Multiphase Model for Predicting the Thermal Conductivity of Cement Paste and Its Applications

Abstract

1. Introduction

2. Experimental Tests

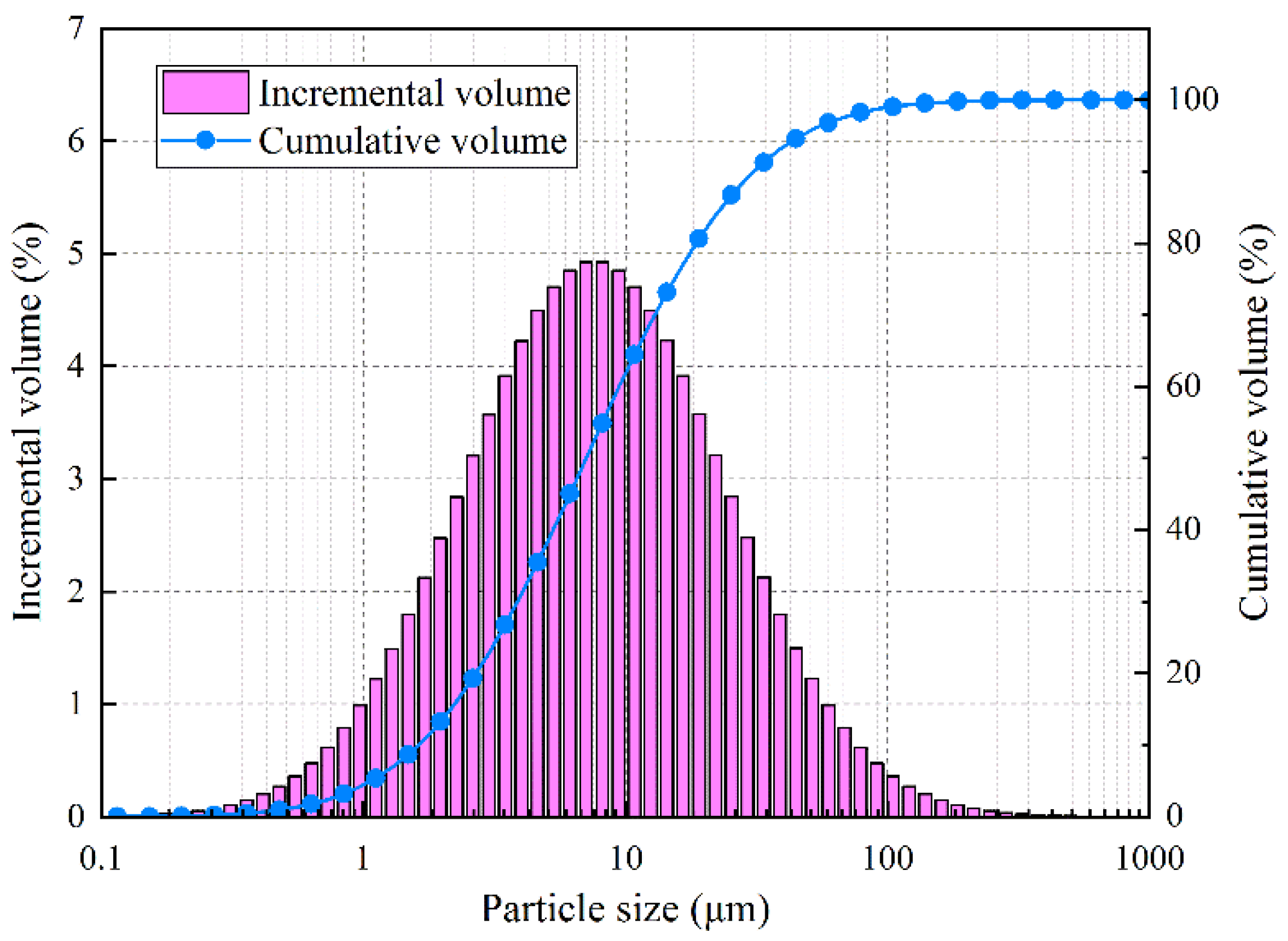

2.1. Materials and Specimen Preparation

2.2. Thermal Conductivity Measurement

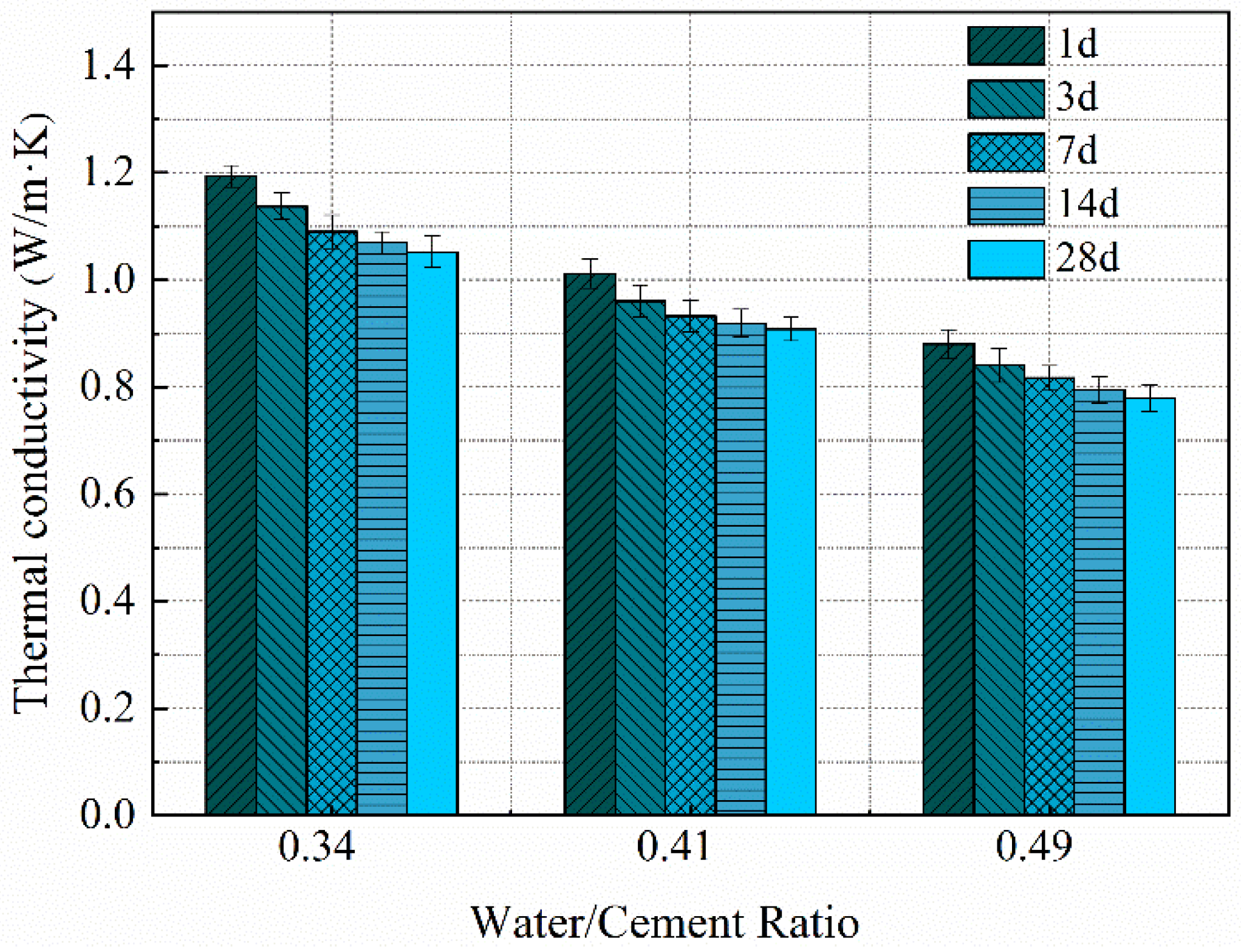

2.3. Experimental Results

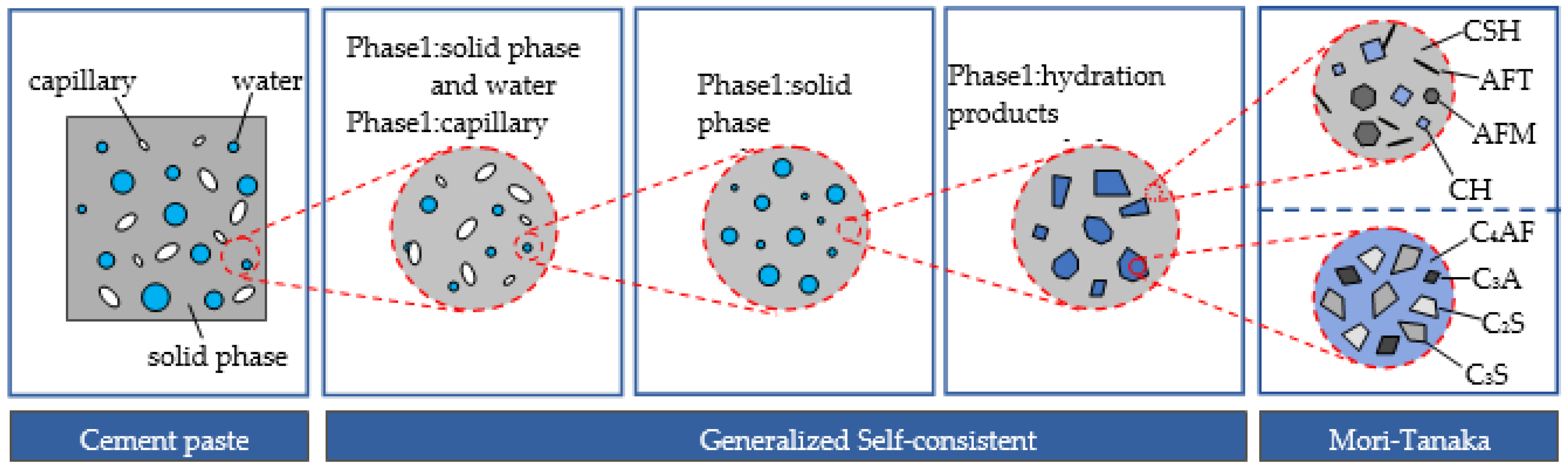

3. Multiphase Model for the Thermal Conductivity of Cement Paste

4. Model Parameters

4.1. Thermal Conductivity of Constituent Phases in Cement Paste

4.1.1. Theory Background

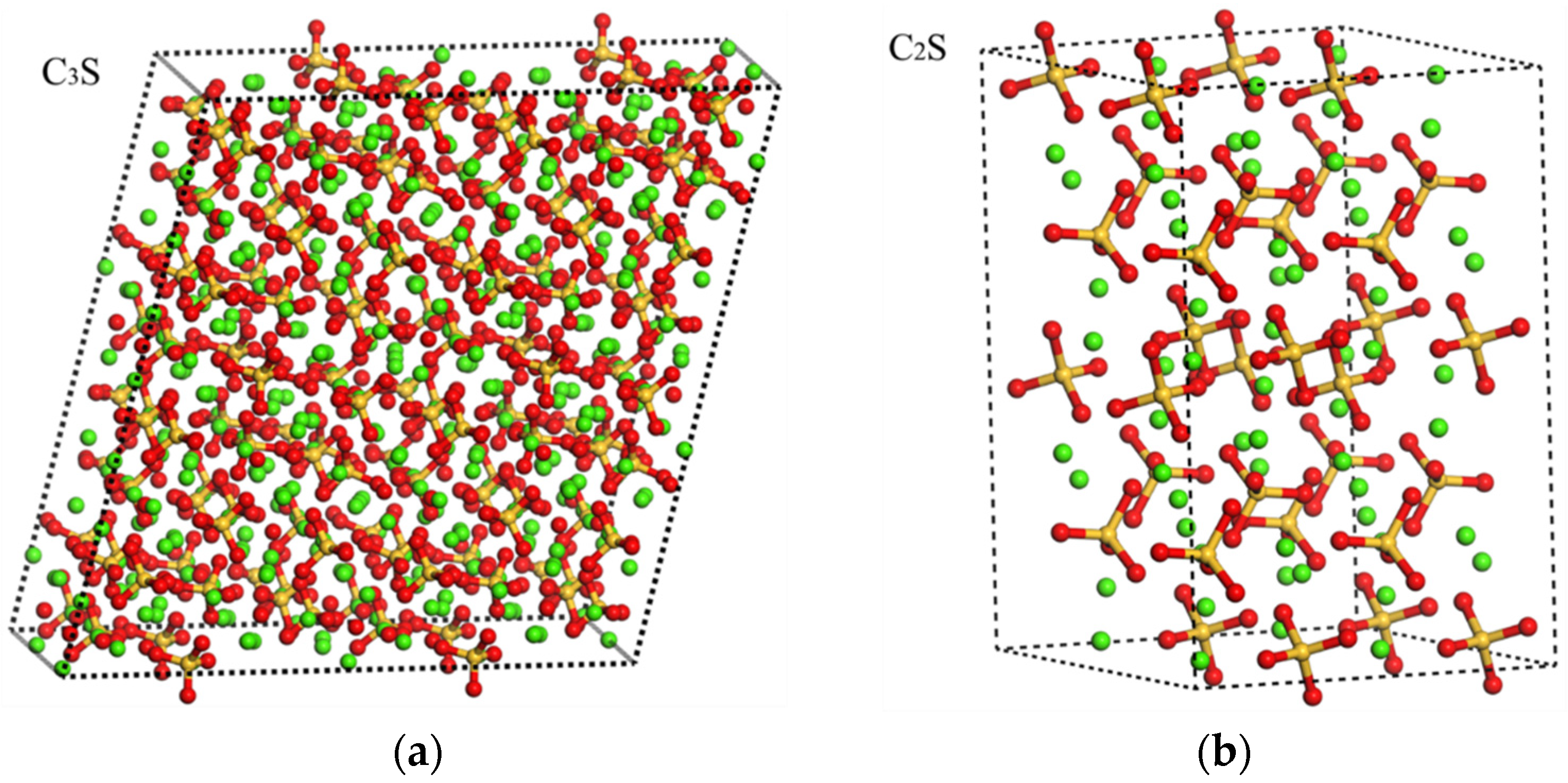

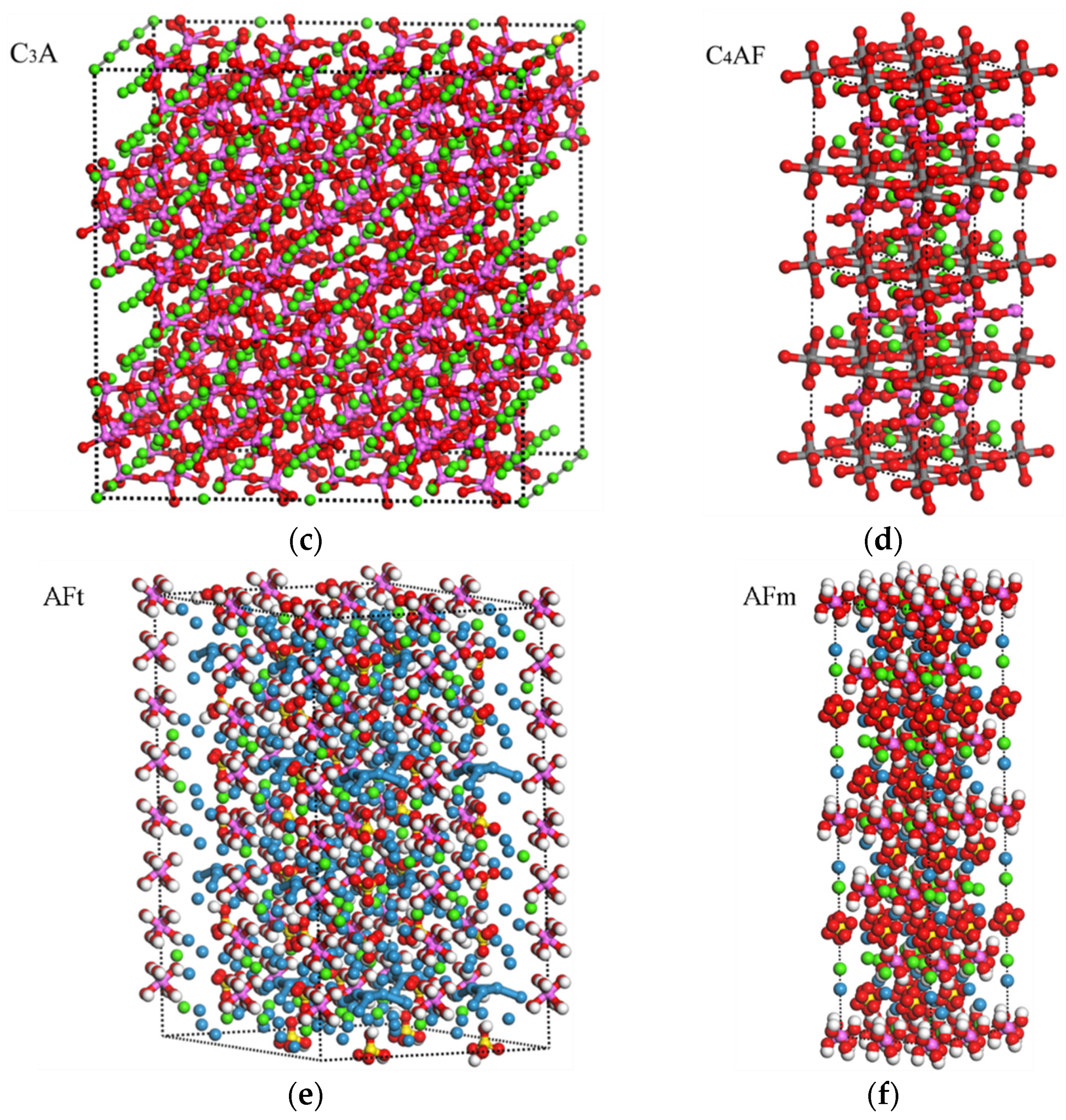

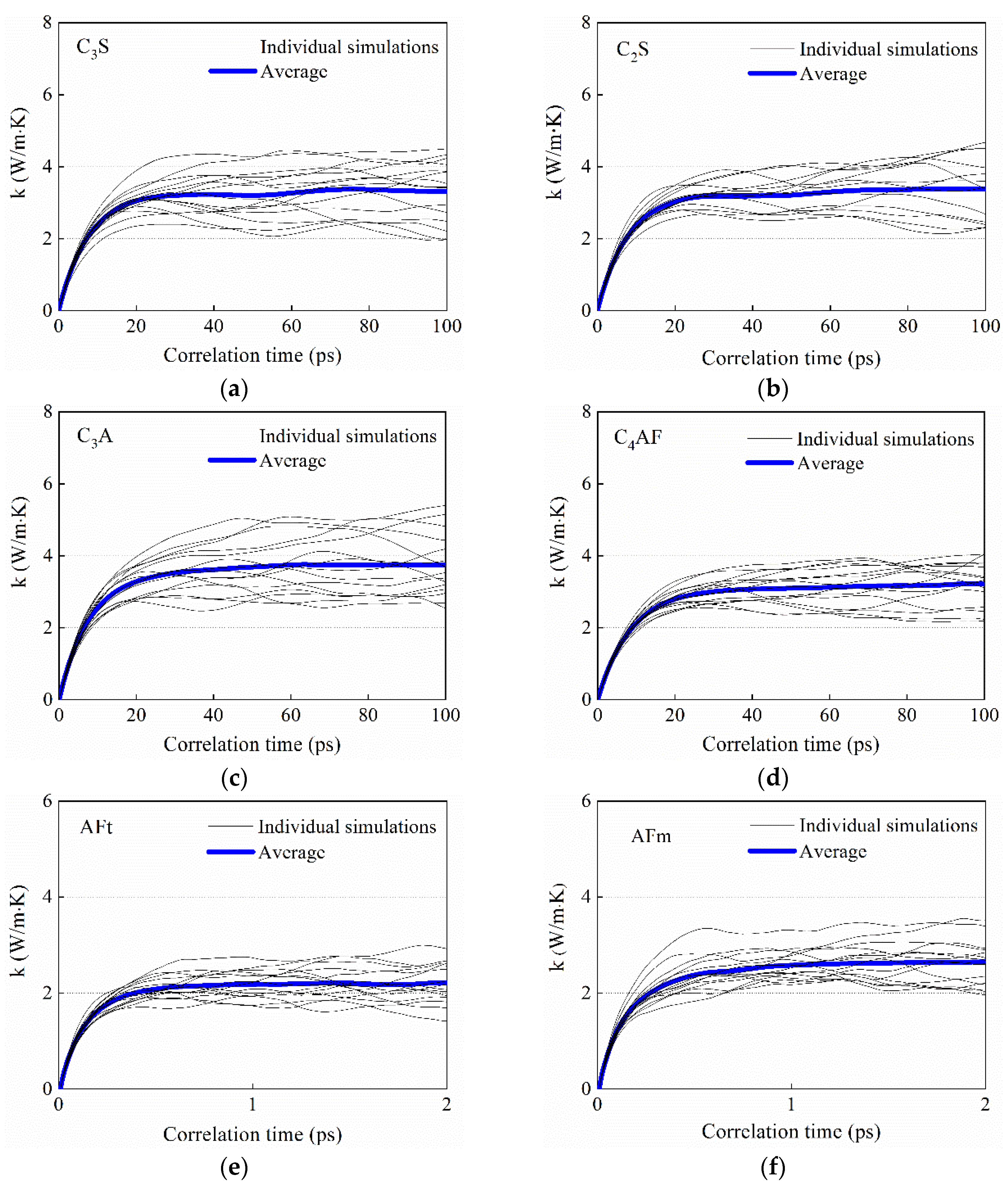

4.1.2. Simulation Details and Results

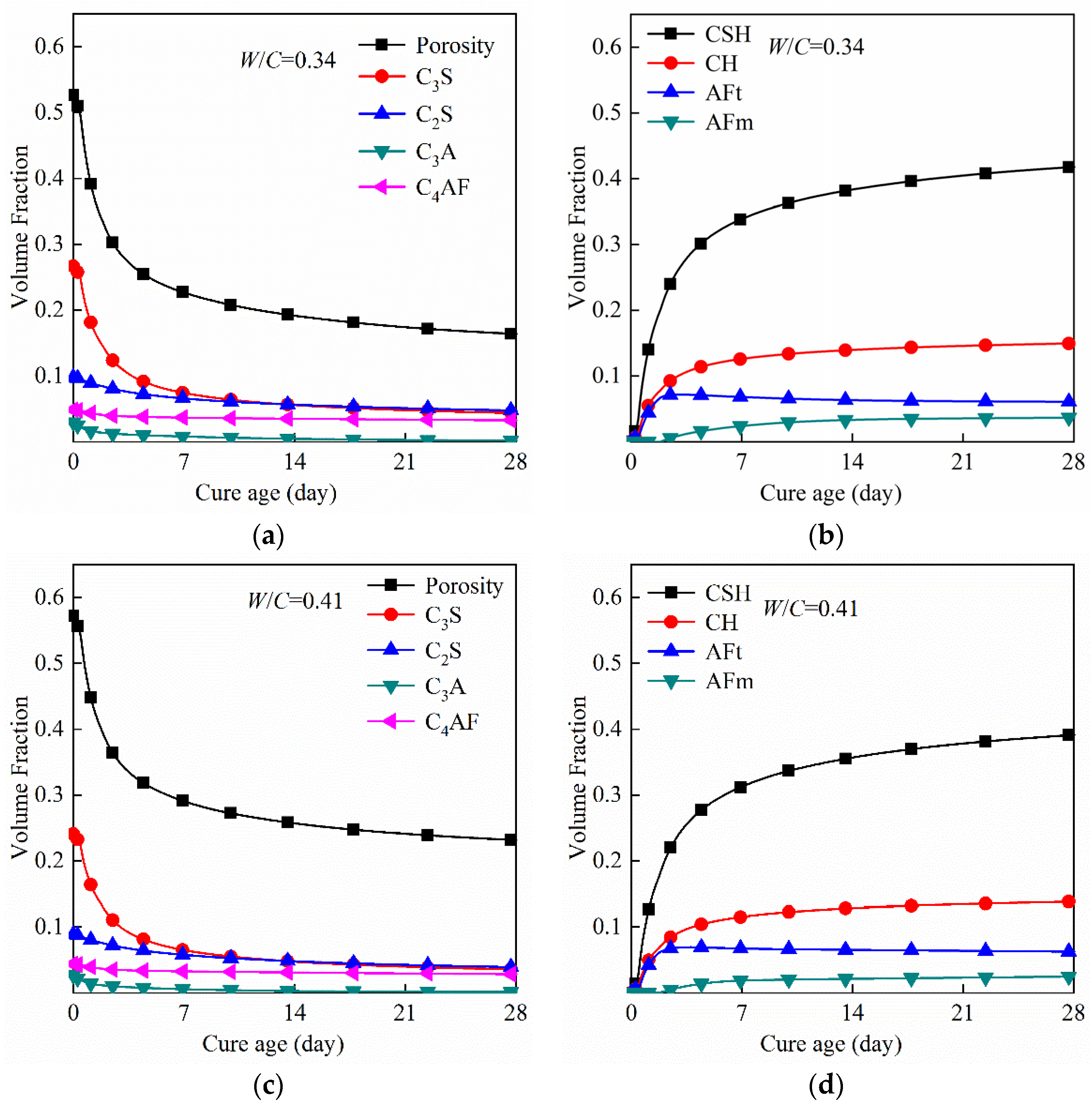

4.2. Volume Fraction of Constituent Phase in Cement Paste

5. Model Validation and Application

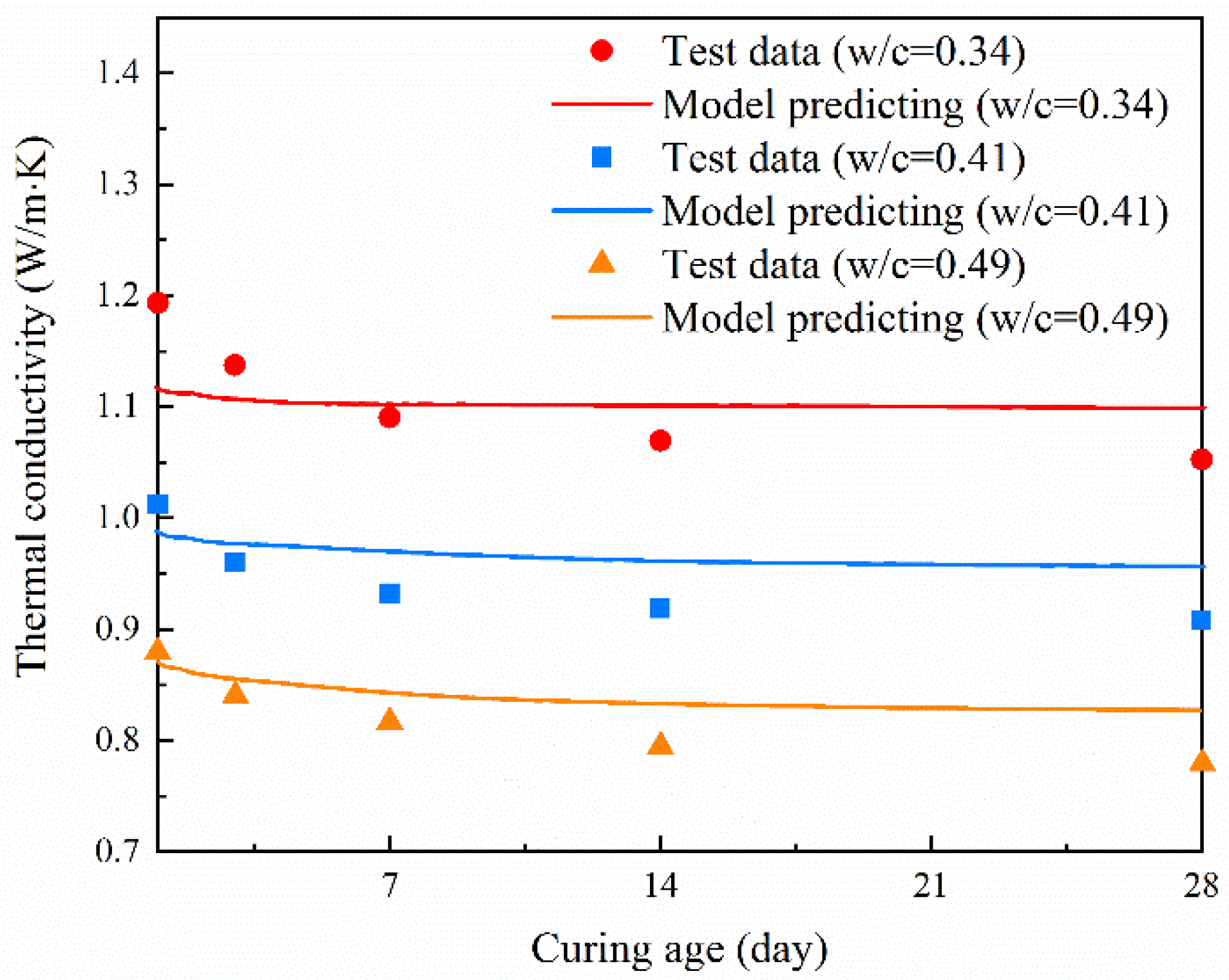

5.1. Comparison of Experimental Data with Model Predictions

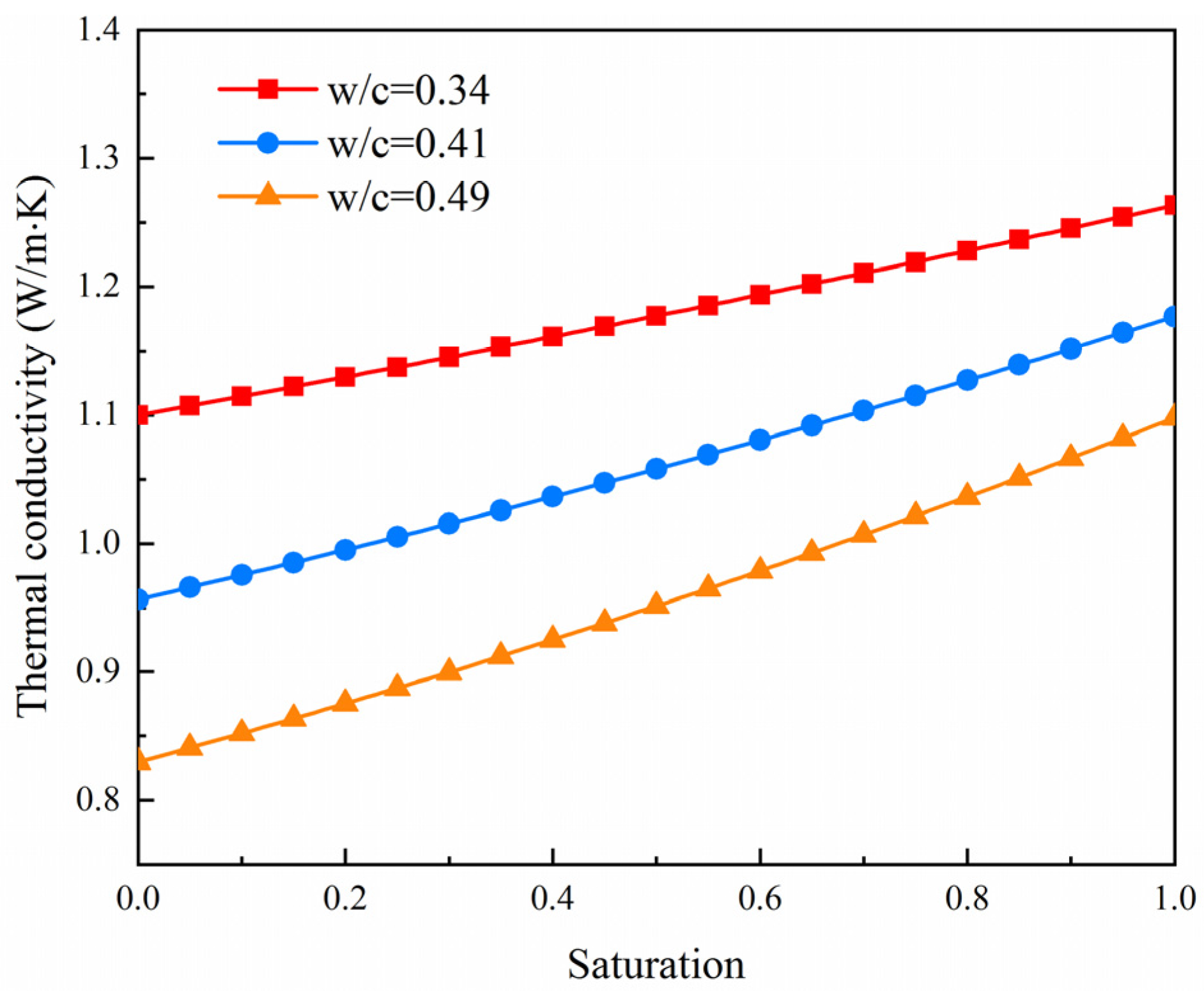

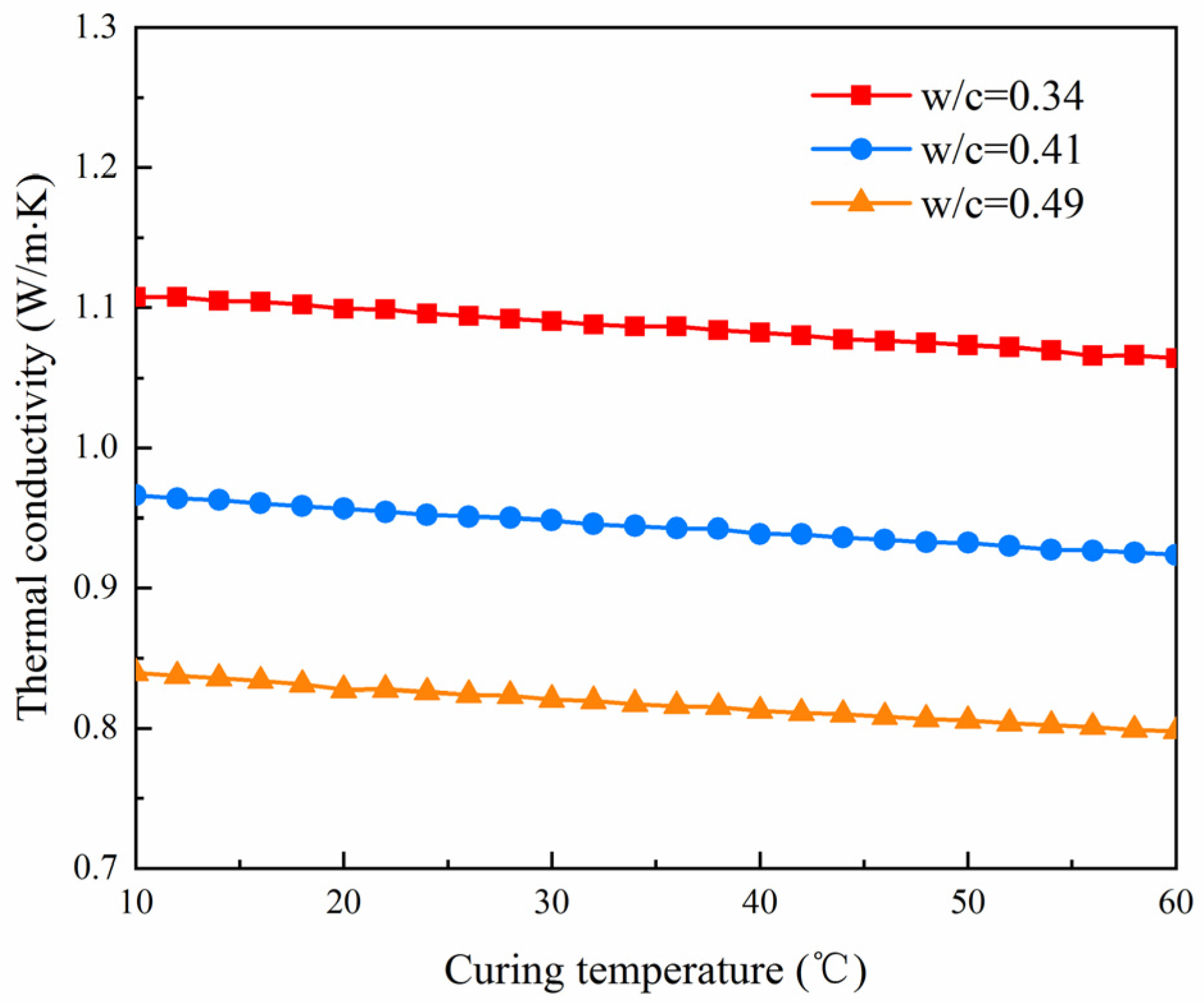

5.2. Influence of Saturation and Curing Temperature on the Thermal Conductivity of Paste

6. Conclusions

- The thermal conductivity of cement paste decreased gradually with the extension of curing age. For the same curing age, the thermal conductivity of cement paste decreased with the increase of the water/cement ratio.

- By combining the Mori–Tanaka method and Self-Consistent method, a multiscale prediction model for the thermal conductivity of cement paste was proposed, which can link constituent phase conductivity to the overall thermal conductivity of cement paste. The relatively errors between the predicted and measured values are in the range of 1.1% to 6.5%.

- The simulated thermal conductivity for C3S and C2S were, respectively, 3.35 ± 0.3 and 3.45 ± 0.2 W/(m K), which agreed well with the previously published results. In addition, the simulated thermal conductivities for C3A, C4AF, AFT and AFM were 3.74 ± 0.2, 3.17 ± 0.2, 2.19 ± 0.4 and 2.56 ± 0.2 W/(m K), respectively.

- The thermal conductivity of cement paste increased linearly with an increasing degree of saturation. The thermal conductivity of cement paste in saturated conditions was 14.9%–32.3% higher than that in a dry state. Moreover, the increase of curing temperatures from 10 °C to 60 °C resulted in a 3.9%–4.9% decrease in thermal conductivity of cement paste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xin, J.; Zhang, G.; Liu, Y.; Wang, Z.; Wu, Z. Effect of temperature history and restraint degree on cracking behavior of early-age concrete. Constr. Build. Mater. 2018, 192, 381–390. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, H.; Fang, B.; Sun, Y.; Zhong, Y.; Shi, T. Tensile Creep Model of Slab Concrete Based on Microprestress-Solidification Theory. Materials 2020, 13, 3157. [Google Scholar] [CrossRef] [PubMed]

- Issa, C.; Debs, P. Experimental study of epoxy repairing of cracks in concrete. Constr. Build. Mater. 2007, 21, 157–163. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Chen, H.; Wan, C. Microstructure-based modelling of drying shrinkage and microcracking of cement paste at high relative humidity. Constr. Build. Mater. 2016, 126, 410–425. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Huang, S.; Cui, H.; Liu, P.; Sun, Q. An Automatic Concrete Crack-Detection Method Fusing Point Clouds and Images Based on Improved Otsu’s Algorithm. Materials 2021, 21, 1581. [Google Scholar] [CrossRef]

- Jiang, F.; Deng, M.; Mo, L.; Wu, W. Effects of MgO Expansive Agent and Steel Fiber on Crack Resistance of a Bridge Deck. Materials 2020, 13, 3074. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Chen, E.; Shao, H.; Li, Z. A fractal approach to determine thermal conductivity in cement pastes. Constr. Build. Mater. 2015, 74, 73–82. [Google Scholar] [CrossRef]

- Abdelalim, A.; Abdallah, S.; Easawi, K.; Negm, S.; Talaat, H. Thermal properties of hydrated cement pastes studied by the photoacoustic technique. J. Phys. Conf. 2010, 214, 012136. [Google Scholar] [CrossRef]

- Kim, K.; Jeon, S.; Kim, J.; Yang, S. An experimental study on thermal conductivity of concrete. Cem. Concr. Res. 2003, 33, 363–371. [Google Scholar] [CrossRef]

- Baghban, M.; Hovde, P.; Jacobsen, S. Analytical and experimental study on thermal conductivity of hardened cement pastes. Mater. Struct. 2013, 46, 1537–1546. [Google Scholar] [CrossRef]

- Choktaweekarn, P.; Saengsoy, W.; Tangtermsirikul, S. A model for predicting thermal conductivity of concrete. Mag. Concr. Res. 2009, 61, 271–280. [Google Scholar] [CrossRef]

- Olmeda, J.; Sánchez de Rojas, M.; Frías, M.; Donatello, S.; Cheeseman, C. Effect of petroleum (pet) coke addition on the density and thermal conductivity of cement pastes and mortars. Fuel 2013, 107, 138–146. [Google Scholar] [CrossRef]

- Mounanga, P.; Khelidj, A.; Bastian, G. Experimental study and modeling approaches for the thermal conductivity evolution of hydrating cement paste. Adv. Cem. Res. 2004, 16, 95–103. [Google Scholar] [CrossRef][Green Version]

- GB/T 1346-2001. Test Methods of Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cement; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2001.

- Bentz, D.P. Transient plane source measurements of the thermal properties of hydrating cement pastes. Mater. Struct. 2007, 40, 1073–1080. [Google Scholar] [CrossRef]

- Zhang, G.; Ren, Q.; He, J.; Jiang, S.; Cheng, X.; Yu, Y.; Huang, S.; Zhang, C.; Zhou, M. New understanding of early hydration of C4AF under surface vitrification. Powder Technol. 2021, 377, 372–378. [Google Scholar] [CrossRef]

- Geiker, M.; Nielsen, E.P.; Herfort, D. Prediction of chloride ingress and binding in cement paste. Mater. Struct. 2007, 40, 405–417. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 71–574. [Google Scholar] [CrossRef]

- Hill, R. A self-consistent mechanics of composite materials. J. Mech. Phys. Solids 1965, 13, 213–222. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Wang, R. Quantitative evaluation of elastic modulus of concrete with nanoidentation and homogenization method. Constr. Build. Mater. 2019, 212, 295–303. [Google Scholar] [CrossRef]

- Quang, H.L.; Pham, D.C.; Bonnet, G.; He, Q.C. Estimations of the effective conductivity of anisotropic multiphase composites with imperfect interfaces. Int. J. Heat Mass Transf. 2013, 58, 175–187. [Google Scholar] [CrossRef][Green Version]

- Böhm, H.J.; Nogales, S. Mori-Tanaka models for the thermal conductivity of composites with interfacial resistance and particle size distributions. Compos. Sci. Technol. 2008, 68, 1181–1187. [Google Scholar] [CrossRef]

- Qomi, M.J.A.; Ulm, F.J.; Pellenq, R.J.M. Physical origins of thermal properties of cement paste. Phys. Rev. Appl. 2015, 3, 064010. [Google Scholar] [CrossRef]

- Xiao, H.; Long, C.; Tian, X.; Chen, H. Effect of thorium addition on the thermophysical properties of uranium dioxide: Atomistic simulations. Mater. Des. 2016, 96, 335–340. [Google Scholar] [CrossRef]

- Tanaka, K.; Ogata, S.; Kobayashi, R.; Tamura, T.; Kouno, T. A molecular dynamics study on thermal conductivity of thin epoxy polymer sandwiched between alumina fillers in heat-dissipation composite material. Int. J. Heat Mass Transf. 2015, 89, 714–723. [Google Scholar] [CrossRef]

- Green, M.S. Markoff Random Processes and the Statistical Mechanics of Time-Dependent Phenomena. II. Irreversible Processes in Fluids. J. Chem. Phys. 1954, 22, 398–413. [Google Scholar] [CrossRef]

- Müller-Plathe, F. A simple nonequilibrium molecular dynamics method for calculating the thermal conductivity. J. Chem. Phys. 1997, 106, 6082–6085. [Google Scholar] [CrossRef]

- Khadem, M.H.; Wemhoff, A.P. Comparison of Green-Kubo and NEMD heat flux formulations for thermal conductivity prediction using the Tersoff potential. Comput. Mater. Sci. 2013, 69, 428–434. [Google Scholar] [CrossRef]

- Prathiraja, P.; Daivis, P.J.; Snook, I.K. A molecular simulation study of shear viscosity and thermal conductivity of liquid carbon disulphide. J. Mol. Liq. 2010, 154, 6–13. [Google Scholar] [CrossRef]

- Golovastikov, N.I.; Matveeva, R.G.; Belov, N.V. Crystal Structure of Tricalcium Silicate 3CaO.SiO2=C3S. Kristallografiya 1975, 20, 721–729. [Google Scholar]

- Midgley, C.M. The crystal structure of beta dicalcium silicate. Acta Crystallogr. 1952, 5, 307–312. [Google Scholar] [CrossRef]

- Mondal, P.; Jeffery, J.W. The crystal structure of tricalcium aluminate, Ca3Al2O6. Acta Crystallogr. Sect. B Struct. Crystallogr. Cryst. Chem. 1975, 31, 689–697. [Google Scholar] [CrossRef]

- Colville, A.A.; Geller, S. The crystal structure of brownmillerite, Ca2FeAlO5. Acta Crystallogr. Sect. B Struct. Crystallogr. Cryst. Chem. 1971, 27, 2311–2315. [Google Scholar] [CrossRef]

- Goetz-Neunhoeffer, F.; Neubauer, J. Refined ettringite (Ca6Al2(SO4)3(OH)12∙26H2O) structure for quantitative X-ray diffraction analysis. Powder Diffr. 2006, 21, 4–11. [Google Scholar] [CrossRef]

- Allmann, R.N. Refinement of the hybrid layer structure [Ca2Al(OH)6]+·[1/2SO4·3H2O]−. Neues Jahrb. Miner. 1977, 4, 136–144. [Google Scholar]

- Mai, N.L.; Hoang, N.H.; Do, H.T.; Pilz, M.; Trinh, T.T. Elastic and thermodynamic properties of the major clinker phases of Portland cement: Insights from first principles calculations. Constr. Build. Mater. 2021, 287, 122873. [Google Scholar] [CrossRef]

- Jennings, H.M.; Tennis, P.D. Model for the developing microstructure in Portland cement pastes. J. Am. Ceram. Soc. 2010, 77, 3161–3172. [Google Scholar] [CrossRef]

- Bentz, D.P. Three-dimensional computer simulation of cement hydration and microstructure development. J. Am. Ceram. Soc. 1997, 80, 3–21. [Google Scholar] [CrossRef]

- Valentini, L.; Parisatto, M.; Russo, V.; Ferrari, G.; Bullard, J.W.; Angel, R.J.; Dalconi, M.C.; Artioli, G. Simulation of the hydration kinetics and elastic moduli of cement mortars by microstructural modelling. Cem. Concr. Compos. 2014, 52, 54–63. [Google Scholar] [CrossRef]

- Breugel, K.V. Simulation of Hydration and Formation of Structure in Hardening Cement-Based Materials. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1991. [Google Scholar]

- Bullard, J.W.; Stutzman, P.E. Analysis of CCRL proficiency cements 151 and 152 using the Virtual Cement and Concrete Testing Laboratory. Cem. Concr. Res. 2006, 36, 1548–1555. [Google Scholar] [CrossRef]

- Watts, B.E.; Tao, C.; Ferraro, C.C.; Masters, F.J. Proficiency analysis of VCCTL results for heat of hydration and mortar cube strength. Constr. Build. Mater. 2018, 161, 606–617. [Google Scholar] [CrossRef]

- Bullard, J.W.; Garboczi, E.J. A model investigation of the influence of particle shape on Portland cement hydration. Cem. Concr. Res. 2006, 36, 1007–1015. [Google Scholar] [CrossRef]

- Khan, M.I. Factors affecting the thermal properties of concrete and applicability of its prediction models. Build. Environ. 2002, 37, 607–614. [Google Scholar] [CrossRef]

- Honorio, T.; Bary, B.; Benboudjema, F. Thermal properties of cement-based materials: Multiscale estimations at early-age. Cem. Concr. Compos. 2018, 87, 205–219. [Google Scholar] [CrossRef]

- Liu, J.; Xu, S.; Qiang, Z. A multi-scale micromechanical investigation on thermal conductivity of cement-based composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 167, 012069. [Google Scholar] [CrossRef]

| Components | Al2O3 | SiO2 | Fe2O3 | CaO | MgO | Na2O | SO3 | Loss of Ignition |

|---|---|---|---|---|---|---|---|---|

| Contents/wt% | 4.49 | 21.88 | 3.45 | 64.65 | 2.36 | 0.51 | 2.44 | 1.31 |

| Phase | C3S | C2S | C3A | C4AF | CaSO4·2H2O |

|---|---|---|---|---|---|

| Contents/wt% | 56.54 | 20.87 | 6.22 | 10.31 | 6.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Ge, Y. Multiphase Model for Predicting the Thermal Conductivity of Cement Paste and Its Applications. Materials 2021, 14, 4525. https://doi.org/10.3390/ma14164525

Du Y, Ge Y. Multiphase Model for Predicting the Thermal Conductivity of Cement Paste and Its Applications. Materials. 2021; 14(16):4525. https://doi.org/10.3390/ma14164525

Chicago/Turabian StyleDu, Yuanbo, and Yong Ge. 2021. "Multiphase Model for Predicting the Thermal Conductivity of Cement Paste and Its Applications" Materials 14, no. 16: 4525. https://doi.org/10.3390/ma14164525

APA StyleDu, Y., & Ge, Y. (2021). Multiphase Model for Predicting the Thermal Conductivity of Cement Paste and Its Applications. Materials, 14(16), 4525. https://doi.org/10.3390/ma14164525