The Effects of La Doping on the Crystal Structure and Magnetic Properties of Ni2In-Type MnCoGe1−xLax (x = 0, 0.01, 0.03) Alloys

Abstract

:1. Introduction

2. Experimental Method

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, G.Z.; Liu, E.K.; Du, Y.; Li, G.J.; Liu, G.D.; Wang, W.H.; Wu, G.H. A New Spin Gapless Semiconductors Family: Quaternary Heusler Compounds. Europhys. Lett. 2013, 102, 17007. [Google Scholar] [CrossRef] [Green Version]

- Bazela, W.; Szytula, A.; Todorovic, J.; Tomkowicz, Z.; Zięba, A. Crystal and magnetic structure of NiMnGe. Phys. Status Solidi A 1976, 38, 721–729. [Google Scholar] [CrossRef]

- Galanakis, I.; Dederichs, P.H.; Papanikolaou, N. Slater-Pauling behavior and origin of the half-metallicity of the full-Heusler alloys. Phys. Rev. B 2002, 66, 174429. [Google Scholar] [CrossRef] [Green Version]

- Imbierwitz, F.; Pelzl, J.; Arnscheidt, E.; Acet, M.; Zähres, H.; Bach, H.; Saunders, G.A. Magnetic and elastic properties of superparamagnetic CoMn-alloys. J. Magn. Magn. Mater. 1999, 196–197, 863–864. [Google Scholar] [CrossRef]

- Ma, S.C.; Ge, Q.; Hu, Y.F.; Wang, L.; Liu, K.; Jiang, Q.Z.; Wang, D.H.; Hu, C.C.; Huang, H.B.; Cao, G.P. Driving higher magnetic field sensitivity of the martensitic transformation in MnCoGc ferromagnet. Appl. Phys. Lett. 2017, 111, 192406. [Google Scholar] [CrossRef]

- Shen, C.J.; Liu, Q.; Gong, Y.Y.; Wang, D.; Du, Y. Magnetic phase transition magnetocaloric effect in Mn1−xZnxCoGe alloys. Chin. Phys. B 2014, 23, 97502. [Google Scholar] [CrossRef]

- Ma, S.C.; Liu, Y.H.; Shih, C.W.; Lee, Y.I.; Chang, W.C. Microstructure and magnetic properties in meltspun MnV0 02CoGe0.99 ribbons. J. Magn. Magn. Mater. 2014, 357, 41–44. [Google Scholar] [CrossRef]

- Caron, L.; Trung, N.T.; Brück, E. Pressure-tuned magnetocaloric effect in Mn0.93Cr0.77CoGe. Phys. Rev. B 2011, 84, 945–949. [Google Scholar] [CrossRef] [Green Version]

- Liu, E.K.; Zhu, W.; Feng, L.; Chen, J.L.; Wang, W.H.; Wu, G.H.; Liu, H.Y.; Meng, F.B.; Luo, H.Z.; Li, Y.X. Vacancy-tuned paramagnetic/ferromagnetic martensitic transformation in Mn-poor Mn1−xCoGe alloys. Europhys. Lett. 2010, 91, 17003. [Google Scholar] [CrossRef] [Green Version]

- Koyama, K.; Sakai, M.; Kanomata, T.; Watanabe, K. Field-Induced Martensitic Transformation in New Ferromagnetic Shape Memory Compound Mn1.07Co0.92Ge. Jpn. J. Appl. Phys. 2004, 43, 8036–8039. [Google Scholar] [CrossRef]

- Dincer, I.; Yüzüak, E.; Durak, G.; Elerman, Y.; Bell, A.M.T.; Ehrenberg, H. Exploring the details of the martensitic phase transition and magnetocaloric effect of CoMnGe0.95Ga0.05, by synchrotron and magnetic measurements. J. Alloys Compd. 2012, 540, 236–240. [Google Scholar] [CrossRef]

- Niziol, S.; Binczycka, H.; Szytula, A.; Todorović, J.; Fruchart, R.; Senateur, J.P.; Fruchart, D. Structure magnetique des MnCoSi. Phys. Status Solidi 2010, 45, 591–597. [Google Scholar] [CrossRef]

- Trung, N.T.; Zhang, L.; Caron, L.; Buschow, K.H.J.; Brück, E. Giant magnetocaloric effects by tailoring the phase transitions. Appl. Phys. Lett. 2010, 96, R381. [Google Scholar] [CrossRef]

- Gbara, P.; Niadecki, Z. Structure, magnetocaloric properties and thermodynamic modeling of enthalpies of formation of (Mn,X)-Co-Ge (X = Zr, Pd) alloys. J. Alloys Compd. 2019, 796, 153–159. [Google Scholar] [CrossRef]

- Kanomata, T.; Ishigaki, H.; Suzuki, T.; Yoshida, H.; Abe, S.; Kaneko, T. Magneto-volume effect of MnCo1−xGe(0 ⩽ x ⩽ 0.2). J. Magn. Magn. Mater. 1995, 140, 131–132. [Google Scholar] [CrossRef]

- Wang, J.T.; Wang, D.S.; Chen, C.; Nashima, O.; Kanomata, T.; Mizuseki, H.; Kawazoe, Y. Vacancy induced structural and magnetic transition in MnCo1−xGe. Appl. Phys. Lett. 2006, 89, 1187. [Google Scholar] [CrossRef]

- Hassan, N.U.; Chen, F.; Zhang, M.; Shah, I.A.; Liu, J.; Gong, Y.; Xu, G.; Xu, F. Realisation of magnetostructural couplingand a large magnetocaloric effect in the MnCoGe1+x system. J. Magn. Magn. Mater. 2017, 439, 120–125. [Google Scholar] [CrossRef]

- Niziol, S.; Zie Ba, A.; Zach, R.; Baj, M.; Dmowski, L. Structural and magnetic phase transitions in CoxNi1−xMnGe system under pressure. J. Magn. Magn. Mater. 1983, 38, 205–213. [Google Scholar] [CrossRef]

- Yuce, S.; Bruno, N.M.; Emre, B.; Karaman, I. Accessibility investigation of large magnetic entropy change in CoMn1−xFexGe. J. Appl. Phys. 2016, 119, 622–655. [Google Scholar] [CrossRef] [Green Version]

- Trung, N.T.; Biharie, V.; Zhang, L.; Caron, L.; Buschow, K.H.J.; Brück, E. From single-to double-first-order magnetic phase transition in magnetocaloric Mn1−xCrxCoGe compounds. Appl. Phys. Lett. 2010, 96, 162507. [Google Scholar] [CrossRef] [Green Version]

- Bao, L.F.; Huang, W.D.; Ren, Y.J. Tuning Martensitic Phase Transition by Non-Magnetic Atom Vacancy in MnCoGe Alloys and Related Giant Magnetocaloric Effect. Chin. Phys. Lett. 2016, 33, 077502. [Google Scholar] [CrossRef]

- Yuan, Z.M.; He, J.; Yang, L.; Xia, Z.J.; Zhao, D.L.; You, C.Y.; Ren, W.J. Influence of microstructural changes on magnetic refrigeration performance for La(Fe0.94Co0.06)11.8Si1.2 alloys during magnetic field cycling. J. Appl. Phys. 2015, 117, 162406. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.G.; Tang, Y.B.; Xiao, D.Q. 1:13 phase formation mechanism and first-order magnetic transition strengthening characteristics in (La, Ce)Fe(13–x)Six alloys. Rare Met. 2016, 9, 33–42. [Google Scholar]

- Guchowski, P.; Nikonkov, R.; Tomala, R.; Stręk, W.; Shulha, T.; Serdechnova, M.; Zheludkevich, M.; Pakalaniškis, A.; Skaudžius, R.; Kareiva, A.; et al. Magnetic Properties of La0.9A0.1MnO3 (A: Li, Na, K) Nanopowders and Nanoceramics. Materials 2020, 13, 1788. [Google Scholar] [CrossRef] [PubMed]

- Botello-Zubiate, M.; Grijalva-Castillo, M.; Soto-Parra, D.; Sáenz-Hernández, R.J.; Santillán-Rodríguez, C.R.; Matutes-Aquino, J.A. Preparation of La0.7Ca0.3−xSrxMnO3 Manganites by Four Synthesis Methods and Their Influence on the Magnetic Properties and Relative Cooling Power. Materials 2019, 12, 309. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.K.; Yeh, C.C.; Chang, C.W.; Chang, W.C.; Zhu, M.G.; Li, W. Large low-field magnetocaloric effect in MnCo0.95Ge1.14 alloy. Scr. Mater. 2007, 57, 453–456. [Google Scholar] [CrossRef]

- Jeitschko, W. A high-temperature X-ray study of the displacive phase transition in MnCoGe. Acta Crystallograph. Sect. B Struct. Ence 2010, 31, 1187–1190. [Google Scholar] [CrossRef]

- Wu, X.; He, W.; Yang, T.; Xiao, G.; Chen, P.; Bi, Y.; Wu, W. The magnetic and electronic properties of REAgSb2 compounds. J. Magn. Magn. Mater. 2021, 519, 167442. [Google Scholar] [CrossRef]

- Zhao, F.Q.; Dagula, W.; Tegus, O.; Buschow, K.H.J. Magnetic-entropy change in Mn5Ge3-xSix alloys. J. Alloys Compounds 2006, 416, 43–45. [Google Scholar] [CrossRef]

- Banerjee, B.K. On a generalised approach to first and second order magnetic transitions. Phys. Lett. 1964, 12, 16–17. [Google Scholar] [CrossRef]

- Zhang, D.; Nie, Z.; Wang, Z.; Huang, L.; Zhang, Q.; Wang, Y.D. Giant magnetocaloric effect in MnCoGe with minimal Ga substitution. J. Magn. Magn. Mater. 2015, 387, 107–110. [Google Scholar] [CrossRef]

- Bao, L.F.; Hu, F.X.; Wu, R.R.; Wang, J.; Chen, L.; Sun, J.R.; Shen, B.G.; Li, L.; Zhang, B.; Zhang, X.X. Evolution of magnetostructural transition and magnetocaloric effect with Al doping in MnCoGe1−xAlx compounds. J. Phys. Appl. Phys. 2014, 47, 1–7. [Google Scholar] [CrossRef]

- Si, X.; Shen, Y.; Ma, X.; Chen, S.; Lin, J.; Yang, J.; Gao, T.; Liu, Y. Field dependence of magnetic entropy change and estimation of spontaneous magnetization in Cd substituted MnCoGe. Acta Mater. 2017, 143, 306–317. [Google Scholar] [CrossRef]

- Choudhury, D.; Suzuki, T.; Tokura, Y.; Taguchi, Y. Tuning structural instability toward enhanced magnetocaloric effect around room temperature in MnCo(1-x)Zn(x)Ge. Sci. Rep. 2014, 4, 7544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ren, Q.Y.; Hutchison, W.D.; Wang, J.L.; Studer, A.J.; Din, M.M.; Pérez, S.M.; Cadogan, J.M.; Campbell, S.J. The magneto-structural transition in Mn1−xFexCoGe. J. Phys. D Appl. Phys. 2016, 49, 175003. [Google Scholar] [CrossRef] [Green Version]

- Provenzano, V.; Shapiro, A.J.; Shull, R.D. Reduction of hysteresis losses in the magnetic refrigerant Gd5Ge2Si2 by the addition of iron. Nature 2004, 429, 853. [Google Scholar] [CrossRef]

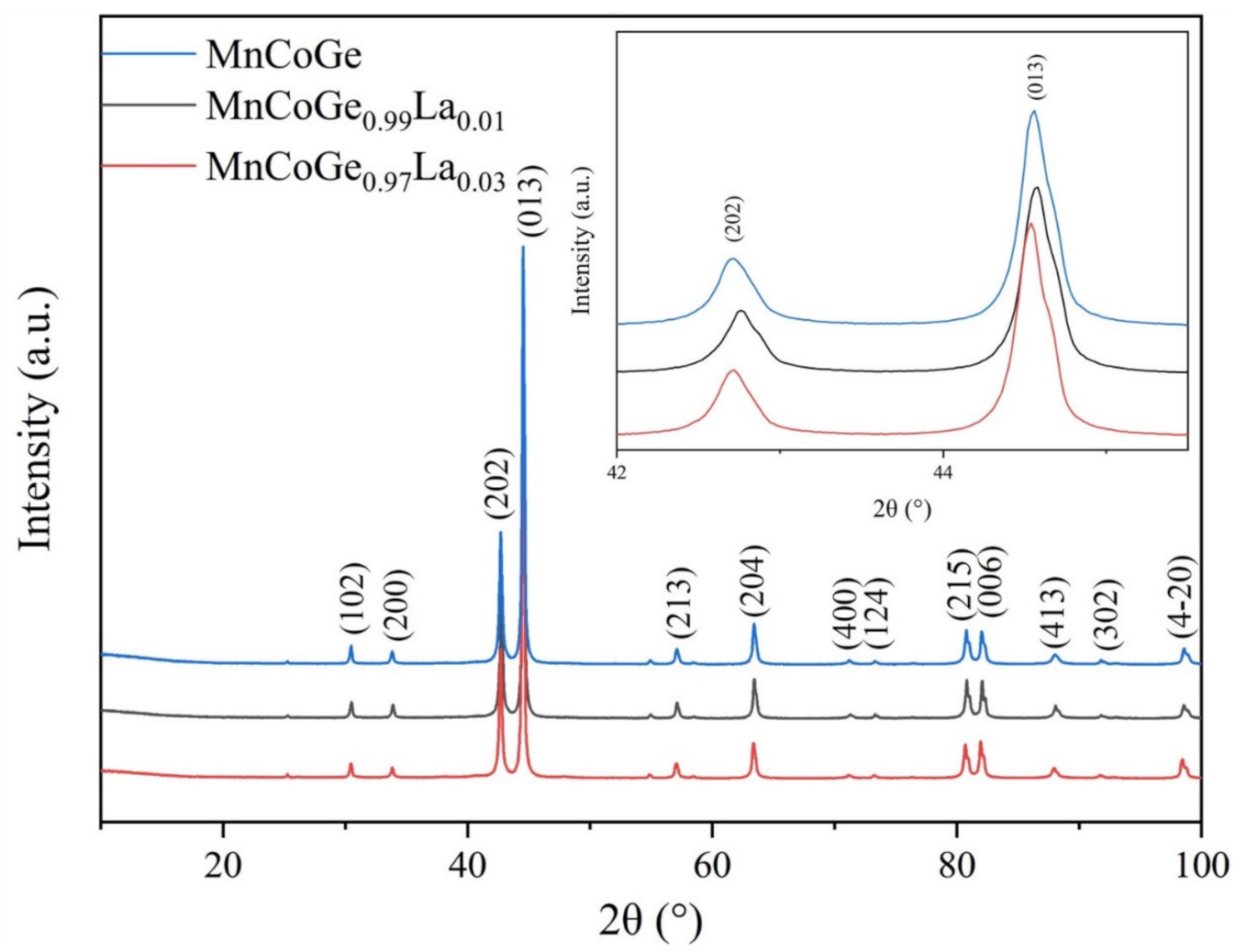

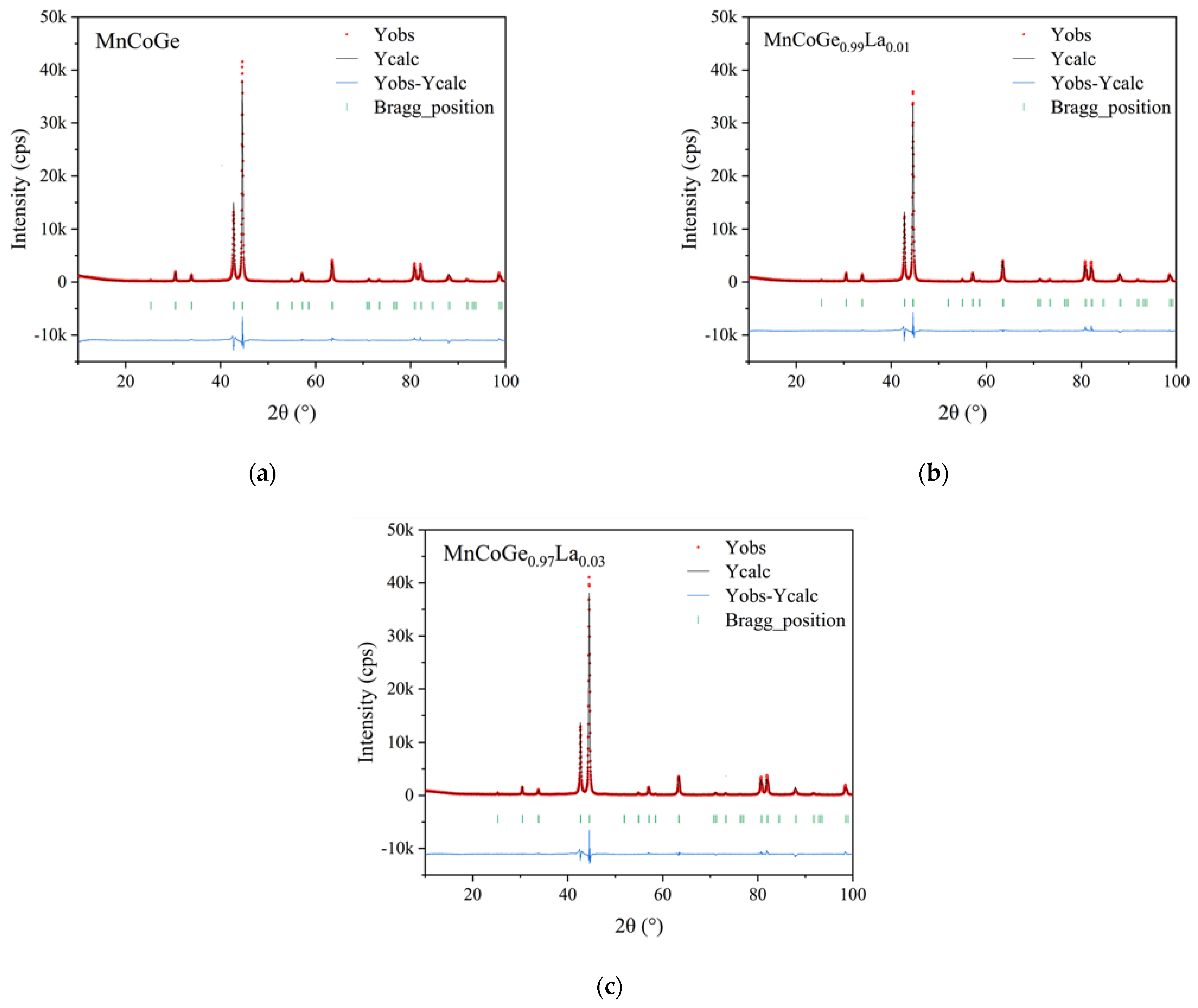

| Compounds | MnCoGe | MnCoGe0.99La0.01 | MnCoGe0.97La0.03 |

|---|---|---|---|

| Space group | P63/mmc (194) | ||

| Radiation | CuKα | ||

| Unit cell parameters | |||

| a/(Å) | 4.0641(1) | 4.0648(1) | 4.0695(1) |

| b/(Å) | 4.0641(1) | 4.0648(1) | 4.0695(1) |

| c/(Å) | 5.2882(2) | 5.2905(2) | 5.2980(2) |

| Lattice volume V(Å3) | 87.337(5) | 87.430(7) | 87.761(2) |

| Reliability factors | |||

| Rp (%) | 12.9 | 13.3 | 13.0 |

| RWP (%) | 15.5 | 15.7 | 15.7 |

| Rexp (%) | 5.14 | 4.96 | 4.96 |

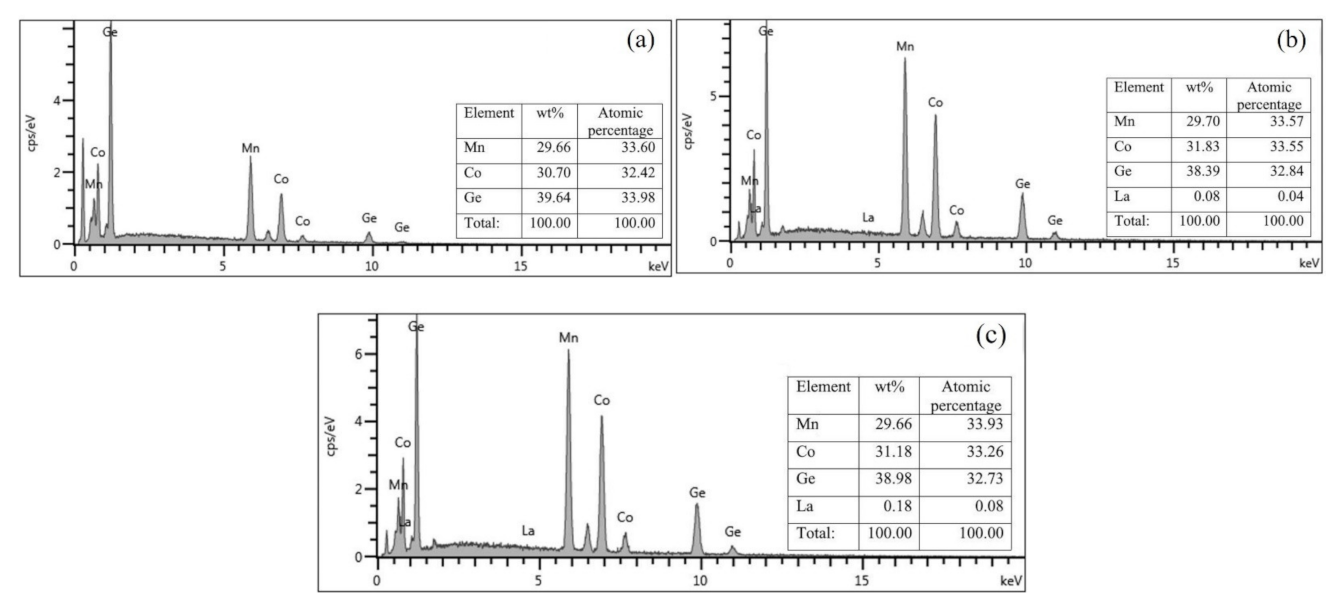

| Doping Content x | Atoms | Site Occupation | x | y | z | Occupancy |

|---|---|---|---|---|---|---|

| 0 | Mn | 2a | 0 | 0 | 0 | 1 |

| Co | 2d | 1/3 | 2/3 | 3/4 | 1 | |

| Ge | 2c | 1/3 | 2/3 | 1/4 | 1 | |

| 0.01 | Mn | 2a | 0 | 0 | 0 | 1 |

| Co | 2d | 1/3 | 2/3 | 3/4 | 1 | |

| M1 * | 2c | 1/3 | 2/3 | 1/4 | 0.993Ge + 0.007La | |

| 0.03 | Mn | 2a | 0 | 0 | 0 | 1 |

| Co | 2d | 1/3 | 2/3 | 3/4 | 1 | |

| M2 ** | 2c | 1/3 | 2/3 | 1/4 | 0.976Ge + 0.024La |

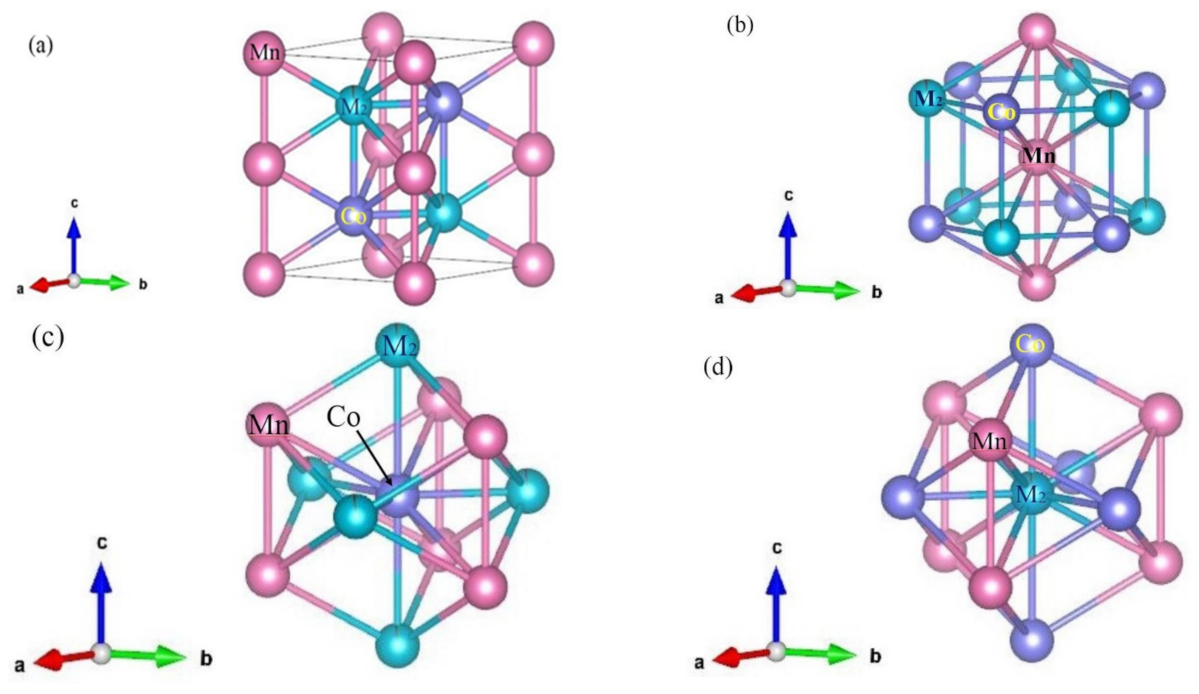

| Central Atom | Connected to the Atom | Atomic Number | Distance (Å) | ||

|---|---|---|---|---|---|

| 0 | 0.01 | 0.03 | |||

| Mn | Mn | 2 | 2.6441(10) | 2.6453(10) | 2.6490(10) |

| Co | 6 | 2.6930(7) | 2.6937(8) | 2.6970(8) | |

| Ge/M1/M2 | 6 | 2.6930(7) | 2.6937(8) | 2.6970(8) | |

| Co | Mn | 6 | 2.6930(7) | 2.6937(8) | 2.6970(8) |

| Ge/M1/M2 | 5 | 2.3462(6) | 2.3466(8) | 2.3493(8) | |

| Ge/M1/M2 | Mn | 6 | 2.6930(7) | 2.6937(8) | 2.6970(8) |

| Co | 5 | 2.3462(6) | 2.3466(8) | 2.3493(8) | |

| Doping Content x | TC/K | θC/K | C | Effective Magnetic Moment/(μB/Formula) |

|---|---|---|---|---|

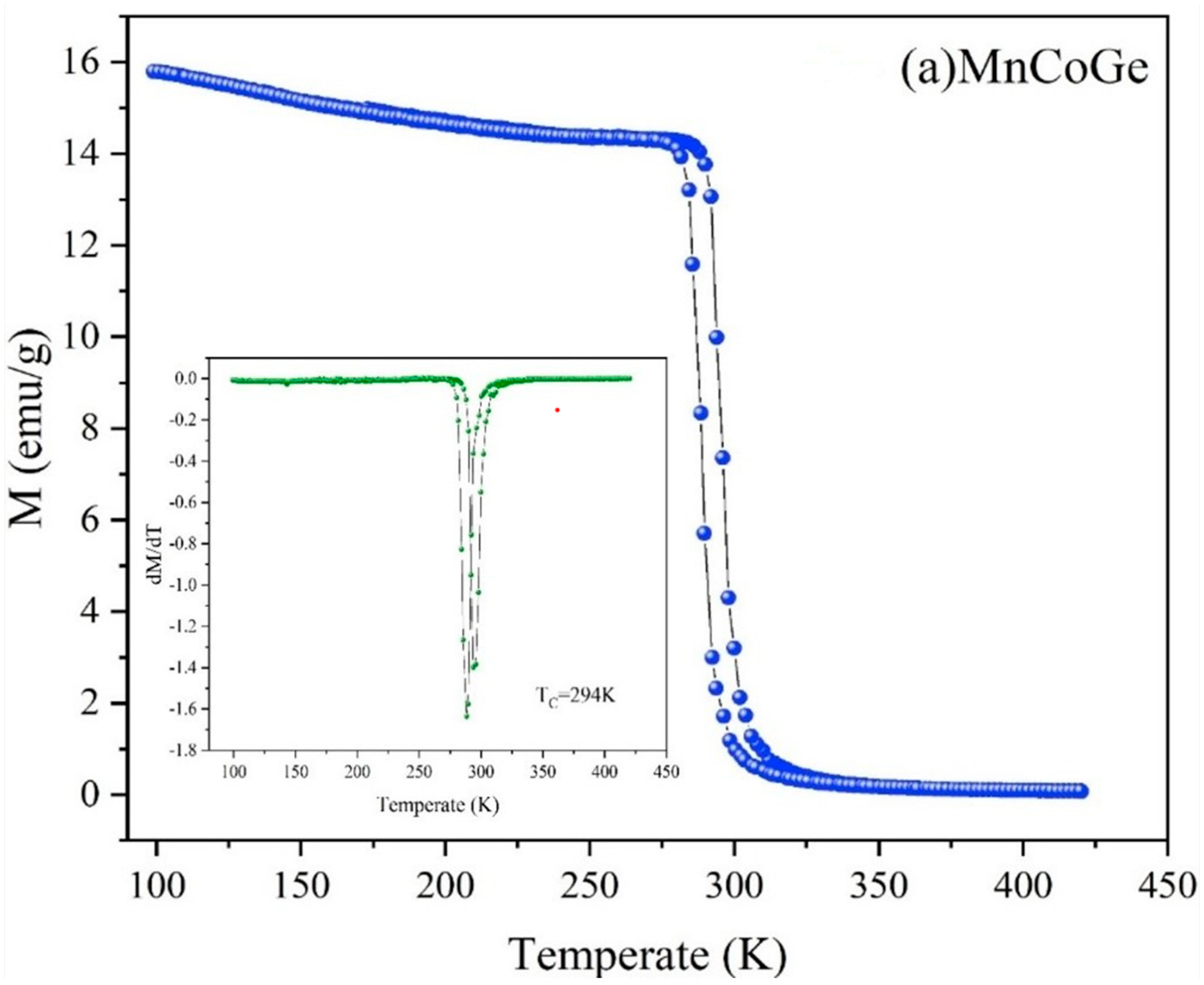

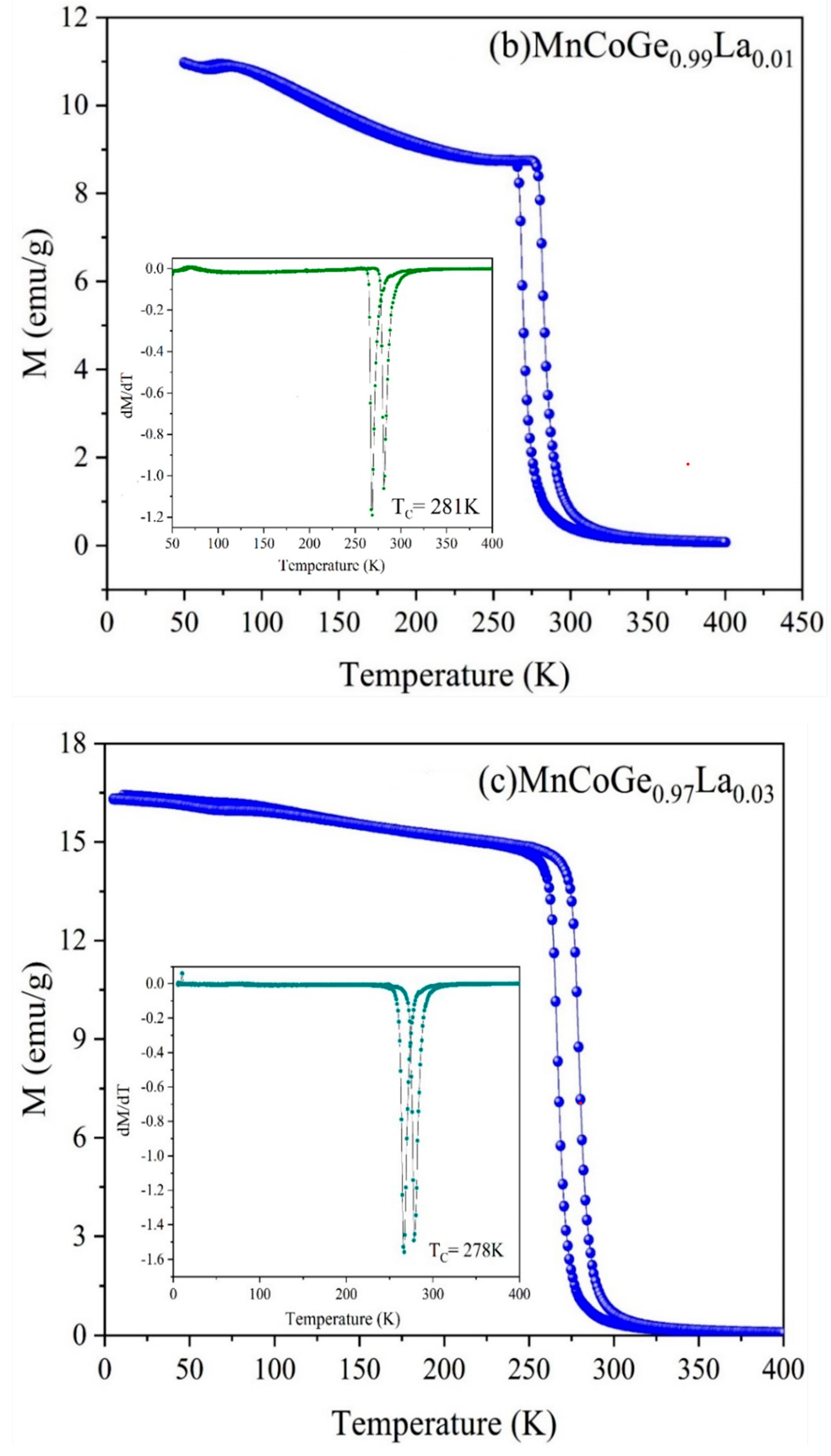

| 0 | 294 | 300.36(2) | 0.0181(2) | 5.20 |

| 0.01 | 281 | 291.36(5) | 0.0179(2) | 5.17 |

| 0.03 | 278 | 289.97(3) | 0.0174(3) | 5.12 |

| Materials | Magnetic Field/T | Tpk/K | RC/J·kg−1 | δTFWHM | Reference | |

|---|---|---|---|---|---|---|

| MnCoGe | 1 | 1.24 | 281 | 38.44 | 31 | This work |

| 1.5 | 1.64 | 281 | 60.68 | 37 | ||

| MnCoGe0.99La0.01 | 1 | 1.13 | 279 | 36.16 | 32 | This work |

| 1.5 | 1.52 | 279 | 59.28 | 39 | ||

| MnCoGe0.97La0.03 | 1 | 1.16 | 279 | 34.80 | 30 | This work |

| 1.5 | 1.56 | 279 | 57.72 | 37 | ||

| MnCoGe0.5Si0.5 | 5 | 4.4 | 373 | 282 | 96 | [34] |

| Mn0.97Fe0.03CoGe | 5 | 9 | 276 | 221 | 31 | [35] |

| Mn0.96Fe0.04CoGe | 5 | 5 | 247 | 261 | 28 | [35] |

| Gd5Si2Ge2 | 5 | 5.8 | 300 | 305 | / | [36] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, Y.; He, W.; Yang, T.; Wu, W.; Wen, J.; Yu, X.; Chen, F. The Effects of La Doping on the Crystal Structure and Magnetic Properties of Ni2In-Type MnCoGe1−xLax (x = 0, 0.01, 0.03) Alloys. Materials 2021, 14, 3998. https://doi.org/10.3390/ma14143998

Bi Y, He W, Yang T, Wu W, Wen J, Yu X, Chen F. The Effects of La Doping on the Crystal Structure and Magnetic Properties of Ni2In-Type MnCoGe1−xLax (x = 0, 0.01, 0.03) Alloys. Materials. 2021; 14(14):3998. https://doi.org/10.3390/ma14143998

Chicago/Turabian StyleBi, Yifei, Wei He, Tonghan Yang, Weining Wu, Jingxian Wen, Xi Yu, and Feikuo Chen. 2021. "The Effects of La Doping on the Crystal Structure and Magnetic Properties of Ni2In-Type MnCoGe1−xLax (x = 0, 0.01, 0.03) Alloys" Materials 14, no. 14: 3998. https://doi.org/10.3390/ma14143998