Determining Johnson-Cook Constitutive Equation for Low-Carbon Steel via Taylor Anvil Test

Abstract

:1. Introduction

2. Materials and Methods

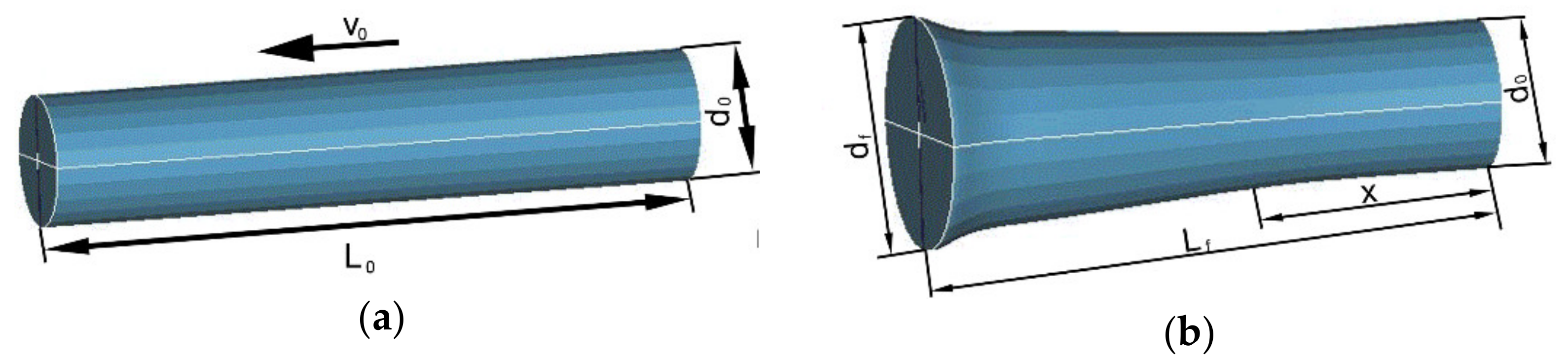

2.1. Taylor Test, Theoretical Background

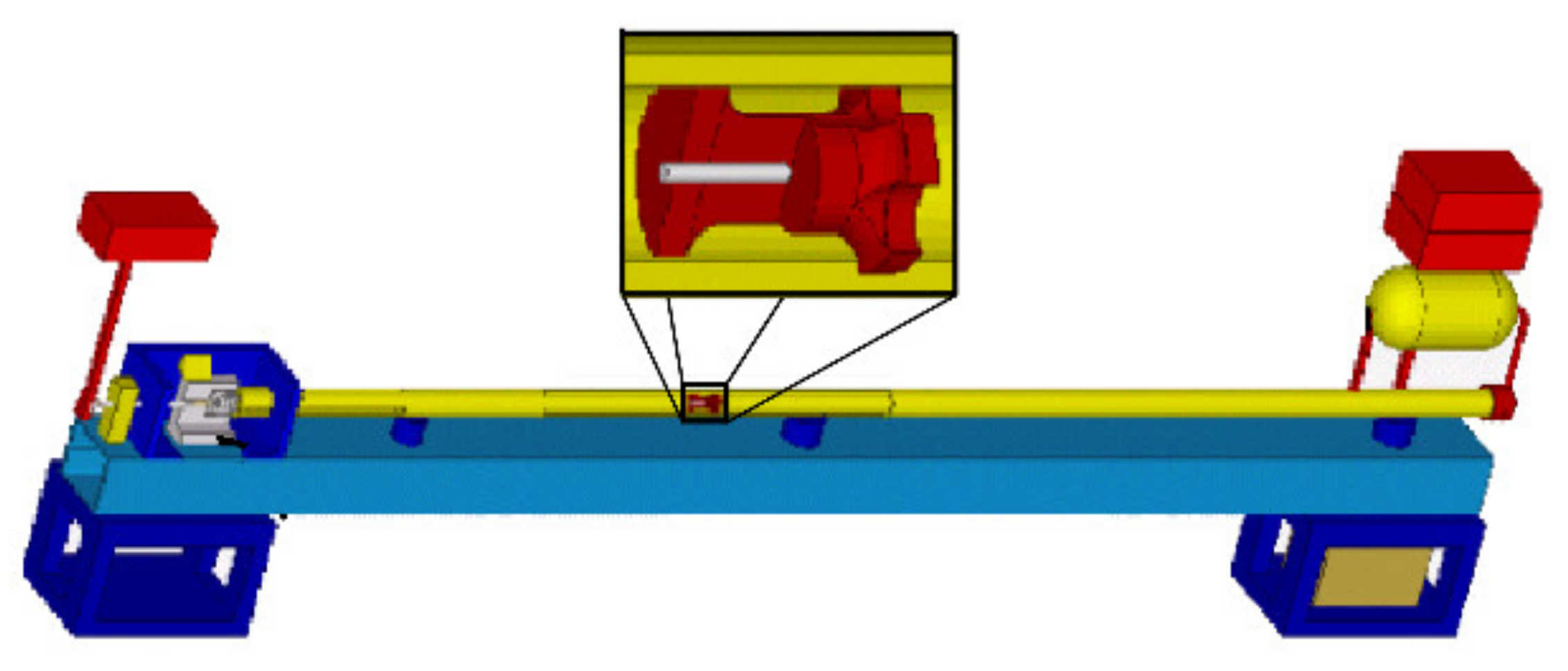

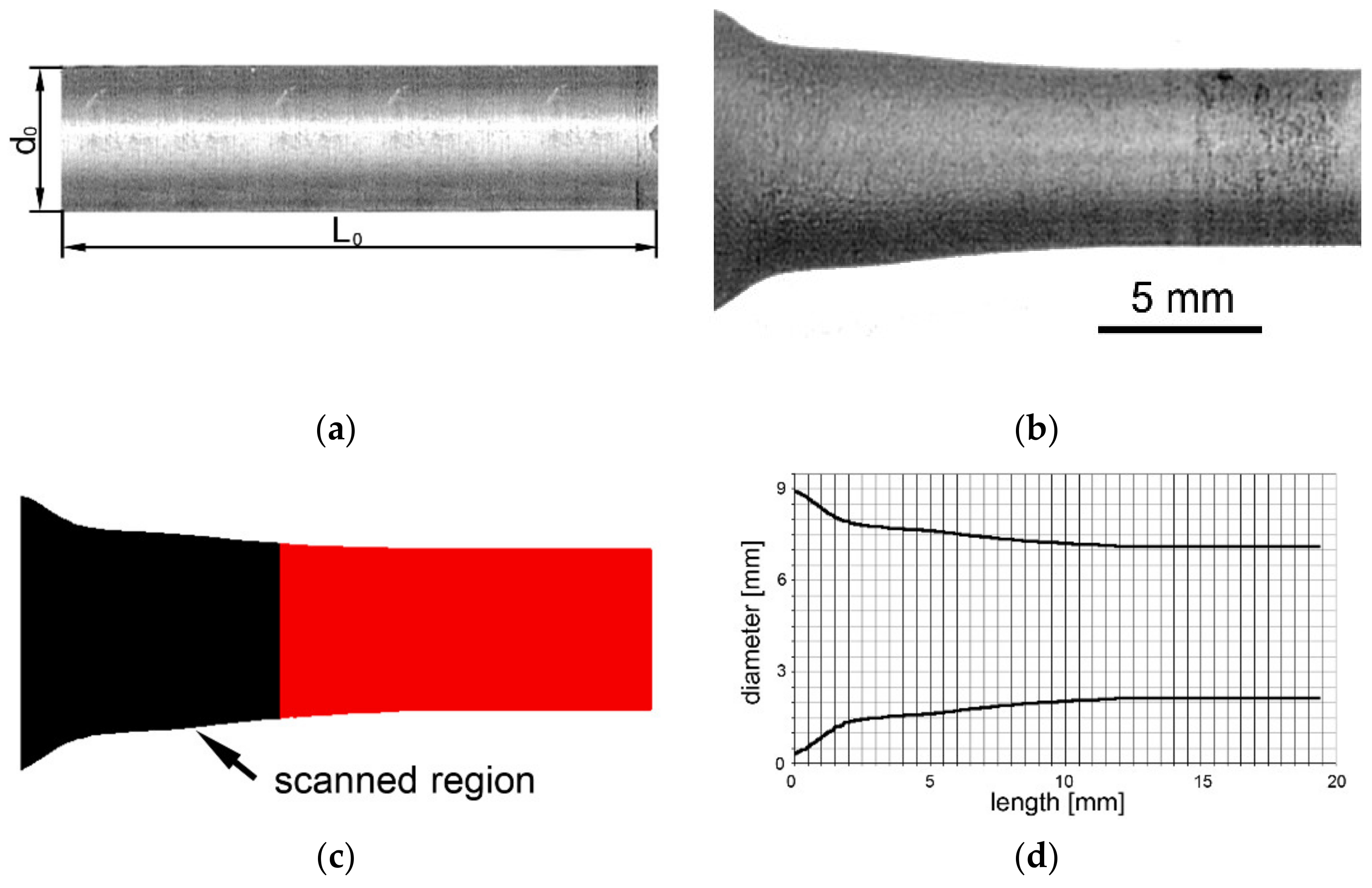

2.2. Experimental

2.3. Numerical Simulation

3. Results

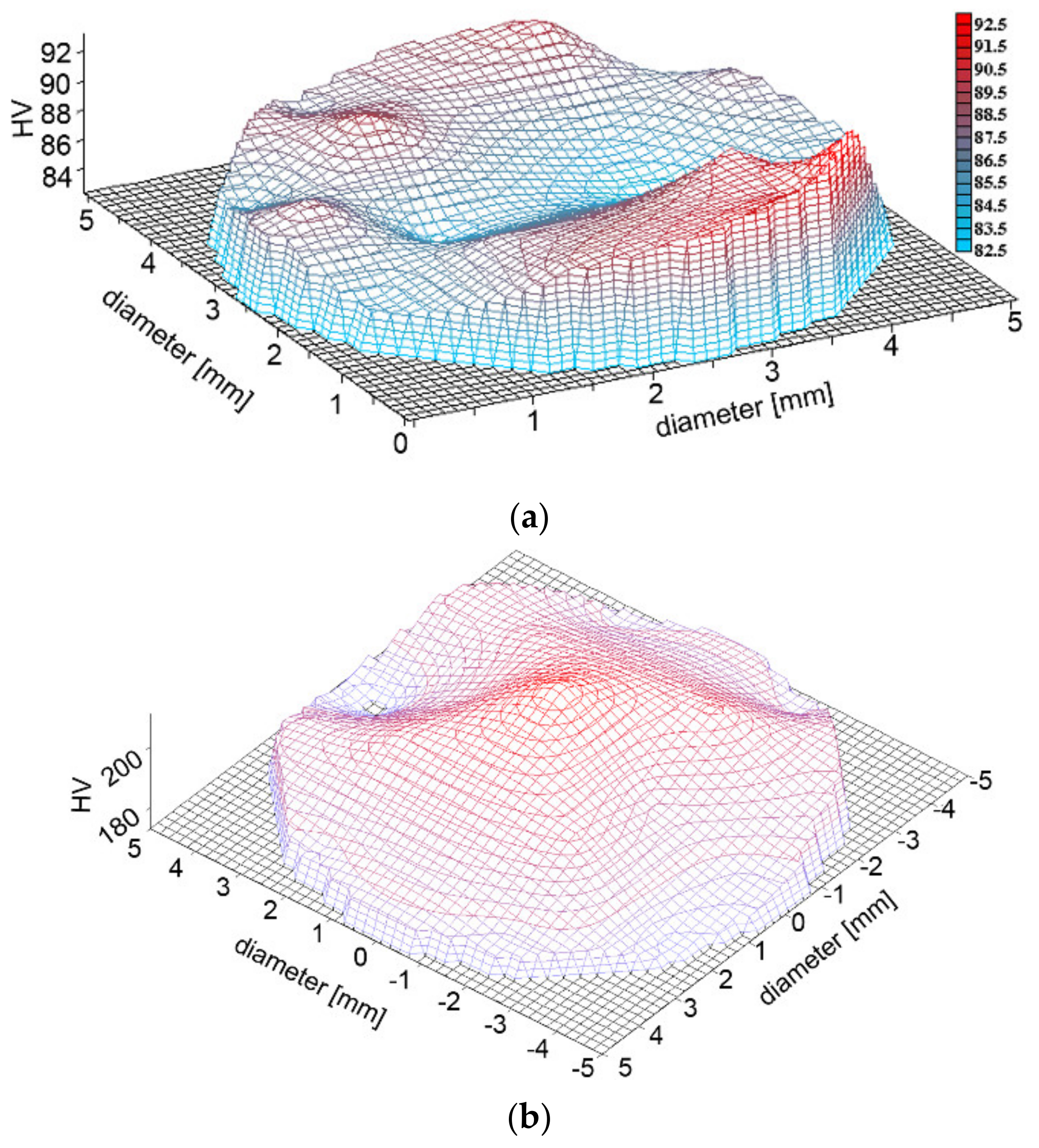

3.1. Structure Analyses

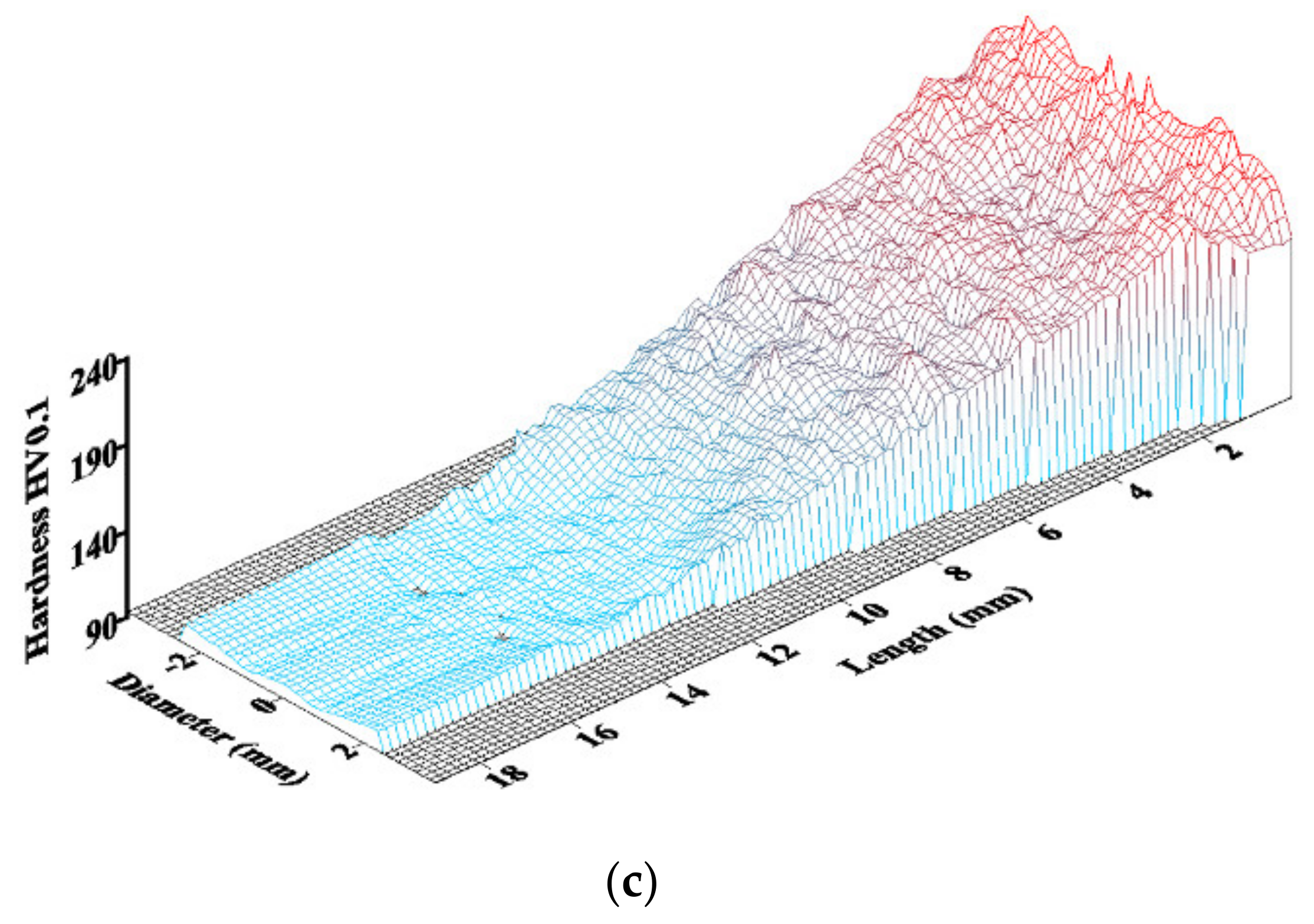

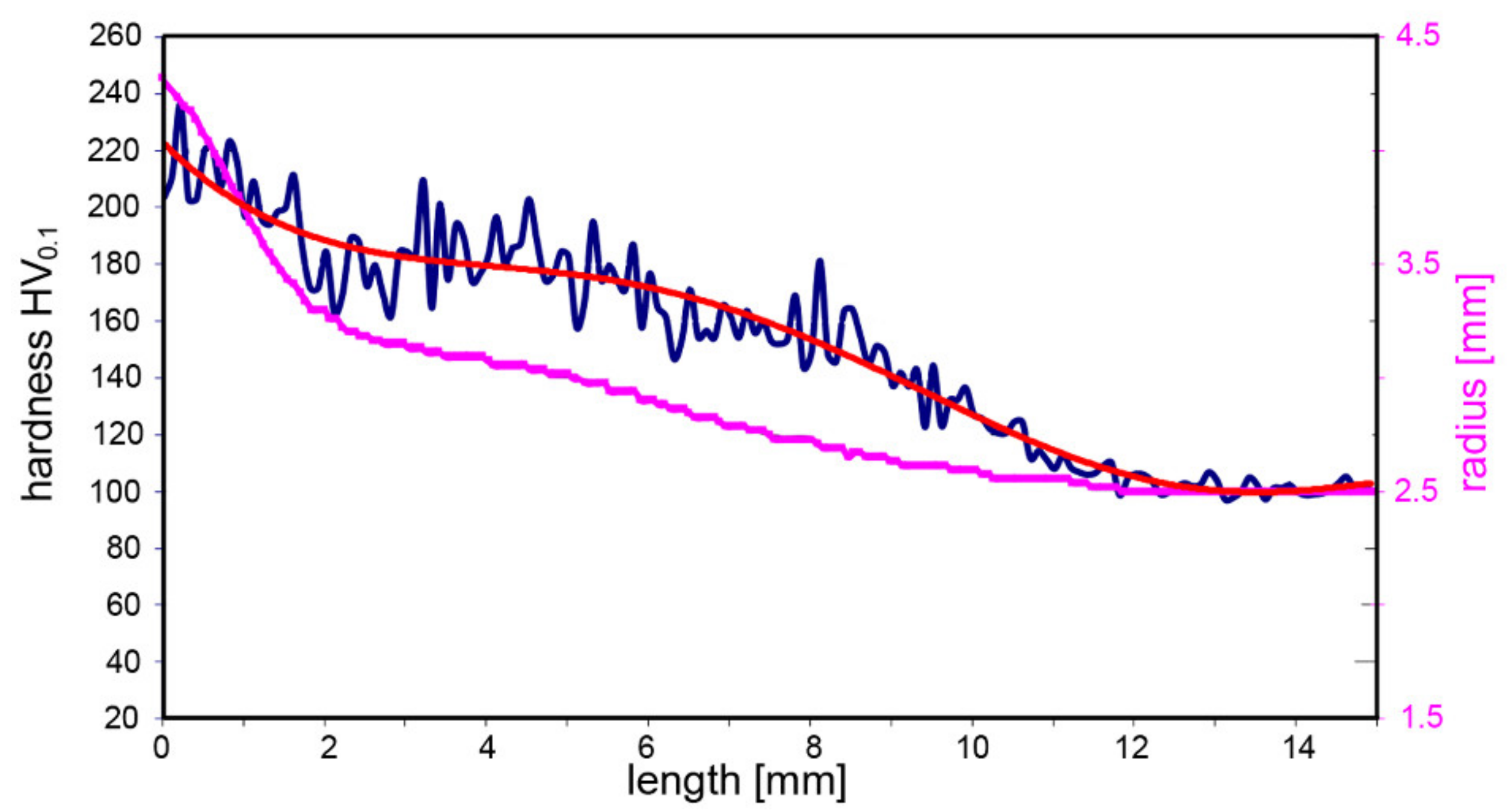

3.2. Hardness Measurements

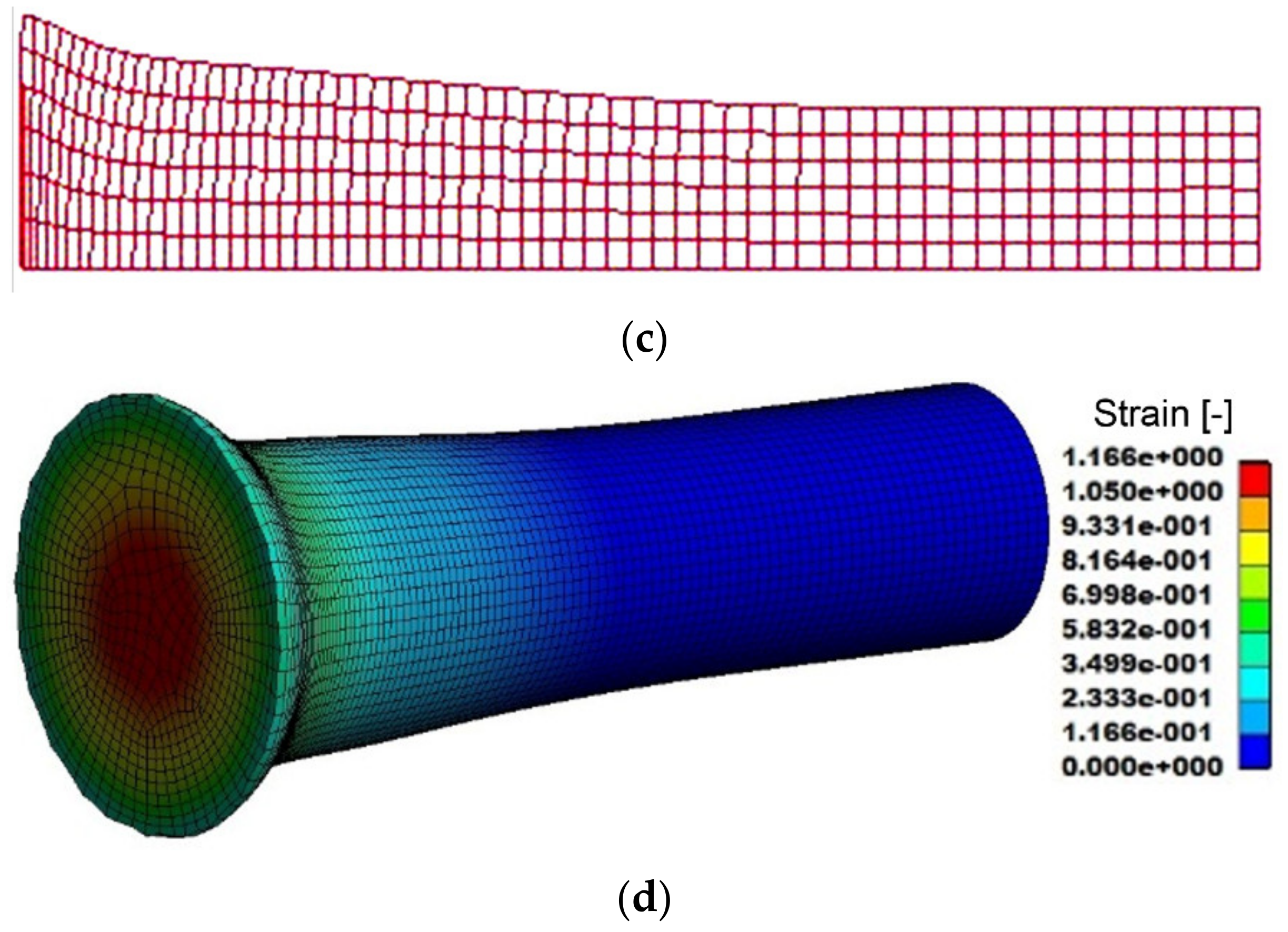

3.3. TAT Specimen Analyses

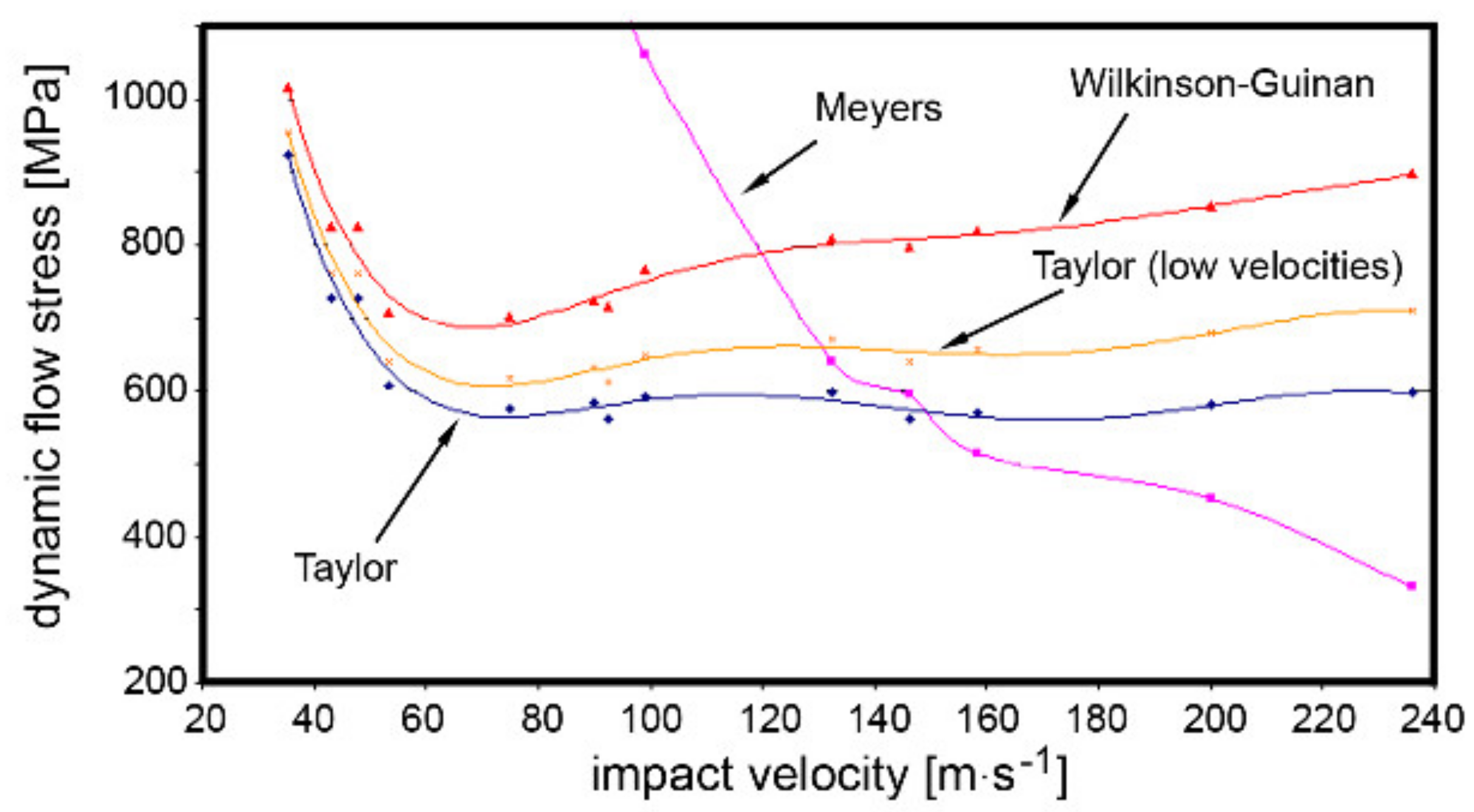

3.4. Dynamic Flow Stress Analysis

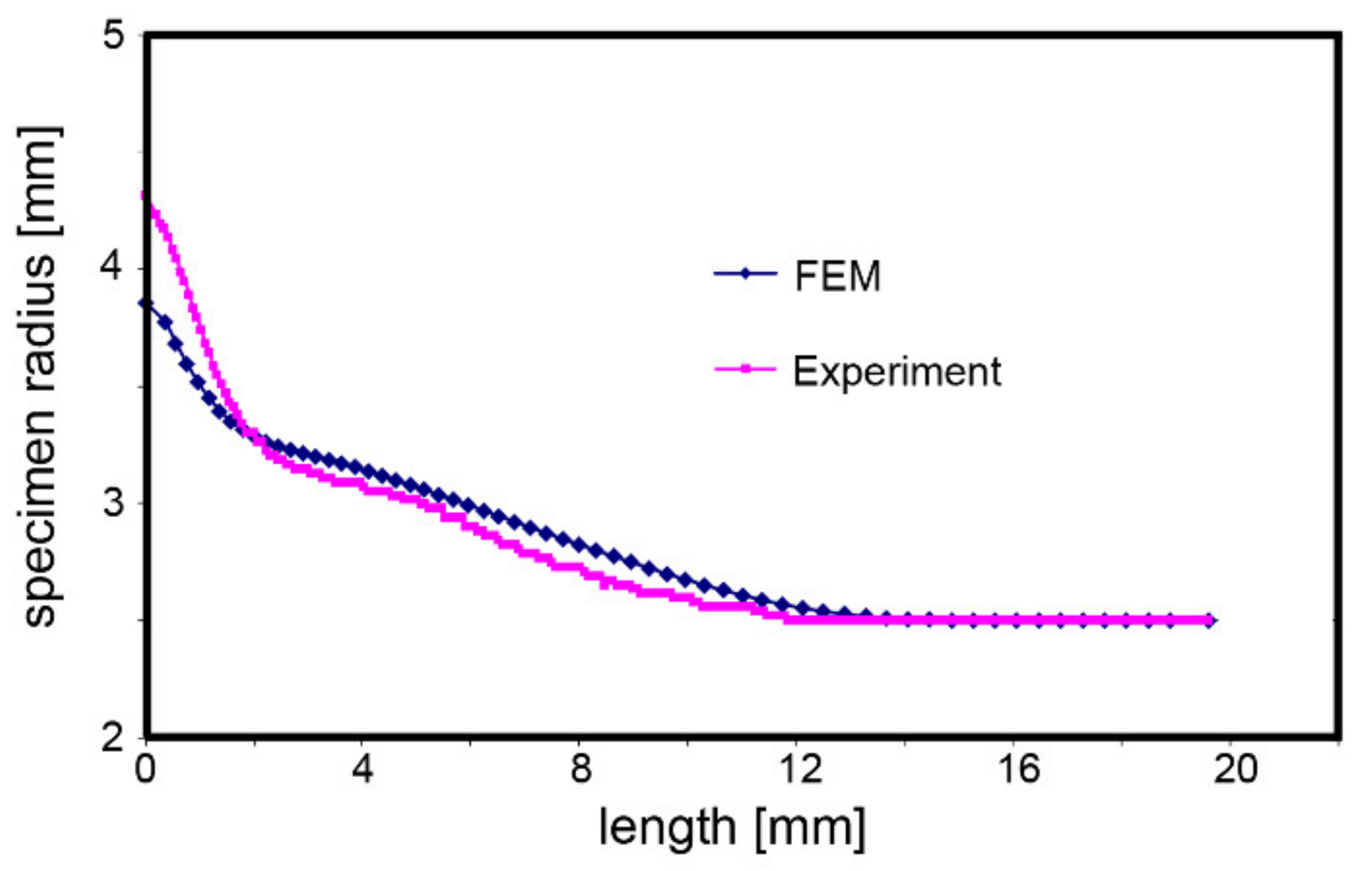

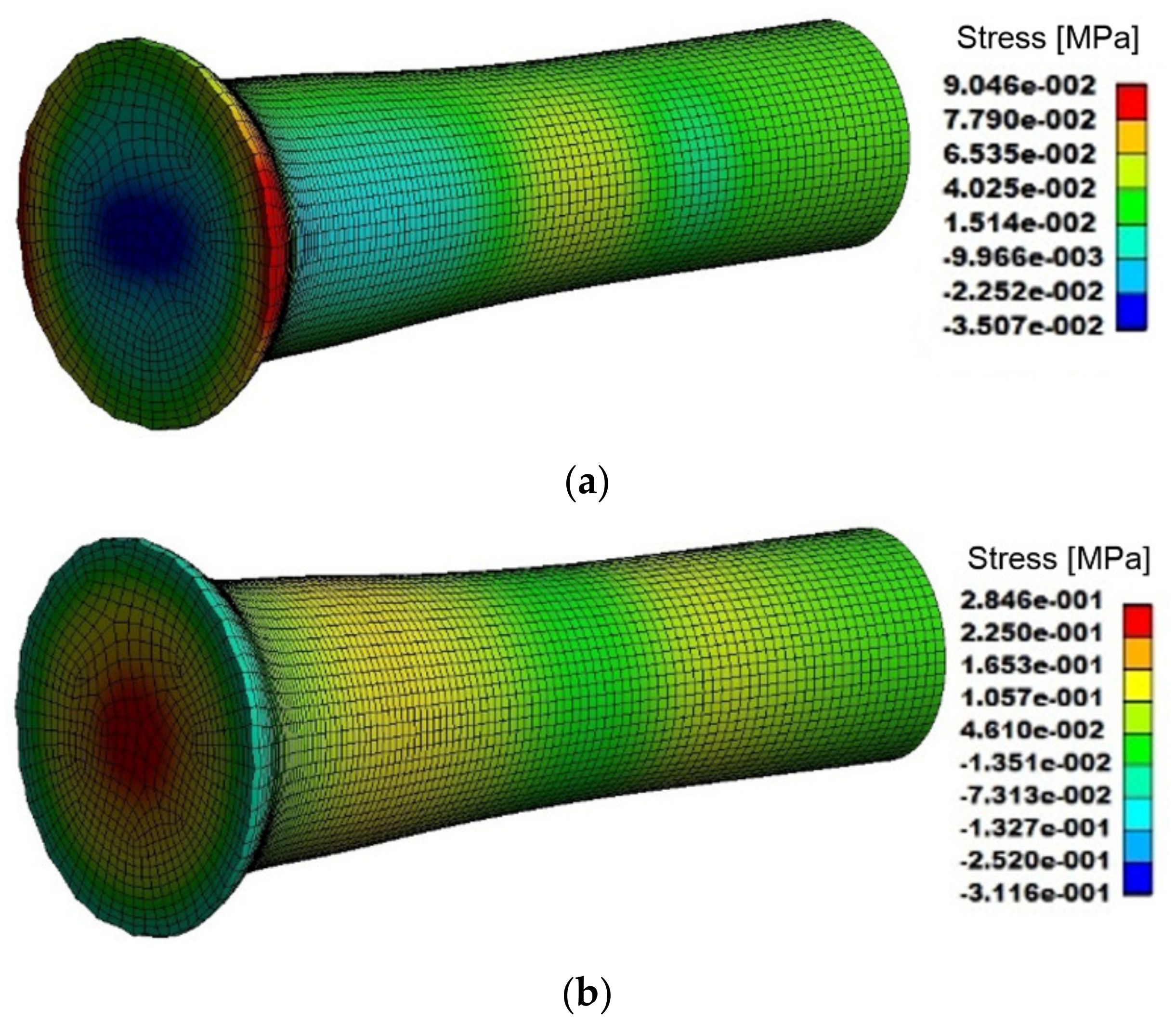

3.5. Finite Element Analyses

3.6. Determination of Parameters for Johnson–Cook Model

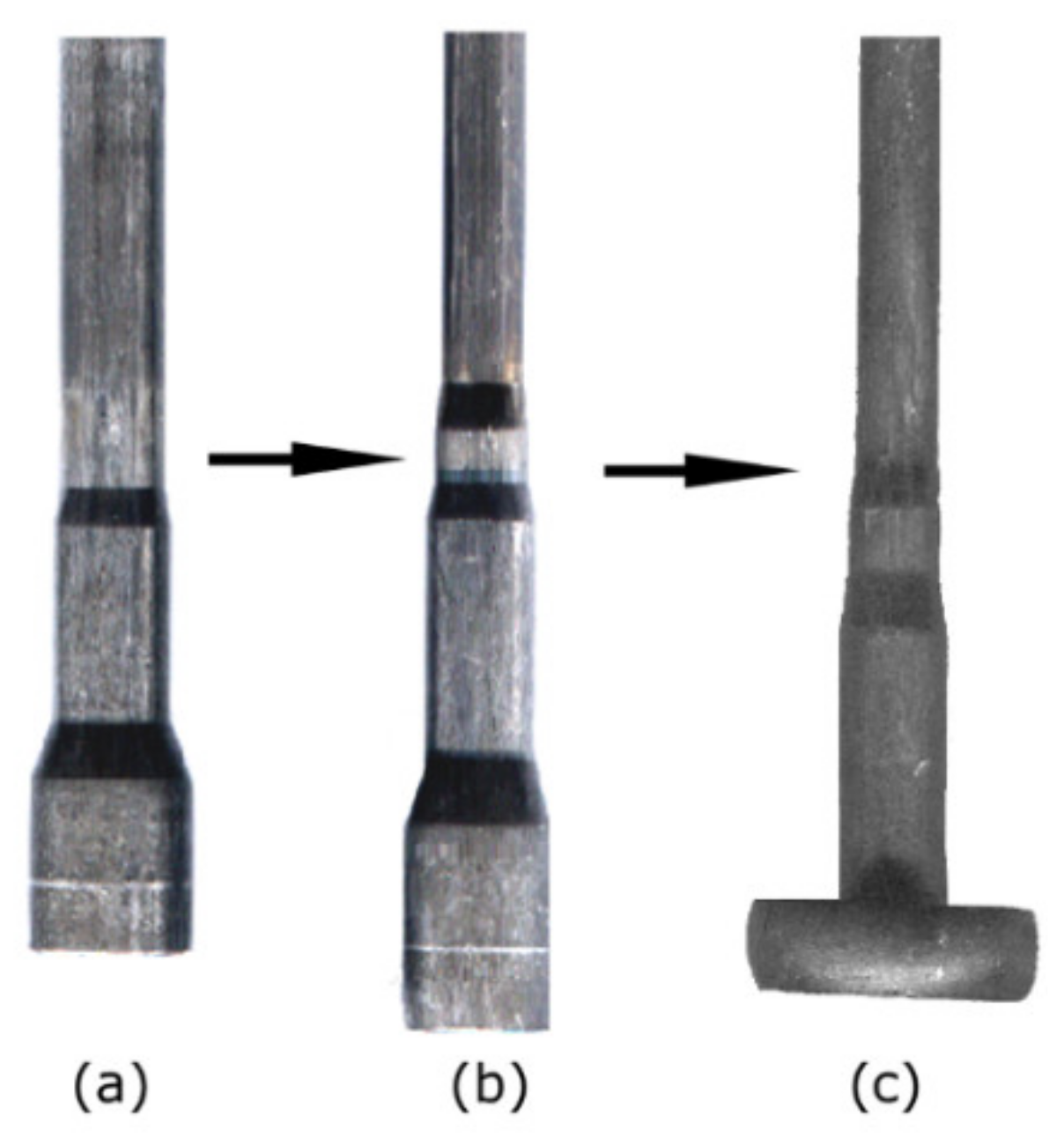

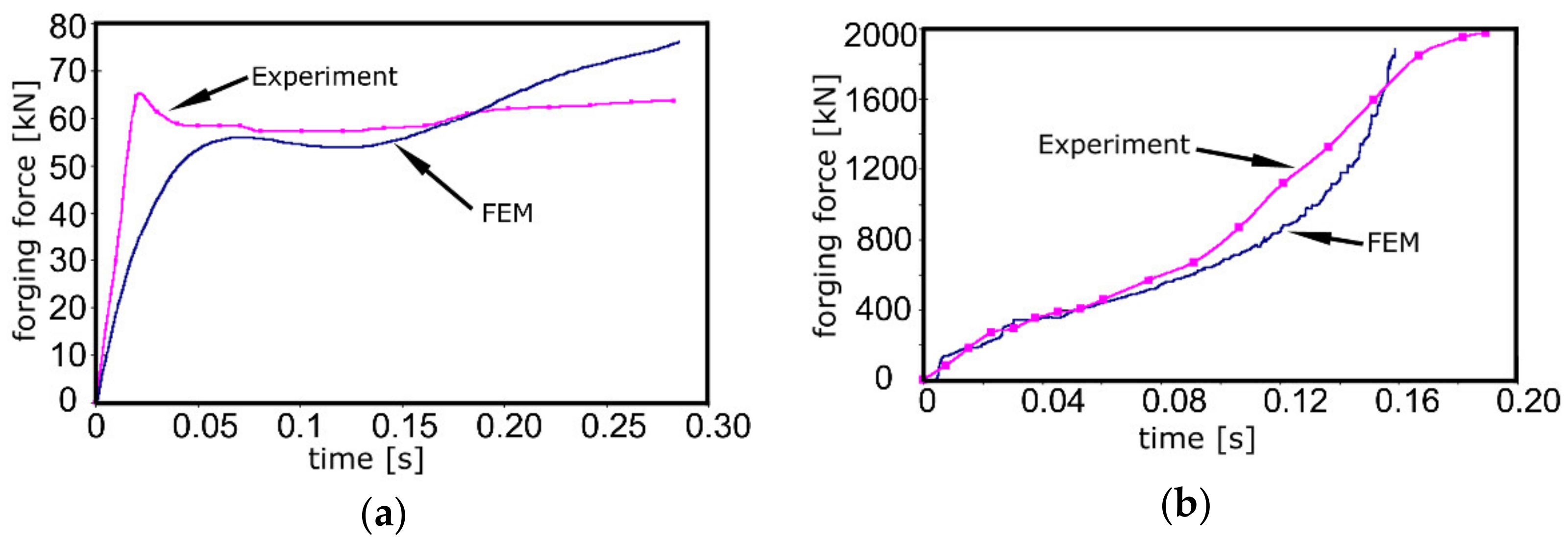

3.7. Experimental Verification of Developed Johnson–Cook Model

4. Discussion

5. Conclusions

- The predicted distribution of stress-strain parameters was in accordance with the deformed geometry and hardness of the experimental specimen;

- n hardening exponent and m strain rate sensitivity coefficient change at a value of effective strain of ~0.50;

- Optimised parameters of the Johnson–Cook equation for TRISTAL steel were n = 0.3 and m = 0.72;

- The results are not affected by friction-predicted geometry corresponded to the experiment when negligible friction was applied (due to ultra-high strain rate);

- The final verification of the material model performed via real production on TPZD25 automatic sequential machine, documented satisfactory correlation of predicted and experimental results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hammer, J. Automatic defensive control of asynchronous sequential machines. Int. J. Control 2016, 89, 193–209. [Google Scholar] [CrossRef]

- Chen, D.Y.; Xu, Y.; Zhang, S.H.; Ma, Y.; El-Aty, A.A.; Pokrovsky, A.I.; Bakinovskaya, A.A. A novel method to evaluate the high strain rate formability of sheet metals under impact hydroforming. J. Mater. Process. Technol. 2021, 287, 116553. [Google Scholar] [CrossRef]

- Malvar, L.; Crawford, J. Dynamic Increase Factors for Steel Reinforcing Bars. In Proceedings of the Twenty-Eighth DoD Explosives Safety Seminar Proceedings, Orlando, FL, USA, 18–20 August 1998. [Google Scholar]

- Razaqpur, G.; Mekky, W.; Foo, S. Fundamental concepts in blast resistance evaluation of structures. Can. J. Civ. Eng. 2009, 36, 1292–1304. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Dvořák, K.; Macháčková, A. Rotary swaged laminated Cu-Al composites: Effect of structure on residual stress and mechanical and electric properties. Mater. Sci. Eng. 2019, 742, 742–750. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. Deformation behaviour of Cu-Al clad composites produced by rotary swaging. IOP Conf. Ser. Mater. Sci. Eng. 2018, 369, 012029. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Strunz, P.; Macháčková, A. Texture and residual stress within rotary swaged Cu/Al clad composites. Mater. Lett. 2018, 230, 88–91. [Google Scholar] [CrossRef]

- Ma, Y.; Xu, Y.; Zhang, S.H.; Banabic, D.; El-Aty, A.A.; Chen, D.; Cheng, M.; Song, H.; Pokrovsky, A.I.; Chen, G. Investigation on formability enhancement of 5A06 aluminium sheet by impact hydroforming. CIRP Ann. 2018, 67, 281–284. [Google Scholar] [CrossRef]

- El-Aty, A.A.; Xu, Y.; Zhang, S.H.; Ha, S.; Ma, Y.; Chen, D. Impact of high strain rate deformation on the mechanical behavior, fracture mechanisms and anisotropic response of 2060 Al-Cu-Li alloy. J. Adv. Res. 2019, 18, 19–37. [Google Scholar] [CrossRef]

- Kosing, O.E.; Skews, B.W. High speed metal forming of circular disks and cylindrical tubes in a liquid shock tube. Trans. Built Environ. 1998, 32, 661–670. [Google Scholar]

- Kunčická, L.; Macháčková, A.; Lavery, N.P.; Kocich, R.; Cullen, J.C.T.; Hlaváč, L.M. Effect of thermomechanical processing via rotary swaging on properties and residual stress within tungsten heavy alloy. Int. J. Refract. Met. Hard Mater. 2020, 87, 105120. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, J.; Besnard, C.; Kunčická, L.; Kocich, R.; Korsunsky, A.M. In situ neutron diffraction investigation of texture-dependent Shape Memory Effect in a near equiatomic NiTi alloy. Acta Mater. 2021, 202, 135–148. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Davis, C.F.; Lowe, T.C.; Szurman, I.; Macháčková, A. Deformation behavior of multilayered Al-Cu clad composite during cold-swaging. Mater. Des. 2016, 90, 379–388. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates, and High Temperatures. In Proceedings of the 7th International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Buchar, J.; Forejt, M.; Jopek, M.; Křivánek, I. Evaluation of constitutive relations for high strain rate behaviour using the Taylor Test. J. DePhysique 2000, 9, 75–80. [Google Scholar] [CrossRef]

- Khan, A.S.; Huang, S. Experimental and theoretical study of mechanical behavior of 1100 aluminum in the strain rate range 10−5−104s−1. Int. J. Plast. 1992, 8, 397–424. [Google Scholar] [CrossRef]

- Huh, H.; Lee, H.J.; Song, J.H. Dynamic hardening equation of the auto-body steel sheet with the variation of temperature. Int. J. Automot. Technol. 2012, 13, 43–60. [Google Scholar] [CrossRef]

- Zerilli, F.J.; Armstrong, R.W. Dislocation-mechanics-based constitutive relations for material dynamics calculations. J. Appl. Phys. 1987, 61, 1816–1825. [Google Scholar] [CrossRef] [Green Version]

- Preston, D.L.; Tonks, D.L.; Wallace, D.C. Model of plastic deformation for extreme loading conditions. J. Appl. Phys. 2003, 93, 211–220. [Google Scholar] [CrossRef] [Green Version]

- Piao, M.; Huh, H.; Lee, I.; Ahn, K.; Kim, H.; Park, P. Characterization of flow stress at ultra-high strain rates by proper extrapolation with Taylor impact tests. Int. J. Impact Eng. 2016, 91, 142–157. [Google Scholar] [CrossRef]

- Asala, G.; Andersson, J.; Ojo, O.A. A study of the dynamic impact behaviour of IN 718 and ATI 718Plus® superalloys. Philos. Mag. 2019, 99, 419–437. [Google Scholar] [CrossRef]

- Kouraytem, N.; Chanut, R.A.; Watring, D.S.; Loveless, T.; Varga, J.; Spear, A.D.; Kingstedt, O.T. Dynamic-loading behavior and anisotropic deformation of pre- and post-heat-treated IN718 fabricated by laser powder bed fusion. Addit. Manuf. 2020, 33, 101083. [Google Scholar] [CrossRef]

- Forni, D.; Mazzucato, F.; Valente, A.; Cadoni, E. High strain-rate behaviour of as-cast and as-build Inconel 718 alloys at elevated temperatures. Mech. Mater. 2021, 159, 103859. [Google Scholar] [CrossRef]

- Chakravarthi, K.V.A.; Koundinya, N.T.B.N.; Narayana Murty, S.V.S.; Nageswara Rao, B. Microstructure, properties and hot workability of M300 grade maraging steel. Def. Technol. 2018, 14, 51–58. [Google Scholar] [CrossRef]

- Song, B.; Sanborn, B.; Wakeland, P.E.; Furnish, M.D. Dynamic Characterization and Stress-Strain Symmetry of Vascomax ® C250 Maraging Steel in Compression and Tension. Procedia Eng. 2017, 197, 42–51. [Google Scholar] [CrossRef]

- Dehgahi, S.; Alaghmandfard, R.; Tallon, J.; Odeshi, A.; Mohammadi, M. Microstructural evolution and high strain rate compressive behavior of as-built and heat-treated additively manufactured maraging steels. Mater. Sci. Eng. A 2021, 815, 141183. [Google Scholar] [CrossRef]

- Chapman, D.J.; Radford, D.D.; Walley, S.M. A history of the Taylor test and its present use in the study of lightweight materials. In Proceedings of the 3rd Design and Use of Light-Weight Materials Conference, University of Aveiro, Aveiro, Portugal, 8–10 October 2005; pp. 12–24. [Google Scholar]

- Taylor, G.I. The use of flat-ended projectiles for determining dynamic yield stress I. Theoretical considerations. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1948, 194, 289–299. [Google Scholar] [CrossRef]

- Meyers, M.A. Dynamic Behavior of Materials, 1st ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Gillis, P.P.; Jones, S.E. A direct correlation of strength with impact velocity in the Taylor test. J. Eng. Mater. Technol. Trans. 1989, 111, 327–330. [Google Scholar] [CrossRef]

- Chakraborty, S.; Shaw, A.; Banerjee, B. An axisymmetric model for Taylor impact test and estimation of metal plasticity. Proc. R. Soc. A Math. Phys. Eng. Sci. 2015, 471, 20140556. [Google Scholar] [CrossRef]

- Kumar, B.P.; Joshi, D.; Mohith, M.; Gopikrishna, N. Experimental Study of Micro Structural and Anti-Corrosion Behaviorof Ni & Ni-Cr Coating on Mild Steel. Mater. Today Proc. 2019, 18, 2496–2508. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hetherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier Ltd.: Oxford, UK, 2004. [Google Scholar]

- Kocich, R.; Kunčická, L.; Mihola, M.; Skotnicová, K. Numerical and experimental analysis of twist channel angular pressing (TCAP) as a SPD process. Mater. Sci. Eng. A 2013, 563, 86–94. [Google Scholar] [CrossRef]

- Kocich, R.; Macháčková, A.; Kunčická, L. Twist channel multi-angular pressing (TCMAP) as a new SPD process: Numerical and experimental study. Mater. Sci. Eng. A 2014, 612, 445–455. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | P | S | Cr | Ni | W | Cu |

|---|---|---|---|---|---|---|---|---|---|

| (wt.%) | 0.1 | 0.38 | 0.07 | 0.012 | 0.008 | 0.05 | 0.04 | 0.01 | 0.1 |

| Parameter | A [MPa] | B [MPa] | C [-] | n [-] | m [-] |

|---|---|---|---|---|---|

| value | 273 | 391 | 0.051 | 0.3 | 0.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kunčická, L.; Jopek, M.; Kocich, R.; Dvořák, K. Determining Johnson-Cook Constitutive Equation for Low-Carbon Steel via Taylor Anvil Test. Materials 2021, 14, 4821. https://doi.org/10.3390/ma14174821

Kunčická L, Jopek M, Kocich R, Dvořák K. Determining Johnson-Cook Constitutive Equation for Low-Carbon Steel via Taylor Anvil Test. Materials. 2021; 14(17):4821. https://doi.org/10.3390/ma14174821

Chicago/Turabian StyleKunčická, Lenka, Miroslav Jopek, Radim Kocich, and Karel Dvořák. 2021. "Determining Johnson-Cook Constitutive Equation for Low-Carbon Steel via Taylor Anvil Test" Materials 14, no. 17: 4821. https://doi.org/10.3390/ma14174821

APA StyleKunčická, L., Jopek, M., Kocich, R., & Dvořák, K. (2021). Determining Johnson-Cook Constitutive Equation for Low-Carbon Steel via Taylor Anvil Test. Materials, 14(17), 4821. https://doi.org/10.3390/ma14174821