Research into the Disintegration of Abrasive Materials in the Abrasive Water Jet Machining Process

Abstract

:1. Introduction

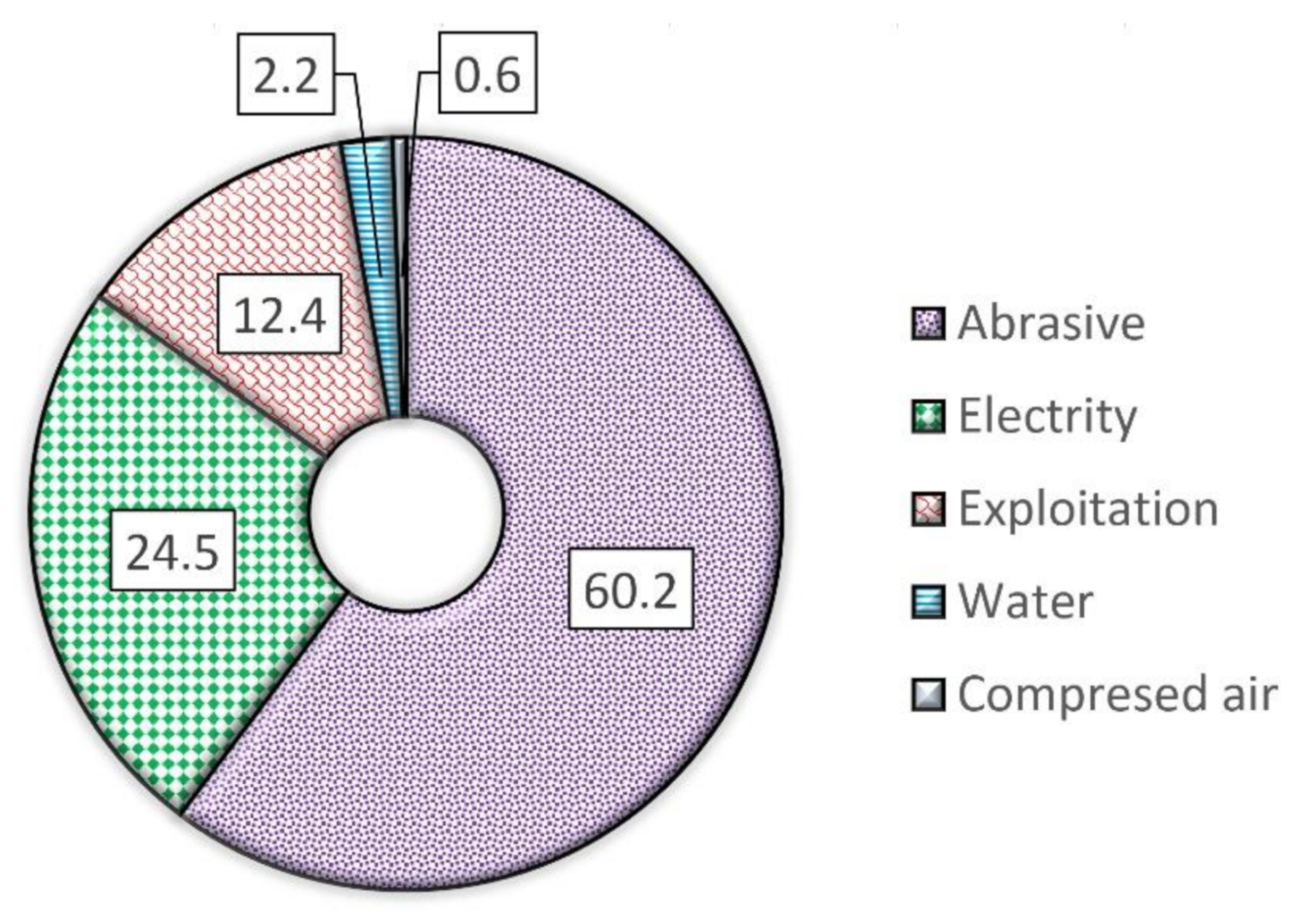

2. Materials and Methods

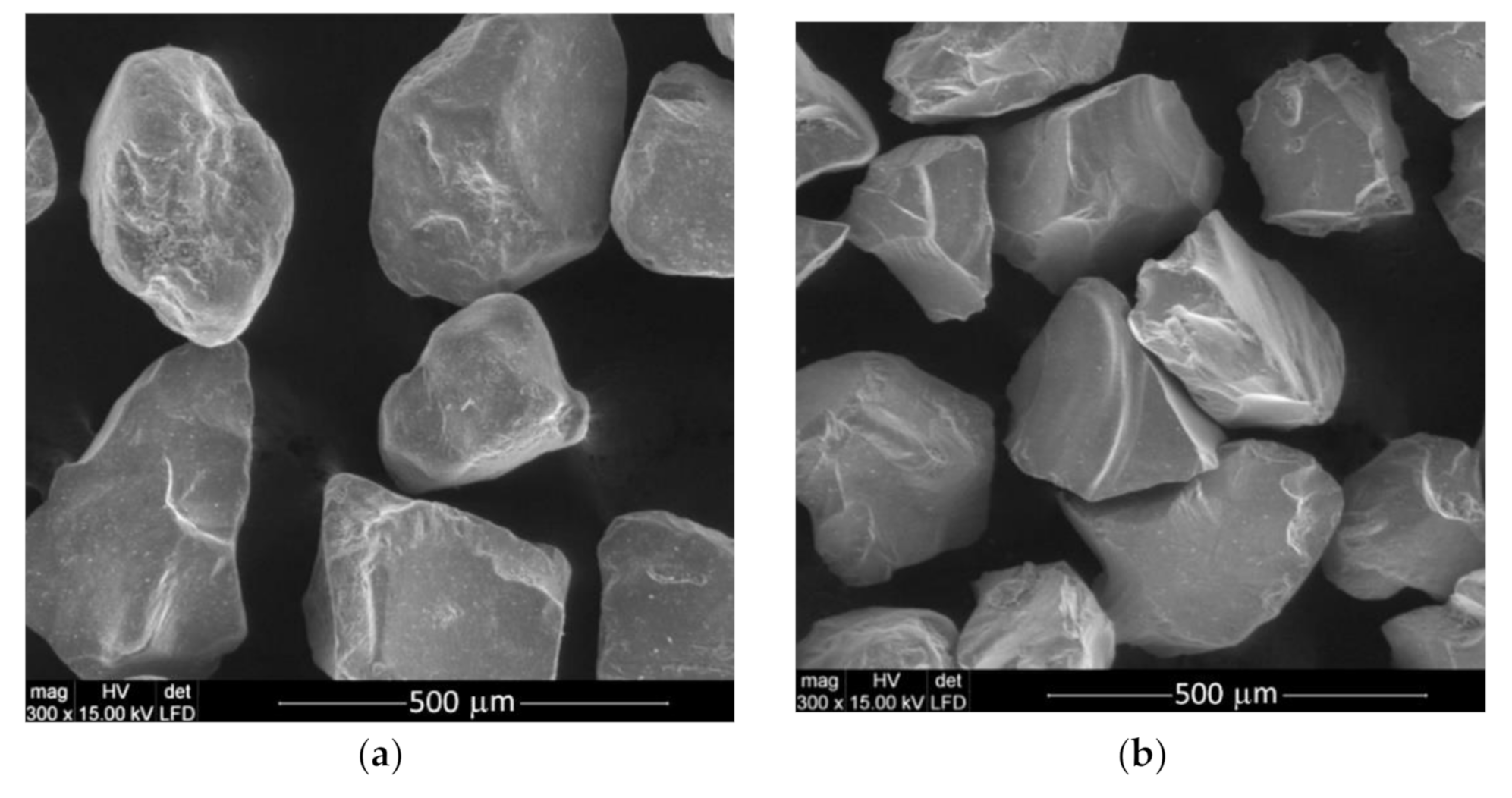

2.1. Alluvial Garnet

2.2. Recycled Garnet

2.3. Corundum

2.4. Olivine

2.5. Apparatus and Method

3. Results and Discussion

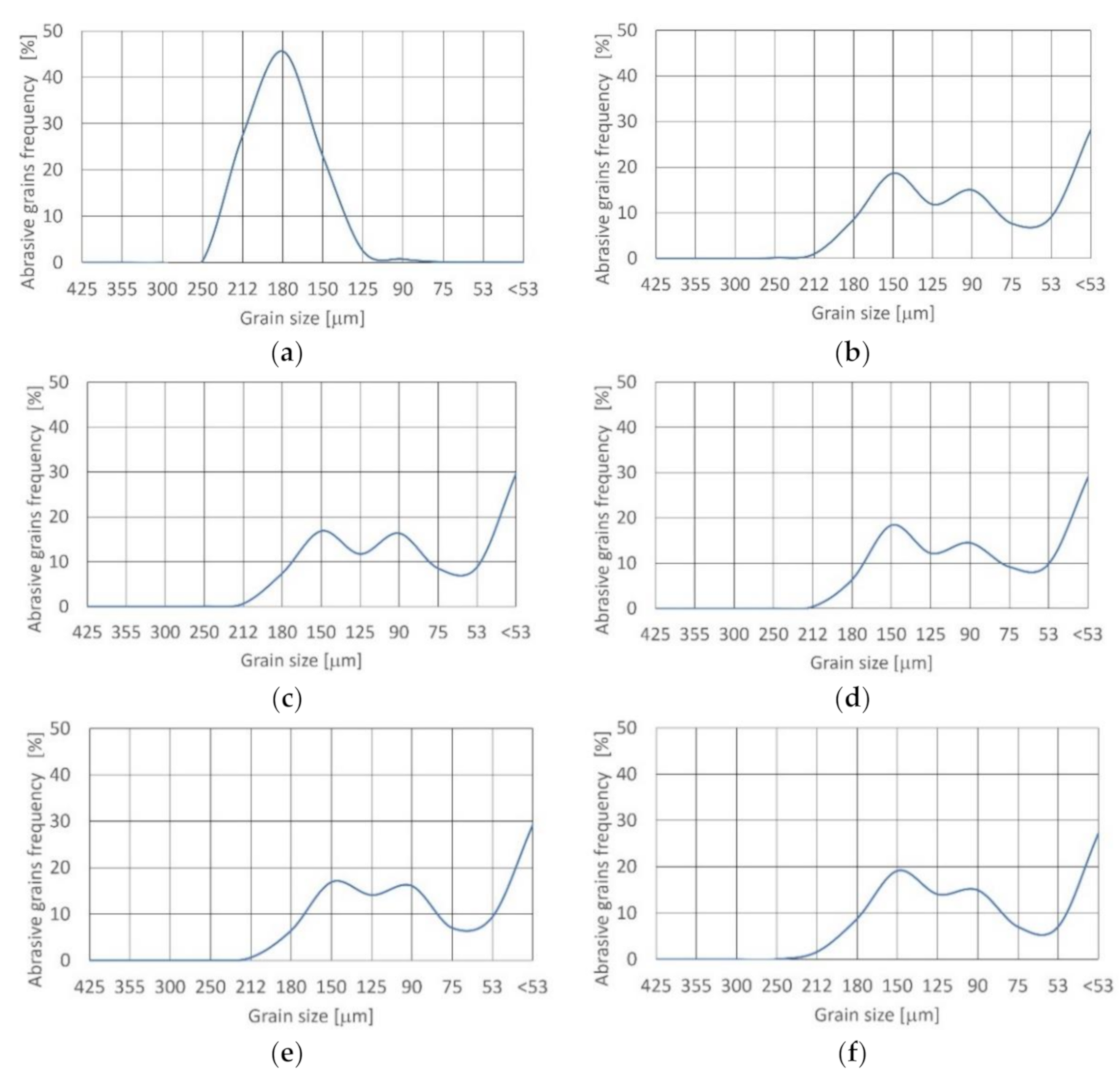

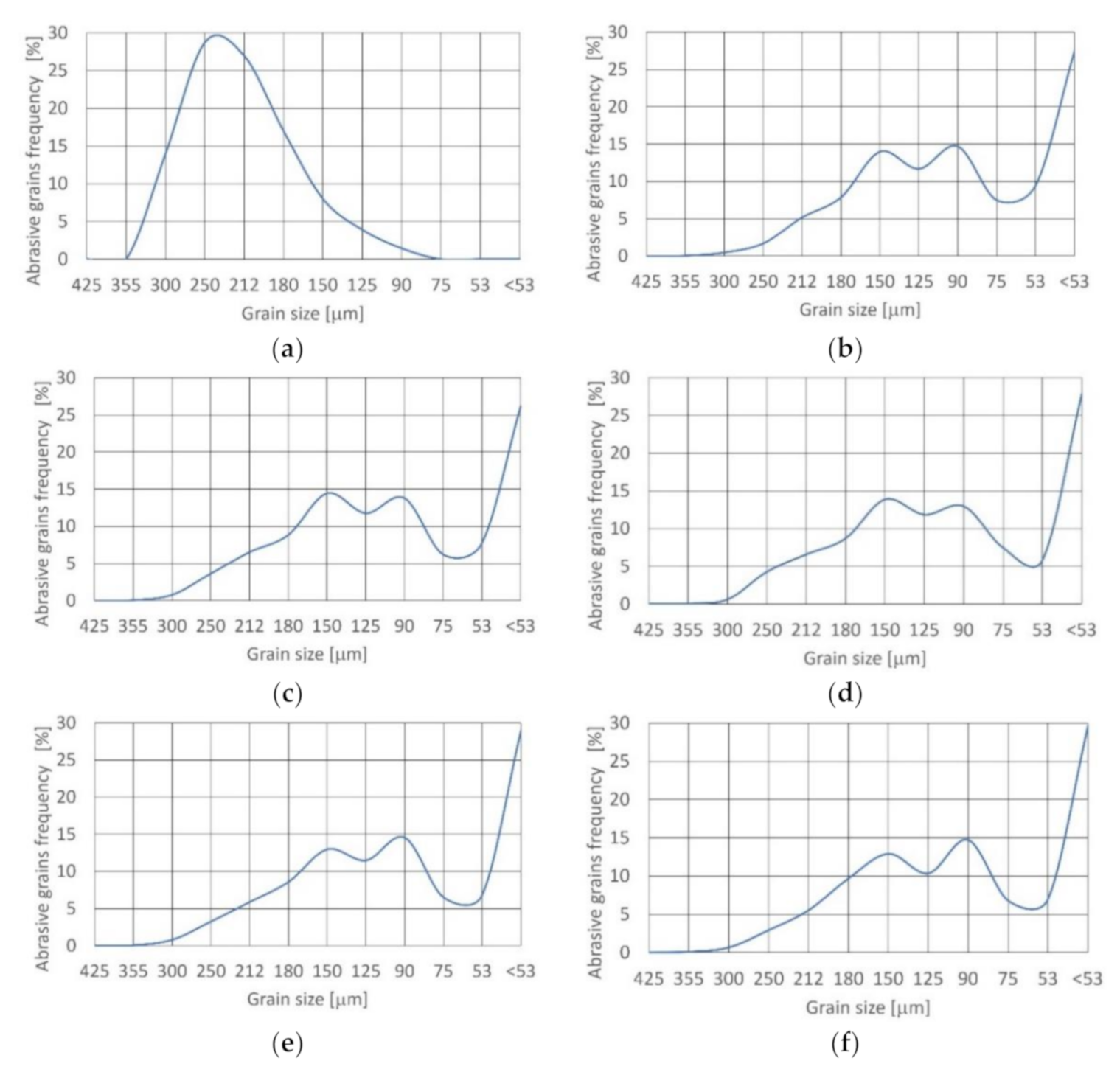

3.1. Abrasive Grain Disintegration

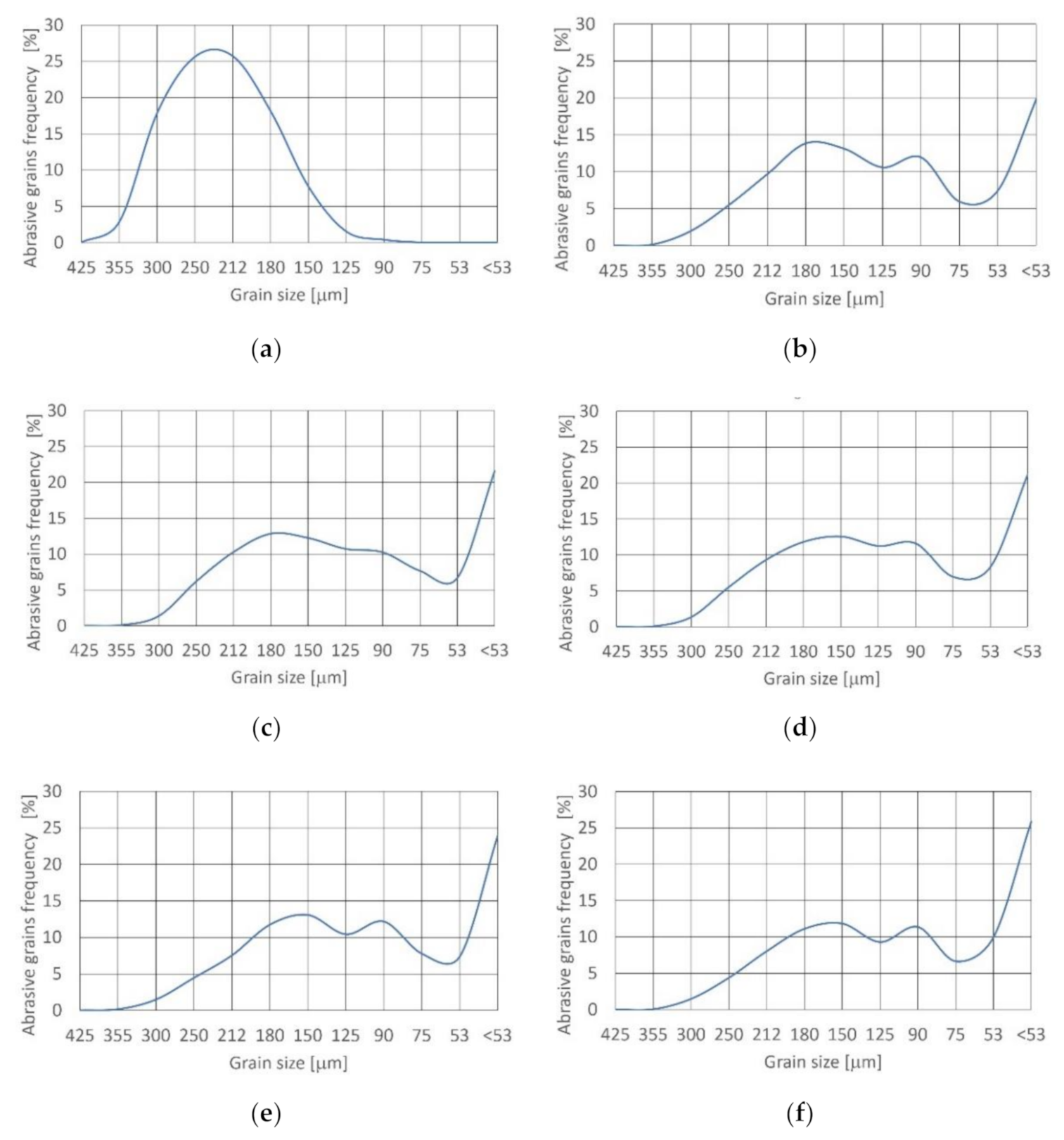

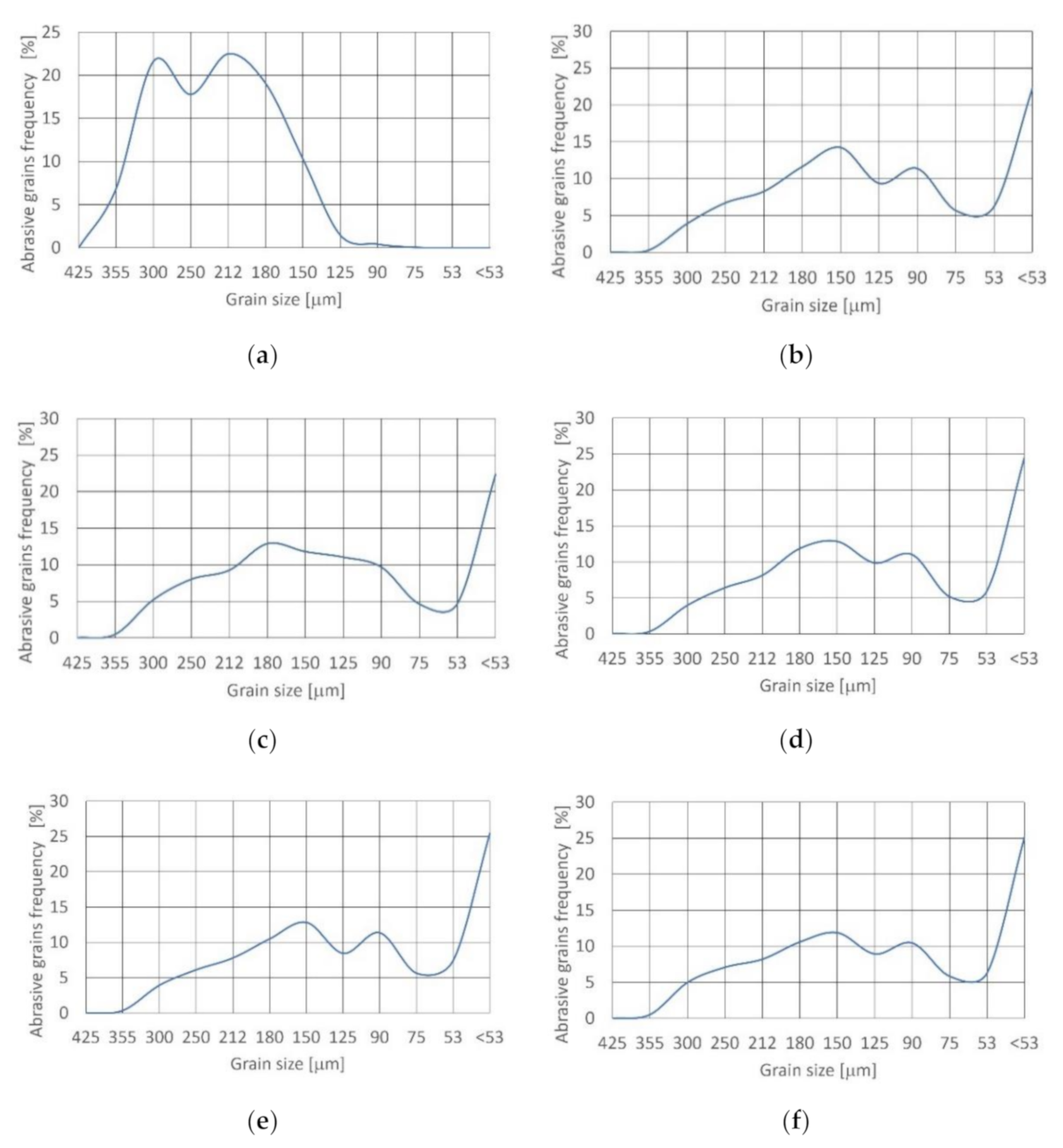

3.1.1. Alluvial Garnet

3.1.2. Recycled Garnet

3.1.3. Corundum

3.1.4. Olivine

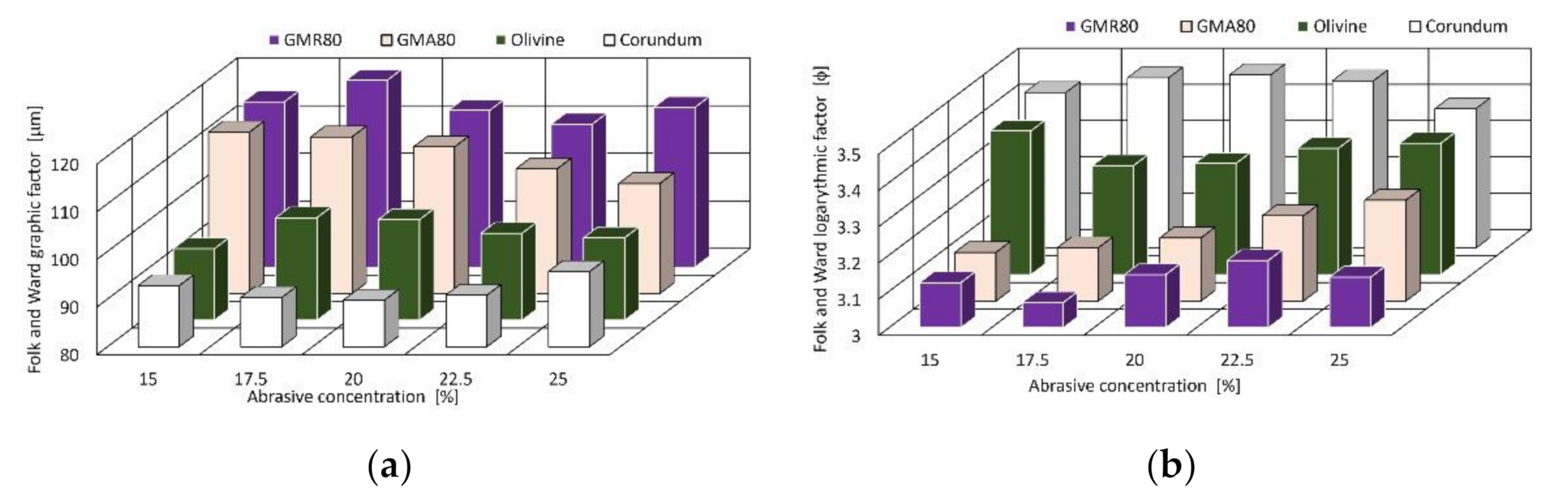

3.2. Comparison of Abrasive Grain Distribution Changes

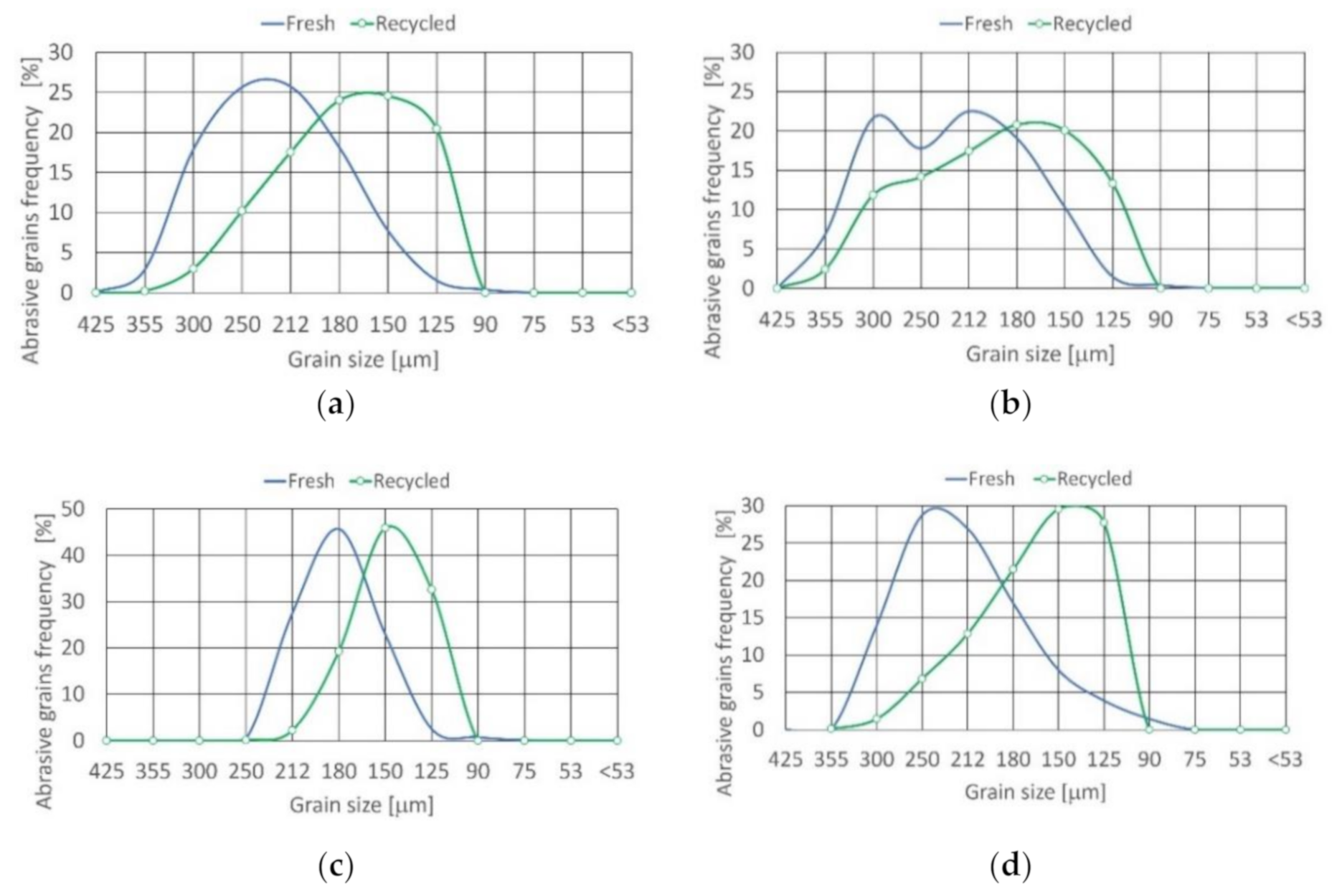

3.3. Recycling of Abrasive Materials

4. Conclusions

- The biggest recycling potential, from 51–61% range, characterized garnet;

- For olivine, the recycling potential is equal to 46%;

- The recycling potential of corundum is almost 40%, but abrasive wear of the focusing tube is much greater than for garnet.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nadolny, K.; Rokosz, K.; Kapłonek, W.; Wienecke, M.; Heeg, J. SEM-EDS-based analysis of the amorphous carbon-treated grinding wheel active surface after reciprocal internal cylindrical grinding of Titanium Grade 2® alloy. Int. J. Adv. Manuf. Technol. 2017, 90, 2293–2308. [Google Scholar] [CrossRef] [Green Version]

- Kukielka, L.; Kustra, J.; Kukielka, K. Numerical analysis of states of strain and stress of material during machining with a single abrasive grain. WIT Trans. Eng. Sci. 2005, 49. [Google Scholar] [CrossRef]

- Królczyk, G.; Kacalak, W.; Wieczorowski, M. 3D Parametric and Nonparametric Description of Surface Topography in Manufacturing Processes. Materials 2021, 14, 1987. [Google Scholar] [CrossRef]

- Kukie, L.; Kustra, J. Numerical analysis of thermal phenomena and deformations in processing zone in the centerless continuous grinding process. WIT Trans. Eng. Sci. 2003, 39. [Google Scholar] [CrossRef]

- Grochała, D.; Berczyński, S.; Grządziel, Z. Analysis of Surface Geometry Changes after Hybrid Milling and Burnishing by Ceramic Ball. Materials 2019, 12, 1179. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hloch, S.; Srivastava, M.; Krolczyk, J.; Chattopadhyaya, S.; Lehocká, D.; Simkulet, V.; Krolczyk, G. Strengthening Effect after Disintegration of Stainless-Steel Using Pulsating Water Jet. Teh. Vjesn. Tech. Gaz. 2018, 25, 1075–1079. [Google Scholar] [CrossRef]

- Říha, Z.; Zeleňák, M.; Kruml, T.; Poloprudský, J. Comparison of the disintegration abilities of modulated and continuous water jets. Wear 2021, 478-479, 203891. [Google Scholar] [CrossRef]

- Kacalak, W.; Lipiński, D.; Różański, R.; Królczyk, G.M. Assessment of the classification ability of parameters characterizing surface topography formed in manufacturing and operation processes. Measurement 2021, 170, 108715. [Google Scholar] [CrossRef]

- Kacalak, W.; Lipiński, D.; Bałasz, B.; Rypina, Ł.; Tandecka, K.; Szafraniec, F. Performance evaluation of the grinding wheel with aggregates of grains in grinding of Ti-6Al-4V titanium alloy. Int. J. Adv. Manuf. Technol. 2017, 94, 301–314. [Google Scholar] [CrossRef] [Green Version]

- Perec, A.; Radomska-Zalas, A. Modeling of abrasive water suspension jet cutting process using response surface method. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2019; Volume 2078. [Google Scholar]

- Perec, A. Disintegration and recycling possibility of selected abrasives for water jet cutting. DYNA 2017, 84, 249–256. [Google Scholar] [CrossRef]

- Prazmo, J.; Sobczak, R.; Perec, A. Abrasive grain disintegration during high-pressure abrasive water jet cutting in the abrasive reuse aspect. In Proceedings of the Conference on Water Jetting Technology: Water Jet 2017—Research, Development, Application, Lednice, Czech Republic, 13–15 September 2017; pp. 137–150, ISBN 978-80-86407-71-5. [Google Scholar]

- Perec, A. Environmental aspects of abrasive water jet cutting. Rocznik Ochrona Środowiska 2018, 20, 258–274. [Google Scholar]

- Babu, M.K.; Chetty, O.K. A study on recycling of abrasives in abrasive water jet machining. Wear 2003, 254, 763–773. [Google Scholar] [CrossRef]

- Hlaváč, L.M.; Hlavacova, I.M.; Jandacka, P.; Zegzulka, J.; Viliamsová, J.; Vašek, J.; Mádr, V. Comminution of material particles by water jets — Influence of the inner shape of the mixing chamber. Int. J. Miner. Process. 2010, 95, 25–29. [Google Scholar] [CrossRef]

- Aydin, G. Recycling of abrasives in abrasive water jet cutting with different types of granite. Arab. J. Geosci. 2013, 7, 4425–4435. [Google Scholar] [CrossRef]

- Aydin, G. Performance of recycling abrasives in rock cutting by abrasive water jet. J. Central South Univ. 2015, 22, 1055–1061. [Google Scholar] [CrossRef]

- Oh, T.-M.; Joo, G.-W.; Cha, Y.; Cho, G.-C. Effect of Garnet Characteristics on Abrasive Waterjet Cutting of Hard Granite Rock. Adv. Civ. Eng. 2019, 2019, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Galecki, G.; Mazurkiewicz, M.; Jordan, R. Abrasive Grains disintegration effect during jet injection. In Proceedings of the International Jet Symposium, Beijing, China, 9–11 September 1987; pp. 471–477. [Google Scholar]

- Guo, C.-W.; Dong, L. Energy Consumption in Comminution of Mica with Cavitation Abrasive Water Jet. J. China Univ. Min. Technol. 2007, 17, 251–254. [Google Scholar] [CrossRef]

- Li, Y.; Galecki, G.; Şen, G.A.; Şen, S. Effects of operating pressure and stand-off distance on coal comminution by waterjet. Physicochem. Prob. Mineral Proc. 2017, 53, 394–401. [Google Scholar] [CrossRef]

- Hlavac, L.; Vasek, J.; Hlavacova, I.; Jandačka, P. Potential of liquid jets for preparation of micro and nano particles. In Green Chemistry & Engineering Proc. International Conference on Process Intensification & Nanotechnology; Muir, A., Ed.; BHR Group: Albany, NY, USA, 15–18 September 2008; pp. 205–218. ISBN 9781855981010. [Google Scholar]

- Hreha, P.; Radvanská, A.; Carach, J.; Lehocka, D.; Monkova, K.; Krolczyk, G.; Ruggiero, A.; Samardzić, I.; Kozak, D.; Hloch, S. Monitoring of focusing tube wear during abrasive waterjet (AWJ) cutting of AISI 309. Metalurgija 2014, 53, 533–536. [Google Scholar]

- Perec, A.; Pude, F.; Grigoryev, A.; Kaufeld, M.; Wegener, K. A study of wear on focusing tubes exposed to corundum-based abrasives in the waterjet cutting process. Int. J. Adv. Manuf. Technol. 2019, 104, 2415–2427. [Google Scholar] [CrossRef]

- Nag, A.; Ščučka, J.; Hlaváček, P.; Klichová, D.; Srivastava, A.K.; Hloch, S.; Dixit, A.R.; Foldyna, J.; Zelenak, M. Hybrid aluminium matrix composite AWJ turning using olivine and Barton garnet. Int. J. Adv. Manuf. Technol. 2017, 94, 2293–2300. [Google Scholar] [CrossRef]

- Perec, A. Investigation of Limestone Cutting Efficiency by the Abrasive Water Suspension Jet. In Recent Advances in Computational Mechanics and Simulations; Springer Science and Business Media LLC: Berlin, Germany, 2018; pp. 124–134. [Google Scholar]

- Martín, C.G.; Lauand, C.; Hennies, W.; Ciccu, R. Abrasives in Water Jet Cutting Systems; Informa UK Limited: London, UK, 2018; pp. 641–645. [Google Scholar]

- GMA. Garnet Producing GMA in Australia. Available online: https://www.gmagarnet.com/en-gb/about-gma/producing-gma-australia (accessed on 18 March 2021).

- GMA. Garnet Group Our Garnet for Future Generations. Available online: https://www.gmagarnet.com/en-us/recycling (accessed on 23 March 2021).

- Sand Blasting Aluminium Oxide/Brown Fused Alumina—Products—Dengfeng Sweet Abrasives Co., Ltd.—Ruixiangmc.Com. Available online: http://dfsweet.ruixiangmc.com/sell/itemid-950.shtml (accessed on 30 December 2020).

- GREEN LIGHTNING® Olivine Technical Data. Available online: https://www.euroblastme.com/pdf/1245-290-1470227404.pdf (accessed on 23 June 2021).

- Blott, S.J.; Pye, K. GRADISTAT: A grain size distribution and statistics package for the analysis of unconsolidated sediments. Earth Surf. Process. Landforms 2001, 26, 1237–1248. [Google Scholar] [CrossRef]

- Folk, R.L.; Ward, W.C. Brazos River bar [Texas]; a study in the significance of grain size parameters. J. Sediment. Res. 1957, 27, 3–26. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A. Modeling of High-Pressure Abrasive Water Jet Cutting of Marble. Facta Univ. Ser. Mech. Eng. 2021. Online first. [Google Scholar] [CrossRef]

| Properties | Units | Value |

|---|---|---|

| Chemical composition | ||

| Fe3Al2(SiO4)3 | % | >97.0 |

| FeTiO3 | % | <2.0 |

| CaCO3 | % | <1.00 |

| ZrSiO4 | % | <0.10 |

| SiO2 | % | <0.10 |

| Melting point | °C | 1250 |

| Density | kg/m3 | 4100 |

| Bulk Density | kg/m3 | 2300 |

| Hardness | Mohs | 7.5–8.0 |

| Properties | Units | Value |

|---|---|---|

| Chemical composition | ||

| Al2O3 | % | 94.5–95.5 |

| SiO2 | % | 1.33–1.50 |

| Fe2O3 | % | 0.18–0.30 |

| Ti2O | % | 2.45–3.50 |

| CaO | % | 0.11–0.30 |

| Melting point | °C | 2050 |

| Density | kg/m3 | 3900 |

| Hardness | Mohs | 9.0 |

| Properties | Units | Value |

|---|---|---|

| Chemical composition | ||

| MgO | % | 48.8–49.7 |

| SiO2 | % | 41.5–41.9 |

| Fe2O3 | % | 7.3–7.6 |

| Al2O3 | % | 0.4–0.5 |

| Cr2O3 | % | 0.31–0.66 |

| Density | kg/m3 | 3300 |

| Bulk Density | kg/m3 | 1700 |

| Hardness | Mohs | 6.5–7.0 |

| Concentration (%) | Fresh | 15 | 17.5 | 20 | 22.5 | 25 | |

|---|---|---|---|---|---|---|---|

| Folk and Ward Method (μm) | MEAN | 244.6 | 113.9 | 112.9 | 110.8 | 106.2 | 103.1 |

| SORTING | 1.273 | 1.907 | 1.920 | 1.901 | 1.891 | 1.899 | |

| SKEWNESS | −0.039 | −0.304 | −0.285 | −0.259 | −0.212 | −0.121 | |

| KURTOSIS | 0.920 | 0.719 | 0.676 | 0.678 | 0.634 | 0.604 | |

| Folk and Ward Method (φ) | MEAN | 2.032 | 3.134 | 3.147 | 3.174 | 3.235 | 3.278 |

| SORTING | 0.348 | 0.931 | 0.941 | 0.927 | 0.919 | 0.925 | |

| SKEWNESS | 0.039 | 0.304 | 0.285 | 0.259 | 0.212 | 0.121 | |

| KURTOSIS | 0.920 | 0.719 | 0.676 | 0.678 | 0.634 | 0.604 |

| Concentration (%) | Fresh | 15 | 17.5 | 20 | 22.5 | 25 | |

|---|---|---|---|---|---|---|---|

| Folk and Ward Method (μm) | MEAN | 246.4 | 114.7 | 119.2 | 112.9 | 110.0 | 113.5 |

| SORTING | 1.315 | 1.964 | 2.007 | 1.972 | 1.971 | 2.005 | |

| SKEWNESS | 0.033 | −0.272 | −0.298 | −0.252 | −0.186 | −0.206 | |

| KURTOSIS | 0.819 | 0.686 | 0.695 | 0.627 | 0.618 | 0.612 | |

| Folk and Ward Method (φ) | MEAN | 2.021 | 3.124 | 3.069 | 3.146 | 3.185 | 3.139 |

| SORTING | 0.395 | 0.974 | 1.005 | 0.980 | 0.979 | 1.004 | |

| SKEWNESS | −0.033 | 0.272 | 0.298 | 0.252 | 0.186 | 0.206 | |

| KURTOSIS | 0.819 | 0.686 | 0.695 | 0.627 | 0.618 | 0.612 |

| Concentration (%) | Fresh | 15 | 17.5 | 20 | 22.5 | 25 | |

|---|---|---|---|---|---|---|---|

| Folk and Ward Method (μm) | MEAN | 194.8 | 92.82 | 90.33 | 89.76 | 90.83 | 95.77 |

| SORTING | 1.163 | 1.741 | 1.730 | 1.720 | 1.721 | 1.746 | |

| SKEWNESS | −0.067 | −0.162 | −0.109 | −0.094 | −0.155 | −0.261 | |

| KURTOSIS | 1.004 | 0.573 | 0.577 | 0.570 | 0.579 | 0.575 | |

| Folk and Ward Method (φ) | MEAN | 2.360 | 3.429 | 3.469 | 3.478 | 3.461 | 3.384 |

| SORTING | 0.218 | 0.800 | 0.791 | 0.782 | 0.783 | 0.804 | |

| SKEWNESS | 0.067 | 0.162 | 0.109 | 0.094 | 0.155 | 0.261 | |

| KURTOSIS | 1.004 | 0.573 | 0.577 | 0.570 | 0.579 | 0.575 |

| Concentration (%) | Fresh | 15 | 17.5 | 20 | 22.5 | 25 | |

|---|---|---|---|---|---|---|---|

| Folk and Ward Method (μm) | MEAN | 235.7 | 94.99 | 101.5 | 101.1 | 98.23 | 97.28 |

| SORTING | 1.274 | 1.802 | 1.856 | 1.869 | 1.853 | 1.848 | |

| SKEWNESS | −0.137 | −0.104 | −0.185 | −0.169 | −0.125 | −0.102 | |

| KURTOSIS | 1.020 | 0.619 | 0.618 | 0.614 | 0.616 | 0.607 | |

| Folk and Ward Method (φ) | MEAN | 2.085 | 3.396 | 3.300 | 3.306 | 3.348 | 3.362 |

| SORTING | 0.349 | 0.850 | 0.892 | 0.902 | 0.889 | 0.886 | |

| SKEWNESS | 0.137 | 0.104 | 0.185 | 0.169 | 0.125 | 0.102 | |

| KURTOSIS | 1.020 | 0.619 | 0.618 | 0.614 | 0.616 | 0.607 |

| Abrasive Material | Alluvial Garnet | Recycled Garnet | Corundum | Olivine | |

|---|---|---|---|---|---|

| Folk and Ward Method (μm) | MEAN | 187.1 | 209.9 | 160.7 | 175.7 |

| SORTING | 1.287 | 1.355 | 1.165 | 1.267 | |

| SKEWNESS | 0.071 | 0.098 | 0.029 | 0.181 | |

| KURTOSIS | 0.889 | 0.857 | 0.928 | 0.918 | |

| Folk and Ward Method (φ) | MEAN | 2.418 | 2.252 | 2.638 | 2.509 |

| SORTING | 0.364 | 0.438 | 0.221 | 0.341 | |

| SKEWNESS | −0.071 | −0.098 | −0.029 | −0.181 | |

| KURTOSIS | 0.889 | 0.857 | 0.928 | 0.918 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perec, A. Research into the Disintegration of Abrasive Materials in the Abrasive Water Jet Machining Process. Materials 2021, 14, 3940. https://doi.org/10.3390/ma14143940

Perec A. Research into the Disintegration of Abrasive Materials in the Abrasive Water Jet Machining Process. Materials. 2021; 14(14):3940. https://doi.org/10.3390/ma14143940

Chicago/Turabian StylePerec, Andrzej. 2021. "Research into the Disintegration of Abrasive Materials in the Abrasive Water Jet Machining Process" Materials 14, no. 14: 3940. https://doi.org/10.3390/ma14143940

APA StylePerec, A. (2021). Research into the Disintegration of Abrasive Materials in the Abrasive Water Jet Machining Process. Materials, 14(14), 3940. https://doi.org/10.3390/ma14143940