Wool Keratin Hydrolysates for Bioactive Additives Preparation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Keratin Hydrolysates Preparation

2.3. Keratin Hydrolysates Characterisation

2.4. Antimicrobial Activity Evaluation

2.5. Bioactive Properties Test on Maize Seeds and Plants

2.6. Statistical Analysis

3. Results

3.1. Keratin Hydrolysate Preparation

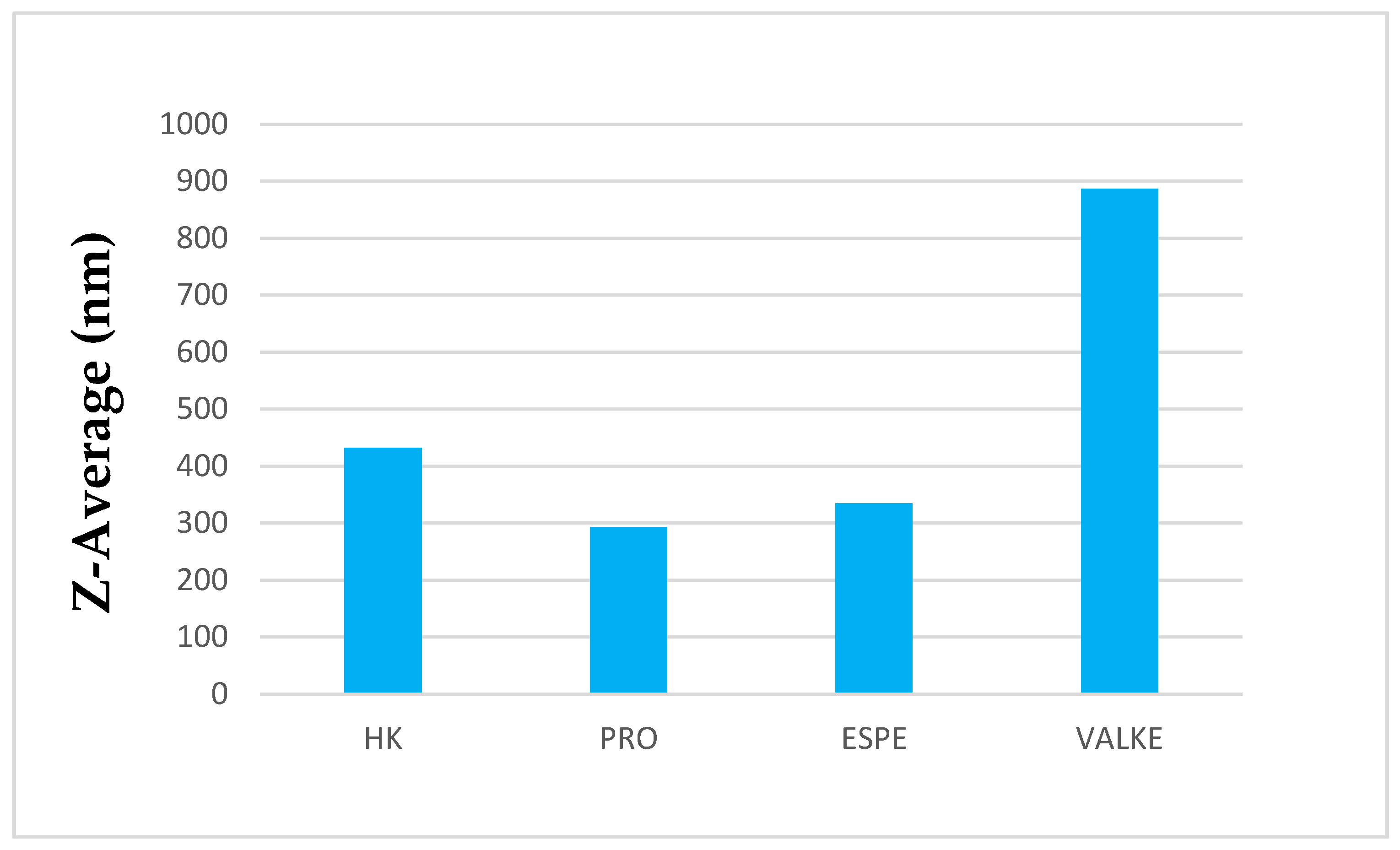

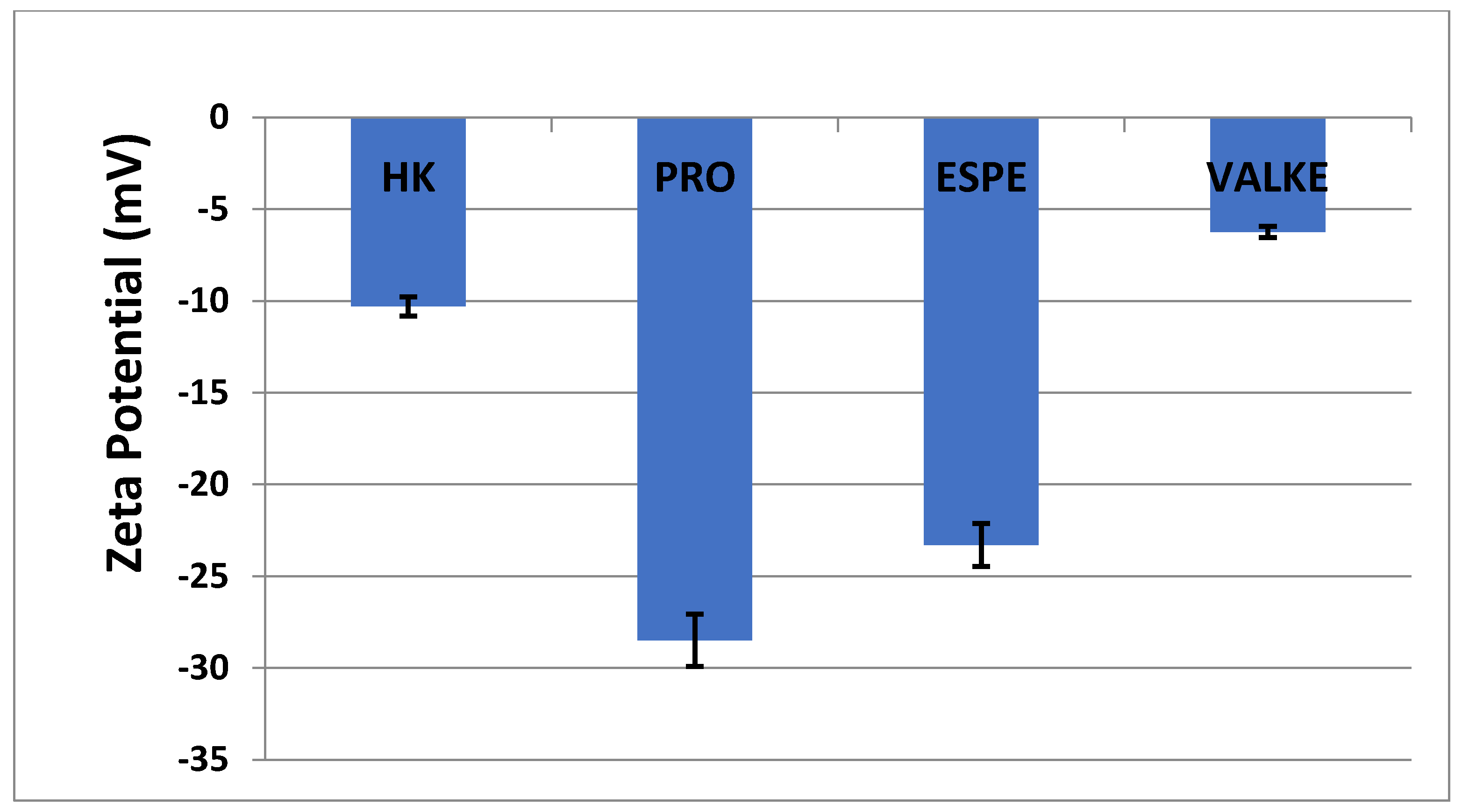

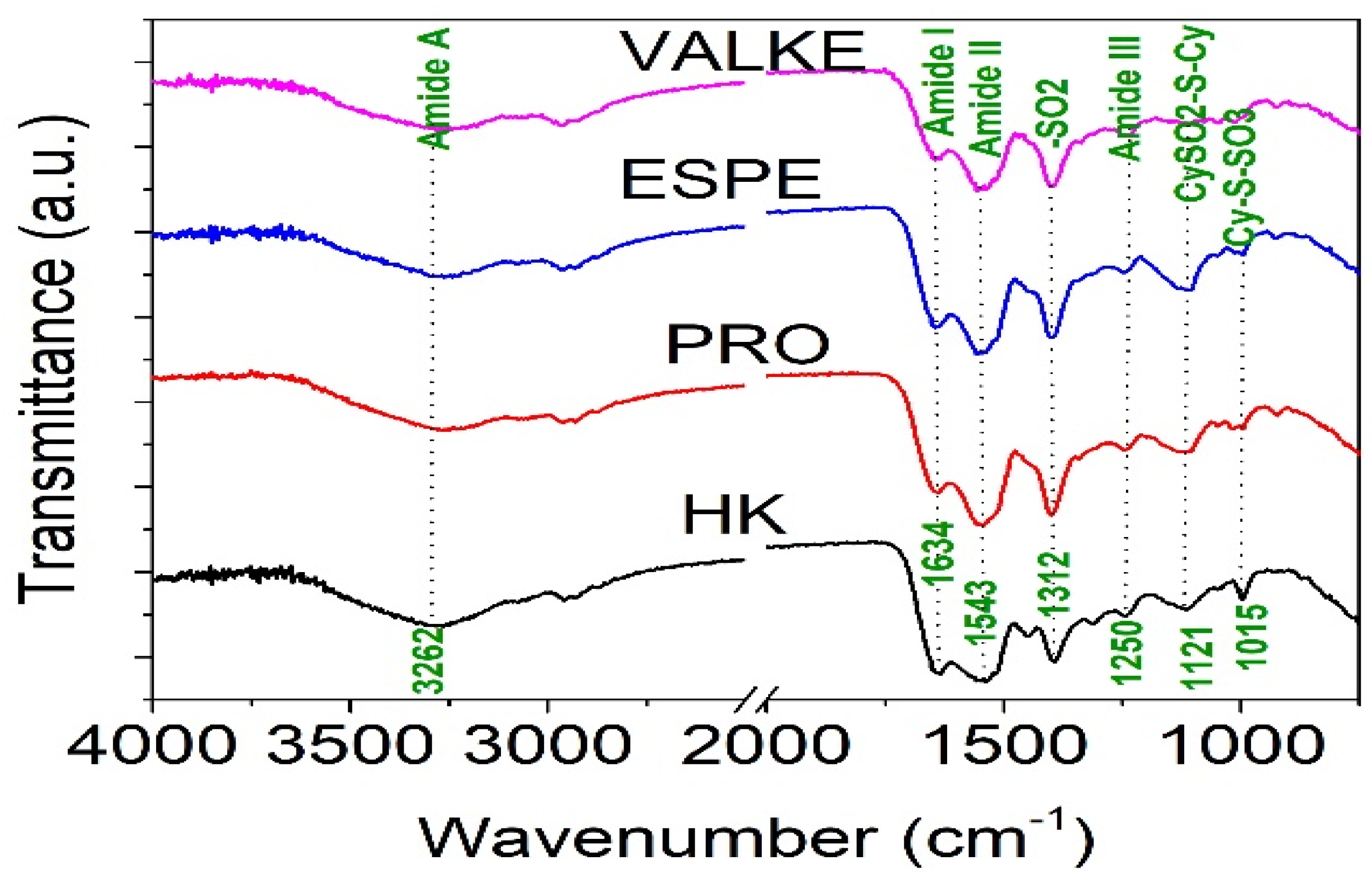

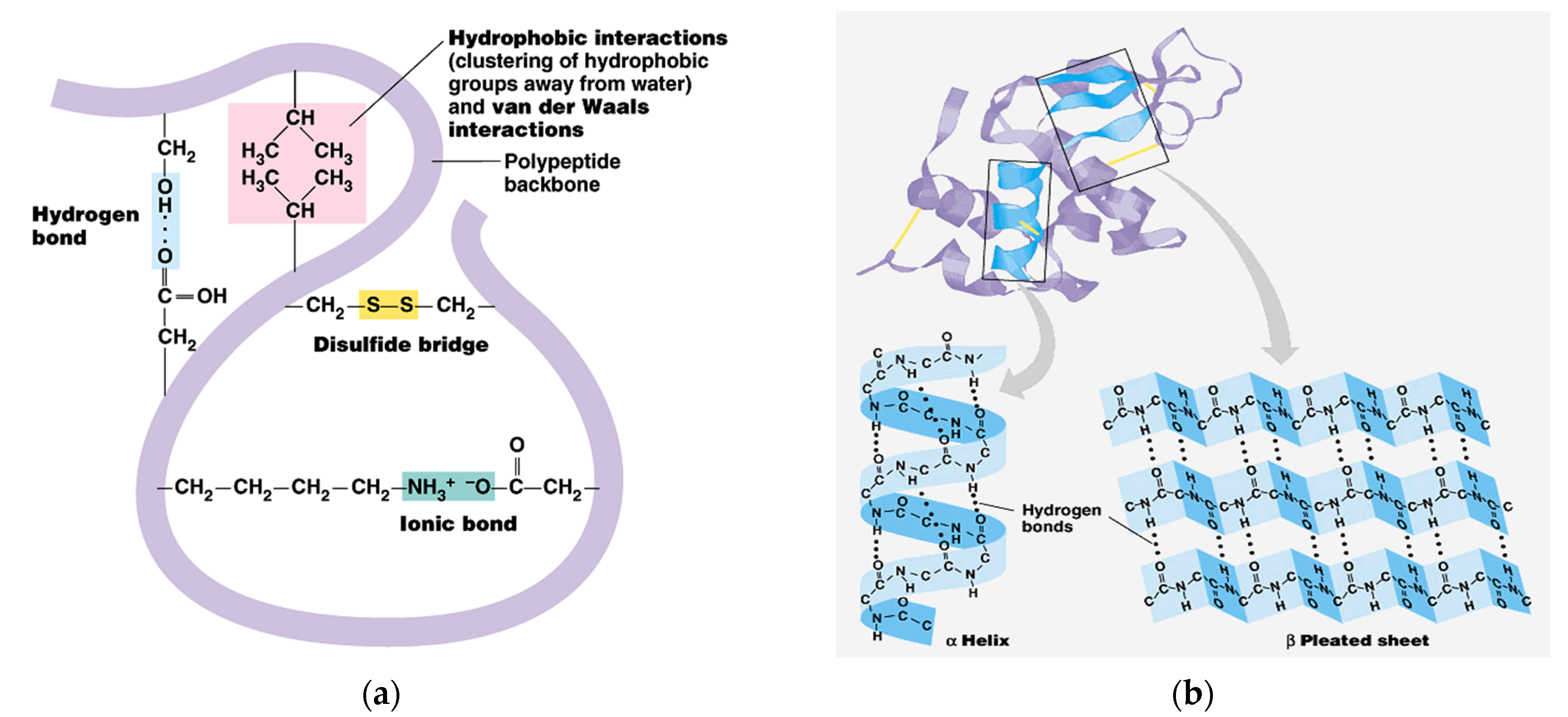

3.2. Keratin Hydrolysates Characterisation

3.3. Antifungal Properties of Keratin Hydrolysates

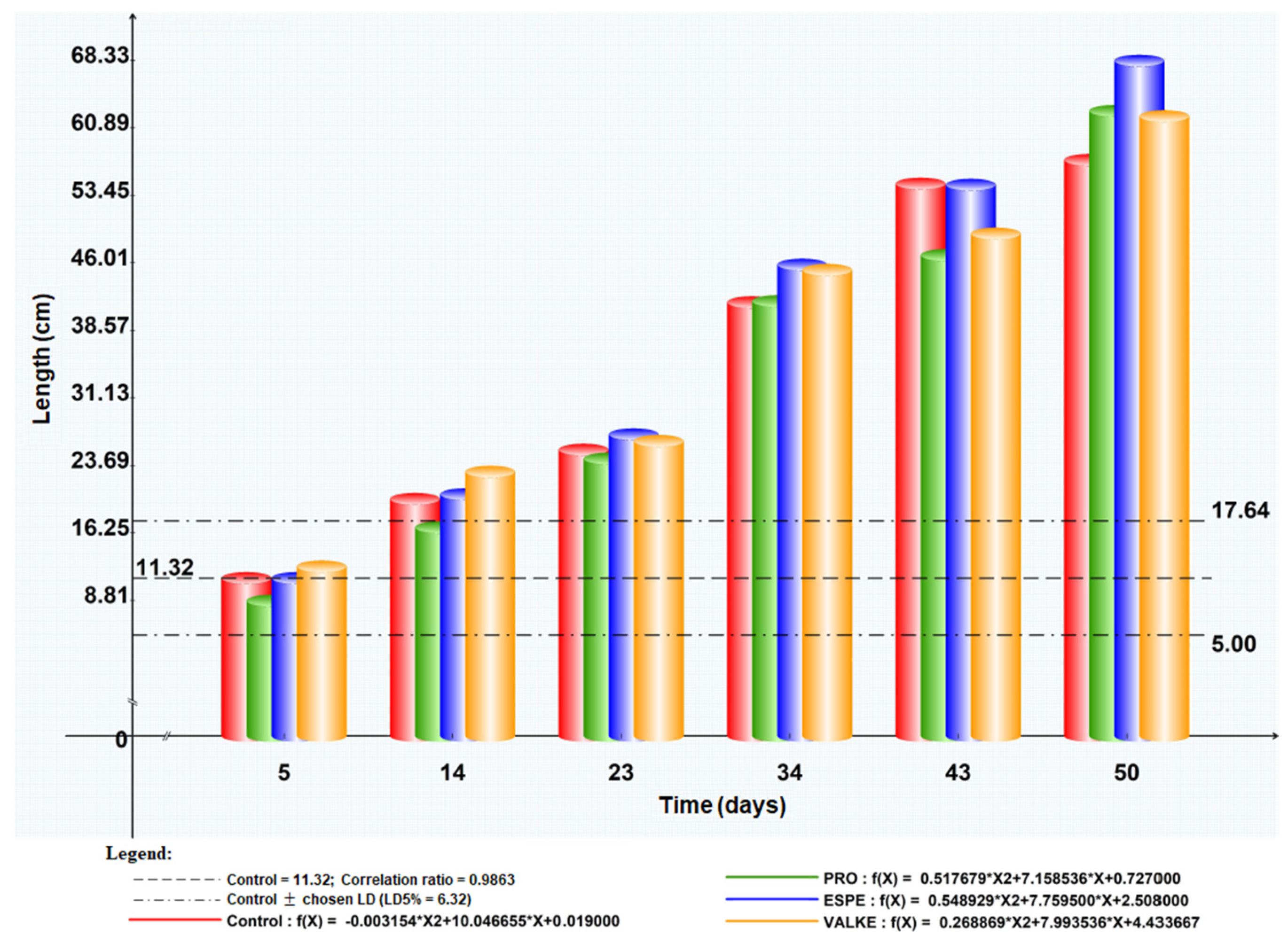

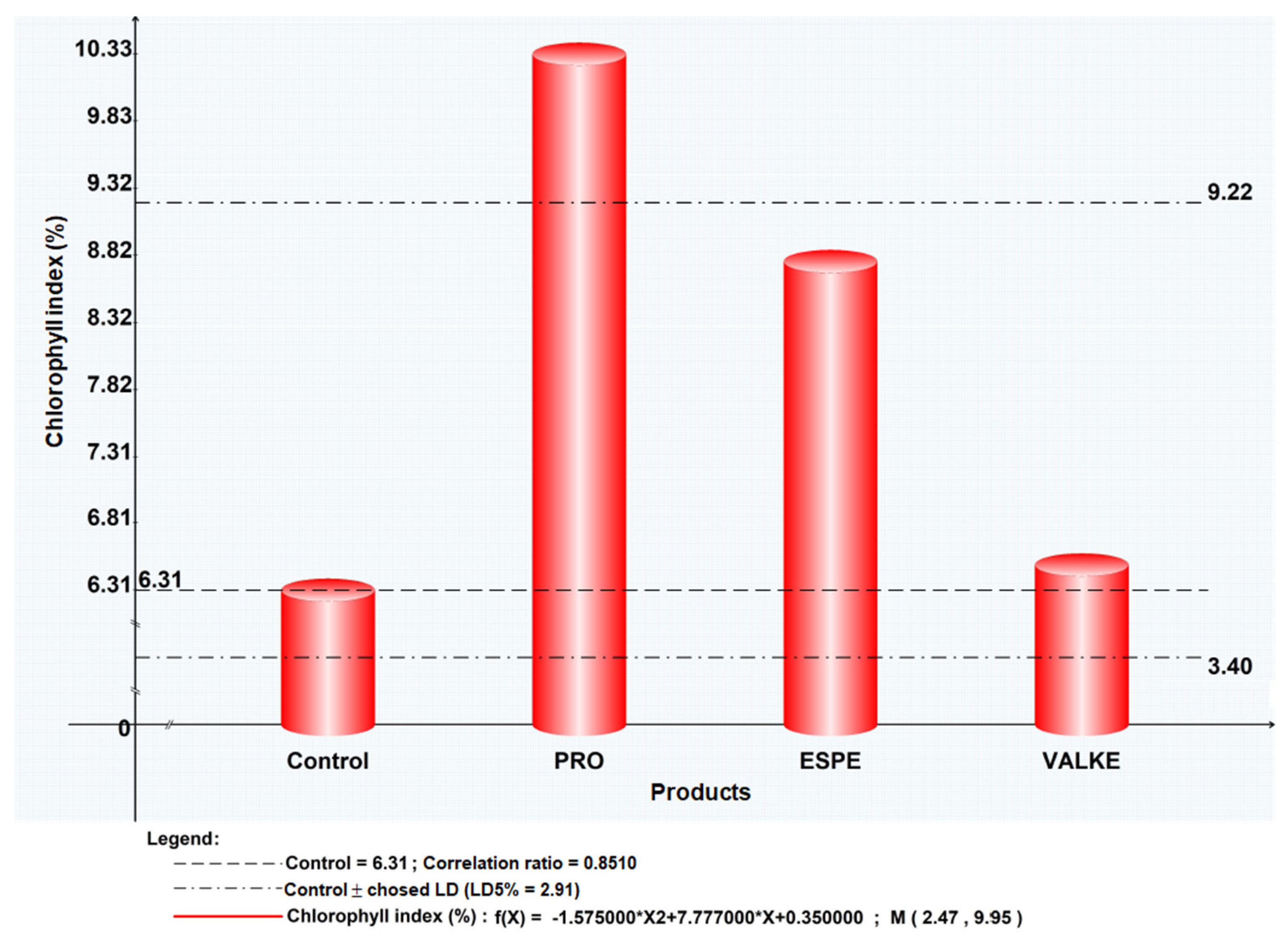

3.4. Bioactive Keratin Hydrolysates for Plant Growth Biostimulation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dullaart, R.; Martinez-Hernandez, A.L.; Velasco-Santos, C. Keratin fibers from chicken feathers: Structure and advances in polymer composites. In Keratin: Structure, Properties and Applications; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2012; pp. 149–211. [Google Scholar]

- Sharma, S.; Kumar, A.; Adelere, I.A.; Latee, A. Degradation of keratin biomass by different microorganisms. In Keratin as a Protein Biopolymer; Springer series on polymer and composite materials; Springer: Charm, Switzerland, 2019. [Google Scholar] [CrossRef]

- Roberts, M.; Williams, J.; Halberstadt, P.; Sanders, D.; Adams, T. Animal waste to marketable products. In Proceedings of the Natural Gas Technologies Conference, Phoenix, AZ, USA, 8–11 February 2004. [Google Scholar]

- Perta-Crisan, S.; Ursachi, C.S.; Gavrilas, S.; Oancea, F.; Munteanu, F.-D. Closing the loop with keratin-rich fibrous materials. Polymers 2021, 13, 1896. [Google Scholar] [CrossRef]

- Reddy, C.C.; Irshad Ahamad Khilji, I.A.; Gupta, A.; Bhuyar, P.; Mahmood, S.; AL-Japairai, K.A.S.; Chua, G.K. Valorization of keratin waste biomass and its potential applications. J. Water Process. Eng. 2021, 40, 101707. [Google Scholar] [CrossRef]

- Goldsmith, L.A.; Gillespie, J.M. The structural proteins of hair: Isolation, characterization and regulation of biosynthesis. In Physiology, Biochemistry and Molecular Biology of the Skin; Oxford University Press: Oxford, UK, 1991; Volume I, pp. 625–659. [Google Scholar]

- Sharma, R.; Devi, S. Versatility and commercial status of microbial keratinases: A review. Rev. Environ. Sci. Biotechnol. 2018, 17, 19–45. [Google Scholar] [CrossRef]

- Loan, N.F.; Cassidy, S.; Marsh, C.; Simcock, J. Keratin-based products for effective wound care management in superficial and partial thickness burns injuries. Burns 2016, 42, 541–547. [Google Scholar] [CrossRef] [PubMed]

- Su, C.; Gong, J.-S.; Ye, J.-P.; He, J.-M.; Li, R.-Y.; Jiang, M.; Geng, Y.; Zhang, Y.; Chen, J.-H.; Xu, Z.-H.; et al. Enzymatic extraction of bioactive and self-assembling wool keratin for biomedical applications. Macromol. Biosci. 2020, 20, 2000073. [Google Scholar] [CrossRef]

- Kelly, R.A.; Ellis, G.D.; Macdonalds, R.J.; Mcpherson, R.A.; Middlewod, P.G.; Nuthall, M.G.; Rao, G.-F.; Rod, D.-L.; Alisa, D.; Sigurjonsson, G.E.; et al. Keratin and Soluble Derivatives Therefore for a Nutraceutical and to Reduce Oxidative Stress and to Reduce Inflammation and to Promote Skin Health. Patent No. WO 099309A2, 21 June 2006. [Google Scholar]

- Sharma, S.; Kumar, A.; McLellan, J.; Thornhill, S.G.; Shelton, S.; Kumar, M. Keratin-based biofilms, hydrogels, and biofibers. In Keratin as a Protein Biopolymer; Springer Series on Polymer and Composite Materials; Springer: Charm, Switzerland, 2019; pp. 187–200. [Google Scholar] [CrossRef]

- Vesela, M.; Friedrich, J. Amino acid and soluble protein cocktail from waste keratin hydrolysed by a fungal keratinase of Paecilomyces marquandii. Biotechnol. Bioprocess. Eng. 2009, 14, 84–90. [Google Scholar] [CrossRef]

- Chojnacka, K.; Gorecka, H.; Michalak, I.; Gorecki, H. A review: Valorization of keratinous materials. Waste Biomass Valorization 2011, 2, 317–321. [Google Scholar] [CrossRef]

- Bhavsar, P.S.; Zoccola, M.; Patrucco, A.; Montarsolo, A.; Mossotti, R.; Rovero, G.; Giansetti, M.; Tonin, C. Superheated water hydrolysis of waste wool in a semi-industrial reactor to obtain nitrogen fertilizers. ACS Sustain. Chem. Eng. 2016, 4, 6722–6731. [Google Scholar] [CrossRef]

- Chen, Y.; Li, W.; Zhang, S. A multifunctional eco-friendly fertilizer used keratin-based superabsorbent as coatings for slow-release urea and remediation of contaminated soil. Prog. Org. Coat. 2021, 154, 106158. [Google Scholar] [CrossRef]

- Calin, M.; Raut, I.; Arsene, M.L.; Capra, L.; Gurban, A.M.; Doni, M.; Jecu, L. Applications of fungal strains with keratin-degrading and plant growth promoting characteristics. Agronomy 2019, 9, 543. [Google Scholar] [CrossRef] [Green Version]

- Gaidau, C.; Epure, D.-G.; Enascuta, C.E.; Carsote, C.; Sendrea, C.; Proietti, N.; Chen, W.; Gu, H. Wool keratin total solubilisation for recovery and reintegration—An ecological approach. J. Clean. Prod. 2019, 236, 117586. [Google Scholar] [CrossRef]

- Zoccola, M.; Montarsolo, A.; Mossotti, R.; Patrucco, A.; Tonin, C. Green hydrolysis as an emerging technology to turn wool waste into organic nitrogen fertilizer. Waste Biomass Valorization 2015, 6, 891–897. [Google Scholar] [CrossRef]

- Drobota, M.; Gradinaru, L.M.; Vlad, S.; Bargan, A.; Butnaru, M.; Angheloiu, M.; Aflori, M. Preparation and Characterization of electrospun collagen based composites for biomedical applications. Materials 2020, 13, 3961. [Google Scholar] [CrossRef]

- Rice, R.H.; Wong, V.J.; Pinkerton, K.E. Ultrastructural visualization of cross-linked protein features in epidermal appendages. J. Cell Sci. 1994, 107, 1985–1992. [Google Scholar] [CrossRef] [PubMed]

- Feroz, S.; Muhammadb, N.; Ranayakea, J.; Diasa, G. Keratin-based materials for biomedical applications. Bioact. Mater. 2020, 5, 496–509. [Google Scholar] [CrossRef] [PubMed]

- Kunert, J. Keratin decomposition by dermatophytes II. Presence of S-sulfocysteine and cysteic acid in soluble decomposition products. Z. Allg. Mikrobiol. 1976, 16, 97–105. [Google Scholar] [CrossRef]

- Rajabinejad, H. Material Keratinic cu Potențiale Bio-Aplicații/Keratin Based Material for Perspective Bio-Application. Ph.D. Thesis, Technical University Gheorghe Asachi, Iasi, Romania, 2018. Available online: http://www.doctorat.tuiasi.ro/doc/SUSTINERI_TEZE/TP/Rabajineh/Rezumat%20teza%20HOSSEIN_Final.pdf (accessed on 1 June 2021).

- Available online: https://sites.lps.org/sputnam/AdvancedChem/Ch%2018%20Notes_files/20.11.2020 (accessed on 2 June 2021).

- Available online: http://www.biocomes.eu/20.11.2020 (accessed on 5 June 2021).

- Calin, M.; Constantinescu-Aruxandrei, D.; Alexandrescu, E.; Raut, I.; Badea Doni, M.; Arsene, M.-L.; Oancea, F.; Jecu, L.; Lazar, V. Degradation of keratin substrates by keratinolytic fungi. Electron. J. Biotechnol. 2017, 28, 101–112. [Google Scholar] [CrossRef]

- Colla, G.; Svecova, E.; Cardarelli, M.; Rouphael, Y.; Canaguier, R.; Planques, B. Effectiveness of a plant-derived protein hydrolysate to improve crop performances under different growing conditions. Acta Hortic. 2013, 1009, 175–179. [Google Scholar] [CrossRef]

- Ertani, A.; Francioso, O.; Ferrari, E.; Schiavon, M.; Nardi, S. Spectroscopic-chemical fingerprint and biostimulant activity of a protein-based product in solid form. Molecules 2018, 23, 1031. [Google Scholar] [CrossRef] [Green Version]

- Rana, R.; Herz, K.; Bruelheide, H.; Dietz, S.; Haider, S.; Jandt, U.; Pena, R. Leaf Attenuated total reflection fourier transform infrared (ATR-FTIR) biochemical profile of grassland plant species related to land-use intensity. Ecol. Indic. 2018, 84, 803–810. [Google Scholar] [CrossRef]

- Wu, K.; Du, C.; Ma, F.; Shen, Y.; Liang, D.; Zhou, J. Rapid diagnosis of nitrogen status in rice based on Fourier transform infrared photoacoustic spectroscopy (FTIR-PAS). Plant Methods 2019, 15, 1–10. [Google Scholar] [CrossRef]

- da Silva Leite, R.; Hernandéz-Navarro, S.; Neves do Nascimento, M.; Potosme, N.M.R.; Carrión-Prieto, P.; dos Santos Souza, E. Nitrogen fertilisation affects fourier transform infrared spectra (FTIR) in Physalis L. species. Comput. Electron. Agric. 2018, 150, 411–417. [Google Scholar] [CrossRef]

- Chojnacka, K.; Moustakas, K.; Witek-Krowiak, A. Bio-based fertilizers: A practical approach towards circular economy. Bioresour. Technol. 2020, 295, 122223. [Google Scholar] [CrossRef] [PubMed]

- Cardamone, J.M.; Nunez, A.; Garcia, R.A.; Aldema-Ramos, M. Characterizing wool keratin. Res. Lett. Mater. Sci. 2009, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Shavandi, A.; Bekhit, A.E.-D.A.; Carne, A.; Bekhit, A. Evaluation of keratin extraction from wool by chemical methods for bio-polymer application. J. Bioact. Compat. Polym. 2016, 32, 1–15. [Google Scholar] [CrossRef]

- Tonin, C.; Zoccola, M.; Aluigi, A.; Varesano, A.; Montarsolo, A.; Vineis, C.; Zimbardi, F. Study on the conversion of wool keratin by steam explosion. Biomacromolecules 2006, 7, 3499–3504. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Shi, Z.; Zhao, Q.; Yun, Y. Study on the structure and properties of biofunctional keratin from rabbit hair. Materials 2021, 14, 379. [Google Scholar] [CrossRef]

- Ntumba, Y.-H.T.; Przepiórkowska, A.; Prochoń, M. The effect of enzymatic keratin hydrolyzate on the susceptibility of cellulosic-elastomeric material to biodecomposition. Int. J. Chem. Mol. Nucl. Mat. Metal Eng. 2014, 8, 586–590. [Google Scholar]

| Characterisation | SD ± | Samples | |||

|---|---|---|---|---|---|

| HK | PRO | ESPE | VALKE | ||

| Dry substance, % | 0.35 | 9.68 | 10.60 | 9.26 | 9.24 |

| Total ash, % | 0.24 | 15.28 | 13.21 | 15.12 | 14.61 |

| Total nitrogen, % | 0.34 | 11.78 | 12.64 | 13.07 | 12.12 |

| Protein substance, % | 0.34 | 71.39 | 76.60 | 79.20 | 73.45 |

| pH, pH units | 0.10 | 7.49 | 7.37 | 7.50 | 6.99 |

| Aminic nitrogen, % (% at protein substance) | 0.05 | 0.86 | 1.01 | 0.91 | 1.21 |

| Cysteine, % | 0.03 | 0.95 | 3.38 | 2.18 | 1.91 |

| Cystinic sulphur, % | 0.03 | 0.25 | 0.90 | 0.58 | 0.51 |

| Mw, mol/g | - | 38,099 | 35,112 | 12,400 | 3758 |

| Mn | - | 38,005 | 29,030 | 12,397 | 3586 |

| Polydispersity index | 1 | 1.21 | 1 | 1.05 | |

| Free amino acids, % (% at protein substance) | - | - | - | 4.9 | 4.3 |

| Sample | β-Sheets (%) | Random Coils (%) | α-Helix (%) |

|---|---|---|---|

| HK | 64.71 | - | 35.28 |

| PRO | 74.54 | - | 25.44 |

| ESPE | 45.30 | 28.15 | 26.53 |

| VALKE | 27.66 | 45.20 | 27.11 |

| Sample | Results, (CFU/mL) | Reduction (%) | Log10 Reduction |

|---|---|---|---|

| Inoculums Concentration | T0 = 6.8 × 103 | - | - |

| HK | T24 = 0 | 100% | 3.83 |

| PRO | T24 = 0 | 100% | 3.83 |

| ESPE | T24 = 0 | 100% | 3.83 |

| VALKE | T24 = 1 | 99.99% | 3.83 |

| Bands | νNH | νCH | νCH | νC=O Ester | Amide I | Amide II | δ CH | δ CH | Amide III | νC–O Ester | νC–O Polysach | νC–O Polysach | Fingerprint Region Bands | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 3341 | 2917 | 2849 | 1714 | 1640 | 1555 | 1462 | 1424 | 1259 | 1157 | 1048 | 1034 | 729 | 719 | 664 |

| ESPE | 3353 | 2917 | 2849 | 1715 | 1640 | * | 1463 | 1422 | 1243 | 1155 | 1048 | 1034 | 729 | 719 | 661 |

| VALKE | 3352 | 2917 | 2849 | 1715 | 1642 | 1553 | 1463 | 1416 | 1258 | 1156 | 1046 | 1034 | 729 | 719 | 661 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaidau, C.; Stanca, M.; Niculescu, M.-D.; Alexe, C.-A.; Becheritu, M.; Horoias, R.; Cioineag, C.; Râpă, M.; Stanculescu, I.R. Wool Keratin Hydrolysates for Bioactive Additives Preparation. Materials 2021, 14, 4696. https://doi.org/10.3390/ma14164696

Gaidau C, Stanca M, Niculescu M-D, Alexe C-A, Becheritu M, Horoias R, Cioineag C, Râpă M, Stanculescu IR. Wool Keratin Hydrolysates for Bioactive Additives Preparation. Materials. 2021; 14(16):4696. https://doi.org/10.3390/ma14164696

Chicago/Turabian StyleGaidau, Carmen, Maria Stanca, Mihaela-Doina Niculescu, Cosmin-Andrei Alexe, Marius Becheritu, Roxana Horoias, Cristian Cioineag, Maria Râpă, and Ioana Rodica Stanculescu. 2021. "Wool Keratin Hydrolysates for Bioactive Additives Preparation" Materials 14, no. 16: 4696. https://doi.org/10.3390/ma14164696

APA StyleGaidau, C., Stanca, M., Niculescu, M.-D., Alexe, C.-A., Becheritu, M., Horoias, R., Cioineag, C., Râpă, M., & Stanculescu, I. R. (2021). Wool Keratin Hydrolysates for Bioactive Additives Preparation. Materials, 14(16), 4696. https://doi.org/10.3390/ma14164696