Influence of Rapid Heat Treatment on the Shrinkage and Strength of High-Performance Concrete

Abstract

:1. Introduction

2. Materials and Methods

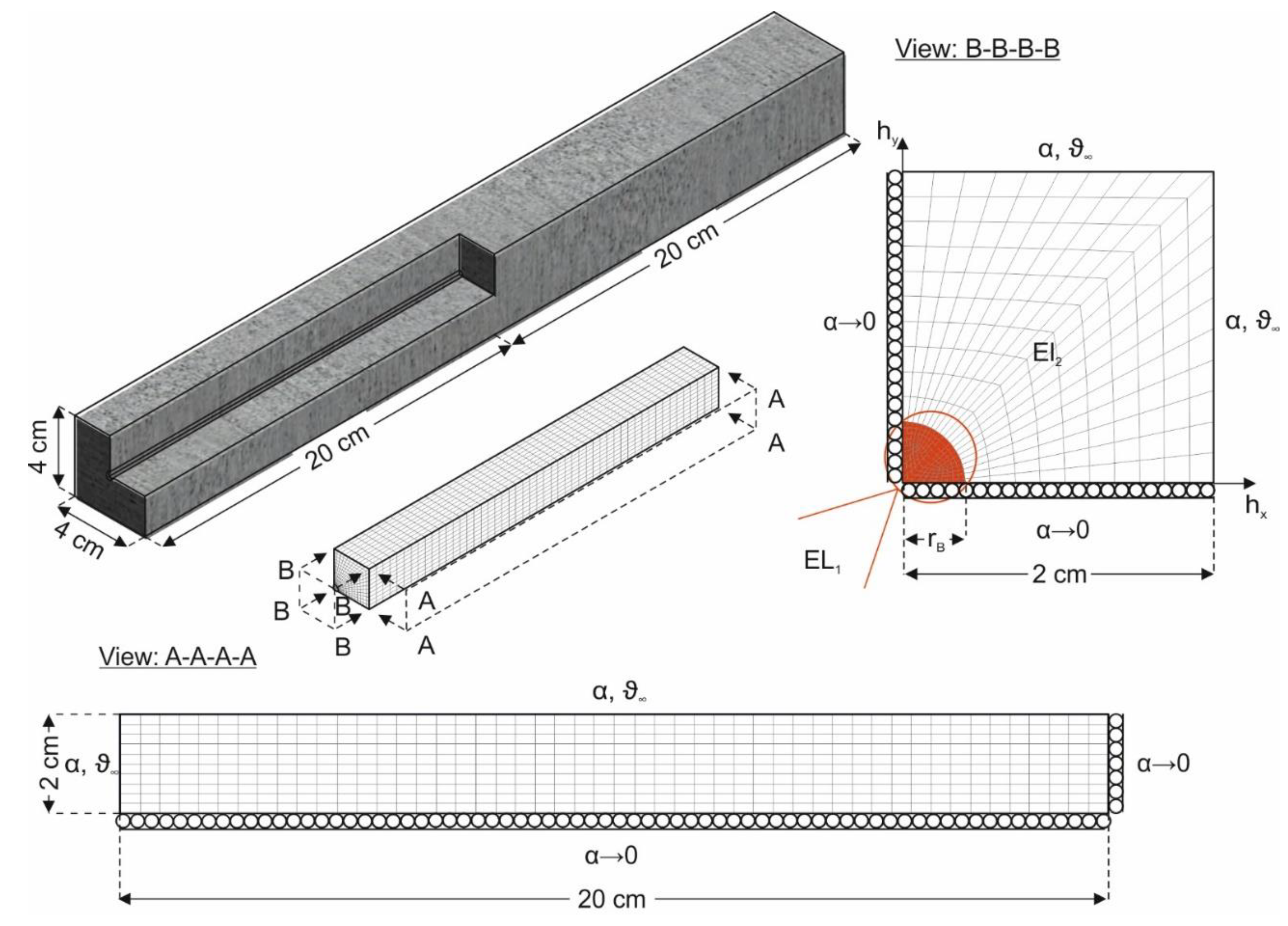

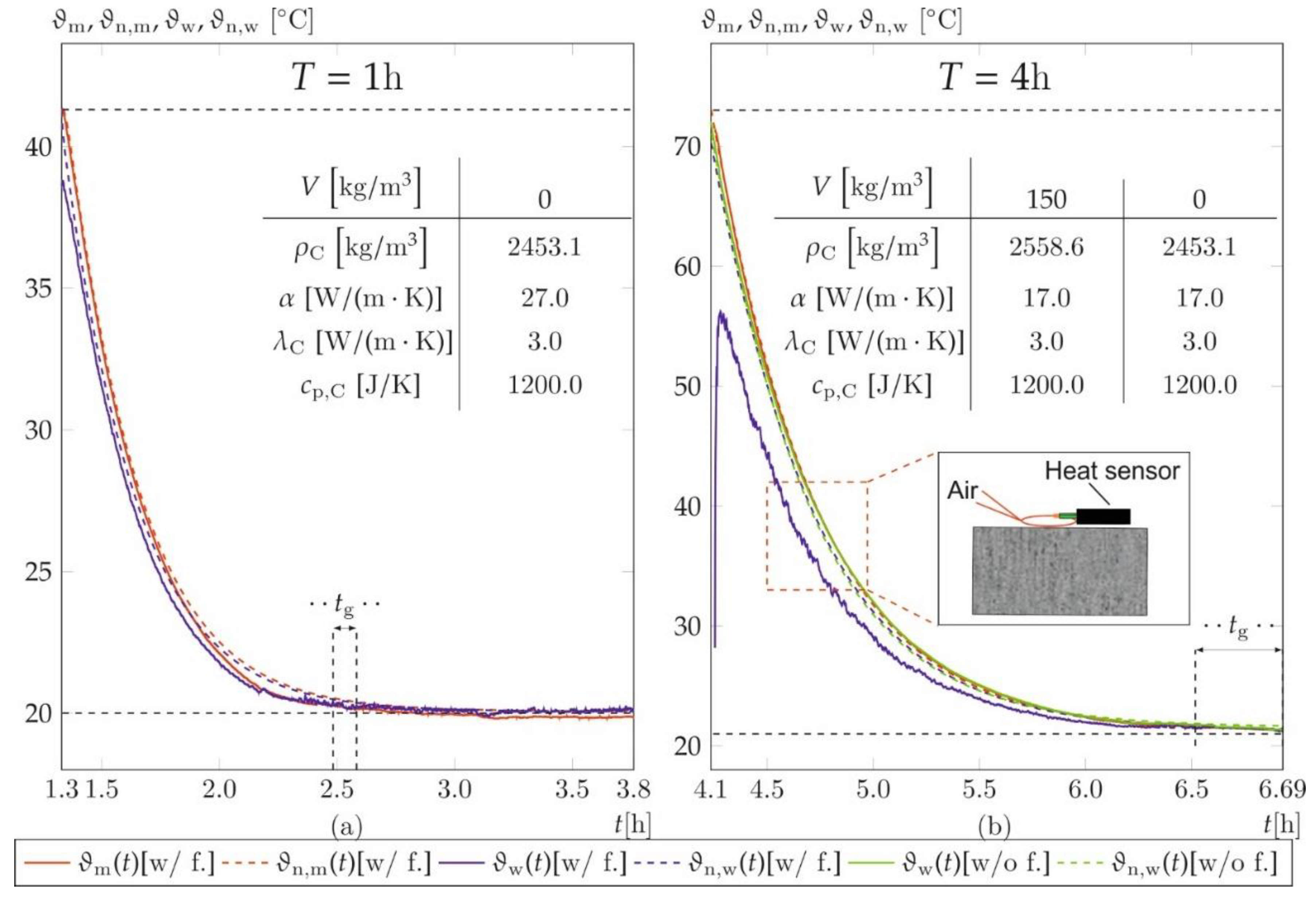

2.1. Temperature Measurement

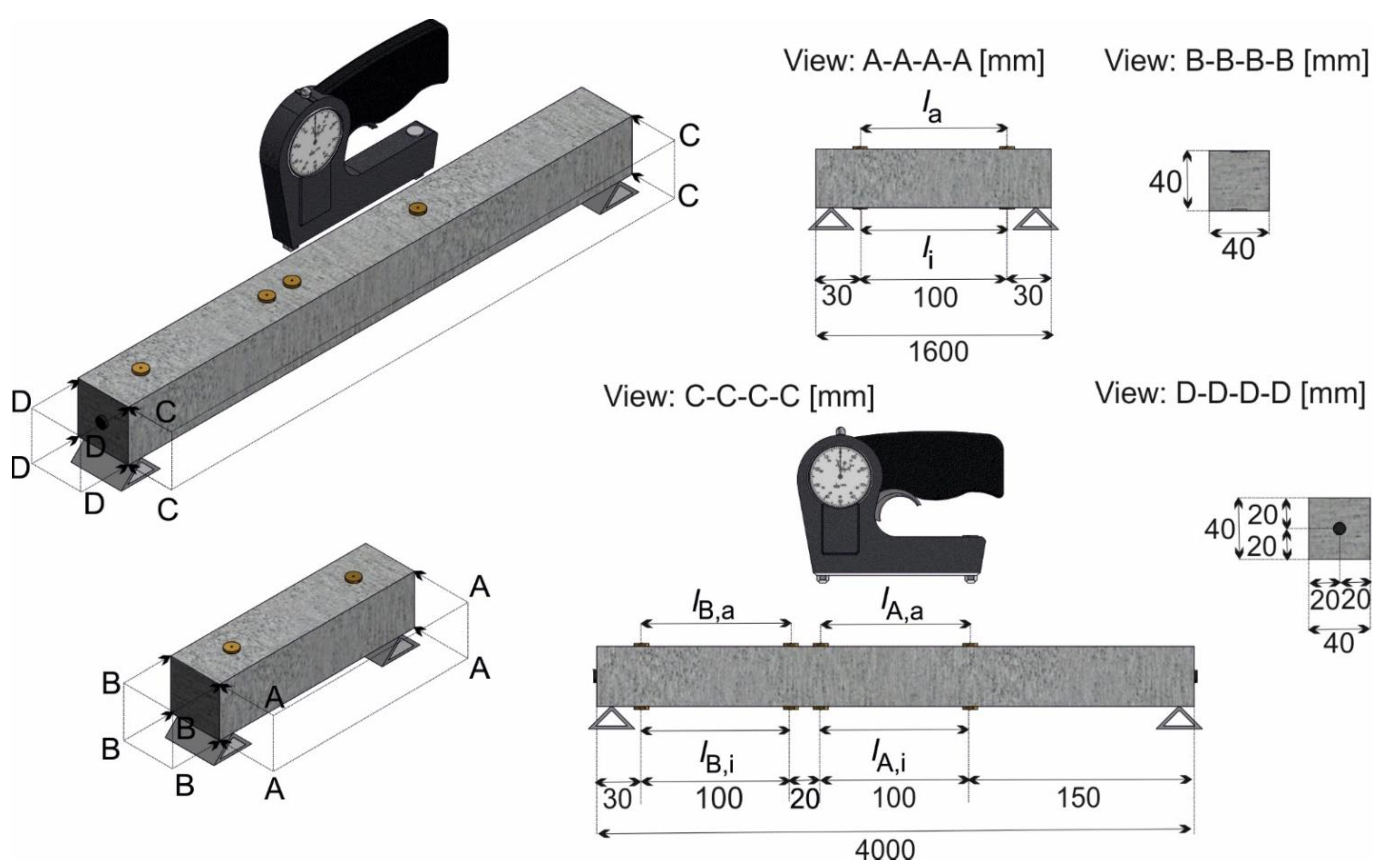

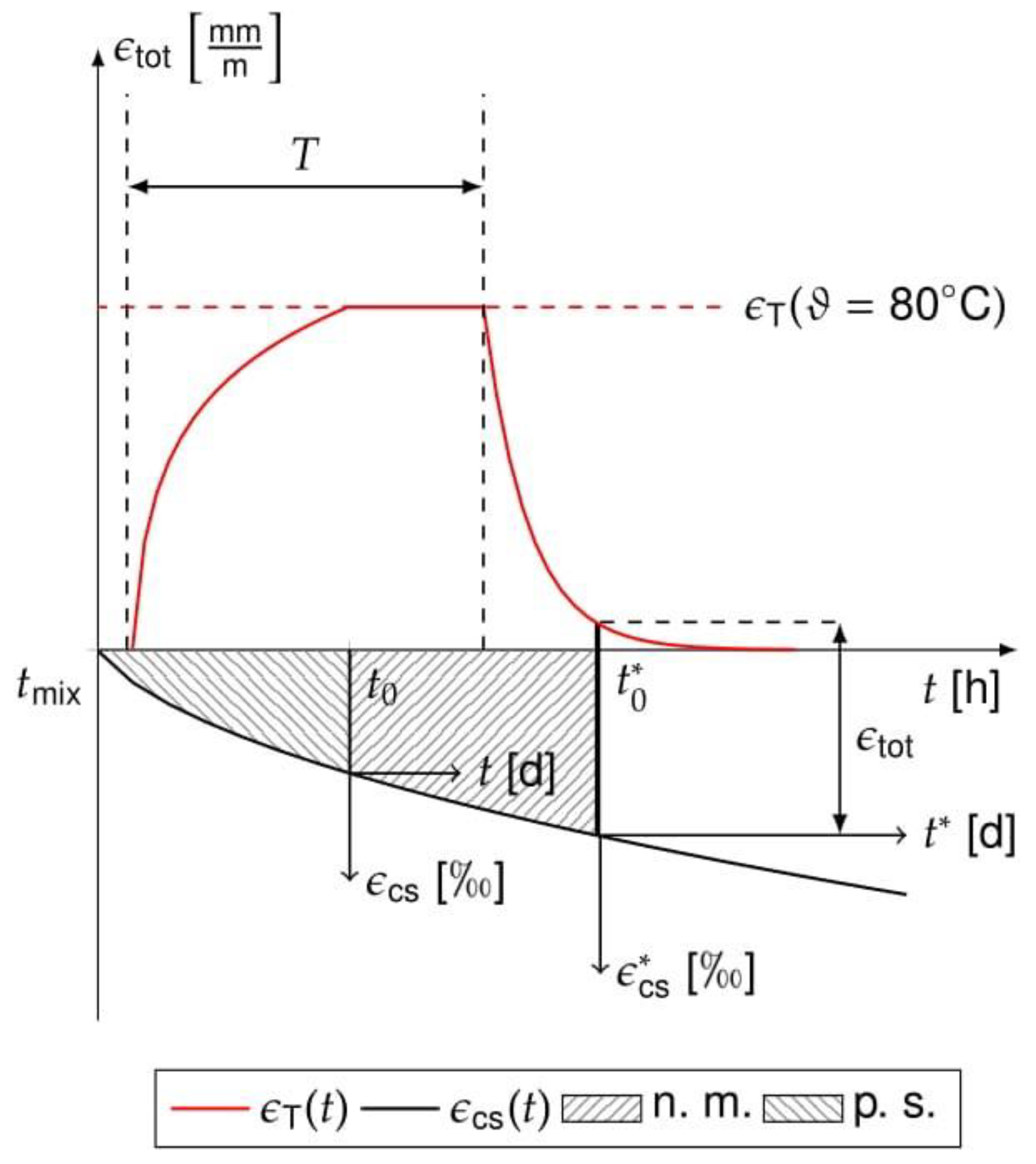

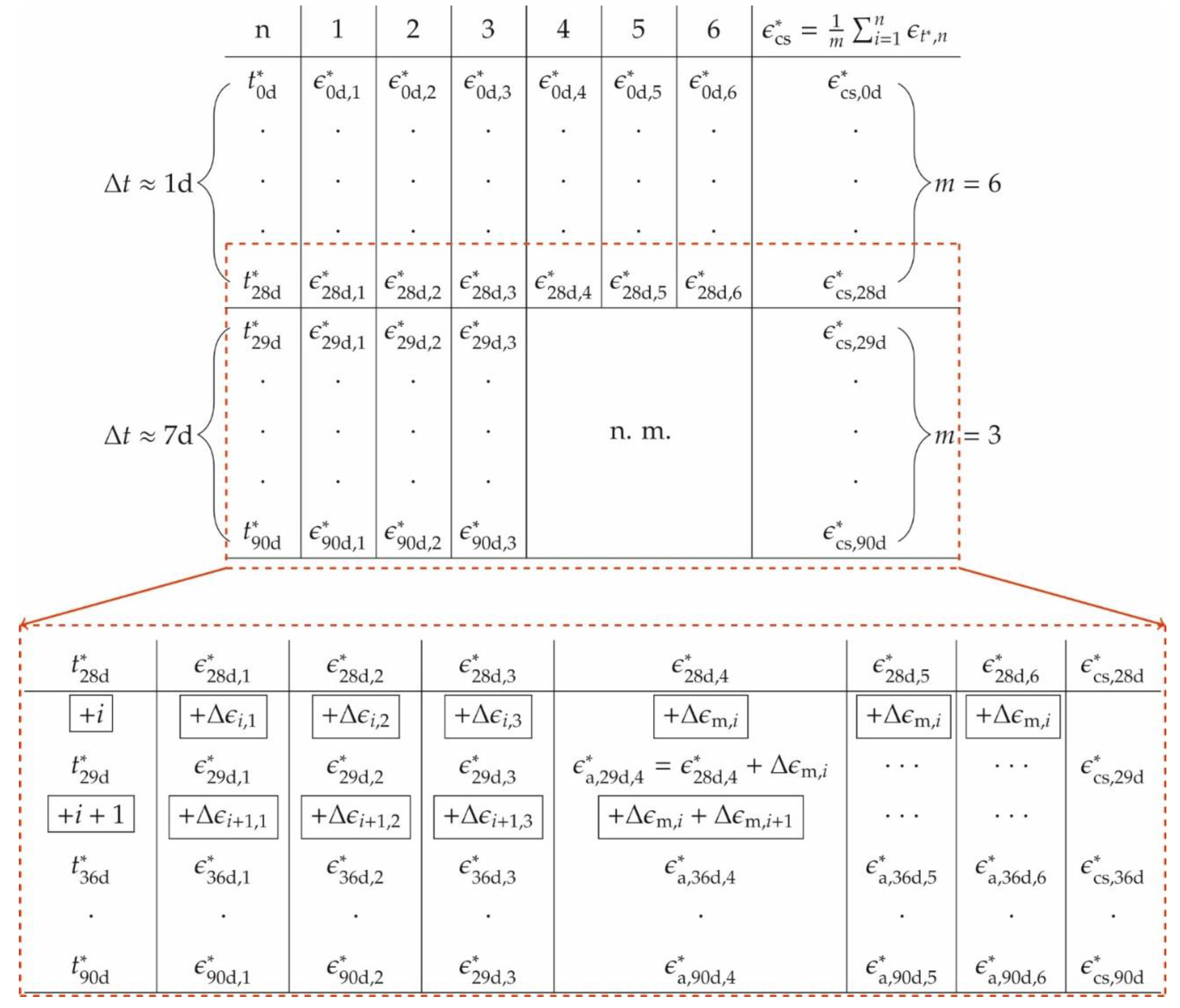

2.2. Shrinkage Measurement

2.3. Strength Measurement

3. Results

3.1. Results of the Temperature Measurement

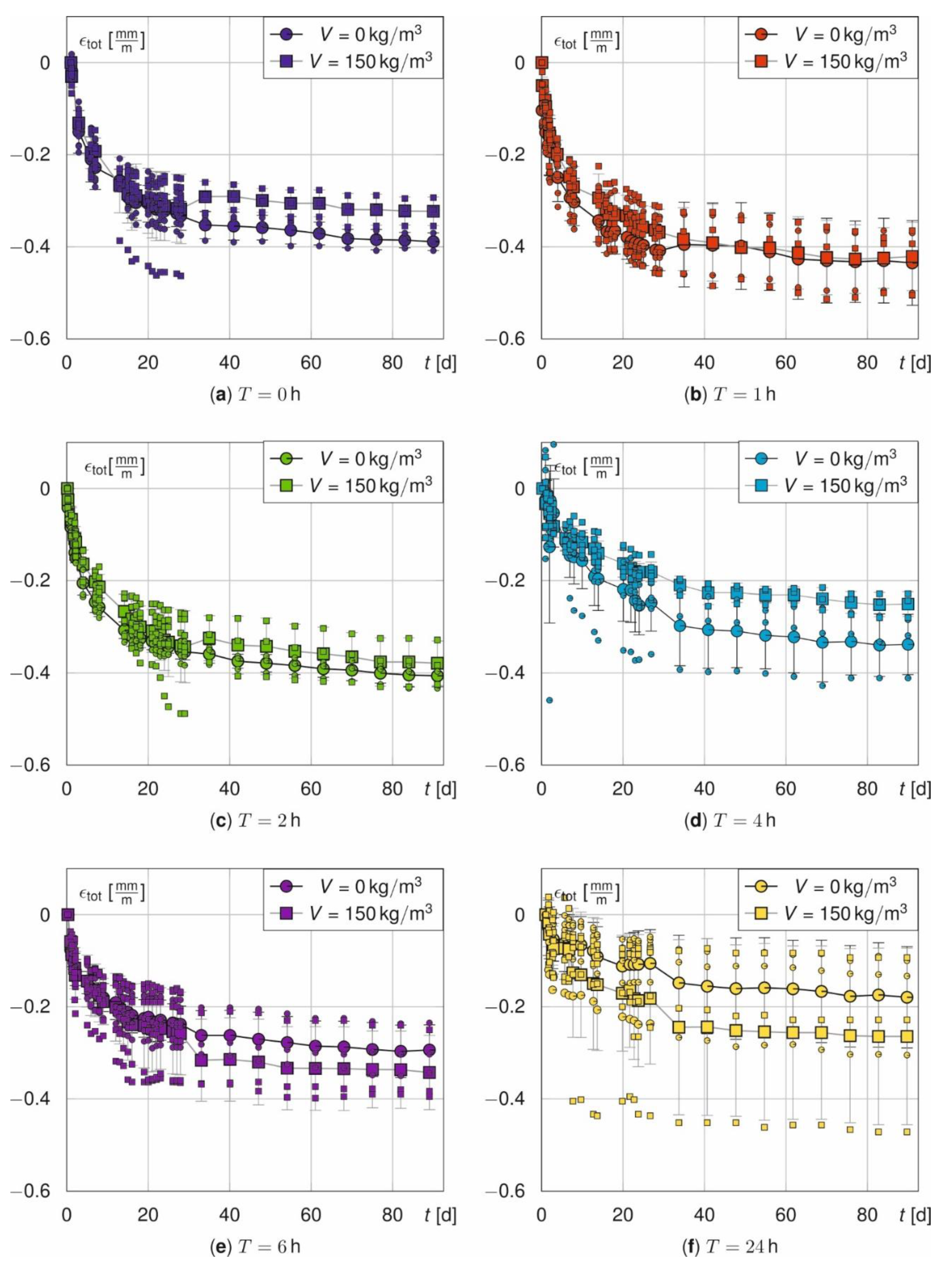

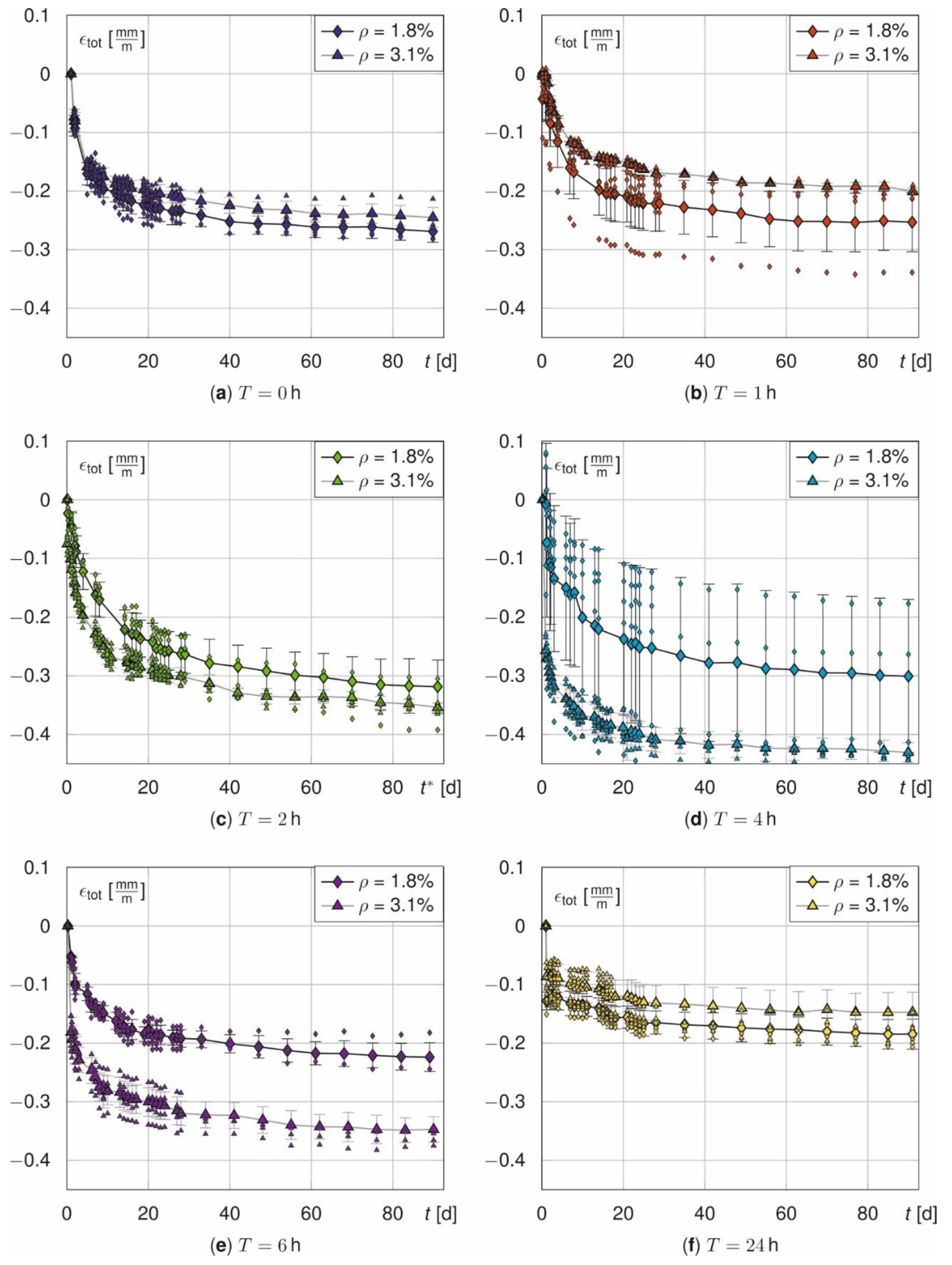

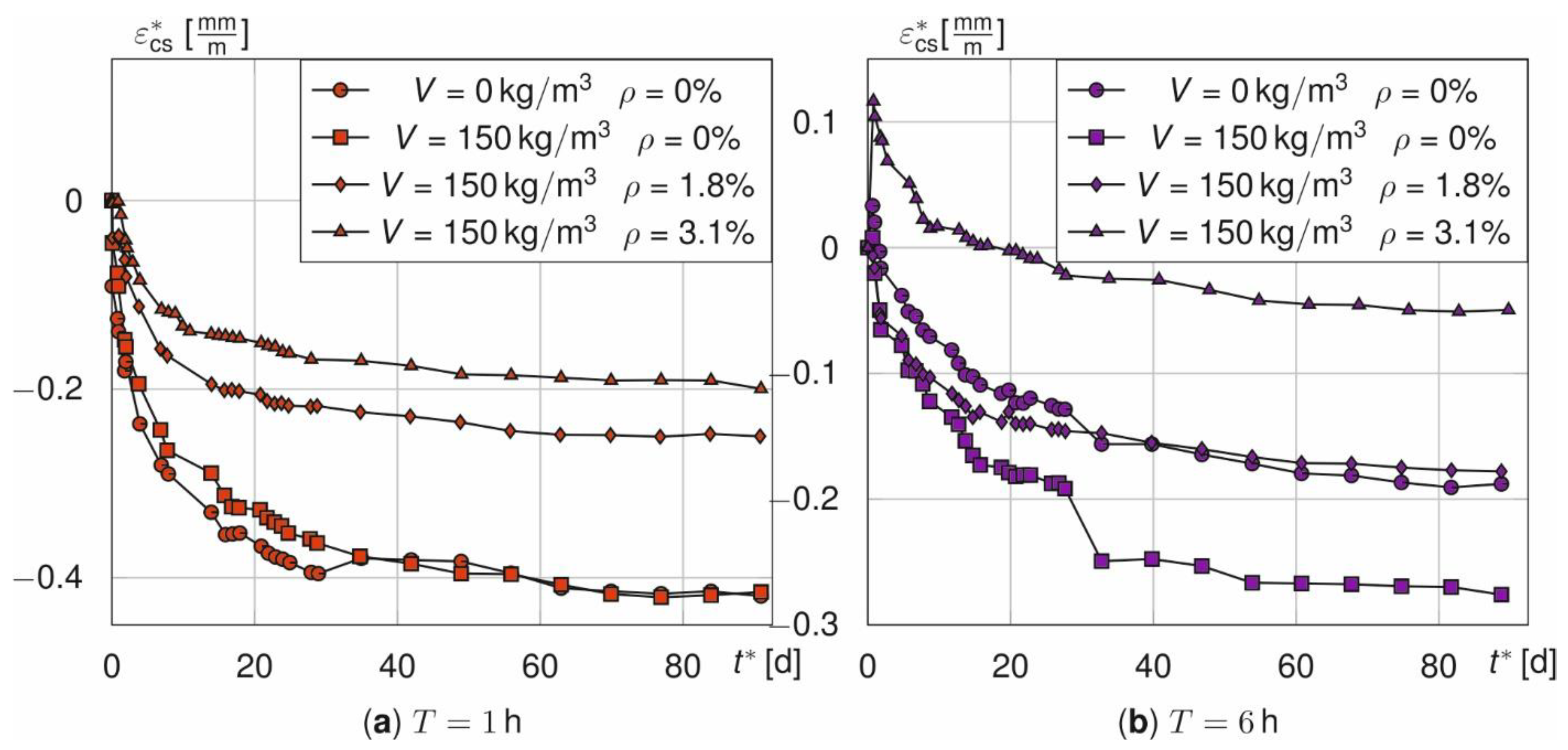

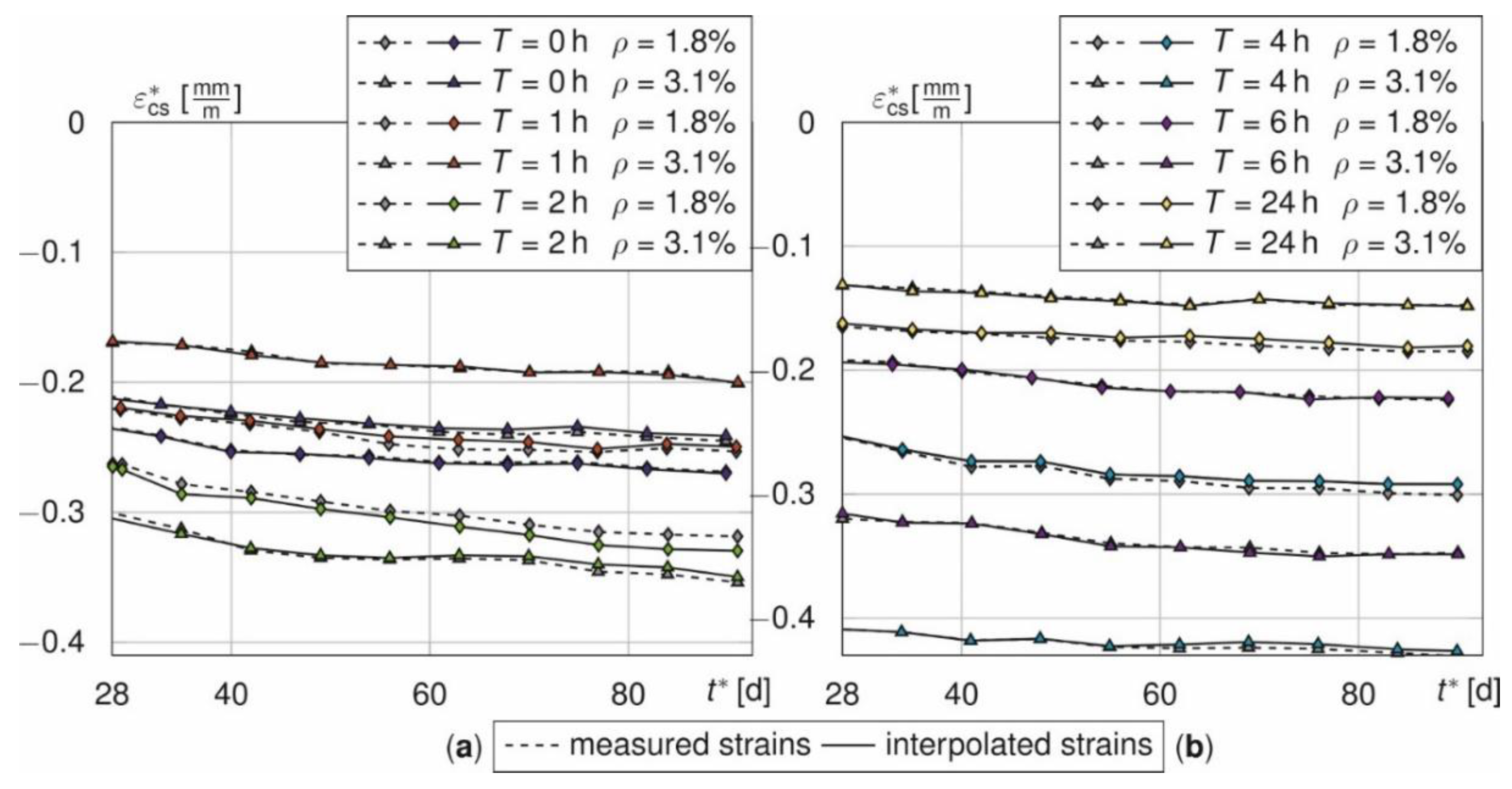

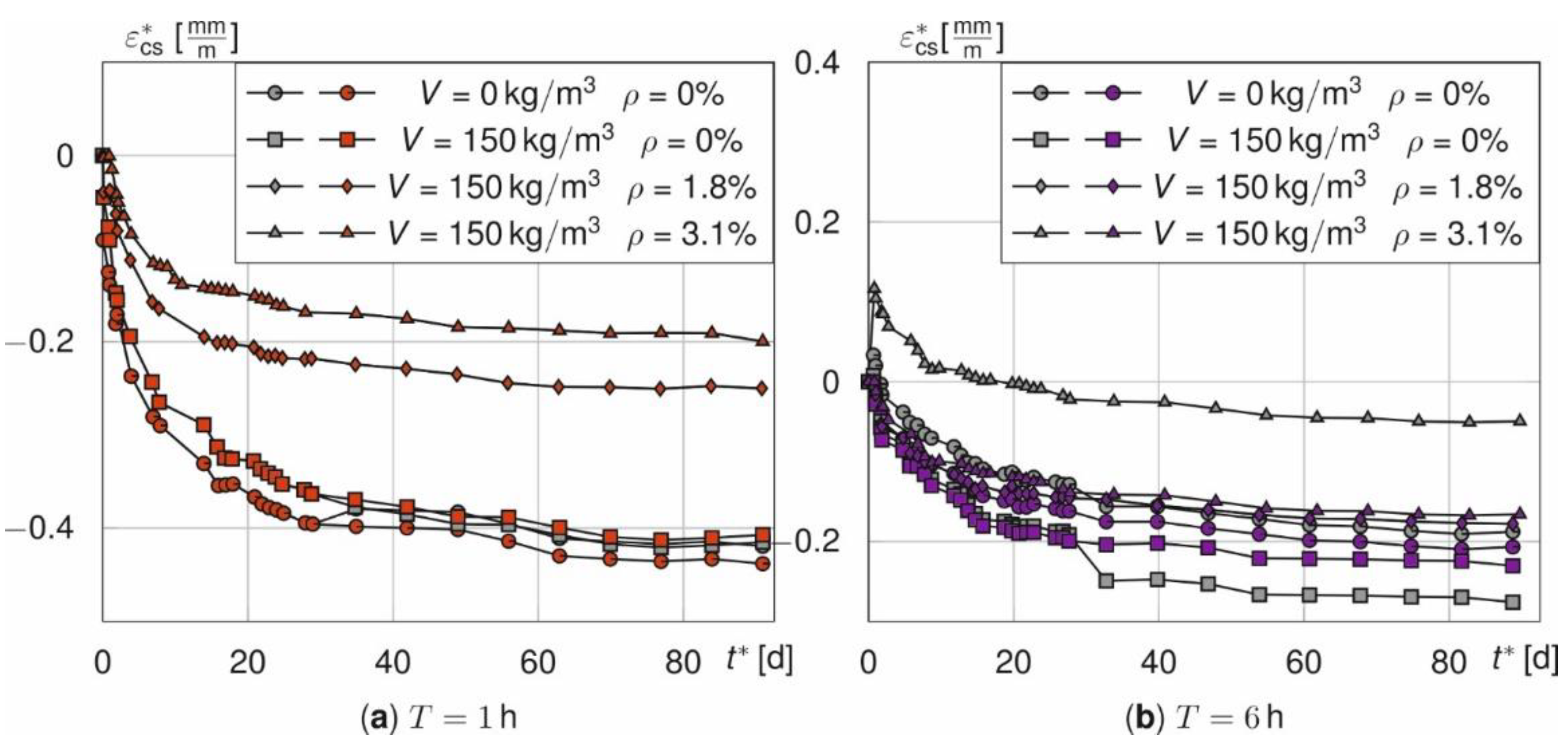

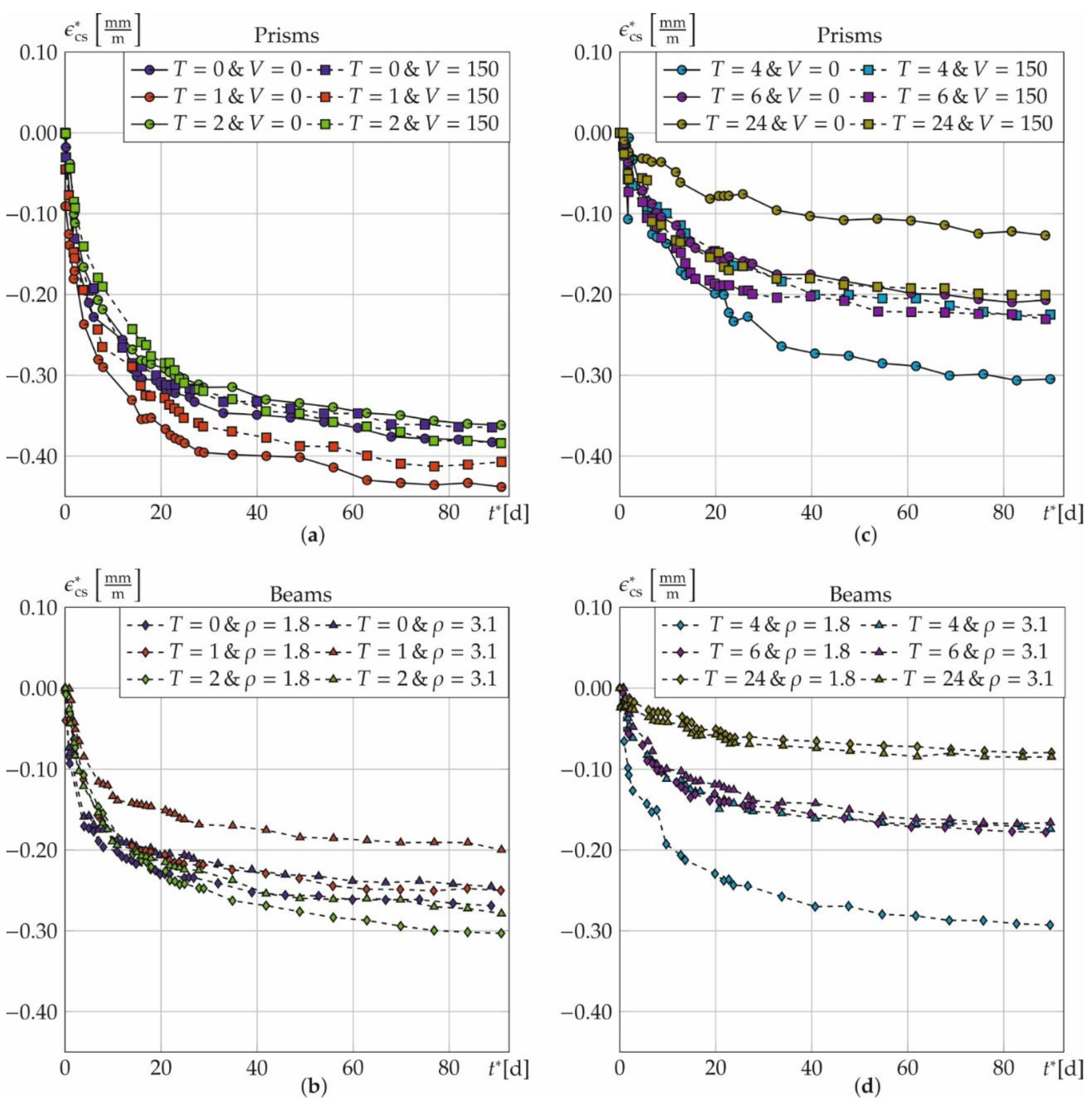

3.2. Shrinkage

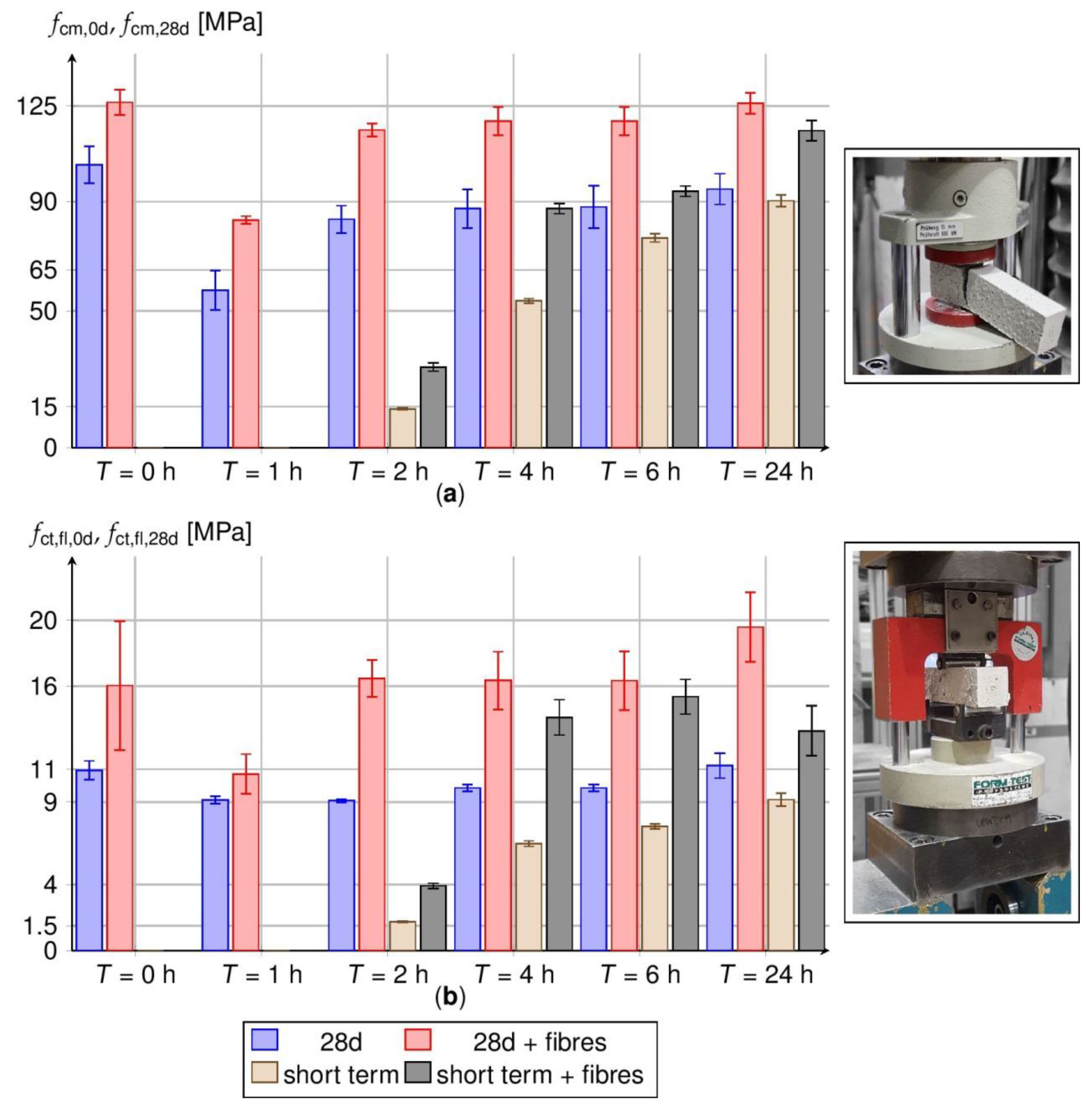

3.3. Flexural and Compressive Strength

4. Conclusions

- With increasing treatment time T, the shrinkage strains decrease. For T = 24 h it is reduced to 66.8% (no fibres) or 44.9% (fibres) compared to the reference samples without heat treatment (0.383 mm/m without steel fibres and 0.364 mm/m with steel fibres for T = 0 h).

- Short treatment times of T = 1 to 2 h have no beneficial or even slightly negative effects on shrinkage strains. Heat treatment durations greater than 2 h must be selected to improve the shrinkage behaviour.

- For T = 4 and 6 h, the residual shrinkage strains can be reduced up to 0.176 mm/m for prisms and 0.09 mm/m for beams what corresponds to 45.9% and 33.8% compared to the reference samples without heat treatment. However, the investigations show high scatter for different treatment times and specimen types.

- Rebar serves as a “shrinkage brake”. Reinforcing bars reduce shrinkage proportional to its longitudinal stiffness.

- The compressive strength of the prisms decreases up to 44% for T = 1 h. To prevent losses of compressive strength due to structural damage, tempering of T ≥ 2 h is recommended.

- An addition of steel fibres significantly increases the compressive strength as well as the flexural strength, as fibres prevent structural damage in the matrix induced by internal stresses.

- For practical application, the use of steel fibres and reinforcement is recommended to improve the shrinkage behaviour.

- For practical applications it is recommended to use tempering at around 80 °C with durations greater than 2 h. Durations of 2 to about 6 h are most effective. Durations exceeding 24 h are not recommended, as the beneficial effect on shrinkage more and more decreases over time and then reaches a plateau. Micro steel fibres should be added to preserve the bearing abilities of the HPC that otherwise noticeably decreases by temperature induced constraints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Smarslik, M.; Mark, P. Hybrid reinforcement design of longitudinal joints for segmental concrete linings. Struct. Concr. 2019, 20, 1926–1940. [Google Scholar] [CrossRef]

- Gaganelis, G.; Mark, P. Downsizing weight while upsizing efficiency: An experimental approach to develop optimized ultra-light UHPC hybrid beams. Struct. Concr. 2019, 20, 1883–1895. [Google Scholar] [CrossRef]

- Forman, P.; Gaganelis, G.; Mark, P. Optimization-based design. Bautechnik 2020, 97, 697–707. [Google Scholar] [CrossRef]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-High Performance Concrete: Mechanical Performance, Durability, Sustainability and Implementation Challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef] [Green Version]

- Mark, P.; Lanza, G.; Lordick, D.; Albers, A.; König, M.; Borrmann, A.; Stempniewski, L.; Forman, P.; Frey, A.M.; Renz, R.; et al. Industrializing precast productions. Civil. Eng. Des. 2021. [Google Scholar] [CrossRef]

- Frey, A.M.; Stindt, J.; Lanza, G.; Mark, P. Geometric evaluation and optimization of module arrangement in load bearing structures—towards adaptive manufacturing in civil engineering. Bautechnik 2021. [Google Scholar] [CrossRef]

- Grübl, P.; Weigler, H.; Karl, S. Beton: Arten, Herstellung und Eigenschaften, 2nd ed.; Ernst & Sohn: Berlin, Germany, 2001; ISBN 9783433013403. [Google Scholar]

- Holschemacher, K.; Dehn, F.; Müller, T.; Lobisch, F. Grundlagen des Faserbetons. In Beton-Kalender 2017: Schwerpunkte: Spannbeton, Spezialbetone; Bergmeister, K., Fingerloos, F., Wörner, J.-D., Eds.; Ernst Sohn: Berlin, Germany, 2017; pp. 381–472. ISBN 9783433031230. [Google Scholar]

- Li, Q.; Zhang, Q. Experimental study on the compressive strength and shrinkage of concrete containing fly ash and ground granulated blast-furnace slag. Struct. Concr. 2019, 20, 1551–1560. [Google Scholar] [CrossRef]

- Gowripalan, N. Autogenous Shrinkage of Concrete at Early Ages. In Proceedings of the 25th Australasian Conference on Mechanics of Structures and Materials, Brisbane, Australia, December 2018; Wang, C.M., Ho, J.C.M., Kitipornchai, S., Eds.; Springer: Singapore, 2020; pp. 269–276. [Google Scholar]

- Zhang, M.H.; Tam, C.T.; Leow, M.P. Effect of water-to-cementitious materials ratio and silica fume on the autogenous shrinkage of concrete. Cem. Concr. Res. 2003, 33, 1687–1694. [Google Scholar] [CrossRef]

- Jiang, C.; Yang, Y.; Wang, Y.; Zhou, Y.; Ma, C. Autogenous shrinkage of high performance concrete containing mineral admixtures under different curing temperatures. Constr. Build. Mater. 2014, 61, 260–269. [Google Scholar] [CrossRef]

- Wu, L.; Farzadnia, N.; Shi, C.; Zhang, Z.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Lee, K.M.; Lee, H.K.; Lee, S.H.; Kim, G.Y. Autogenous shrinkage of concrete containing granulated blast-furnace slag. Cem. Concr. Res. 2006, 36, 1279–1285. [Google Scholar] [CrossRef]

- Fang, C.; Ali, M.; Xie, T.; Visintin, P.; Sheikh, A.H. The influence of steel fibre properties on the shrinkage of ultra-high performance fibre reinforced concrete. Constr. Build. Mater. 2020, 242, 117993. [Google Scholar] [CrossRef]

- Zacharda, V.; Němeček, J.; Štemberk, P. Micromechanical performance of interfacial transition zone in fiber-reinforced cement matrix. IOP Conf. Ser. Mater. Sci. Eng. 2017, 246, 12018. [Google Scholar] [CrossRef]

- Saje, D.; Bandelj, B.; Šušteršic, J.; Lopatic, J.; Saje, F. Autogenous and Drying Shrinkage of Fibre Reinforced High-Performance Concrete. ACT 2012, 10, 59–73. [Google Scholar] [CrossRef] [Green Version]

- Han, S.; Cui, Y.; Huang, H.; An, M.; Yu, Z. Effect of Curing Conditions on the Shrinkage of Ultra High-Performance Fiber-Reinforced Concrete. Adv. Civ. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Pietro, L.; van Klaas, B.; Ippei, M. Effect of curing temperature and type of cement on early-age shrinkage of high-performance concrete. Cem. Concr. Res. 2001, 1867–1872. [Google Scholar]

- Selleng, C.; Meng, B.; Gröger, K.; Fontana, P. Influencing factors for the effectivity of heat treatment of ultrahigh performance concrete (UHPC). Beton und Stahlbetonbau 2017, 112, 12–21. [Google Scholar] [CrossRef]

- Sylla, H.-M. Reaktionen im Zementstein durch Wärmebehandlung. Beton 1988, 11, 449–465. [Google Scholar]

- Kang, S.-H.; Lee, J.-H.; Hong, S.-G.; Moon, J. Microstructural Investigation of Heat-Treated Ultra-High Performance Concrete for Optimum Production. Materials 2017, 10, 1106. [Google Scholar] [CrossRef] [Green Version]

- Schultz-Cornelius, M.; Pahn, M. Influence of moisture on tensile and flexural tensile strength of UHPC. Beton und Stahlbetonbau 2020, 115, 731–739. [Google Scholar] [CrossRef]

- Wischers, G. Merkblatt für die Herstellung geschlossener Betonoberflächen bei einer Wärmebehandlung. Beton 1967, 4, 142–160. [Google Scholar]

- Deutscher Ausschuss für Stahlbeton. Wärmebehandlung von Beton; Beuth Verlag: Berlin, Germany, 2012. [Google Scholar]

- Pavoine, A.; Divet, L.; Fenouillet, S. A concrete performance test for delayed ettringite formation: Part I optimisation. Cem. Concr. Res. 2006, 36, 2138–2143. [Google Scholar] [CrossRef]

- ACI Committee 517. Accelerated Curing of Concrete at Atmospheric Pressure State of the Art; ACI (American Concrete Institute): Farmington Hills, MI, USA, 1980; (ACI 517.2R-80). [Google Scholar]

- Beverly, P. Fib Model Code for Concrete Structures 2010; Ernst & Sohn: Berlin, Germany, 2013; ISBN 9783433030615. [Google Scholar]

- Deutscher Ausschuss für Stahlbeton. Sachstandbericht Ultrahochfester Beton, Heft 561; Beuth Verlag: Berlin, Germany, 2008. [Google Scholar]

- Rhau, M.; Schnellenbach-Held, M.; Welsch, T. Influence of Thermal Treatment on the Strength of Fine-Grained Ultra-High Performance Concrete (UHPC/RPC). Beton Stahlbetonbau 2018, 113, 535–542. [Google Scholar] [CrossRef]

- Müller, C. Influence of steel fibers on the stress strain relationship of concrete under compression. Beton und Stahlbetonbau 2017, 112, 228–237. [Google Scholar] [CrossRef]

- Žirgulis, G.; Švec, O.; Sarmiento, E.V.; Geiker, M.R.; Cwirzen, A.; Kanstad, T. Importance of quantification of steel fibre orientation for residual flexural tensile strength in FRC. Mater. Struct. 2016, 49, 3861–3877. [Google Scholar] [CrossRef]

- Barnett, S.J.; Lataste, J.-F.; Parry, T.; Millard, S.G.; Soutsos, M.N. Assessment of fibre orientation in ultra high performance fibre reinforced concrete and its effect on flexural strength. Mater. Struct. 2010, 43, 1009–1023. [Google Scholar] [CrossRef]

- Kamkar, S.; Eren, Ö. Evaluation of maturity method for steel fiber reinforced concrete. KSCE J. Civ Eng 2018, 22, 213–221. [Google Scholar] [CrossRef]

- Stengel, T. Fibre reinforced ultra high-performance concrete—From single fibre bond behavior to fibre composite performance. Beton und Stahlbetonbau 2017, 112, 795–803. [Google Scholar] [CrossRef]

- Look, K.; Heek, P.; Mark, P. Practical calculation, design and optimization of steel fibre reinforced concrete structures. Beton und Stahlbetonbau 2019, 114, 296–306. [Google Scholar] [CrossRef]

- Sagmeister, B. Maschinenteile aus Zementgebundenem Beton, 1st ed.; Beuth Verlag GmbH: Berlin, Germany, 2017; ISBN 978-3-410-27186-4. [Google Scholar]

- TESTING Bluhm & Feuerherdt GmbH. Bedienungsanleitung: Setzdehnungsmesser-Bauart PFENDER. 2008. Available online: https://testing.de/sites/default/files/productpdf_original/10.1305-betriebsanleitung-1-bam-setzdehnungsmesser-v4-de.pdf (accessed on 23 June 2021).

- Deutsches Institut für Normung e.V. Prüfung von Festbeton—Teil 5: Biegezugfestigkeit von Probekörpern; Beuth Verlag GmbH: Berlin, Germany, 2019; 91.100.30 (12390-5:2019). [Google Scholar]

- Deutsches Institut für Normung e.V. Prüfung von Festbeton—Teil 3: Druckfestigkeit von Probekörpern; Beuth Verlag GmbH: Berlin, Germany, 2019; 91.100.30 (12390-3:2019). [Google Scholar]

- Spille, J.; Zehfuß, J. New approach on thermal conductivity of concrete in case of fire. Bautechnik 2019, 96, 450–458. [Google Scholar] [CrossRef]

- Bouziadi, F.; Boulekbache, B.; Haddi, A.; Djelal, C.; Hamrat, M. Numerical analysis of shrinkage of steel fiber reinforced high-strength concrete subjected to thermal loading. Constr. Build. Mater. 2018, 181, 381–393. [Google Scholar] [CrossRef]

- Fessel, D.; Simon, P.; Guder, T.; Dehn, F. Thermal conductivity of steel fibre reinforced—A theoretical view. Beton und Stahlbetonbau 2016, 111, 546–554. [Google Scholar] [CrossRef]

- Heek, P.; Tkocz, J.; Mark, P. A thermo-mechanical model for SFRC beams or slabs at elevated temperatures. Mater. Struct. 2018, 51. [Google Scholar] [CrossRef]

- Lu, T.; Li, Z.; van Breugel, K. Modelling of autogenous shrinkage of hardening cement paste. Constr. Build. Mater. 2020, 264, 120708. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Autogenous deformation and RH-change in perspective. Cem. Concr. Res. 2001, 31, 1859–1865. [Google Scholar] [CrossRef]

- Sanio, D.; Mark, P.; Ahrens, M.A. Computation of temperature fields on bridges—Implementation by means of spread-sheets. Beton- und Stahlbetonbau 2017, 112, 85–95. [Google Scholar] [CrossRef]

- Madenci, E.; Guven, I. The Finite Element Method and Applications in Engineering Using ANSYS®; Springer US: Boston, MA, USA, 2015; ISBN 978-1-4899-7549-2. [Google Scholar]

- Stindt, J.; Forman, P.; Mark, P. Experiments on shrinkage reduction of high-performance concrete components by heat treatment. Beton- und Stahlbetonbau 2021, 116, 594–606. [Google Scholar] [CrossRef]

- Matthes, W.; Vollpracht, A.; Villagrán, Y.; Kamali-Bernard, S.; Hooton, D.; Gruyaert, E.; Soutsos, M.; de Belie, N. Ground Granulated Blast-Furnace Slag. In Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials; de Belie, N., Soutsos, M., Gruyaert, E., Eds.; Springer International Publishing: Basel, Switzerland, 2018; pp. 1–53. ISBN 978-3-319-70605-4. [Google Scholar]

- Thomas, A. Ein Modell zur Beschreibung der Hydratation von Beton in Abhängigkeit vom Feuchtegehalt. Dissertation; Technischen Universität Darmstadt: Darmstadt, Germany, 2006. [Google Scholar]

- Röhling, S.; Meichsner, H. Rissbildungen im Stahlbetonbau: Ursachen—Auswirkungen—Maßnahmen; Fraunhofer IRB Verlag: Stuttgart, Germany, 2018; ISBN 978-3-8167-9645-9. [Google Scholar]

- Ding, Y.; Kusterle, W. Eigenschaften von jungem Faserbeton. Beton und Stahlbetonbau 1999, 94, 362–368. [Google Scholar] [CrossRef]

- Lanwer, J.-P.; Javidmehr, S.; Empelmann, M. Statistical evaluation of compressive strength of ultra-high strength concrete. Beton und Stahlbetonbau 2021, 116, 431–440. [Google Scholar] [CrossRef]

- Iqbal, S.; Ali, I.; Room, S.; Khan, S.A.; Ali, A. Enhanced mechanical properties of fiber reinforced concrete using closed steel fibers. Mater. Struct. 2019, 52. [Google Scholar] [CrossRef]

- Doyon-Barbant, J.; Charron, J.-P. Impact of fibre orientation on tensile, bending and shear behaviors of a steel fibre reinforced concrete. Mater. Struct. 2018, 51. [Google Scholar] [CrossRef]

- Hadl, P.; Gröger, J.; Nguyen, V.T. Experimental investigations on the scattering in the post cracking tensile behaviour of steel fibre reinforced concrete. Bautechnik 2015, 92, 385–393. [Google Scholar] [CrossRef]

| Component | Type | Mass [kg/m³] |

|---|---|---|

| River sand | 0/2 | 426.0 |

| Crushed stone basalt | 1/3 | 882.0 |

| Binder | Nanodur® Compound 5941 | 1042.0 |

| Water | - | 159.8 |

| Superplasticizer | Master Glenium ACE 430 | 12.3 |

| Shrinkage reducer | Eclipse Floor | 8.0 |

| Hardening accelerator | Master X-Seed 100 | 12.3 |

| Steel fibres | d/l = 0.19/13 [mm] | 0/150.0 |

| Experimental Set-Ups | Concrete Age t | Test Specimens | |||

|---|---|---|---|---|---|

| Prisms V = 0 kg/m³ | Prisms V = 150 kg/m³ | Beams ρ = 1.8% | Beams ρ = 3.1% | ||

| Temperature measurement | ≤1 d | 6/36 | 6/36 | - | - |

| Shrinkage | ≤28 d | 36/36 | 36/36 | 36/36 | 36/36 |

| >28 d | 18/36 | 18/36 | 36/36 | 36/36 | |

| Compressive strength | ≈0 h | 12/12 | 12/12 | - | - |

| 28 d | 18/36 | 18/36 | - | - | |

| Flexural strength | ≈0 h | 12/12 | 12/12 | - | - |

| 28 d | 18/36 | 18/36 | - | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stindt, J.; Forman, P.; Mark, P. Influence of Rapid Heat Treatment on the Shrinkage and Strength of High-Performance Concrete. Materials 2021, 14, 4102. https://doi.org/10.3390/ma14154102

Stindt J, Forman P, Mark P. Influence of Rapid Heat Treatment on the Shrinkage and Strength of High-Performance Concrete. Materials. 2021; 14(15):4102. https://doi.org/10.3390/ma14154102

Chicago/Turabian StyleStindt, Jan, Patrick Forman, and Peter Mark. 2021. "Influence of Rapid Heat Treatment on the Shrinkage and Strength of High-Performance Concrete" Materials 14, no. 15: 4102. https://doi.org/10.3390/ma14154102

APA StyleStindt, J., Forman, P., & Mark, P. (2021). Influence of Rapid Heat Treatment on the Shrinkage and Strength of High-Performance Concrete. Materials, 14(15), 4102. https://doi.org/10.3390/ma14154102