The Influence of CFRP Sheets on the Load-Bearing Capacity of the Glued Laminated Timber Beams under Bending Test

Abstract

:1. Literature Survey

2. Research Significance

3. Materials and Methods

3.1. Materials

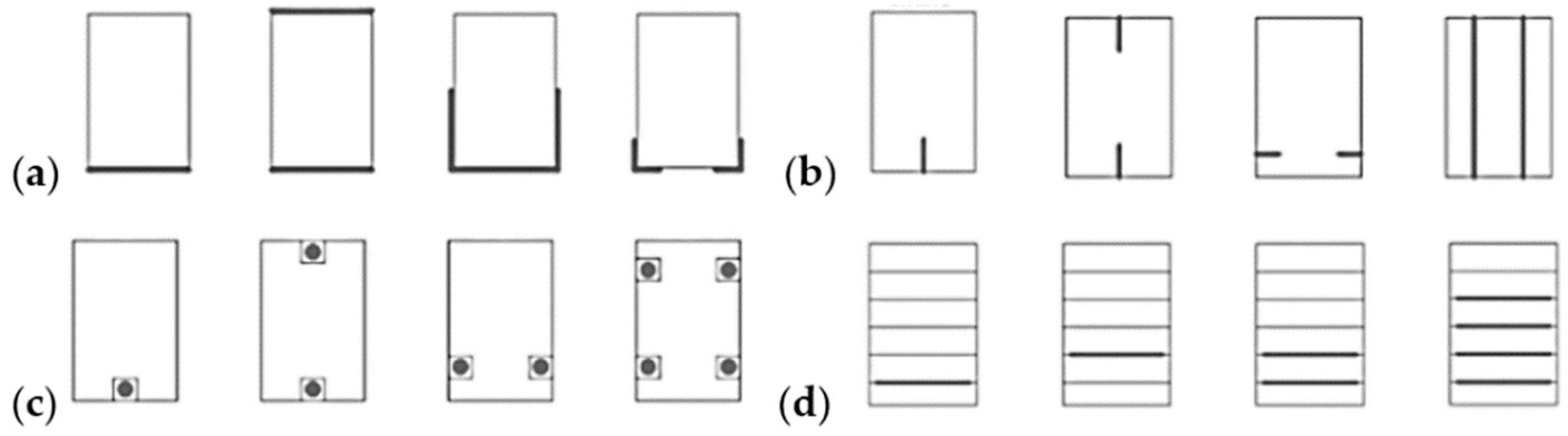

3.2. Lamination Process

3.3. Bending Test

3.4. X-ray Computed Tomography Test

4. Results

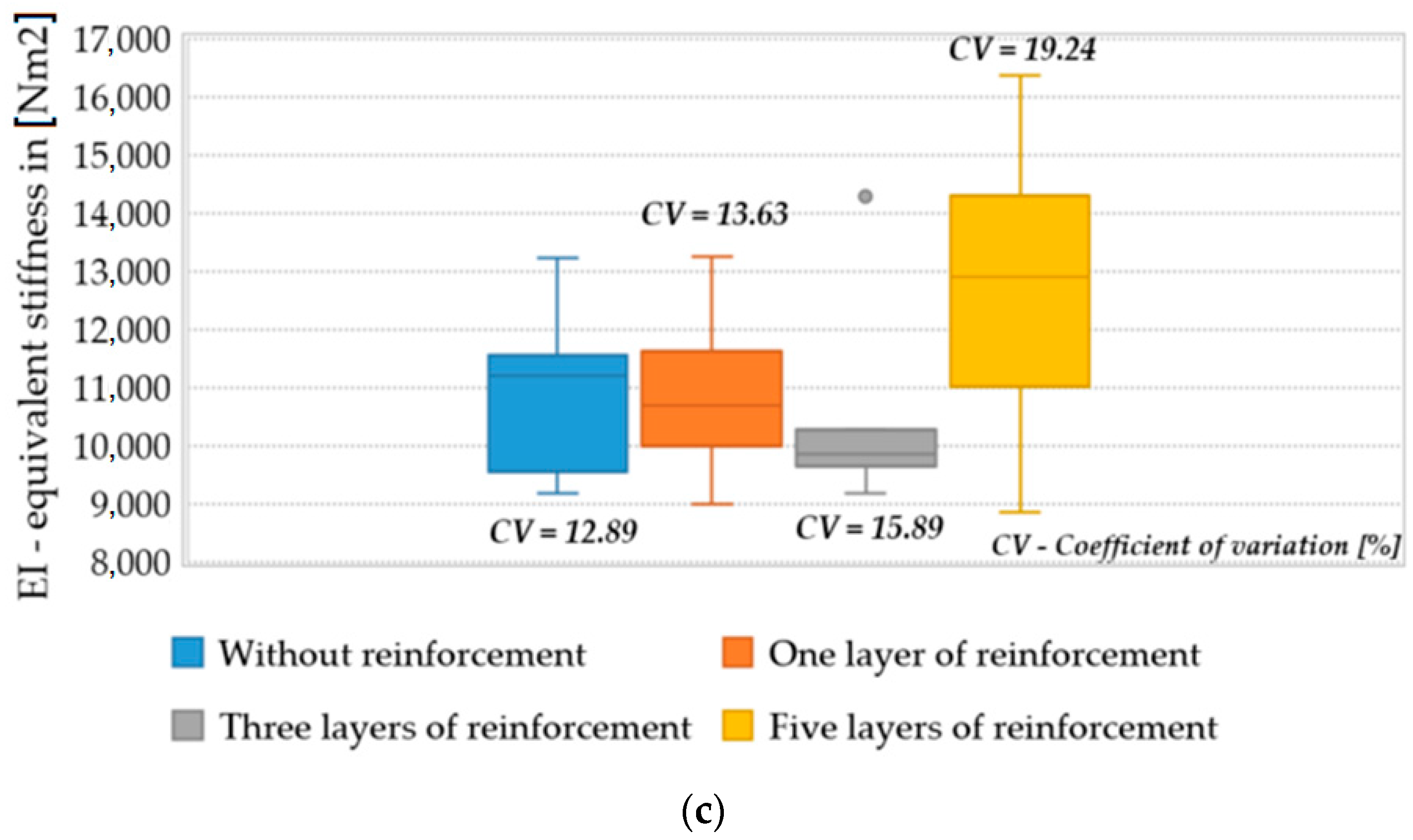

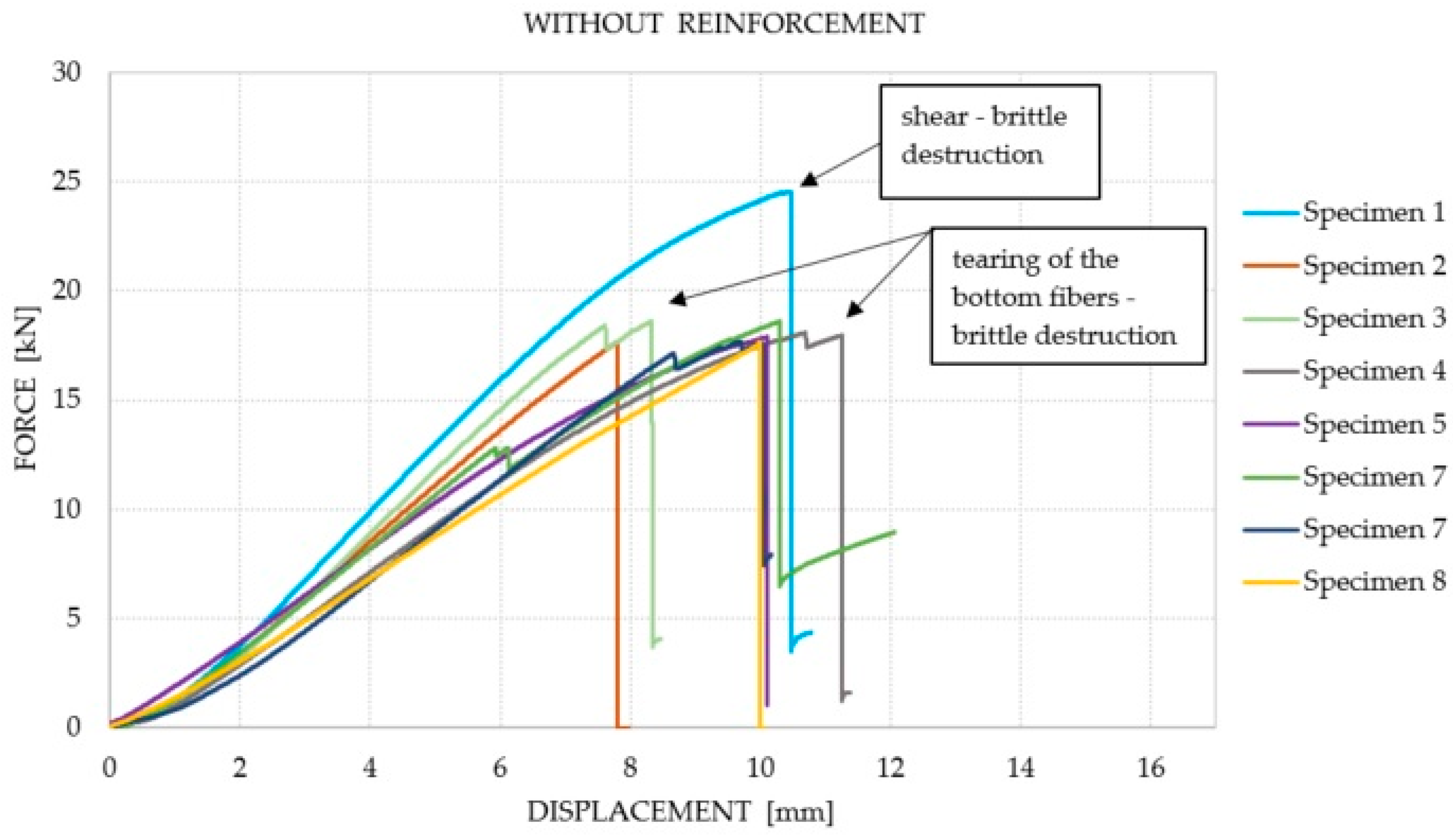

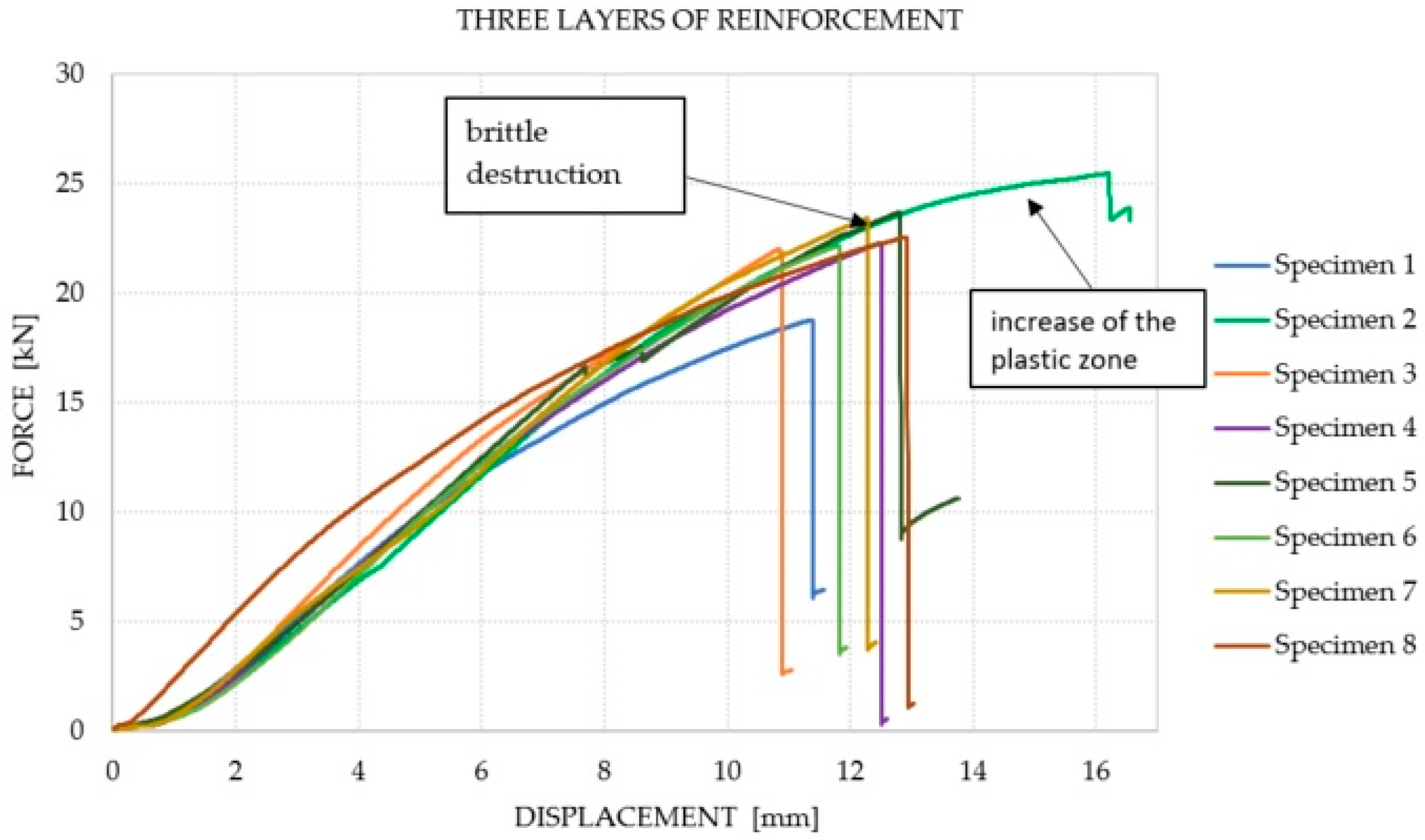

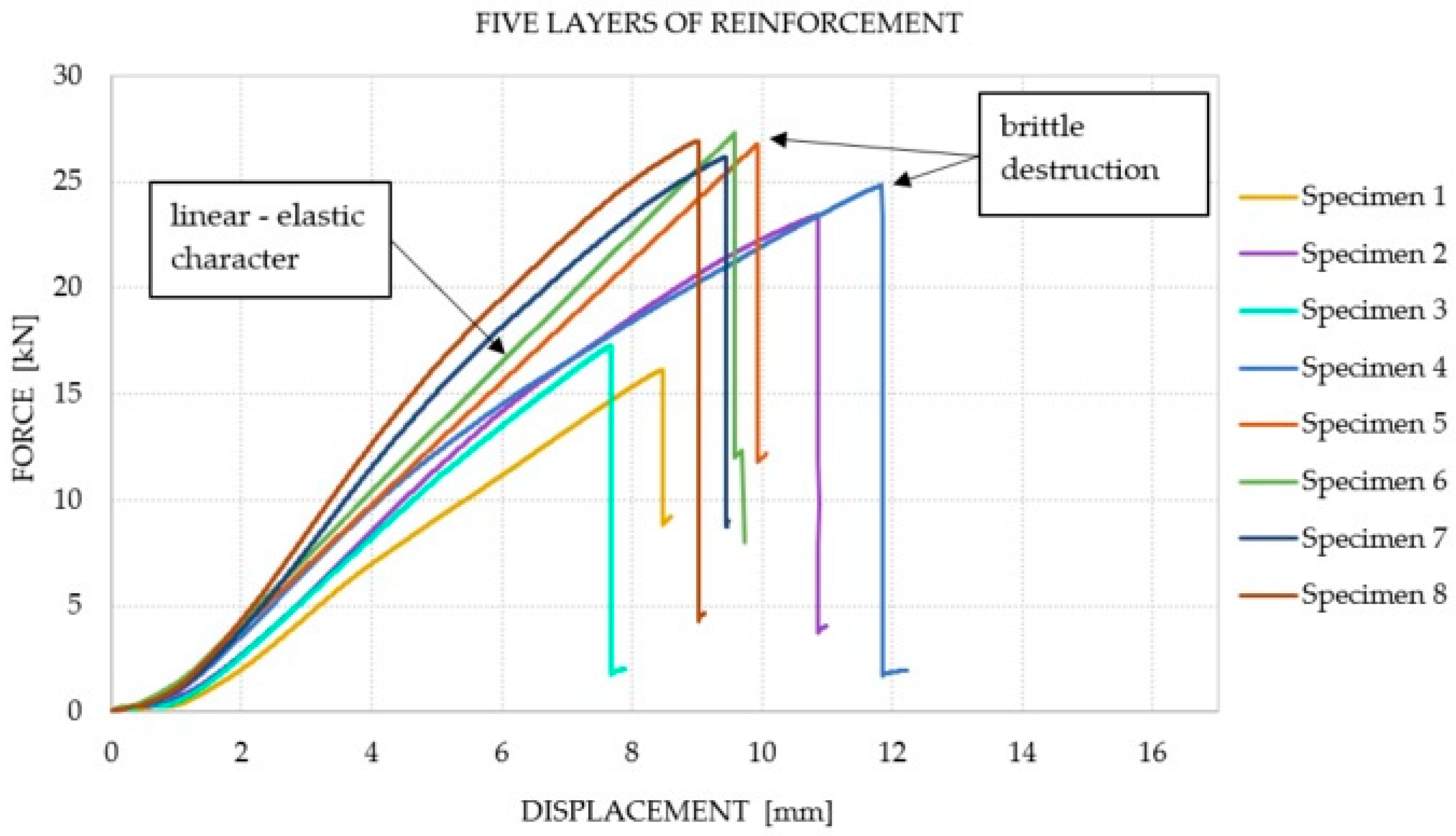

4.1. Load-Bearing Capacity

4.2. X-ray Computed Tomography Analysis

5. Conclusions

- In the Glued Laminated Timber beams subjected to bending, the dominant failure was the failure caused by the exceeding of the limit tensile stresses, and the crack occurred on the bottom surface of the beam. The most common type of failure was the breaking of the bottom fibers in the tensile zone, which was rarely accompanied by shear.

- CFRP-reinforced beams exhibit linear elasticity until the moment of failure. Strengthening the bottom surface of a beam by gluing a composite allows its ability to absorb tensile stresses to be extended, which leads to an increase in the load-bearing capacity and ductility of the beam. During the conducted experiment, there were no breaks in the reinforcement fibers.

- The computed tomography examination before the application of the load, and also after the destruction of the beams, enabled the very good integrity between the beams and CFRP to be confirmed—regardless of the number of reinforcement layers, the laminate did not detach.

- It was noticed that the number of CFRP laminate layers has an influence on the mechanism of failure. For the beams reinforced with three and five layers, the dominant failure mechanism began with a crack at the connection of the wood and the adhesive layer in the support zone. This is related to the phenomenon of the concentration of interfacial shear and pull-off stresses. In practice, this phenomenon may have a negative impact on the final strength of reinforced elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Symbols

| fm,g,k | bending strength of the GL28h spruce wood |

| ft,0,g,k | tensile strength of the GL28h spruce wood |

| fc,0,g,k | compressive strength of the GL28h spruce wood |

| E0,g,mean | mean value of modulus of elasticity of the GL28h spruce wood |

| ft,cf | tensile strength of carbon fiber mats (MPa) |

| elastic modulus of the carbon fiber mats (GPa) | |

| elongation at break of the carbon fiber mats (%) | |

| elongation at break of the epoxy resin (%) | |

| Eer | modulus of elasticity in flexural of the epoxy resin (GPa) |

| Ft,er | tensile strength of the epoxy resin (MPa) |

| F | destructive force (kN) |

| l | span of the beam (m) |

| u | vertical displacement of the beam (mm) |

| equivalent stiffness within the displacement range of 2–6 mm (Nm2) | |

| CV | coefficient of variation (%) |

References

- Nilson, T.; Rowell, R. Historical Wood—Structure and Properties. J. Cult. Herit. 2012, 13, S5–S9. [Google Scholar] [CrossRef]

- Nowak, T.; Karolak, A.; Sobótka, M.; Wyjadłowski, M. Assessment of the Condition of Wharf Timber Sheet Wall Material by Means of Selected Non-Destructive Methods. Materials 2019, 12, 1532. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jasieńko, J.; Nowak, T.P. Solid Timber Beams Strengthened with Steel Plates–Experimental studies. Constr. Build. Mater. 2014, 63, 81–88. [Google Scholar] [CrossRef]

- Cruz, H.; Custódio, J. Adhesives for On-Site Rehabilitation of Timber Structures. J. Adhes. Sci. Technol. 2010, 24, 1473–1499. [Google Scholar] [CrossRef]

- Duarte, A.C.; Negrão, J.H.; Cruz, H.M.; Balseiro, A.M. Bending Strength of Timber Beams Rehabilitated with Reinforced Epoxy Mortar Plates. J. Struct. Eng. 2008, 134, 792–800. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M. Strengthening of Timber Beams with High Strength Steel Cords. Compos. Part B Eng. 2011, 42, 1480–1491. [Google Scholar] [CrossRef]

- Lim, J.C.; Ozbakkaloglu, T. Confinement Model for FRP-Confined High-Strength Concrete. J. Compos. Constr. 2014, 18, 04013058. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, G.; Li, G. Performance of Circular Concrete-Filled Fiber-Reinforced Polymer-Steel Composite Tube Columns under Axial Compression. J. Reinf. Plast. Compos. 2014, 33, 1911–1928. [Google Scholar] [CrossRef]

- Barbieri, G.; Biolzi, L.; Bocciarelli, M.; Cattaneo, S. Pull out of FRP Reinforcement from Masonry Pillars: Experimental and Numerical Results. Compos. Part B Eng. 2015, 69, 516–525. [Google Scholar] [CrossRef]

- Pichandi, S.; Rana, S.; Oliveira, D.; Fangueiro, R. Fibrous and Composite Materials for Blast Protection of Structural Elements—A State-of-the-art Review. J. Reinf. Plast. Compos. 2013, 32, 1477–1500. [Google Scholar] [CrossRef]

- Ostrowski, K. Does the Carbon Fibre Coating Reinforcement Have An Influence on the Bearing Capacity of High-Performance Self-Compacting Fibre-Reinforced Concrete? Materials 2019, 12, 4054. [Google Scholar] [CrossRef] [Green Version]

- Gilfillan, J.R.; Gilbert, S.G.; Patrick, G.R.H. The Use of FRP Composites in Enhancing the Structural Behavior of Timber Beams. J. Reinf. Plast. Compos. 2003, 22, 1373–1388. [Google Scholar] [CrossRef]

- Jankowski, L.J.; Jasieńko, J.; Nowak, T.P. Experimental Assessment of CFRP Reinforced Wooden Beams by 4-Point Bending Tests and Photoelastic Coating Technique. Mater. Struct. 2010, 43, 141–150. [Google Scholar] [CrossRef]

- Jasieńko, J. Połączenia Klejowe i Inżynierskie w Naprawie, Konserwacji i Wzmacnianiu Zabytkowych Konstrukcji Drewnianych (Glue and Engineering Joints in Repair, Conservation and Reinforcement of Historiacl Timber Structures), 1st ed.; Dolnośląskie Wydaw Edukacyjne: Wroclaw, Poland, 2003. (In Polsih) [Google Scholar]

- Issa, C.A.; Kmeid, Z. Advanced wood engineering: Glulam beams. Constr. Build. Mater. 2005, 19, 99–106. [Google Scholar] [CrossRef]

- Balmori, J.-A.; Basterra, L.-A.; Acuña, L. Internal GFRP Reinforcement of Low-Grade Maritime Pine Duo Timber Beams. Materials 2020, 13, 571. [Google Scholar] [CrossRef] [Green Version]

- Triantafillou, T.C.; Deskovic, N. Prestressed FRP Sheets as External Reinforcement of Wood Members. J. Struct. Eng. 1992, 118, 1270–1284. [Google Scholar] [CrossRef]

- Li, Y.F.; Xie, Y.M.; Tsai, M.J. Enhancement of the Flexural Performance of Retrofitted Wood Beams Using CFRP Composite Sheets. Constr. Build. Mater. 2009, 23, 411–422. [Google Scholar] [CrossRef]

- Nowak, T.P.; Jasieńko, J.; Czepiżak, D. Experimental Tests and Numerical Analysis of Historic Bent Timber Elements Reinforced with CFRP Strips. Constr. Build. Mater. 2013, 40, 197–206. [Google Scholar] [CrossRef]

- Fiorelli, J.; Dias, A.A. Glulam Beams Reinforced with FRP Externally-Bonded: Theoretical and Experimental Evaluation. Mater. Struct. 2011, 44, 1431–1440. [Google Scholar] [CrossRef]

- Raftery, G.M.; Harte, A.M. Low-Grade Glued Laminated Timber Reinforced with FRP Plate. Compos. Part. B Eng. 2011, 42, 724–735. [Google Scholar] [CrossRef]

- Kim, Y.J.; Harries, K.A. Modeling of Timber Beams Strengthened with Various CFRP Composites. Eng. Struct. 2010, 32, 3225–3234. [Google Scholar] [CrossRef]

- de Jesus, A.M.; Pinto, J.M.; Morais, J.J. Analysis of Solid Wood Beams Strengthened with CFRP Laminates of Distinct Lengths. Constr. Build. Mater. 2012, 35, 817–828. [Google Scholar] [CrossRef]

- Bulleit, W.M. Reinforcement of Wood Materials: A Review. Wood Fiber Sci. 1984, 16, 391–397. [Google Scholar]

- Martin, Z.A.; Stith, J.K.; Tingley, D.A. Commercialisation of FRP Reinforced Glulam Beam Technology. In Proceedings of the 6th World Conference on Timber Engineering WCTE, Whistler, BC, Canada, 31 July–3 August 2000. [Google Scholar]

- Parisi, M.A.; Piazza, M. Restoration and Strengthening of TIMBER STructures: Principles, criteria and Examples. Pract. Period. Struct. Des. Constr. 2007, 12, 177–185. [Google Scholar] [CrossRef]

- Meier, U. Strengthening of Structures Using Carbon Fibre/Epoxy Composites. Constr. Build. Mater. 1995, 9, 341–351. [Google Scholar] [CrossRef]

- Meier, U. Composite Materials in Bridge Repair. Appl. Compos. Mater. 2000, 7, 75–94. [Google Scholar] [CrossRef]

- Ntibarikure, M.C. Low Intrusion Conservation Systems for Timber Structures. In Proceedings of the Final Meeting Minutes, Task 9: Real Life Case StudyTrials, Lucca, Italy, 17 March 2005. [Google Scholar]

- Meier, U. Strengthening and Stiffening of Historic Wooden Structures with CFRP. In Proceedings of the FRP Composites in Civil Engineering, Hong Kong, China, 12–15 December 2001; pp. 967–974. [Google Scholar]

- Ajdukiewicz, A.; Brol, J.; Malczyk, A.; Wlaszczuk, M. Rehabilitation of the Highest Wooden Tower in Poland. Struct. Eng. Int. 2010, 10, 161–163. [Google Scholar] [CrossRef]

- Blasz, H.J.; Romani, M. Investigations of the Load Carrying Behaviour of Composite Glued Laminated Timber Beams Reinforced with Fiber Reinforced Plastic. Eur. J. Wood Wood Prod. 2001, 59, 364–373. [Google Scholar]

- Guan, Z.W.; Rodd, P.D.; Pope, D.J. Study of Glulam Beams Pre-Stressed with Pultruded GRP. Comput. Struct. 2005, 83, 2476–2487. [Google Scholar] [CrossRef]

- Raftery, G.M.; Harte, A.M.; Rodd, P.D. Bonding of FRP Materials to Wood Using Thin Epoxy Gluelines. Int. J. Adhes. Adhes. 2009, 29, 580–588. [Google Scholar] [CrossRef]

- Balmori, J.A.; Branco, J.M.; Basterra, L.A. Behaviour of the Adhesive Bond between Low-Grade Wood and GFRP Reinforcements Using Epoxy Resin. Constr. Build. Mater. 2021, 271, 121516. [Google Scholar] [CrossRef]

- Sena-Cruz, J.; Branco, J.; Jorge, M.; Barros, J.A.; Silva, C.; Cunha, V.M. Bond Behavior between Glulam and GFRP’s by Pullout Tests. Compos. Part. B Eng. 2012, 43, 1045–1055. [Google Scholar] [CrossRef] [Green Version]

- Fava, G.; Carvelli, V.; Poggi, C. Pull-Out Strength of Glued-In FRP Plates Bonded in Glulam. Constr. Build. Mater. 2013, 43, 362–371. [Google Scholar] [CrossRef]

- Raftery, G.M.; Harte, A.M. Nonlinear Numerical Modelling of FRP Reinforced Glued Laminated Timber. Compos. Part. B Eng. 2013, 52, 40–50. [Google Scholar] [CrossRef]

- Raftery, G.M.; Rodd, P.D. FRP Reinforcement of Low-Grade Glulam Timber Bonded with Wood Adhesive. Constr. Build. Mater. 2015, 91, 116–125. [Google Scholar] [CrossRef]

- Valipour, H.R.; Crews, K. Efficient Finite Element Modelling of Timber Beams Strengthened with Bonded Fibre Reinforced Polymers. Constr. Build. Mater. 2011, 25, 3291–3300. [Google Scholar] [CrossRef]

- Coronado, C. Characterization, Modeling and Size Effect of Concrete-Epoxy Interfaces. Ph.D. Thesis, The Pennsylvania State University, Pennsylvania, PA, USA, 2006. [Google Scholar]

- Biscaia, H.C.; Cruz, D.; Chastre, C. Analysis of the Debonding Process of CFRP-to-Timber Interfaces. Constr. Build. Mater. 2016, 113, 96–112. [Google Scholar] [CrossRef]

- Dagher, H.J. High—Performance Wood Composites for Construction. Vii Ebramem 2000, 154, 154–163. [Google Scholar]

- Schober, K.U.; Rauntenstrauch, K. Experimental Investigation on Flexural Strengthening of Timber Structures with CFRP. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures, Hong Kong, China, 7–9 December 2005; pp. 457–464. [Google Scholar]

- Jaskowska-Lemańska, J.; Wałach, D. Methods of Reinforcing Historical Wooden Ceilings on the Example of the Palace Complex in Gorzanów. Tech. Trans. 2013, 110, 13–27. [Google Scholar]

- Rescalvo, F.J.; Valverde-Palacios, I.; Suarez, E.; Gallego, A. Experimental Comparison of Different Carbon Fiber Composites in Reinforcement Layouts for Wooden Beams of Historical Buildings. Materials 2017, 10, 1113. [Google Scholar] [CrossRef] [Green Version]

- De la Rosa García, P.; Escamilla, A.C.; García, M.N.G. Analysis of the Flexural Stiffness of Timber Beams Reinforced with Carbon and Basalt Composite Materials. Compos. Part B Eng. 2016, 86, 152–159. [Google Scholar] [CrossRef]

- Basterra, L.A.; Balmori, J.A.; Morillas, L.; Acuña, L.; Casado, M. Internal Reinforcement of Laminated Duo Beams of Low-Grade Timber with GFRP Sheets. Constr. Build. Mater. 2017, 154, 914–920. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M.; Grazini, A. A Method for Flexural Reinforcement of Old Wood Beams with CFRP Materials. Compos. Part B Eng. 2005, 36, 143–153. [Google Scholar] [CrossRef]

- Schober, K.U.; Harte, A.M.; Kliger, R.; Jockwer, R.; Xu, Q.; Chen, J.F. FRP Reinforcement of Timber Structures. Constr. Build. Mater. 2015, 97, 106–118. [Google Scholar] [CrossRef] [Green Version]

- Polish Committee for Standardization. PN-EN 14080:2013-07 Timber Structures—Glued Laminated Timber and Glued Solid Timber—Requirements, Polish Standard, 1st ed.; Polish Committee for Standardization: Warszawa, Poland, 2013. [Google Scholar]

- SikaWrap 300C—Technical Information. Available online: https://pol.sika.com/content/dam/dms/plcon/e/sikawrap_-300_c.pdf (accessed on 5 April 2021).

- Polish Committee for Standardization. PN-EN ISO 10618:2006 Carbon fibre—Determination of Tensile Properties of Resin-Impregnated Yarn, Polish Standard, 1st ed.; Polish Committee for Standardization: Warszawa, Poland, 2006. [Google Scholar]

- Polish Committee for Standardization. PN-EN ISO 527-1:2020-01 Plastics—Determination of Tensile Properties—Part 1: General Principles, 1st ed.; Polish Committee for Standardization: Warszawa, Poland, 2020. [Google Scholar]

- Polish Committee for Standardization. PN-EN 408 + A1:2012 Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties, 1st ed.; Polish Committee for Standardization: Warszawa, Poland, 2012. [Google Scholar]

- de la Rosa García, P.; Escamilla, A.C.; García, M.N.G. Bending Reinforcement of Timber Beams with Composite Carbon Fiber and Basalt Fiber Materials. Compos. Part. B Eng. 2013, 55, 528–536. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value |

|---|---|

| Source voltage | 60 kV |

| Source current | 900 μA |

| Voxel size | 70 μm |

| Filter | none |

| Exposure time | 250 ms |

| Number of X-rays used to reconstruct a 3D image | 3200 |

| Number of CFRP Reinforcement Layers | Specimen No. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||

| 0 | F (kN) | 24.55 | 17.67 | 18.61 | 18.09 | 17.75 | 18.6 | 17.67 | 17.54 |

| u (mm) | 10.46 | 7.80 | 8.32 | 10.69 | 11.24 | 10.29 | 9.99 | 9.97 | |

| EI (Nm2) | 13,224 | 11,450 | 11,808 | 9615 | 11,309 | 11,072 | 9171 | 9354 | |

| 1 | F (kN) | 17.68 | 26.46 | 26.64 | 25.21 | 24.55 | 25.32 | 23.97 | 25.50 |

| u (mm) | 9.70 | 13.55 | 13.69 | 13.29 | 13.50 | 13.88 | 14.42 | 15.08 | |

| EI (Nm2) | 8989 | 12,733 | 11,250 | 10,420 | 9473 | 13,246 | 10,961 | 10,157 | |

| 3 | F (kN) | 18.80 | 25.50 | 22.05 | 22.29 | 23.74 | 22.17 | 23.43 | 22.59 |

| u (mm) | 11.37 | 16.22 | 10.83 | 12.47 | 12.81 | 11.82 | 12.27 | 12.92 | |

| EI (Nm2) | 10,042 | 9181 | 10,929 | 9784 | 9762 | 9314 | 9928 | 14,278 | |

| 5 | F (kN) | 16.15 | 23.43 | 17.29 | 24.86 | 26.77 | 27.31 | 26.17 | 26.94 |

| u (mm) | 8.46 | 10.86 | 7.68 | 11.84 | 9.92 | 9.58 | 9.44 | 9.01 | |

| EI (Nm2) | 8843 | 11,098 | 10,724 | 12,594 | 13,218 | 14,069 | 14,968 | 16,357 | |

| Number of CFRP Reinforcement Layers | |||||

|---|---|---|---|---|---|

| Without Reinforcement (for 7 Specimens) | 1 Layer (for 7 Specimens) | 3 Layers (for 7 Specimens) | 5 Layers (for 8 Specimens) | ||

| Mean ultimate force for each beam series | [kN] | 17.99 | 25.38 | 23.11 | 23.62 |

| Standard deviation | [kN] | 0.45 | 0.96 | 1.24 | 4.45 |

| Coefficient of variation | [%] | 2.52 | 3.76 | 5.35 | 18.84 |

| Mean value of the bending moment for each beam series | [kNm] | 2.04 | 2.88 | 2.62 | 2.68 |

| Average value of the increase in the load-bearing capacity of the beams reinforced with CFRP in relation to the reference beams | [%] | - | 41.07 | 28.46 | 31.29 |

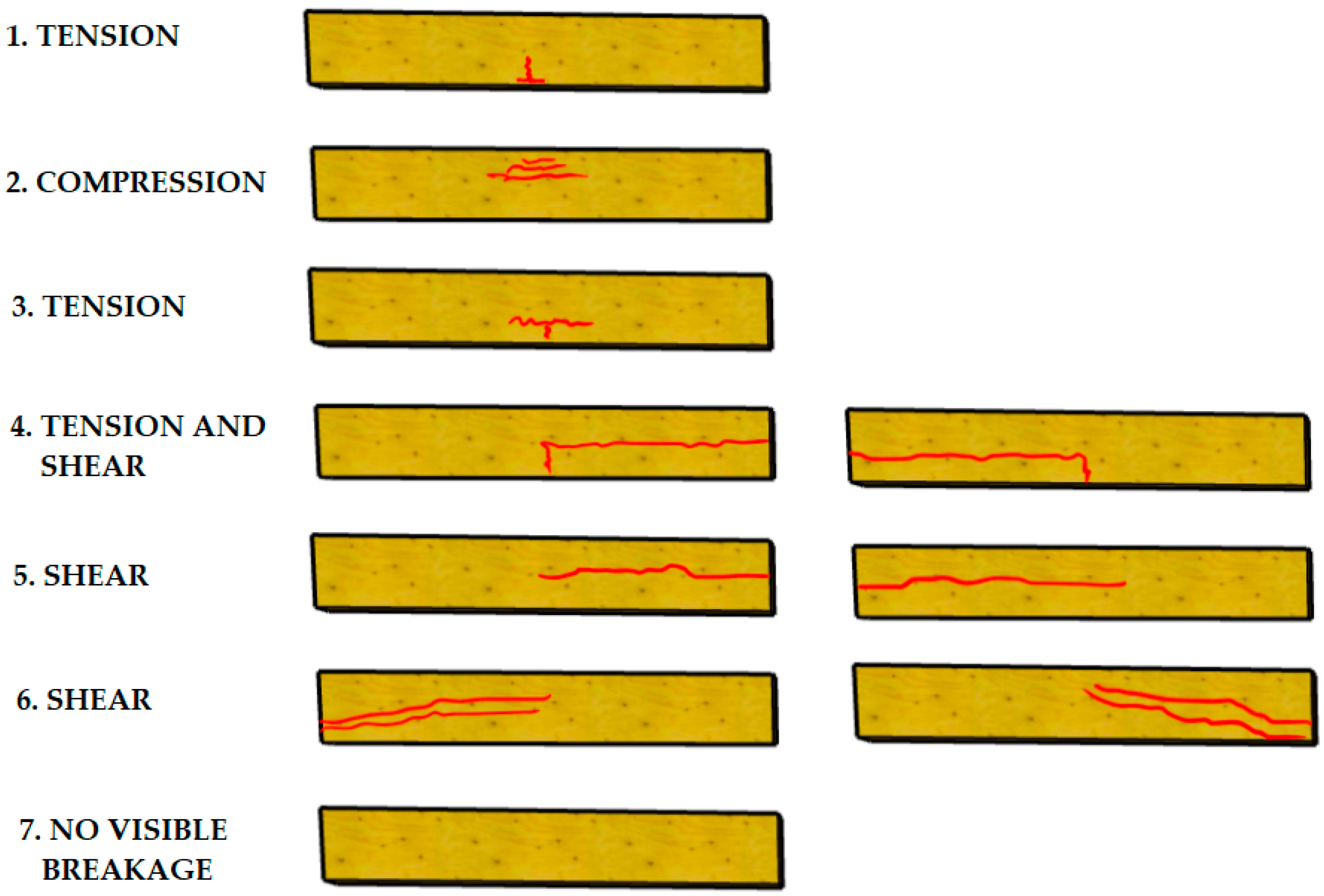

| Type of Beam | Failure Mode (Scheme 1 to 7 according to De la Rosa) | Dominant Course of Failure | Detachment of the Reinforcement |

|---|---|---|---|

| Reference beam From 0/1 to 0/8 | 3 (tension)—7 times 6 (shear)—1 time | Fracture at the border of a growth ring (tangent)—delamination, tearing of the bottom fibers, destruction initiated and running through knots | not applicable |

| One layer of reinforcement from beam 1/1 to 1/8 | 5 (shear)—6 times 6 (shear)—1 time 4 (shear + tension) + 2 compression—1 time | Shear of the cross-section-destructive longitudinal crack above the knot line, spreading from the center, fracture at the border of a growth ring (tangent)—delamination from the center towards the support or delamination going to the knot in the middle of the span | no |

| Three layers of reinforcement from beam 3/1 to 3/8 | 6 (shear)—7 times 7 (no visible breakage)—1 time | Shear of the bottom part of the cross-section in the support zone, which runs to the center of the beam and passes through a knot (right next to the support), delamination of the beam | no |

| Five layers of reinforcement from beam 5/1 to 5/8 | 5 (shear)—5 times 6 (shear)—3 times | Shear of the bottom part of the cross-section in the support zone, which runs horizontally to the center or which runs through the entire beam to the opposite top part of the cross-section, partial adhesive failure at the wood-glue interface, delamination of the element | no (6 times) a part next to a support (2 times) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Śliwa-Wieczorek, K.; Ostrowski, K.A.; Jaskowska-Lemańska, J.; Karolak, A. The Influence of CFRP Sheets on the Load-Bearing Capacity of the Glued Laminated Timber Beams under Bending Test. Materials 2021, 14, 4019. https://doi.org/10.3390/ma14144019

Śliwa-Wieczorek K, Ostrowski KA, Jaskowska-Lemańska J, Karolak A. The Influence of CFRP Sheets on the Load-Bearing Capacity of the Glued Laminated Timber Beams under Bending Test. Materials. 2021; 14(14):4019. https://doi.org/10.3390/ma14144019

Chicago/Turabian StyleŚliwa-Wieczorek, Klaudia, Krzysztof Adam Ostrowski, Justyna Jaskowska-Lemańska, and Anna Karolak. 2021. "The Influence of CFRP Sheets on the Load-Bearing Capacity of the Glued Laminated Timber Beams under Bending Test" Materials 14, no. 14: 4019. https://doi.org/10.3390/ma14144019

APA StyleŚliwa-Wieczorek, K., Ostrowski, K. A., Jaskowska-Lemańska, J., & Karolak, A. (2021). The Influence of CFRP Sheets on the Load-Bearing Capacity of the Glued Laminated Timber Beams under Bending Test. Materials, 14(14), 4019. https://doi.org/10.3390/ma14144019