Laboratory Research and Evaluation on Design and Application Performance of High-Performance Cold-Mix Resin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Resin and Resin Asphalts

2.1.1. Materials

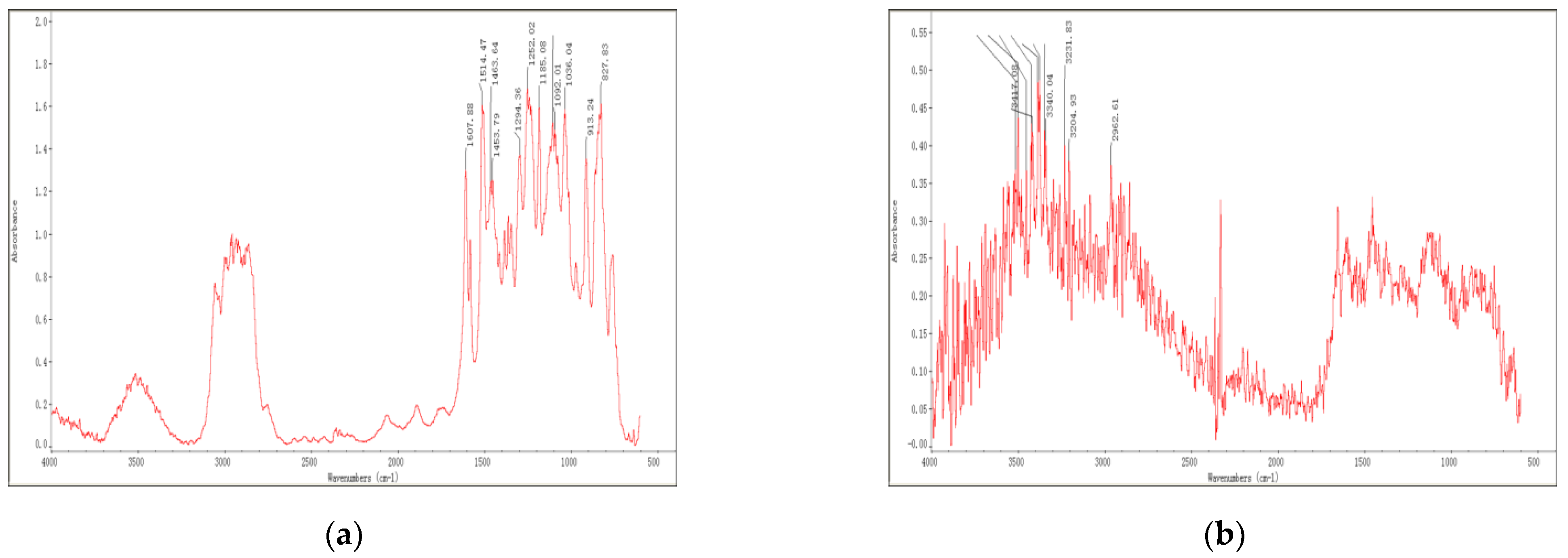

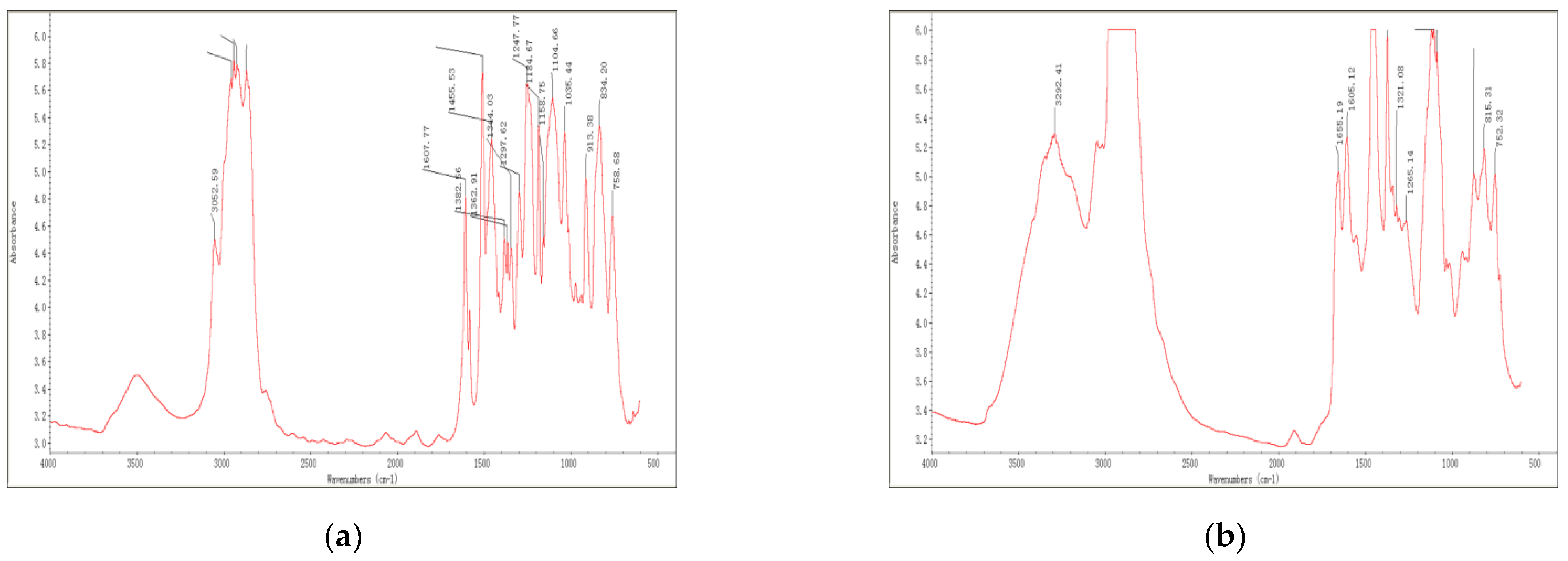

2.1.2. Infrared Spectrum

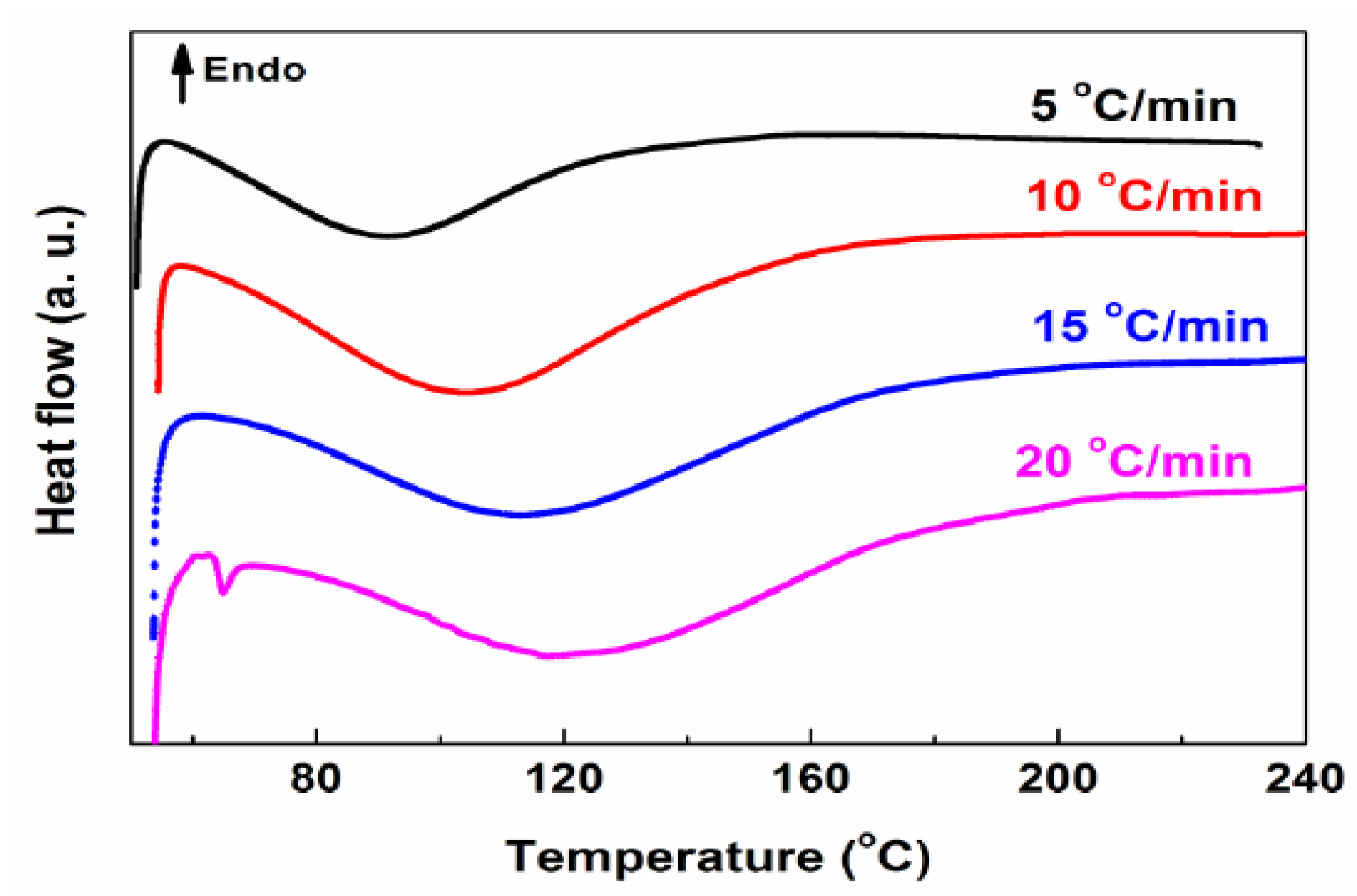

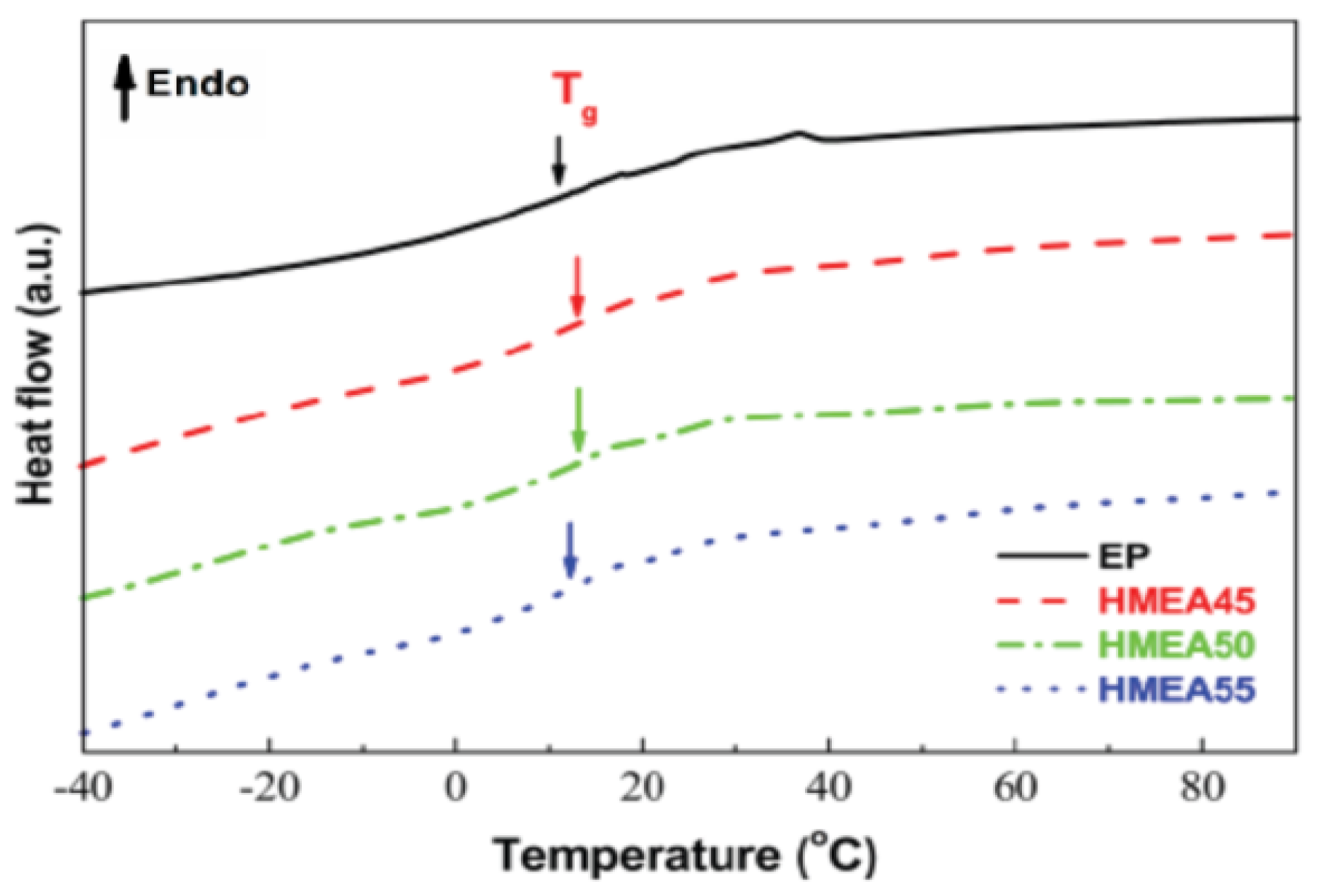

2.1.3. Differential Scanning Calorimetry

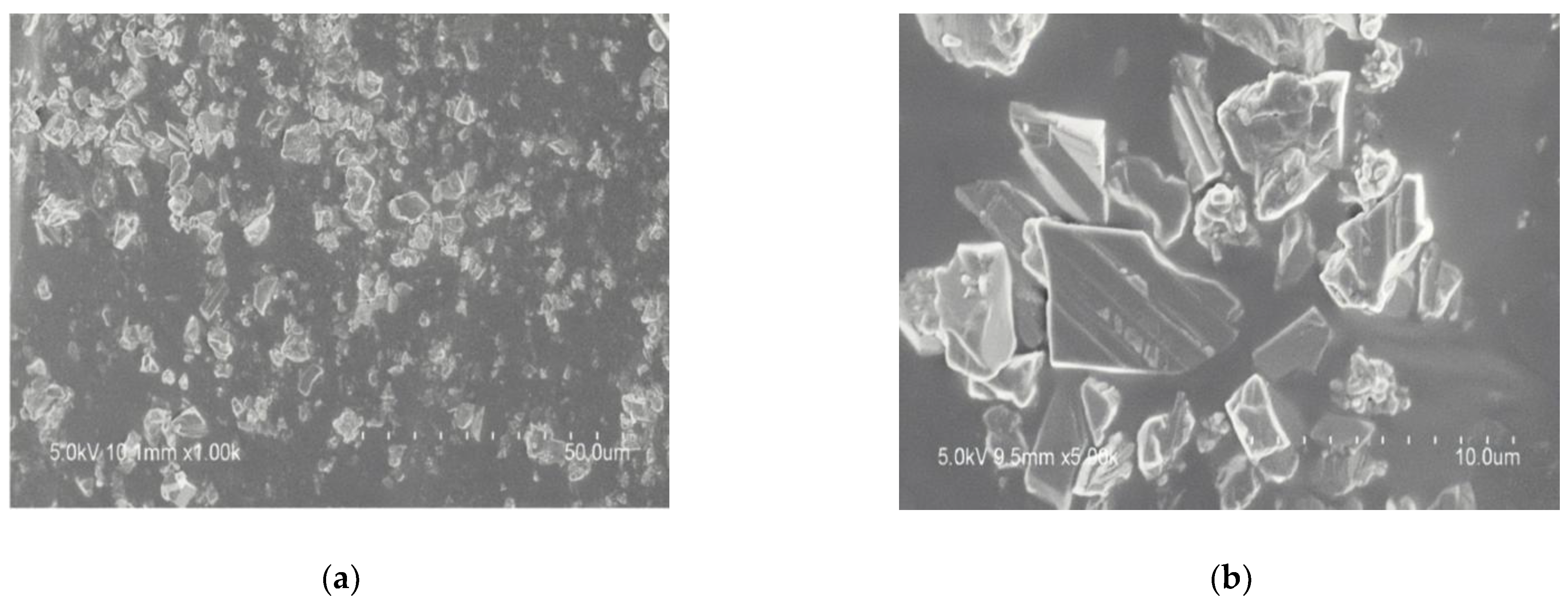

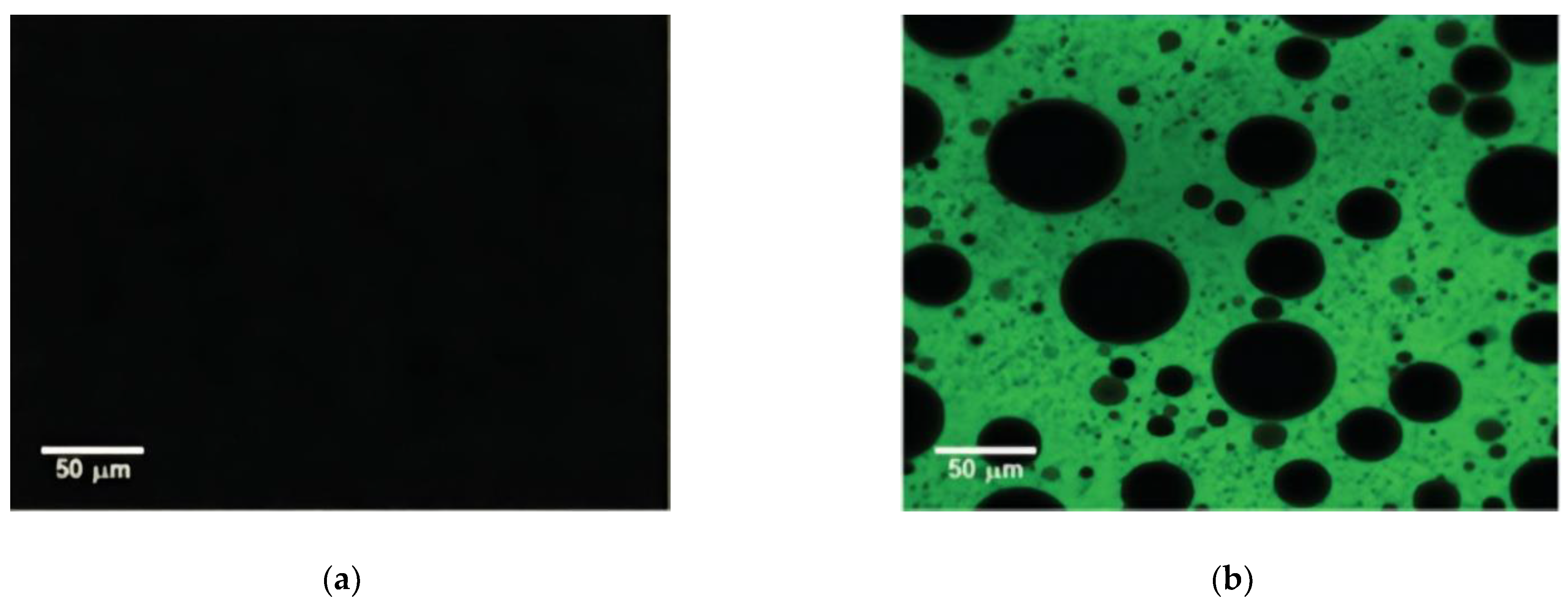

2.1.4. Microscopic Appearance

2.1.5. Fracture Tensile Test

2.2. High-Performance Cold-Mix Resin Mixtures and Hot-Mix Epoxy Asphalt Mixtures

2.2.1. Mix Proportion

2.2.2. Pavement Performance Test

2.2.3. Four-Point Bending Fatigue Test

3. Results and Discussions

3.1. IR Spectra

3.2. DSC

3.3. Microscopic Appearance

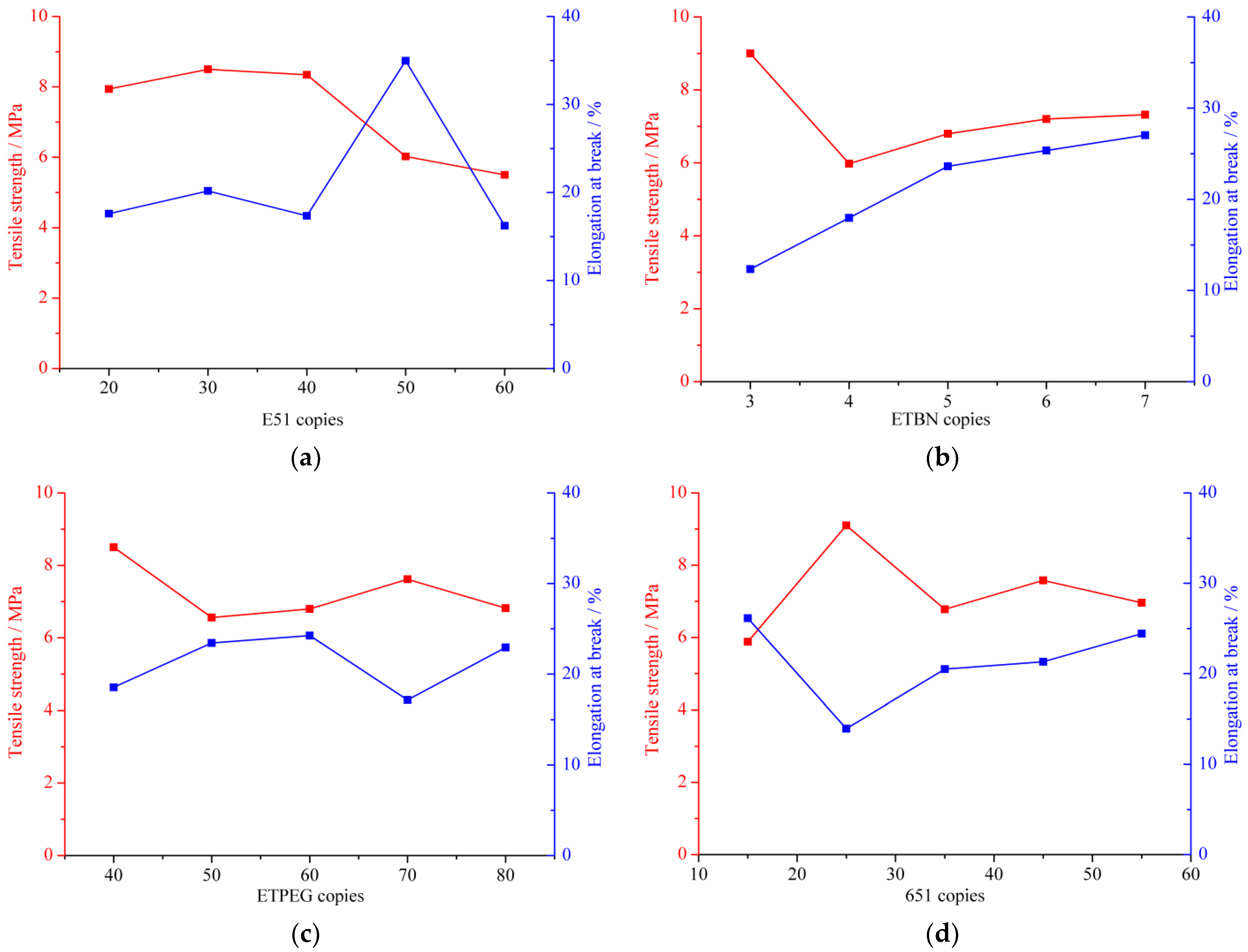

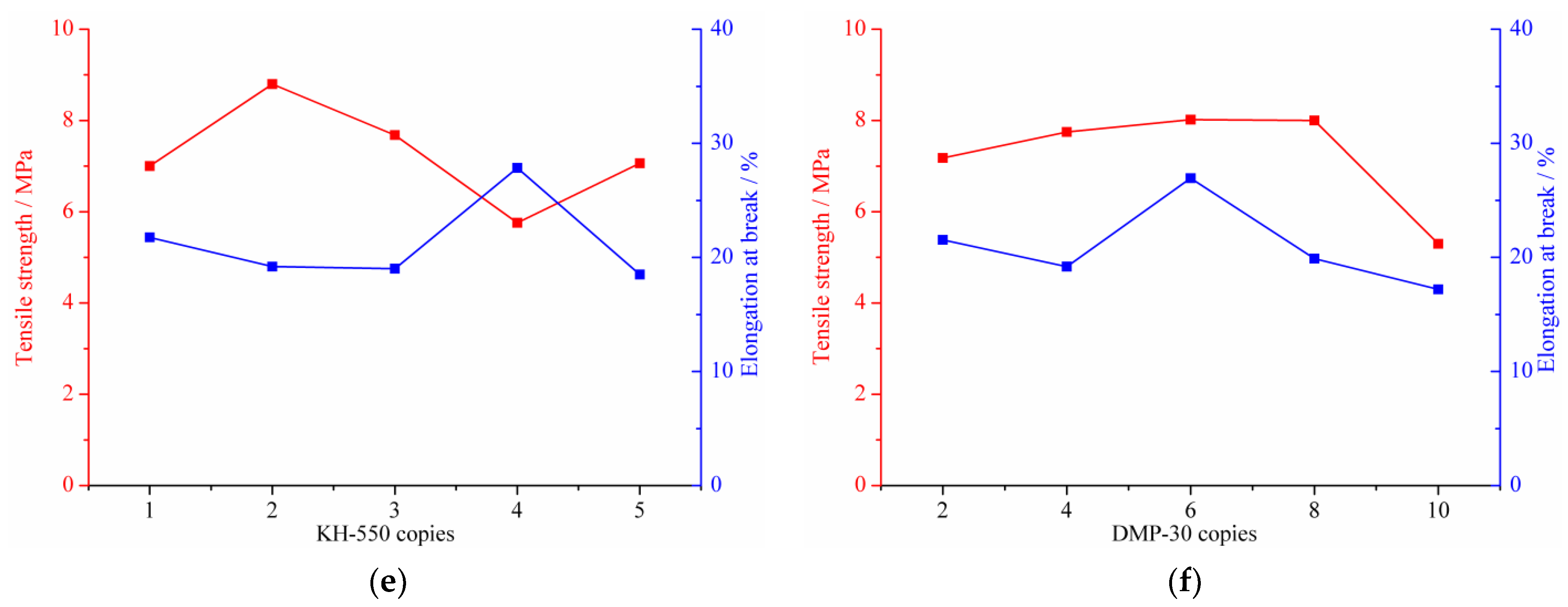

3.4. Influence of Component Content on Mechanical Properties of High-Performance Cold-Mix Resin

3.5. Pavement Performances

3.5.1. Water Stability

3.5.2. High and Low-Temperature Performances

3.6. Fatigue Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siwowski, T.; Kulpa, M.; Janas, L. Remaining fatigue life prediction of welded details in an orthotropic steel bridge deck. J. Bridge Eng. 2019, 24, 05019013. [Google Scholar] [CrossRef]

- Wang, F.; Tian, L.J.; Lyu, Z.D.; Zhao, Z.; Chen, Q.K.; Mei, H.L. Stability of full-scale orthotropic steel plates under axial and biased loading: Experimental and numerical studies. J. Constr. Steel Res. 2021, 181, 106613. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Yamada, K.; Ya, S.; Zhao, X.L. Stress analyses and fatigue evaluation of rib-to-deck joints in steel orthotropic decks. Int. J. Fatigue 2008, 30, 1387–1397. [Google Scholar] [CrossRef]

- Chen, X.H.; Huang, W.; Qian, Z.D.; Zhang, L. Design principle of deck pavements for long-span steel bridges with heavy-duty traffic in China. Road. Mater. Pavement. 2017, 18, 1–14. [Google Scholar] [CrossRef]

- Kolstein, M.H. Fatigue Classification of Welded Joints in Orthotropic Steel Bridge Decks. Ph.D. Thesis, Technische Universiteit (TU), Delft, The Netherlands, 2007. [Google Scholar]

- Corte, W.D.; Boel, V.; Helincks, P.; Schutter, G.D. Fatigue assessment of a lightweight steel-concrete bridge deck concept. Bridge Struct. 2016, 12, 11–19. [Google Scholar] [CrossRef]

- Wang, C.S.; Feng, Y.C.; Duan, L. Fatigue damage evaluation and retrofit of steel orthotropic bridge decks. In Key Engineering Materials; Trans Tech Publications, Ltd.: Stafa-Zurich, Switzerland, 2009; Volume 413–414, p. 05019013. [Google Scholar]

- Cui, C.; Xu, Y.L.; Zhang, Q.H. Multiscale fatigue damage evolution in orthotropic steel deck of cable-stayed bridges. Eng. Struct. 2021, 237, 112144. [Google Scholar] [CrossRef]

- Fang, Z.; Ding, Y.L.; Wei, X.C.; Li, A.Q.; Geng, F.F. Fatigue failure and optimization of double-sided weld in orthotropic steel bridge decks. Eng. Fail. Anal. 2020, 116, 104750. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Picado-Santos, L.G.; Capitao, S.D. Influence of recycled concrete and steel slag aggregates on warm-mix asphalt properties. Constr. Build. Mater. 2018, 185, 684–696. [Google Scholar] [CrossRef]

- Kim, Y.J.; Im, S.H.; Lee, D.; Hwang, S.D. Evaluation of warm mix asphalt mixtures with foaming technology and addtives using new simple performance testing equipment. Int. J. Highway Eng. 2008, 10, 19–29. [Google Scholar]

- Pan, R.; Li, Y.M. Effect of warm mix rubber modified asphalt mixture as stress absorbing layer on anti-crack performance in cold region. Constr. Build. Mater. 2020, 251, 118985. [Google Scholar] [CrossRef]

- Zeng, G.D.; Xu, W.; Huang, H.M.; Zhang, X.N. Study on the microstructure and properties of hot-mix epoxy asphalt. Int. J. Pavement Res. Technol. 2019, 12, 147–153. [Google Scholar] [CrossRef]

- Cristescu, N.D.; Craciun, E.M.; Soós, E. Mechanics of Elastic Composites; Chapman & Hall/CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Xu, W.; Wei, J.T.; Chen, Z.X.; Wang, F.; Zhao, J. Evaluation of the Effects of Filler Fineness on the Properties of an Epoxy Asphalt Mixture. Materials 2021, 14, 2003. [Google Scholar] [CrossRef] [PubMed]

- Fuhaid, A.A.; Lu, Q.; Luo, S. Laboratory Evaluation of Biobased Epoxy Asphalt Binder for Asphalt Pavement. J. Mater. Civ. Eng. 2018, 30, 06018007. [Google Scholar] [CrossRef]

- Min, Z.H.; Wang, Q.C.; Xie, Y.X.; Xie, J.Q.; Zhang, B. Influence of polyethylene glycol chain on the performance of epoxy asphalt binder and mixture. Constr. Build. Mater. 2020, 272, 121614. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Sun, J.; Huang, Z.G.; Wang, F.; Jia, M.; Lv, W.J.; Ye, J.J. A laboratory study of epoxy/polyurethane modified asphalt binders and mixtures suitable for flexible bridge deck pavement. Constr. Build. Mater. 2021, 274, 122084. [Google Scholar] [CrossRef]

- Gaul, R.W. Epoxy asphaly concrete- a polymer concrete with 25 years’ experience. Am. Soc. Test. Mater. 1996, 166, 233–251. [Google Scholar]

- Yu, J.Y.; Cong, P.L.; Wu, S.P. Laboratory investigation of the properties of asphalt modified with epoxy resin. J. Appl. Polym. Sci. 2009, 113, 3557–3563. [Google Scholar] [CrossRef]

- Kang, Y.; Song, M.Y.; Pu, L.; Liu, T.F. Rheological behaviors of epoxy asphalt binder in comparison of base asphalt binder and SBS modified asphalt binder. Constr. Build. Mater. 2015, 76, 343–350. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Yilmaz, M. Effect of polyester resin additive on the properties of asphalt binders and mixtures. Constr. Build. Mater. 2008, 22, 481–486. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Li, J.S.; Wang, Z.Y.; Long, S.Y.; Jiang, S.J.; Liu, G.L. Preparation and performance characterization of a novel high-performance epoxy resin modified reactive liquid asphalt. Constr. Build. Mater. 2020, 263, 120113. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.D.; Shi, X.J.; Zhang, Y.H.; Ren, H.S. Developing cold-mixed epoxy resin-based ultra-thin antiskid surface layer for steel bridge deck pavement. Constr. Build. Mater. 2021, 291, 123366. [Google Scholar] [CrossRef]

- Lei, Y.B.; Cao, X.J. Preparation of epoxy-resin concrete using microwave curing method and its pavement performance evaluation. J. Mater. Civ. Eng. 2015, 27, 04014221. [Google Scholar] [CrossRef]

- Ge, Z.S.; Wang, H.; Zhang, Q.S.; Xiong, C.L. Glass fiber reinforced asphalt membrane for interlayer bonding between asphalt overlay and concrete pavement. Constr. Build. Mater. 2015, 101, 918–925. [Google Scholar] [CrossRef]

- Shanbara, H.K.; Ruddock, F.; Atherton, W. A laboratory study of high-performance cold mix asphalt mixtures reinforced with natural and synthetic fibres. Constr. Build. Mater. 2018, 172, 166–175. [Google Scholar] [CrossRef]

- Ma, S.Q.; Liu, W.Q.; Hu, C.H.; Wang, Z.F.; Tang, C.Y. Toughening of epoxy resin system using a novel dendritic polysiloxane. Macromol. Res. 2010, 18, 392–398. [Google Scholar] [CrossRef]

- GB/T 6040-2002. General Rules for Infrared Analysis; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2002.

- Hanaoka, T.; Arao, Y.; Kayaki, Y.; Kuwata, S.; Kubouchi, M. Analysis of nitric acid decomposition of epoxy resin network structures for chemical recycling. Polym. Degrad. Stabil. 2021, 186, 109537. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, P.W.; Pan, Y.Q.; Li, K.; Zhang, Z.X.; Geng, F. Development of cold-mix high-toughness resin and experimental research into its performance in a steel deck pavement. Constr. Build. Mater. 2020, 235, 117427. [Google Scholar]

- Si, J.J.; Jia, Z.X.; Wang, J.Y.; Yu, X.; Li, Y.; Dong, F.Q.; Jiang, R.L. Comparative analysis of cold-mixed epoxy and epoxy SBS-modified asphalts: Curing rheology, thermal, and mechanical properties. Constr. Build. Mater. 2018, 176, 165–171. [Google Scholar] [CrossRef]

- JTG E20-2011. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; The People’s Republic of China Ministry of Transport: Beijing, China, 2011.

- Han, S.O.; Drzal, L.T. Water absorption effects on hydrophilic polymer matrix of carboxyl functionalized glucose resin and epoxy resin. Eur. Polym. J. 2003, 39, 1791–1799. [Google Scholar] [CrossRef]

- Liu, J.Y.; Sun, Y.R.; Wang, W.Y.; Chen, J.Y. Using the viscoelastic parameters to estimate the glass transition temperature of asphalt binders. Constr. Build. Mater. 2017, 153, 908–917. [Google Scholar] [CrossRef]

- Kang, Y.; Chen, Z.M.; Jiao, Z.; Huang, W. Rubber-like thermosetting epoxy asphalt composites exhibiting atypical yielding behaviors. J. Appl. Polym. Sci. 2010, 116, 1678–1685. [Google Scholar] [CrossRef]

| Sieve Size (mm) | Mass Percentage of the Mixtures Passing through the Following Sieves (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16.0 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| Upper limit (%) | 100 | 100 | 85 | 68 | 50 | 38 | 28 | 20 | 15 | 12 |

| Lower limit (%) | 100 | 90 | 68 | 38 | 24 | 15 | 10 | 7 | 5 | 4 |

| Composite gradation | 100.0 | 97.1 | 78.5 | 46.3 | 38.5 | 30.5 | 19.5 | 13.4 | 11.1 | 9.5 |

| Sieve Size (mm) | Mass Percentage of the Mixtures Passing through the Following Sieves (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16.0 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| Upper limit (%) | 100 | 100 | 100 | 85 | 70 | 55 | 40 | 32 | 23 | 14 |

| Lower limit (%) | 100 | 100 | 95 | 65 | 50 | 39 | 28 | 21 | 14 | 7 |

| Composite gradation | 100.0 | 100 | 97.5 | 75 | 60 | 45.5 | 34 | 25 | 17 | 10.5 |

| Items | Component A | Component B |

|---|---|---|

| DOW epoxy resin | DER 332 | Hardener XU-HY 943 * |

| TY-RA epoxy resin | DER 324 | Paramul ERO-SB *** |

| YC-YN epoxy resin | EPON 828 | Paramul ERO-SB |

| Index | Test Result | |

|---|---|---|

| High-Performance Cold-Mix Resin Mixtures | Hot-Mix Epoxy Asphalt Mixtures | |

| Immersed Marshall stability (kN) | 77.91 | 56.06 |

| Standard Marshall stability (kN) | 80.00 | 57.20 |

| Residual Marshall stability MS0 (%) | 97.4 | 98.0 |

| Splitting tensile strength after freeze-thaw cycles (MPa) | 7.21 | 2.79 |

| Standard splitting tensile strength (MPa) | 8.02 | 2.82 |

| Freeze-thaw splitting tensile strength ratio TSR (%) | 90.0 | 98.9 |

| Condition | Index | Test Result | |

|---|---|---|---|

| High-Performance Cold-Mix Resin Mixtures | Hot-Mix Epoxy Asphalt Mixtures | ||

| High temperature (60 °C) | Dynamic stability (cycles/mm) | 62,327 | 61,931 |

| Low temperature (−10 °C) | Flexural tensile strength (MPa) | 35.2 | 37.3 |

| Ultimate flexural tensile strain (με) | 4158.0 | 4157.2 | |

| Stress Level (με) | Index | Test Result | |

|---|---|---|---|

| High-Performance Cold-Mix Resin Mixtures | Hot-Mix Epoxy Asphalt Mixtures | ||

| 400 | Initial stiffness modulus (MPa) | 21,000 | 16,200 |

| Mean fatigue life (×104 cycles) | >100 | 20 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Q.-W.; Gao, P.-W.; Xu, Y.-F.; Dong, G.-Q.; Chen, M.-M.; Zhao, J.-W.; Jin, G.-L. Laboratory Research and Evaluation on Design and Application Performance of High-Performance Cold-Mix Resin. Materials 2021, 14, 4828. https://doi.org/10.3390/ma14174828

Zeng Q-W, Gao P-W, Xu Y-F, Dong G-Q, Chen M-M, Zhao J-W, Jin G-L. Laboratory Research and Evaluation on Design and Application Performance of High-Performance Cold-Mix Resin. Materials. 2021; 14(17):4828. https://doi.org/10.3390/ma14174828

Chicago/Turabian StyleZeng, Qing-Wei, Pei-Wei Gao, Yang-Fu Xu, Guo-Qing Dong, Man-Man Chen, Jing-Wei Zhao, and Guang-Lai Jin. 2021. "Laboratory Research and Evaluation on Design and Application Performance of High-Performance Cold-Mix Resin" Materials 14, no. 17: 4828. https://doi.org/10.3390/ma14174828

APA StyleZeng, Q.-W., Gao, P.-W., Xu, Y.-F., Dong, G.-Q., Chen, M.-M., Zhao, J.-W., & Jin, G.-L. (2021). Laboratory Research and Evaluation on Design and Application Performance of High-Performance Cold-Mix Resin. Materials, 14(17), 4828. https://doi.org/10.3390/ma14174828