The results indicated that the ANN model was more accurate compared to the ANFIS method. Golafshani et al. [

28] combined ANN and ANFIS with GWO to develop the hybrid algorithms for predicting the compressive strength of normal strength concrete and high-performance concrete incorporating fly ash and blast furnace slag. It was indicated that hybrid models can increase the accuracy of the prediction. Douma et al. [

29] developed an ANN model to predict the fresh properties and compressive strength of SCC incorporating fly ash. It was reported that the artificial neural network is an appropriate technique for evaluating the properties of SCC. Elemam et al. [

30] studied the fresh properties and compressive strength of SCC containing limestone powder, silica fume and fly ash using an ANN model. It was concluded that the proposed optimization model is able to determine the optimum values of variables to achieve the desirable properties of SCC. Azimi-Pour et al. [

31] deployed linear and non-linear support vector machine models to predict the compressive strength and fresh characteristics of high volume fly ash SCC. They deduced that compared to other kernel functions, the results of the SVM with radial basis function are more reliable.

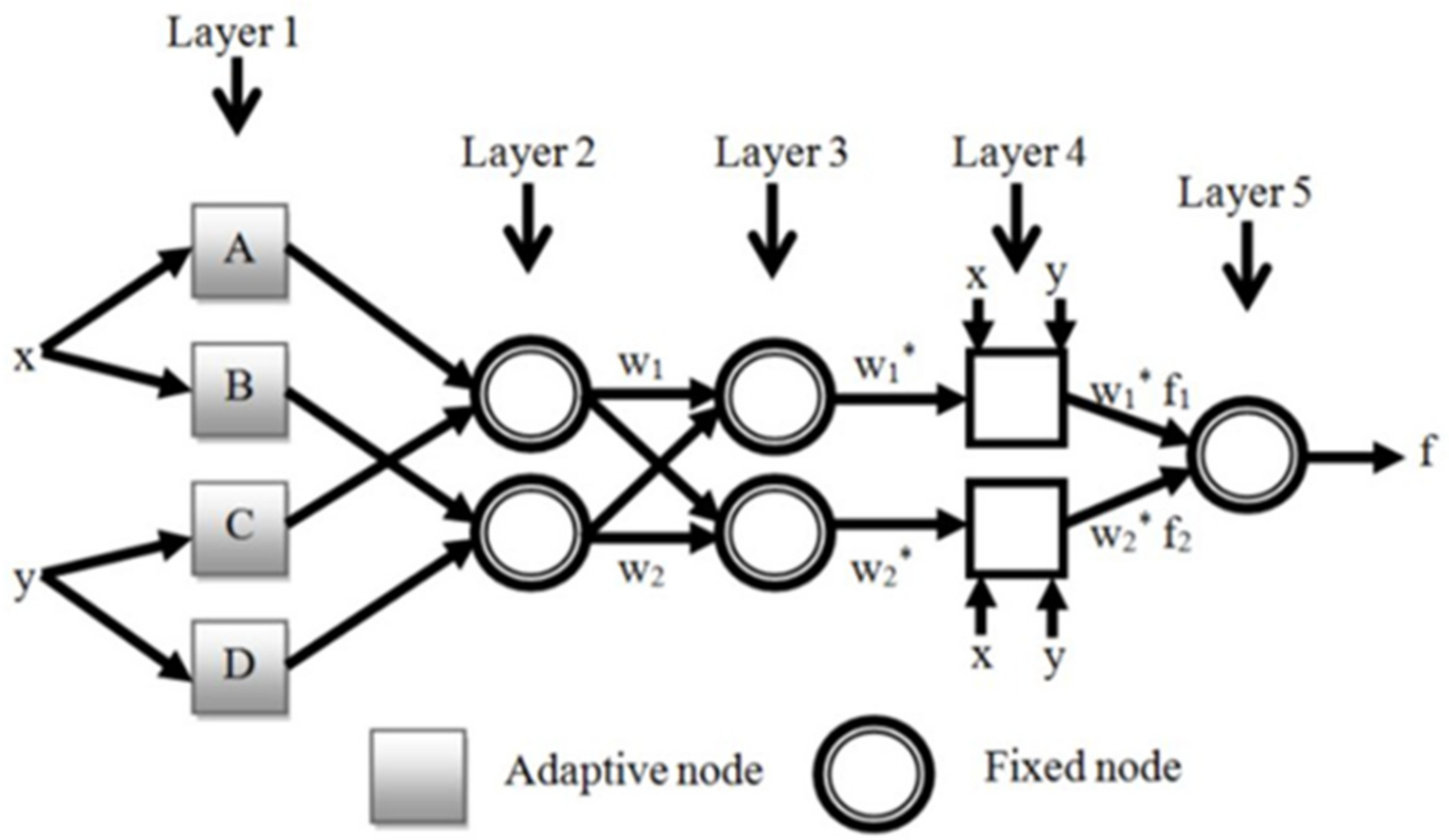

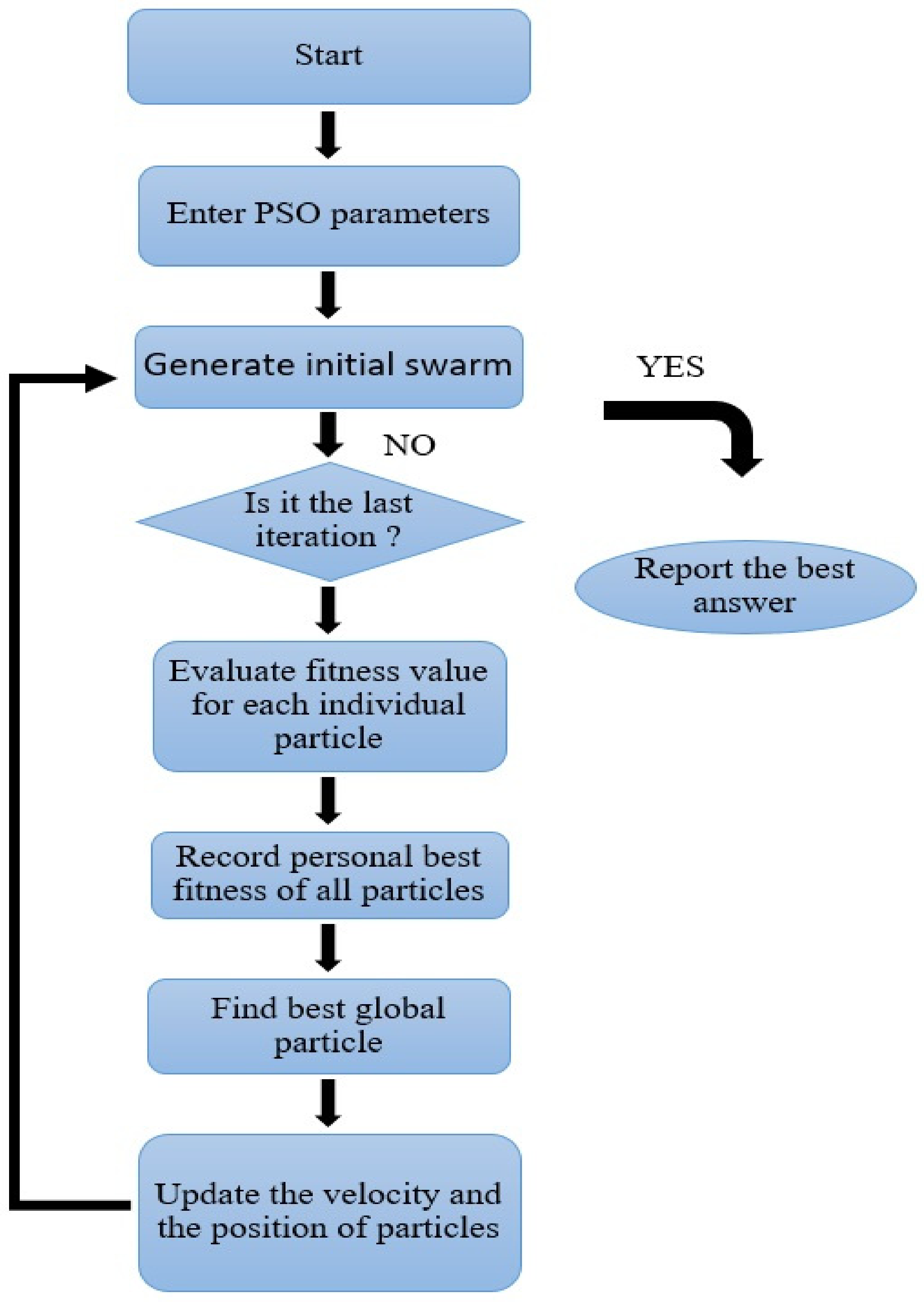

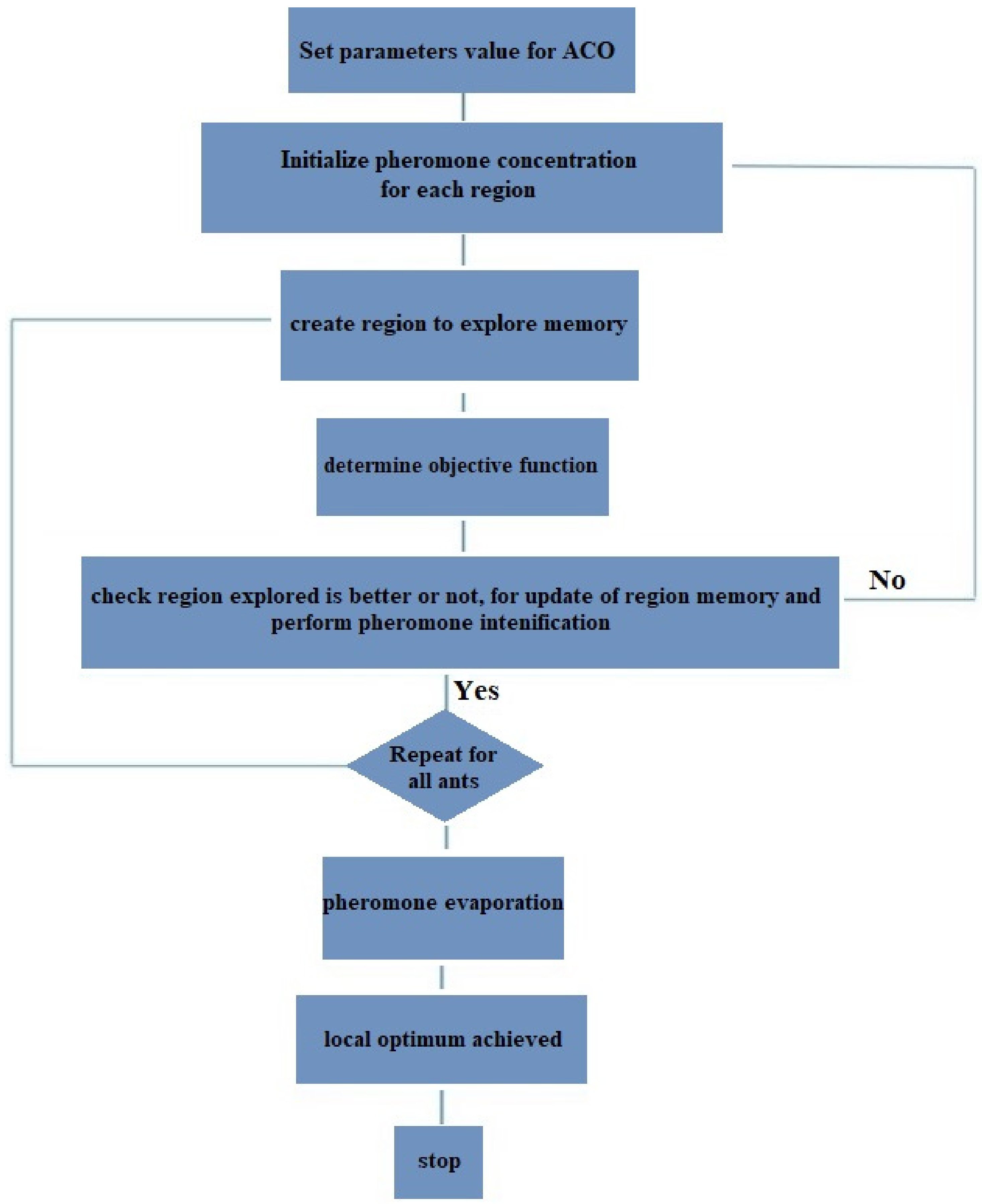

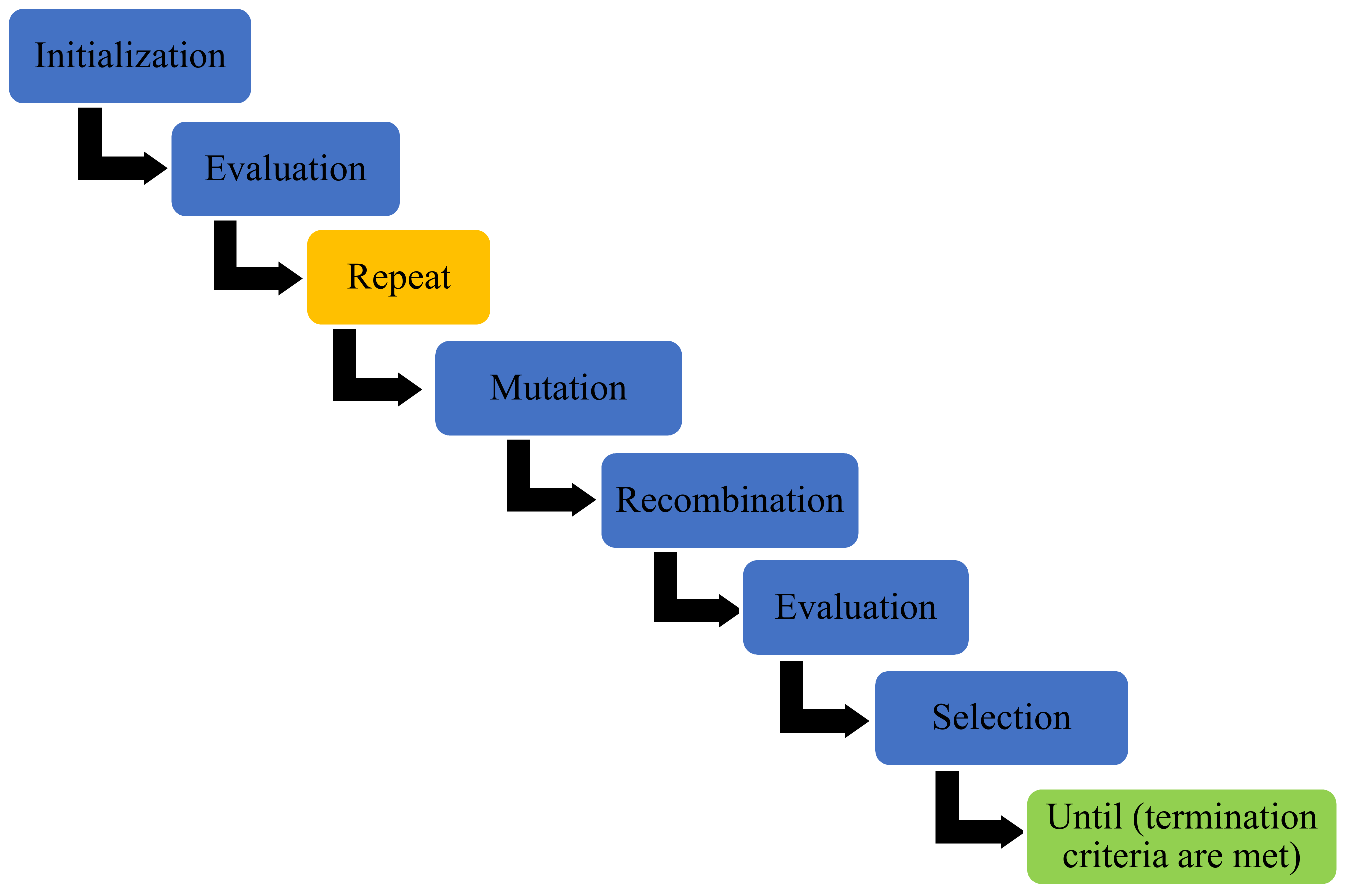

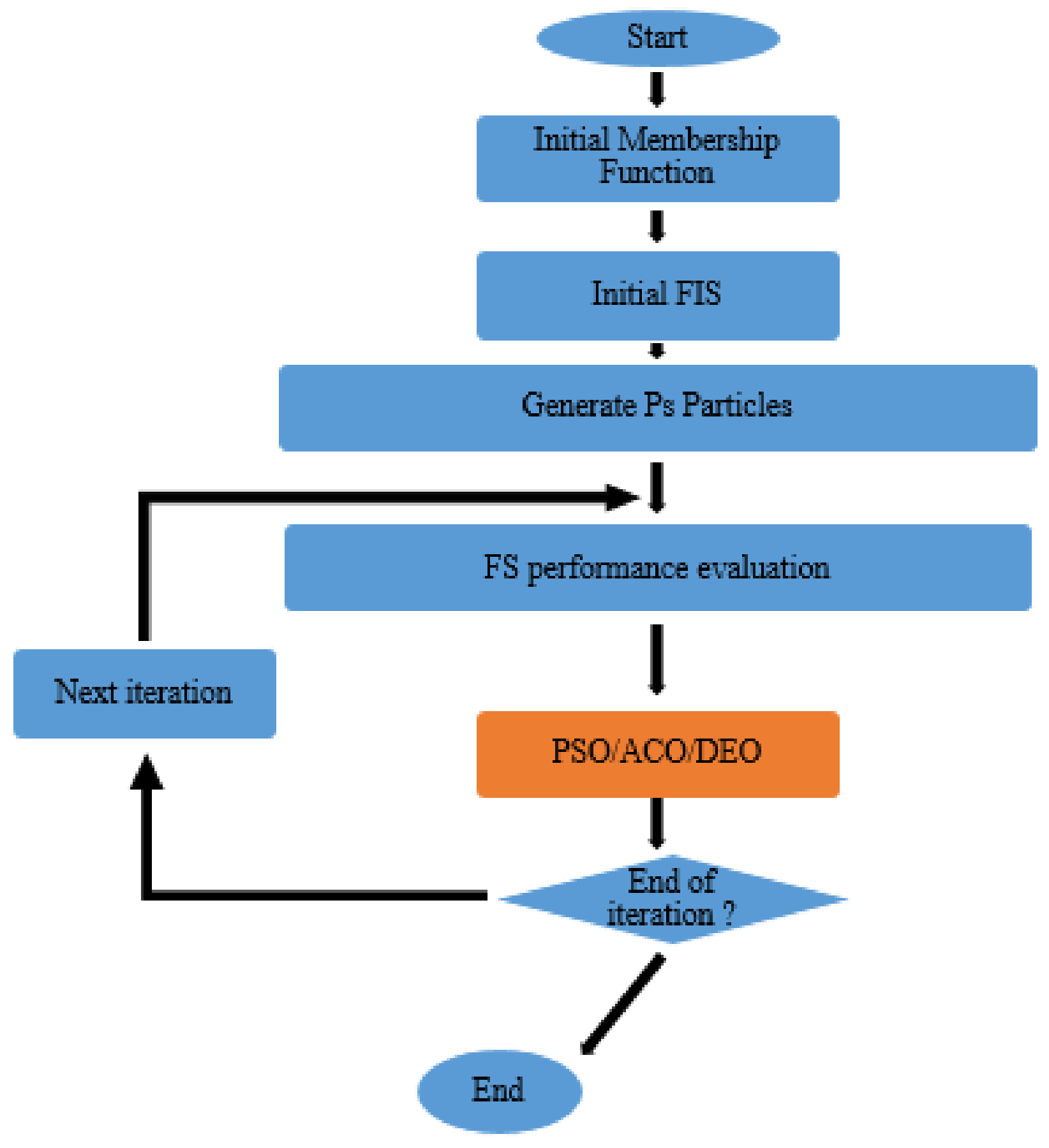

Adaptive neuro-fuzzy inference system (ANFIS) as an intelligence method can learn and adapt automatically to solve optimization problems. In contrast to most analytical approaches, ANFIS does not require identifying the system parameters and therefore can find simpler solutions for multivariable problems. ANFIS is able to produce the best estimate circumstances by eliminating the vagueness in the process via excluding some input parameters. The ANFIS network is used to transform the compound performance characteristics into a single performance index. Generally, fuzzy systems are applied to interpret and assess the experimental data. However, some shortcomings in the accuracy and versatility of ANFIS have been identified, which were addressed by incorporating classic computing algorithms and optimization techniques [

32,

33,

34,

35,

36]. Kennedy and Eberhart [

37] introduced particle swarm optimization (PSO) in 1995, which was an intelligence evolutionary algorithm stimulated by the social behavior of bird flocking or fish schooling. This algorithm has a remarkable convergence rate compared to other evolutionary algorithms. Besides, ant colony optimization (ACO) is a continuous space algorithm inspired by observations on ant colonies, which show that they are social insects living in colonies where colony survival is more important than the survival of a component. One of the main aspects of ants’ behavior is their performance in finding food, particularly detecting the shortest path between food sources and nests. This mass intelligence aspect in ant behavior has attracted scientists’ attention to use ACO in different applications. On the other hand, differential evolution optimization (DEO) algorithm was presented to overwhelm the primary flaw of the genetic algorithm, namely the lack of local search. In the last few years, different types of AI models have been applied to predict and evaluate the performance of structural elements using experimental data [

38,

39,

40,

41,

42].

Several AI-based models have been utilized to predict the hardened and fresh properties of concrete. Studies have revealed that using hybrid algorithms in many cases can lead to improving the performance of predictive models [

43,

44,

45,

46]. The main objective of this paper is to predict the SP demand of specific SCC by soft computing methods to avoid mathematical approaches with high nonlinearity. For this purpose, ANFIS algorithm is developed and combined with three metaheuristic algorithms, namely particle swarm optimization (PSO), ant colony optimization (ACO) and differential evolution optimization (DEO). Besides, the verified experimental data from the literature [

18,

19] are used to obtain an appropriate replacement for cement and optimize it by reducing environmental pollution and increasing the durability and properties of fresh concrete. In addition, the results of hybrid algorithms are compared and interpreted to determine the best one.

5. Discussion of Results

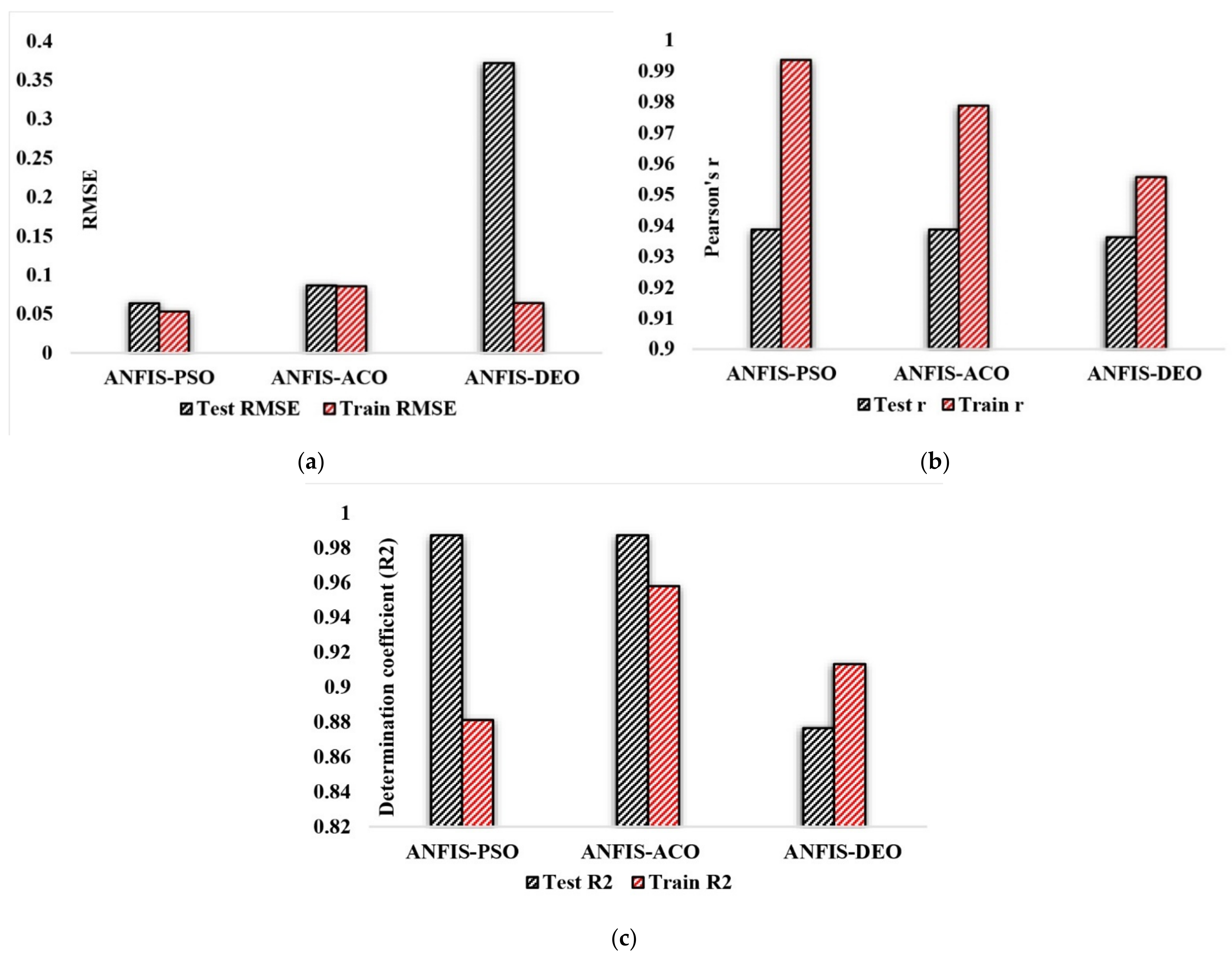

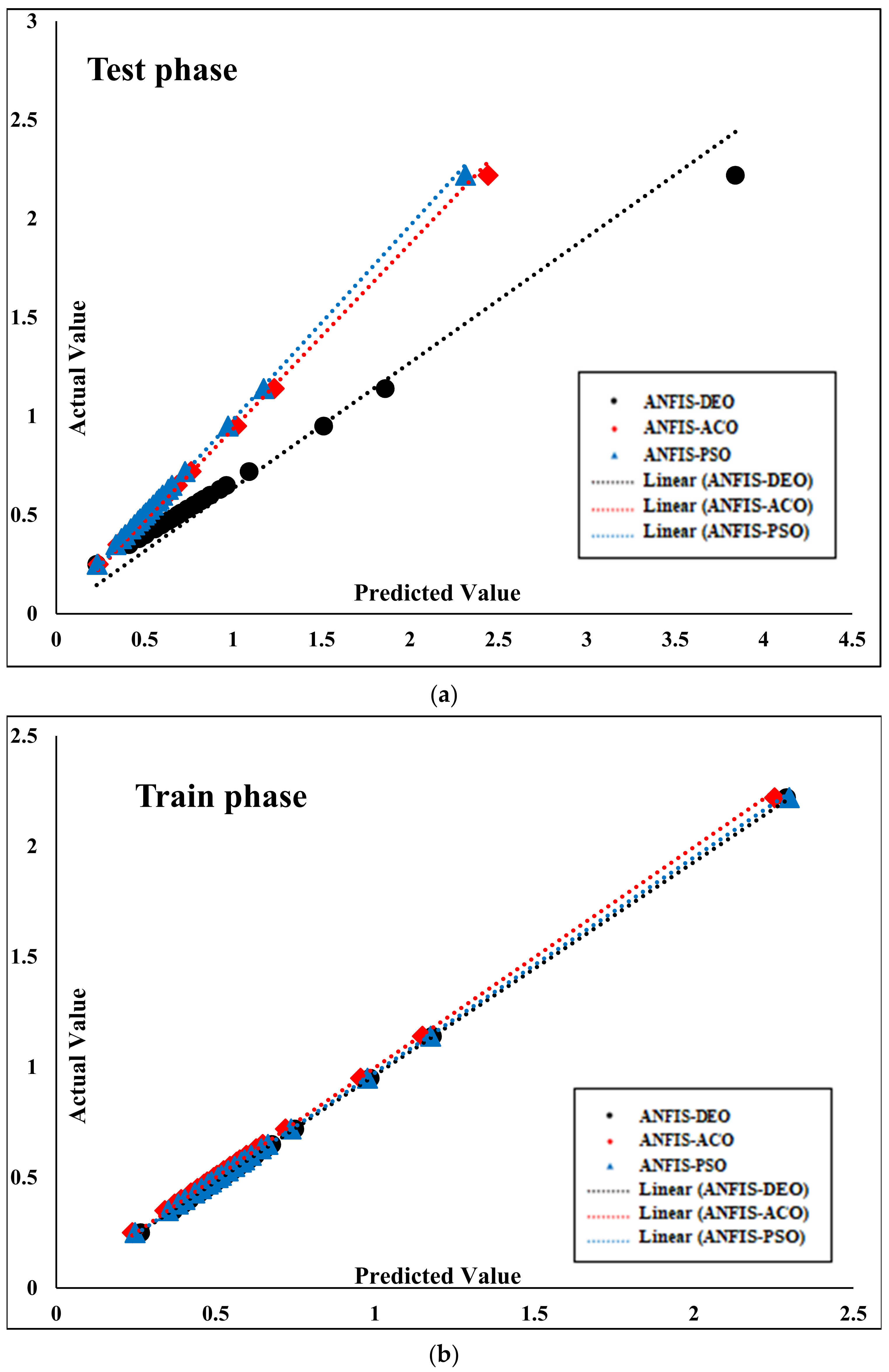

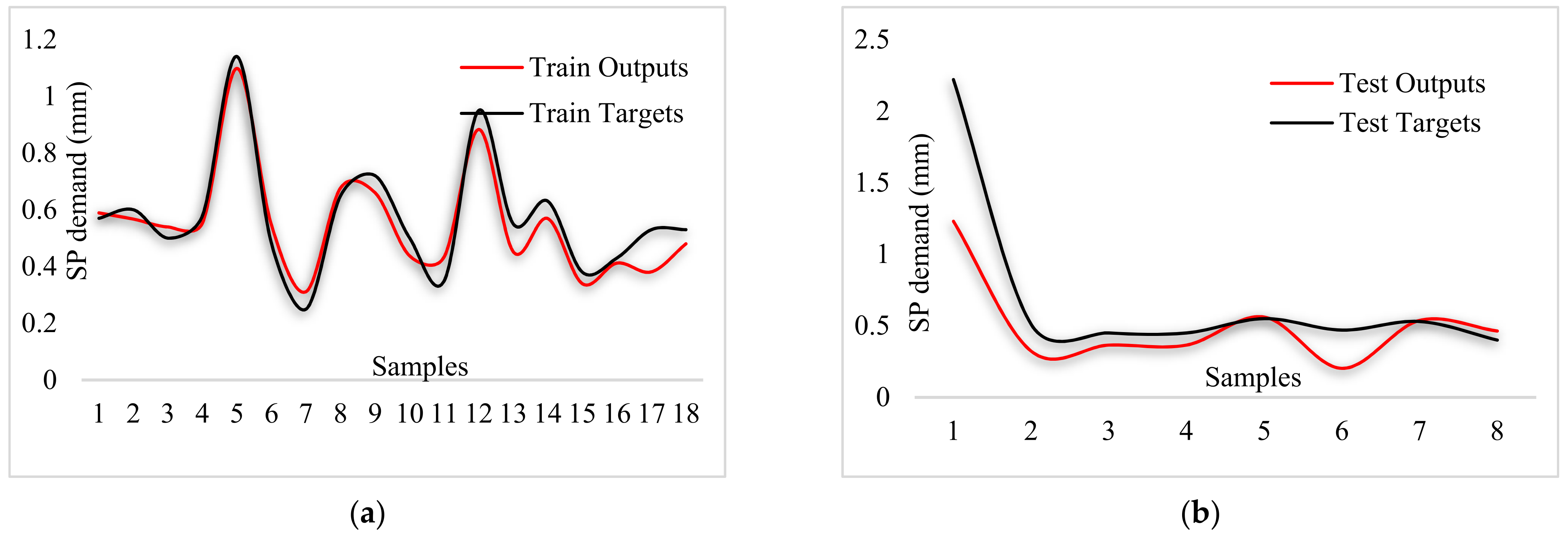

ANFIS was integrated with three metaheuristic algorithms, including PSO, ACO and DEO, to calculate the amount of required superplasticizer in concrete. The ANFIS parameters were constant in all three states. Cluster account has chosen 10% of data for training (70% of the input data) and testing (30% of the input data). The results show that all three hybrid neural networks are reliable. However,

Figure 10 and

Table 9 show that the ANFIS-DEO algorithm has slightly overtrained. After performing several experiments that combined different input states as well as various states of neural network algorithm parameters, the best results were selected for each algorithm as follows:

As shown in

Table 9, the performance parameters in the testing phase for ANFIS-PSO model are RMSE = 0.0633, r = 0.9387 and R

2 = 0.9871, for ANFIS-ACO are RMSE = 0.0864, r = 0.9073 and R

2 = 0.8231, and for ANFIS-DEO are RMSE = 0.3717, r = 0.9362 and R

2 = 0.8765. In the training phase, these parameters for ANFIS-PSO were RMSE = 0.0529, r = 0.9935 and R

2 = 0.8811 while ANFIS-ACO provided RMSE = 0.0854, r = 0.9787 and R

2 = 0.9579, and ANFIS-DEO obtained RMSE = 0.0638, r = 0.9556 and R

2 = 0.9132.

Given that the best result for RMSE is the lowest one, and for r, the best positive correlation coefficient is 1.0, the numbers closer to 1.0 are; therefore, better results. Considering all the conditions stated above, it is clear that the ANFIS-PSO algorithm performs better than the other two algorithms in the testing phase, as shown in

Figure 10.

Figure 11 shows comparable slope lines of both training and testing phases of employed algorithms. According to

Figure 11a, ANFIS-PSO and ANFIS-ACO algorithms produced very good results and performed better in the training phase. By observing the slope of the lines in

Figure 11b, it is clear that ANFIS-PSO and ANFIS-ACO algorithms are able to find a better relationship between the input and output data and also provide appropriate results in the testing phase.

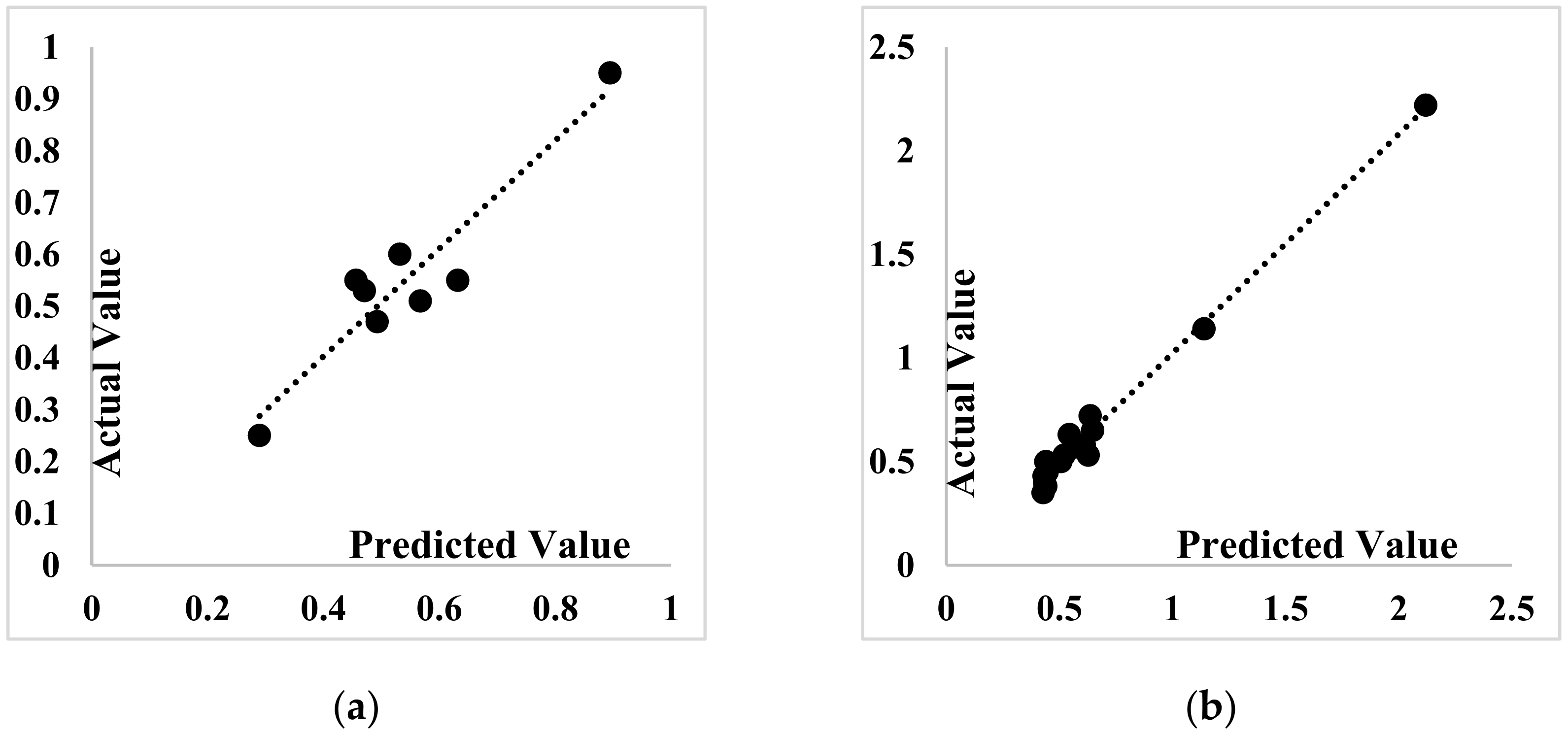

The calculated regression equations for each algorithm are shown in

Table 10, and the corresponding graphs are indicated in

Figure 12,

Figure 13 and

Figure 14. In both training and testing phases, the ANFIS-PSO algorithm performs better than ANFIS-ACO and ANFIS-DEO.

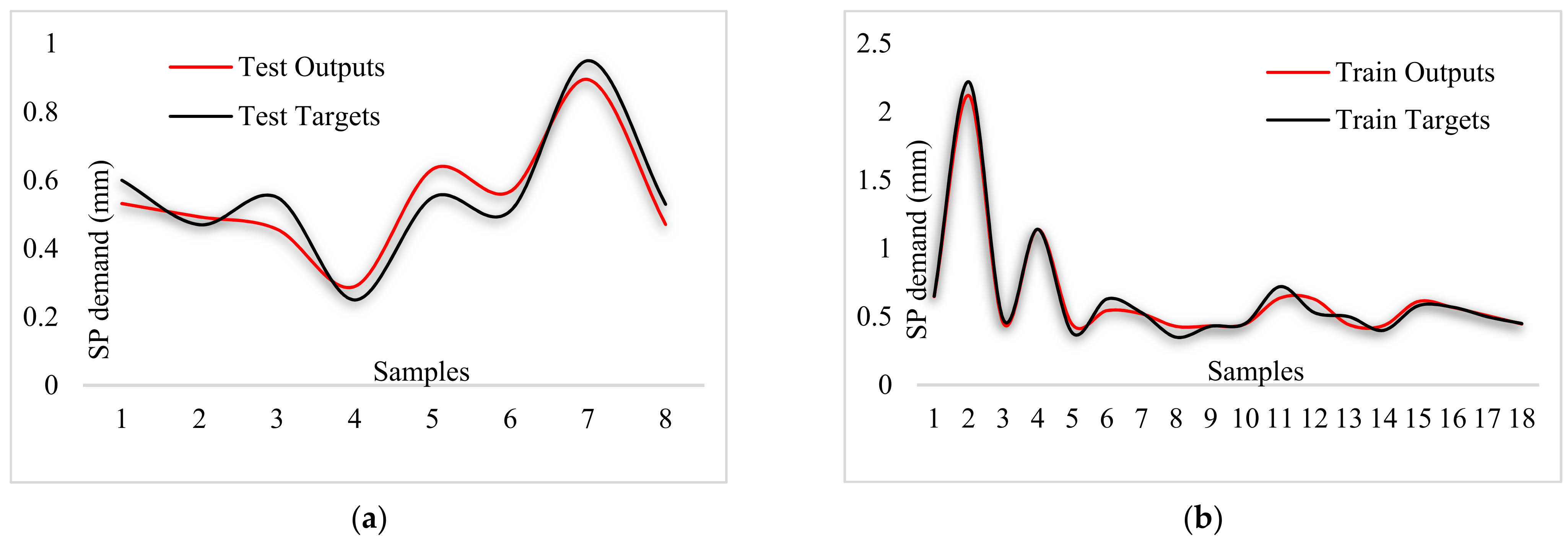

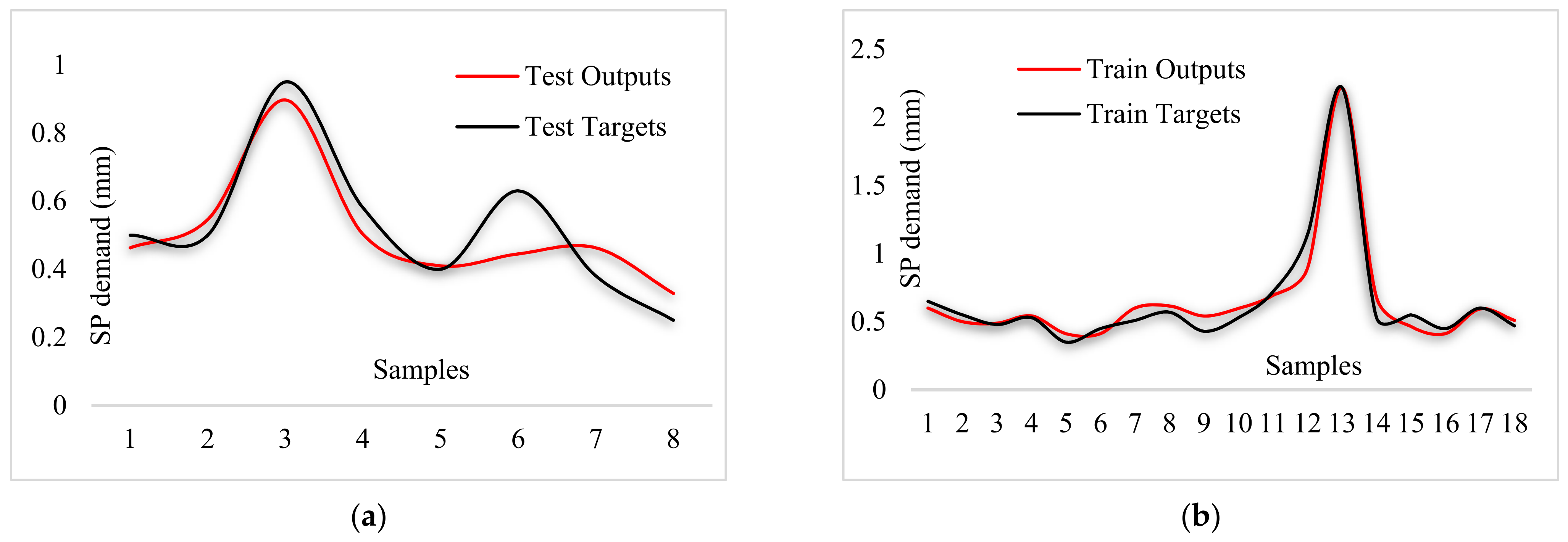

By comparing

Figure 15,

Figure 16 and

Figure 17, the better capability of the ANFIS-PSO model for predicting each of the measured values of the test samples can be observed, which is more accurate than other models.

According to

Table 11, error numbers indicate the accuracy of the results in which the smaller value implies the accurate process. The standard deviation value directly illustrates the behavior of the results in accordance with the mean value, where the smaller the standard deviation number, the closer the results are to the mean value. Therefore, the ANFIS-PSO algorithm performs better in both the testing and training phases.

Figure 18 shows the error diagrams with corresponding envelop for all hybrid algorithms. It can be seen that the ANFIS-PSO has a smaller error interval, indicating the least error mean of this model.

As discussed comprehensively, ANFIS can be considered as a reliable predictive method to be integrated with other metaheuristics algorithms, like previous studies [

28,

43,

44] which have used hybrid algorithms to solve non-linear relationships between input and output variables.

6. Conclusions

Self-consolidating concrete (SCC) requires a higher dosage of cement compared to normal concrete, which is a controversial issue from an environmental point of view. In order to solve this problem, researchers studied different natural and synthetic powders as partial replacements. The remaining workability of SCC is an important factor to achieve a sustainable mix design, which is directly related to superplasticizer (SP) content in the SCC mix. SP demand is an optimum value of a dosage, which is derived from non-destructive tests. This study was aimed to investigate the application of artificial intelligence algorithms to overcome the difficulties in the prediction of SP demand through non-destructive tests including J-ring, U-box, V-funnel, 3 min slump and T50. To this end, ANFIS was integrated with three metaheuristic algorithms, namely PSO, ACO and DEO. The most important results can be summarized as follows:

The developed hybrid algorithms were trained by the collected dataset and, finally, the SP demand values were predicted for specified SCC mixes. In terms of performance parameters, all hybrid algorithms obtained promising results.

Compared to other proposed algorithms, ANFIS-PSO represented the best evaluation criteria including RMSE = 0.0633, r = 0.9387 and R2 = 0.9871 in the testing phase and RMSE = 0.0529, r = 0.9935 and R2 = 0.8811 in the training phase. Prediction errors were also in an acceptable range where the ANFIS-PSO indicated the lowest ones. Additionally, test and train results of all three algorithms were presented in an analogous regression diagram for a better understanding of the accuracy and eligibility of each technique.

It was found that metaheuristic algorithms, especially the PSO technique, are able to cover the prediction problems of non-linear data. In general, the best performance of hybrid models was obtained for ANFIS-PSO, ANFIS-ACO and ANFIS-DEO, respectively. In addition, it seems that ANFIS can be a good base for other metaheuristic optimization algorithms such as genetic algorithm, firefly and bee colony.