Investigation of Mechanical and Physical Properties of Big Sheep Horn as an Alternative Biomaterial for Structural Applications

Abstract

:1. Introduction

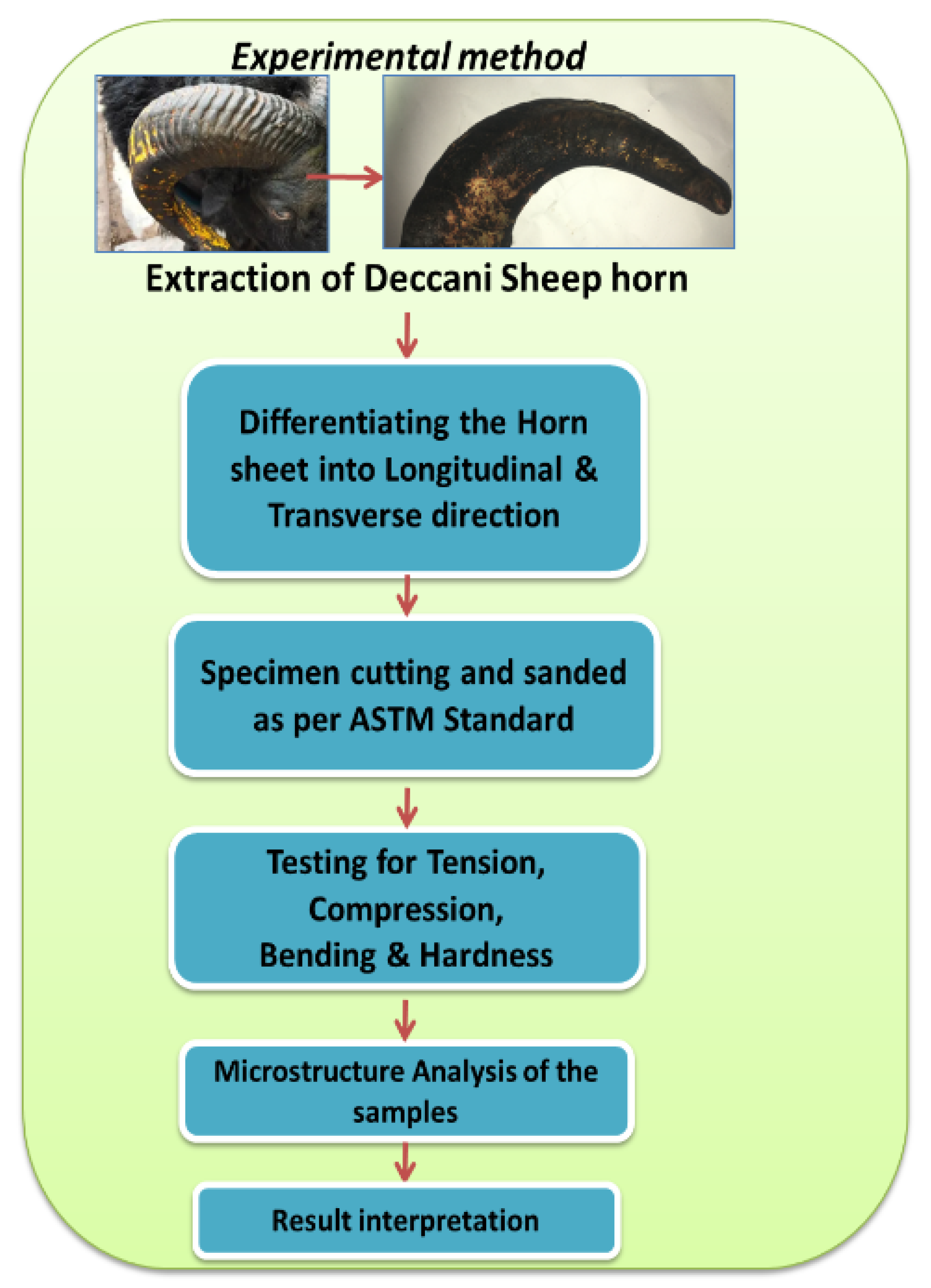

2. Materials and Methods

2.1. Materials

2.2. Methodology

3. Experimental Tests

3.1. Physical Testing

3.1.1. Density Test

- Actual density of specimen (g/cc);

- Weight of a specimen in the air (g);

- .

3.1.2. Water Absorption Test

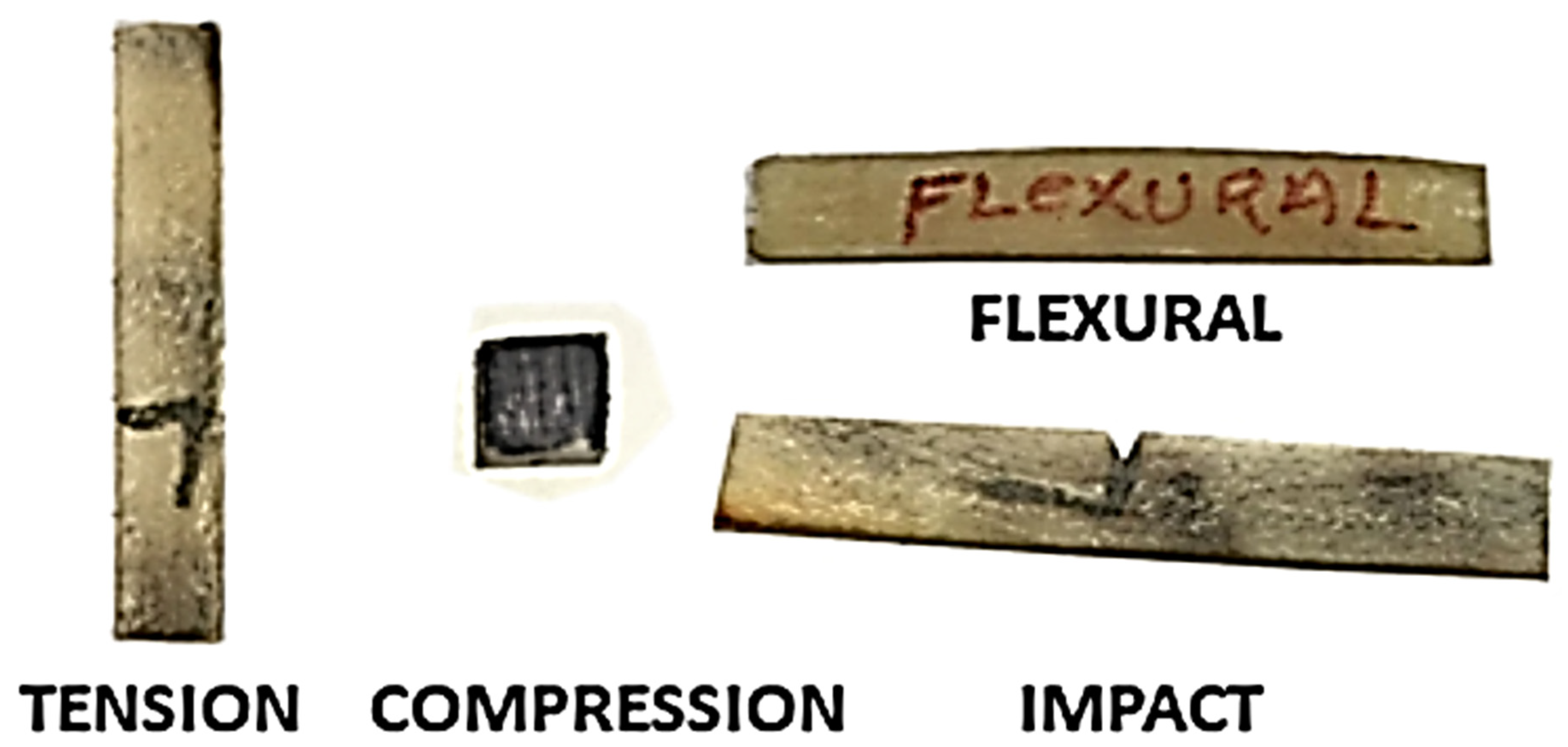

3.2. Mechanical Testing

3.2.1. Tensile Test

3.2.2. Compression Test

3.2.3. Flexural Test

3.2.4. Hardness Test

3.2.5. Impact Test

4. Results and Discussion

4.1. Physical Test

4.1.1. Density Test

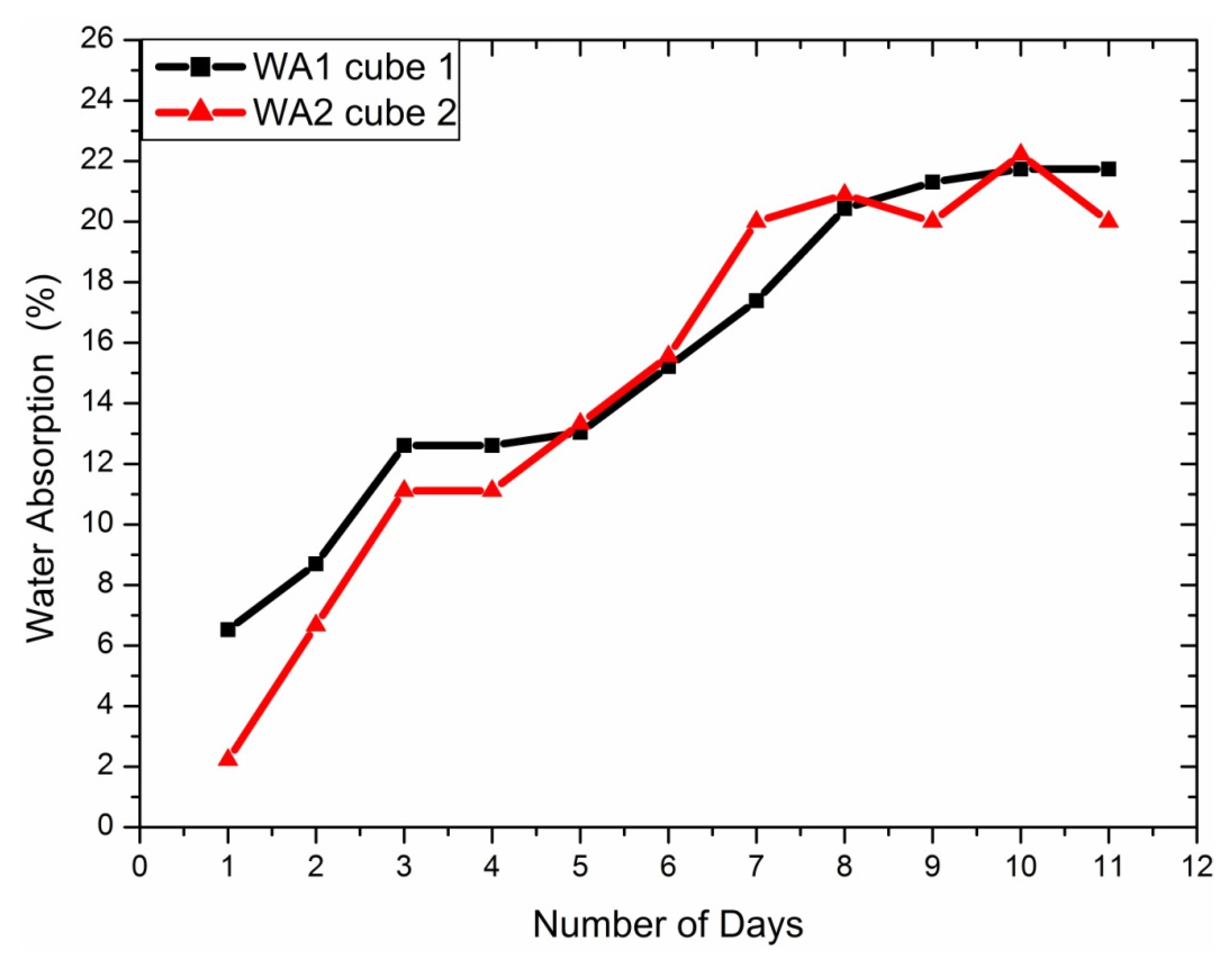

4.1.2. Water Absorption Test

4.2. Mechanical Tests

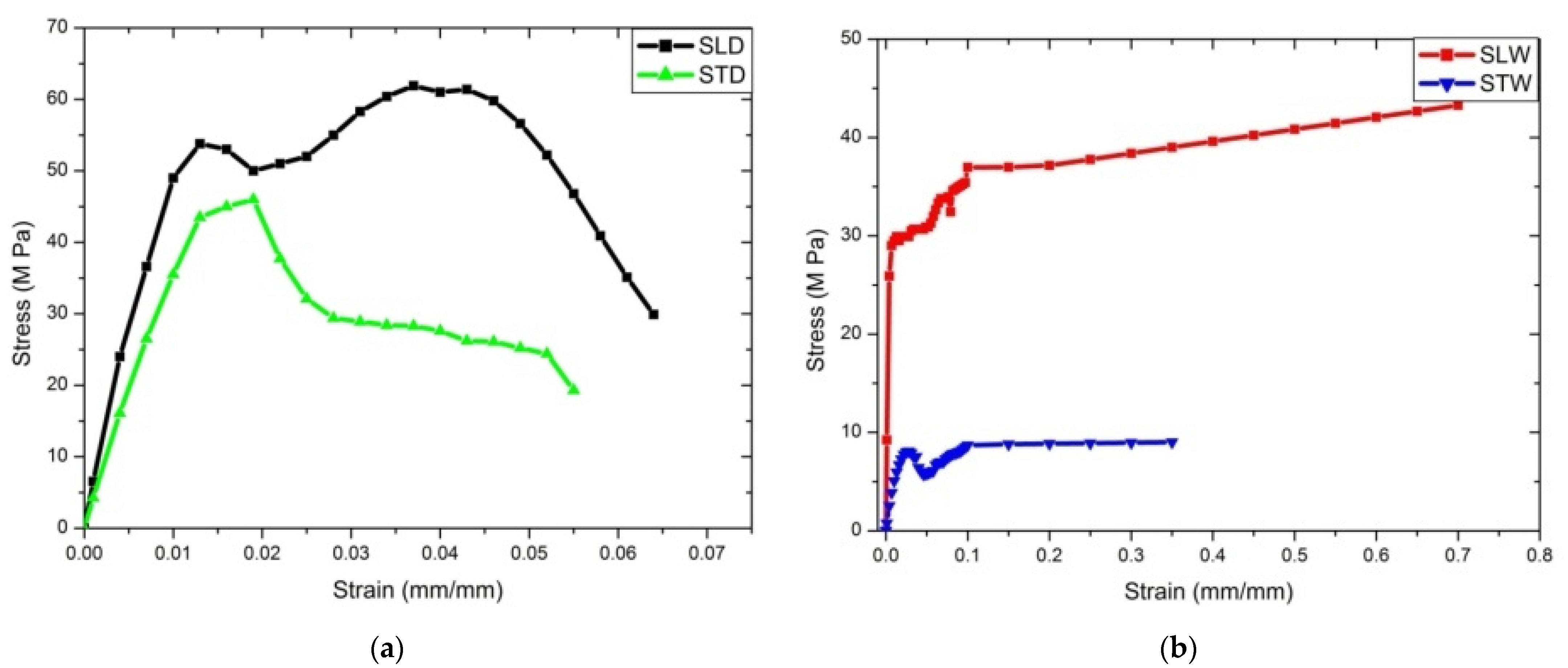

4.2.1. Tensile Strength Test

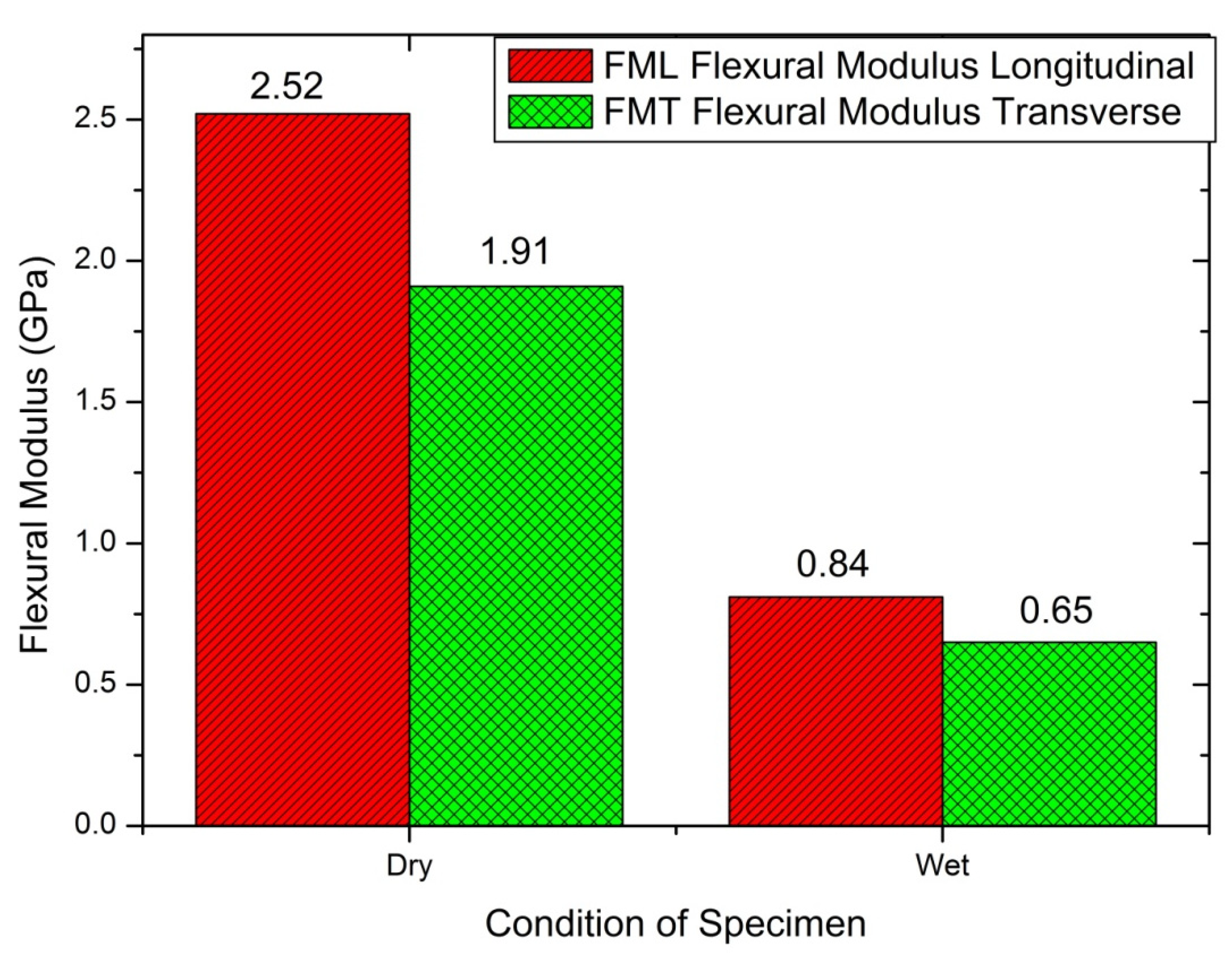

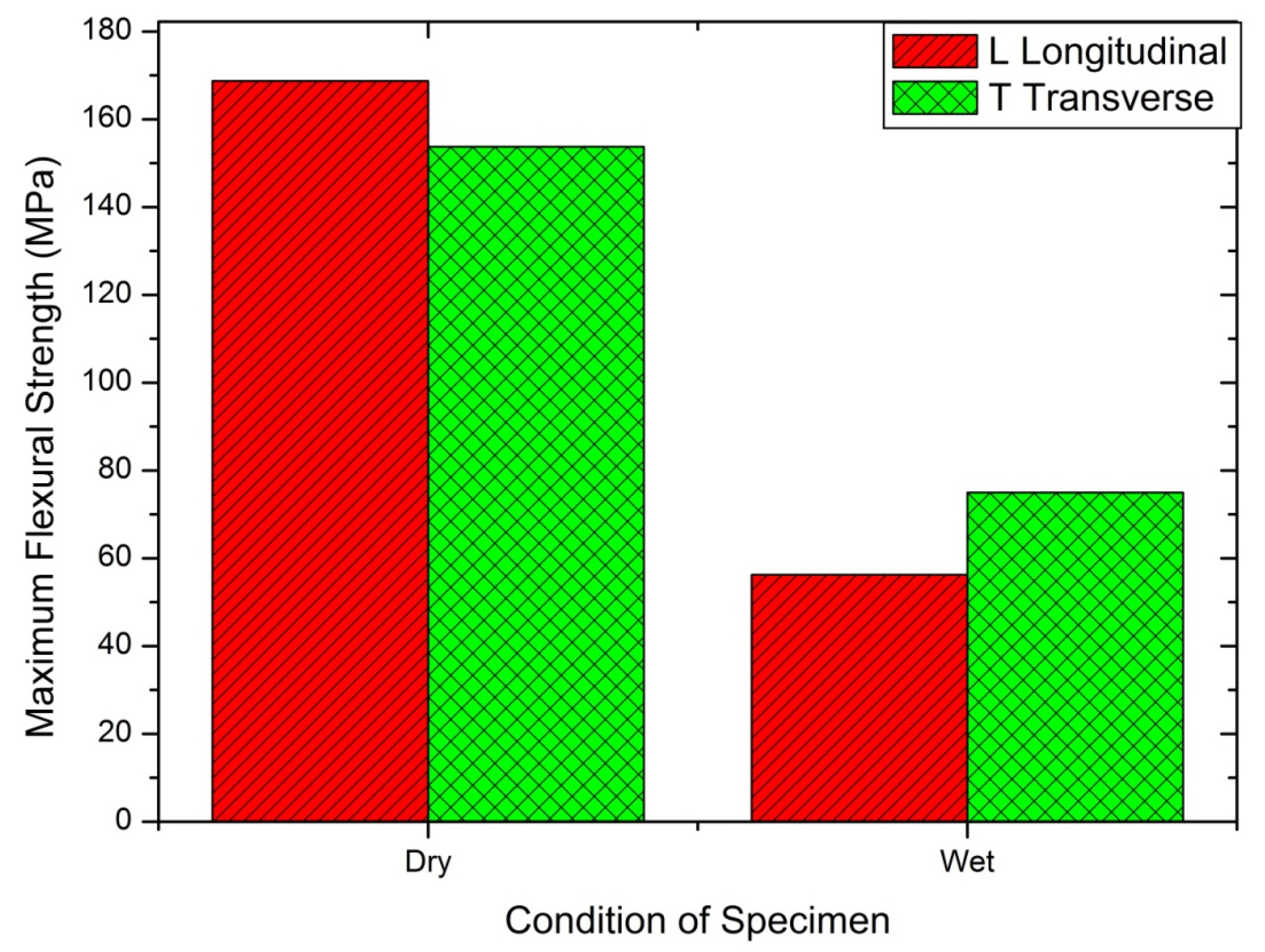

4.2.2. Flexural Strength Test

| Formula | |

| Specimen Dimension | Where Total length = 40 mm Gauge length(L) = 25 mm Width of specimen (b) = 5 mm Thickness of specimen(d) = 2 mm |

| Sample Calculation | |

| Flexural Modulus |

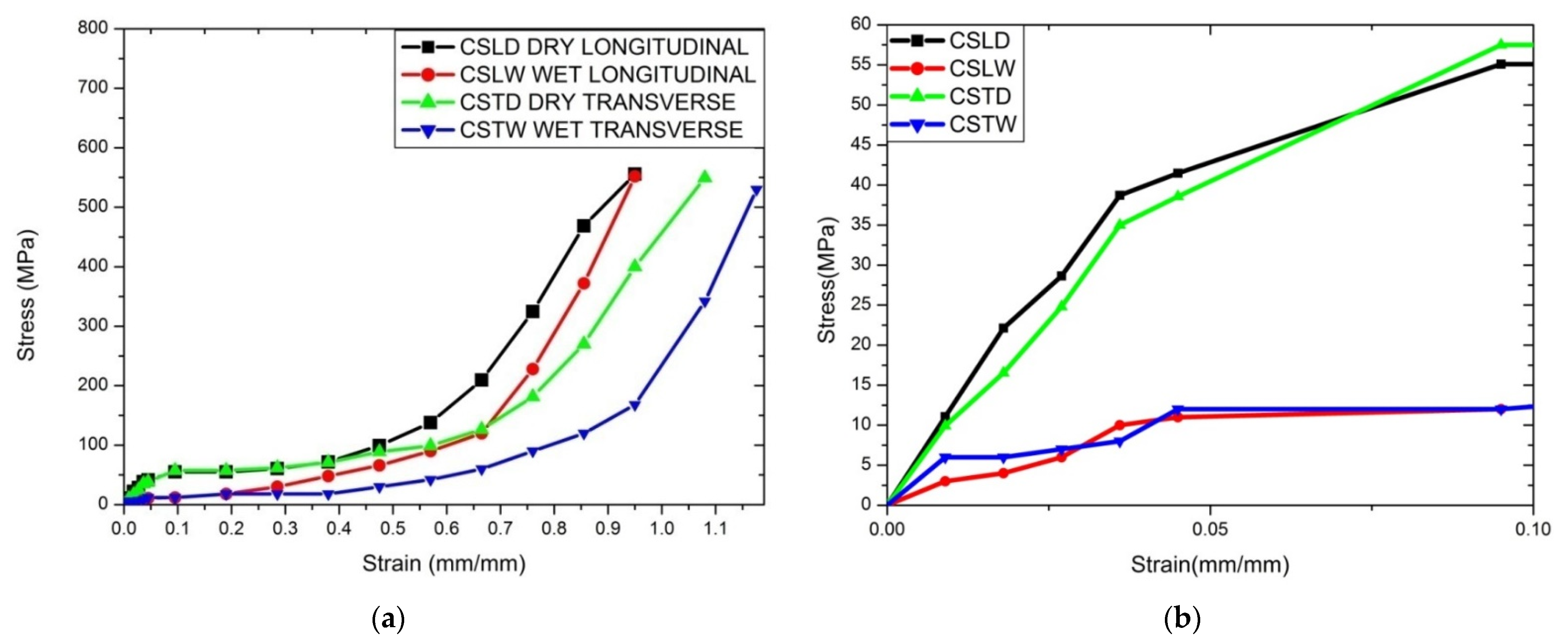

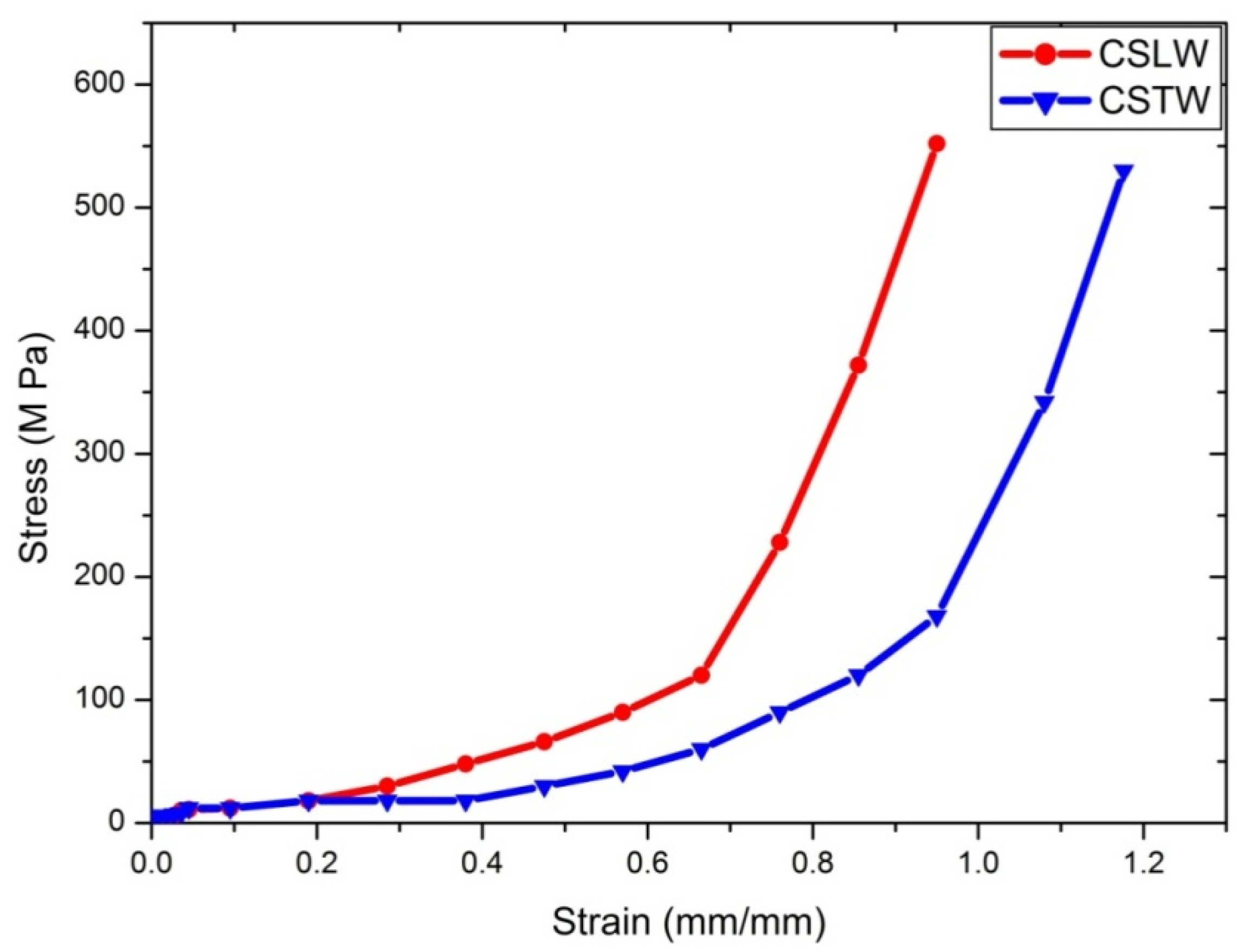

4.2.3. Compression Test

4.2.4. Hardness Test

4.2.5. Impact Test

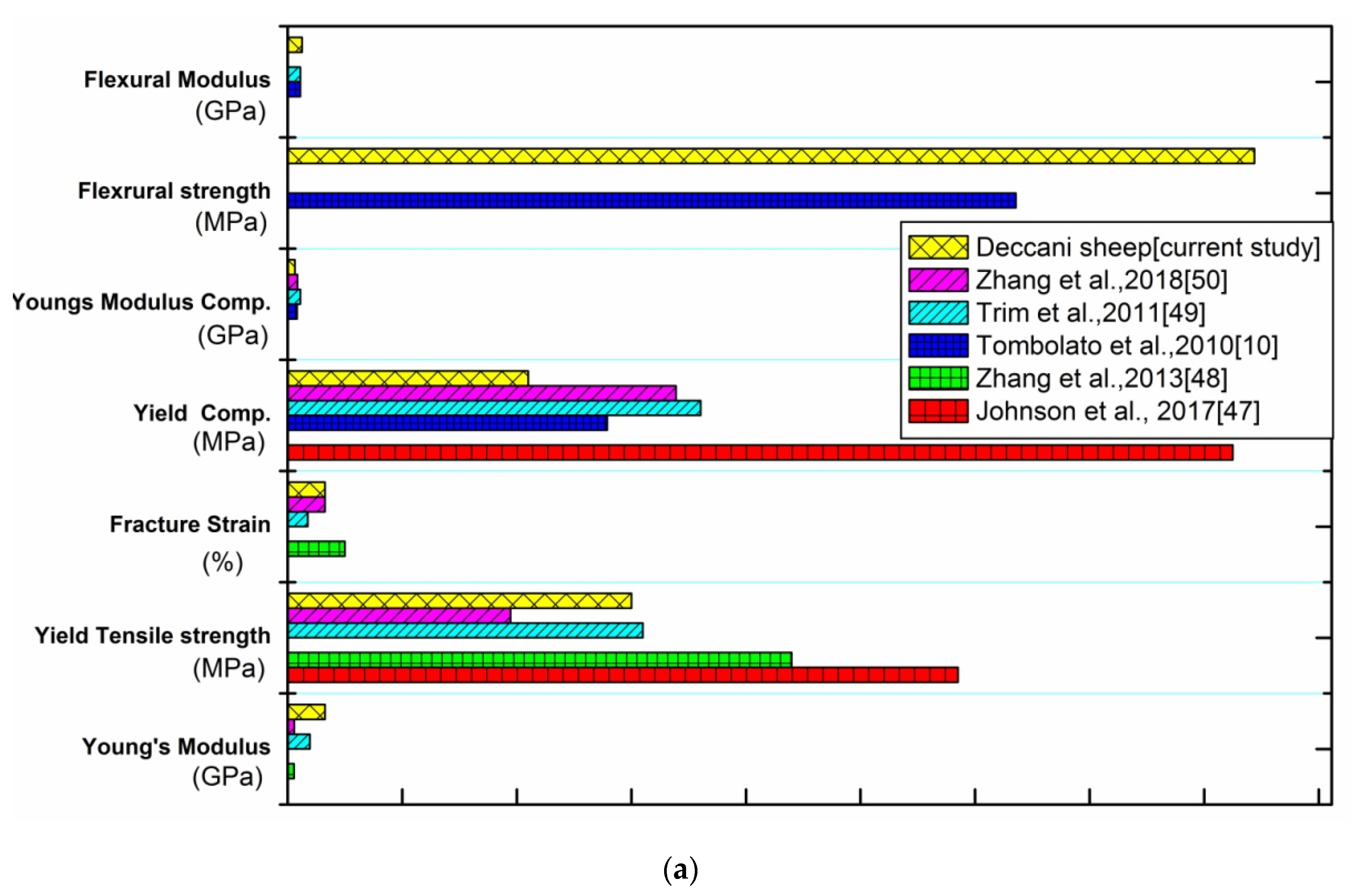

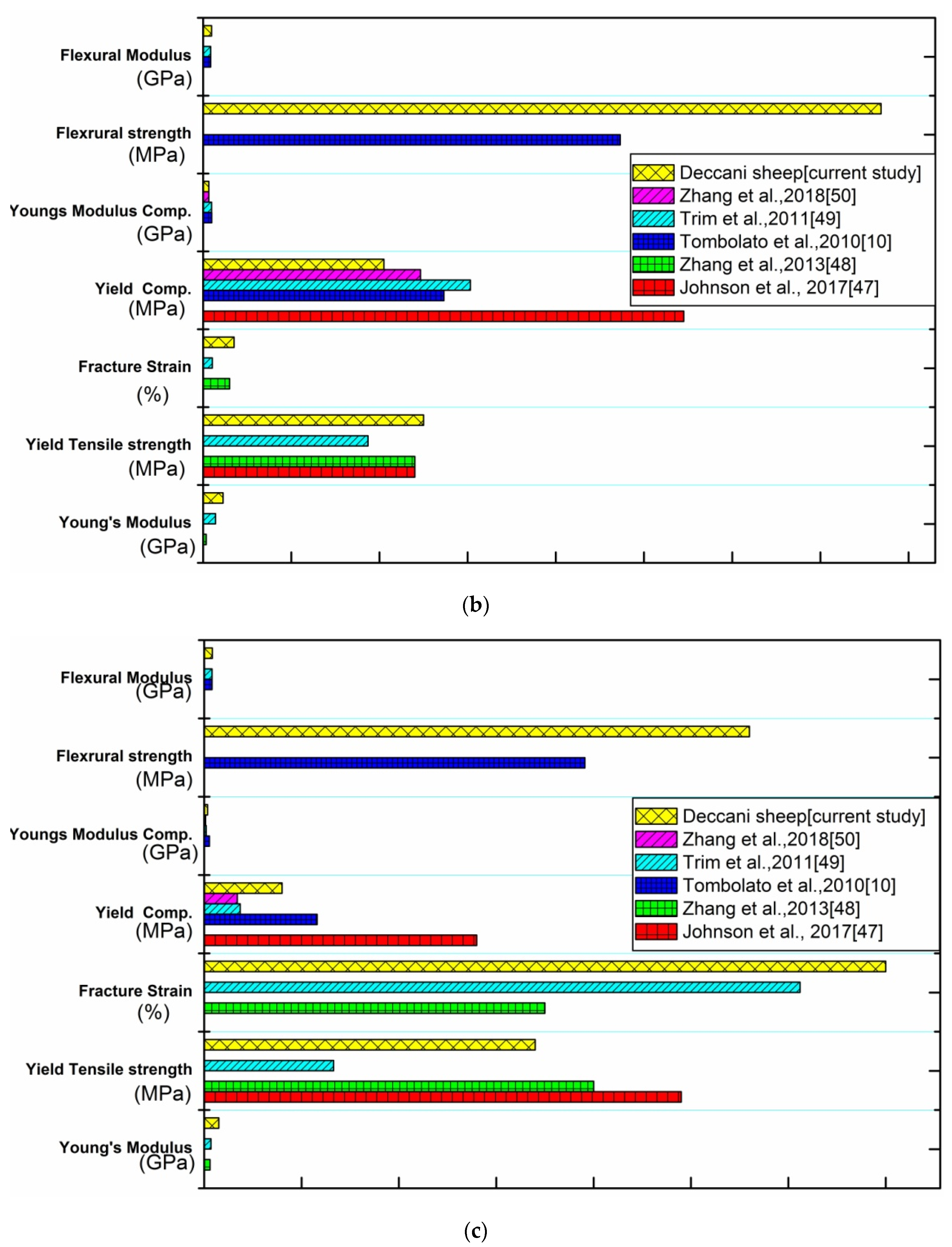

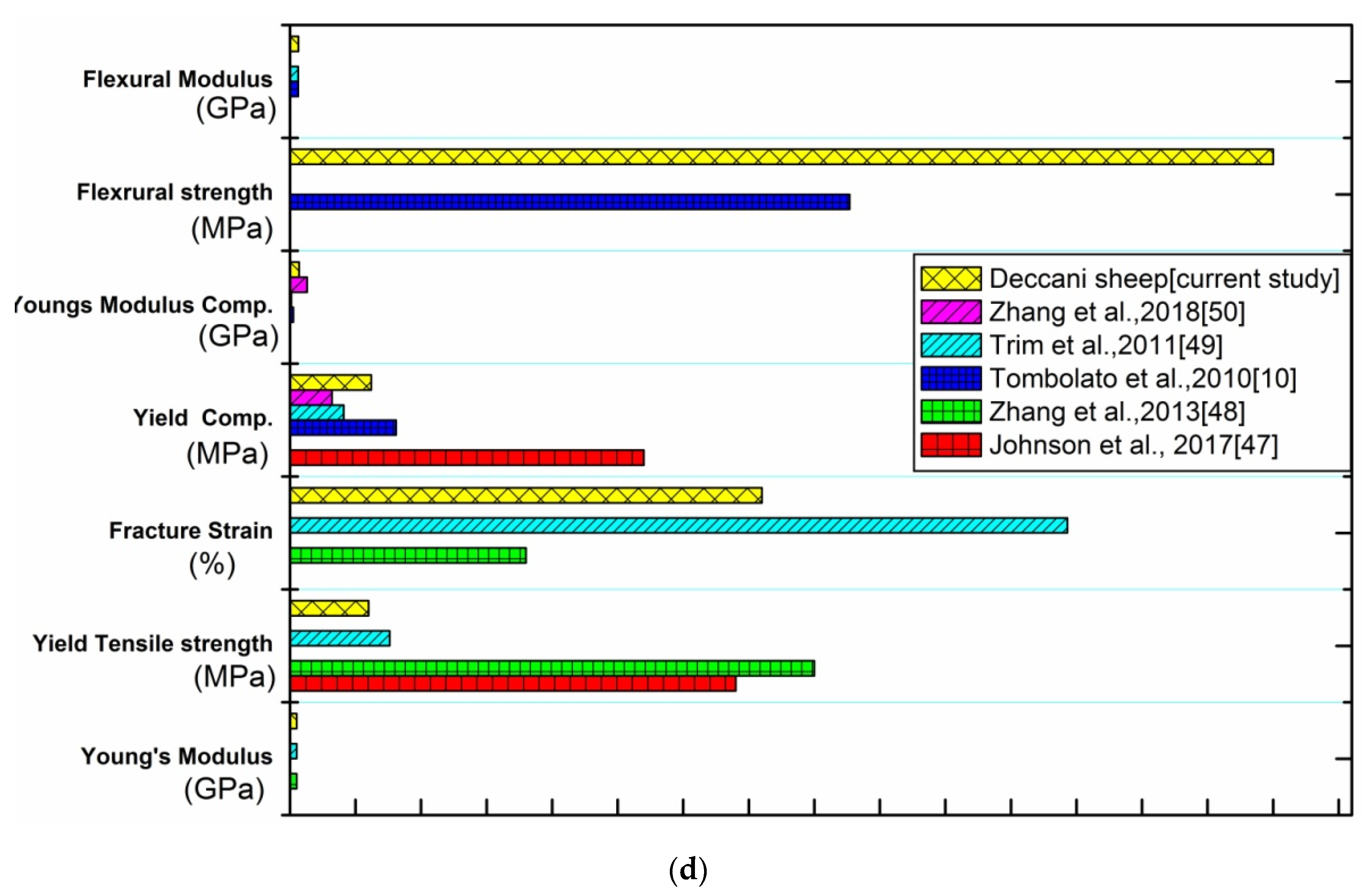

5. Experimental Comparative Study

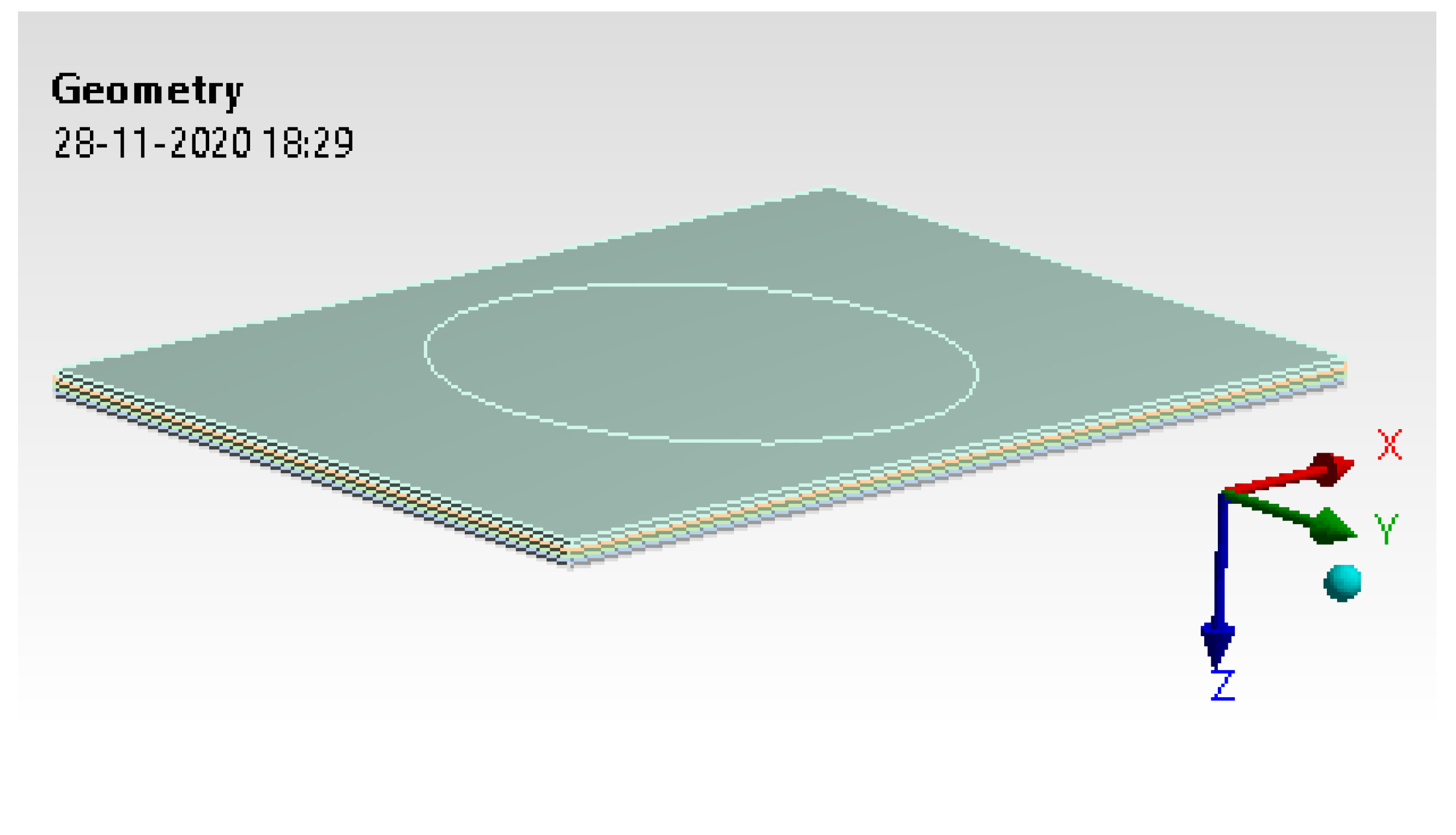

6. Simulation Study

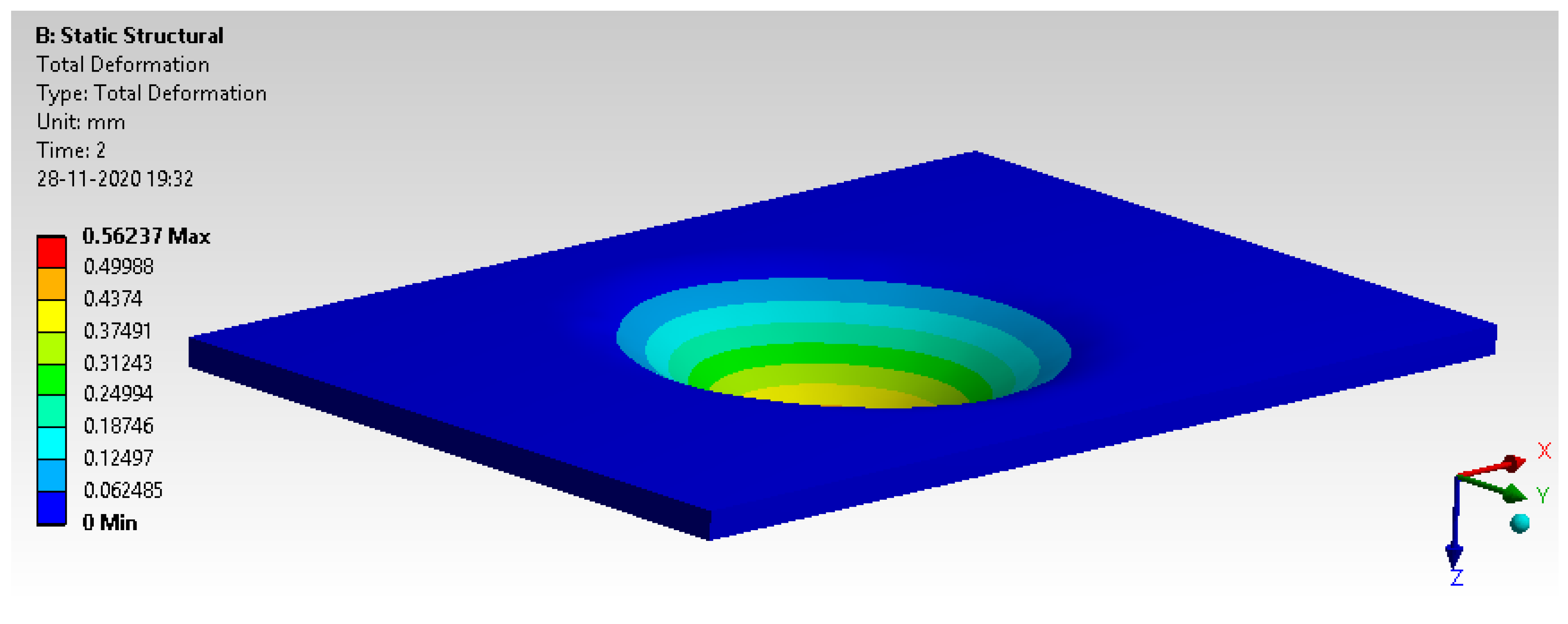

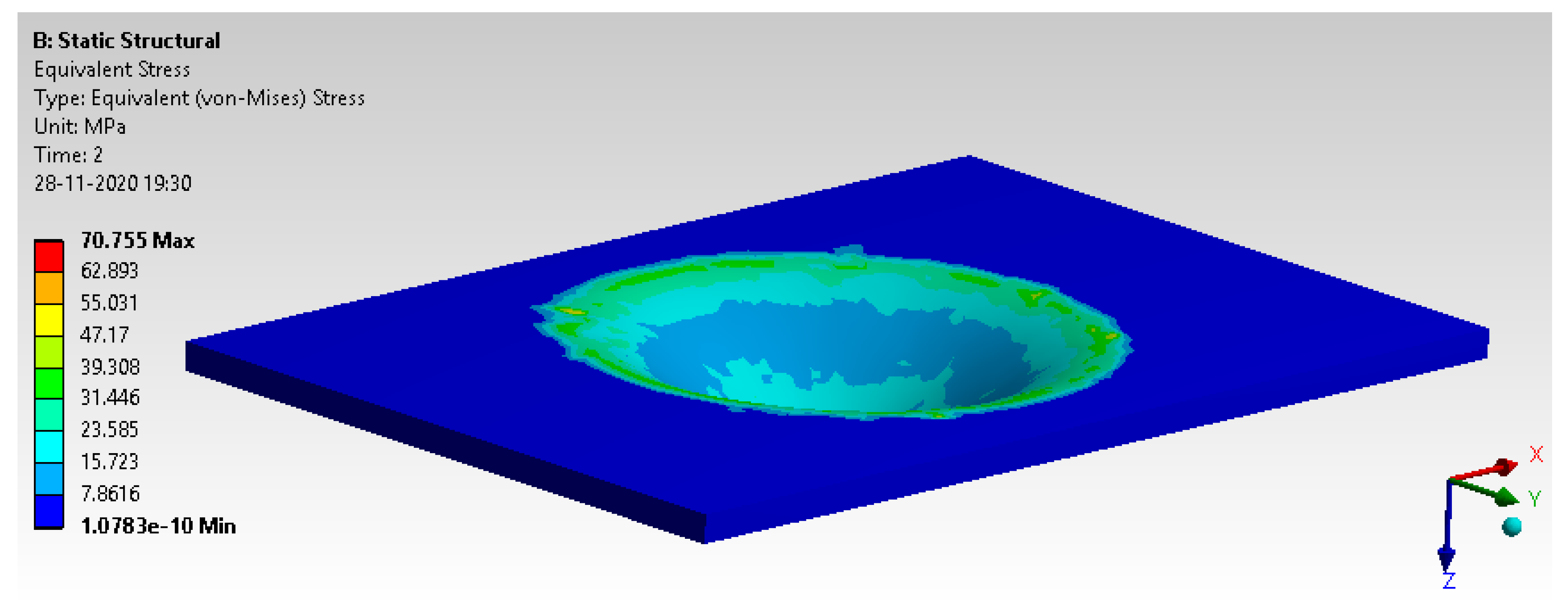

6.1. Impact Analysis

6.1.1. Geometry

6.1.2. Contact Generation

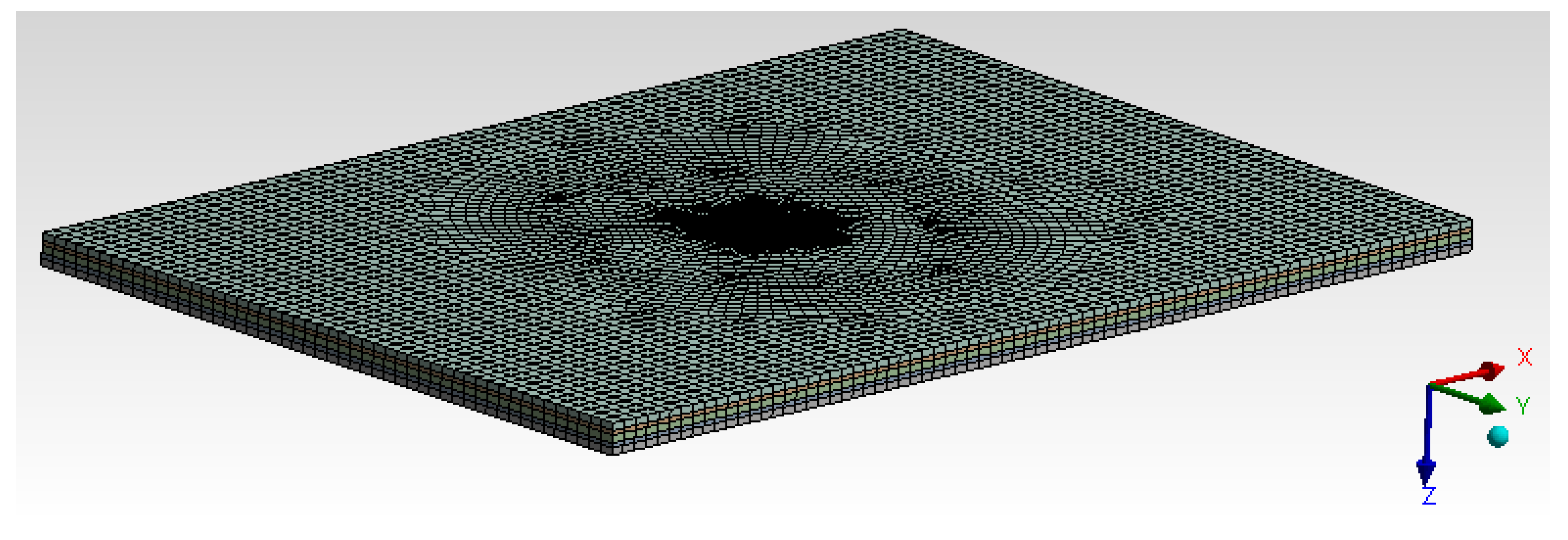

6.1.3. Mesh Generation

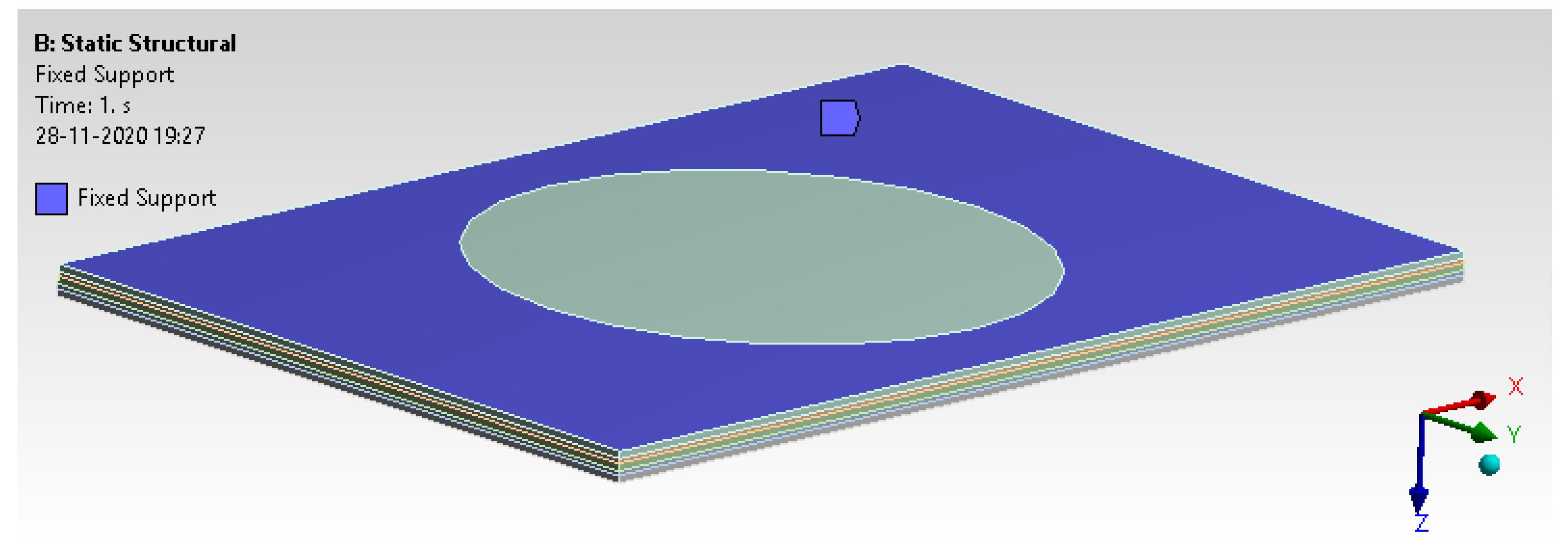

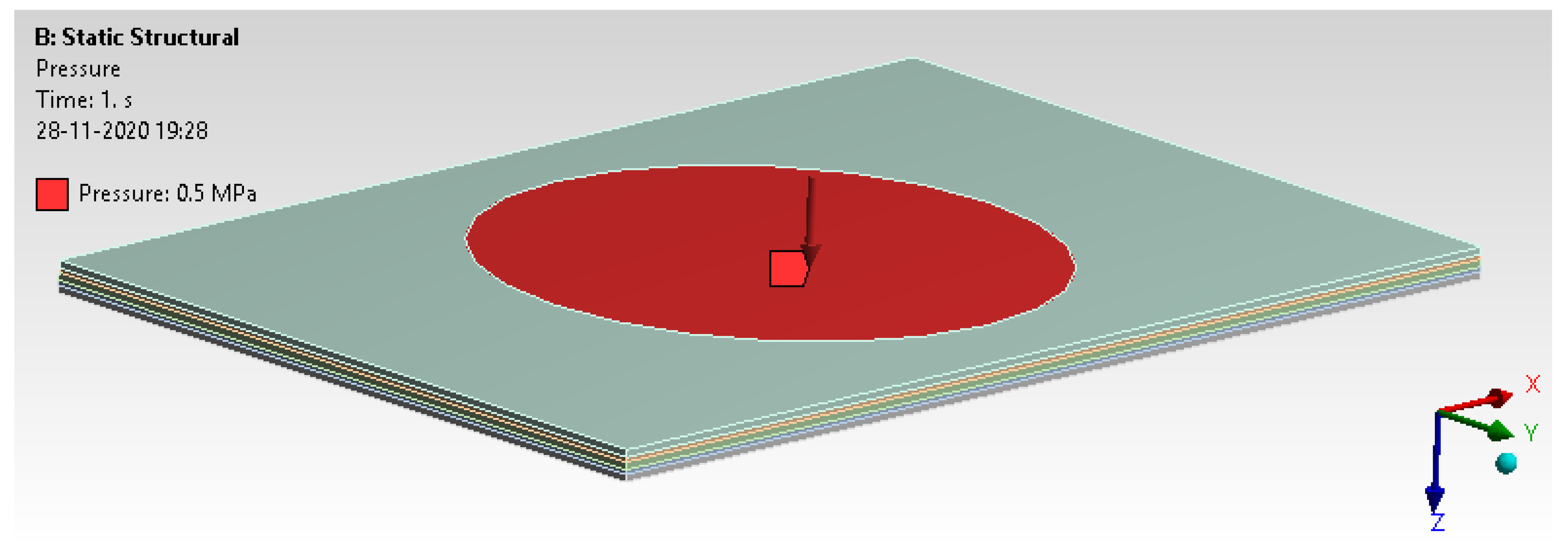

6.1.4. Loads and Boundary Conditions

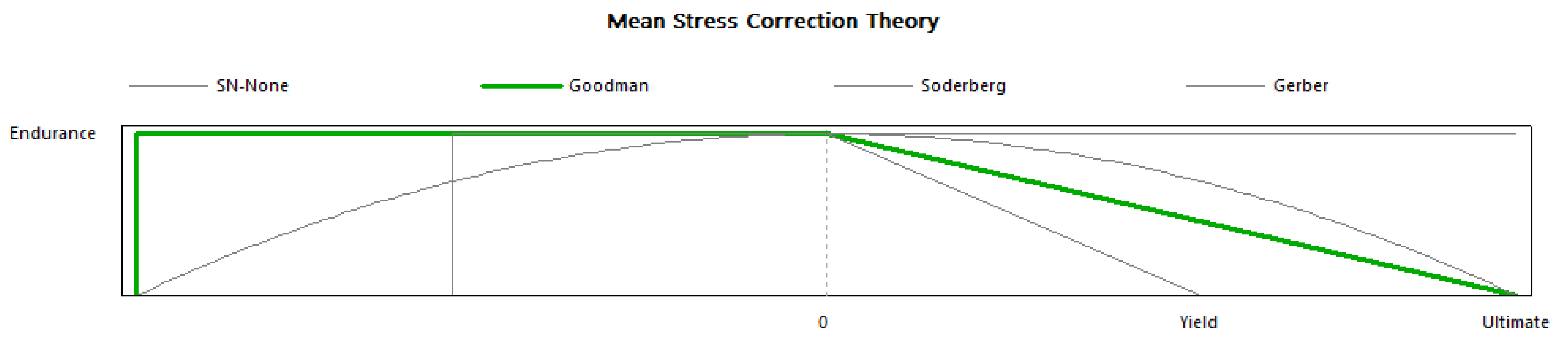

6.2. Fatigue Analysis

6.2.1. Life Cycle

6.2.2. Damage

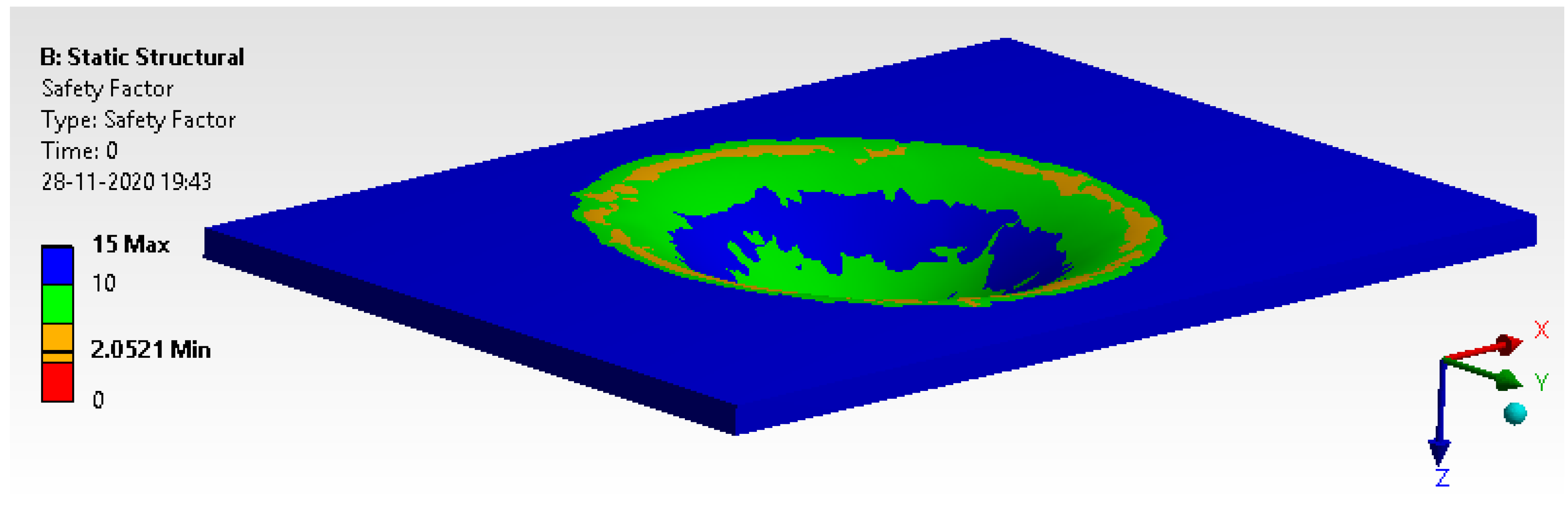

6.2.3. Factor of Safety

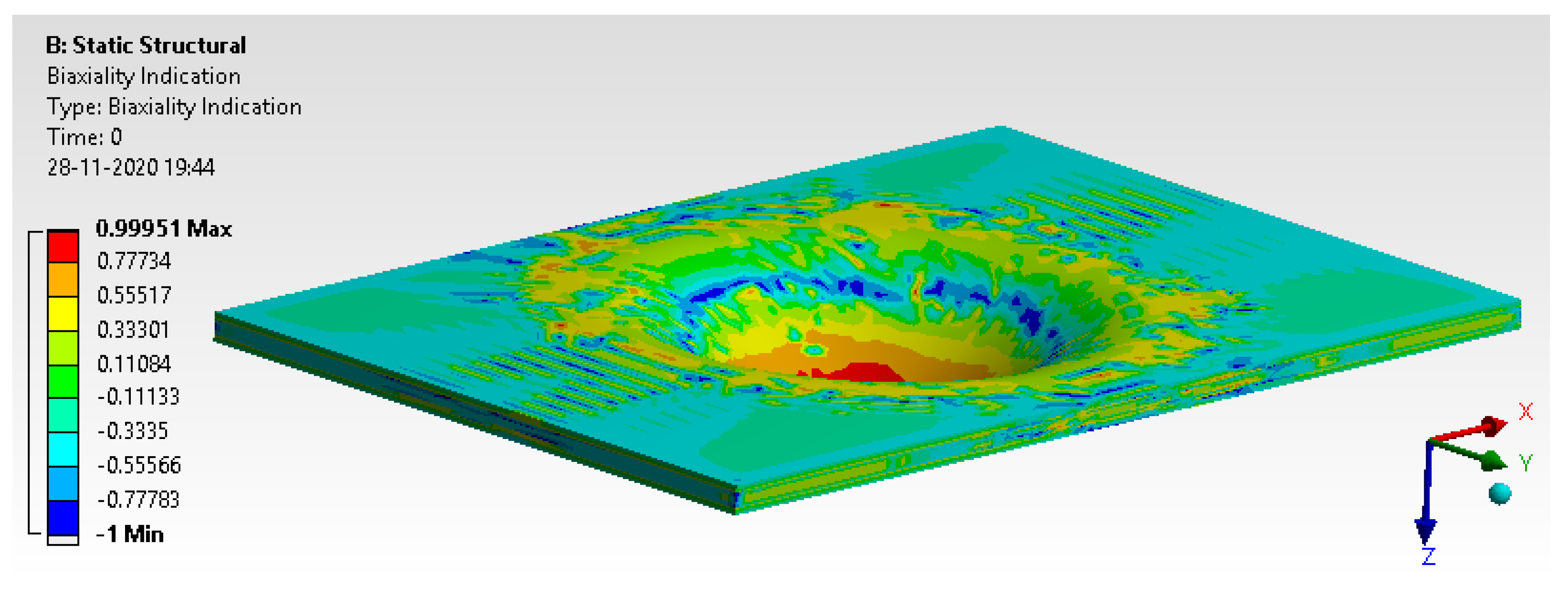

6.2.4. Bi-axiality Indication

6.3. Comparison of Experimental and Simulation Studies

6.4. Applications

7. Conclusions

- The density of big sheep horn keratin is 1.2 g/cc, which is the lowest among its peer breeds, and it can replace many thermo-set and thermoplastic polymers.

- Moisture absorption of SLD is 20.87%. This is by far the best among big sheep horns from other countries. For domestic sheep, it is 21%, pronghorn 38%, and mountain goat 15%. The tensile yield strength of SLD is 60 MPa, and Young’s modulus is 6.5 ± 0.5 GPa. The values are far more lucrative than many thermoplastics and fiber-reinforced polymer composites.

- The failure strain rate is 6.5 ± 0.5%, which is at par with the peer competitor species.

- Flexural strength is 168.75 MPa and the flexural modulus is 2.52 GPa. The observed values are tailor-made for use in moderate-duty load to light-duty load applications.

- Compression strength showed 43.5 MPa, which is slightly lower than its peers, but the maximum compressive stress is 563 MPa. Microhardness showed better results with 60 HRB in the case of the Rockwell hardness test.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lundrigan, B. Morphology of horns and fighting behavior in the family Bovidae. J. Mammal. 1996, 77, 462–475. [Google Scholar] [CrossRef]

- Kitchener, A. Fighting and the mechanical design of horns and antlers. In Biomechanics in Animal Behavior; Domenici, P., Blake, R.W., Eds.; BIOS Scientific Publishers Limited: Oxford, UK, 2000; pp. 229–253. [Google Scholar]

- Emlen, D.J. The evolution of animal weapons. Ann. Rev. Ecol. Evol. Syst. 2008, 39, 387–413. [Google Scholar] [CrossRef] [Green Version]

- McKittrick, J.; Chen, P.-Y.; Bodde, S.; Yang, W.; Novitskaya, E.; Meyers, M. The structure, functions and mechanical properties of Keratin. JOM 2012, 64, 449–468. [Google Scholar] [CrossRef]

- Wang, B.; Yang, W.; McKittrick, J.; Meyers, M.A. Keratin: Structure, Mechanical properties, occurance in biological organisms, and efforts at bioinspiration. Prog. Mater. Sci. 2016, 76, 229–318. [Google Scholar] [CrossRef] [Green Version]

- Ashby, M.; Gibson, L.; Wegst, U.; Olive, R. The mechanical properties of natural materials. l. Material property charts. Proc. R. Soc. Land. A 1995, 450, 123–140. [Google Scholar] [CrossRef]

- Wegst, U.; Ashby, M. The mechanical efficiency of natural materials. Philos. Mag. 2004, 84, 2167–2186. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chen, P.-Y.; Lin, A.Y.-M.; Seki, Y. Biological materials: Structure and Mechanical properties. Prog. Mater. Sci. 2008, 53, 1–206. [Google Scholar] [CrossRef] [Green Version]

- McKittrick, J.; Chen, P.Y.; Tombolato, L.; Novitskaya, E.E.; Trim, M.W.; Hirata, G.A.; Olevsky, E.A.; Horstemeyer, M.F.; Meyers, M.A. Energy absorbent natural materials and bioinspired design stratergies: A review. Mater. Sci. Eng. C 2010, 30, 331. [Google Scholar] [CrossRef]

- Tombolato, L.; Novitskaya, E.E.; Chen, P.Y.; Sheppardd, F.A.; McKittrick, J. Microstructure, elastic properties and deformation mechanisms of horn keratin. Acta Biomater. 2010, 6, 319–330. [Google Scholar] [CrossRef]

- Kitchener, A. Fracture toughness of horns and a reinterpreation of the horning behavior of bovids. J. Zool. Lond. 1987, 213, 621–639. [Google Scholar] [CrossRef]

- Chen, P.Y.; Mckittrick, J.; Meyers, M.A. Biological materials: Funcitonal adaptations and bioinspired designs. Prog. Mater. Sci. 2012, 57, 1492–1704. [Google Scholar] [CrossRef]

- Makinson, K.R. The elastic anisotropy of keratinous solids. The dilatational elastic constants. Aust. J. Biol. Sci. 1954, 7, 336–347. [Google Scholar] [CrossRef] [Green Version]

- Meyers, M.A.; Lin, A.Y.M.; Seki, Y.; Chen, P.Y.; Kad, B.K.; Bodde, S. Structural biological composites: An overview. JOM 2006, 58, 35–41. [Google Scholar] [CrossRef]

- Trim, M.W.; Horstemeyer, M.F.; Rhee, H.; el Kadiri, H.; Williams, L.N.; Liao, J.; Walters, K.B.; Mckittrick, J.; Park, S.J. The effects of water and microstructure of biological materials. J. Mech. Phys. Solids 2004, 52, 1963–1990. [Google Scholar]

- Ji, B.; Gao, H. Mechanical properties of nanostructure of bilogical materials. J. Mech. Phys. Solids 2004, 52, 1963–1990. [Google Scholar] [CrossRef]

- Srivastava, B.; Khatri, M.; Singh, G.; Arya, S.K. Microbial keratinases: An overview of biochemical characterization and its eco-friendly approach for industrial applications. J. Clean. Prod. 2020, 252, 119847. [Google Scholar] [CrossRef]

- Liu, S.; Xu, S.; Song, J.; Zhou, J.; Xu, L.; Li, X.; Zou, M. Mechanical properties and failure deformation mechanisms of yak horn under quasi-static compression and dynamic impact. J. Mech. Behav. Biomed. Mater. 2020, 107, 103753. [Google Scholar] [CrossRef]

- Bonser, R.H.C. Hydration sensitivity of ostrich claw keratin. J. Mater. Sci. Lett. 2002, 21, 1563–1564. [Google Scholar] [CrossRef]

- Taylor, A.M.; Bonser, R.H.C.; Farrent, J.W. The influence of hydration on the tensile and compressive properties of avian keratinous tissues. J. Mater. Sci. 2004, 39, 939–942. [Google Scholar] [CrossRef]

- Li, B.W.; Zhao, H.P.; Feng, X.Q.; Guo, W.W.; Shan, S.C. Experimental study on the mechanical properties of the horn sheaths from cattle. J. Exp. Biol. 2010, 213, 479–486. [Google Scholar] [CrossRef] [Green Version]

- Feughelman, M. Mechanical Properties and Structure of Alpha-Keratin Fibers: Wool, Human Hair, and Related Fibers; UNSW Press: Sydney, Australia, 1997. [Google Scholar]

- Bertram, J.E.; Gosline, J.M. Functional design of horse hoof keratin: The modulation of mechanical properties through hydration effects. J. Exp. Biol. 1987, 130, 121–136. [Google Scholar] [CrossRef]

- ASTM D792—20. Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement; ASTM: West Conshohocken, PA, USA, 1991. [Google Scholar]

- ASTM D5229/D5229M—20. Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials; ASTM: West Conshohocken, PA, USA, 1992. [Google Scholar]

- ASTM D3039/D3039M—17. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM E9—19. Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature; ASTM: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM D790—07. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM D785—08(2015). Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM-D256-Standard-Test-Methods-for-Determining-the-Izod-Pendulum-Impact-Resistance-of-Plastics; ASTM: West Conshohocken, PA, USA, 2010.

- Lin, H.; Mertens, K.; Kemps, B.; Govaerts, T.; de Ketelaere, B.; de Baerdemaeker, J.; Decuypere, E.; Buyse, J. New approach of testing the effect of heat stress on eggshell quality: Mechanical and material properties of eggshell and membrane. Br. Poult. Sci. 2004, 45, 476–482. [Google Scholar] [CrossRef] [PubMed]

- Bolat, G.; Yaman, Y.T.; Abaci, S. Highly sensitive electrochemical assay for Bisphenol A detection based on poly (CTAB)/MWCNTs modified pencil graphite electrodes. Sens. Actuators B Chem. 2018, 255, 140–148. [Google Scholar] [CrossRef]

- Vert, M.; Doi, Y.; Hellwich, K.-H.; Hess, M.; Hodge, P.; Kubisa, P.; Rinaudo, M.; Schué, F. Terminology for biorelated polymers and applications (IUPAC Recommendations 2012). Pure Appl. Chem. 2012, 84, 377–410. [Google Scholar] [CrossRef]

- Mooney, B.P. The second green revolution? Production of plant-based biodegradable plastics. Biochem. J. 2009, 418, 219–232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johnson, K.L.; Trim, M.W.; Francis, D.K.; Whittington, W.R.; Miller, J.A.; Bennett, C.E.; Horstemeyer, M.F. Moisture, Anisotropy, Stress State, and Strain Rate Effects on Bighorn Sheep Horn Keratin Mechanical Properties. Acta Biomater. 2017, 48, 300–308. [Google Scholar] [CrossRef] [Green Version]

- Hervy, M.; Santmarti, A.; Lahtinen, P.; Tammelin, T.; Lee, K.Y. Sample geometry dependency on the measured tensile properties of cellulose nanopapers. Mater. Des. 2017, 121, 421–429. [Google Scholar] [CrossRef]

- Fu, S.Y.; Lauke, B.; Mader, E.; Yue, C.Y.; Hu, X. Tensile properties of short glass fiber and short carbon fiber reinforced polypropylene composites. Compos. A Appl. Sci. Manuf. 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Sabir, E.C.; Zervent Ünal, B. The Using of Nettle Fiber in Towel Production and Investigation of the Performance Properties. J. Nat. Fibers 2017, 14, 781–787. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Bajwa, D.S.; Bajwa, S.G. Mechanical properties of polylactic acid composites reinforced withcotton gin waste and flax fibers. Procedia Eng. 2017, 200, 370–376. [Google Scholar] [CrossRef]

- Kandimalla, R.; Kalita, S.; Choudhury, B.; Devi, D.; Kalita, D.; Kalita, K.; Dashe, S.; Kotokya, J. Fiber from ramie plant (Boehmeria nivea): A novel suture biomaterial. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 62, 816–822. [Google Scholar] [CrossRef]

- López-Alba, E.; Schmeer, S.; Díaz, F. Energy Absorption Capacity in Natural Fiber Reinforcement Composites Structures. Materials 2018, 11, 418. [Google Scholar] [CrossRef] [Green Version]

- Jia, W.; Gong, R.H.; Soutis, C.; Hogg, P.J. Biodegradable fiber-reinforced composites composed of polylactic acid and polybutylene succinate. Plast. Rubber Compos. 2014, 43, 82–88. [Google Scholar] [CrossRef]

- Vigneswaran, C.; Pavithra, V.; Gayathri, V.; Mythili, K. Banana fiber: Scope and value added product. J. Text. Appar. Technol. Manag. 2015, 9, 1–7. [Google Scholar]

- Monteiro, S.N. Polymer matrix composites: New fibers offer new possibilities. JOM 2019, 61. Available online: www.tms.org/jom.html (accessed on 5 July 2021).

- Mallillin, A.C.; Trinidad, T.P.; Raterta, R.; Dagbay, K.; Loyola, A.S. Dietary fibre and fermentability characteristics of root crops and legumes. Br. J. Nutr. 2008, 100, 485–488. [Google Scholar] [CrossRef] [Green Version]

- Arumugaprabu, V.; Uthayakumar, M.; Cardona, F.; Sultan, M.T.H. Mechanical characterization of coir/palmyra waste fiber hybrid composites. IOP Conf. Ser. Mater. Sci. Eng. 2016, 152, 012054. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.-B.; Li, C.; Pan, Y.-T.; Shan, G.-H.; Cao, P.; He, J.; Lin, Z.-S.; Ao, N.-J.; Huang, Y.-X. Microstructure and mechanical properties of horns derived from three domestic bovines. Mater. Sci. Eng. C 2013, 33, 5036–5043. [Google Scholar] [CrossRef]

- Trim, M.W.; Horstemeyer, M.F.; Rhee, H.; El Kadiri, H.; Williams, L.N.; Liao, J.; Walters, K.B.; McKittrick, J.; Park, S.J. The effects of water and microstructure on the mechanical properties of bighorn sheep (Ovis canadensis) horn keratin. Acta Biomater. 2011, 7, 1228–1240. [Google Scholar] [CrossRef]

- Flegler, S.L.; Heckman, J.W.; Klomparens, K.L. Scanning and Transmission Electron Microscopy: An Introduction; W. H. Freeman: New York, NY, USA, 1993. [Google Scholar]

- Ashby, M.F.; Jones, D.R.H. Engineering Materials 2: An Introduction to Microstructures and Processing; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Purdue University, Department of Statistics. Available online: http://www.stat.purdue.edu/~jtroisi/STAT350Spring2015/tables/FTable.pdf (accessed on 12 June 2021).

- Irez, A.B.; Zambelis, G.; Bayraktar, E. A New design of recycled Ethylene Propylene Diene Monomer Rubber Modified Epoxy Based Composites Reinforced with Alumina Fiber; Fracture Behaviour and Damage Analyses. Materials 2019, 12, 2729. [Google Scholar] [CrossRef] [Green Version]

- Warburton, F.L. Determination of the elastic properties of horn keratin. J. Text. Inst. 1948, 39, 297–307. [Google Scholar] [CrossRef]

- Kitchener, A.; Vincent, J.F.V. Composite theory and effect of water on the stiffness of horn keratin. J. Mater. Sci. 1987, 22, 1385–1389. [Google Scholar] [CrossRef]

- Yavagal, P.S.; Kulkarni, P.A.; Patil, N.M.; Salimath, N.S.; Patil, A.Y.; Savadi, R.S.; Kotturshettar, B.B. Cleaner production of edible straw as replacement for thermoset plastic. Mater. Today Proc. 2020, 32, 492–497. [Google Scholar] [CrossRef]

- Totla, S.K.; Pillai, A.M.; Chetan, M.; Warad, C.; Vinodkumar, S.K.; Patil, A.Y.; Kotturshettar, B.B. Analysis of Helmet with Coconut Shell as the Outer Layer. Mater. Today Proc. 2020, 32, 365–373. [Google Scholar] [CrossRef]

- Kohli, A.; Ishwar, S.; Charan, M.J.; Adarsha, C.M.; Patil, A.Y.; Kotturshettar, B.B. Design and Simulation study of pineapple leaf reinforced fiberglass as an alternative material for prosthetic limb. IOP Conf. Ser. Mater. Sci. Eng. 2020, 872, 012118. [Google Scholar] [CrossRef]

- Kandekar, P.; Acharaya, A.; Chatta, A.; Kamat, A.; Patil, A.Y.; Kotturshettar, B.B. A feasibility study of plastic as an alternative to air package in performance vehicle. IOP Conf. Ser. Mater. Sci. Eng. 2020, 872, 012076. [Google Scholar] [CrossRef]

- Patil, A.Y.; Banapurmath, N.R.; Shivangi, U.S. Feasibility study of Epoxy coated Poly Lactic Acid as a sustainable replacement for River sand. J. Clean. Prod. 2020, 267, 121750. [Google Scholar] [CrossRef]

- Patil, A.Y.; Banapurmath, N.R.; Yaradoddi, J.S.; Kotturshettar, B.B.; Shettar, A.S.; Basavaraj, G.D.; Keshavamurthy, R.; Khan, T.M.Y.; Mathad, S.N. Experimental and simulation studies on waste vegetable peels as bio-composite fillers for light duty applications. Arab. J. Eng. Sci. 2019, 44, 7895–7907. [Google Scholar] [CrossRef]

- Patil, A.Y.; Hrishikesh, N.U.; Basavaraj, G.D.; Chalageri, G.R.; Kodancha, K.G. Influence of Bio-degradable Natural Fiber Embedded in Polymer Matrix. Mater. Today Proc. 2018, 5, 7532–7540. [Google Scholar] [CrossRef]

- Poornakanta, H.; Kadam, K.; Pawar, D.; Medar, K.; Makandar, I.; Patil, A.Y.; Kotturshettar, B.B. Optimization of sluice gate under fatigue life subjected for forced vibration by fluid flow. J. Mech. Eng. Stroj. Gruyter. 2018, 68, 129–142. [Google Scholar] [CrossRef] [Green Version]

- Patil, V.S.; Banoo, F.; Kurahatti, R.V.; Patil, A.Y.; Raju, G.U.; Afzal, A.; Soudagarg, M.E.M.; Kumarh, R.; Saleel, C.A. A study of sound pressure level (SPL) inside the truck cabin for new acoustic materials: An experimental and FEA approach. Alex. Eng. J. 2020, 60, 5949–5976. [Google Scholar] [CrossRef]

- Arun, Y.P.; Akash, N.; Bhavik, V.; Rahul, K.; Banapurmath, N.R.; Roseline, M.; Lekha, K.; Shridhar, N.M. Next Generation material for dental teeth and denture base material: Limpet Teeth (LT) as an alternative reinforcement in Polymethylmethacrylate (PMMA). J. Nano Electron. Phys. 2021, 5, 04001. [Google Scholar]

- Patil, A.Y.; Banapurmath, N.R.; EP, S.; Chitawadagi, M.V.; Khan, T.M.; Badruddin, I.A.; Kamangar, S. Multi-Scale Study on Mechanical Property and Strength of New Green Sand (Poly Lactic Acid) as Replacement of Fine Aggregate in Concrete Mix. Symmetry 2020, 12, 1823. [Google Scholar] [CrossRef]

- Yashasvi, D.N.; Badkar, J.; Kalburgi, J.; Koppalkar, K.; Purohit, K.; Patil, A.Y.; Fattepur, G.; Kotturshettar, B.B. Simulation study on mechanical properties of a sustainable alternative material for electric cable cover. IOP Conf. Ser. Mater. Sci. Eng. 2020, 872, 012016. [Google Scholar] [CrossRef]

- Dhaduti, S.C.; Sarganachari, S.G.; Patil, A.Y.; Khan, T.Y. Prediction of injection molding parameters for symmetric spur gear. J. Mol. Model. 2020, 26, 302. [Google Scholar] [CrossRef] [PubMed]

- Hallad, S.A.; Patil, A.Y.; Banapurmath, N.R.; Hunashyal, A.M.; Shettar, A.S.; Ayachit, N.H. Experimental and Numerical Validation on the Utilization of Polymer Based Nano-Composites for Structural Applications Using FEA Software Tool, Material Focus. Am. Sci. Publ. 2017, 6, 685–690. [Google Scholar] [CrossRef]

- Hallad, S.A.; Banapurmath, N.R.; Patil, A.Y.; Hunashyal, A.M.; Shettar, A.S. Studies on the effect of multi-walled carbon nano tube–reinforced polymer based nano-composites using finite element analysis software tool. J. Nano Eng. Nano Syst. 2016, 230, 200–212. [Google Scholar]

- Sharath, B.N.; Venkatesh, C.V.; Afzal, A. Multi Ceramic Particles Inclusion in the Aluminium Matrix and Wear Characterization through Experimental and Response Surface-Artificial Neural Networks. Materials 2021, 14, 2895. [Google Scholar] [CrossRef]

- Sathish, T.; Kaladgi, A.R.R.; Mohanavel, V.; Arul, K.; Afzal, A.; Aabid, A. Experimental Investigation of the Friction Stir Weldability of AA8006 with Zirconia Particle Reinforcement and Optimized Process Parameters. Materials 2021, 14, 2782. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Khan, M.; Khan, S.A.; Afzal, A.; Subbiah, R.; Bakar, E.A. Determination of Non-Recrystallization Temperature for Niobium Micro alloyed Steel. Materials 2021, 14, 2639. [Google Scholar] [CrossRef]

- Nagaraja, S.; Nagegowda, K.U.; Kumar, V.A.; Alamri, S.; Afzal, A.; Thakur, D.; Kaladgi, A.R.; Panchal, S.; Saleel, C.A. Influence of the Fly Ash Material Inoculants on the Tensile and Impact Characteristics of the Aluminum AA 5083/7.5SiC Composites. Materials 2021, 14, 2452. [Google Scholar] [CrossRef] [PubMed]

| Specimen | Weight of Specimen in Air (g) | Weight of Specimen in Water (g) | the Density of Specimen (g/cc) | Moisture Absorption (%) |

|---|---|---|---|---|

| 1 | 0.65 | 0.13 | 1.25 | 21.74 |

| 2 | 0.80 | 0.14 | 1.212 | 20 |

| Symbol | Designation |

|---|---|

| SLD | Stress in Longitudinal direction of Dry Specimen |

| SLW | Stress in Longitudinal direction of Wet Specimen |

| STD | Stress in Transverse direction ofDry Specimen |

| STW | Stress in Transverse direction of Wet Specimen |

| Properties | Dry Longitudinal | Wet Longitudinal | Dry Transverse | Wet Transverse |

|---|---|---|---|---|

| Young’s Modulus (GPa) | 6.5 ± 0.5 | 1.5 ± 0.6 | 4.5 ± 0.15 | 0.45 ± 0.5 |

| Yield Strength (MPa) | 53.5 ± 6.5 | 26 ± 6.5 | 43 ± 7.5 | 5 ± 1.5 |

| Ultimate Strength (MPa) | 62 ± 4.5 | 43 ± 3.5 | 46 ± 4.5 | 8.1 ± 2.5 |

| Failure Strain (%) | 6.5 ± 0.5 | 70 ± 0.5 | 5.3 ± 0.5 | 35 ± 0.1 |

| Toughness (M J/ | 3.14 ± 0.3 | 26.9 ± 0.1 | 1.62 ± 0.5 | 2.9 ± 0.1 |

| Two-Way ANOVA | Yield Stress | Young’s Modulus | ||||

|---|---|---|---|---|---|---|

| Condition (Dry and Wet) | Direction (Longitudinal and Transverse) | Interaction | Condition (Dry and Wet) | Direction (Longitudinal and Transverse) | Interaction | |

| DF | 1 | 1 | 1 | 1 | 1 | 1 |

| SS | 6079.5845 | 1221.4845 | 187.8845 | 107.973 | 9.072 | 0.5882 |

| MS | 6079.5845 | 1221.4845 | 187.8845 | 107.973 | 9.072 | 0.5882 |

| F- Statistic Value (df1,df2) | 746.1215 (1,16) | 149.9076 (1,16) | 23.0583 (1,16) | 1023.126 (1,16) | 85.9645 (1,16) | 5.5741 (1,16) |

| p-value | 7.43 × 10−15 | 1.54 × 10−9 | 0.0001956 | 6.66 × 10−16 | 7.78 × 10−8 | 0.03125 |

| Two-Way ANOVA | Ultimate Strength | Failure Strain | ||||

|---|---|---|---|---|---|---|

| Condition (Dry and Wet) | Direction (Longitudinal and Transverse) | Interaction | Condition (Dry and Wet) | Direction (Longitudinal and Transverse) | Interaction | |

| DF | 1 | 1 | 1 | 1 | 1 | 1 |

| SS | 3953.72 | 3120.002 | 618.272 | 10,875.9816 | 1507.0216 | 1427.881 |

| MS | 3953.672 | 3120.002 | 618.272 | 10,875.9816 | 1507.0216 | 1427.881 |

| F- Statistic Value (df1,df2) | 586.9466 (1,16) | 463.1832 (1,16) | 91.7862 (1,16) | 16,824.6857 (1,16) | 2331.299 (1,16) | 2208.8718 (1,16) |

| p-value | 0 | |||||

| Properties | Dry Longitudinal | Wet Longitudinal | Dry Transverse | Wet Transverse |

|---|---|---|---|---|

| Flexural Strength (M Pa) | 168.75 | 56.25 | 153.75 | 75 |

| Flexural Modulus (G Pa) | 2.52 | 0.84 | 1.91 | 0.651 |

| Ultimate Load (KN) | 0.09 | 0.03 | 0.082 | 0.04 |

| Two-Way ANOVA | Flexural Modulus | Flexural Strength | ||||

|---|---|---|---|---|---|---|

| Condition (Dry and Wet) | Direction (Longitudinal and Transverse) | Interaction | Condition (Dry and Wet) | Direction (Longitudinal and Transverse) | Interaction | |

| DF | 1 | 1 | 1 | 1 | 1 | 1 |

| SS | 7.4164 | 1.0301 | 0.3078 | 42527.2531 | 45.7781 | 1500.7781 |

| MS | 7.4164 | 1.0301 | 0.3078 | 42527.2531 | 45.7781 | 1500.7781 |

| F- Statistic Value (df1,df2) | 118.7768 (1,16) | 16.4979 (1,16) | 4.929 (1,16) | 3347.6965 (1,16) | 4.3674 (1,16) | 118.1395 (1,16) |

| p-value | 8.19 × 10−9 | 0.0009064 | 0.0412 | 8.51 × 10−9 | ||

| Symbol | Designation |

|---|---|

| CSLD | Compressive Stress in Longitudinal direction of Dry Specimen |

| CSLW | Compressive Stress in Longitudinal direction of Wet Specimen |

| CSTD | Compressive Stress in Transverse direction of Dry Specimen |

| CSTW | Compressive Stress in Transverse direction of Wet Specimen |

| Properties | Dry Longitudinal | Wet Longitudinal | Dry Transverse | Wet Transverse |

|---|---|---|---|---|

| Young’s Modulus (GPa) | 1.25 ± 0.2 | 0.33 ± 0.1 | 1.01 ± 0.2 | 0.6 ± 0.1 |

| Yield Strength (MPa) | 41 ± 2.5 | 8 ± 1.2 | 38 ± 2.2 | 5.93 ± 1.2 |

| Yield Strain (%) | 4.5 ± 0.6 | 3.2 ± 0.2 | 4.2 ± 0.1 | 1.7 ± 0.2 |

| Max. stress (MPa) | 557.71 ± 5 | 557.71 ± 5 | 550 ± 5 | 520.1 ± 6 |

| Name of Hardness Test | Rockwell Hardness Test |

|---|---|

| Applied Load | 60 Kgf |

| Indenture Used | 1/16″ Ball indenture(2.5 mm) |

| The hardness of Deccani Sheep Horn @ base part | 61 HRB/60/30 |

| The hardness of Deccani Sheep Horn @ middle part | 60 HRB/60/30 |

| The hardness of Deccani Sheep Horn @ tip | 28 HRB/60/30 |

| 60 HRB/load of 60/time of 30 s | 60 HRB/60/30 |

| Name of Test | Energy Absorbed (U) (J) | Impact Strength | Angle of Pendulum |

|---|---|---|---|

| Izode (ASTM D256) | 14 | 274.51 | 90 |

| Charpy | 20 | NA | 140 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mysore, T.H.M.; Patil, A.Y.; Raju, G.U.; Banapurmath, N.R.; Bhovi, P.M.; Afzal, A.; Alamri, S.; Saleel, C.A. Investigation of Mechanical and Physical Properties of Big Sheep Horn as an Alternative Biomaterial for Structural Applications. Materials 2021, 14, 4039. https://doi.org/10.3390/ma14144039

Mysore THM, Patil AY, Raju GU, Banapurmath NR, Bhovi PM, Afzal A, Alamri S, Saleel CA. Investigation of Mechanical and Physical Properties of Big Sheep Horn as an Alternative Biomaterial for Structural Applications. Materials. 2021; 14(14):4039. https://doi.org/10.3390/ma14144039

Chicago/Turabian StyleMysore, Tajammul Hussain M., Arun Y. Patil, G. U. Raju, N. R. Banapurmath, Prabhakar M. Bhovi, Asif Afzal, Sagr Alamri, and C Ahamed Saleel. 2021. "Investigation of Mechanical and Physical Properties of Big Sheep Horn as an Alternative Biomaterial for Structural Applications" Materials 14, no. 14: 4039. https://doi.org/10.3390/ma14144039

APA StyleMysore, T. H. M., Patil, A. Y., Raju, G. U., Banapurmath, N. R., Bhovi, P. M., Afzal, A., Alamri, S., & Saleel, C. A. (2021). Investigation of Mechanical and Physical Properties of Big Sheep Horn as an Alternative Biomaterial for Structural Applications. Materials, 14(14), 4039. https://doi.org/10.3390/ma14144039