Key Factors Determining the Self-Healing Ability of Cement-Based Composites with Mineral Additives

Abstract

:1. Introduction

- autogenous (natural),

2. Materials and Methods

2.1. The Research Plan

2.2. Preparation of Mortar Samples

2.3. Preparation of Concrete Samples

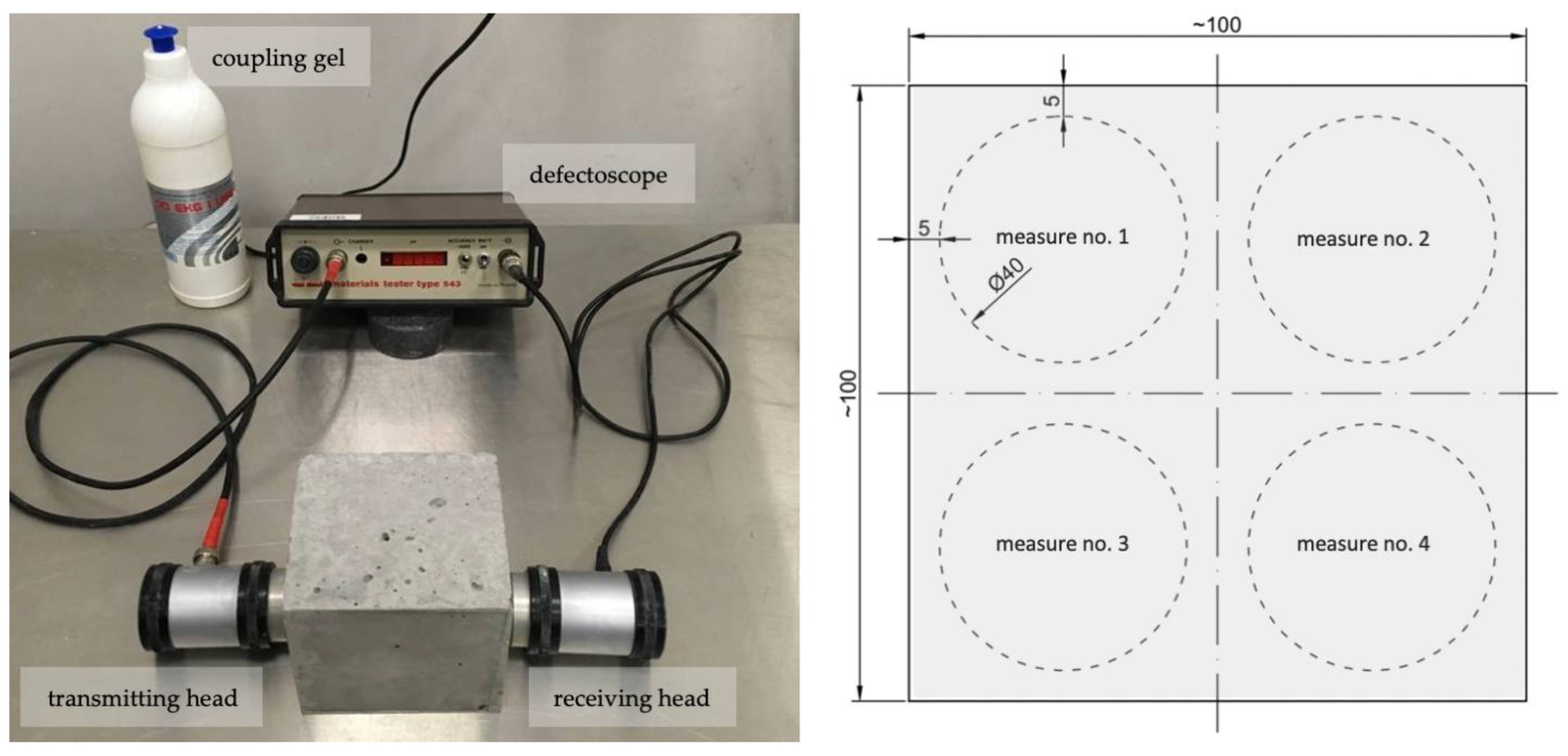

2.4. Induction of Defects

2.5. Test Methods

3. Results and Discussions

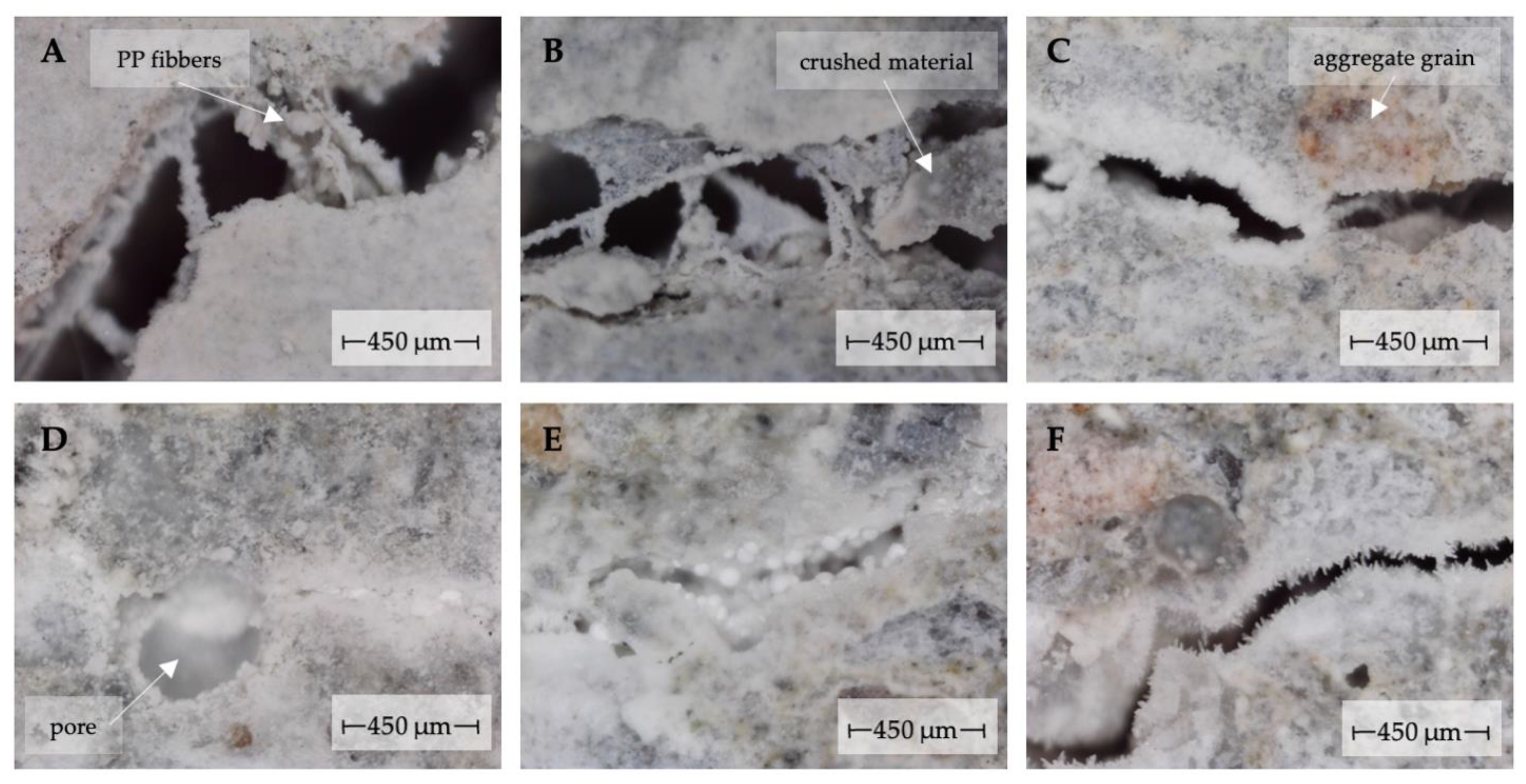

3.1. Microscopic Observations

3.2. Microstructure and Age of the Composite at the Time of Defect Formation vs. Self-Sealing Efficiency

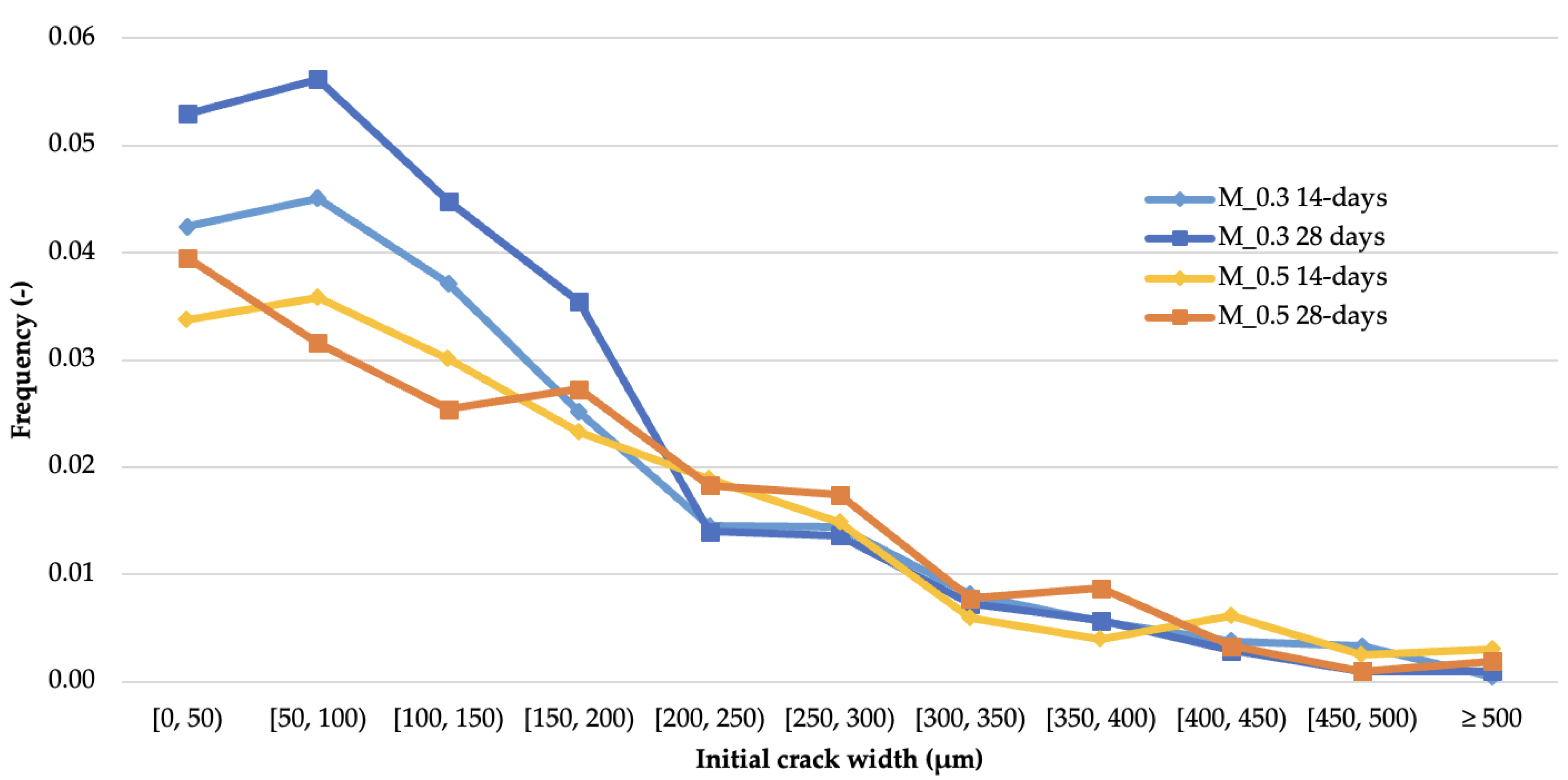

3.3. Initial Crack Geometry vs. Cases of Complete Crack Sealing

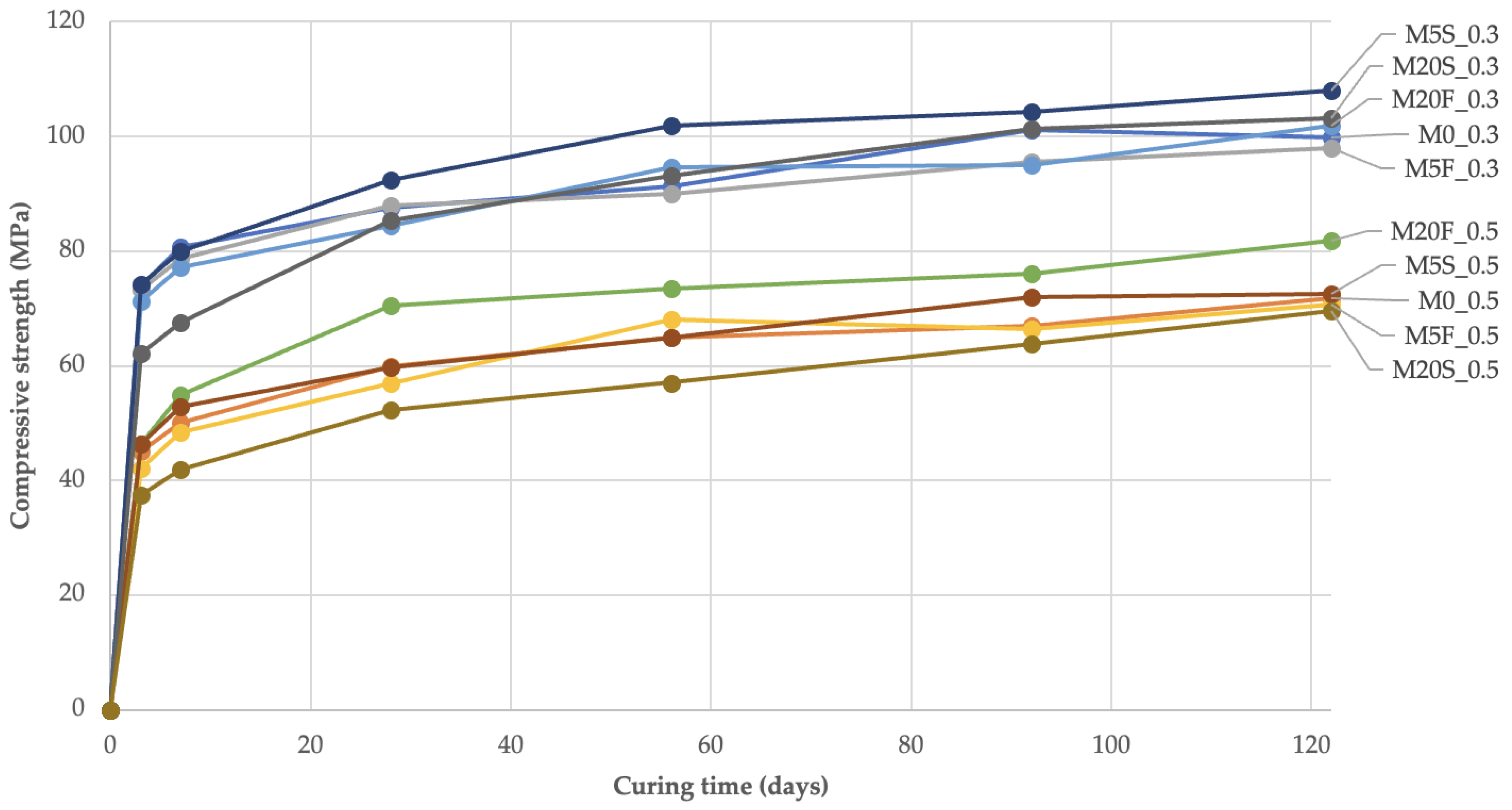

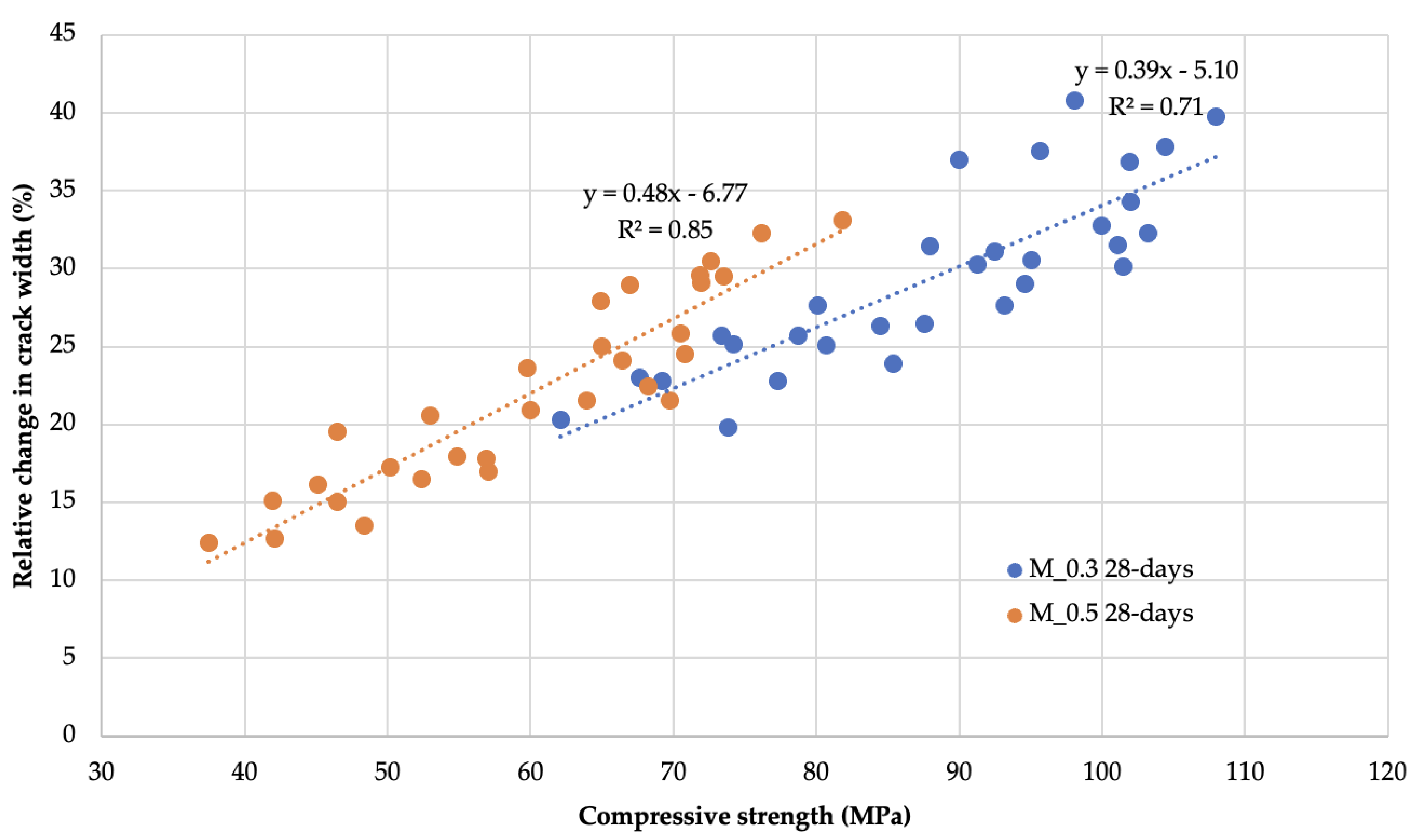

3.4. Binder Activity in the Composite vs. Reduction of Crack Width

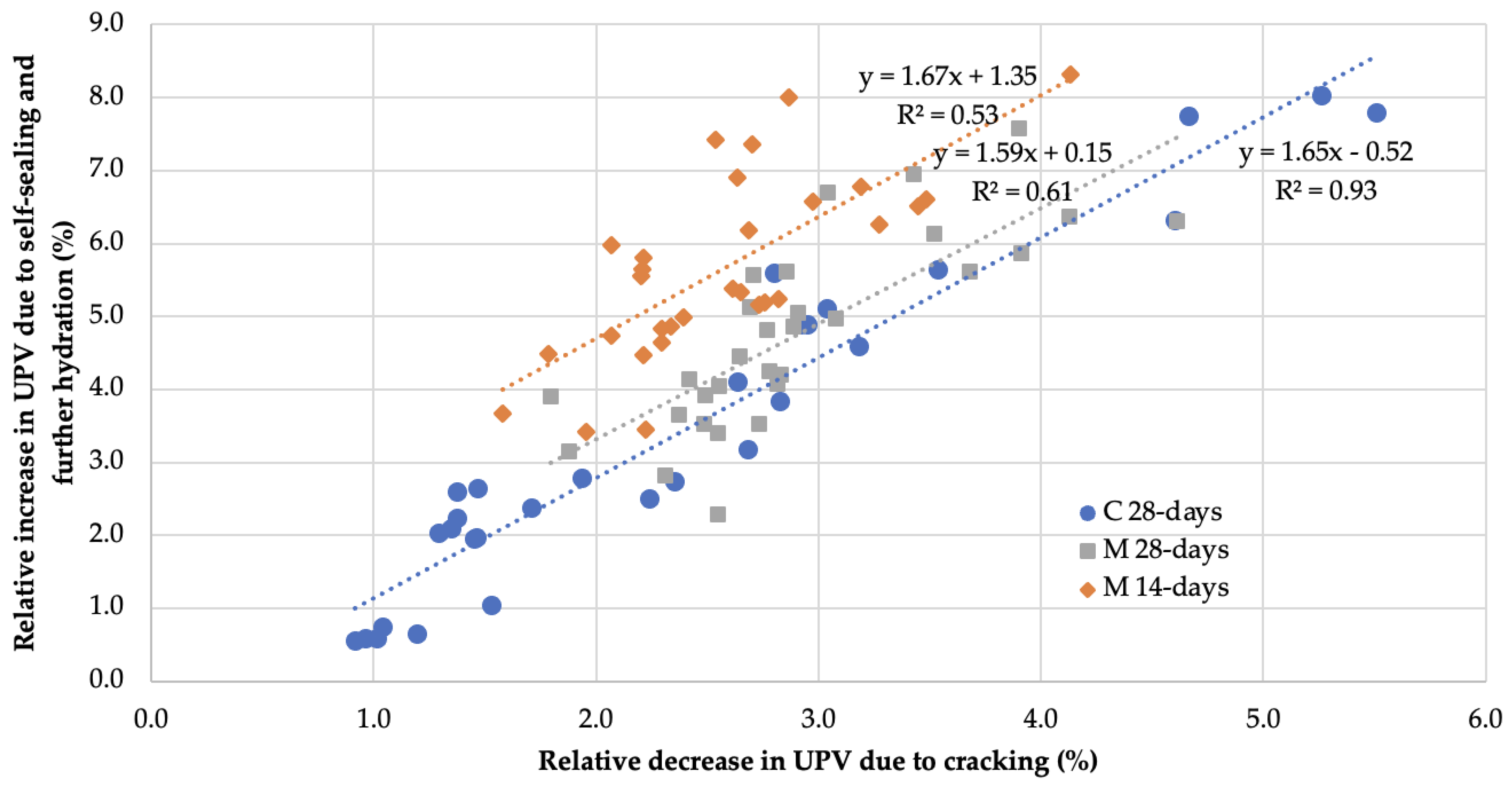

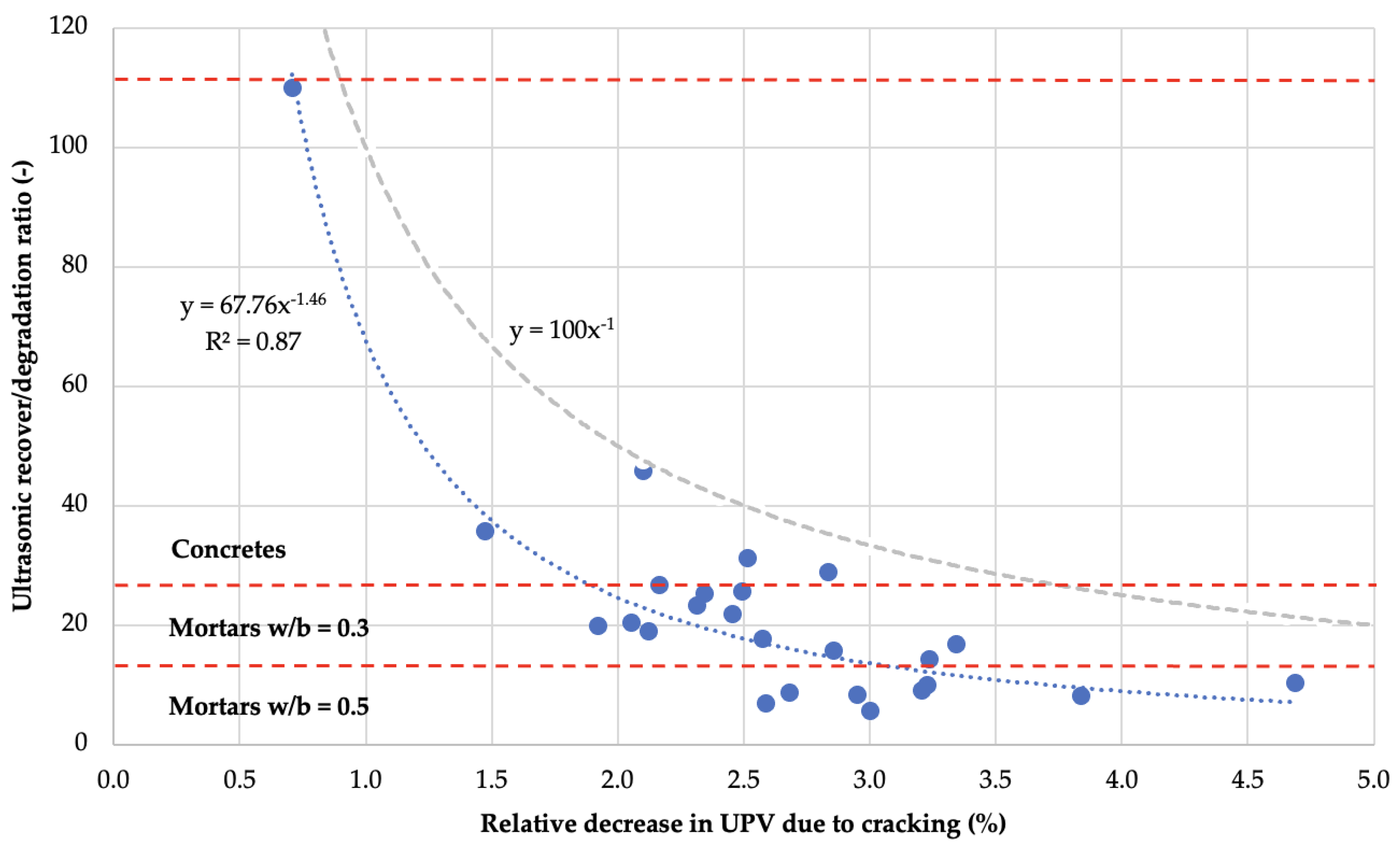

3.5. Degree of Composite Damage vs. Self-Sealing Efficiency

4. Conclusions

- Apart from certain deviations from the general course, the percentage of cases of complete filling of cracks clearly decreased with increasing initial crack width. These data indicate a significant influence of the initial crack width on the efficiency of self-sealing, particularly in terms of the recovery of the complete integrity of the composite structure.

- In a composite with dispersed reinforcement subjected to mechanical loading, the course of deformation, as well as crack propagation, depends on the deformability of the material and the development of bonds between the reinforcement fibers and the cement matrix. In this case, a shorter aging time was associated with a greater susceptibility to deformation and poorer fiber bonds with the surrounding matrix, which in effect may lead to a change in geometric characteristics of micro- and macro-defects formed during loading in comparison to an analogous material and loading method after a longer aging period.

- According to the captured data quantitatively describing changes in the vicinity of cracks as a result of post-damage curing, the shorter the composite aging time or lower water-to-binder ratio, the higher the self-sealing effects.

- As demonstrated by the analysis of the results, the compressive strength as a mechanical measure of binder activity can be used to predict the self-sealing ability of cement composites and the dynamics of this process.

- The analyses of the dependence of ultrasonic wave velocity changes caused by the created defects and the subsequent self-sealing process confirmed the existence of the dependence of self-sealing efficiency on the damage degree of the material. Moreover, the linear dependence in the whole range of the analyzed data indicates that the damage state introduced in the mortar and concrete samples did not reach the limit above which the intensity of self-sealing decreases.

- Significant differences in the self-sealing efficiency for mortars and concretes were observed when the results describing pure self-sealing were analyzed. The results indicated that the phenomena related strictly to self-sealing led to more intense changes in the case of micro-defects in concretes, which have much smaller widths than in the case of macro-defects in mortar samples.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yuan, Y.C.; Yin, T.; Rong, M.Z.; Zhang, M.Q. Self healing in polymers and polymer composites. Concepts, realization and outlook: A review. Express Polym. Lett. 2008, 2, 238–250. [Google Scholar] [CrossRef]

- Van der Zwaag, S. An Introduction to Material Design Principles: Damage Prevention versus Damage Management. In Self Healing Materials. An Alternative Approach to 20 Centuries of Materials Science; Springer: Dordrecht, The Netherlands, 2007; Volume 100, pp. 1–18. [Google Scholar]

- Rooij, D.; van Tittelboom, K.; Belie, N.; Schlangen, E. Self-Healing Phenomena in Cement-Based Materials; Springer: Dordrecht, The Netherlands, 2013; Volume 11. [Google Scholar]

- Alyousif, A.; Lachemi, M.; Yildirim, G.; Şahmaran, M. Effect of self-healing on the different transport properties of cementitious composites. J. Adv. Concr. Technol. 2015, 13, 112–123. [Google Scholar] [CrossRef] [Green Version]

- Gruyaert, E.; van Tittelboom, K.; Rahier, H.; de Belie, N. Activation of pozzolanic and latent-hydraulic reactions by alkalis in order to repair concrete cracks. J. Mater. Civ. Eng. 2015, 27, 04014208. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Zhang, Z.; Yang, Y.; Yao, Y. Measurement and correlation of ductility and compressive strength for engineered cementitious composites (ECC) produced by binary and ternary systems of binder materials: Fly ash, slag, silica fume and cement. Constr. Build. Mater. 2014, 68, 192–198. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yildirim, G.; Erdem, T.K. Self-healing capability of cementitious composites incorporating different supplementary cementitious materials. Cem. Concr. Compos. 2013, 35, 89–101. [Google Scholar] [CrossRef] [Green Version]

- Kishi, T.; Ahn, T.; Hosoda, A.; Suzuki, S.; Takaoka, H. Self healing behaviour by cementitious recrystallization of cracked concrete incorporating expansive agent. In Proceedings of the First International Conference on Self Healing Materials, Noordwijk, The Netherlands, 18–20 April 2007. [Google Scholar]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Effect of exposure conditions on self healing behavior of strain hardening cementitious composites incorporating various cementitious materials. Constr. Build. Mater. 2013, 42, 217–224. [Google Scholar] [CrossRef]

- Bang, S.S.; Galinat, J.K.; Ramakrishnan, V. Calcite precipitation induced by polyurethane-immobilized Bacillus pasteurii. Enzyme Microb. Technol. 2001, 28, 404–409. [Google Scholar] [CrossRef]

- Sarda, D.; Choonia, H.S.; Sarode, D.D.; Lele, S.S. Biocalcification by Bacillus pasteurii urease: A novel application. J. Ind. Microbiol. Biotechnol. 2009, 36, 1111–1115. [Google Scholar] [CrossRef]

- De Muynck, W.; Cox, K.; de Belie, N.; Verstraete, W. Bacterial carbonate precipitation as an alternative surface treatment for concrete. Constr. Build. Mater. 2008, 22, 875–885. [Google Scholar] [CrossRef]

- De Muynck, W.; de Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Siddique, R.; Chahal, N.K. Effect of ureolytic bacteria on concrete properties. Constr. Build. Mater. 2011, 25, 3791–3801. [Google Scholar] [CrossRef]

- Braissant, O.; Decho, A.W.; Dupraz, C.; Glunk, C.; Przekop, K.M.; Visscher, P.T. Exopolymeric substances of sulfate-reducing bacteria: Interactions with calcium at alkaline pH and implication for formation of carbonate minerals. Geobiology 2007, 5, 401–411. [Google Scholar] [CrossRef]

- Łukowski, P.; Adamczewski, G. Preliminary evaluation of possibilities of self-repair of epoxy-cement composite. In Proceedings of the XXV Konferencja Naukowo-Techniczna “Awarie Budowlane 2011”, Międzyzdroje, Poland, 24–27 May 2011; pp. 1135–1142. [Google Scholar]

- Li, W.; Jiang, Z.; Yang, Z.; Zhao, N.; Yuan, W. Self-healing efficiency of cementitious materials containing microcapsules filled with healing adhesive: Mechanical restoration and healing process monitored by water absorption. PLoS ONE 2013, 8, e0081616. [Google Scholar] [CrossRef] [PubMed]

- Van Tittelboom, K.; de Belie, N.; van Loo, D.; Jacobs, P. Self-healing efficiency of cementitious materials containing tubular capsules filled with healing agent. Cem. Concr. Compos. 2011, 33, 497–505. [Google Scholar] [CrossRef]

- Sangadji, S.; Schlangen, E. Self healing of concrete structures—Novel approach using porous network concrete. J. Adv. Concr. Technol. 2012, 10, 185–194. [Google Scholar] [CrossRef] [Green Version]

- Jacobsen, S.; Sellevold, E.J. Self healing of high strength concrete after deterioration by freeze/thaw. Cem. Concr. Res. 1996, 26, 55–62. [Google Scholar] [CrossRef]

- Schlangen, E.; ter Heide, N.; van Breugel, K. Crack healing of early age cracks in concrete. In Measuring, Monitoring and Modeling Concrete Properties; Springer: Dordrecht, The Netherlands, 2006; pp. 273–284. [Google Scholar]

- Edvardsen, C. Water permeability and autogenous healing of cracks in concrete. ACI Mater. J. 1999, 96, 448–454. [Google Scholar]

- Yang, Y.; Lepech, M.D.; Yang, E.H.; Li, V.C. Autogenous healing of engineered cementitious composites under wet-dry cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Parks, J.; Edwards, M.; Vikesland, P.; Dudi, A. Effects of bulk water chemistry on autogenous healing of concrete. J. Mater. Civ. Eng. 2010, 22, 515–524. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Qian, C.; Schlangen, E. Self-healing in cementitious materials: Materials, methods and service conditions. Mater. Des. 2016, 92, 499–511. [Google Scholar] [CrossRef]

- Ramm, W.; Biscoping, M. Autogenous healing and reinforcement corrosion of water-penetrated separation cracks in reinforced concrete. Nucl. Eng. Des. 1998, 179, 191–200. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J. The effects of age, cement content, and healing time on the self-healing ability of high-strength concrete. Constr. Build. Mater. 2018, 187, 149–159. [Google Scholar] [CrossRef]

- Van Breugel, K. Societal Burden and Engineering Challenges of Ageing Infrastructure. Procedia Eng. 2017, 171, 53–63. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Gruyaert, E.; Rahier, H.; de Belie, N. Influence of mix composition on the extent of autogenous crack healing by continued hydration or calcium carbonate formation. Constr. Build. Mater. 2012, 37, 349–359. [Google Scholar] [CrossRef]

- Nergis, D.D.B.; Vizureanu, P.; Ardelean, I.; Sandu, A.V.; Corbu, O.C.; Matei, E. Revealing the Influence of Microparticles on Geopolymers’ Synthesis and Porosity. Materials 2020, 13, 3211. [Google Scholar] [CrossRef]

- De Belie, N. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 17. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D. Microscopic observations of self-healing products in calcareous fly ash mortars. Microsc. Res. Tech. 2015, 78, 22–29. [Google Scholar] [CrossRef]

- Siad, H. Influence of limestone powder on mechanical, physical and self-healing behavior of Engineered Cementitious Composites. Constr. Build. Mater. 2015, 99, 1–10. [Google Scholar] [CrossRef]

- Yildirim, G.; Sahmaran, M.; Ahmed, H.U. Influence of Hydrated Lime Addition on the Self-Healing Capability of High-Volume Fly Ash Incorporated Cementitious Composites. J. Mater. Civ. Eng. 2015, 27, 04014187. [Google Scholar] [CrossRef]

- Yıldırım, G.; Khiavi, A.H.; Yeşilmen, S.; Şahmaran, M. Self-healing performance of aged cementitious composites. Cem. Concr. Compos. 2018, 87, 172–186. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J.; Kotwica, Ł. Enhanced autogenous self-healing of cement-based composites with mechanically activated fluidized-bed combustion fly ash. Constr. Build. Mater. 2021, 300, 124028. [Google Scholar] [CrossRef]

- Mor, A.; Monteiro, P.; Hester, W. Observations of Healing of Cracks in High-Strength Lightweight Concrete. Cem. Concr. Aggreg. 1989, 11, 121–125. [Google Scholar] [CrossRef]

- Granger, S.; Cabot, G.P.; Loukili, A.; Marlot, D.; Lenain, J.C. Monitoring of cracking and healing in an ultra high performance cementitious material using the time reversal technique. Cem. Concr. Res. 2009, 39, 296–302. [Google Scholar] [CrossRef] [Green Version]

- Qian, S.; Zhou, J.; de Rooij, M.R.; Schlangen, E.; Ye, G.; van Breugel, K. Self-healing behavior of strain hardening cementitious composites incorporating local waste materials. Cem. Concr. Compos. 2009, 31, 613–621. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Moscato, S.; Serna, P.; Ferrara, L. Self-healing capability of concrete with crystalline admixtures in different environments. Constr. Build. Mater. 2015, 86, 1–11. [Google Scholar] [CrossRef]

- Zamorowski, W. The phenomenon of self-regeneration of concrete. Int. J. Cem. Compos. Light. Concr. 1985, 7, 199–201. [Google Scholar] [CrossRef]

- Hosoda, A.; Higuchi, T.; Eguchi, M.; Yoshida, H.; Aoki, H. Self Healing of Longitudinal Cracks in Utility Concrete Pole. J. Adv. Concr. Technol. 2012, 10, 278–284. [Google Scholar] [CrossRef] [Green Version]

- Zhong, W.; Yao, W. Influence of damage degree on self-healing of concrete. Constr. Build. Mater. 2008, 22, 1137–1142. [Google Scholar] [CrossRef]

- Li, V.C.; Yang, E.-H. Self Healing in Concrete Materials. In Self Healing Materials; Springer Series in Materials Science; van der Zwaag, S., Ed.; Springer: Dordrecht, The Netherlands, 2007; Volume 100, pp. 161–193. [Google Scholar]

- Yang, E. Designing Added Functions in Engineered Cementitious Composites; University of Michigan: Ann Arbor, MI, USA, 2008. [Google Scholar]

- Li, V.C. Engineered Cementitious Composites (ECC): Bendable Concrete for Sustainable and Resilient Infrastructure; Springer: Dordrecht, The Netherlands, 2019. [Google Scholar]

- Hosoda, A.; Komatsu, S.; Ahn, T.; Kishi, T.; Ikeno, S.; Kobayashi, K. Self healing properties with various crack widths under continuous water leakage. In Concrete Repair, Rehabilitation and Retrofitting II, Proceedings of the 2nd International Conference on Concrete Repair, Rehabilitation and Retrofitting (ICCRRR), Cape Town, South Africa, 24–26 November 2008; CRC Press: Boca Raton, FL, USA, 2008; pp. 121–122. [Google Scholar] [CrossRef]

- Palin, D.; Wiktor, V.; Jonkers, H.M. Autogenous healing of marine exposed concrete: Characterization and quantification through visual crack closure. Cem. Concr. Res. 2015, 73, 17–24. [Google Scholar] [CrossRef]

- Khan, M.B.E.; Shen, L.; Dias-da-Costa, D. Characterisation of autogenous healing in cracked mortars under marine water exposure. Mag. Concr. Res. 2021, 1–16. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Jooss, M. Permeability and self-healing of cracked concrete as a function of temperature and crack width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- Suleiman, A.R.; Nehdi, M.L. Effect of environmental exposure on autogenous self-healing of cracked cement-based materials. Cem. Concr. Res. 2018, 111, 197–208. [Google Scholar] [CrossRef]

- Gazdič, D.; Fridrichová, M.; Kulísek, K.; Vehovská, L. The Potential Use of the FBC Ash for the Preparation of Blended Cements. Procedia Eng. 2017, 180, 1298–1305. [Google Scholar] [CrossRef]

- Robl, T.; Mahboub, K.; Stevens, W.; Rathbone, R. Fluidized bed combustion ash utilization: CFBC fly ash as a pozzolanic additive to portland cement concrete. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 169–177. [Google Scholar]

- Łagosz, A.; Tracz, T.; Mróz, R. Extending the Life Cycle of Cement Binders by Partially Replacing Portland Cement with Different Types Fluidized Bed Combustion Fly Ash. Minerals 2021, 11, 690. [Google Scholar] [CrossRef]

- Stryczek, S.; Brylicki, W.; Małolepszy, J.; Gonet, A.; Wiśniowski, R.; Kotwica, Ł. Potential use of fly ash from fluidal combustion of brown coal in cementing slurries for drilling and geotechnical works. Arch. Min. Sci. 2009, 54, 775–786. [Google Scholar]

- Blajer, M.; Stopkowicz, A.; Adamczyk, J.; Cala, M. The preliminary research of the physico-mechanical properties of aggregates based on the colliery shale, supplemented by fly ash. Arch. Min. Sci. 2019, 64, 21–34. [Google Scholar] [CrossRef]

- Konkol, J.; Prokopski, G. The optimization of concretes modified with FBC fly ash. Roads Bridg. Drog. Most. 2014, 13, 103–114. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Jóźwiak-Niedzwiedzka, D.; Dabrowski, M. The influence of fluidized bed combustion fly ash on the phase composition and microstructure of cement paste. Materials 2019, 12, 2838. [Google Scholar] [CrossRef] [Green Version]

- Zahedi, M.; Rajabipour, F. Fluidized Bed Combustion (FBC) fly ash and its performance in concrete. ACI Mater. J. 2019, 116, 163–172. [Google Scholar] [CrossRef]

- AT-15-9464/2015. FLUBET Additive for Concrete Modification (in Polish); Instytut Techniki Budowlanej: Warsaw, Poland, 2015. [Google Scholar]

- Zapotoczna-Sytek, G.; Łaskawiec, K.; Gębarowski, P.; Małolepszy, J.; Szymczak, J. Popioły Lotne Nowej Generacji Do Produkcji Autoklawizowanego Betonu Komórkowego—Monografia (in Polish); Wydawnictwo Instytut Śląski Sp. z o.o.: Opole, Poland, 2013. [Google Scholar]

- Tomczak, K.; Jakubowski, J.; Fiołek, P. Method for Assessment of Changes in the Width of Cracks in Cement Composites with Use of Computer Image Processing and Analysis. Stud. Geotech. Mech. 2017, 39, 73–80. [Google Scholar] [CrossRef] [Green Version]

- Tomczak, K.; Jakubowski, J.; Kotwica, Ł. Self-Sealing Process Evaluation Method Using Ultrasound Technique in Cement Composites with Mineral Additives. Materials 2020, 13, 3336. [Google Scholar] [CrossRef] [PubMed]

- Kotwica, Ł.; Pichór, W.; Kapeluszna, E.; Różycka, A. Utilization of waste expanded perlite as new effective supplementary cementitious material. J. Clean. Prod. 2017, 140, 1344–1352. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- Xu, J.; Tang, Y.; Wang, X.; Wang, Z.; Yao, W. Application of ureolysis-based microbial CaCO3 precipitation in self-healing of concrete and inhibition of reinforcement corrosion. Constr. Build. Mater. 2020, 265, 120364. [Google Scholar] [CrossRef]

| Designation of | Material Type | Samples Dimensions (mm) | Sample Count | Crack Indications | Research Conducted | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Groups | Types | Materials | Age (Days) | Method | MT | HRS | UPV | MO | |||

| M | M_q | Mp(F/S)_q | mortar | 25 × 25 × 100 | 360 | - | - | + | − | − | − |

| M 14-days | mortar with PP fibers | 40 × 40 × 160 | 60 | 14 | three-point bending | − | + | + | + | ||

| M 28-days | 28 | ||||||||||

| C 28-days | C_q | Cp(F)_q | concrete | 100 × 100 × 100 | 60 | 28 | cyclic compression | − | − | + | − |

| Content of Ingredient (%) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | SO3 | Na2O | K2O | P2O5 | Cl | Other | Loss on Ignition | CaOfree 1 | Na2Oeq. 2 | |

| CEM I 42.5R | 17.90 | 5.60 | 2.61 | 63.11 | 1.17 | 0.36 | 4.02 | 0.34 | 0.78 | 0.13 | 0.09 | 0.25 | 3.66 | 1.49 | 0.85 |

| MAFBC fly ash | 37.78 | 31.55 | 3.61 | 10.87 | 2.00 | 3.40 | 3.84 | 2.13 | 1.17 | 0.34 | 0.03 | 0.40 | 2.89 | 2.65 | 2.90 |

| Siliceous fly ash | 46.92 | 28.54 | 7.23 | 3.39 | 2.31 | 1.32 | 1.87 | 4.83 | 2.08 | 0.31 | 0.02 | 0.45 | 0.72 | 0.30 | 6.19 |

| Mortar Type M_q | Mortar Mp(F/S)_q | CEM I 42.5R (g) | MAFBC Fly Ash (g) | Siliceous Fly Ash (g) | CEN-Standard Sand (g) | Water (g) | SP (g) | PP 1 (g) | w/b 2 (−) |

|---|---|---|---|---|---|---|---|---|---|

| M_0.3 | M0_0.3 | 550.0 | 0.0 | 0.0 | 1350.0 | 160.83 | 5.50 | 15.63 | 0.30 |

| M5F_0.3 | 522.5 | 27.5 | 0.0 | 156.65 | 11.00 | 15.67 | |||

| M20F_0.3 | 440.0 | 110.0 | 0.0 | 148.30 | 22.00 | 15.79 | |||

| M5S_0.3 | 522.5 | 0.0 | 27.5 | 157.69 | 9.63 | 15.70 | |||

| M20S_0.3 | 440.0 | 0.0 | 110.0 | 149.35 | 20.63 | 15.93 | |||

| M_0.5 | M0_0.5 | 550.0 | 0,0 | 0.0 | 274.50 | 0.66 | 17.61 | 0.50 | |

| M5F_0.5 | 522.5 | 27.5 | 0.0 | 273.96 | 1.38 | 17.64 | |||

| M20F_0.5 | 440.0 | 110.0 | 0.0 | 272.91 | 2.75 | 17.72 | |||

| M5S_0.5 | 522.5 | 0.0 | 27.5 | 273.96 | 1.38 | 17.68 | |||

| M20S_0.5 | 440.0 | 0.0 | 110.0 | 272.91 | 2.75 | 17.87 |

| Concrete Type C_q | Concrete Cp(F)_q | CEM I 42.5R (kg) | MAFBC Fly Ash (kg) | Aggregate 0/2 (kg) | Aggregate 2/8 (kg) | Water (kg) | SP (kg) | w/b 1 (−) |

|---|---|---|---|---|---|---|---|---|

| C_0.25 | C0_0.25 | 480.2 | 0.0 | 541.1 | 1288.4 | 123.6 | 10.474 | 0.25 |

| C20F_0.25 | 380.3 | 95.1 | 114.6 | 20.533 | ||||

| C_0.4 | C0_0.4 | 400.0 | 0.0 | 175.3 | 1.217 | 0.40 | ||

| C5F_0.4 | 369.4 | 19.4 | 170.8 | 2.205 | ||||

| C20F_0.4 | 314.7 | 78.7 | 169.5 | 4.851 |

| Mortar Mp(F/S)_q | Mortar Type M_q | Average Crack Width Change (μm) | Average Relative Crack Width Change (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| M 14-Days | M 28-Days | M 14-Days | M 28-Days | ||||||

| M0_0.3 | M_0.3 | 116.9 | 116.2 | 80.8 | 103.9 | 40.6 | 37.2 | 32.2 | 36.3 |

| M5F_0.3 | 128.8 | 118.4 | 42.3 | 40.7 | |||||

| M20F_0.3 | 110.3 | 115.4 | 35.6 | 36.2 | |||||

| M5S_0.3 | 100.6 | 114.3 | 29.2 | 40.2 | |||||

| M20S_0.3 | 124.2 | 90.5 | 38.2 | 32.1 | |||||

| M0_0.5 | M_0.5 | 101.4 | 110.1 | 76.9 | 87.4 | 31.3 | 33.3 | 32.4 | 28.3 |

| M5F_0.5 | 113.8 | 70.7 | 32.8 | 23.8 | |||||

| M20F_0.5 | 105.6 | 106.5 | 33.1 | 32.5 | |||||

| M5S_0.5 | 114.3 | 90.3 | 35.7 | 30.2 | |||||

| M20S_0.5 | 115.2 | 92.5 | 33.7 | 22.5 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomczak, K.; Jakubowski, J.; Kotwica, Ł. Key Factors Determining the Self-Healing Ability of Cement-Based Composites with Mineral Additives. Materials 2021, 14, 4211. https://doi.org/10.3390/ma14154211

Tomczak K, Jakubowski J, Kotwica Ł. Key Factors Determining the Self-Healing Ability of Cement-Based Composites with Mineral Additives. Materials. 2021; 14(15):4211. https://doi.org/10.3390/ma14154211

Chicago/Turabian StyleTomczak, Kamil, Jacek Jakubowski, and Łukasz Kotwica. 2021. "Key Factors Determining the Self-Healing Ability of Cement-Based Composites with Mineral Additives" Materials 14, no. 15: 4211. https://doi.org/10.3390/ma14154211

APA StyleTomczak, K., Jakubowski, J., & Kotwica, Ł. (2021). Key Factors Determining the Self-Healing Ability of Cement-Based Composites with Mineral Additives. Materials, 14(15), 4211. https://doi.org/10.3390/ma14154211