Effect of Boron and Vanadium Addition on Friction-Wear Properties of the Coating AlCrN for Special Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experiment Procedures

3. Results

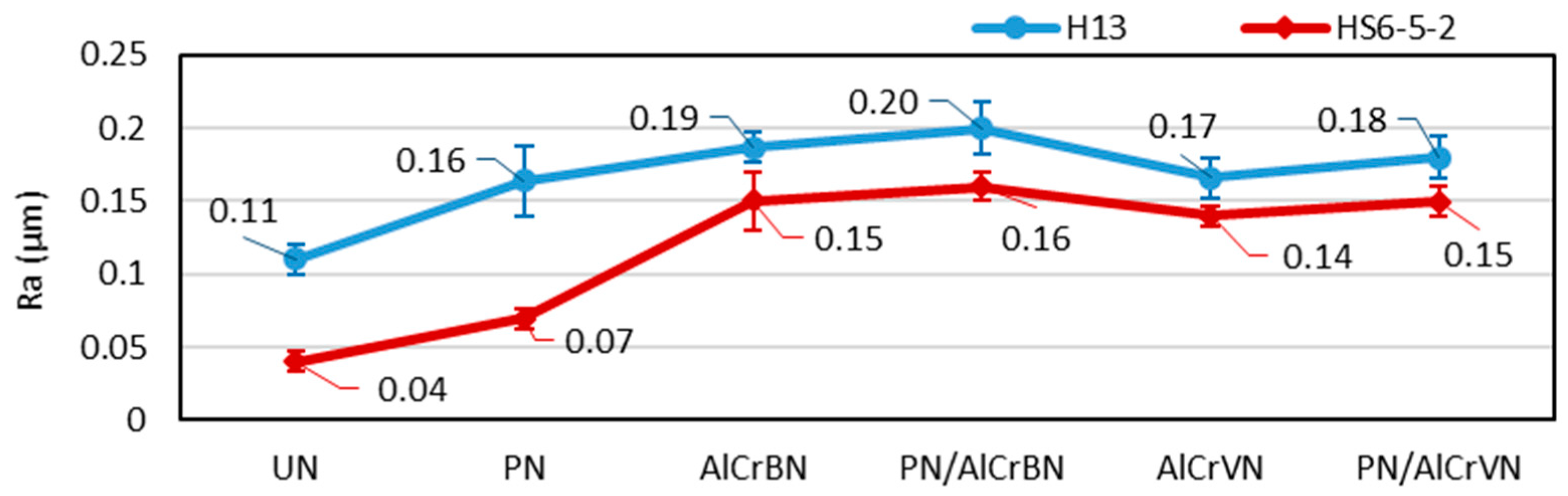

3.1. Surface Roughness

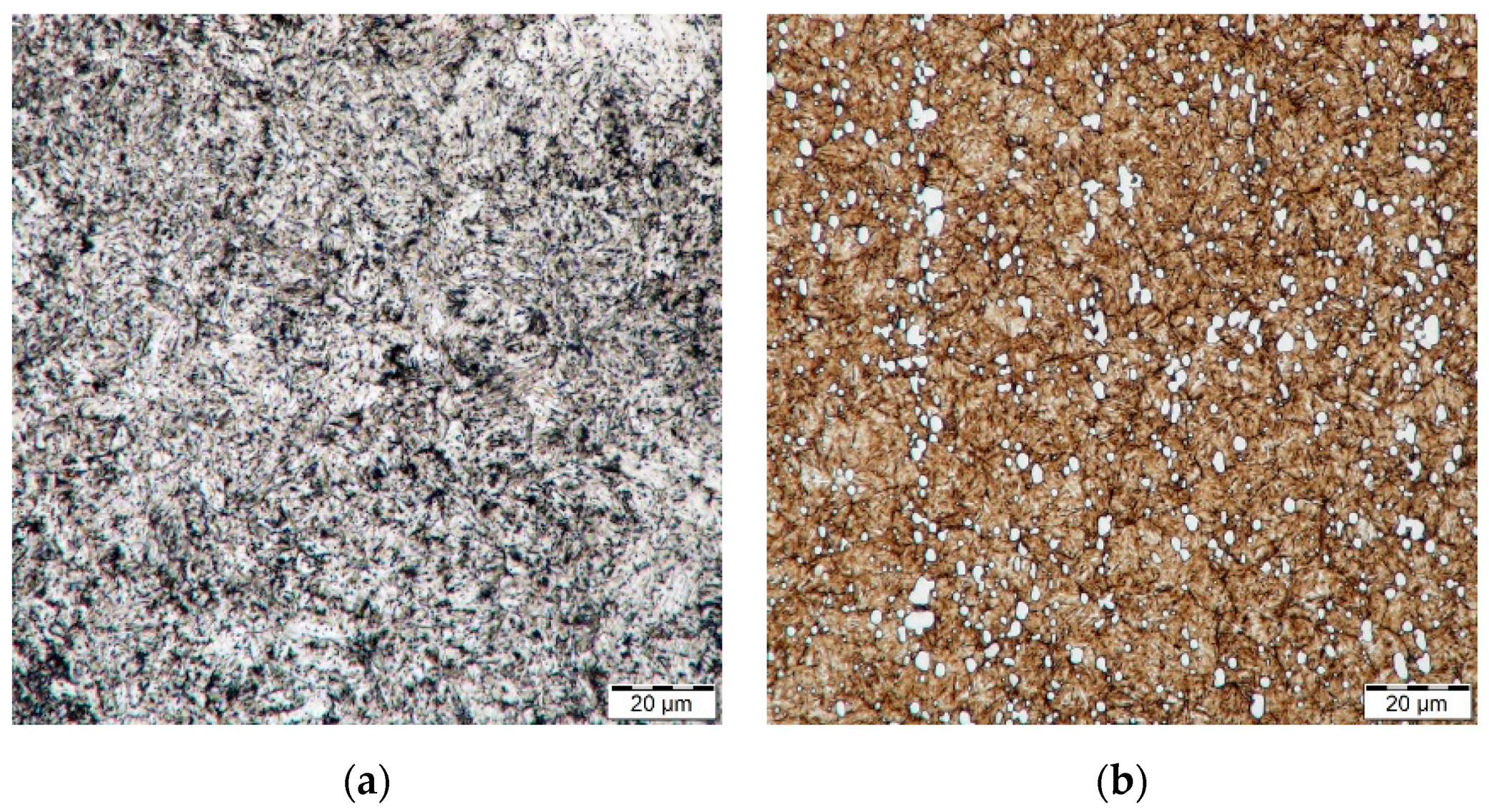

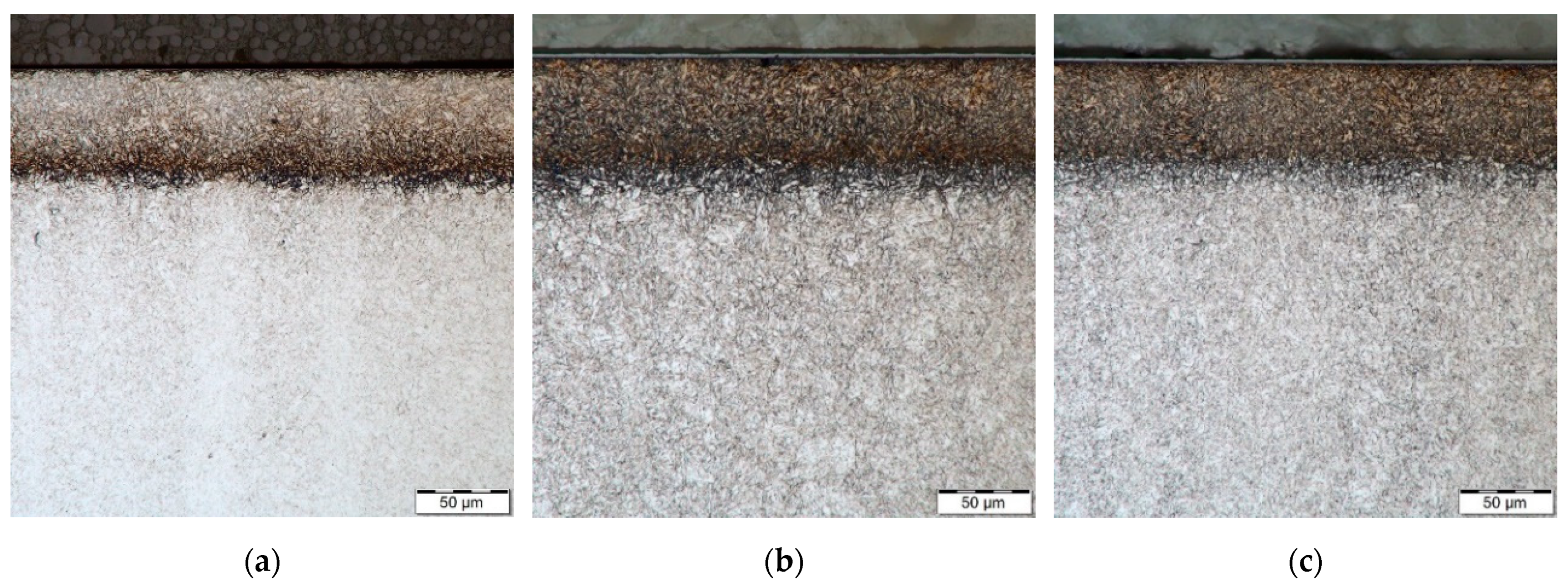

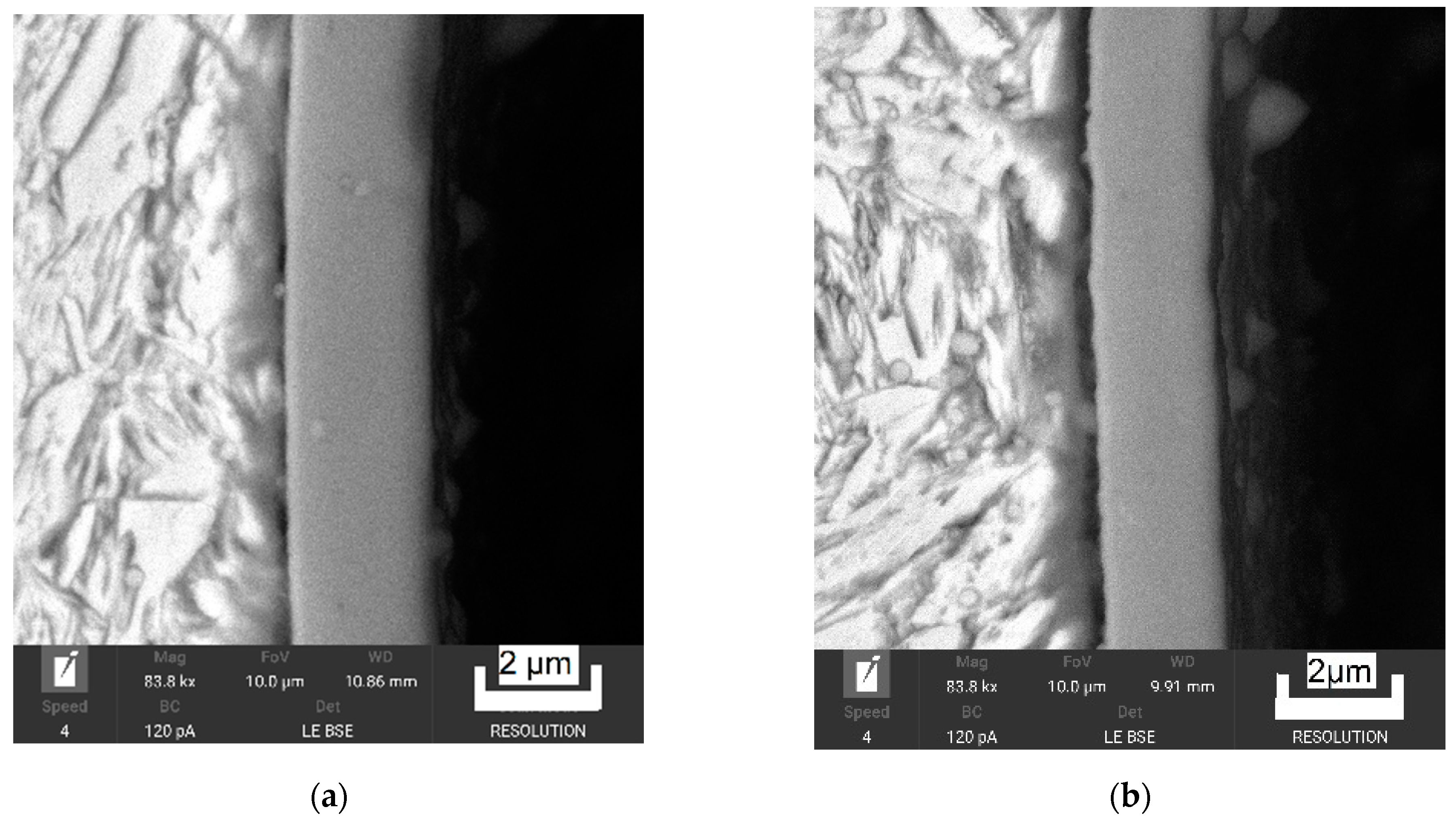

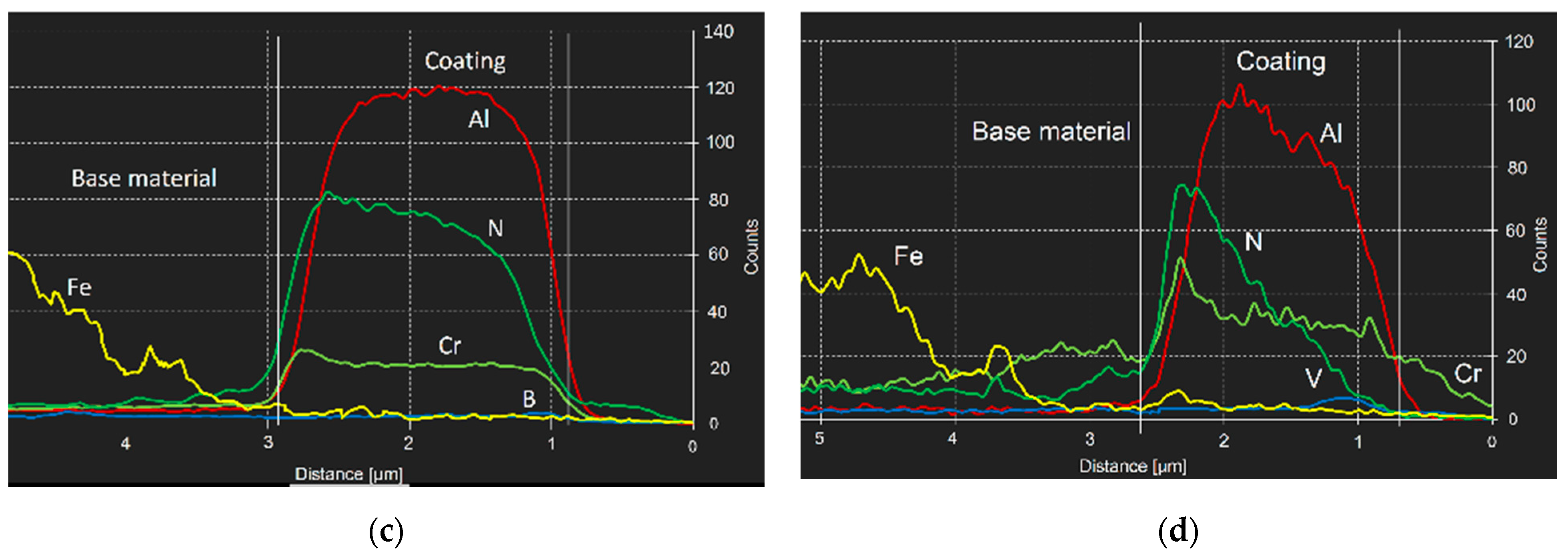

3.2. Microstructures

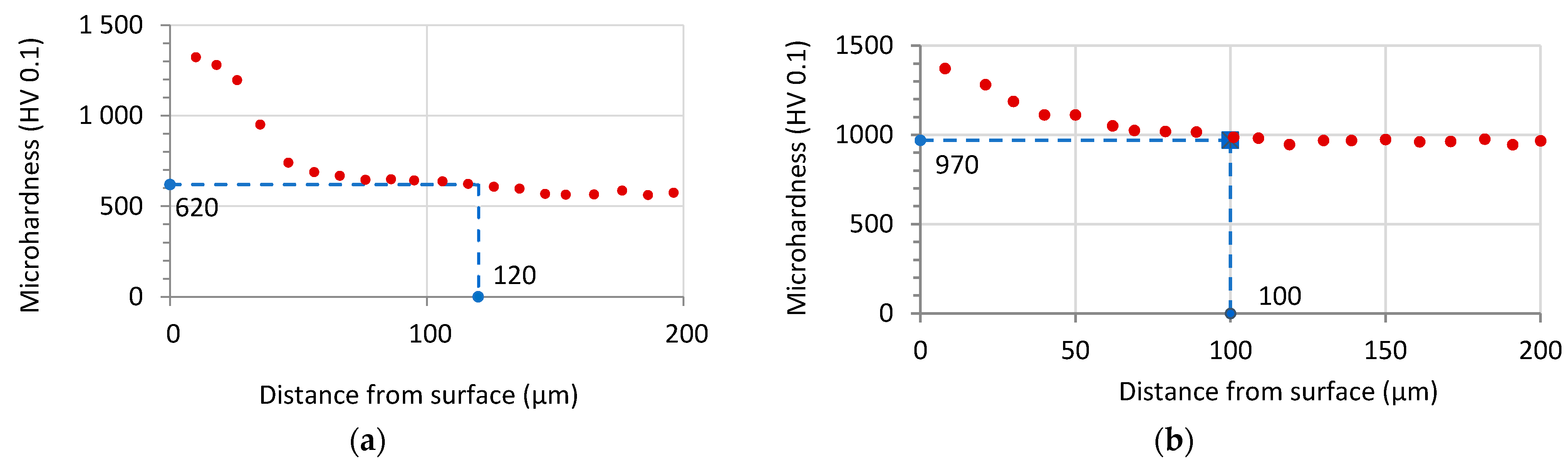

3.3. Hardness

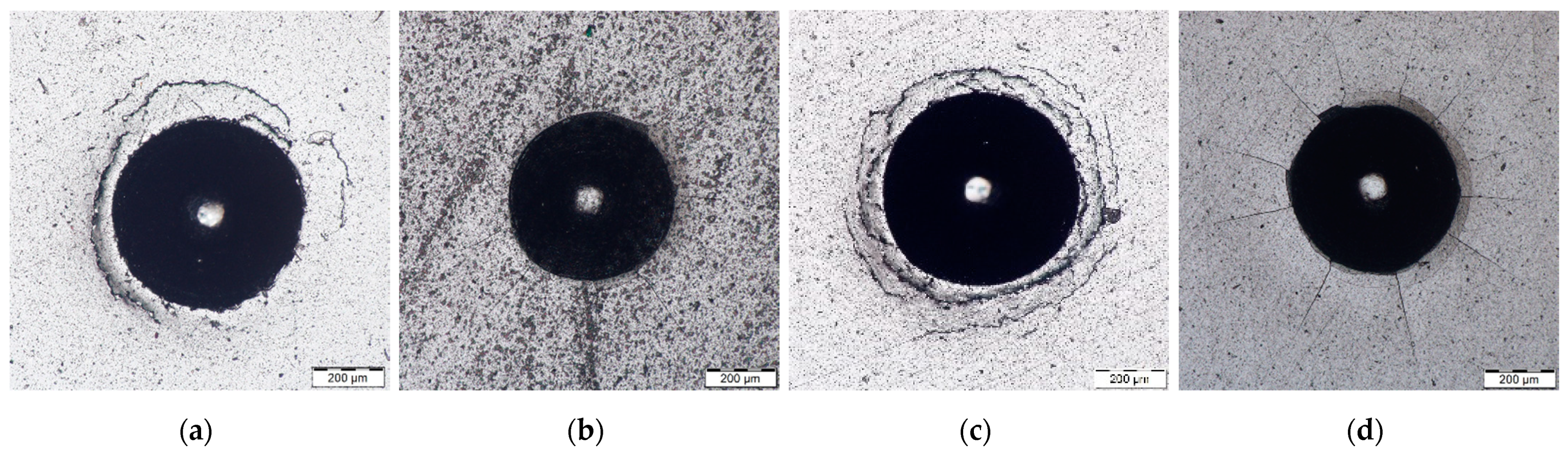

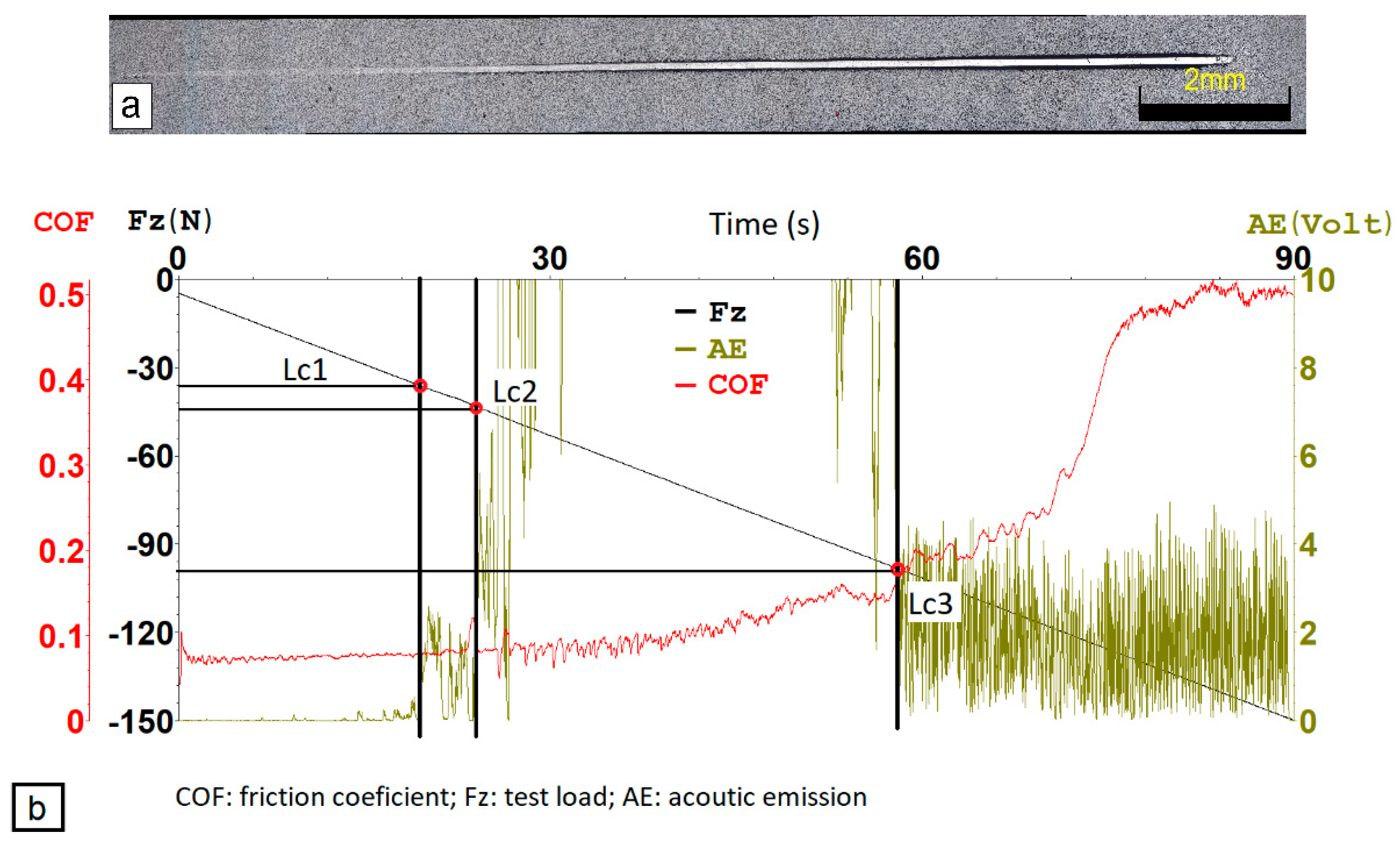

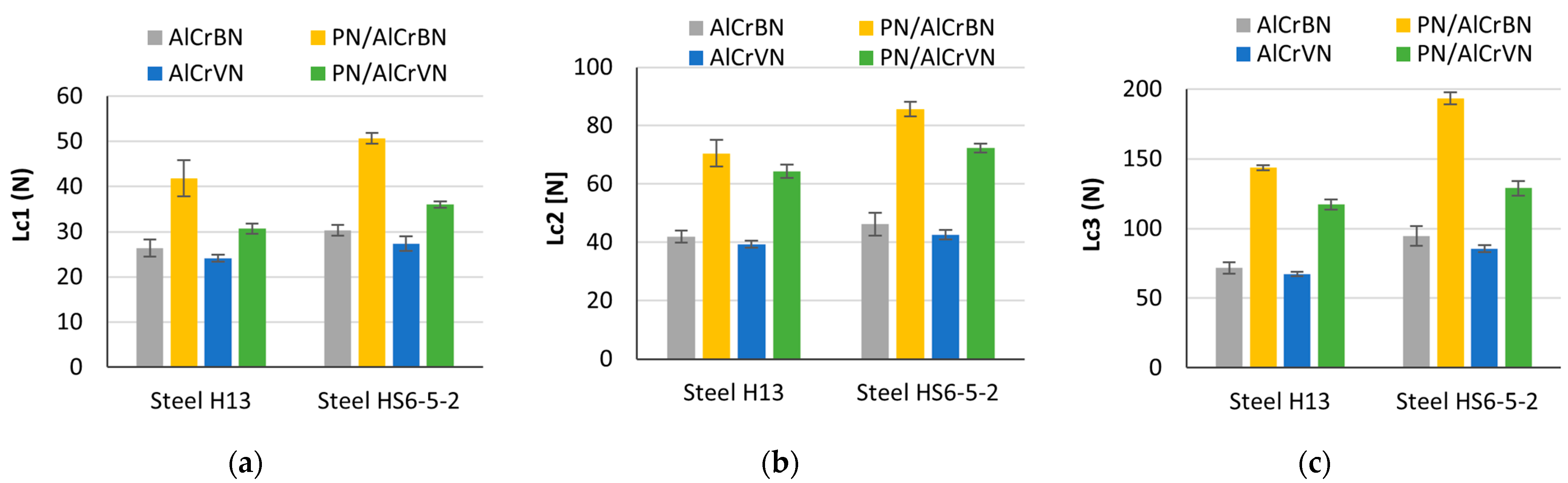

3.4. Adhesion Strength

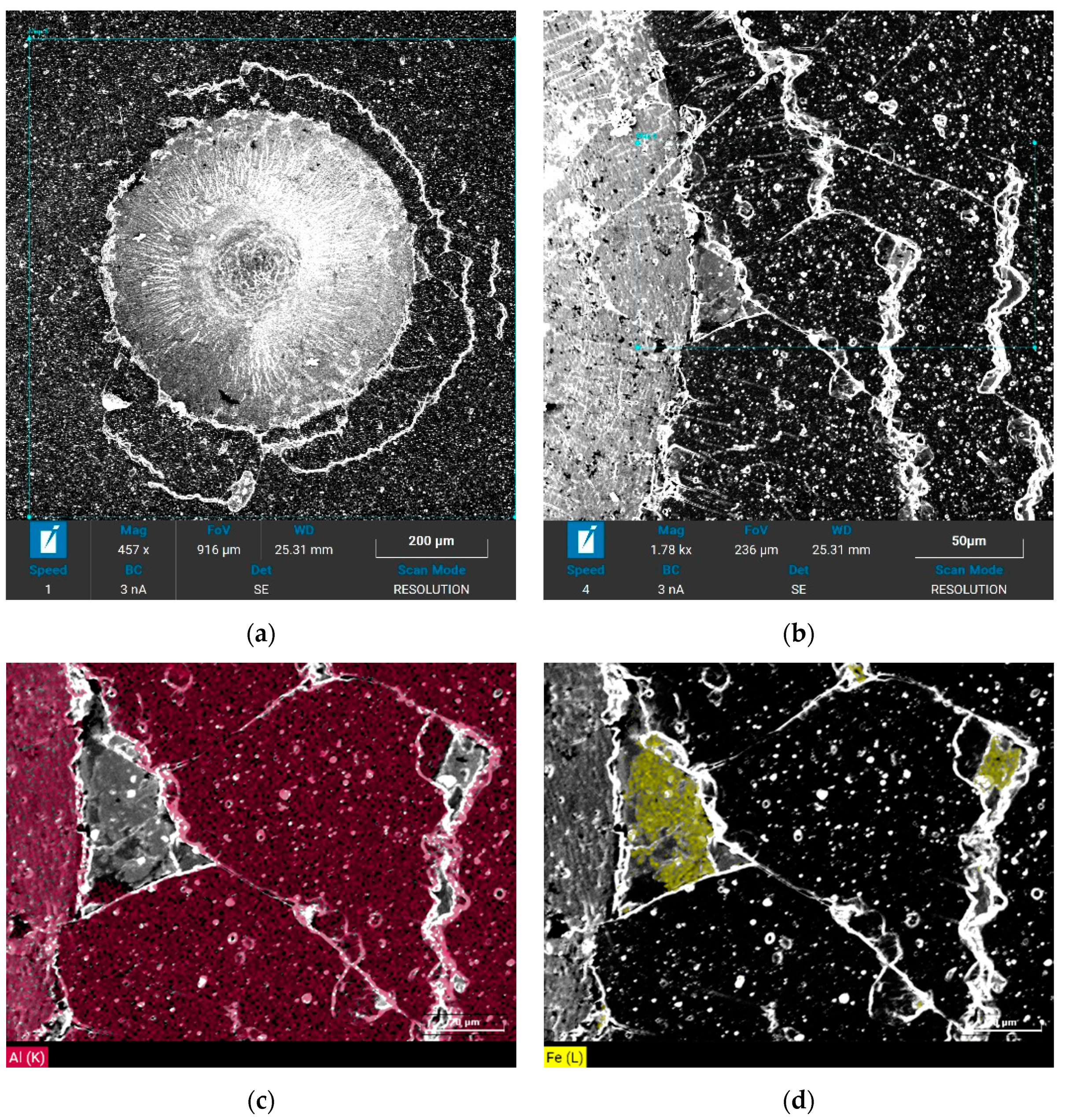

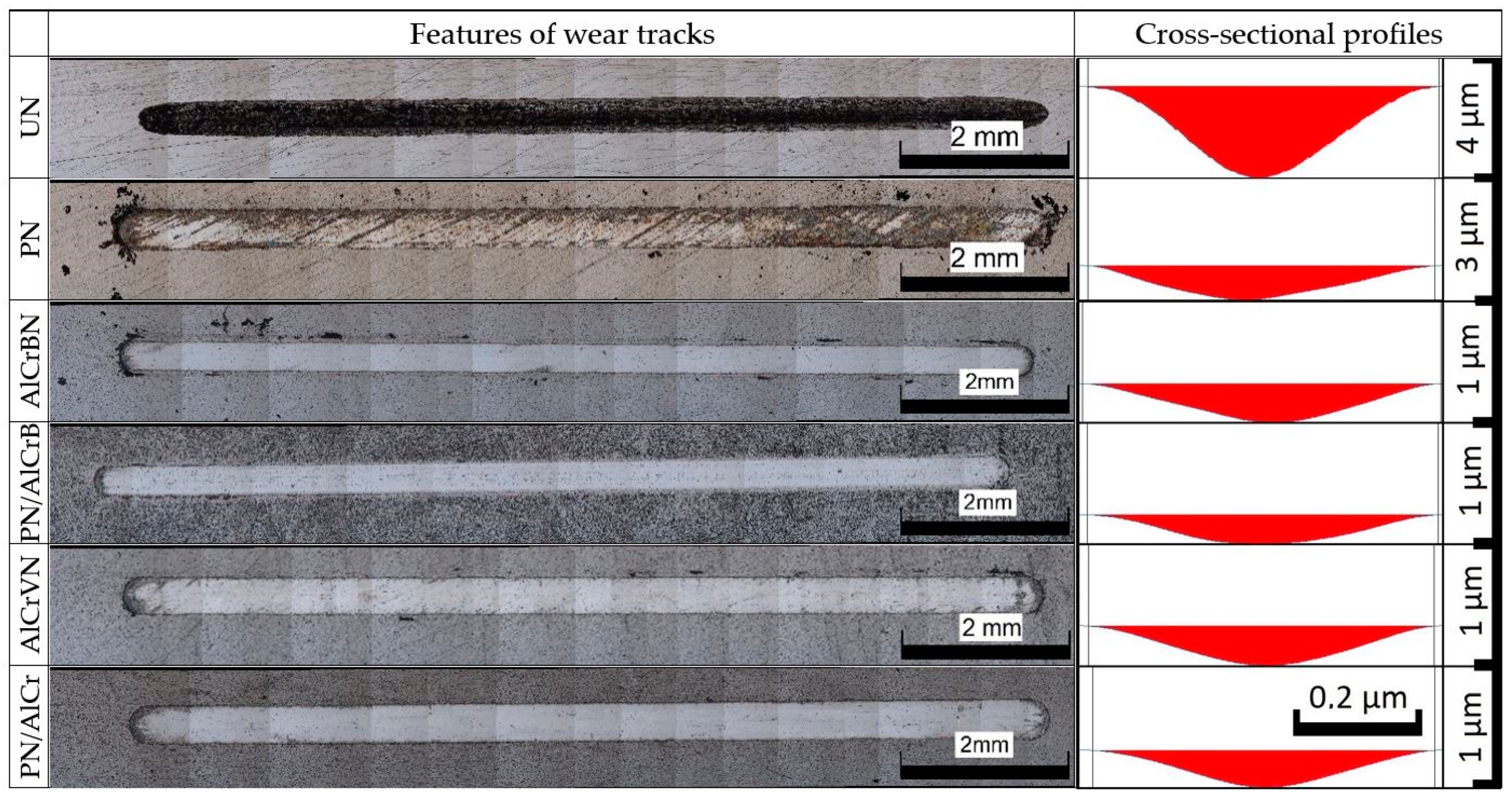

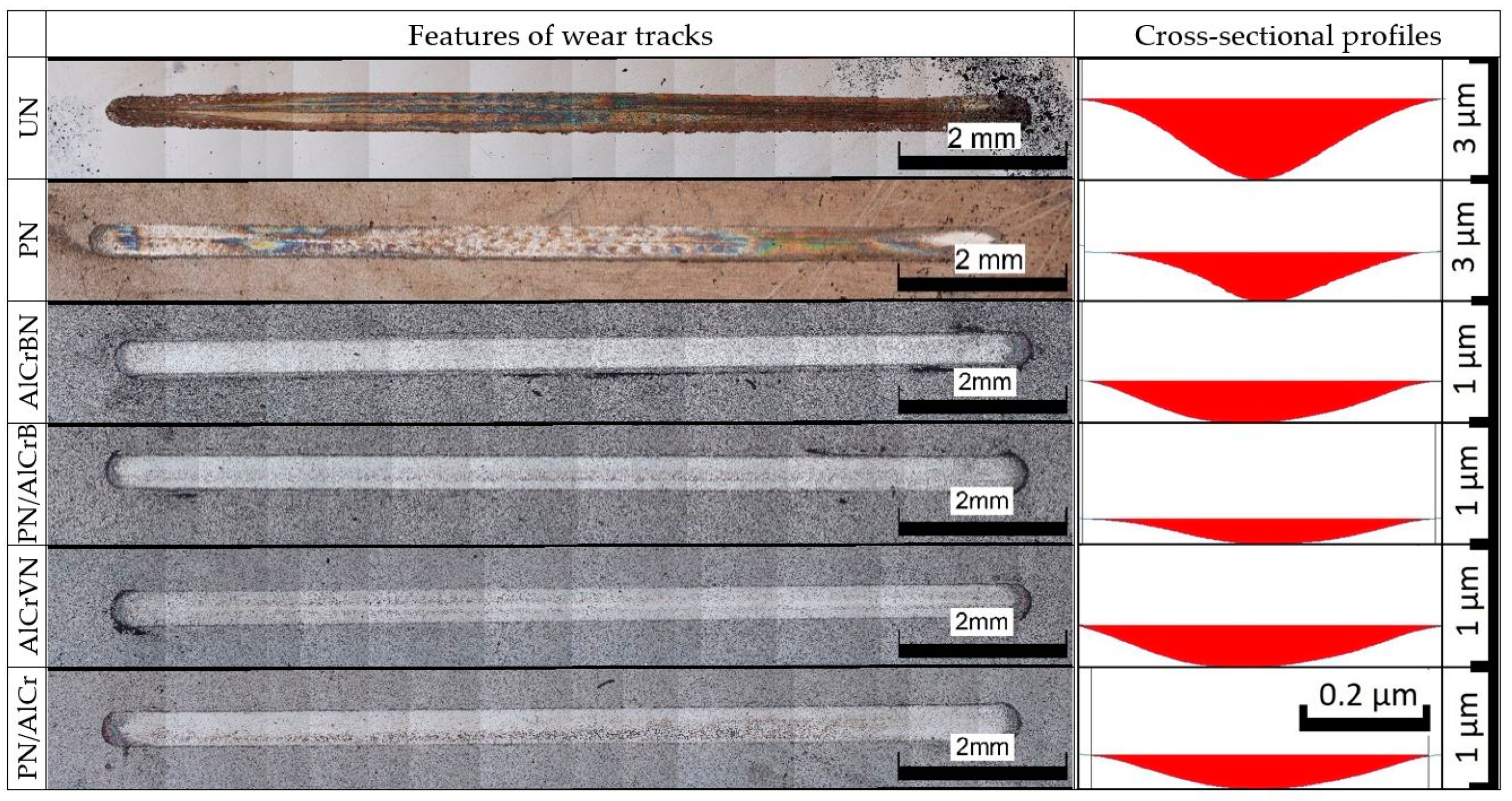

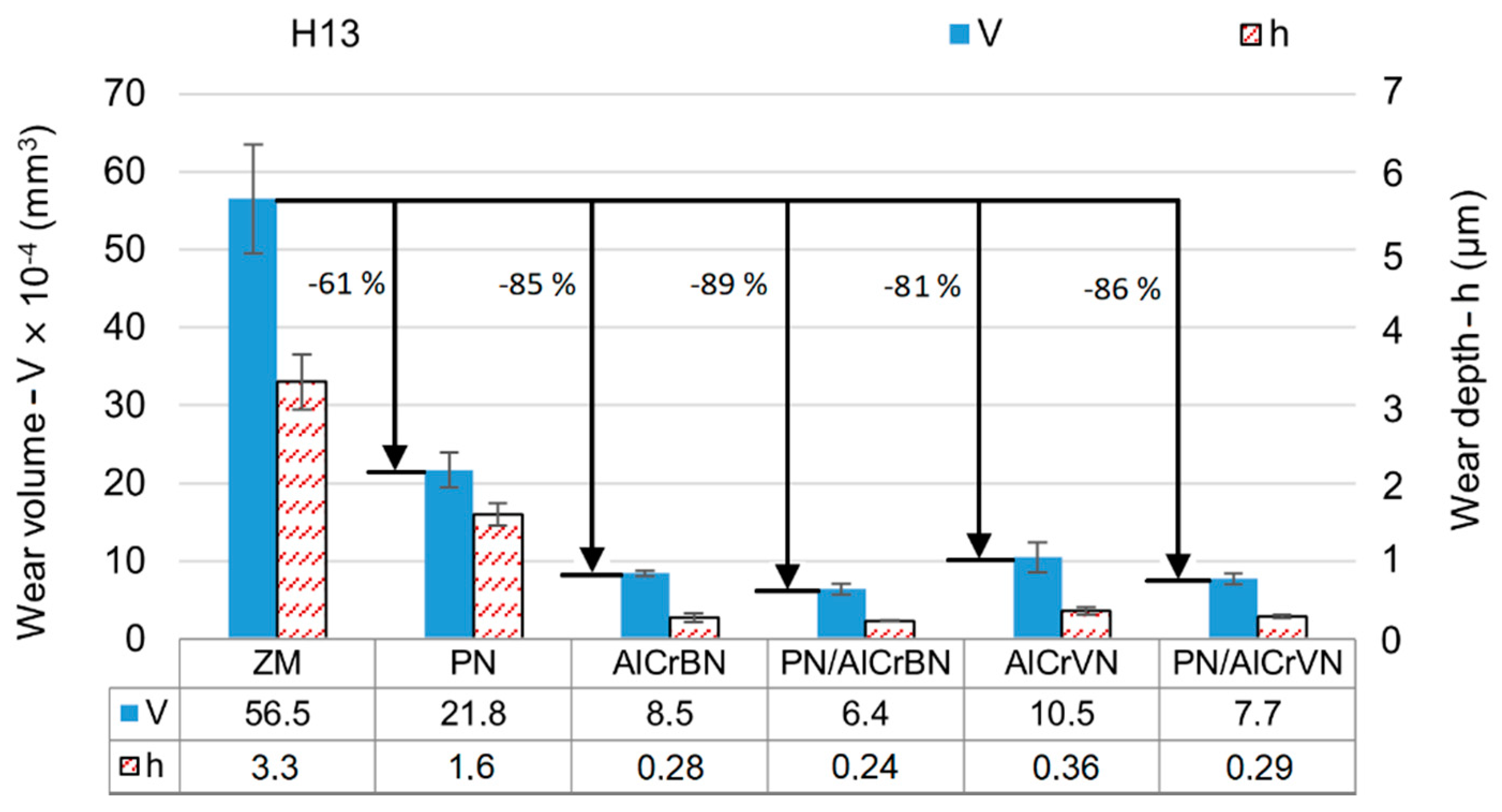

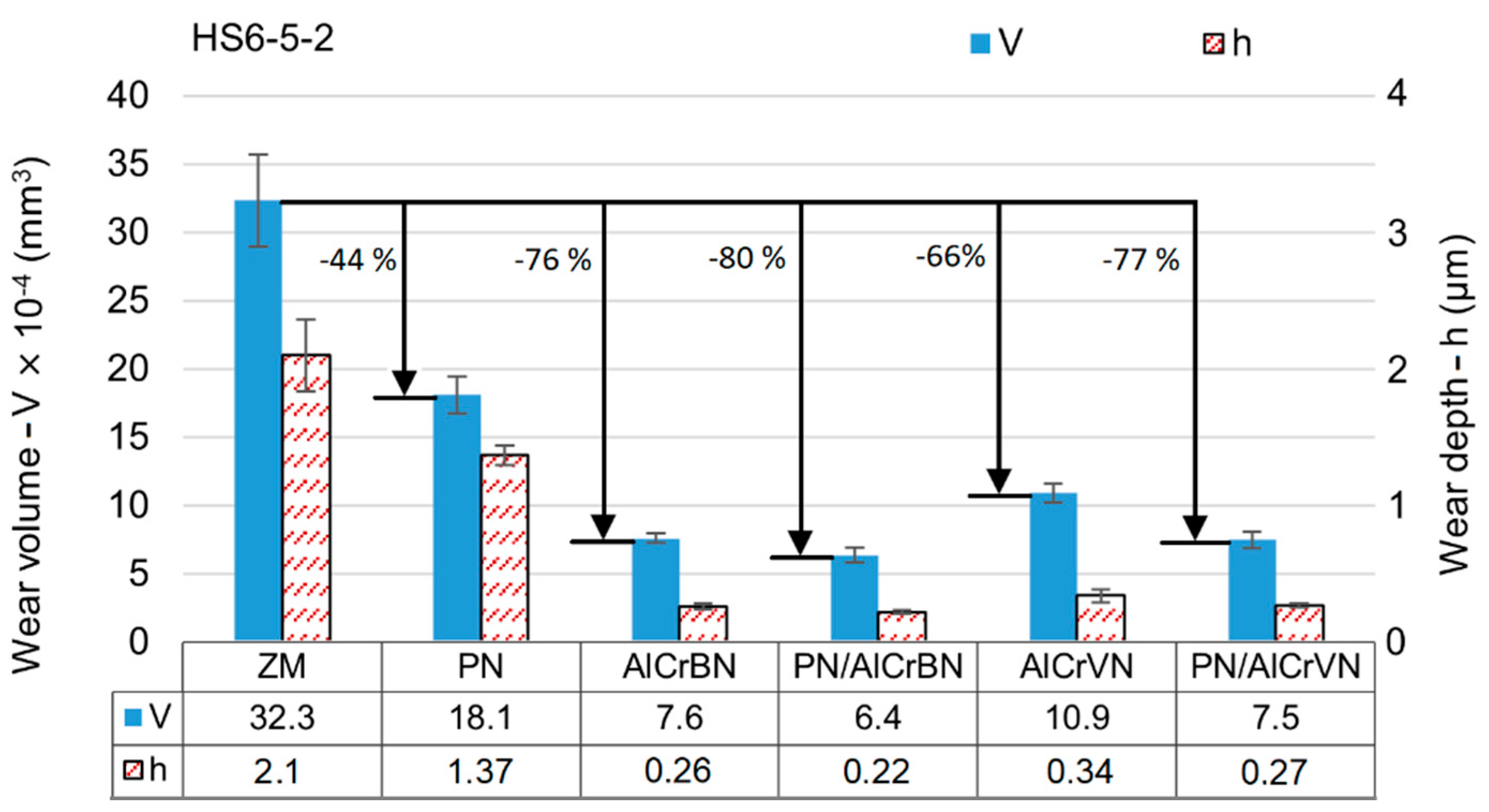

3.5. Friction-Wear Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hrbáčková, L.; Stojanović, A.; Tuček, D.; Hrušecká, D. Environmental Aspects of Product Life Cycle Management and Purchasing Logistics: Current Situation in Large and Medium-Sized Czech Manufacturing Companies. Acta Polytech. Hung. 2019, 16, 79–94. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Rachbauer, R.; Holec, D.; Rovere, F.; Schneider, J.M. Protective Transition Metal Nitride Coatings. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; Volume 4, pp. 355–388. [Google Scholar] [CrossRef]

- Kalss, W.; Reiter, A.; Derflinger, V.; Gey, C.; Endrino, J.L. Modern Coatings in High Performance Cutting Applications. Int. J. Refract. Met. Hard Mater. 2006, 24, 399–404. [Google Scholar] [CrossRef]

- Kawate, M.; Hashimoto, A.K.; Suzuki, T. Oxidation Resistance of Cr1-XAlxN and Ti1-XAlxN Films. Surf. Coat. Technol. 2003, 165, 163–167. [Google Scholar] [CrossRef]

- Spain, E.; Avelar-Batista, J.C.; Letch, M.; Housden, J.; Lerga, B. Characterisation and Applications of Cr-Al-N Coatings. Surf. Coat. Technol. 2005, 200, 1507–1513. [Google Scholar] [CrossRef]

- Franz, R.; Sartory, B.; Kaindl, R.; Tessadri, R.; Reiter, A.; Derflinger, V.H.; Polcik, P.; Mitterer, C. High-Temperature Tribological Studies of Arc- Evaporated Al x Cr 1-x N Coatings. In Proceedings of the 16th International Plansee Seminar, Reutte, Austria, 30 May–3 June 2005. [Google Scholar]

- Sato, T.; Yamamoto, T.; Hasegawa, H.; Suzuki, T. Effects of Boron Contents on Microstructures and Microhardness in CrxAlyN Films Synthesized by Cathodic Arc Method. Surf. Coat. Technol. 2006, 201, 1348–1351. [Google Scholar] [CrossRef]

- Musil, J. Hard and Superhard Nanocomposite Coatings. Surf. Coat. Technol. 2000, 125, 322–330. [Google Scholar] [CrossRef]

- Tritremmel, C.; Daniel, R.; Rudigier, H.; Polcik, P.; Mitterer, C. Mechanical and Tribological Properties of Al-Ti-N/Al-Cr-B-N Multilayer Films Synthesized by Cathodic Arc Evaporation. Surf. Coat. Technol. 2014, 246, 57–63. [Google Scholar] [CrossRef]

- Franz, R.; Neidhardt, J.; Sartory, B.; Kaindl, R.; Tessadri, R.; Polcik, P.; Derflinger, V.H.; Mitterer, C. High-Temperature Low-Friction Properties of Vanadium-Alloyed AlCrN Coatings. Tribol. Lett. 2006, 23, 101–107. [Google Scholar] [CrossRef]

- Iram, S.; Cai, F.; Wang, J.; Zhang, J.; Liang, J.; Ahmad, F.; Zhang, S. Effect of Addition of Mo or V on the Structure and Cutting Performance of AlCrN-Based Coatings. Coatings 2020, 10, 298. [Google Scholar] [CrossRef] [Green Version]

- Franz, R.; Neidhardt, J.; Kaindl, R.; Sartory, B.; Tessadri, R.; Lechthaler, M.; Polcik, P.; Mitterer, C. Influence of Phase Transition on the Tribological Performance of Arc-Evaporated AlCrVN Hard Coatings. Surf. Coat. Technol. 2009, 203, 1101–1105. [Google Scholar] [CrossRef]

- Dinesh Kumar, D.; Kumar, N.; Kalaiselvam, S.; Dash, S.; Jayavel, R. Substrate Effect on Wear Resistant Transition Metal Nitride Hard Coatings: Microstructure and Tribo-Mechanical Properties. Ceram. Int. 2015, 41, 9849–9861. [Google Scholar] [CrossRef]

- Tritremmel, C.; Daniel, R.; Lechthaler, M.; Rudigier, H.; Polcik, P.; Mitterer, C. Microstructure and Mechanical Properties of Nanocrystalline Al-Cr-B-N Thin Films. Surf. Coat. Technol. 2012, 213, 1–7. [Google Scholar] [CrossRef]

- Beutner, M.; Lümkemann, A.; Jilek, M.; Bloesch, D.; Cselle, T.; Welzel, F.; Ag, P. High Speed Gear Hobbing with Customized AlCrBN Coatings Coating of Fly-Hobbing Teeth LACS ® Lateral ARC and Central Sputtering Doping AlCrN with Boron by LACS ® Hobbing with Boron Doped AlCr (Ti) N. In Proceedings of the 16th International Conference on Plasma Surface Engineering, Garmisch-Partenkirchen, Germany, 17–21 September 2018. [Google Scholar]

- Matthews, A.; Leyland, A. Hybrid Techniques in Surface Engineering. Surf. Coat. Technol. 1995, 71, 88–92. [Google Scholar] [CrossRef]

- Morita, T.; Inoue, K.; Ding, X.; Usui, Y.; Ikenaga, M. Effect of Hybrid Surface Treatment Composed of Nitriding and DLC Coating on Friction-Wear Properties and Fatigue Strength of Alloy Steel. Mater. Sci. Eng. A 2016, 661, 105–114. [Google Scholar] [CrossRef]

- Joska, Z.; Kadlec, J.; Hrubý, V.; Mrázková, T.; Maňas, K. Characteristics of Duplex Coating on Austenitic Stainless Steel. Key Eng. Mater. 2011, 255–258. [Google Scholar] [CrossRef]

- Prochazka, J.; Pokorny, Z.; Dobrocky, D. Service Behavior of Nitride Layers of Steels for Military Applications. Coatings 2020, 10, 975. [Google Scholar] [CrossRef]

- Slany, M.; Sedlak, J.; Zouhar, J.; Zemcik, O.; Chladil, J.; Jaros, A.; Kouril, K.; Varhanik, M.; Majerik, J.; Barenyi, I.; et al. Material and Dimensional Analysis of Bimetallic Pipe Bend with Defined Bending Radii. Teh. Vjesn. 2021, 28, 974–982. [Google Scholar] [CrossRef]

- TSCHIPTSCHIN, A.P. Duplex Coatings. Encyclopedia of Tribology; Springer Science: Berlin/Heidelberg, Germany, 2013; pp. 794–799. [Google Scholar] [CrossRef]

- ISO-18203. Steel—Determination of the Thickness of Surface-Hardened Layers; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- ASTM G133-02. Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- Klanica, O.; Svoboda, E.; Joska, Z. Changes of the Surface Texture after Surface Treatment HS6-5-2-5 Steel. Manuf. Technol. J. 2015, 15, 47–53. [Google Scholar] [CrossRef]

- Krbaťa, M.; Majerík, J.; Barényi, I.; Mikušová, I.; Kusmič, D. Mechanical and tribological features of the 90MnCrV8 steel after plasma nitriding. Manuf. Technol. J. 2019, 19, 238–242. [Google Scholar] [CrossRef]

- Bell, T.; Dong, H.; Sun, Y. Realising the Potential of Duplex Surface Engineering. Tribol. Int. 1998, 31, 127–137. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Musil, J.; Jirout, M. Toughness of Hard Nanostructured Ceramic Thin Films. Surf. Coat. Technol. 2007, 201, 5148–5152. [Google Scholar] [CrossRef]

- Wang, Z.W.; Li, Y.; Zhang, Z.H.; Zhang, S.Z.; Ren, P.; Qiu, J.X.; Wang, W.W.; Bi, Y.J.; He, Y.Y. Friction and Wear Behavior of Duplex-Treated AISI 316L Steels by Rapid Plasma Nitriding and (CrWAlTiSi)N Ceramic Coating. Results Phys. 2021, 24, 104132. [Google Scholar] [CrossRef]

- Brizmer, V.; Kligerman, Y.; Etsion, I. The Effect of Contact Conditions and Material Properties on the Elasticity Terminus of a Spherical Contact. Int. J. Solids Struct. 2006, 43, 5736–5749. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Wang, L.; Wang, Q.; Li, M. A Superhard CrAlSiN Superlattice Coating Deposited by Multi-Arc Ion Plating: I. Microstructure and Mechanical Properties. Surf. Coat. Technol. 2013, 214, 160–167. [Google Scholar] [CrossRef]

- Vidakis, N.; Antoniadis, A.; Bilalis, N. The VDI 3198 Indentation Test Evaluation of a Reliable Qualitative Control for Layered Compounds. J. Mater. Process. Technol. 2003, 143–144, 481–485. [Google Scholar] [CrossRef]

- Tian-Shun, D.; Ran, W.; Guo-Lu, L.; Ming, L. Failure Mechanism and Acoustic Emission Signal Characteristics of Coatings under the Condition of Impact Indentation. High Temp. Mater. Process. 2019, 38, 601–611. [Google Scholar] [CrossRef]

- ASTM C1624-05. Standard Test Method for Adhesion Strength and Mechanical Failure Modes Of Ceramic Coatings By Quantitative Single Point Scratch Testing; ASTM International, 100 Barr Harbor Drive, PO Box C700: West Conshohocken, PA, USA, 2005. [Google Scholar] [CrossRef]

- Shugurov, A.; Akulinkin, A.; Voronov, A. Investigation of Adhesive Behavior of Ti-Al-N/Ti-Al Multilayers by Scratch Testing. AIP Conf. Proc. 2018, 2051, 020282. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Chen, Z.; Li, J.; Li, M. Influence of Deposition Parameters on Hard Cr-Al-N Coatings Deposited by Multi-Arc Ion Plating. Appl. Surf. Sci. 2012, 258, 3629–3636. [Google Scholar] [CrossRef]

- Chen, W.; Zheng, J.; Lin, Y.; Kwon, S.; Zhang, S. Comparison of AlCrN and AlCrTiSiN Coatings Deposited on the Surface of Plasma Nitrocarburized High Carbon Steels. Appl. Surf. Sci. 2015, 332, 525–532. [Google Scholar] [CrossRef]

- Shtansky, D.V.; Sheveiko, A.N.; Petrzhik, M.I.; Kiryukhantsev-Korneev, F.V.; Levashov, E.A.; Leyland, A.; Yerokhin, A.L.; Matthews, A. Hard Tribological Ti-B-N, Ti-Cr-B-N, Ti-Si-B-N and Ti-Al-Si-B-N Coatings. Surf. Coat. Technol. 2005, 200, 208–212. [Google Scholar] [CrossRef]

- Zmitrowicz, A. Wear Debris: A Review of Properties and Constitutive Models. J. Theor. Appl. Mech. 2005, 43, 3–35. [Google Scholar]

- Shi, H.; Du, S.; Sun, C.; Song, C.; Yang, Z.; Zhang, Y. Behavior of Wear Debris and Its Action Mechanism on the Tribological Properties of Medium-Carbon Steel with Magnetic Field. Materials 2018, 12, 45. [Google Scholar] [CrossRef] [Green Version]

- Hutchings, I.M. Tribology: Friction and Wear of Engineering Materials; Edward Arnold: London, UK, 1992; Volume 13. [Google Scholar] [CrossRef]

- Yang, Q.; Senda, T.; Ohmori, A. Effect of Carbide Grain Size on Microstructure and Sliding Wear Behavior of HVOF-Sprayed WC-12% Co Coatings. Wear 2003, 254, 23–34. [Google Scholar] [CrossRef]

- Usmani, S.; Sampath, S.; Houck, D.L.; Lee, D. Effect of Carbide Grain Size on the Sliding and Abrasive Wear Behaviour of Thermally Sprayed WC-Co Coatings. Tribol. Trans. 1997, 40, 470–478. [Google Scholar] [CrossRef]

- Franz, R. High-Temparature, Low-Friction Properties of the Vanadium Alloyed AlCrN Coatings. Coaitngs 2007, 10, 298. [Google Scholar] [CrossRef]

| C | Mn | Si | Cr | Mo | V | P | S | |

|---|---|---|---|---|---|---|---|---|

| ASTM A681 | 0.32–0.45 | 0.2–0.6 | 0.8–1.25 | 4.75–5.5 | 1.1–1.75 | 0.8–1.2 | Max. 0.03 | Max. 0.03 |

| Measured | 0.36 | 0.47 | 0.97 | 4.80 | 1.24 | 0.84 | 0.030 | 0.01 |

| C | Mn | Si | Cr | Mo | W | V | P | S | |

|---|---|---|---|---|---|---|---|---|---|

| EN ISO 4957 | 0.8–0.88 | Max. 0.4 | Max. 0.45 | 3.8–4.5 | 4.7–5.2 | 5.9–6.7 | 1.7–2.1 | Max. 0.03 | Max. 0.03 |

| Measured | 0.82 | 0.35 | 0.23 | 4.50 | 5.35 | 1.94 | 7.00 | 0.028 | 0.010 |

| Stroke Length (mm) | Oscillating Frequency (Hz) | Test Duration (s) | Ambient Temperature (°C) | Relative Humidity (%) | Lubrication |

|---|---|---|---|---|---|

| 10 | 3.5 | 2000 | 22 ± 0.5 | 40–60 | None applied |

| Steel | Material | Hardness (HV 5) |

|---|---|---|

| H13 | UN | 502 ± 6 |

| PN | 1120 ± 15 | |

| HS6-5-2 | UN | 874 ± 8 |

| PN | 1335 ± 10 |

| Steel | Maximal Microhardness Value (HV 0.1) | Limit Microhardness Value (HV 0.1) | Case Depth (µm) |

|---|---|---|---|

| H13 | 1325 ± 65 | 620 | 120 ± 12 |

| HS6-5-2 | 1375 ± 52 | 970 | 100 ± 10 |

| Material-Steel | HIT (GPa) | E* (GPa) | H/E* × 10−3 | H3/E*2 × 10−3 (GPa) |

|---|---|---|---|---|

| UN-H13 | 5.6 ± 0.4 | 230.8 ± 15 | 24 ± 3 | 3.3 ± 1.1 |

| PN-H13 | 11.5 ± 0.6 | 224.2 ± 8 | 51 ± 5 | 30.3 ± 6.9 |

| UN-HS6-5-2 | 9.5 ± 0.4 | 230.0 ± 10 | 41 ± 4 | 16.2 ± 3.5 |

| PN-HS6-5-2 | 13.9 ± 0.5 | 237.4 ± 7 | 59 ± 4 | 47.7 ± 8 |

| AlCrBN | 40.9 ± 0.5 | 455.2 ± 9 | 90 ± 3 | 330.2 ± 25.2 |

| AlCrVN | 39.3 ± 0.5 | 438.3 ± 8 | 89 ± 3 | 315.5 ± 23.6 |

| Steel | UN | PN | AlCrBN | PN/AlCrBN | AlCrVN | PN/AlCrVN |

|---|---|---|---|---|---|---|

| H13 | 0.57 ± 0.05 | 0.63 ± 0.04 | 0.53 ± 0.02 | 0.50 ± 0.03 | 0.60 ± 0.03 | 0.62 ± 0.02 |

| HS6-5-2 | 0.62 ± 0.04 | 0.64 ± 0.04 | 0.55 ± 0.02 | 0.56 ± 0.03 | 0.59 ± 0.03 | 0.57 ± 0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, H.C.; Joska, Z.; Pokorný, Z.; Studený, Z.; Sedlák, J.; Majerík, J.; Svoboda, E.; Dobrocký, D.; Procházka, J.; Tran, Q.D. Effect of Boron and Vanadium Addition on Friction-Wear Properties of the Coating AlCrN for Special Applications. Materials 2021, 14, 4651. https://doi.org/10.3390/ma14164651

Nguyen HC, Joska Z, Pokorný Z, Studený Z, Sedlák J, Majerík J, Svoboda E, Dobrocký D, Procházka J, Tran QD. Effect of Boron and Vanadium Addition on Friction-Wear Properties of the Coating AlCrN for Special Applications. Materials. 2021; 14(16):4651. https://doi.org/10.3390/ma14164651

Chicago/Turabian StyleNguyen, Huu Chien, Zdeněk Joska, Zdeněk Pokorný, Zbyněk Studený, Josef Sedlák, Josef Majerík, Emil Svoboda, David Dobrocký, Jiří Procházka, and Quang Dung Tran. 2021. "Effect of Boron and Vanadium Addition on Friction-Wear Properties of the Coating AlCrN for Special Applications" Materials 14, no. 16: 4651. https://doi.org/10.3390/ma14164651

APA StyleNguyen, H. C., Joska, Z., Pokorný, Z., Studený, Z., Sedlák, J., Majerík, J., Svoboda, E., Dobrocký, D., Procházka, J., & Tran, Q. D. (2021). Effect of Boron and Vanadium Addition on Friction-Wear Properties of the Coating AlCrN for Special Applications. Materials, 14(16), 4651. https://doi.org/10.3390/ma14164651