Estimation of Number of Graphene Layers Using Different Methods: A Focused Review

Abstract

:1. Introduction

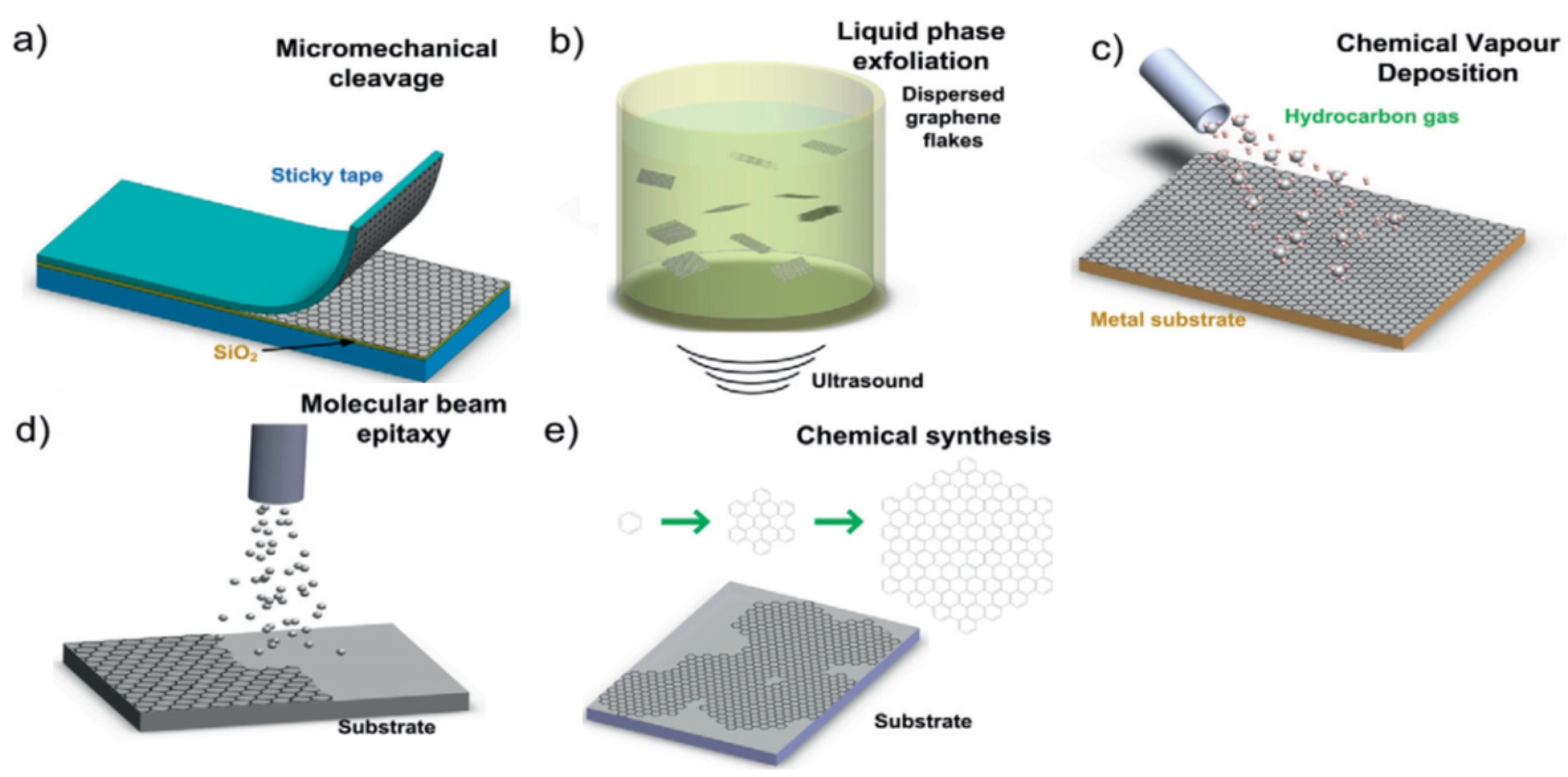

2. Production of Graphene

3. Significance of the Number of Graphene Layers

3.1. Properties vs. Numbers of Graphene Layers

3.1.1. Mechanical Properties and Number of Layers

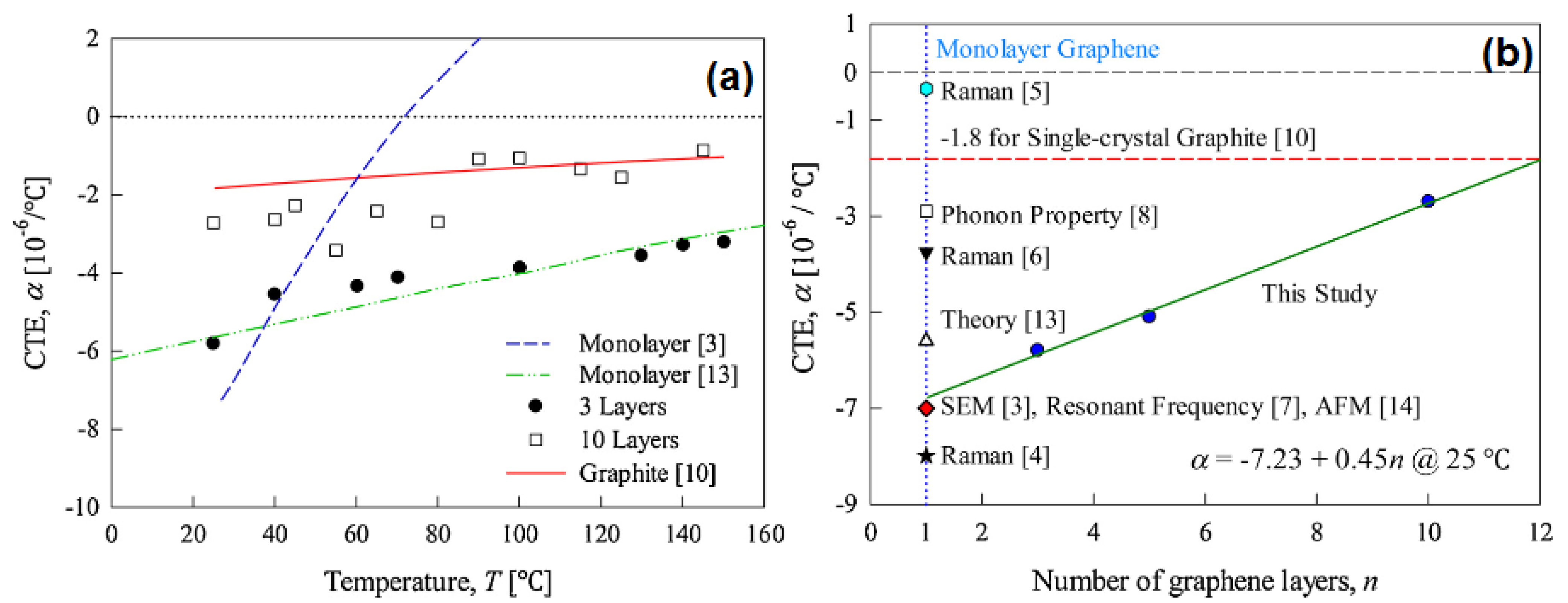

3.1.2. Effects of Layer Number on Thermal Properties

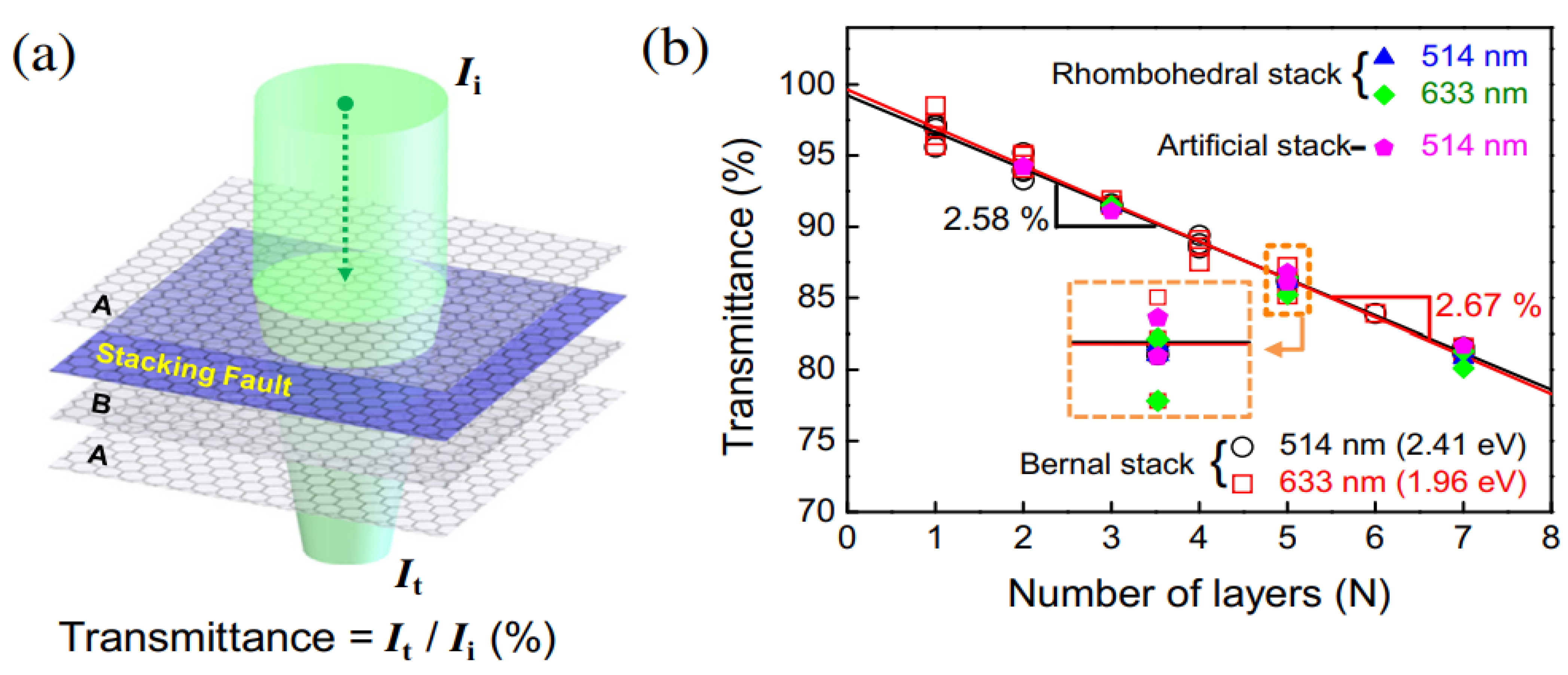

3.1.3. Optical Properties and Number of Layers

3.2. Restacking and Intercalation for Different Layer Numbers

4. Techniques Used to Determine Numbers of Graphene Layers

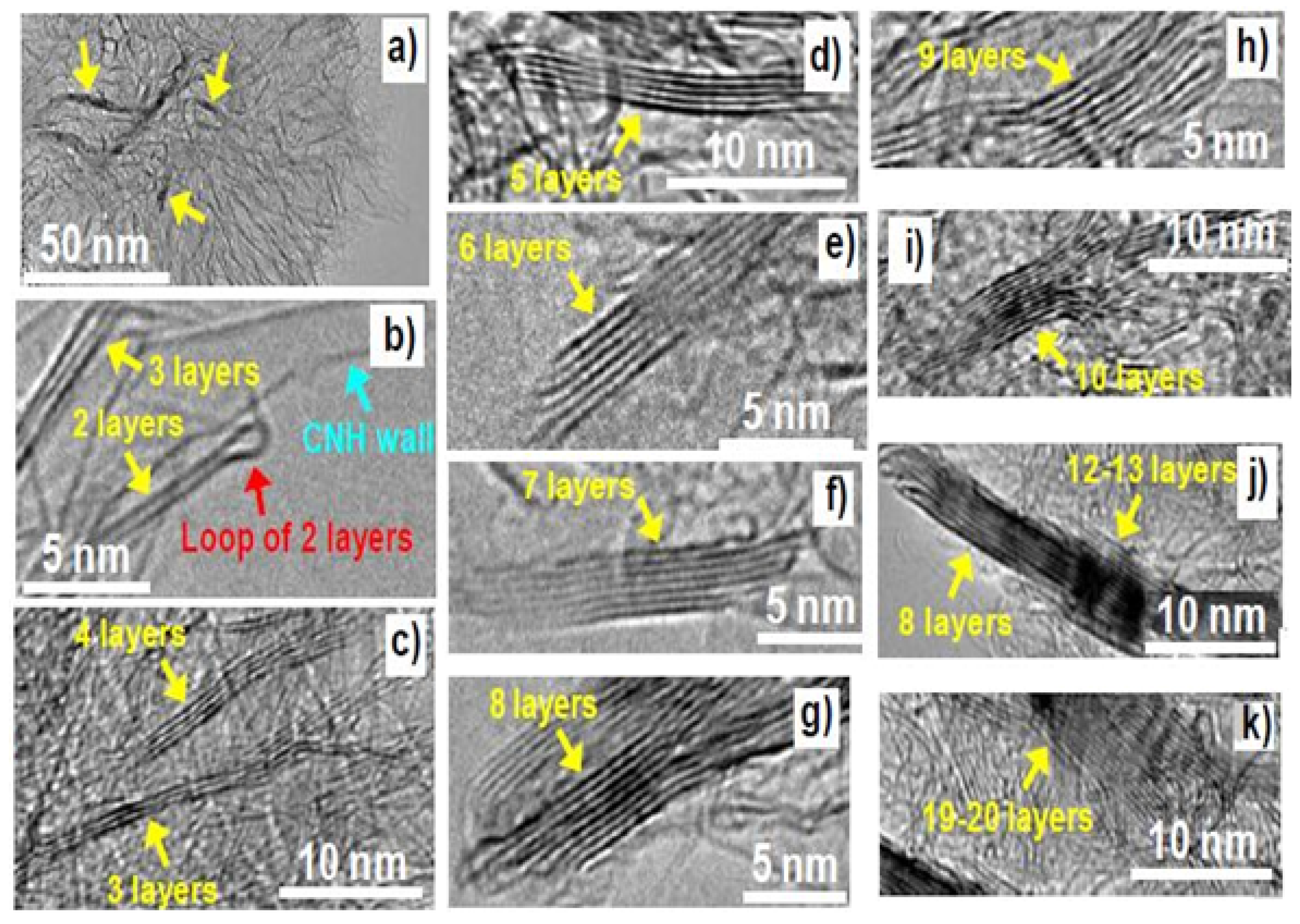

4.1. Transmission Electron Microscopy

4.2. Scanning Electron Microscopy (SEM)

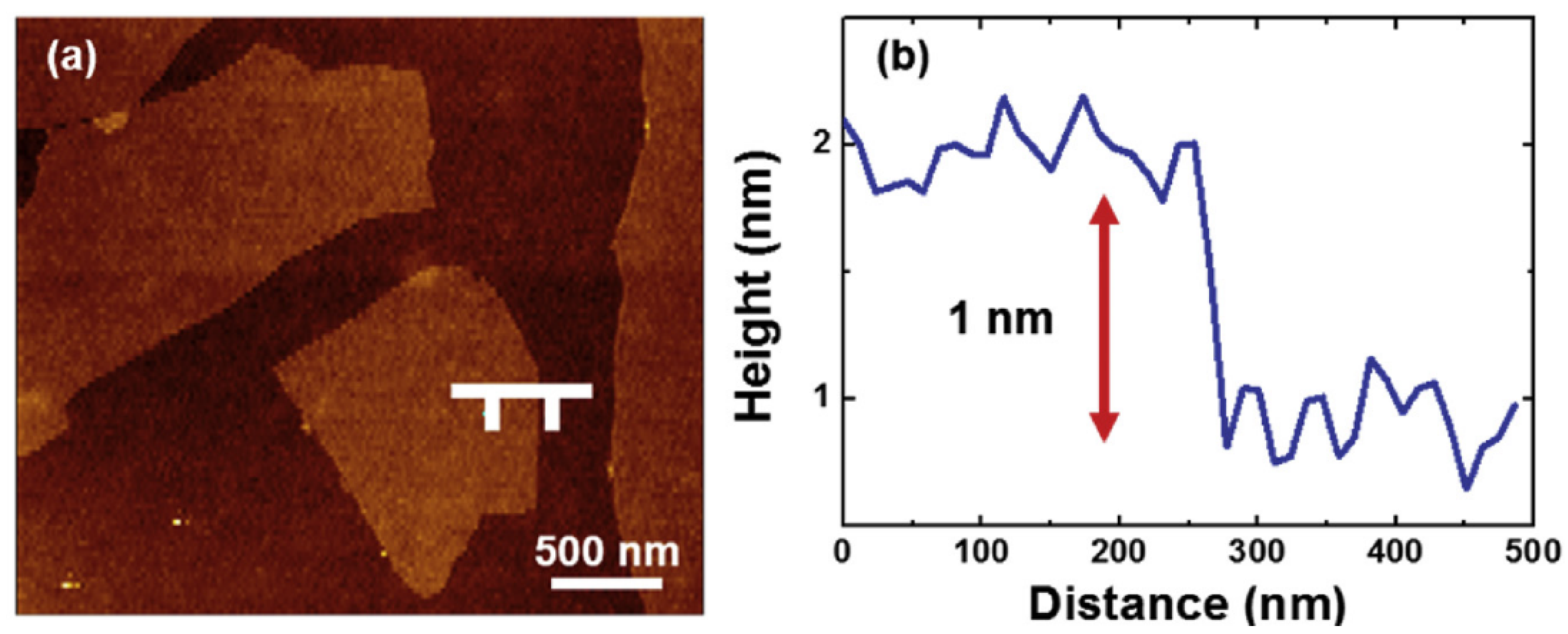

4.3. Atomic Force Microscopy

4.4. Optical Microscopy

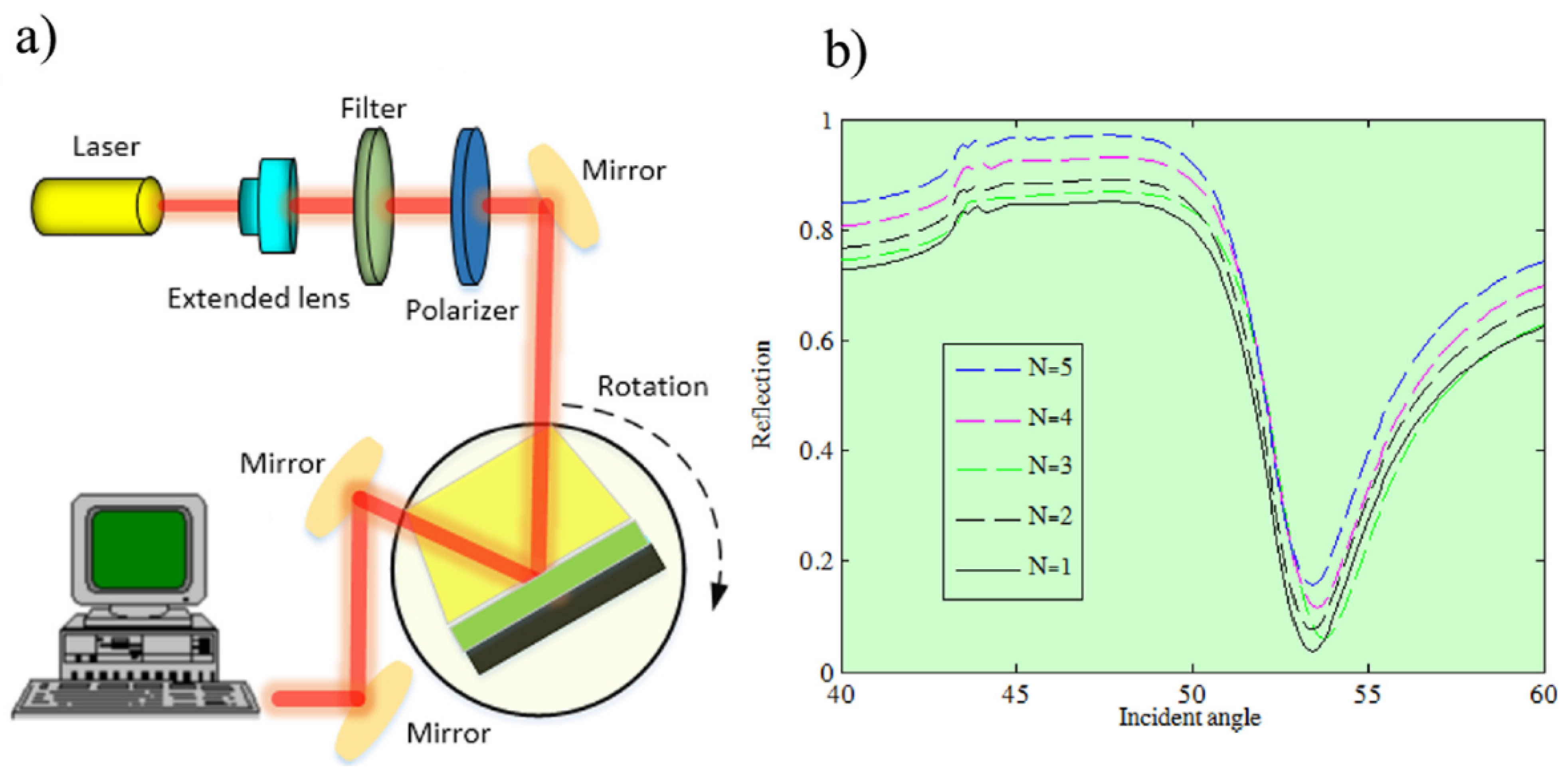

4.5. Plasmon Exciton Coupling Spectroscopy

4.6. X-ray Diffraction

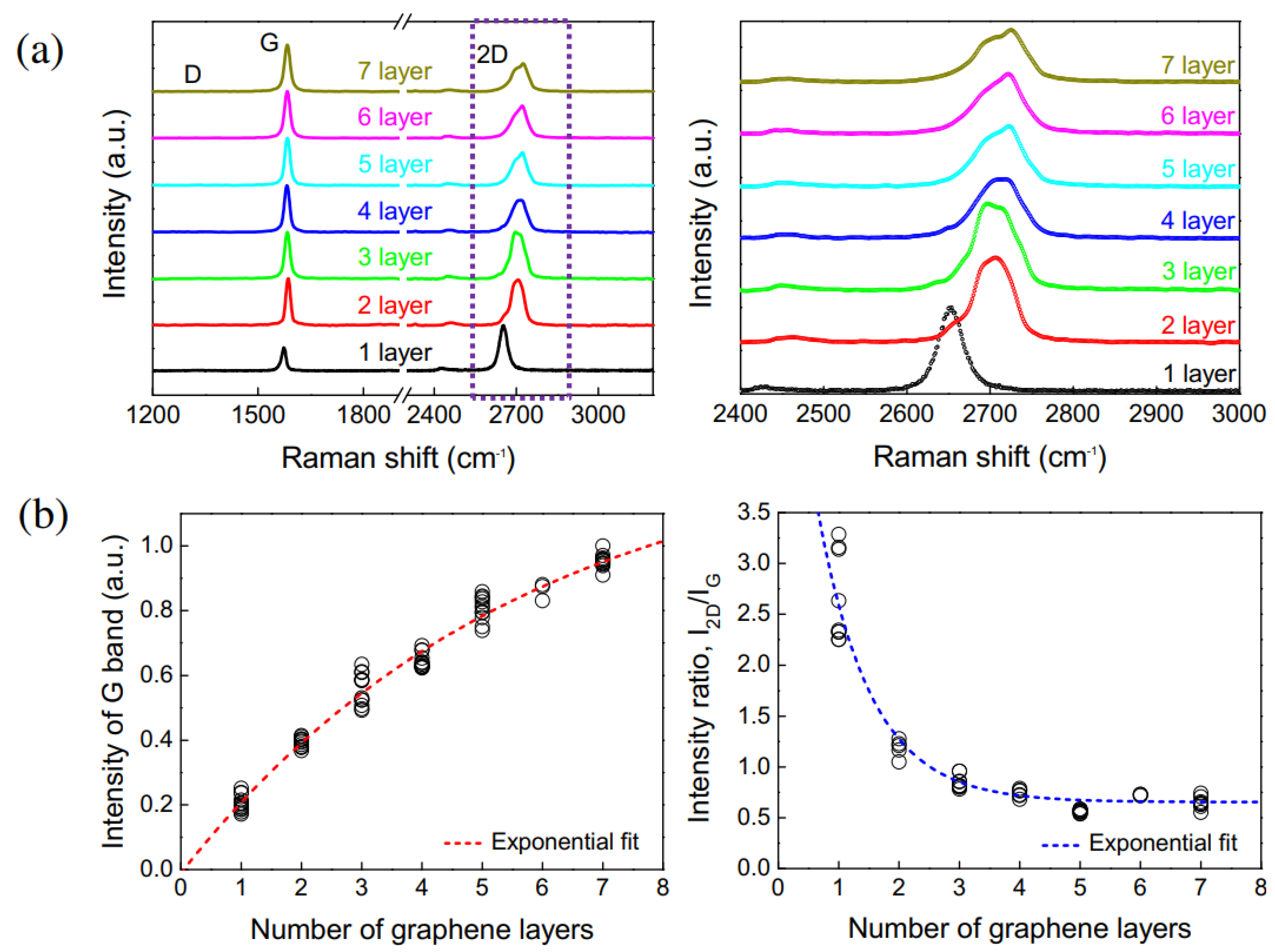

4.7. Raman Spectroscopy

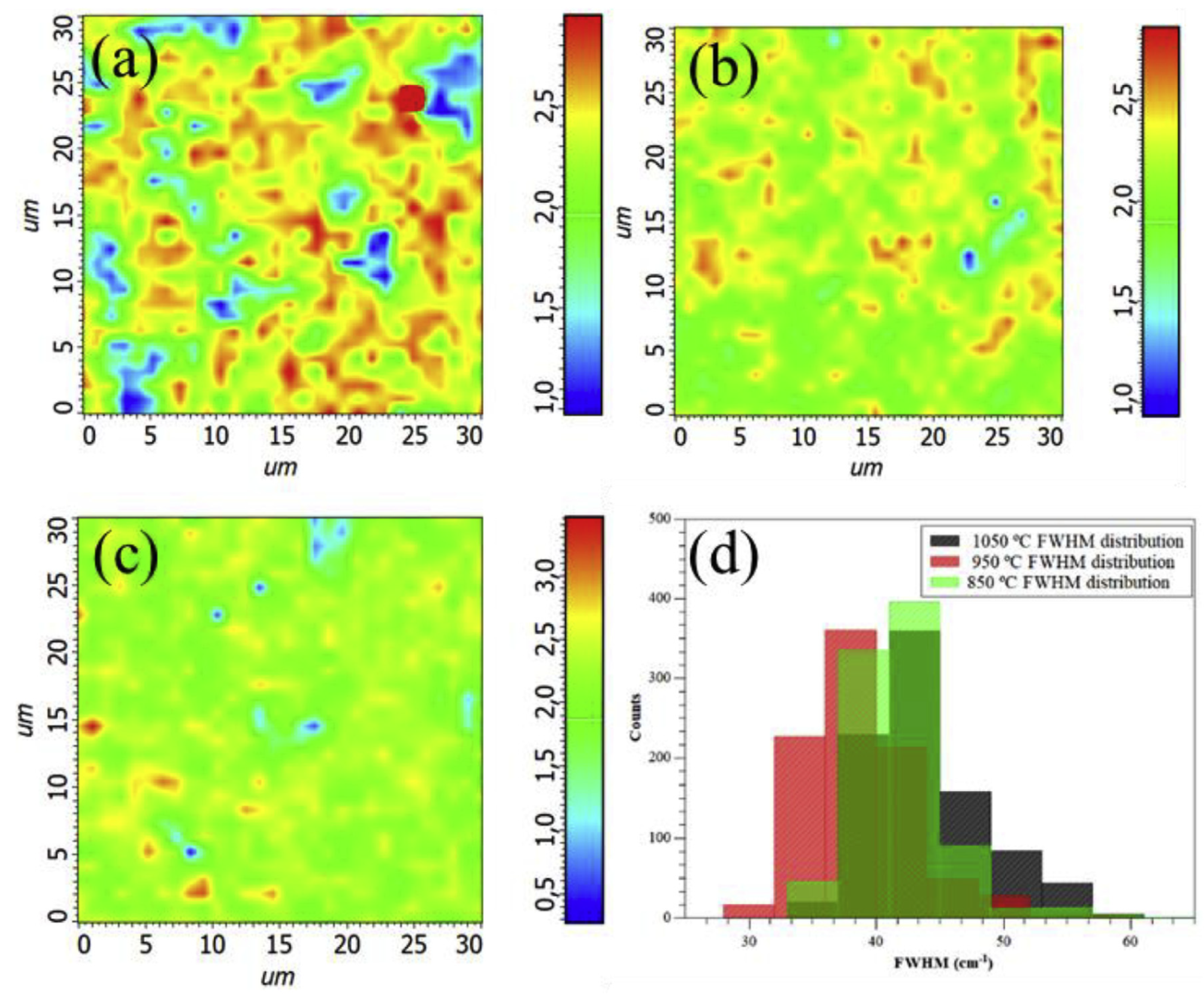

4.8. Raman Mapping

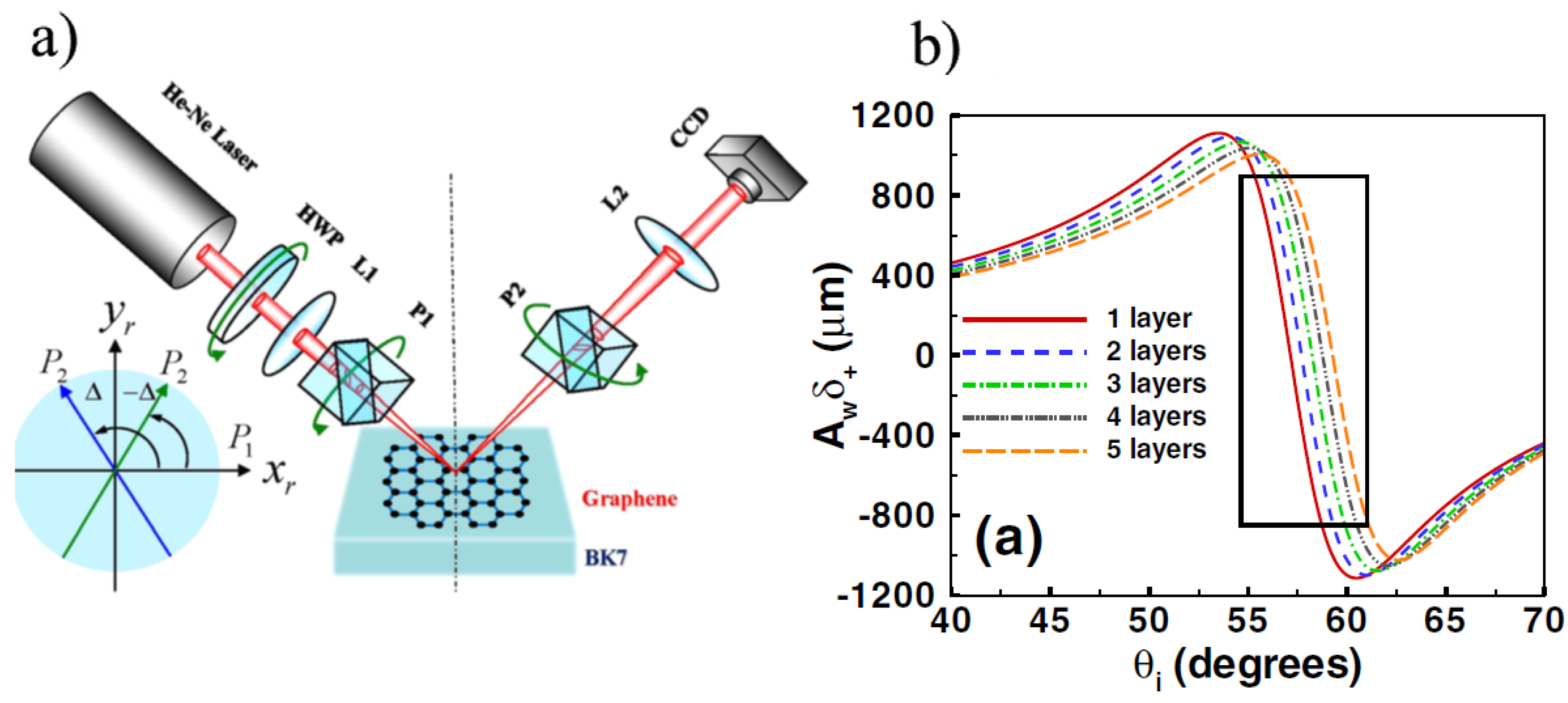

4.9. Spin Hall Effect

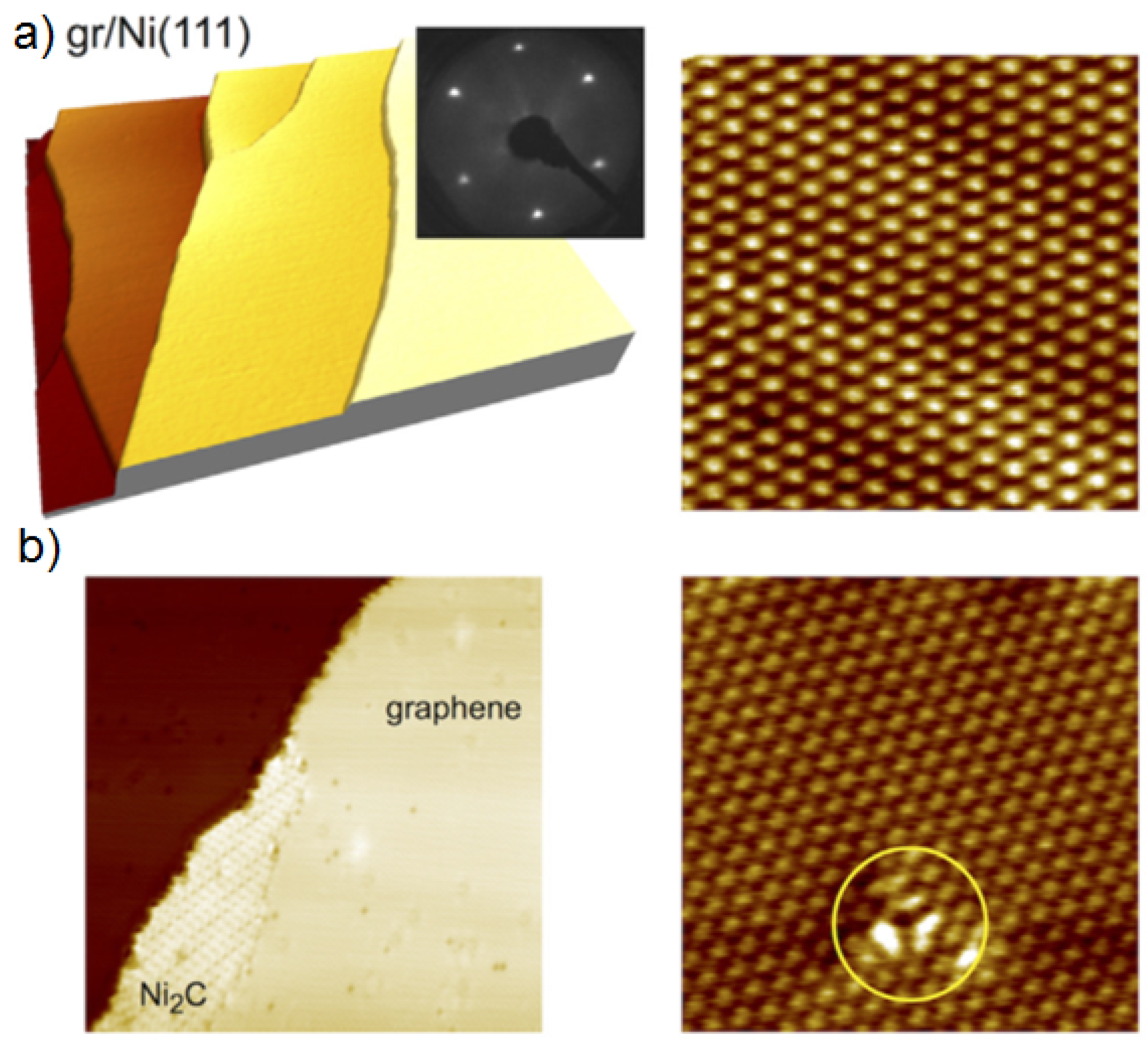

4.10. Scanning Tunnelling Microscopy

4.11. Scanning Electrochemical Microscopy

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarikavak-Lisesivdin, B.; Lisesivdin, S.; Ozbay, E.; Jelezko, F. Structural parameters and electronic properties of 2D carbon allotrope: Graphene with a kagome lattice structure. Chem. Phys. Lett. 2020, 760, 138006. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Rinzler, A.G.; Dai, H.; Hafner, J.H.; Bradley, R.K.; Boul, P.J.; Lu, A.; Iverson, T.; Shelimov, K.; Huffman, C.B.; et al. Fullerene pipes. Science 1998, 280, 1253–1256. [Google Scholar] [CrossRef] [PubMed]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Bianco, A.; Cheng, H.-M.; Enoki, T.; Gogotsi, Y.; Hurt, R.H.; Koratkar, N.; Kyotani, T.; Monthioux, M.; Park, C.R.; Tascon, J.M.D.; et al. All in the graphene family–A recommended nomenclature for two-dimensional carbon materials. Carbon 2013, 65, 1–6. [Google Scholar] [CrossRef]

- Peierls, R.E. Quelques proprietes typiques des corpses solides. Annales l’Institut Henri Poincaré 1935, 5, 177–222. [Google Scholar]

- Landau, L.D. Zur Theorie der phasenumwandlungen II. Phys. Z. Sowjetunion 1937, 11, 26–35. [Google Scholar]

- Wallace, P.R. The Band Theory of Graphite. Phys. Rev. 1947, 71, 622–634. [Google Scholar] [CrossRef]

- McClure, J.W. Diamagnetism of Graphite. Phys. Rev. 1956, 104, 666–671. [Google Scholar] [CrossRef]

- Slonczewski, J.C.; Weiss, P.R. Band Structure of Graphite. Phys. Rev. 1958, 109, 272–279. [Google Scholar] [CrossRef]

- Semenoff, G.W. Condensed-Matter Simulation of a Three-Dimensional Anomaly. Phys. Rev. Lett. 1984, 53, 2449–2452. [Google Scholar] [CrossRef]

- Fradkin, E. Critical behavior of disordered degenerate semiconductors. Phys. Rev. B 1986, 33, 3263–3268. [Google Scholar] [CrossRef]

- Haldane, F.D.M. Model for a Quantum Hall Effect without Landau Levels: Condensed-Matter Realization of the “Parity Anomaly”. Phys. Rev. Lett. 1988, 61, 2015–2018. [Google Scholar] [CrossRef]

- Ganguly, S.; Ghosh, S.; Das, P.; Das, T.K.; Ghosh, S.K.; Das, N.C. Poly(N-vinylpyrrolidone)-stabilized colloidal graphene-reinforced poly(ethylene-co-methyl acrylate) to mitigate electromagnetic radiation pollution. Polym. Bull. 2020, 77, 2923–2943. [Google Scholar] [CrossRef]

- Tour, J.M. Top-Down versus Bottom-Up Fabrication of Graphene-Based Electronics. Chem. Mater. 2013, 26, 163–171. [Google Scholar] [CrossRef]

- Whitener, K.; Sheehan, P.E. Graphene synthesis. Diam. Relat. Mater. 2014, 46, 25–34. [Google Scholar] [CrossRef]

- Hernandez, Y.; Nicolosi, V.; Lotya, M.; Blighe, F.M.; Sun, Z.; De, S.; McGovern, I.T.; Holland, B.; Byrne, M.; Gun’Ko, Y.; et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotechnol. 2008, 3, 563–568. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Silva, K.K.H.; Huang, H.-H.; Yoshimura, M. Progress of reduction of graphene oxide by ascorbic acid. Appl. Surf. Sci. 2018, 447, 338–346. [Google Scholar] [CrossRef]

- Park, S.; An, J.; Potts, J.R.; Velamakanni, A.; Murali, S.; Ruoff, R.S. Hydrazine-reduction of graphite- and graphene oxide. Carbon 2011, 49, 3019–3023. [Google Scholar] [CrossRef]

- Chernysheva, M.; Rychagov, A.; Kornilov, D.; Tkachev, S.; Gubin, S. Investigation of sulfuric acid intercalation into thermally expanded graphite in order to optimize the synthesis of electrochemical graphene oxide. J. Electroanal. Chem. 2020, 858, 113774. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Kim, Y.C.; Ahn, Y.H.; Lee, S.; Park, J.-Y. Large-area growth of high-quality graphene/MoS2 vertical heterostructures by chemical vapor deposition with nucleation control. Carbon 2020, 168, 580–587. [Google Scholar] [CrossRef]

- Lee, S.; Park, W.K.; Yoon, Y.; Baek, B.; Yoo, J.S.; Bin Kwon, S.; Kim, D.H.; Hong, Y.J.; Kang, B.K.; Yoon, D.H.; et al. Quality improvement of fast-synthesized graphene films by rapid thermal chemical vapor deposition for mass production. Mater. Sci. Eng. B 2019, 242, 63–68. [Google Scholar] [CrossRef]

- Svavil’Nyi, M.; Panarin, V.; Shkola, A.; Nikolenko, A.; Strelchuk, V. Plasma Enhanced Chemical Vapor Deposition synthesis of graphene-like structures from plasma state of CO2 gas. Carbon 2020, 167, 132–139. [Google Scholar] [CrossRef]

- Yu, J.; Hao, Z.; Deng, J.; Yu, W.; Wang, L.; Luo, Y.; Wang, J.; Sun, C.; Han, Y.; Xiong, B.; et al. Influence of nitridation on III-nitride films grown on graphene/quartz substrates by plasma-assisted molecular beam epitaxy. J. Cryst. Growth 2020, 547, 125805. [Google Scholar] [CrossRef]

- Yu, J.; Hao, Z.; Deng, J.; Li, X.; Wang, L.; Luo, Y.; Wang, J.; Sun, C.; Han, Y.; Xiong, B.; et al. Low-temperature van der Waals epitaxy of GaN films on graphene through AlN buffer by plasma-assisted molecular beam epitaxy. J. Alloys Compd. 2021, 855, 157508. [Google Scholar] [CrossRef]

- Partoens, B.; Peeters, F.M. From graphene to graphite: Electronic structure around the K point. Phys. Rev. B 2006, 74, 075404. [Google Scholar] [CrossRef] [Green Version]

- Obraztsova, E.A.; Osadchy, A.V.; Obraztsova, E.D.; Lefrant, S.; Yaminsky, I.V. Statistical analysis of atomic force microscopy and Raman spectroscopy data for estimation of graphene layer numbers. Phys. Status Solidi B 2008, 254, 2055–2059. [Google Scholar] [CrossRef]

- Ganguly, S.; Mondal, S.; Das, P.; Bhawal, P.; Das, T.K.; Bose, M.; Choudhary, S.; Gangopadhyay, S.; Das, A.K.; Das, N.C. Natural saponin stabilized nano-catalyst as efficient dye-degradation catalyst. Nano-Struct. Nano-Objects 2018, 16, 86–95. [Google Scholar] [CrossRef]

- Plachá, D.; Jampilek, J. Graphenic Materials for Biomedical Applications. Nanomaterials 2019, 9, 1758. [Google Scholar] [CrossRef] [Green Version]

- Kamedulski, P.; Truszkowski, S.; Lukaszewicz, J. Highly Effective Methods of Obtaining N-Doped Graphene by Gamma Irradiation. Materials 2020, 13, 4975. [Google Scholar] [CrossRef]

- Yu, H.; He, Y.; Xiao, G.; Fan, Y.; Ma, J.; Gao, Y.; Hou, R.; Yin, X.; Wang, Y.; Mei, X. The roles of oxygen-containing functional groups in modulating water purification performance of graphene oxide-based membrane. Chem. Eng. J. 2020, 389, 124375. [Google Scholar] [CrossRef]

- Bonaccorso, F.; Lombardo, A.; Hasan, T.; Sun, Z.; Colombo, L.; Ferrari, A.C. Production and processing of graphene and 2d crystals. Mater. Today 2012, 15, 564–589. [Google Scholar] [CrossRef]

- Niyogi, S.; Bekyarova, E.; Itkis, M.E.; McWilliams, J.L.; Hamon, M.A.; Haddon, R. Solution Properties of Graphite and Graphene. J. Am. Chem. Soc. 2006, 128, 7720–7721. [Google Scholar] [CrossRef]

- Wei, Y.; Sun, Z. Liquid-phase exfoliation of graphite for mass production of pristine few-layer graphene. Curr. Opin. Colloid Interface Sci. 2015, 20, 311–321. [Google Scholar] [CrossRef]

- Zhao, W.; Fang, M.; Wu, F.; Wu, H.; Wang, L.; Chen, G. Preparation of graphene by exfoliation of graphite using wet ball milling. J. Mater. Chem. 2010, 20, 5817–5819. [Google Scholar] [CrossRef]

- Arao, Y.; Mori, F.; Kubouchi, M. Efficient solvent systems for improving production of few-layer graphene in liquid phase exfoliation. Carbon 2017, 118, 18–24. [Google Scholar] [CrossRef]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, Y. Mechanical properties of graphene: Effects of layer number, temperature and isotope. Comput. Mater. Sci. 2013, 71, 197–200. [Google Scholar] [CrossRef] [Green Version]

- Hwangbo, Y.; Lee, C.-K.; Mag-Isa, A.; Jang, J.-W.; Lee, H.-J.; Lee, S.-B.; Kim, S.S.; Kim, J.-H. Interlayer non-coupled optical properties for determining the number of layers in arbitrarily stacked multilayer graphenes. Carbon 2014, 77, 454–461. [Google Scholar] [CrossRef]

- Cui, T.; Mukherjee, S.; Cao, C.; Sudeep, P.M.; Tam, J.; Ajayan, P.M.; Singh, C.V.; Sun, Y.; Filleter, T. Effect of lattice stacking orientation and local thickness variation on the mechanical behavior of few layer graphene oxide. Carbon 2018, 136, 168–175. [Google Scholar] [CrossRef]

- Mag-Isa, A.E.; Kim, S.-M.; Kim, J.-H.; Oh, C.-S. Variation of thermal expansion coefficient of freestanding multilayer pristine graphene with temperature and number of layers. Mater. Today Commun. 2020, 25, 101387. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Chen, G.; Wu, D.; Weng, W.; Wu, C. Exfoliation of graphite flake and its nanocomposites. Carbon 2003, 41, 619–621. [Google Scholar] [CrossRef]

- Nakamura, M.; Kawai, T.; Irie, M.; Yuge, R.; Iijima, S.; Bandow, S.; Yudasaka, M. Graphite-like thin sheets with even-numbered layers. Carbon 2013, 61, 644–647. [Google Scholar] [CrossRef]

- Navik, R.; Gai, Y.; Wang, W.; Zhao, Y. Curcumin-assisted ultrasound exfoliation of graphite to graphene in ethanol. Ultrason. Sonochem. 2018, 48, 96–102. [Google Scholar] [CrossRef] [PubMed]

- Stobinski, L.; Lesiak-Orłowska, B.; Małolepszy, A.; Mazurkiewicz-Pawlicka, M.; Mierzwa, B.; Zemek, J.; Jiricek, P.; Bieloshapka, I. Graphene oxide and reduced graphene oxide studied by the XRD, TEM and electron spectroscopy methods. J. Electron Spectrosc. Relat. Phenom. 2014, 195, 145–154. [Google Scholar] [CrossRef]

- Al-Hagri, A.; Li, R.; Rajput, N.S.; Lu, C.; Cong, S.; Sloyan, K.; Almahri, M.A.; Tamalampudi, S.R.; Chiesa, M.; Al Ghaferi, A. Direct growth of single-layer terminated vertical graphene array on germanium by plasma enhanced chemical vapor deposition. Carbon 2019, 155, 320–325. [Google Scholar] [CrossRef]

- Ding, J.; Zhao, H.; Yu, H. Graphene nanofluids based on one-step exfoliation and edge-functionalization. Carbon 2021, 171, 29–35. [Google Scholar] [CrossRef]

- Ying, H.; Wang, W.; Liu, W.; Wang, L.; Chen, S. Layer-by-layer synthesis of bilayer and multilayer graphene on Cu foil utilizing the catalytic activity of cobalt nano-powders. Carbon 2019, 146, 549–556. [Google Scholar] [CrossRef]

- Huet, B.; Raskin, J.-P. Role of Cu foil in-situ annealing in controlling the size and thickness of CVD graphene domains. Carbon 2018, 129, 270–280. [Google Scholar] [CrossRef]

- Lin, C.; Yang, L.; Ouyang, L.; Liu, J.; Wang, H.; Zhu, M. A new method for few-layer graphene preparation via plasma-assisted ball milling. J. Alloys Compd. 2017, 728, 578–584. [Google Scholar] [CrossRef]

- Yoshihara, N.; Noda, M. Chemical etching of copper foils for single-layer graphene growth by chemical vapor deposition. Chem. Phys. Lett. 2017, 685, 40–46. [Google Scholar] [CrossRef]

- Mohanty, A.; Baaziz, W.; Lafjah, M.; Da Costa, V.; Janowska, I. Few layer graphene as a template for Fe-based 2D nanoparticles. FlatChem 2018, 9, 15–20. [Google Scholar] [CrossRef]

- Mendoza, C.; Caldas, P.; Freire, F.; Da Costa, M.M. Growth of single-layer graphene on Ge (1 0 0) by chemical vapor deposition. Appl. Surf. Sci. 2018, 447, 816–821. [Google Scholar] [CrossRef]

- Kim, J.; Lee, K.E.; Kim, K.H.; Wi, S.; Lee, S.; Nam, S.; Kim, C.; Kim, S.O.; Park, B. Single-layer graphene-wrapped Li4Ti5O12 anode with superior lithium storage capability. Carbon 2017, 114, 275–283. [Google Scholar] [CrossRef]

- Prakash, G.; Capano, M.A.; Bolen, M.L.; Zemlyanov, D.; Reifenberger, R.G. AFM study of ridges in few-layer epitaxial graphene grown on the carbon-face of 4H–SiC. Carbon 2010, 48, 2383–2393. [Google Scholar] [CrossRef]

- Temiryazev, A.; Frolov, A.; Temiryazeva, M. Atomic-force microscopy study of self-assembled atmospheric contamination on graphene and graphite surfaces. Carbon 2018, 143, 30–37. [Google Scholar] [CrossRef]

- Singh, A.; Guha, P.; Panwar, A.K.; Tyagi, P.K. Estimation of intrinsic work function of multilayer graphene by probing with electrostatic force microscopy. Appl. Surf. Sci. 2017, 402, 271–276. [Google Scholar] [CrossRef]

- Yao, Y.; Ren, L.; Gao, S.; Li, S. Histogram method for reliable thickness measurements of graphene films using atomic force microscopy (AFM). J. Mater. Sci. Technol. 2017, 33, 815–820. [Google Scholar] [CrossRef]

- Margaryan, N.; Kokanyan, N.; Kokanyan, E. Low-temperature synthesis and characteristics of fractal graphene layers. J. Saudi Chem. Soc. 2019, 23, 13–20. [Google Scholar] [CrossRef]

- Bartlam, C.; Morsch, S.; Heard, K.W.; Quayle, P.; Yeates, S.G.; Vijayaraghavan, A. Nanoscale infrared identification and mapping of chemical functional groups on graphene. Carbon 2018, 139, 317–324. [Google Scholar] [CrossRef]

- Luo, Q.; Wirth, C.; Pentzer, E. Efficient sizing of single layer graphene oxide with optical microscopy under ambient conditions. Carbon 2019, 157, 395–401. [Google Scholar] [CrossRef]

- Campanelli, D.; Menezes, J.; Valsecchi, C.; Zegarra, L.; Jacinto, C.; Armas, L. Interaction between Yb3+ doped glasses substrates and graphene layers by raman spectroscopy. Thin Solid Films 2020, 712, 138315. [Google Scholar] [CrossRef]

- Farmani, H.; Farmani, A. Graphene sensing nanostructure for exact graphene layers identification at terahertz frequency. Phys. E 2020, 124, 114375. [Google Scholar] [CrossRef]

- Mauro, M.; Cipolletti, V.; Galimberti, M.; Longo, P.; Guerra, G. Chemically Reduced Graphite Oxide with Improved Shape Anisotropy. J. Phys. Chem. C 2012, 116, 24809–24813. [Google Scholar] [CrossRef]

- Galimberti, M.; Kumar, V.; Coombs, M.; Cipolletti, V.; Agnelli, S.; Pandini, S.; Conzatti, L. Filler networking of a nanographite with a high shape anisotropy and synergism with carbon black in poly(1,4-cis-isoprene)-based nanocomposites. Rubber Chem. Technol. 2014, 87, 197–218. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, N.; Lee, D.-J.; Giese, U. Role of low surface area few layer graphene in enhancing mechanical properties of poly (1,4-cis-isoprene) rubber nanocomposites. Rubber Chem. Technol. 2020, 93, 172–182. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman Spectrum of Graphene and Graphene Layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [Green Version]

- Güler, Ö.; Tekeli, M.; Taşkın, M.; Güler, S.H.; Yahia, I.S. The production of graphene by direct liquid phase exfoliation of graphite at moderate sonication power by using low boiling liquid media: The effect of liquid media on yield and optimization. Ceram. Int. 2021, 47, 521–533. [Google Scholar] [CrossRef]

- Niavol, S.S.; Budde, M.; Papadogianni, A.; Heilmann, M.; Moghaddam, H.M.; Aldao, C.M.; Ligorio, G.; List-Kratochvil, E.J.; Lopes, J.M.J.; Barsan, N.; et al. Conduction mechanisms in epitaxial NiO/Graphene gas sensors. Sens. Actuators B Chem. 2020, 325, 128797. [Google Scholar] [CrossRef]

- Schilirò, E.; Nigro, R.L.; Panasci, S.; Gelardi, F.; Agnello, S.; Yakimova, R.; Roccaforte, F.; Giannazzo, F. Aluminum oxide nucleation in the early stages of atomic layer deposition on epitaxial graphene. Carbon 2020, 169, 172–181. [Google Scholar] [CrossRef]

- Gong, P.; Ye, Z.; Yuan, L.; Egberts, P. Evaluation of wetting transparency and surface energy of pristine and aged graphene through nanoscale friction. Carbon 2018, 132, 749–759. [Google Scholar] [CrossRef]

- Hähnlein, B.; Lebedev, S.; Eliseyev, I.; Smirnov, A.; Davydov, V.; Zubov, A.; Lebedev, A.; Pezoldt, J. Investigation of epitaxial graphene via Raman spectroscopy: Origins of phonon mode asymmetries and line width deviations. Carbon 2020, 170, 666–676. [Google Scholar] [CrossRef]

- Kolomiytsev, A.; Jityaev, I.; Svetlichnyi, A.; Fedotov, A.; Ageev, O. Nanoscale profiling of multilayer graphene films on silicon carbide by a focused ion beam. Diam. Relat. Mater. 2020, 108, 107969. [Google Scholar] [CrossRef]

- Yitzhak, N.; Girshevitz, O.; Fleger, Y.; Haran, A.; Katz, S.; Butenko, A.; Kaveh, M.; Shlimak, I. Analysis of fluctuations in the Raman spectra of suspended and supported graphene films. Appl. Surf. Sci. 2021, 536, 147812. [Google Scholar] [CrossRef]

- Silva, D.L.; Campos, J.L.E.; Fernandes, T.F.; Rocha, J.N.; Machado, L.R.; Soares, E.M.; Miquita, D.R.; Miranda, H.; Rabelo, C.; Neto, O.P.V.; et al. Raman spectroscopy analysis of number of layers in mass-produced graphene flakes. Carbon 2020, 161, 181–189. [Google Scholar] [CrossRef]

- Li, L.; Ayub, S.M.I.; Shaw, L.L. Formulation and micro-extrusion of high concentration graphene slurries. Ceram. Int. 2016, 42, 9086–9093. [Google Scholar] [CrossRef] [Green Version]

- Papanai, G.S.; Sharma, I.; Gupta, B.K. Probing number of layers and quality assessment of mechanically exfoliated graphene via Raman fingerprint. Mater. Today Commun. 2019, 22, 100795. [Google Scholar] [CrossRef]

- Niilisk, A.; Kozlova, J.; Alles, H.; Aarik, J.; Sammelselg, V. Raman characterization of stacking in multi-layer graphene grown on Ni. Carbon 2016, 98, 658–665. [Google Scholar] [CrossRef]

- Maruyama, T.; Yamashita, Y.; Saida, T.; Tanaka, S.-I.; Naritsuka, S. Liquid-phase growth of few-layered graphene on sapphire substrates using SiC micropowder source. J. Cryst. Growth 2017, 468, 175–178. [Google Scholar] [CrossRef]

- Barbosa, A.D.N.; Figueroa, N.; Mendoza, C.; Pinto, A.; Freire, F. Characterization of graphene synthesized by low-pressure chemical vapor deposition using N-Octane as precursor. Mater. Chem. Phys. 2018, 219, 189–195. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.-Y.; Jeon, J.H.; An, S.; Hong, J.; Kim, J. Study on the formation of graphene by ion implantation on Cu, Ni and CuNi alloy. Appl. Surf. Sci. 2018, 451, 162–168. [Google Scholar] [CrossRef]

- Bayram, O. A study on 3D graphene synthesized directly on Glass/FTO substrates: Its Raman mapping and optical properties. Ceram. Int. 2019, 45, 16829–16835. [Google Scholar] [CrossRef]

- Shen, B.; Huang, Z.; Ji, Z.; Lin, Q.; Chen, S.; Cui, D.; Zhang, Z. Bilayer graphene film synthesized by hot filament chemical vapor deposition as a nanoscale solid lubricant. Surf. Coat. Technol. 2019, 380, 125061. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Xu, C.; Zhang, X.; Mei, L.; Wang, M.; Xia, Y.; Zhao, P.; Wang, H. Domain-boundary independency of Raman spectra for strained graphene at strong interfaces. Carbon 2018, 134, 37–42. [Google Scholar] [CrossRef]

- Woo, Y.S.; Lee, D.W.; Kim, U.J. General Raman-based method for evaluating the carrier mobilities of chemical vapor deposited graphene. Carbon 2018, 132, 263–270. [Google Scholar] [CrossRef]

- Liu, F.; Wang, M.; Chen, Y.; Gao, J. Thermal stability of graphene in inert atmosphere at high temperature. J. Solid State Chem. 2019, 276, 100–103. [Google Scholar] [CrossRef]

- Amato, G.; Beccaria, F.; Celegato, F. Growth of strained, but stable, graphene on Co. Thin. Solid Films 2017, 638, 324–331. [Google Scholar] [CrossRef]

- Oh, J.; Yoo, H.; Choi, J.; Kim, J.Y.; Lee, D.S.; Kim, M.J.; Lee, J.-C.; Kim, W.N.; Grossman, J.C.; Park, J.H.; et al. Significantly reduced thermal conductivity and enhanced thermoelectric properties of single- and bi-layer graphene nanomeshes with sub-10 nm neck-width. Nano Energy 2017, 35, 26–35. [Google Scholar] [CrossRef]

- Zhou, X.; Ling, X.; Luo, H.; Wen, S. Identifying graphene layers via spin Hall effect of light. Appl. Phys. Lett. 2012, 101, 251602. [Google Scholar] [CrossRef]

- Dedkov, Y.; Klesse, W.; Becker, A.; Späth, F.; Papp, C.; Voloshina, E. Decoupling of graphene from Ni(111) via formation of an interfacial NiO layer. Carbon 2017, 121, 10–16. [Google Scholar] [CrossRef] [Green Version]

- Wain, A.J.; Pollard, A.J.; Richter, C. High-Resolution Electrochemical and Topographical Imaging Using Batch-Fabricated Cantilever Probes. Anal. Chem. 2014, 86, 5143–5149. [Google Scholar] [CrossRef] [PubMed]

| S. No. | Type of Graphene | Method of Synthesis | Method of Investigation | Reference |

|---|---|---|---|---|

| 1. | Monolayer to few-layer to multilayer graphene | - | Optical microscopy, Raman spectra | [37] |

| 2. | Monolayer to few-layer to multilayer graphene | - | Optical microscopy, Raman spectra | [40] |

| 3. | Graphite-like thin sheets | - | TEM | [45] |

| 4. | 1–5-layer thick graphene layers | Ultrasonication-induced exfoliation of graphite to graphene in solvent | TEM | [46] |

| 5. | Reduced graphene oxide | Chemical synthesis | XRD, TEM, and other electron spectroscopic methods | [47] |

| 6. | Monolayer graphene | CVD | TEM | [48] |

| 7. | Mono-bilayer graphene | High sulfonic acid edge functionalized graphene from graphite | HR-TEM | [49] |

| 8. | Mono-few-layer graphene | CVD | SEM, Optical, Raman spectra, Raman mapping | [50] |

| 9. | Single or multilayer Graphene flakes | CVD | SEM, Optical, Raman spectra, Raman mapping, and AFM | [51] |

| 10. | Graphene layers stacked 6 to 20 layers thick | Ball milling | SEM, Raman spectra, HRTEM | [52] |

| 11. | Monolayer graphene | CVD | SEM, Optical, microscopy, Raman spectra, Raman mapping, and AFM | [53] |

| 12. | Few-layer graphene | - | SEM, Optical microscopy, HRTEM, Raman mapping, and AFM | [54] |

| 13. | Monolayer graphene | CVD | SEM, Raman spectra, Raman mapping, and AFM. | [55] |

| 14. | Monolayer graphene | Chemical synthesis | AFM | [56] |

| 15. | Few-layer graphene | CVD | AFM | [57] |

| 16. | Graphene flake with thickness in 4–5 nm | - | AFM | [58] |

| 17. | Multilayer graphene | - | AFM | [59] |

| 18. | Monolayer to few-layer graphene | - | AFM | [60] |

| 19. | Monolayer graphene sheet | Liquid phase exfoliation | AFM | [61] |

| 20. | Functionalized reduced graphene | Chemical synthesis | AFM | [62] |

| 21. | Monolayer graphene oxide | Chemical synthesis | Optical microscopy, AFM, SEM | [63] |

| 22. | Mono-bilayer graphene | Chemical synthesis | Optical microcopy | [64] |

| 23. | Mono-few-layer graphene | - | Plasmon exciton coupling spectroscopy | [65] |

| 24. | Graphene flake with 60, 40 and 30 layers thick | - | X-ray diffraction | [66] |

| 25. | Exfoliated graphene sheets | Graphite sonication in solvents | Raman spectra | [70] |

| 26. | Monolayer graphene | CVD | Raman spectra | [71] |

| 27. | Epitaxial graphene | CVD | Raman spectra | [72] |

| 28. | Few-layer graphene | CVD | Raman spectra | [73] |

| 29. | Monolayer to multi-layer graphene | - | Raman spectra | [74] |

| 30. | Multilayer graphene | - | Raman spectra | [75] |

| 31. | Monolayer to few-layer graphene | - | Raman spectra | [76] |

| 32. | Exfoliation in graphene flake | - | Raman spectra | [77] |

| 33. | Monolayer to few-layer graphene | Raman spectra | [78] | |

| 34. | Monolayer to few-layer graphene | Raman spectra | [79] | |

| 35. | Multilayer graphene | CVD | Raman spectra | [80] |

| 36. | Mono to few-layer graphene | Liquid phase exfoliation | Raman spectra | [81] |

| 37. | Monolayer graphene | CVD | Raman mapping | [82] |

| 38. | Graphene flake | CVD | Raman mapping | [83] |

| 39. | 3D graphene films | CVD | Raman mapping | [84] |

| 40. | Bilayer graphene | CVD | Raman mapping | [85] |

| 41. | Graphene flake | - | Raman mapping | [86] |

| 42. | Graphene flake | CVD | Raman mapping | [87] |

| 43. | Monolayer graphene | - | Raman mapping | [88] |

| 44. | Mono-bilayer graphene | CVD | Raman mapping | [89] |

| 45. | Mono-bilayer graphene | - | Raman mapping | [90] |

| 46. | Mono-few-layer graphene | - | Spin hall effect, Raman spectra | [91] |

| 47. | Mono-bilayer graphene | - | Scanning tunneling microscopy | [92] |

| 48. | Mono-few–multilayer graphene | - | Scanning electrochemical microscopy and AFM | [93] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, V.; Kumar, A.; Lee, D.-J.; Park, S.-S. Estimation of Number of Graphene Layers Using Different Methods: A Focused Review. Materials 2021, 14, 4590. https://doi.org/10.3390/ma14164590

Kumar V, Kumar A, Lee D-J, Park S-S. Estimation of Number of Graphene Layers Using Different Methods: A Focused Review. Materials. 2021; 14(16):4590. https://doi.org/10.3390/ma14164590

Chicago/Turabian StyleKumar, Vineet, Anuj Kumar, Dong-Joo Lee, and Sang-Shin Park. 2021. "Estimation of Number of Graphene Layers Using Different Methods: A Focused Review" Materials 14, no. 16: 4590. https://doi.org/10.3390/ma14164590

APA StyleKumar, V., Kumar, A., Lee, D.-J., & Park, S.-S. (2021). Estimation of Number of Graphene Layers Using Different Methods: A Focused Review. Materials, 14(16), 4590. https://doi.org/10.3390/ma14164590