The Use of Ion Milling for Surface Preparation for EBSD Analysis

Abstract

:1. Introduction

2. Materials and Methods

3. Results

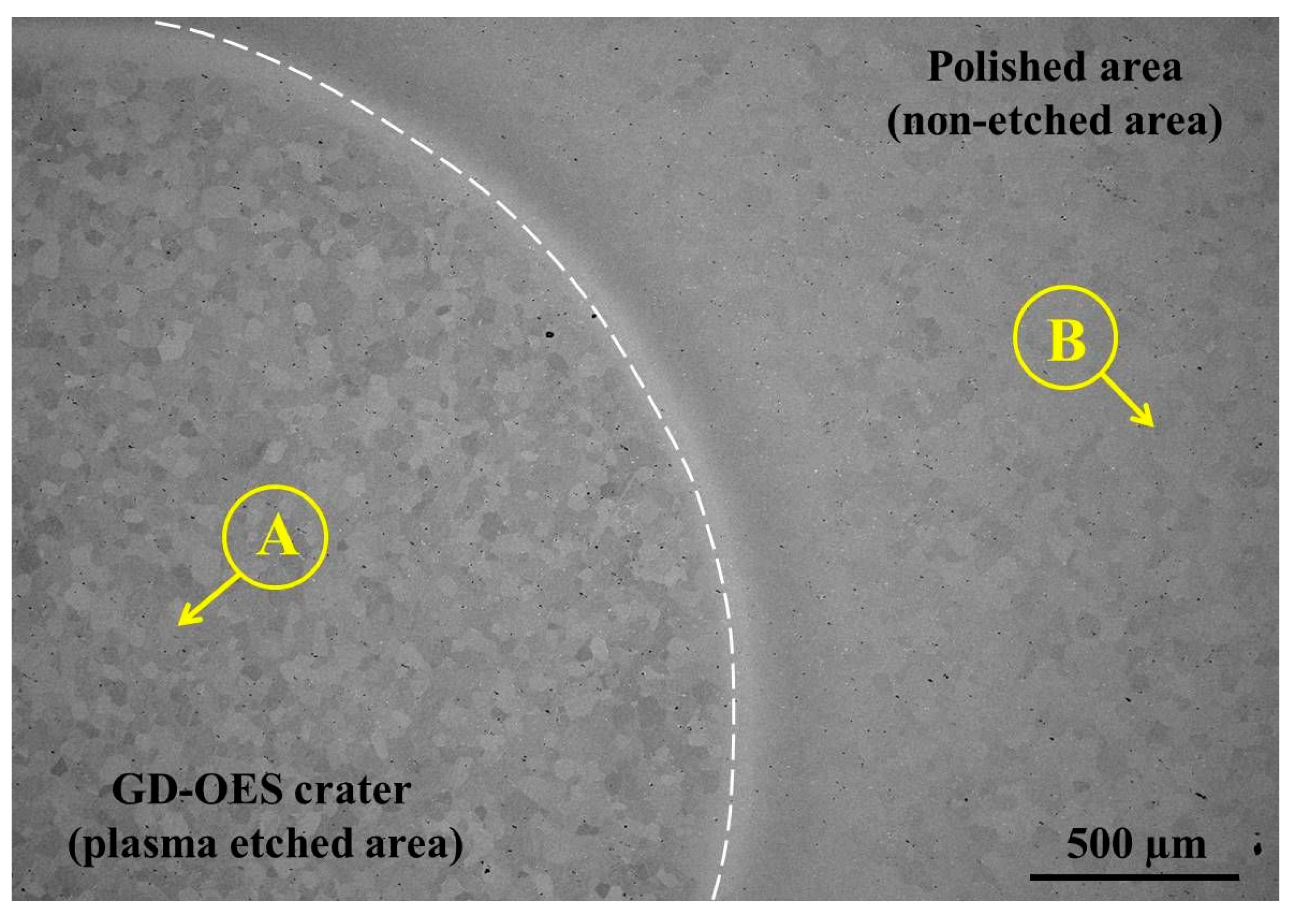

3.1. Studies on Steel Surfaces

3.1.1. Steel 1.4509 (AISI 441)

3.1.2. Steel 1.4521 (AISI 444)

3.2. Studies on Cross-Section

4. Discussion

- -

- Shortening of plasma etching time;

- -

- Lowering the plasma parameters, e.g., argon pressure;

- -

- Using so-called “pulse mode” to lower the sputtering rate.

5. Conclusions

- -

- Plasma etching by GD-OES is a very fast method for surface preparation for EBSD analysis of homogeneous metallic materials;

- -

- The plasma etching is sensitive to the presence of intermetallic phases as well as carbides due to a large difference in their sputtering rates;

- -

- Preparation of oxidized CM247 by plasma etching in GD-OES failed due to the difference in sputtering rate of the oxide scale and metallic matrix;

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sitzman, S.D. Introduction to EBSD Analysis of Micro- to Nanoscale Microstructures in Metals and Ceramics. In Proceedings of the Testing, Reliability, and Application of Micro- and Nano-Material Systems II, San Diego, CA, USA, 21 July 2004. [Google Scholar] [CrossRef]

- Schwarzer, R.A.; Field, D.P.; Adams, B.L.; Kumar, M.; Schwartz, A.J. Present State of Electron Backscatter Diffrac-Tion and Prospective Developments, 2nd ed.; Schwartz, A.J., Kumar, M., Adams, B.L., Field, D.P., Eds.; Electron Backscatter Diffraction in Materials Science; Springer: Berlin/Heidelberg, Germany, 2009; p. 403. [Google Scholar]

- Nolze, G.; Jürgens, M.; Olbricht, J.; Winkelmann, A. Improving the precision of orientation measurements from technical materials via EBSD pattern matching. Acta Mater. 2018, 159, 408–415. [Google Scholar] [CrossRef]

- Nowell, M. EBSD Sample Preparation: Techniques, Tips, and Tricks. Microsc. Microanal. 2005, 13, 44–48. [Google Scholar]

- Kumar, N.K.; Szpunar, J.A.; He, Z. Preferential precipitation of hydrides in textured zircaloy-4 sheets. J. Nucl. Mater. 2010, 403, 101–107. [Google Scholar] [CrossRef]

- Kumar, K.; Szpunar, J. EBSD studies on microstructure and crystallographic orientation of δ-hydrides in zircaloy-4, Zr-1% Nb and Zr-2.5% Nb. Mater. Sci. Eng. A 2011, 528, 6366–6374. [Google Scholar] [CrossRef]

- Kumar, N.K.; Szpunar, J.A.; He, Z. Microstructural studies and crystallographic orientation of different zones and δ-hydrides in resistance welded Zircaloy-4 sheets. J. Nucl. Mater. 2011, 414, 341–351. [Google Scholar] [CrossRef]

- Pshenichnikov, A.; Stuckert, J.; Walter, M. Hydride precipitation, fracture and plasticitymechanisms in pure zirconium and zircaloy-4 at temperatures typical for the postulated loss-of-coolant accident. Nucl. Eng. Des. 2016, 301, 366–377. [Google Scholar] [CrossRef]

- Wang, Z.; Garbe, U.; Li, H.; Wang, Y.; Studer, A.J.; Sun, G.; Harrison, R.P.; Liao, X.; Vicente Alvarez, M.A.; Santisteban, J.R.; et al. Microstructure and texture analysis of δ-hydride precipitation in zircaloy-4 materials by electron microscopy and neutron diffraction. J. Appl. Crystallogr. 2014, 47, 303–315. [Google Scholar] [CrossRef]

- Lin, J.-L.; Han, X.; Heuser, B.J.; Almer, J.D. Study of the mechanical behavior of the hydride blister/rim structure in zircal-oy-4 using in-situ synchrotron x-ray diffraction. J. Nucl. Mater. 2016, 471, 299–307. [Google Scholar] [CrossRef] [Green Version]

- Coburn, J.W.; Winters, H.F.; Chuang, T.J. Ion-surface interactions in plasma etching. J. Appl. Phys. 1977, 48, 3532–3540. [Google Scholar] [CrossRef]

- Arnold, J.C.; Sawin, H.H. Charging of pattern features during plasma etching. J. Appl. Phys. 1991, 70, 5314–5317. [Google Scholar] [CrossRef]

- Gottscho, R.A.; Jurgensen, C.W.; Vitkavage, D.J. Microscopic uniformity in plasma etching. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1992, 10, 2133–2147. [Google Scholar] [CrossRef]

- Dimitrakellis, P.; Gogolides, E. Atmospheric plasma etching of polymers: A palette of applications in cleaning/ashing, pattern formation, nanotexturing and superhydrophobic surface fabrication. Microelectron. Eng. 2018, 194, 109–115. [Google Scholar] [CrossRef]

- Mi, S.; Toros, A.; Graziosi, T.; Quack, N. Non-contact polishing of single crystal diamond by ion beam etching. Diam. Relat. Mater. 2019, 92, 248–252. [Google Scholar] [CrossRef]

- Tsutsumi, T.; Kondo, H.; Hori, M.; Zaitsu, M.; Kobayashi, A.; Nozawa, T.; Kobayashi, N. Atomic layer etching of SiO2 by alternating an O2 plasma with fluorocarbon film deposition. J. Vac. Sci. Technol. A 2017, 35, 01A103. [Google Scholar] [CrossRef]

- Huang, Y.; Yu, Q.; Li, M.; Sun, S.; Zhao, H.; Jin, S.; Fan, J.; Wang, J. An overview of low-temperature plasma surface modification of carbon materials for removal of pollutants from liquid and gas phases. Plasma Process. Polym. 2021, 18. [Google Scholar] [CrossRef]

- Wei, Z.; Yuan, M.; Shen, X.; Han, F.; Yao, Y.; Xin, L.; Yao, L. EBSD investigation on the interface microstructure evolution of Ti-Al3Ti laminated composites during the preparation process. Mater. Charact. 2020, 165, 110374. [Google Scholar] [CrossRef]

- Guo, J.; Amira, S.; Gougeon, P.; Chen, X.-G. Effect of the surface preparation techniques on the EBSD analysis of a friction stir welded AA1100-B4C metal matrix composite. Mater. Charact. 2011, 62, 865–877. [Google Scholar] [CrossRef]

- Priamushko, T.S.; Mikhaylov, A.A.; Babikhina, M.N.; Kudiiarov, V.N.; Laptev, R.S. Glow Discharge Optical Emission Spectrometer Calibration Using Hydrogenated Zr-2.5Nb Alloy Standard Samples. Metals 2018, 8, 372. [Google Scholar] [CrossRef] [Green Version]

- Chapon, P.; Gaiaschi, S.; Shimizu, K. Glow Discharge Optical Emission Spectrometry. In Compendium of Surface and Interface Analysis; Springer: Singapore, 2018; pp. 219–228. [Google Scholar]

- Nowak, W.J. Characterization of oxidized Ni-based superalloys by GD-OES. J. Anal. At. Spectrom. 2017, 32, 1730–1738. [Google Scholar] [CrossRef]

- Nowak, W.J.; Siemek, K.; Ochał, K.; Kościelniak, B.; Wierzba, B. Consequences of Different Mechanical Surface Preparation of Ni-Base Alloys during High Temperature Oxidation. Materals 2020, 13, 3529. [Google Scholar] [CrossRef]

- Niewolak, L.; Wessel, E.; Singheiser, L.; Quadakkers, W.J. Potential suitability of ferritic and austenitic steels as interconnect materials for solid oxide fuel cells operating at 600 °C. J. Power Sources 2010, 195, 7600–7608. [Google Scholar] [CrossRef]

- Echlin, P. Handbook of Sample Preparation for Scanning Electron Microscopy and X-Ray Microanalysis; Springer Science+Business Media, LLC: New York, NY, USA, 2009; pp. 273–274. [Google Scholar]

- Shimizu, K.; Mitani, T. New Horizons of Applied Scanning Electron Microscopy; Springer: Berlin/Heidelberg, Germany; Dordrecht, The Netherland; London, UK; New York, NY, USA, 2010; pp. 115–121. [Google Scholar]

- Nowak, W.J.; Naumenko, D.; Jałowicka, A.; Young, D.J.; Nischwitz, V.; Quadakkers, W.J. Effect of alloy composition on the oxidation-induced boron depletion in cast Ni-base superalloy components. Mater. Corros. 2016, 68, 171–185. [Google Scholar] [CrossRef] [Green Version]

| Alloy | Chemical Composition wt % | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Mn | Mo | Nb | Si | Al. | Ti | Ta | Co | W | Hf | |

| 1.4509 | Bal. | 17.4 | 0.13 | 0.23 | 1.6 | 0.6 | 0.41 | 0.03 | 0.17 | - | - | - | - |

| 1.4521 | Bal. | 17.4 | 0.24 | 0.46 | 0.01 | 1.3 | 0.12 | 0.02 | 0.09 | - | - | - | - |

| CM247 | - | 8.2 | Bal. | - | 0.5 | - | - | 5.4 | 0.7 | 3.4 | 9.4 | 9.8 | 1.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowak, W.J. The Use of Ion Milling for Surface Preparation for EBSD Analysis. Materials 2021, 14, 3970. https://doi.org/10.3390/ma14143970

Nowak WJ. The Use of Ion Milling for Surface Preparation for EBSD Analysis. Materials. 2021; 14(14):3970. https://doi.org/10.3390/ma14143970

Chicago/Turabian StyleNowak, Wojciech J. 2021. "The Use of Ion Milling for Surface Preparation for EBSD Analysis" Materials 14, no. 14: 3970. https://doi.org/10.3390/ma14143970

APA StyleNowak, W. J. (2021). The Use of Ion Milling for Surface Preparation for EBSD Analysis. Materials, 14(14), 3970. https://doi.org/10.3390/ma14143970