Rheological Properties of Graphene/Polyethylene Composite Modified Asphalt Binder

Abstract

:1. Introduction

2. Materials and Methods

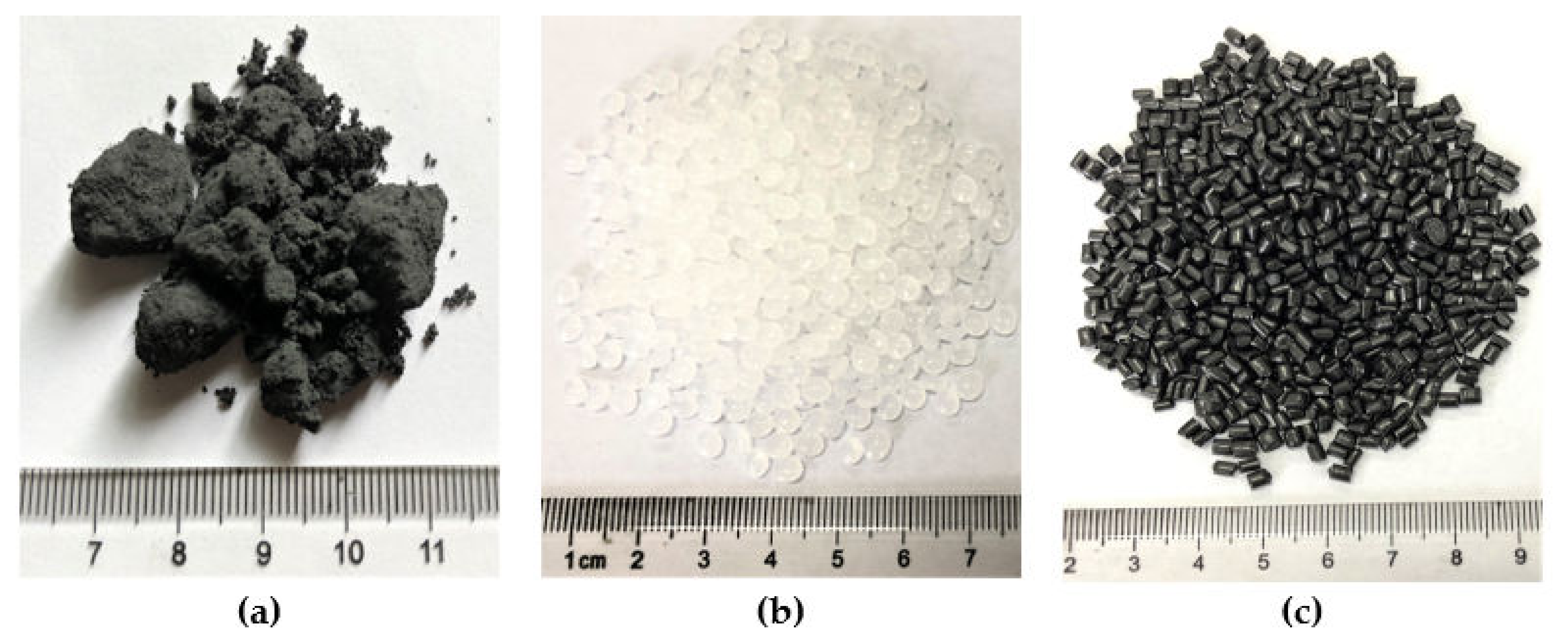

2.1. Materials

2.2. Preparation of PE/GNPs Modified Asphalt Binder

- (1)

- Pre-blended PE/GNPs masterbatch composite (pure PE particles) modified asphalt binder: first, the pre-blended PE/GNPs masterbatch composite (pure PE particles) (4.0%, by weight of the base asphalt) was manually mixed into the molten base asphalt while slowly stirring with a glass rod until the solid modifier was completely dissolved. Then, the mixture containing pre-blended PE/GNPs masterbatch (pure PE particles) and base asphalt was warmed up to 170 °C and sheared with a high-speed shear mixer at a constant speed of 5000 r/min for 30 min. The mixture was then stirred at 170 °C with a mechanical stirrer at 1000 r/min for 60 min. The resulting 4.0% Pre_PE/GNPs or 4.0% PE modified asphalt binders were synthesized.

- (2)

- Combined addition of PE granules and GNPs powder modified asphalt binder: in order to ensure that the amount of modifier in PE+GNPs composite modified asphalt is exactly the same as that in PE/GNPs masterbatch (pure PE granules) (4.0% of the mass of the matrix asphalt), and at the same time based on the mass percentage of GNPs in the premixed PE/GNPs masterbatch is 10% (mass ratio of the masterbatch), thus determining that the content of PE in the PE+GNPs modified asphalt is 4.0% × 90% = 3.6%; the content of GNPs is 4.0% × 10% = 0.4%; that is, the amount of modifier in the PE+GNPs composite modified asphalt is 3.6% PE + 0.4% GNPs.

2.3. Characterization and Measurement

2.3.1. Physical Properties Testing

2.3.2. Temperature Scanning (TeS) Test

2.3.3. Multiple Stress Creep Recovery (MSCR) Test

2.3.4. Linear Amplitude Scanning (LAS) Test

2.3.5. Field Emission Scanning Electron Microscope (FESEM) Characterization

2.3.6. Fourier Transform Infrared Spectroscopy (FT-IR) Testing

3. Results and Discussions

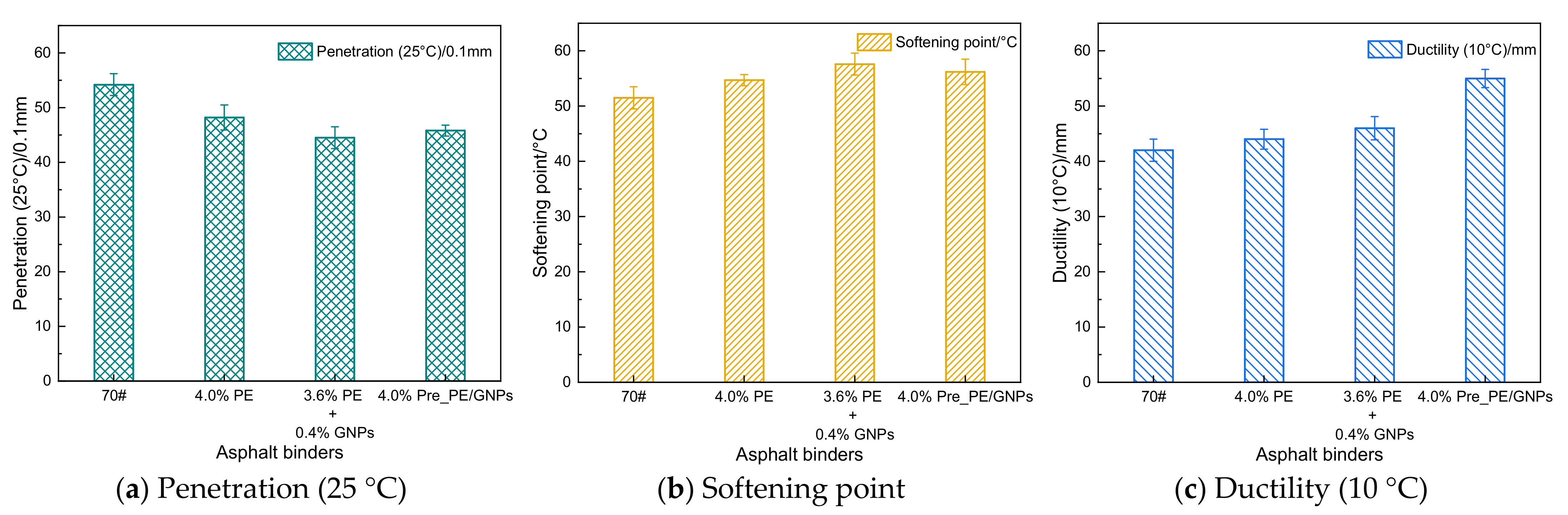

3.1. Physical Properties

3.1.1. Three Major Indicators Data Analysis

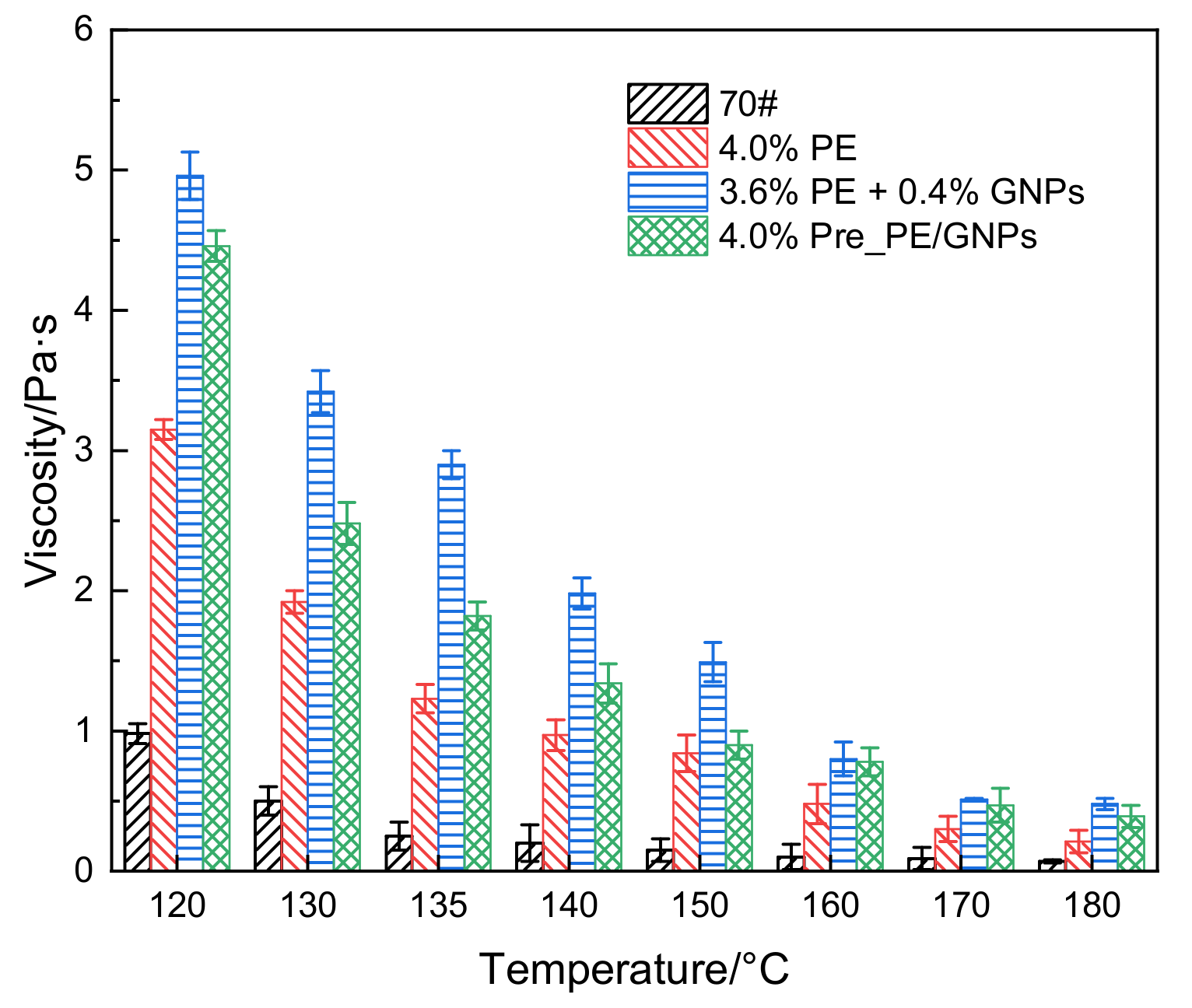

3.1.2. Viscosity–Temperature Characteristics

3.2. Rheological Properties

3.2.1. Temperature Scan Results

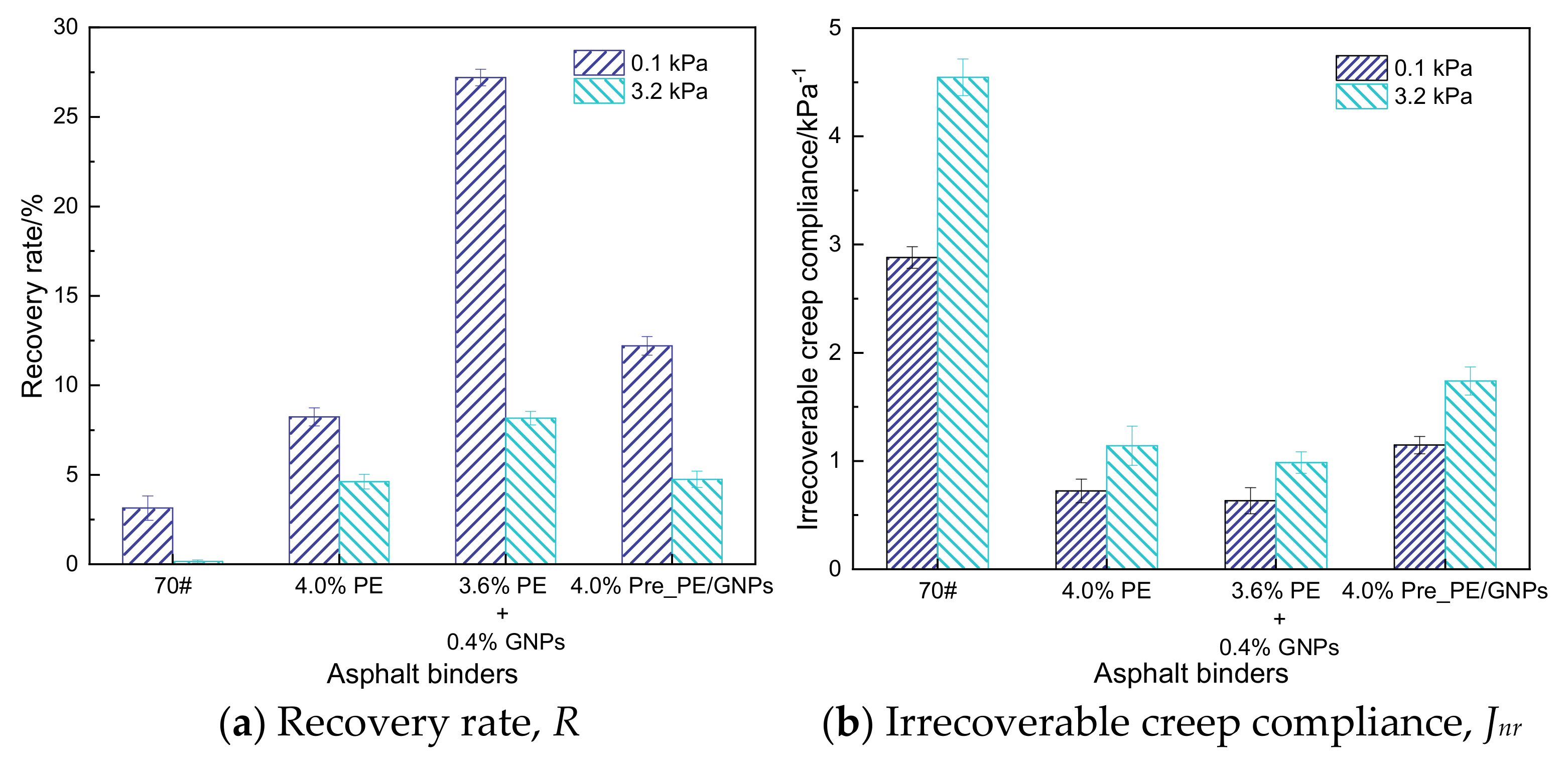

3.2.2. Multi-Stress Creep Recovery (MSCR) Test Results

3.2.3. Linear Amplitude Scanning (LAS) Test Results

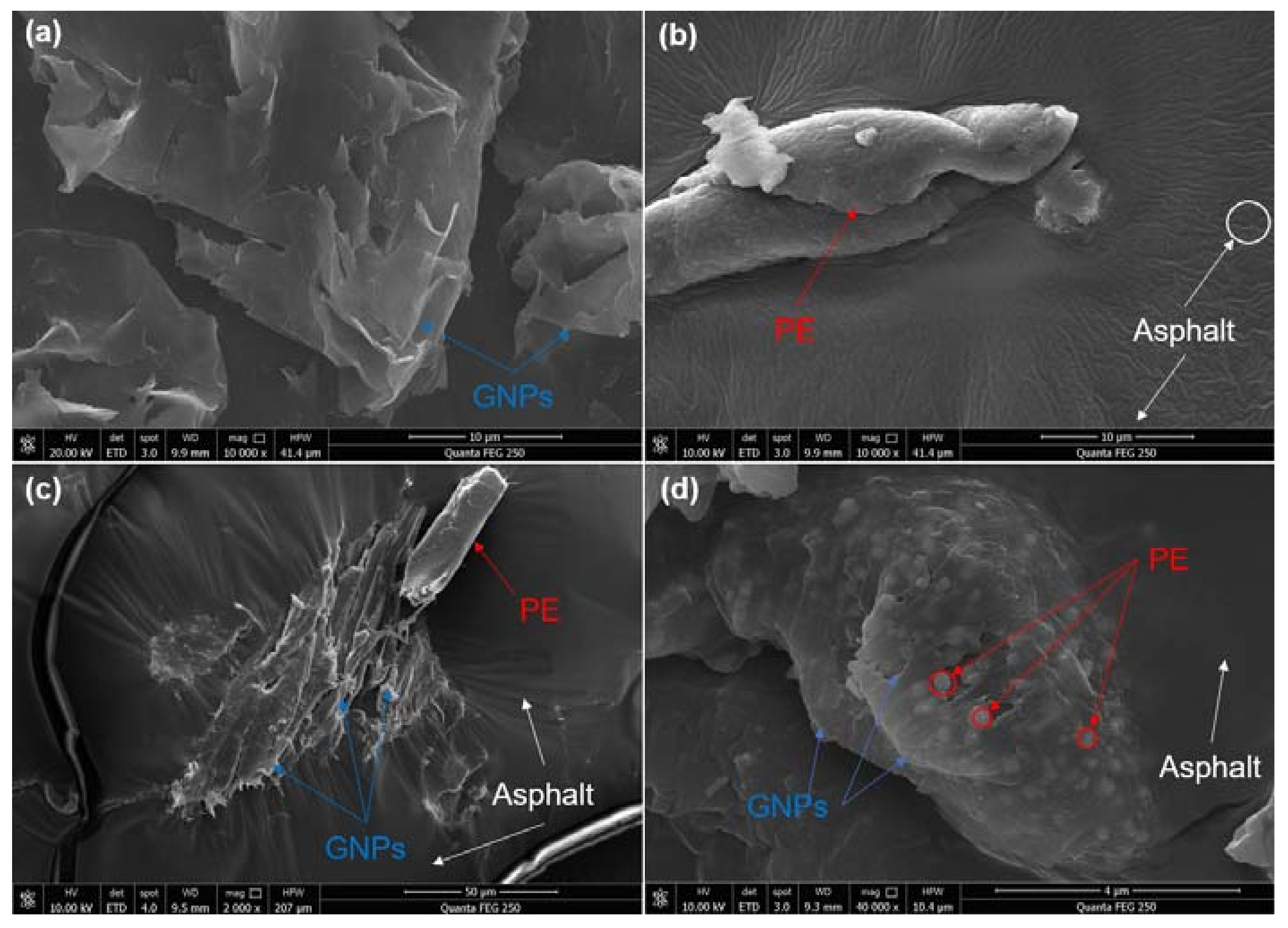

3.3. Microscopic Morphological Characterization

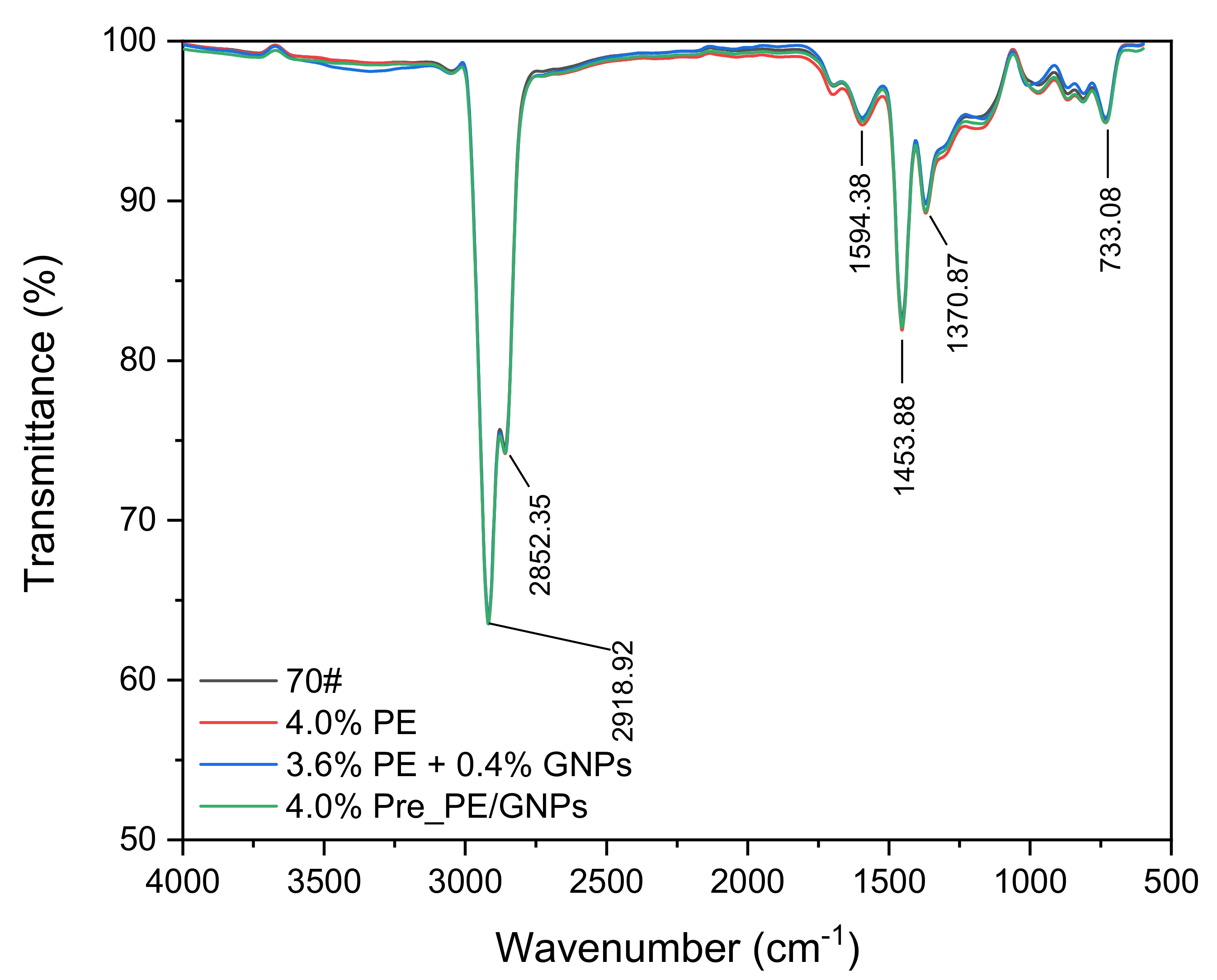

3.4. Fourier Transform Infrared Spectroscopy Analysis

4. Conclusions

- PE and GNPs synergistically improved the high-temperature properties of asphalt binders (increased softening point and viscosity); the premixed PE/GNPs masterbatch modified asphalt exhibited better compatibility compared with 3.6% PE + 0.4% GNPs;

- The PE/GNPs composite additive effectively enhanced the rheological properties of the asphalt binder, in which 3.6% PE + 0.4% GNPs modified asphalt could significantly improve the high-temperature rutting resistance of the asphalt binder. Comparison of the composite modified asphalt binder prepared by the two processes revealed that the 4.0% Pre_PE/GNPs composite modified asphalt presented better medium-temperature fatigue performance and low-temperature cracking resistance;

- Field emission scanning electron microscopy revealed homogeneous dispersion of PE/GNPs composite modifier in the asphalt matrix, where the premixed PE/GNPs masterbatch exhibited a more compact structure and better compatibility with asphalt binder;

- Fourier transform infrared spectroscopy confirmed that no new functional groups or chemical bonds appeared in the PE/GNPs composite modified asphalt, and the rheological properties of base asphalt incorporated with GNPs and PE were enhanced by physical modification.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, M.; Li, J.; Muhammad, Y.; Hou, D.; Zhang, F.; Yin, Y.; Duan, S. Studies on the secondary modification of SBS modified asphalt by the application of octadecyl amine grafted graphene nanoplatelets as modifier. Diam. Relat. Mater. 2018, 89, 140–150. [Google Scholar] [CrossRef]

- Kakar, M.R.; Mikhailenko, P.; Piao, Z.; Bueno, M.; Poulikakos, L. Analysis of waste polyethylene (PE) and its by-products in asphalt binder. Constr. Build. Mater. 2021, 280, 122492. [Google Scholar] [CrossRef]

- Naskar, M.; Chaki, T.K.; Reddy, K.S. Effect of waste plastic as modifier on thermal stability and degradation kinetics of bitumen/waste plastics blend. Thermochim. Acta 2010, 509, 128–134. [Google Scholar] [CrossRef]

- Padhan, R.K.; Sreeram, A. Enhancement of storage stability and rheological properties of polyethylene (PE) modified asphalt using cross linking and reactive polymer based additives. Constr. Build. Mater. 2018, 188, 772–780. [Google Scholar] [CrossRef]

- Cossu, R.; Willianams, I.D. Urban mining: Concepts, terminology, challenges. Waste Manag. 2015, 45, 1–3. [Google Scholar] [CrossRef] [PubMed]

- Poulikakos, L.D.; Papadaskalopoulou, C.; Hofko, B.; Gschösser, F.; Falchetto, A.C.; Bueno, M.; Arraigada, M.; Sousa, J.; Ruiz, R.; Petit, C.; et al. Harvesting the unexplored potential of European waste materials for road construction. Resour. Conserv. Recycl. 2017, 116, 32–44. [Google Scholar] [CrossRef]

- Wan, Y.; Xu, S.; Wu, W.M. Application research of PE modified asphalt mixture on airport runway. Chin. J. Highw. Eng. 2021, 46, 212–216. [Google Scholar]

- DowChemical. Dow Completes Roads Improved with Recycled Plastic. 2019. Available online: https://corporate.dow.com/en-us/news/press-releases/dow-completes-roads-improved-with-recycled-plastic.html (accessed on 26 February 2019).

- Durham. ‘Plastic roads’ trialled in County Durham. 2018. Available online: https://durham.gov.uk/article/19124/-Plastic-roads-trialled-in-County-Durham (accessed on 20 April 2018).

- Writer, S. Work Begins on South Africa’s First Plastic Road. 2019. Available online: https://businesstech.co.za/news/motoring/333307/work-begins-on-south-africas-first-plastic-road/ (accessed on 6 August 2019).

- Movilla, Q.D.; Raposeiras, A.C.; Silva, K.L.T.; Lastra, G.P.; Castro, F.D. Use of plastic scrap in asphalt mixtures added by dry method as a partial substitute for bitumen. Waste Manag. 2019, 87, 751–760. [Google Scholar] [CrossRef]

- Vargas, M.A.; Vargas, M.A.; Sánchez, S.A.; Manero, O. Asphalt/polyethylene blends: Rheological properties, microstructure and viscosity modeling. Constr. Build. Mater. 2013, 45, 243–250. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, S.; Zhu, Y.; Wang, H.; Zhang, Y. Properties of the asphalts modified by typical recycled polyolefin. Chin. J. Polym. Mater. Sci. 2012, 28, 81–84. [Google Scholar]

- Cheng, P.F.; Tong, T.Y. Preparation and properties of recycled PP/SBR composite modified asphalt. Chin. J. Moder. Plast. Pro. 2019, 31, 16–20. [Google Scholar]

- Xin, X.; Yao, Z.; Shi, J.; Liang, M.; Jiang, H.; Zhang, J.; Zhang, X.; Yao, K. Rheological properties, microstructure and aging resistance of asphalt modified with CNTs/PE composites. Constr. Build. Mater. 2020, 262, 120100. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, Q.; Zhong, J.; Hong, B.; Wang, D.; Oeser, M. Rheological and micro-structural characterization of bitumen modified with carbon nanomaterials. Constr. Build. Mater. 2019, 201, 580–589. [Google Scholar] [CrossRef]

- Cheraghian, G.; Wistuba, M.P. Ultraviolet aging study on bitumen modified by a composite of clay and fumed silica nanoparticles. Sci. Rep. UK 2020, 10, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Azarhoosh, A.; Moghaddas, N.F.; Khodaii, A. Evaluation of the effect of nano-TiO2 on the adhesion between aggregate and asphalt binder in hot mix asphalt. Eur. J. Environ. Civ. Eng. 2018, 22, 946–961. [Google Scholar] [CrossRef]

- Qian, G.; Yang, C.; Huang, H.; Gong, X.; Yu, H. Resistance to ultraviolet aging of nano-SiO2 and rubber powder compound modified asphalt. Materials 2020, 13, 5067. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.; Nasir, M.A.; Hafeez, M.; Rafi, J.; Zaidi, S.B.A.; Haroon, W. Carbon nanotubes (CNTs) in asphalt binder: Homogeneous dispersion and performance enhancement. Appl. Sci. Basel 2018, 8, 2651. [Google Scholar]

- Lu, Y.; Zhou, D.H.; Yang, K. Rheological properties of graphene modified asphalt binders. Nanomaterials 2020, 10, 2197. [Google Scholar]

- Li, Y.; Wu, S.; Amirkhanian, S. Investigation of the graphene oxide and asphalt interaction and its effect on asphalt pavement performance. Constr. Build. Mater. 2018, 165, 572–584. [Google Scholar] [CrossRef]

- Wu, S.H.; Tahri, O. State of art carbon and graphene family nanomaterials for asphalt modification. Road Mater. Pavement Des. 2021, 22, 735–756. [Google Scholar] [CrossRef]

- Marasteanu, M.O.; Le, J.L.; Turos, M.I. Graphene nano-platelet (GNP) reinforced asphalt binders and mixtures. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Li, X.; Wang, Y.M.; Wu, Y.L.; Wang, H.R.; Chen, M.; Sun, H.D.; Fan, L. Properties and modification mechanism of asphalt with graphene as modifier. Constr. Build. Mater. 2021, 272, 121919. [Google Scholar] [CrossRef]

- Brcic, H. Investigation of the rheological properties of asphalt binder containing graphene nanoplatelets. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2016. [Google Scholar]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Gámiz, F.; Rubio-Gámez, M.C. Mechanical and thermal properties of graphene modified asphalt binders. Constr. Build. Mater. 2018, 180, 265–274. [Google Scholar] [CrossRef]

- Han, M.Z.; Li, J.; Muhammad, Y.; Hou, D.; Zhang, F.; Yin, Y.; Duan, S. Effect of polystyrene grafted graphene nanoplatelets on the physical and chemical properties of asphalt binder. Constr. Build. Mater. 2018, 174, 108–119. [Google Scholar] [CrossRef]

- Meng, Y.J.; Guo, H.Y.; Xu, R.G.; Liu, L.L. Study on the properties of graphene modified rubber asphalt under the effect of thermal aging. Chin. J. Funct. Mater. 2020, 51, 8001–8006. [Google Scholar]

- Chen, Y.Z.; Wang, Q.; Li, Z.X.; Ding, S.Q. Rhysiological properties of graphene nanoplatelets/rubber crowd composite mod-ified asphalt. Constr. Build. Mater. 2020, 261, 120505. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Zhang, J.; Jiang, H.; Yao, Z. Comparison of rheological properties and compatibility of asphalt modified with various polyethylene. Int. J. Pavement Eng. 2021, 22, 11–20. [Google Scholar] [CrossRef]

- Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering: JTG E20-2011; Ministry of Communications of the People’s Republic of China: Beijing, China, 2011.

- AASHTO. TP 70 Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- AASHTO. TP 101 Estimating Fatigue Resistance of Asphalt Binders Using the Linear Amplitude Sweep (LAS); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- Mikhailenko, P.; Kou, C.; Baaj, H.; Poulikakos, L.; Cannone-Falchetto, A.; Besamusca, J.; Hofko, B. Comparison of ESEM and physical properties of virgin and laboratory aged asphalt binders. Fuel 2019, 235, 627–638. [Google Scholar] [CrossRef]

- Meng, Y.J.; Guo, H.Y.; Xu, R.G.; Zhang, R.J.; Ma, C.X. Rheological and microscopic properties of graphene rubber composite modified asphalt. Chin. J. Build. Mater. 2020, 23, 1246–1251. [Google Scholar]

- Liu, K.; Zhang, K.; Shi, X. Performance evaluation and modification mechanism analysis of asphalt binders modified by graphene oxide. Constr. Build. Mater. 2018, 163, 880–889. [Google Scholar] [CrossRef]

| Items | Results | Requirements |

|---|---|---|

| Penetration (25 °C) (0.1 mm) | 66.80 | 60–80 |

| Softening point (°C) | 47.60 | ≥45 |

| Ductility (15 °C) (cm) | 112 | ≥100 |

| Density (15 °C) (g/cm3) | 1.035 | measurement |

| Dynamic viscosity (60 °C) (Pa·s) | data | ≥180 |

| Properties of GNPs | Properties of PE | ||

|---|---|---|---|

| Items | Test Results | Items | Test Results |

| Average thickness (nm) | <3 | Density (g/cm3) | 0.914 |

| Slice layer size (μm) | 5–10 | Crystallinity (%) | 75 |

| Specific surface area (m2/g) | 40–60 | Melting point (°C) | 126 |

| Ash content (%) | <3 | Melt flow index (MFI) (g/10 min) | 1.8 |

| Film conductivity (S/cm) | >700 | Break elongation (%) | 525 |

| Tap density (g/cm3) | 0.02–0.03 | Break strength (MPa) | 18.4 |

| Types of Asphalt | R0.1/% | R3.2/% | Jnr0.1/kPa−1 | Jnr3.2/kPa−1 | Jnr-diff/% |

|---|---|---|---|---|---|

| 70# | 3.14 | 0.15 | 2.88 | 4.55 | 69.93 |

| 4.0% PE | 8.24 | 4.62 | 0.72 | 1.14 | 57.68 |

| 3.6% PE + 0.4% GNPs | 27.20 | 8.17 | 0.63 | 0.99 | 55.85 |

| 4.0% Pre_PE/GNPs | 12.21 | 4.75 | 1.15 | 1.74 | 51.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.-Y.; Dou, H.-B.; Chen, X.-H. Rheological Properties of Graphene/Polyethylene Composite Modified Asphalt Binder. Materials 2021, 14, 3986. https://doi.org/10.3390/ma14143986

Zhou H-Y, Dou H-B, Chen X-H. Rheological Properties of Graphene/Polyethylene Composite Modified Asphalt Binder. Materials. 2021; 14(14):3986. https://doi.org/10.3390/ma14143986

Chicago/Turabian StyleZhou, Huan-Yun, Huai-Bing Dou, and Xian-Hua Chen. 2021. "Rheological Properties of Graphene/Polyethylene Composite Modified Asphalt Binder" Materials 14, no. 14: 3986. https://doi.org/10.3390/ma14143986

APA StyleZhou, H.-Y., Dou, H.-B., & Chen, X.-H. (2021). Rheological Properties of Graphene/Polyethylene Composite Modified Asphalt Binder. Materials, 14(14), 3986. https://doi.org/10.3390/ma14143986