Compressive Properties of Functionally Graded Bionic Bamboo Lattice Structures Fabricated by FDM

Abstract

:1. Introduction

2. Materials and Methods

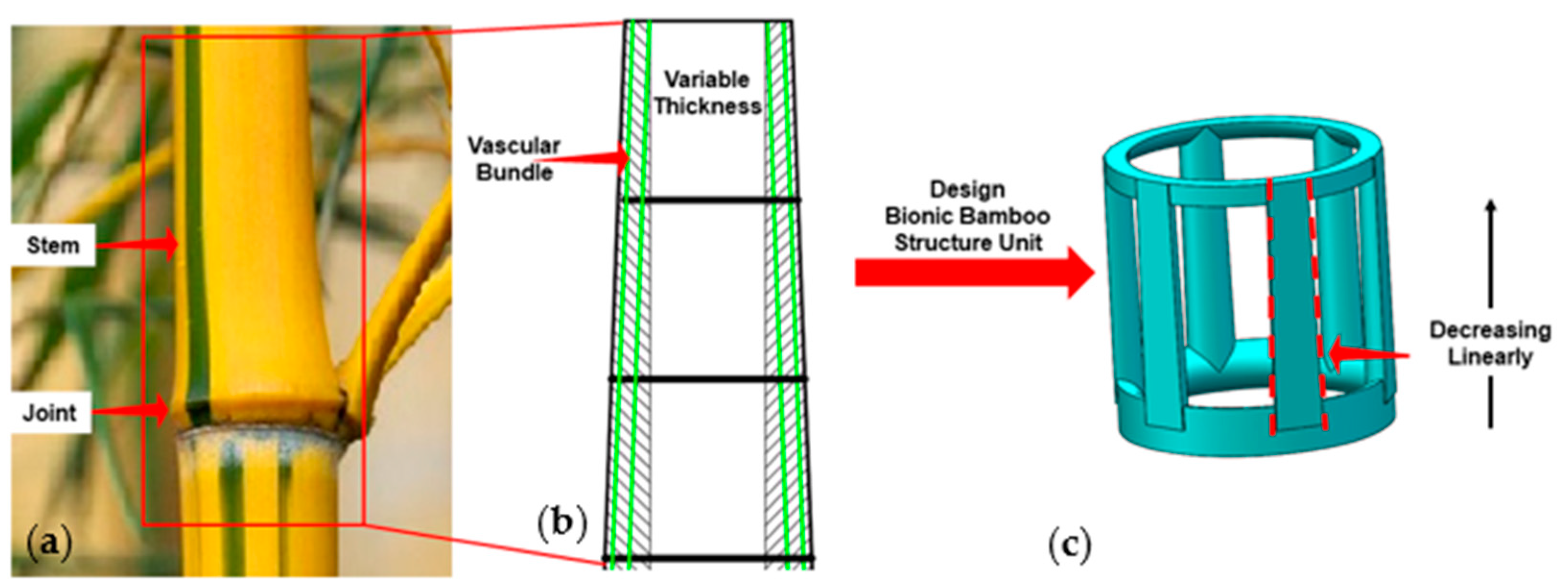

2.1. Design of Bionic Structures Based on Bamboo

2.2. Design and Production of Lattice Structures

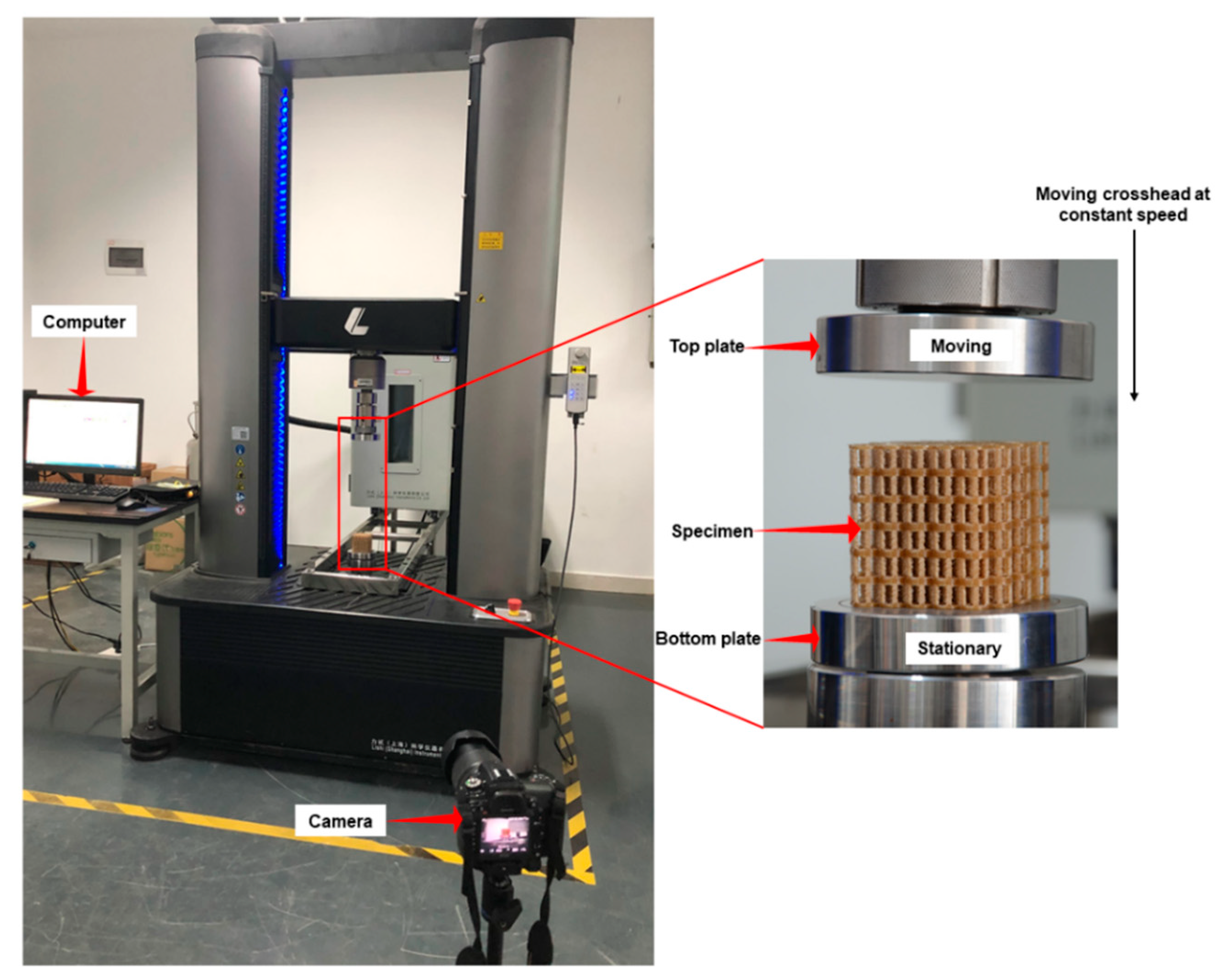

2.3. Mechanical Testing

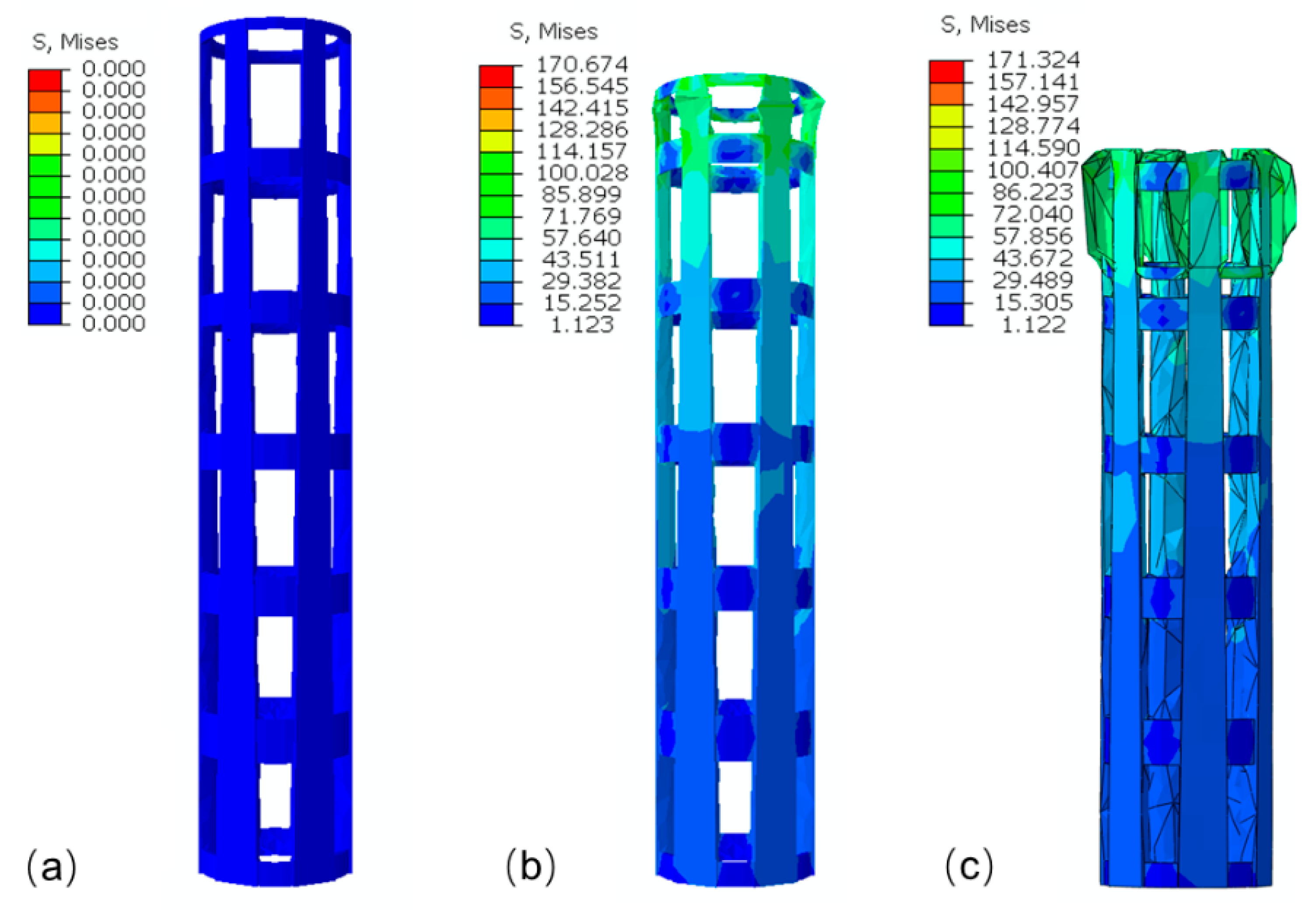

2.4. Finite Element Modeling and Analysis

3. Results and Discussion

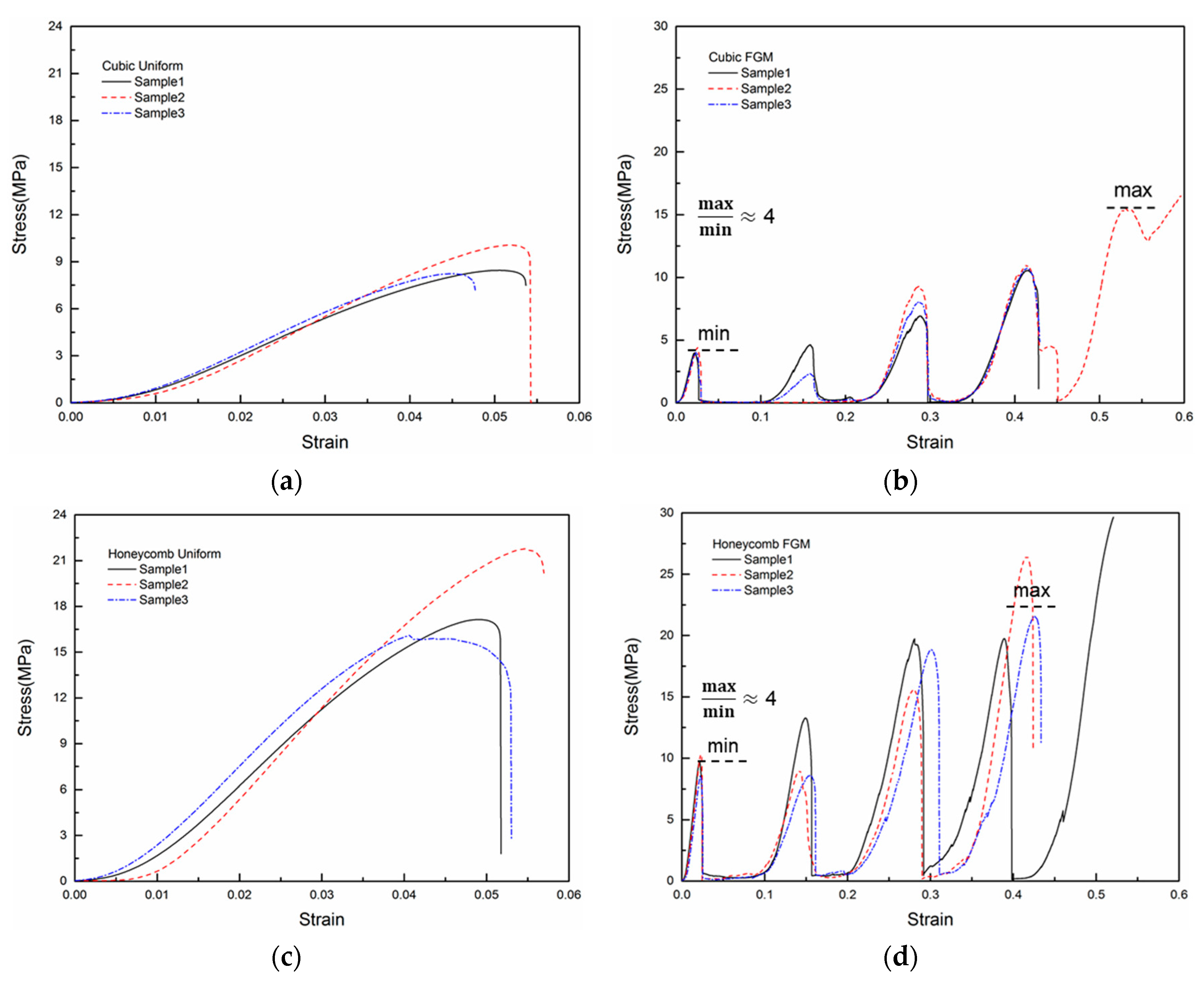

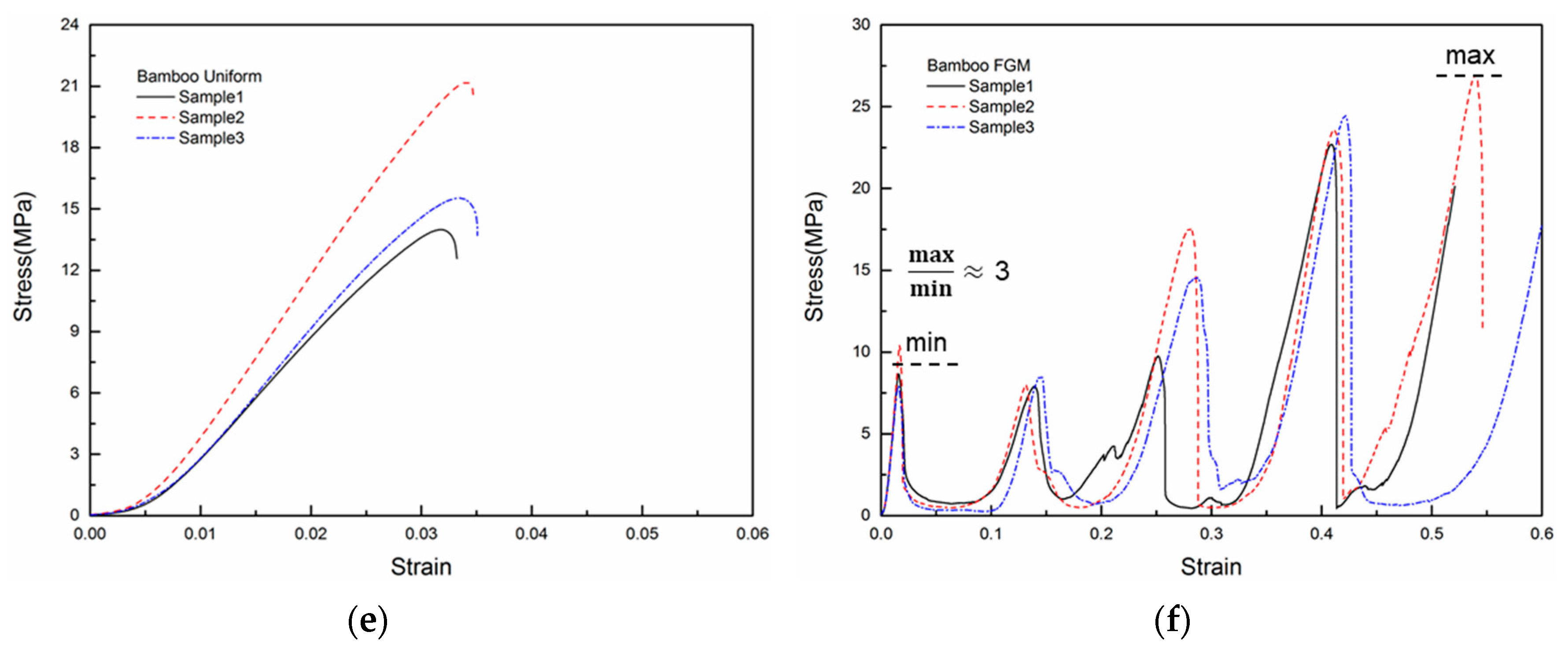

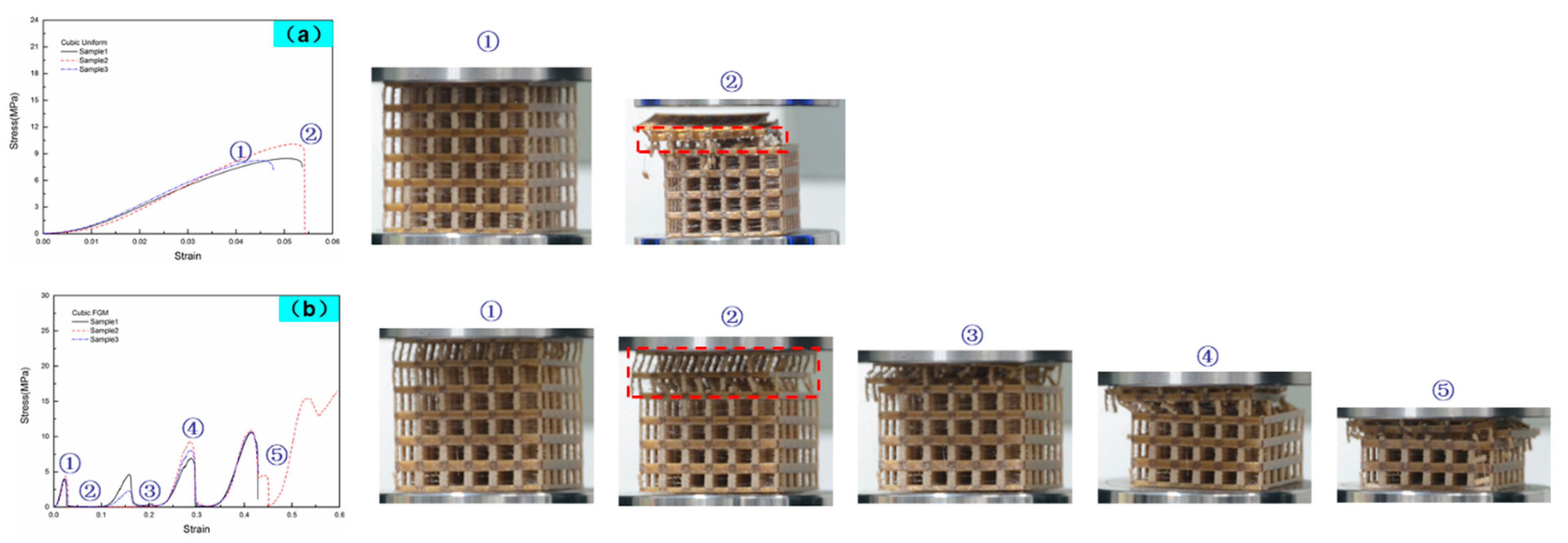

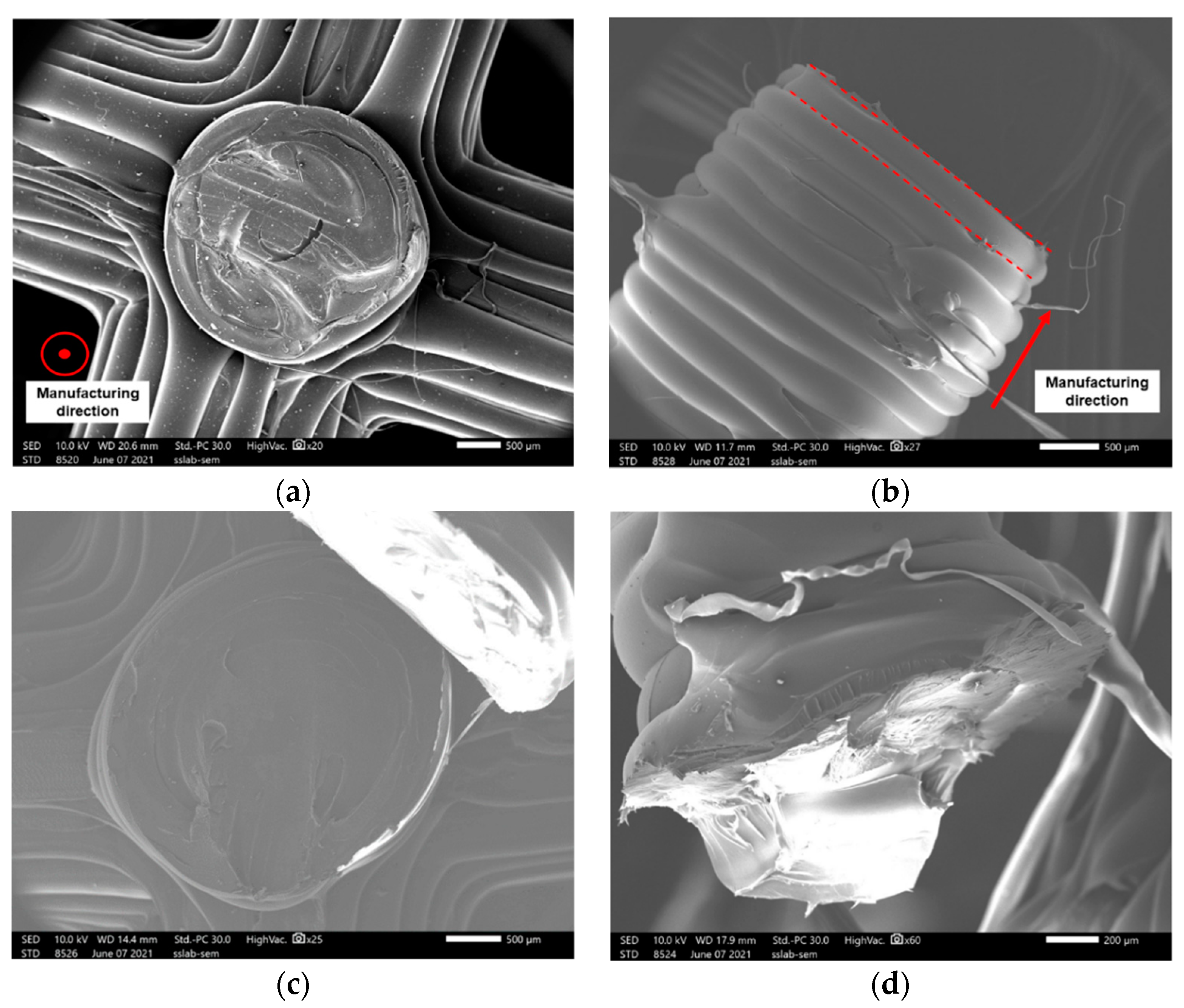

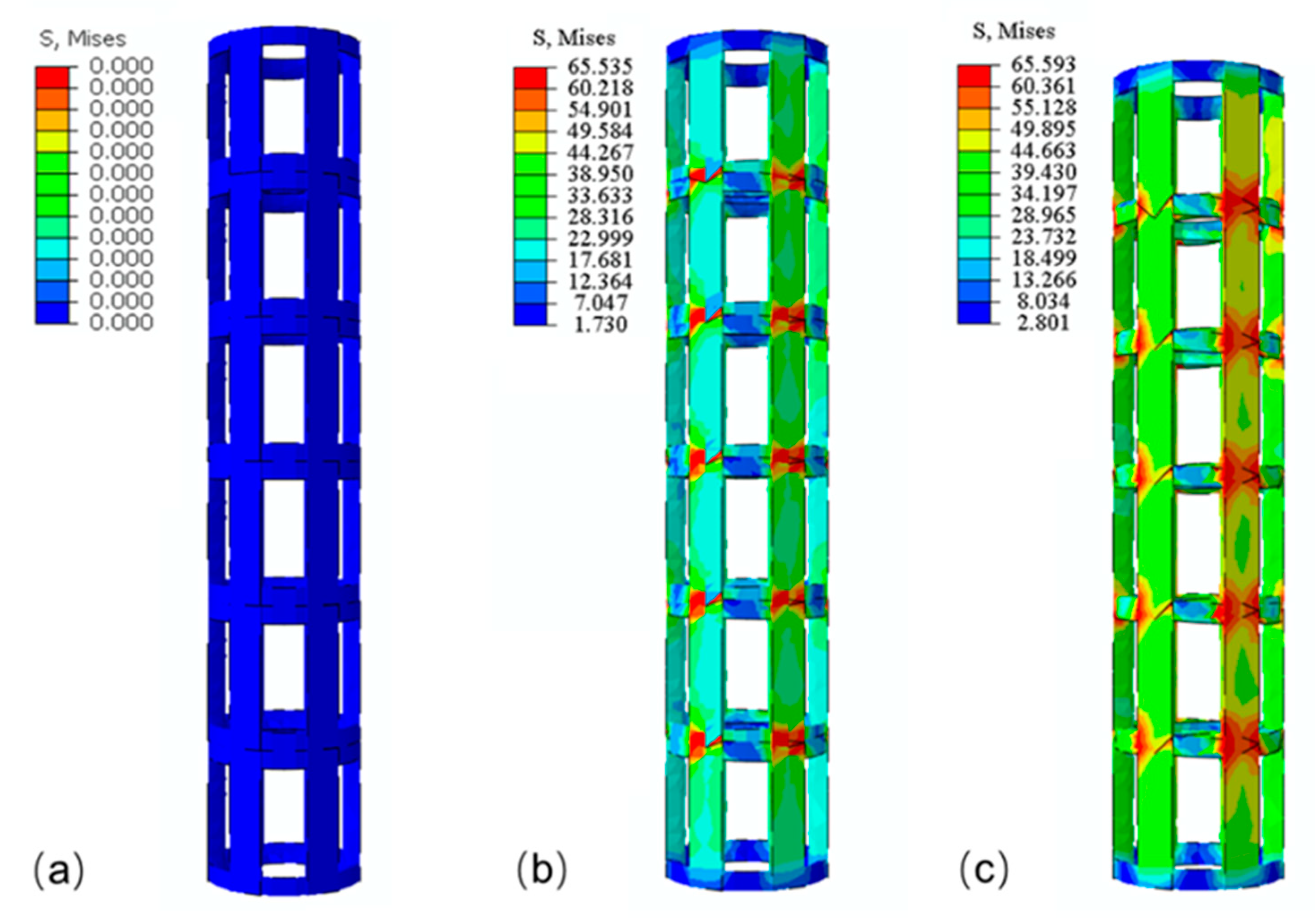

3.1. Mechanical Properties and Energy Absorption

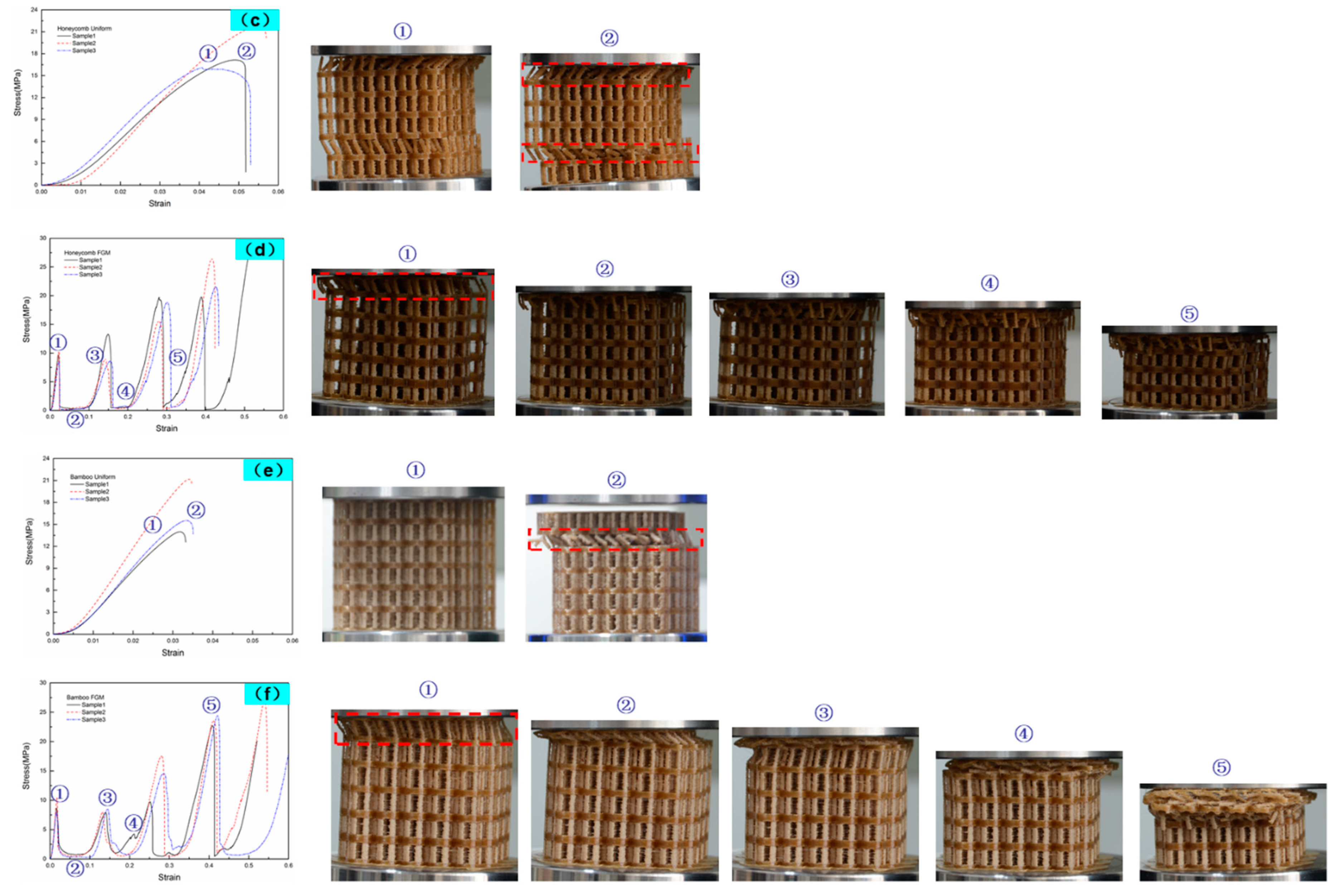

3.2. Deformation Modes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, B.; Jaiswal, P.; Rai, R.; Nelaturi, S. Additive Manufacturing of Functionally Graded Material Objects: A Review. J. Comput. Inf. Sci. Eng. 2018, 18, 041002. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana Sisa, L. Functionally Graded Material: An. Overview. Proc. World Congr. Eng. 2012, 3, 4–6. [Google Scholar]

- Marin, L. Numerical solution of the Cauchy problem for steady–state heat transfer in two–dimensional functionally graded materials. Int. J. Solids Struct. 2005, 42, 4338–4351. [Google Scholar] [CrossRef]

- Abate, K.M. Design, optimization, and validation of mechanical properties of different lattice structures for biomedical application. Int. J. Adv. Manuf. Technol. 2019, 106, 1253–1265. [Google Scholar] [CrossRef]

- Wang, S.; Shi, Z.; Liu, L.; Zhou, X.; Zhu, L.; Hao, Y. The design of Ti6Al4V Primitive surface structure with symmetrical gradient of pore size in biomimetic bone scaffold. Mater. Des. 2020, 193, 108830. [Google Scholar] [CrossRef]

- Niknam, H.; Akbarzadeh, A.H. Graded lattice structures: Simultaneous enhancement in stiffness and energy absorption. Mater. Des. 2020, 196, 09129. [Google Scholar] [CrossRef]

- Al-Saedi, D.S.J.; Masood, S.H.; Faizan-Ur-Rab, M.; Alomarah, A.; Ponnusamy, P. Mechanical properties and energy absorption capability of functionally graded F2BCC lattice fabricated by SLM. Mater. Des. 2018, 144, 32–44. [Google Scholar] [CrossRef]

- YingChoy, S.; Sun, C.; Leong, K.F.; Wei, J. Compressive properties of functionally graded lattice structures manufactured by selective laser melting. Mater. Des. 2017, 131, 112–120. [Google Scholar]

- Li, D.; Liao, W.; Dai, N.; Xie, Y.M. Comparison of Mechanical Properties and Energy Absorption of Sheet–Based and Strut–Based Gyroid Lattice Structures with Graded Densities. Materials 2019, 12, 2183. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cherradi, N. Worldwide trends in functional gradient materials research and development. Compos. Eng. 1994, 4, 883–894. [Google Scholar] [CrossRef]

- Cheng, L. Functionally Graded Lattice Structure Topology Optimization for the Design of Additive Manufactured Components with Stress Constraints. Comput. Methods Appl. Mech. Eng. 2018, 344, 334–359. [Google Scholar] [CrossRef]

- Khalil, S.; Nam, J.; Sun, W. Multi-nozzle deposition for construction of 3D biopolymer tissue scaffolds. Rapid Prototyp. J. 2005, 11, 9–17. [Google Scholar] [CrossRef] [Green Version]

- Attar, H.; Löber, L.; Funk, A.; Calin, M.; Zhang, L.C.; Prashanth, K.G.; Scudino, S.; Zhang, Y.S.; Eckert, J. Mechanical behavior of porous commercially pure Ti and Ti–TiB composite materials manufactured by selective laser melting. Mater. Sci. Eng. A 2015, 625, 350–356. [Google Scholar] [CrossRef]

- Yang, S.; Xue, X.; Lou, S.; Lu, F. Investigation on gradient material fabrication with electron beam melting based on scanning track control. China Weld. 2007, 16, 4. [Google Scholar]

- Deng, X.; Zeng, Z.; Peng, B.; Yan, S.; Ke, W. Mechanical Properties Optimization of Poly–Ether–Ether–Ketone via Fused Deposition Modeling. Materials 2018, 11, 216. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Magri, A.; Mabrouk, K.; Vaudreuil, S.; Chibane, H.; Touhami, M.E. Optimization of printing parameters for improvement of mechanical and thermal performances of 3D printed poly(ether ether ketone) parts. J. Appl. Polym. Sci. 2020, 137, 49087. [Google Scholar] [CrossRef]

- Salem Bala, A.; bin Wahab, S.; binti Ahmad, M. Elements and Materials Improve the FDM Products: A Review. Adv. Eng. Forum 2016, 16, 33–51. [Google Scholar] [CrossRef]

- Nguyen, C.H.P. Design for Additive Manufacturing of Functionally Graded Lattice Structures: A Design Method with Process. Induced Anisotropy Consideration. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 8, 29–45. [Google Scholar] [CrossRef]

- Wang, X. Natural frequency optimization of 3D printed variable–density honeycomb structure via a homogenization–based approach. Addit. Manuf. 2017, 20, 189–198. [Google Scholar] [CrossRef]

- Li, D.; Liao, W.; Dai, N.; Dong, G.; Tang, Y.; Xie, Y. Optimal design and modeling of gyroid–based functionally graded lattice structures for additive manufacturing. Comput. Aided Des. 2018, 104, 87–99. [Google Scholar] [CrossRef]

- Gautam, R.; Idapalapati, S. Compressive Properties of Additively Manufactured Functionally Graded Kagome Lattice Structure. Metals 2019, 9, 517. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.K.; Wu, M.W.; Cheng, T.L.; Chiang, P.H. Continuous compression behaviors of selective laser melting Ti–6Al–4V alloy with cuboctahedron lattice structures. Mater. Sci. Eng. C 2019, 100, 781–788. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.; Xiao, Y.; Wen, G.; Qing, Q.; Wu, X. Crushing analysis and multi–objective optimization design for bionic thin–walled structure. Mater. Des. 2015, 87, 825–834. [Google Scholar] [CrossRef]

- Chen, B.C.; Zou, M.; Liu, G.M.; Song, J.F.; Wang, H.X. Experimental study on energy absorption of bionic tubes inspired by bamboo structures under axial crushing. Int. J. Impact Eng. 2018, 115, 48–57. [Google Scholar] [CrossRef]

- Lakkad, S.C.; Patel, J.M. Mechanical properties of bamboo, a natural composite. Fibre Sci. Technol. 1981, 14, 319–322. [Google Scholar] [CrossRef]

- Song, J.F.; Xu, S.C.; Wang, H.X.; Wu, X.Q.; Zou, M. Bionic design and multi–objective optimization for variable wall thickness tube inspired bamboo structures. Thin-Walled Struct. 2018, 125, 76–88. [Google Scholar] [CrossRef]

- Kumar, A.; Collini, L.; Daurel, A.; Jeng, J. Design and additive manufacturing of closed cells from supportless lattice structure. Addit. Manuf. 2020, 33, 101168. [Google Scholar] [CrossRef]

| FDM Parameters | Values |

|---|---|

| Printing speed (mm/s) | 40 |

| Printing temperature (°C) | 400 |

| Bed temperature (°C) | 120 |

| Cooling fan (%) | 30 |

| Lattice Structure | Cubic Uniform | Cubic FGM | Honeycomb Uniform | Honeycomb FGM | Bamboo Uniform | Bamboo FGM |

|---|---|---|---|---|---|---|

| Initial peak strength (MPa) | 8.5 ± 1 | 4.5 ± 0.3 | 19 ± 3 | 9 ± 1 | 18 ± 3 | 9 ± 1 |

| Compressive modulus (GPa) | 0.15 ± 0.01 | 0.18 ± 0.01 | 0.31 ± 0.05 | 0.44 ± 0.03 | 0.32 ± 0.04 | 0.45 ± 0.01 |

| Energy absorption (J/cm3) (up to strain of 0.4) | 0.22 ± 0.03 | 0.68 ± 0.02 | 0.51 ± 0.05 | 1.86 ± 0.09 | 0.28 ± 0.06 | 1.72 ± 0.06 |

| Relative density | 0.189 | 0.193 | 0.233 | 0.237 | 0.206 | 0.211 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, Z.; Li, M. Compressive Properties of Functionally Graded Bionic Bamboo Lattice Structures Fabricated by FDM. Materials 2021, 14, 4410. https://doi.org/10.3390/ma14164410

Wen Z, Li M. Compressive Properties of Functionally Graded Bionic Bamboo Lattice Structures Fabricated by FDM. Materials. 2021; 14(16):4410. https://doi.org/10.3390/ma14164410

Chicago/Turabian StyleWen, Zhou, and Ming Li. 2021. "Compressive Properties of Functionally Graded Bionic Bamboo Lattice Structures Fabricated by FDM" Materials 14, no. 16: 4410. https://doi.org/10.3390/ma14164410

APA StyleWen, Z., & Li, M. (2021). Compressive Properties of Functionally Graded Bionic Bamboo Lattice Structures Fabricated by FDM. Materials, 14(16), 4410. https://doi.org/10.3390/ma14164410