Fracture Characterization of Ultra-High Performance Concrete Notched Beams under the Influence of Different Material Factors Based on Acoustic Emission Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Proportion of Mixes

2.3. Specimen Preparation

2.4. Specimen Preparation

2.4.1. Slump Test

2.4.2. Four-Point Bending Test

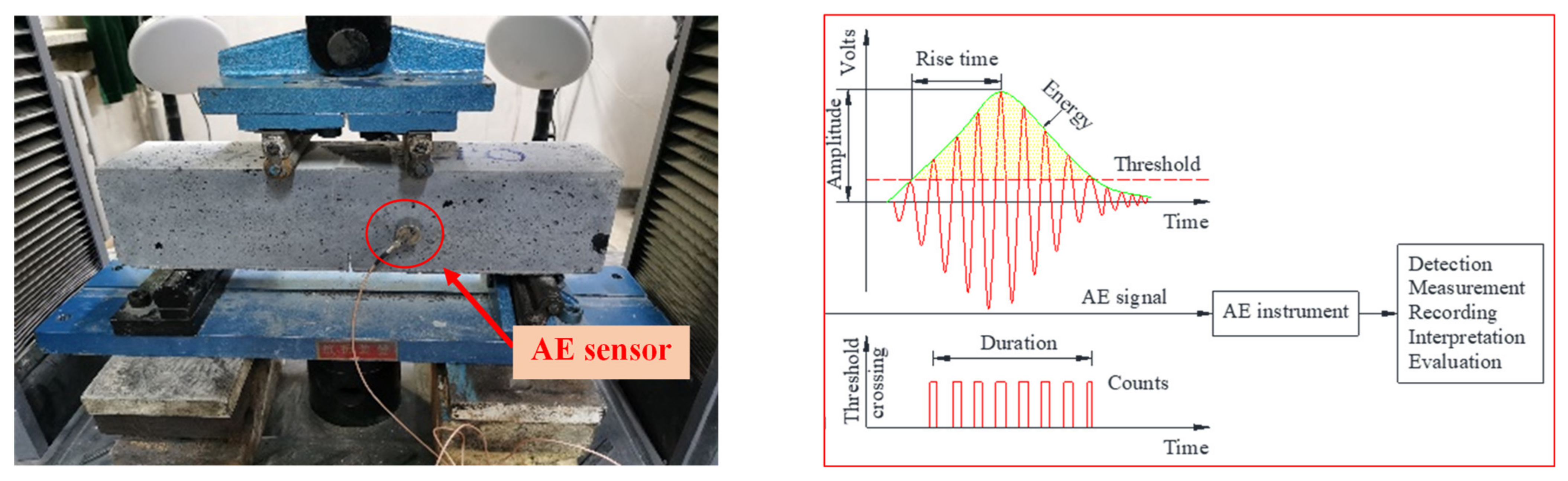

2.4.3. AE Test

3. Results and Discussions

3.1. Slump and Flexural Strength Analysis Based on RSM

3.1.1. Experimental Scheme

3.1.2. Analysis of Variance (ANOVA) Results for Models and Independent Variables

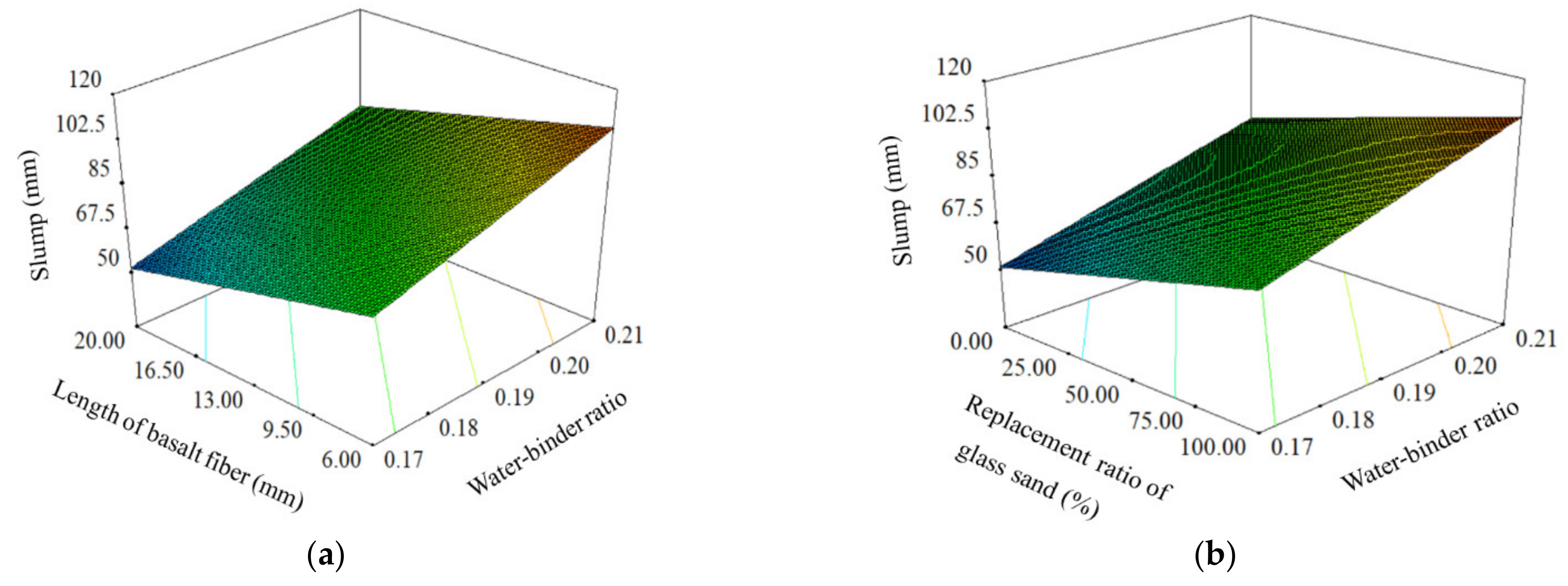

3.1.3. Slump

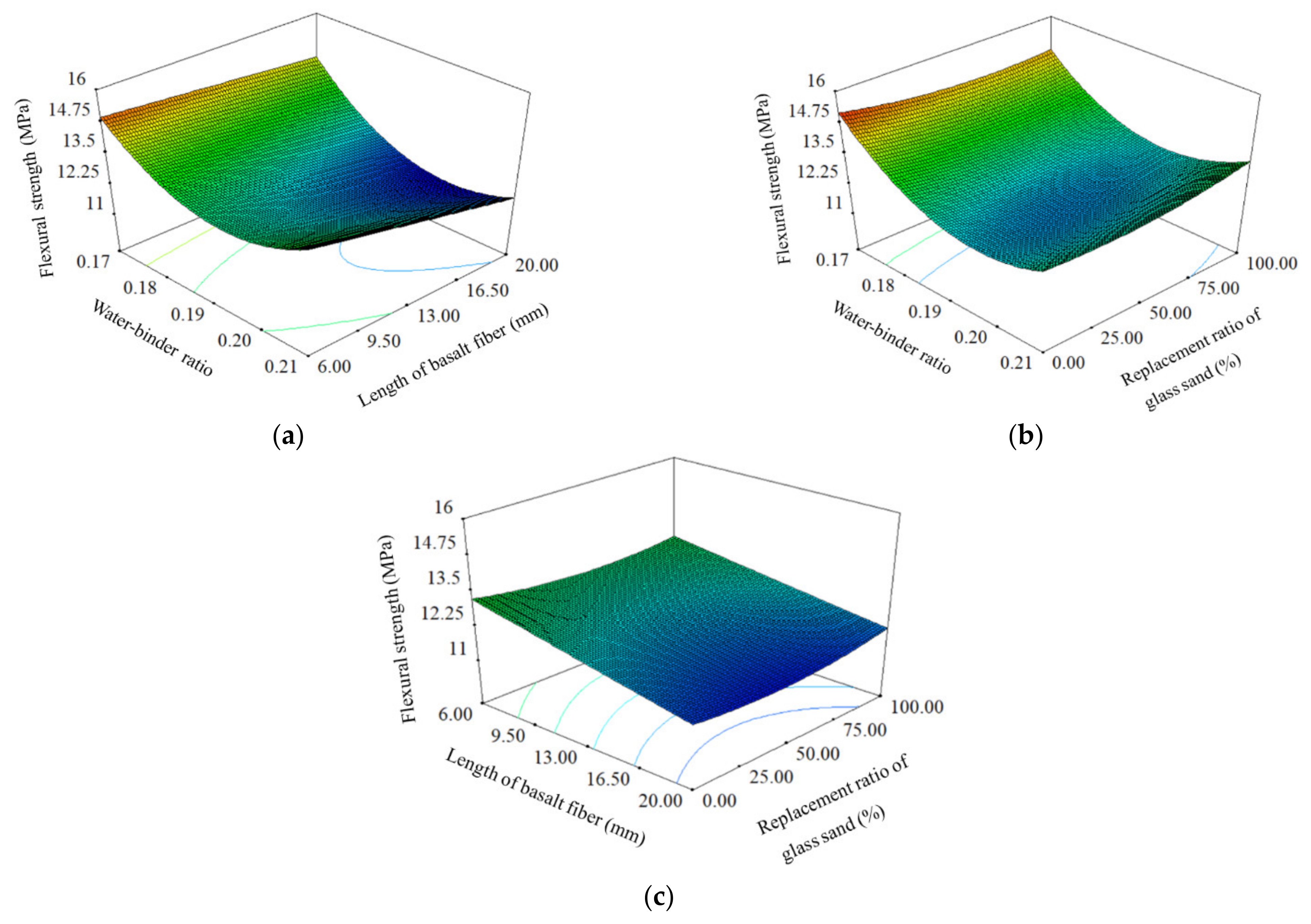

3.1.4. Flexural Strength

3.2. Fracture Analysis Based on AE Parameters

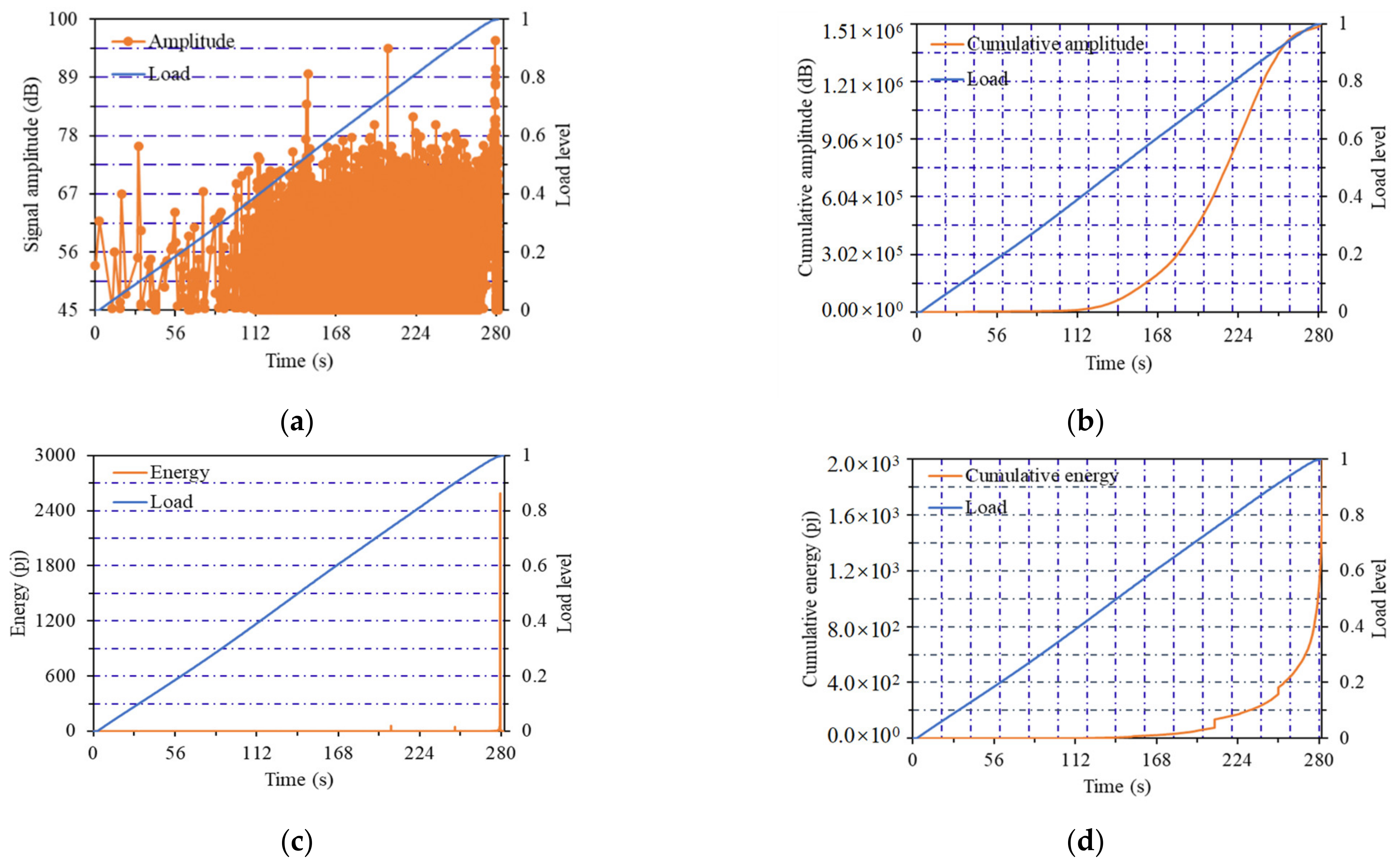

3.2.1. Fracture Characteristics Based on Amplitude and Energy

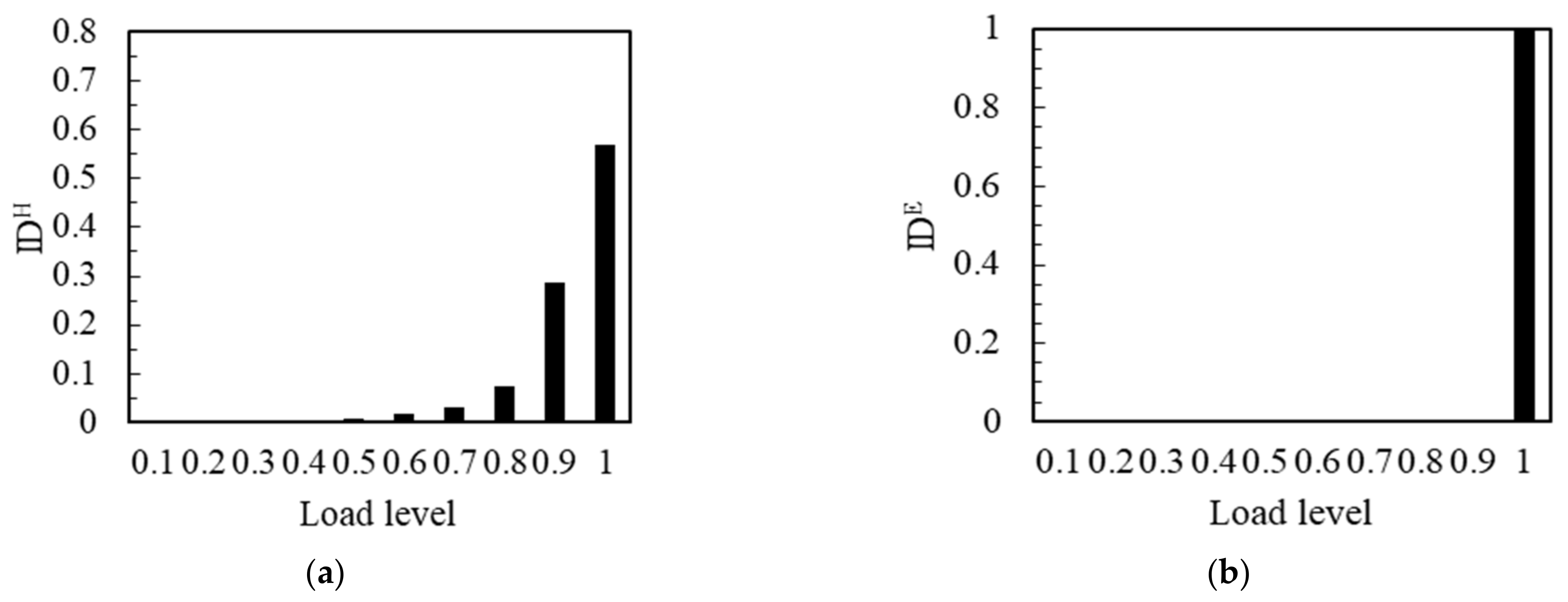

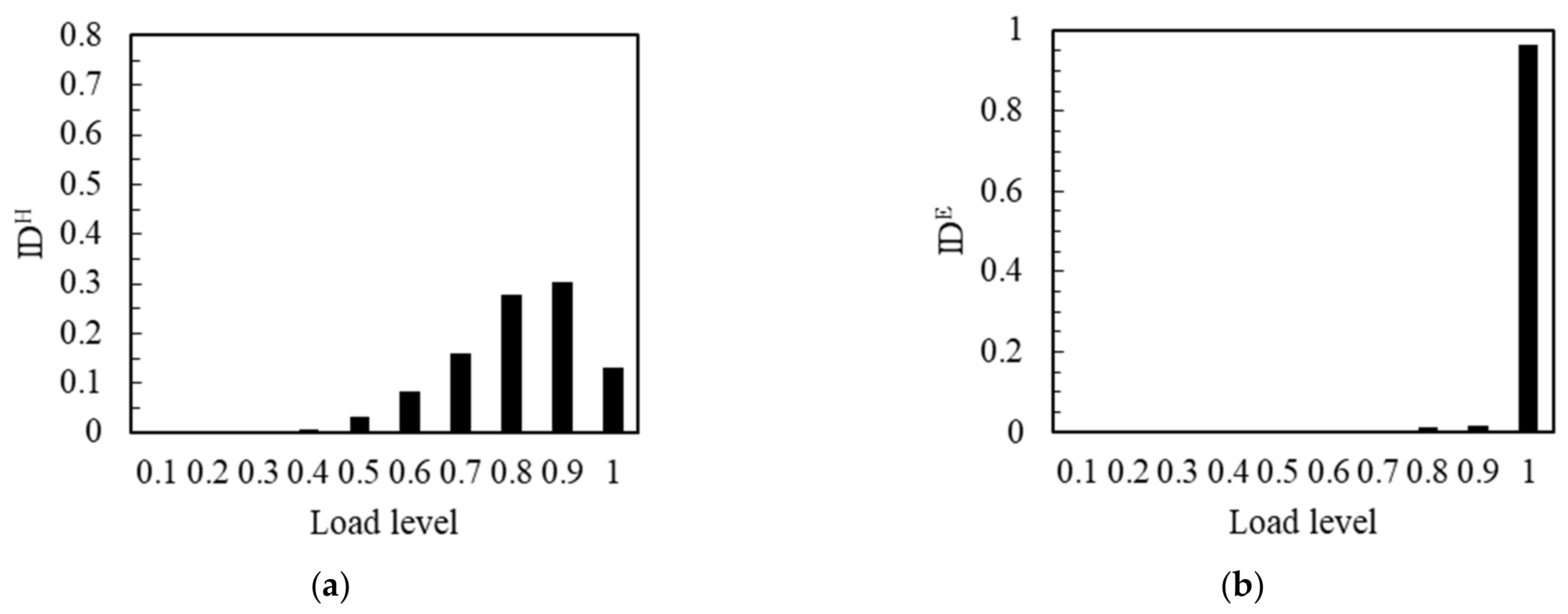

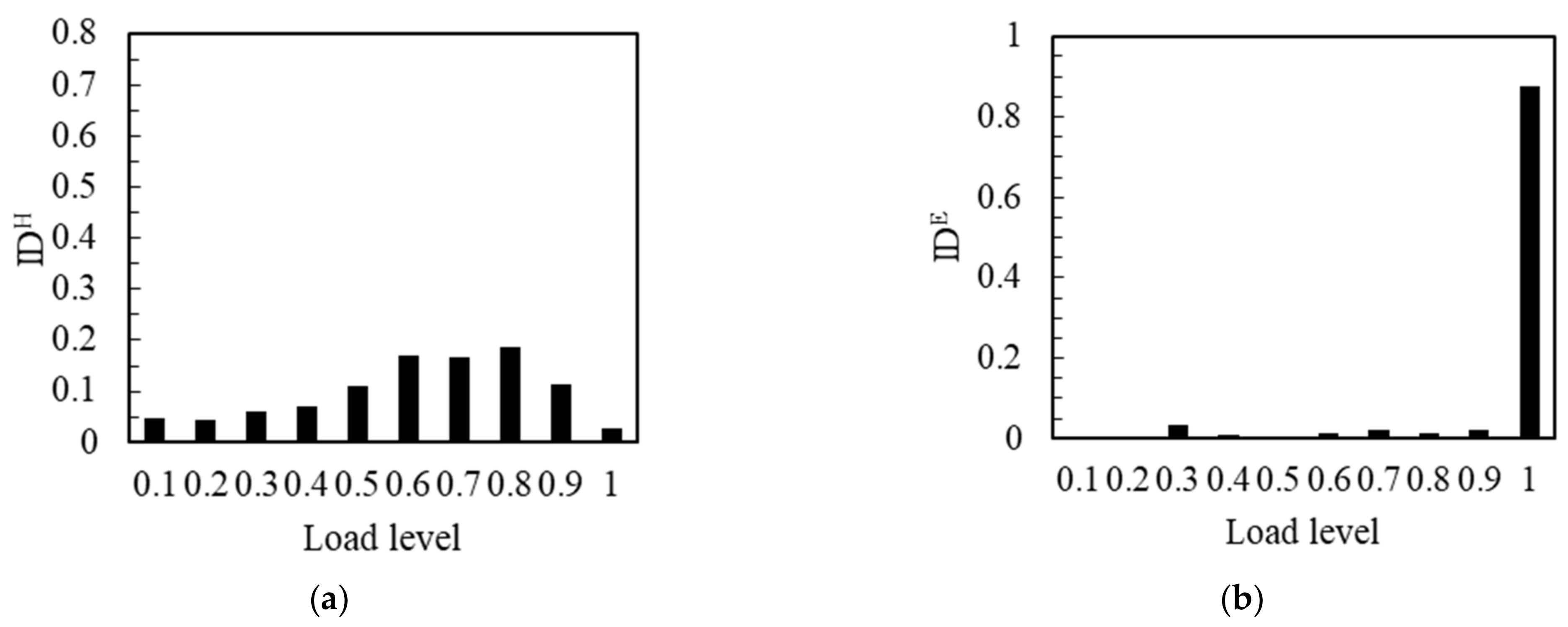

3.2.2. Fracture Characteristics Based on and

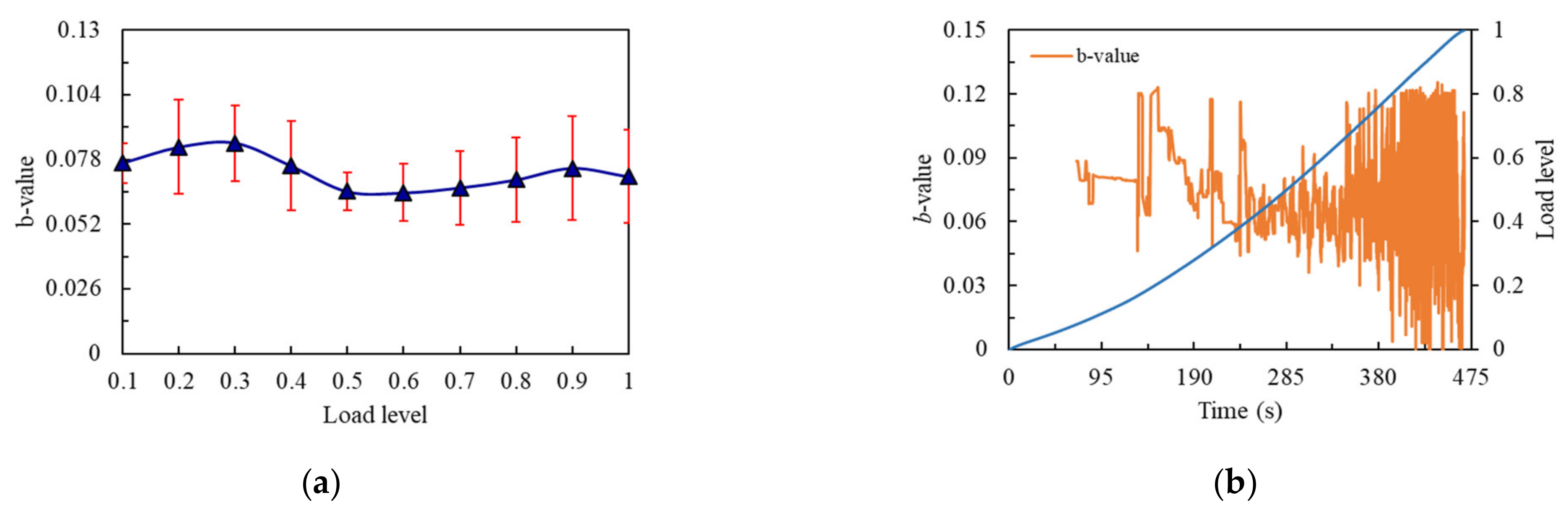

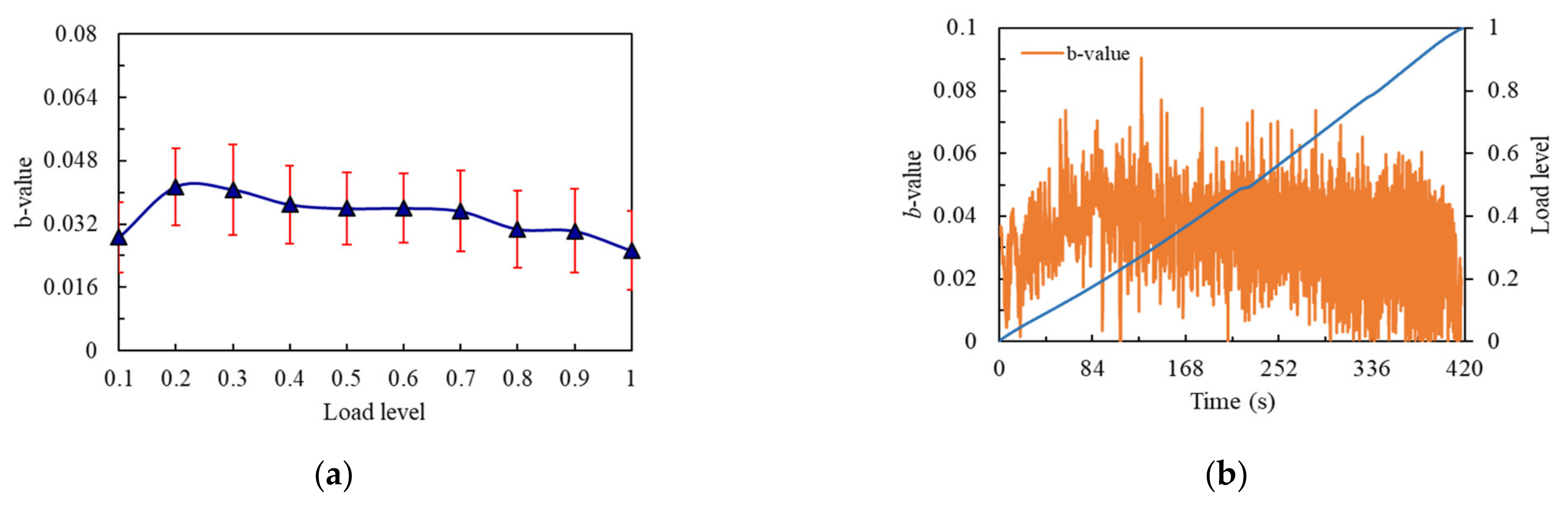

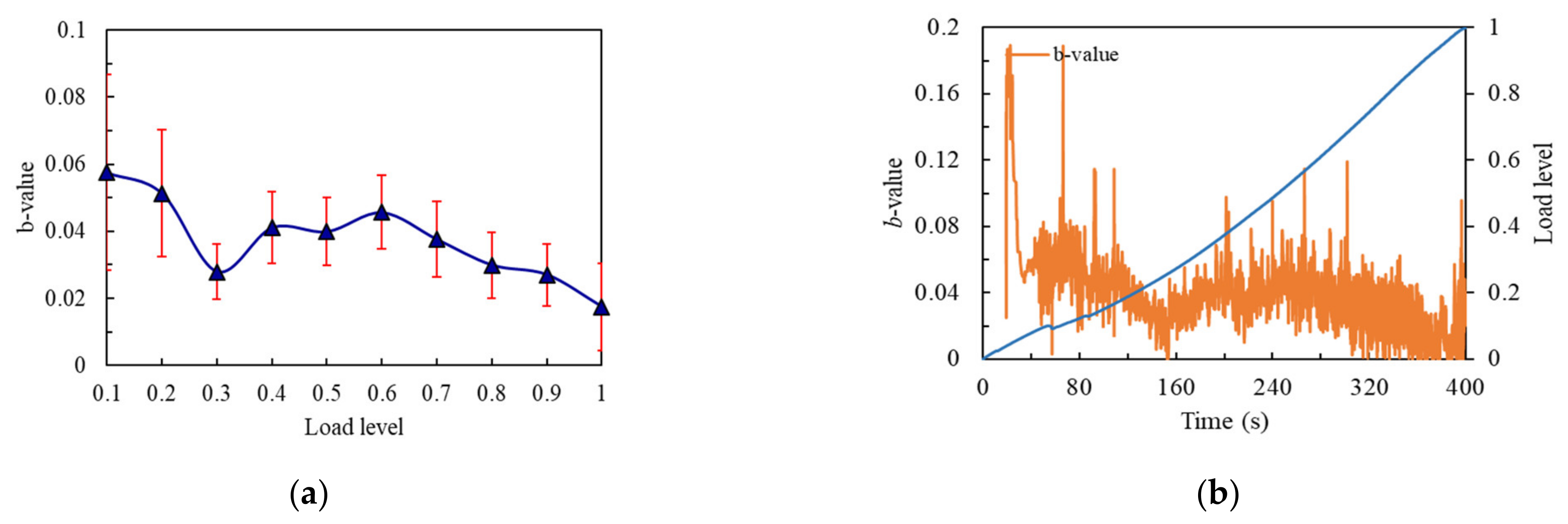

3.2.3. Fracture Characteristics Based on b-Value

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Morin, V.; Cohen-Tenoudji, F.; Feylessoufi, A.; Richard, P. Evolution of the capillary network in a reactive powder concrete during hydration process. Cem. Concr. Res. 2002, 32, 1907–1914. [Google Scholar] [CrossRef]

- Shi, C.J.; Wu, Z.M.; Xiao, J.F.; Wang, D.H.; Huang, Z.Y.; Fang, Z. A review on ultra high performance concrete: Part 1. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Arora, A.; Almujaddidi, A.; Kianmofrad, F.; Mobasher, B.; Neithalath, N. Material design of economical ultra-high performance concrete (UHPC) and evaluation of their properties. Cem. Concr. Compos. 2019, 104, 103346. [Google Scholar] [CrossRef]

- Lampropoulos, A.P.; Paschalis, S.A.; Tsioulou, O.T.; Dritsos, S.E. Strengthening of reinforced concrete beams using ultra high performance fiber reinforced concrete (UHPFRC). Eng. Struct. 2016, 106, 370–384. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.E.; Park, W.S.; Yun, S.H.; Kim, D.G.; Noh, J.M. Development of high performance concrete containing admixture in nuclear power plants. Appl. Mech. Mater. 2013, 357–360, 1062–1065. [Google Scholar] [CrossRef]

- Noshiravani, T.; Bruehwiler, E. Experimental investigation on reinforced ultra-high-performance fiber-reinforced concrete composite beams subjected to combined bending and shear. ACI Struct. J. 2013, 110, 251–261. [Google Scholar] [CrossRef]

- Ye, B.B.; Zhang, Y.T.; Han, J.G.; Pan, P. Effect of water to binder ratio and sand to binder ratio on shrinkage and mechanical properties of High-strength Engineered Cementitious Composite. Constr. Build. Mater. 2019, 226, 899–909. [Google Scholar] [CrossRef]

- Shin, H.O.; Yoo, D.Y.; Lee, J.H.; Lee, S.H.; Yoon, Y.S. Optimized mix design for 180 MPa ultra-high-strength concrete. J. Mater. Res. Technol. 2019, 8, 4182–4197. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Nehdi, M.L.; Abbas, S.; Soliman, A.M. Exploratory study of ultra-high performance fiber reinforced concrete tunnel lining segments with varying steel fiber lengths and dosages. Eng. Struct. 2015, 101, 733–742. [Google Scholar] [CrossRef]

- Yang, S.L.; Millard, S.G.; Soutsos, M.N.; Barnett, S.J.; Le, T.T. Influence of aggregate and curing regime on the mechanical properties of ultra-high performance fibre reinforced concrete (UHPFRC). Constr. Build. Mater. 2009, 23, 2291–2298. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, Y.; Guo, M.; Zhang, L.; Ning, H.; Liu, S. Mechanical and fracture properties of ultra-high performance concrete (UHPC) containing waste glass sand as partial replacement material. J. Clean. Prod. 2020, 277, 123501. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Using glass sand as an alternative for quartz sand in UHPC. Constr. Build. Mater. 2017, 145, 243–252. [Google Scholar] [CrossRef]

- Kravchuk, R.; Loshkov, D.; Landis, E.N. Combining X-ray imaging and acoustic emission to measure damage progression in ultra-high-performance-concrete. Life-Cycle Anal. Assess. Civ. Eng. Integr. Vis. 2019, 2433–2440. [Google Scholar] [CrossRef]

- Vaitkevicius, V.; Serelis, E.; Rudzionis, Z. Nondestructive testing of ultra-high performance concrete to evaluate freeze-thaw resistance. Mechanics 2012, 2, 164–169. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.Y.; Shin, H.O.; Yoon, Y.S. Ultrasonic Monitoring of Setting and Strength Development of Ultra-High-Performance Concrete. Materials. Constr. Build. Mater. 2016, 9, 294. [Google Scholar] [CrossRef]

- Leonhardt, S.; Lowke, D.; Stengel, T.; Gehlen, C. Impact Tests on Ultra-High Performance Concrete—Characterization of Strains and Ultrasonic Velocities. Mater Test. 2011, 53, 736–740. [Google Scholar] [CrossRef]

- Prem, P.R.; Murthy, A.R.; Verma, M. Theoretical modelling and acoustic emission monitoring of RC beams strengthened with UHPC. Constr. Build. Mater. 2018, 158, 670–682. [Google Scholar] [CrossRef]

- Kravchuk, R.; Landis, E.N. Acoustic emission-based classification of energy dissipation mechanisms during fracture of fiber-reinforced ultra-high-performance concrete. Constr. Build. Mater. 2018, 176, 531–538. [Google Scholar] [CrossRef]

- Wang, J.Y.; Guo, J.Y. Damage investigation of ultra high performance concrete under direct tensile test using acoustic emission techniques. Cem. Concr. Compos. 2018, 88, 17–28. [Google Scholar] [CrossRef]

- Dai, Q.L.; Ng, K.; Zhou, J.; Kreiger, E.L.; Ahlborn, T.M. Damage investigation of single-edge notched beam tests with normal strength concrete and ultra high performance concrete specimens using acoustic emission techniques. Constr. Build. Mater. 2012, 31, 231–242. [Google Scholar] [CrossRef]

- Prem, P.R.; Murthy, A.R. Acoustic emission and flexural behaviour of RC beams strengthened with UHPC overlay. Constr. Build. Mater. 2016, 123, 481–492. [Google Scholar] [CrossRef]

- Ohno, K.; Uji, K.; Ueno, A.; Ohtsu, M. Fracture process zone in notched concrete beam under three-point bending by acoustic emission. Constr. Build. Mater. 2014, 67, 139–145. [Google Scholar] [CrossRef]

- Nguyen-Tat, T.; Ranaivomanana, N.; Balayssac, J.P. Characterization of damage in concrete beams under bending with acoustic emission technique (AET). Constr. Build. Mater. 2018, 187, 487–500. [Google Scholar] [CrossRef]

- Lacidogna, G.; Piana, G.; Carpinteri, A. Damage monitoring of three-point bending concrete specimens by acoustic emission and natural frequency analysis. Eng. Fract. Mech. 2019, 210, 203–211. [Google Scholar] [CrossRef]

- Chen, C.; Fan, X.Q.; Chen, X.D. Experimental investigation of concrete fracture behavior with different loading rates based on acoustic emission. Constr. Build. Mater. 2020, 237, 117472. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; National Standardization Management Committee of China. GB175-2007 Common Portland Cement; Standards Press of China: Beijing, China, 2007. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; National Standardization Management Committee of China. GB/T 27690-2011 Silica Fume for Cement Mortar and Concrete; Standards Press of China: Beijing, China, 2011. [Google Scholar]

- Ghafari, E.; Costa, H.; Julio, E. RSM-based model to predict the performance of self-compacting UHPC reinforced with hybrid steel micro-fibers. Constr. Build. Mater. 2014, 66, 375–383. [Google Scholar] [CrossRef]

- Li, W.Z.; Cai, L.C.; Wu, Y.G.; Liu, Q.T.; Yu, H.; Zhang, C. Assessing recycled pavement concrete mechanical properties under joint action of freezing and fatigue via RSM. Constr. Build. Mater. 2018, 164, 1–11. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhang, M.S.; Jiao, Y.B.; Fu, L.X. Preparation parameter analysis and optimization of sustainable asphalt binder modified by waste rubber and diatomite. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Construction of the People’s Republic of China. GB/T 50081-2002 Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Architecture & Building Press: Beijing, China, 2002. [Google Scholar]

- ASTM. ASTM C143-C143M-15a Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: Philadelphia, PA, USA, 2015. [Google Scholar]

- ASTM. ASTM C1609/C1609M-12 Standard Test Method for flexural Performance of Fiber-Reinforced concrete (Using Beam with Third-Point Loading); ASTM International: Philadelphia, PA, USA, 2012. [Google Scholar]

- ASTM. ASTM E1316-18 Standard Terminology for Nondestructive Examination; ASTM International: Philadelphia, PA, USA, 2018. [Google Scholar]

| Group Number | Materials | |||||||

|---|---|---|---|---|---|---|---|---|

| Cement | SF | QS | GS | QP | BF | Water | HRWRA | |

| 1 | 850 | 195.5 | 467.5 | 467.5 | 331.5 | 148.75 (13 mm) | 161.5 | 42.5 |

| 2 | 850 | 195.5 | 935 | 0 | 331.5 | 148.75 (20 mm) | 161.5 | 42.5 |

| 3 | 850 | 195.5 | 467.5 | 467.5 | 331.5 | 148.75 (13 mm) | 161.5 | 42.5 |

| 4 | 850 | 195.5 | 0 | 0 | 331.5 | 148.75 (13 mm) | 178.5 | 42.5 |

| 5 | 850 | 195.5 | 935 | 0 | 331.5 | 148.75 (13 mm) | 178.5 | 42.5 |

| 6 | 850 | 195.5 | 467.5 | 467.5 | 331.5 | 148.75 (20 mm) | 178.5 | 42.5 |

| 7 | 850 | 195.5 | 467.5 | 467.5 | 331.5 | 148.75 (20 mm) | 144.5 | 42.5 |

| 8 | 850 | 195.5 | 935 | 0 | 331.5 | 148.75 (6 mm) | 161.5 | 42.5 |

| 9 | 850 | 195.5 | 467.5 | 467.5 | 331.5 | 148.75 (6 mm) | 178.5 | 42.5 |

| 10 | 850 | 195.5 | 935 | 0 | 331.5 | 148.75 (13 mm) | 144.5 | 42.5 |

| 11 | 850 | 195.5 | 467.5 | 467.5 | 331.5 | 148.75 (13 mm) | 161.5 | 42.5 |

| 12 | 850 | 195.5 | 467.5 | 467.5 | 331.5 | 148.75 (13 mm) | 161.5 | 42.5 |

| 13 | 850 | 195.5 | 467.5 | 467.5 | 331.5 | 148.75 (13 mm) | 161.5 | 42.5 |

| 14 | 850 | 195.5 | 467.5 | 467.5 | 331.5 | 148.75 (6 mm) | 144.5 | 42.5 |

| 15 | 850 | 195.5 | 0 | 935 | 331.5 | 148.75 (6 mm) | 161.5 | 42.5 |

| 16 | 850 | 195.5 | 0 | 935 | 331.5 | 148.75 (20 mm) | 161.5 | 42.5 |

| 17 | 850 | 195.5 | 0 | 935 | 331.5 | 148.75 (13 mm) | 144.5 | 42.5 |

| Coded Value | Actual Value | ||

|---|---|---|---|

| X1 | X2 (mm) | X3 (%) | |

| −1 | 0.17 | 6 | 0 |

| 0 | 0.19 | 13 | 50 |

| 1 | 0.21 | 20 | 100 |

| Group Number | Preparation Parameters | Responses | |||

|---|---|---|---|---|---|

| X1 | X2 (mm) | X3 (%) | Y1 (mm) | Y2 (MPa) | |

| 1 | 0.19 | 13 | 50 | 71 | 12.72 |

| 2 | 0.19 | 20 | 0 | 54 | 11.50 |

| 3 | 0.19 | 13 | 50 | 77 | 11.43 |

| 4 | 0.21 | 13 | 100 | 94 | 13.63 |

| 5 | 0.21 | 13 | 0 | 68 | 13.55 |

| 6 | 0.21 | 20 | 50 | 92 | 11.39 |

| 7 | 0.17 | 20 | 50 | 58 | 14.76 |

| 8 | 0.19 | 6 | 0 | 94 | 13.09 |

| 9 | 0.21 | 6 | 50 | 112 | 13.28 |

| 10 | 0.17 | 13 | 0 | 44 | 14.92 |

| 11 | 0.19 | 13 | 50 | 85 | 12.83 |

| 12 | 0.19 | 13 | 50 | 71 | 11.75 |

| 13 | 0.19 | 13 | 50 | 74 | 13.06 |

| 14 | 0.17 | 6 | 50 | 71 | 15.42 |

| 15 | 0.19 | 6 | 100 | 112 | 13.30 |

| 16 | 0.19 | 20 | 100 | 83 | 12.19 |

| 17 | 0.17 | 13 | 100 | 80 | 13.96 |

| Sources | R2 | Adj. R2 | Adeq. Precision | F Value | p-Value | Significant |

|---|---|---|---|---|---|---|

| Y1 | 0.7992 | 0.7529 | 12.434 | 17.25 | <0.0001 | Yes |

| Y2 | 0.8377 | 0.6289 | 5.895 | 4.01 | <0.05 | Yes |

| Sources | Y1 | Y2 | ||

|---|---|---|---|---|

| F | p | F | p | |

| X1 | 18.85 | 0.0008 | 11.23 | 0.0122 |

| X2 | 15.36 | 0.0018 | 5.95 | 0.0448 |

| X3 | 17.54 | 0.0011 | 0.000084 | 0.9929 |

| X12 | - | - | 0.65 | 0.4460 |

| X13 | - | - | 0.47 | 0.5136 |

| X23 | - | - | 0.10 | 0.7581 |

| X11 | - | - | 16.50 | 0.0048 |

| X22 | - | - | 0.00041 | 0.9843 |

| X33 | - | - | 0.72 | 0.4254 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Liu, D.; Zhang, Y.; Jiao, Y. Fracture Characterization of Ultra-High Performance Concrete Notched Beams under the Influence of Different Material Factors Based on Acoustic Emission Technique. Materials 2021, 14, 4608. https://doi.org/10.3390/ma14164608

Wang X, Liu D, Zhang Y, Jiao Y. Fracture Characterization of Ultra-High Performance Concrete Notched Beams under the Influence of Different Material Factors Based on Acoustic Emission Technique. Materials. 2021; 14(16):4608. https://doi.org/10.3390/ma14164608

Chicago/Turabian StyleWang, Xianqiang, Duo Liu, Yao Zhang, and Yubo Jiao. 2021. "Fracture Characterization of Ultra-High Performance Concrete Notched Beams under the Influence of Different Material Factors Based on Acoustic Emission Technique" Materials 14, no. 16: 4608. https://doi.org/10.3390/ma14164608

APA StyleWang, X., Liu, D., Zhang, Y., & Jiao, Y. (2021). Fracture Characterization of Ultra-High Performance Concrete Notched Beams under the Influence of Different Material Factors Based on Acoustic Emission Technique. Materials, 14(16), 4608. https://doi.org/10.3390/ma14164608