Study on SLM Forming Process, Residual Stress and Thermal Fatigue of 24CrNiMo Alloy Steel

Abstract

:1. Introduction

2. Test Materials and Methods

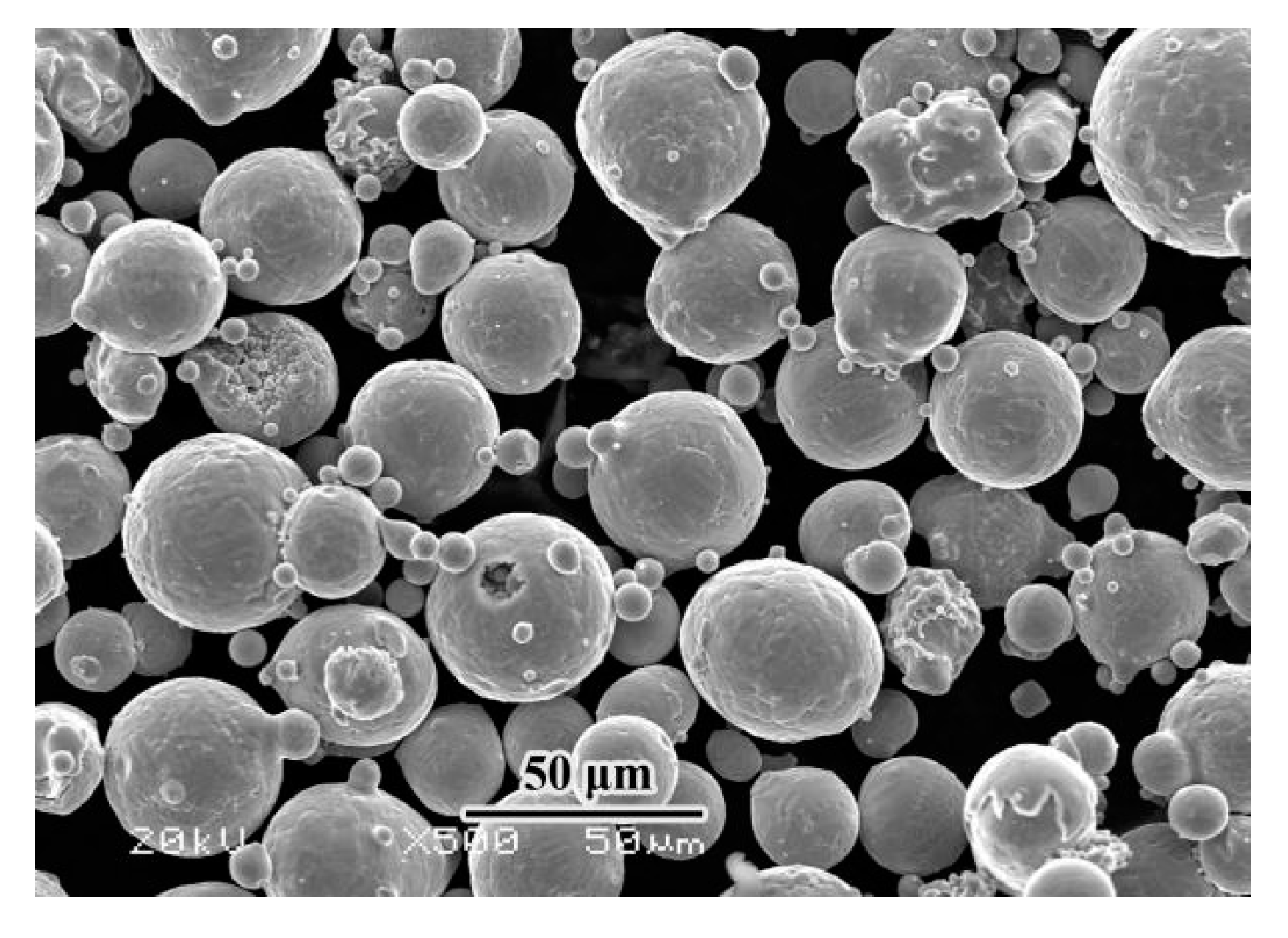

2.1. Powder and Substrate Materials

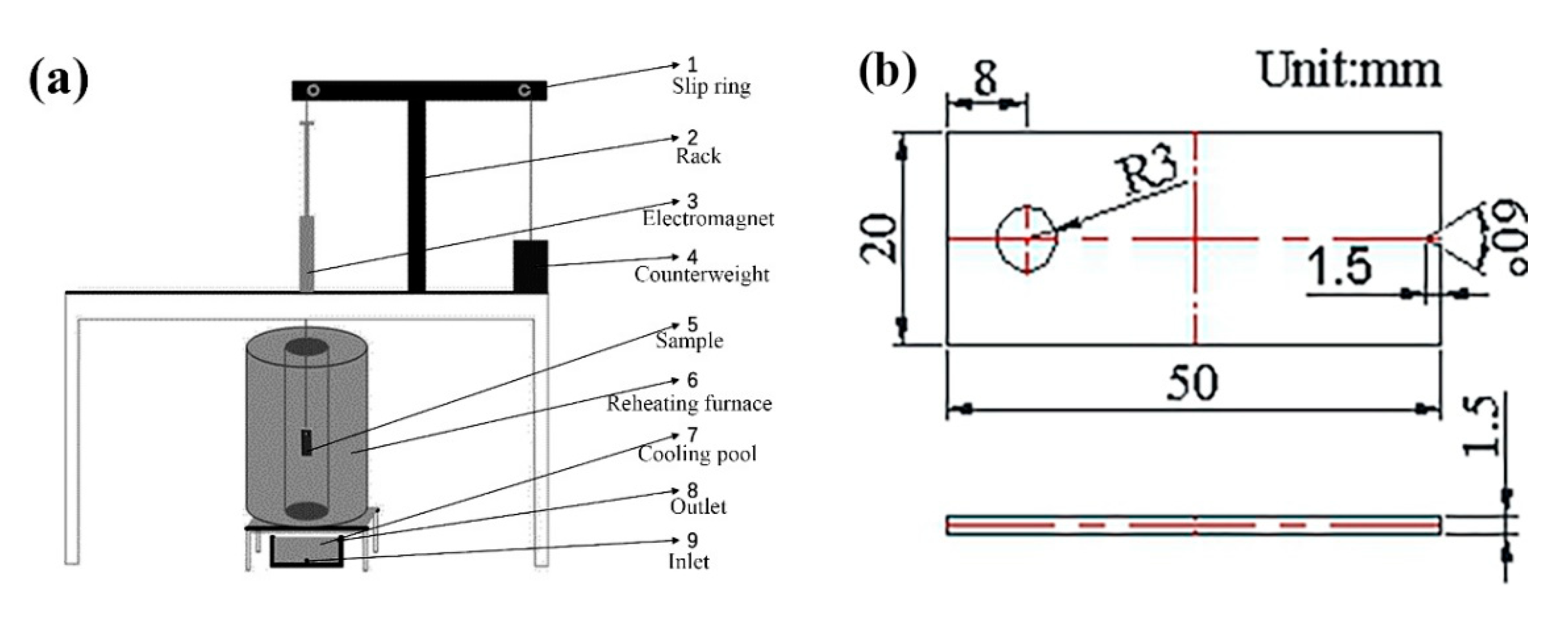

2.2. Test Methods

2.2.1. Orthogonal Test Methods

2.2.2. Sample Preparation and Test Methods

3. Test Results and Analysis

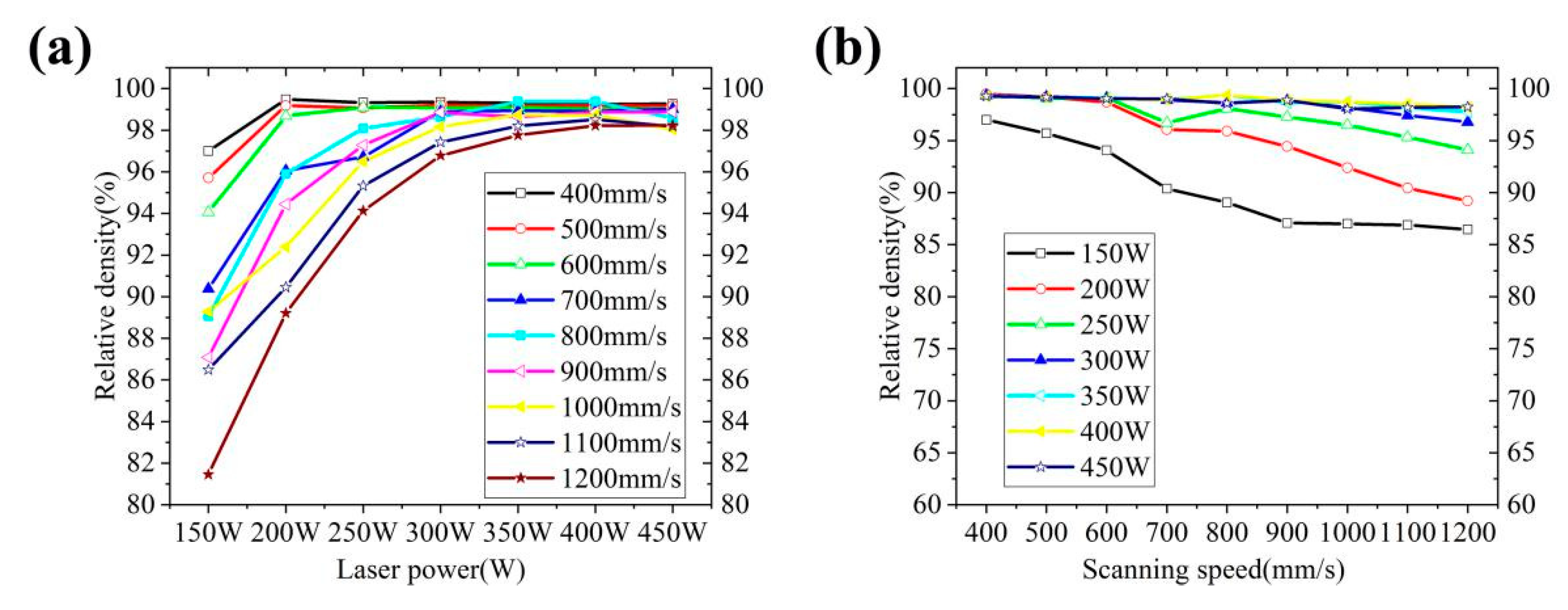

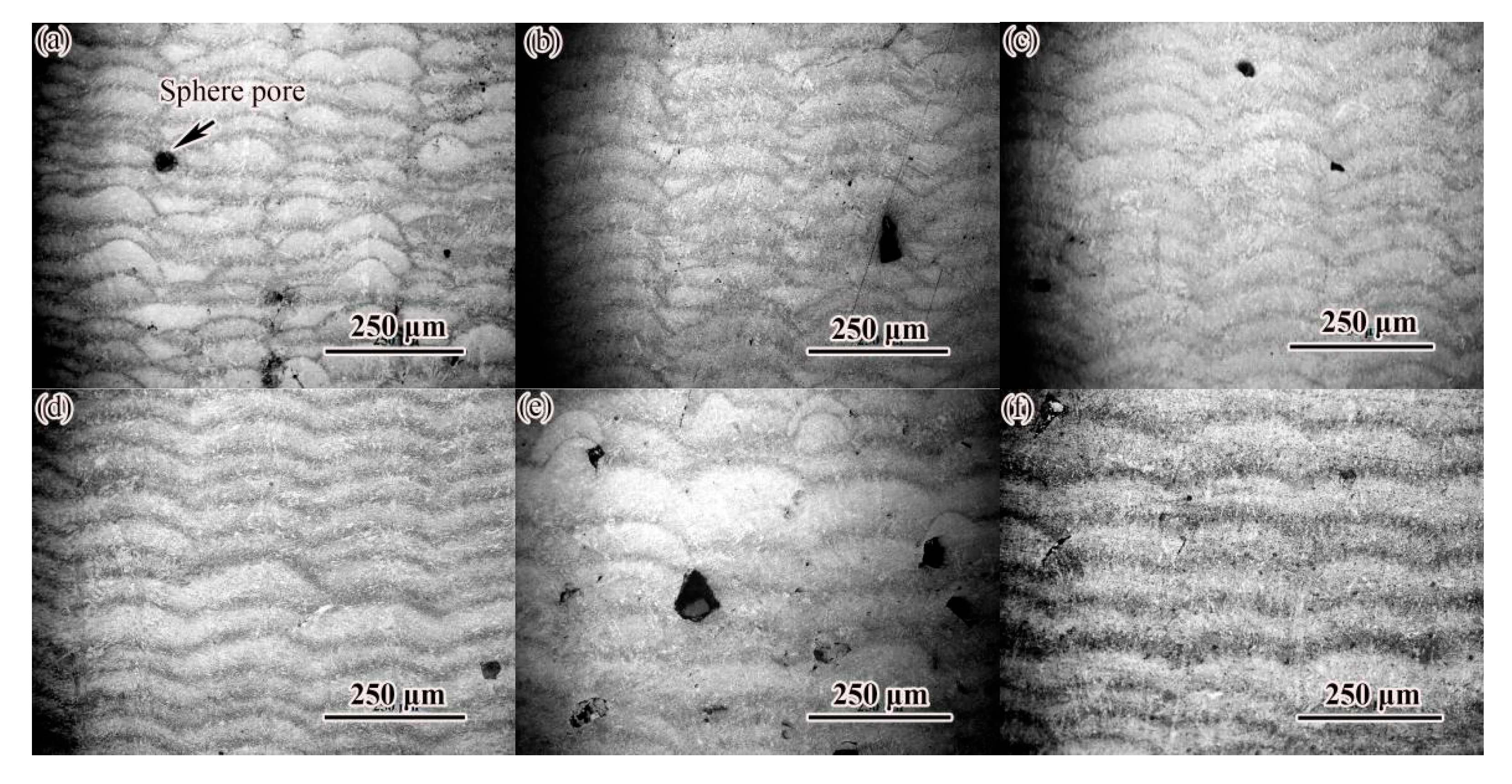

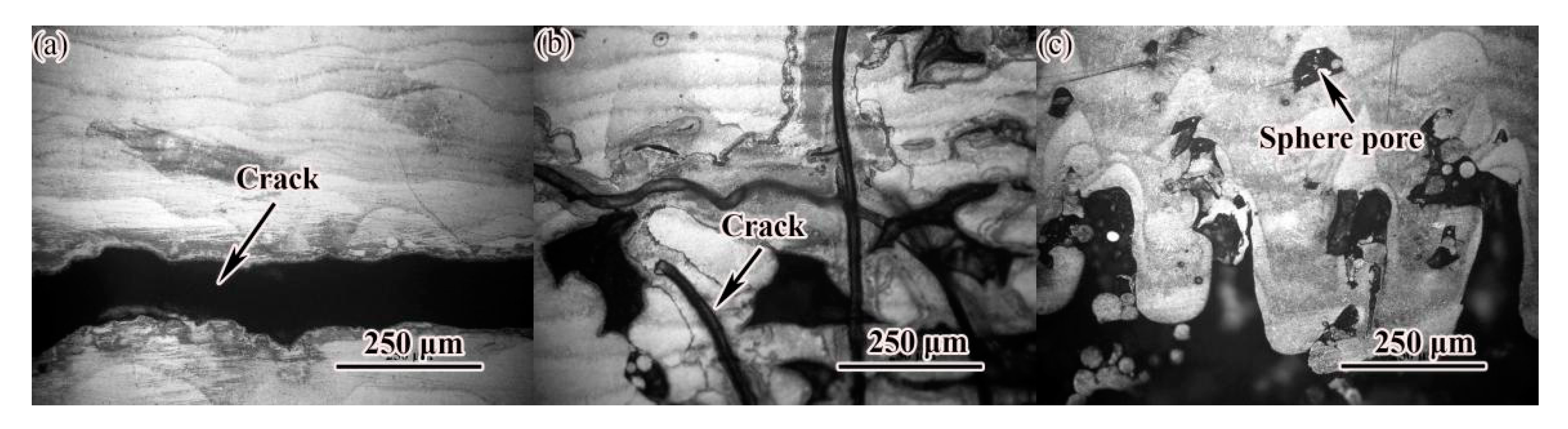

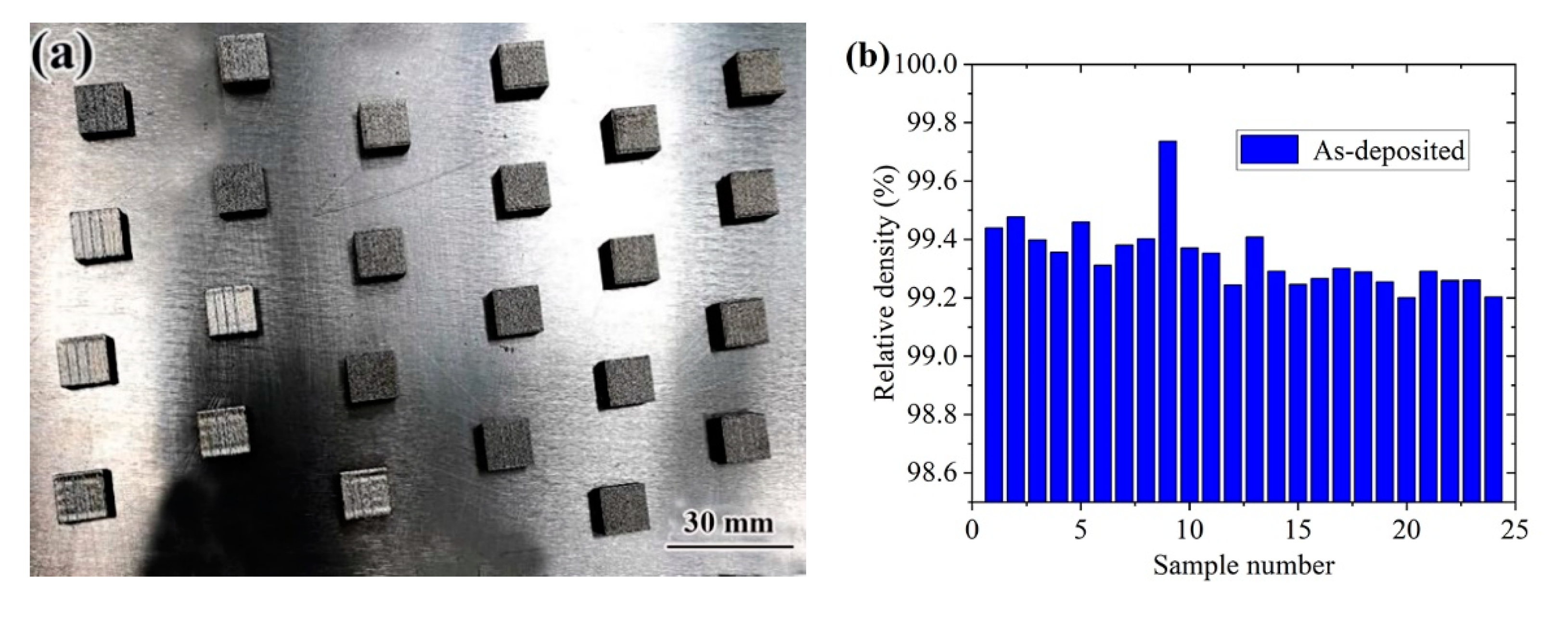

3.1. Effect of SLM Process Parameters on Density of 24CrNiMo Alloy Steel

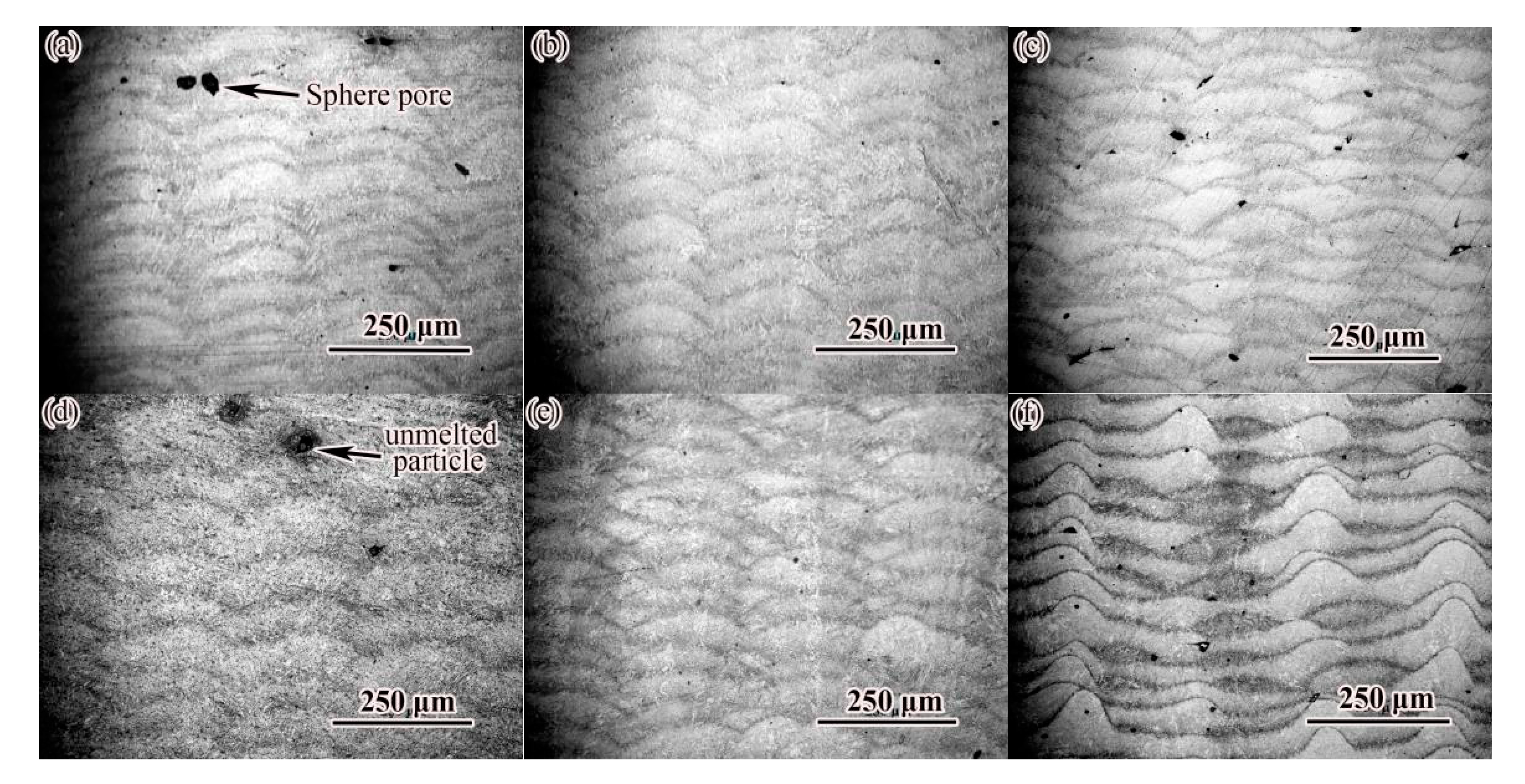

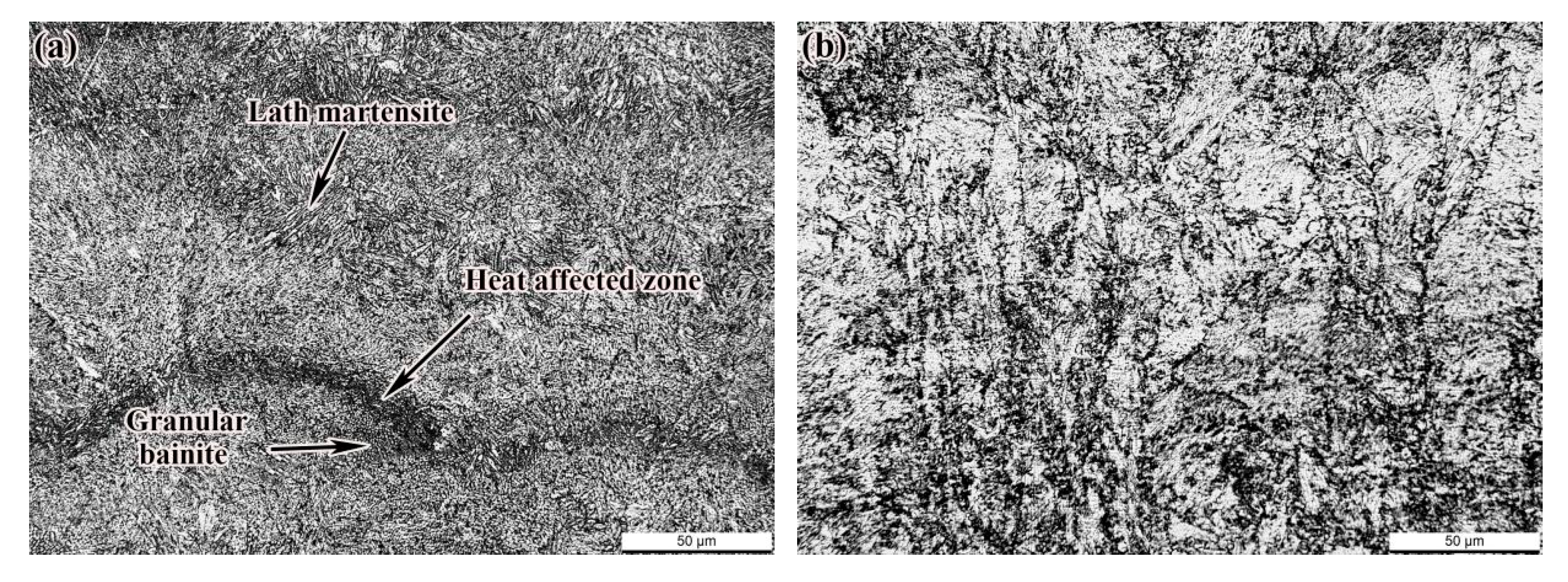

3.2. Effect of SLM Process Parameters on Microstructure of 24CrNiMo Alloy Steel

3.3. Test Results and Analysis of Surface Residual Stress

3.4. Test Results and Analysis of Gradient Residual Stress

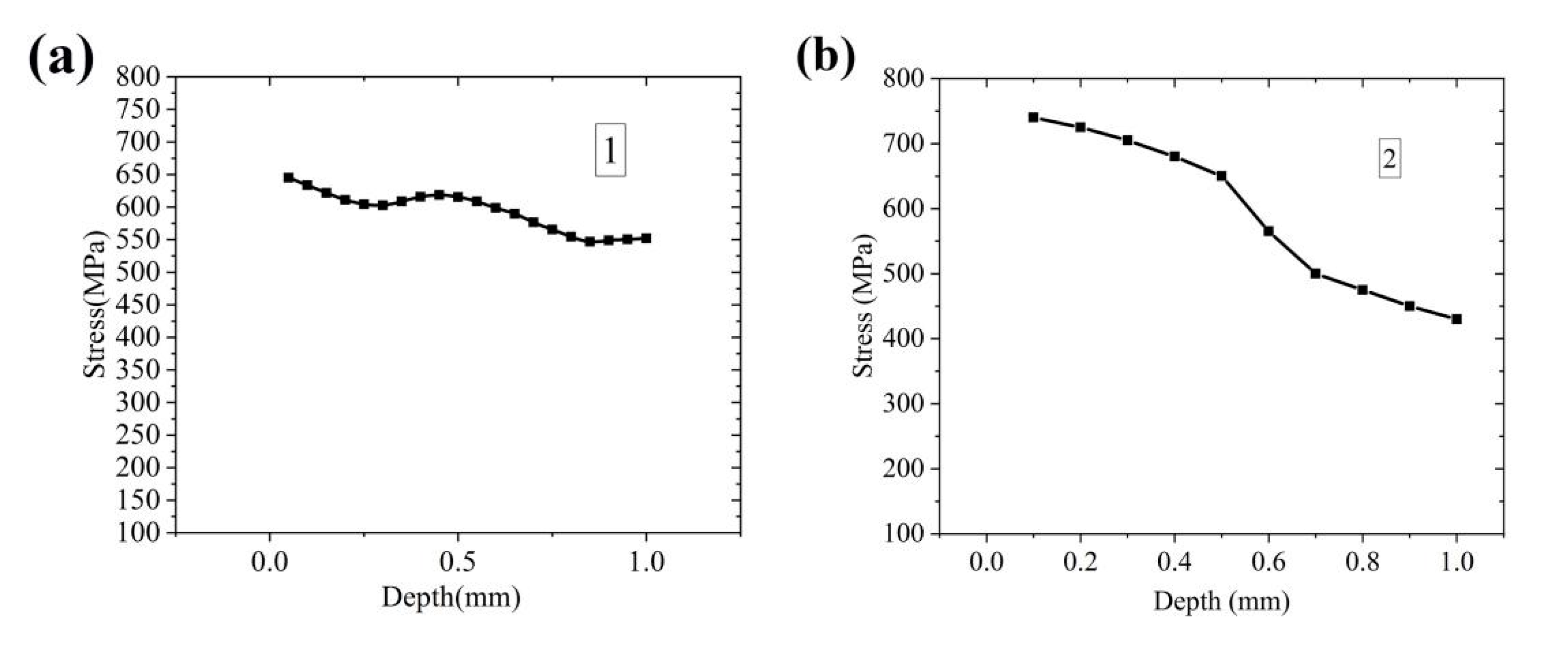

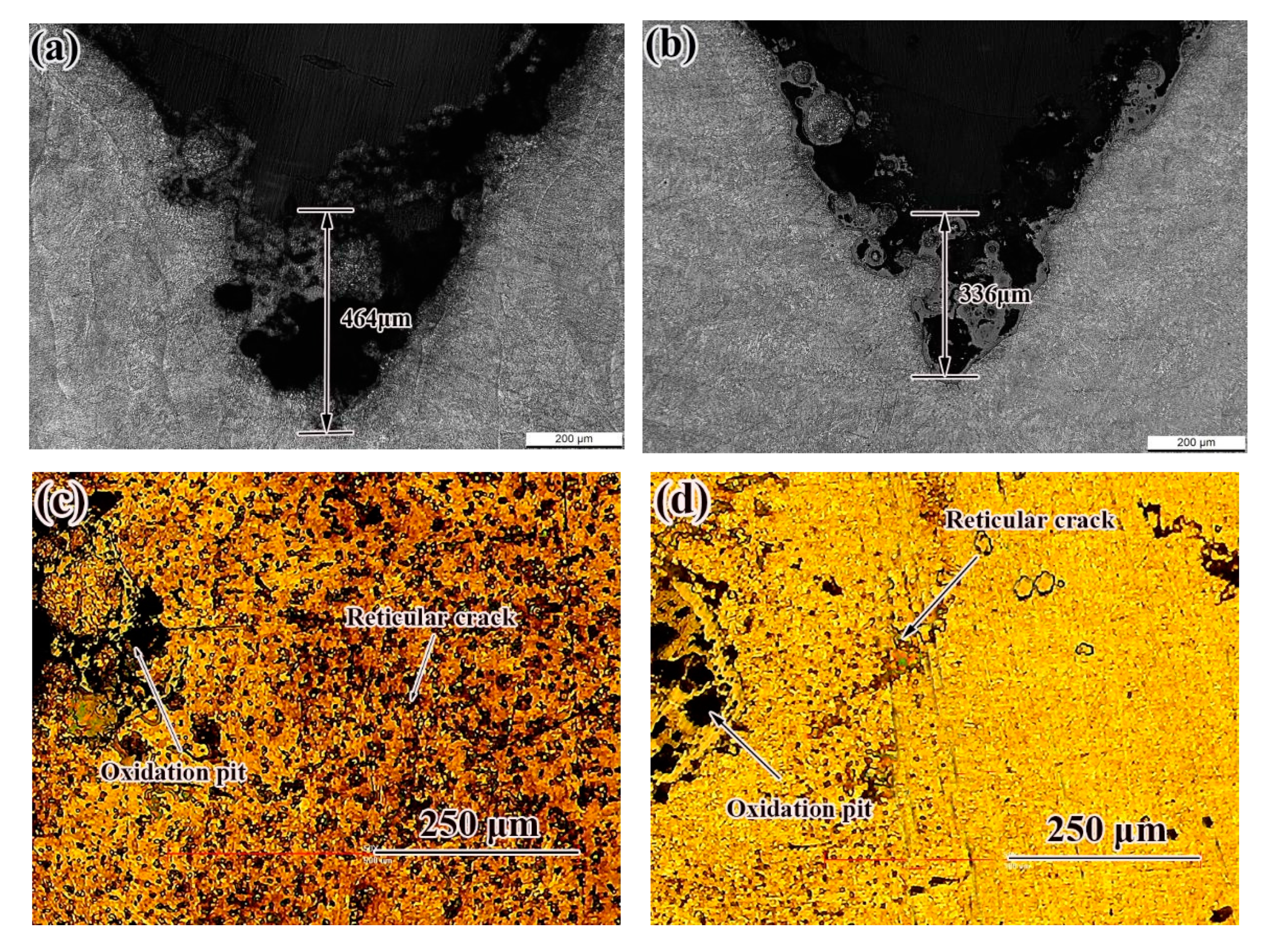

3.5. Thermal Fatigue Test Results and Analysis

4. Conclusions

- (1)

- Through the process optimization, the optimized parameters were obtained as follows: laser power P = 300 W, scanning speed V = 550 mm/s, scanning spacing d = 0.11 mm, fixed layer thickness h = 50 μm. Under the optimized parameters, the alloy steel samples were prepared with SLM, with a density of 99.8% and a hardness of 365–388 HV0.2.

- (2)

- With the increase of laser power, the density of deposited samples increased at first and then decreased, and decreased with the increase of scanning speed. At a low laser power, there were spherical particles in the overlap zone of the molten channel, then the enrichment of oxides or inclusions was easily formed during the solidification of the molten pool and cracks were finally formed under the action of stress.

- (3)

- The residual stress of the deposited sample was relatively large, which was about 50% of the yield strength of the material. The residual stress distribution of the SR sample showed that the residual stress was relatively stable and compressive, which improved the thermal fatigue performance. The gradient residual stress of the deposited sample decreased gradually from the surface layer to the base layer, which was mainly due to the stress caused by the relaxed thermal cycle deposition in front of the deposition layer. After SR, the performance and service life of the brake disc was effectively improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Han, J.; Li, W.; Pan, L. Low cycle fatigue behavior of Cr–Mo–V low alloy steel used for railway brake discs. Mater. Des. 2014, 56, 146–157. [Google Scholar] [CrossRef]

- Zeng, D.; Lu, L.; Gong, Y.; Zhang, N.; Gong, Y. Optimization of strength and toughness of railway wheel steel by alloy design. Mater. Des. 2016, 92, 998–1006. [Google Scholar] [CrossRef]

- Liu, S.; Wan, Y.; Ha, H.K.; Yoshida, Y.; Zhang, A. Impact of high-speed rail network development on airport traffic and traffic distribution: Evidence from China and Japan. Transp. Res. Part A 2019, 127, 115–135. [Google Scholar] [CrossRef]

- Li, W.; Kong, D. Effects of TiO2 Mass Fraction on Friction Reduction and Wear Resistance of Laser-Cladded CrNi Alloy Coating. J. Mater. Eng. Perform. 2021, 30, 2280–2290. [Google Scholar] [CrossRef]

- Bombač, D.; Gintalas, M.; Kugler, G.; Terčelj, M. Mechanisms of Oxidation Degradation of Cr12 Roller Steel during Thermal Fatigue Tests. Metals 2020, 10, 450. [Google Scholar] [CrossRef] [Green Version]

- Halil, K.; Cenk, M.; İbrahim, M. Investigation of the friction behavior of plasma spray Mo/NiCrBSi coated brake discs. Mater. Test. 2021, 63, 259–265. [Google Scholar]

- Song, S.W.; Lee, J.H.; Lee, H.J.; Bae, C.M.; Lee, C.S. Enhancing high-cycle fatigue properties of cold-drawn Fe-Mn-C TWIP steels. Int. J. Fatigue 2016, 85, 57–64. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.; Babu, S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Zhang, L.; Attar, H.; Calin, M.; Eckert, J. Review on manufacture by selective laser melting and properties of titanium based materials for biomedical applications. Mater. Technol. 2016, 31, 66–76. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, S.; Zhang, C.; Chen, J.; Zhang, J.; Liu, Y. Optimization of laser energy density and scanning strategy on the forming quality of 24CrNiMo low alloy steel manufactured by SLM. Mater. Charact. 2020, 170, 110718. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Z.; Tong, X.; Dong, S.; Cui, Z.; Wang, X.; Ren, L. Effects of process parameters on the microstructure and mechanical properties of 24CrNiMo steel fabricated by selective laser melting. Opt. Laser Technol. 2020, 128, 106262. [Google Scholar] [CrossRef]

- Sander, J.; Hufenbach, J.; Bleckmann, M.; Giebeler, L.; Wendrock, H.; Oswald, S.; Gemming, T.; Eckert, J.; Kühn, U. Selective laser melting of ultra-high-strength TRIP steel: Processing, microstructure, and properties. J. Mater. Sci. 2017, 52, 4944–4956. [Google Scholar] [CrossRef]

- Kurgan, N.; Varol, R. Mechanical properties of P/M 316L stainless steel materials. Powder Technol. 2010, 201, 242–247. [Google Scholar] [CrossRef]

- Zuo, P.; Chen, S.; Wei, M.; Zhou, L.; Liang, J.; Liu, C.; Wang, M. Microstructure evolution of 24CrNiMoY alloy steel parts by high power selective laser melting. J. Manuf. Process. 2019, 44, 28–37. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, S.; Yan, S.; Liu, X.; Liu, Y.; Xia, D.; Lv, Y.; He, P.; Xu, B.; Han, H. The effect of different scanning strategies on microstructural evolution to 24CrNiMo alloy steel during direct laser deposition. Mater. Sci. Eng. A 2020, 771, 138557. [Google Scholar] [CrossRef]

- Hajnys, J.; Pagáč, M.; Měsíček, J.; Petru, J.; Król, M. Influence of Scanning Strategy Parameters on Residual Stress in the SLM Process According to the Bridge Curvature Method for AISI 316L Stainless Steel. Materials 2020, 13, 1659. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Residual stress development in selective laser-melted Ti6Al4V: A parametric thermal modelling approach. Int. J. Adv. Manuf. Technol. 2018, 97, 2621–2633. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Dong, Z.H.; Kang, H.W.; Yang, C.; Xie, Y.J.; Ebrahimnia, M.; Peng, X. Enhancement of Strength–Ductility Balance of the Laser Melting Deposited 12CrNi2 Alloy Steel Via Multi-step Quenching Treatment. Acta Metall. Sin. (Engl. Lett.) 2021, 1–11. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Inaekyan, K.; Turenne, S.; Brailovski, V. Temperature- and Time-Dependent Mechanical Behavior of Post-Treated IN625 Alloy Processed by Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2019, 3, 75. [Google Scholar] [CrossRef] [Green Version]

- Tan, Z.; Gao, S.; Lan, L.; He, B. Effect of Rescanning Strategy on Residual Stress and Distortion of Two Alloys Manufactured by Selective Laser Melting. J. Mater. Eng. Perform. 2021, 1–9. [Google Scholar] [CrossRef]

- Van Puymbroeck, E.; Nagy, W.; Schotte, K.; Ul-Abdin, Z.; De Backer, H. Determination of Residual Welding Stresses in a Steel Bridge Component by Finite Element Modeling of the Incremental Hole-Drilling Method. Appl. Sci. 2019, 9, 536. [Google Scholar] [CrossRef] [Green Version]

- Van Den Berg, N.; Xin, H.; Veljkovic, M. Effects of residual stresses on fatigue crack propagation of an orthotropic steel bridge deck. Mater. Des. 2021, 198, 109294. [Google Scholar] [CrossRef]

- Jiang, W.; Xie, X.; Wang, T.; Zhang, X.; Tu, S.T.; Wang, J.; Zhao, X. Fatigue life prediction of 316L stainless steel weld joint including the role of residual stress and its evolution: Experimental and modelling. Int. J. Fatigue 2021, 143, 105997. [Google Scholar] [CrossRef]

- Nguyen, T.; Wahab, M. The effect of weld geometry and residual stresses on the fatigue of welded joints under combined loading. J. Mater. Process. Technol. 1998, 77, 201–208. [Google Scholar] [CrossRef]

- Ngoula, D.T.; Beier, H.; Vormwald, M. Fatigue Crack Growth in Cruciform Welded Joints: Influence of Residual Stresses and of the Weld Toe Geometry. Int. J. Fatigue 2017, 101, 253–262. [Google Scholar] [CrossRef]

- Webster, G.; Ezeilo, A. Residual stress distributions and their influence on fatigue lifetimes. Int. J. Fatigue 2001, 23, 375–383. [Google Scholar] [CrossRef]

- Zhao, Y.; Ding, C. Effect of Heat Treatment on Microstructure and Properties of 24CrNiMo Alloy Steel Formed by Selective Laser Melting (SLM). Materials 2021, 14, 631. [Google Scholar] [CrossRef]

| D10/μM | D50/μM | D90/μM | Testing Reference Standard | Preparation Method |

|---|---|---|---|---|

| 20.8 | 35.0 | 57.2 | GB/T14265 | Gas atomization pulverization |

| O/ppm | N/ppm | Testing Reference Standard |

|---|---|---|

| 256 | 39 | GB/T 19077 |

| Grade | Fe | C | Mn | Ni | Mo | Si | Cr | S |

|---|---|---|---|---|---|---|---|---|

| 24CrNiMo | Bal | 0.23 | 0.72 | 1.81 | 0.47 | 0.21 | 1.12 | 0.0031 |

| 30CrNiMo | Bal | 0.31 | 0.68 | 0.02 | 0.16 | 0.26 | 0.98 | 0.004 |

| Grade | Yield Strength (MPa) | Tensile Strength (MPA) | Elongation after Fracture (%) | Hardness (HV10) |

|---|---|---|---|---|

| 24CrNiMo | 960 | 1073 | 11.42 | 371 |

| 30CrNiMo | 986 | 1086 | 10.96 | 378 |

| V(mm/s) | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | |

|---|---|---|---|---|---|---|---|---|---|---|

| P(W) | ||||||||||

| 150 | 1 | 8 | 15 | 22 | 29 | 36 | 43 | 50 | 57 | |

| 200 | 2 | 9 | 16 | 23 | 30 | 37 | 44 | 51 | 58 | |

| 250 | 3 | 10 | 17 | 24 | 31 | 38 | 45 | 52 | 59 | |

| 300 | 4 | 11 | 18 | 25 | 32 | 39 | 46 | 53 | 60 | |

| 350 | 5 | 12 | 19 | 26 | 33 | 40 | 47 | 54 | 61 | |

| 400 | 6 | 13 | 20 | 27 | 34 | 41 | 48 | 55 | 62 | |

| 450 | 7 | 14 | 21 | 28 | 35 | 42 | 49 | 56 | 63 | |

| V(mm/s) | 470 | 500 | 530 | 570 | 600 | 630 | |

|---|---|---|---|---|---|---|---|

| P(W) | |||||||

| 300 | 1 | 5 | 9 | 13 | 17 | 21 | |

| 320 | 2 | 6 | 10 | 14 | 18 | 22 | |

| 340 | 3 | 7 | 11 | 15 | 19 | 23 | |

| 360 | 4 | 8 | 12 | 16 | 20 | 24 | |

| N | Density (%) | N | Density (%) | N | Density (%) | N | Density (%) | N | Density (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 96.99 | 14 | 99.17 | 27 | 98.90 | 40 | 98.63 | 53 | 97.42 |

| 2 | 99.08 | 15 | 94.05 | 28 | 99.01 | 41 | 98.87 | 54 | 98.20 |

| 3 | 99.02 | 16 | 98.68 | 29 | 89.05 | 42 | 98.88 | 55 | 98.51 |

| 4 | 99.34 | 17 | 99.09 | 30 | 95.89 | 43 | 87.00 | 56 | 98.18 |

| 5 | 99.30 | 18 | 99.07 | 31 | 98.08 | 44 | 92.39 | 57 | 86.45 |

| 6 | 99.24 | 19 | 99.09 | 32 | 98.64 | 45 | 96.49 | 58 | 89.21 |

| 7 | 99.26 | 20 | 99.02 | 33 | 98.37 | 46 | 98.16 | 59 | 94.12 |

| 8 | 95.70 | 21 | 99.03 | 34 | 98.36 | 47 | 98.73 | 60 | 96.78 |

| 9 | 99.18 | 22 | 90.37 | 35 | 98.58 | 48 | 98.72 | 61 | 97.75 |

| 10 | 99.06 | 23 | 96.06 | 36 | 87.08 | 49 | 98.04 | 62 | 98.21 |

| 11 | 99.21 | 24 | 96.71 | 37 | 94.44 | 50 | 86.88 | 63 | 98.23 |

| 12 | 99.17 | 25 | 98.90 | 38 | 97.27 | 51 | 90.45 | ||

| 13 | 99.18 | 26 | 98.93 | 39 | 98.85 | 52 | 95.32 |

| Sample | Residual Stress (MPa) | Test Location | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| Deposited | σx | 495 | 482 | 562 | 549 | 524 | 554 | 539 | 505 | 500 |

| σy | 583 | 566 | 507 | 518 | 522 | 525 | 453 | 477 | 556 | |

| SR | σx | −17 | −5 | −29 | −13 | −36 | −17 | −24 | −32 | −17 |

| σy | −25 | −6 | −35 | −2 | −36 | −14 | −11 | −11 | −23 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Ding, C.; Chen, H.; Chen, Y. Study on SLM Forming Process, Residual Stress and Thermal Fatigue of 24CrNiMo Alloy Steel. Materials 2021, 14, 4383. https://doi.org/10.3390/ma14164383

Zhao Y, Ding C, Chen H, Chen Y. Study on SLM Forming Process, Residual Stress and Thermal Fatigue of 24CrNiMo Alloy Steel. Materials. 2021; 14(16):4383. https://doi.org/10.3390/ma14164383

Chicago/Turabian StyleZhao, Yongsheng, Chenggang Ding, Hui Chen, and Yong Chen. 2021. "Study on SLM Forming Process, Residual Stress and Thermal Fatigue of 24CrNiMo Alloy Steel" Materials 14, no. 16: 4383. https://doi.org/10.3390/ma14164383

APA StyleZhao, Y., Ding, C., Chen, H., & Chen, Y. (2021). Study on SLM Forming Process, Residual Stress and Thermal Fatigue of 24CrNiMo Alloy Steel. Materials, 14(16), 4383. https://doi.org/10.3390/ma14164383