Influence of Co Content and Chemical Nature of the Co Binder on the Corrosion Resistance of Nanostructured WC-Co Hardmetals in Acidic Solution

Abstract

1. Introduction

2. Materials and Methods

3. Results

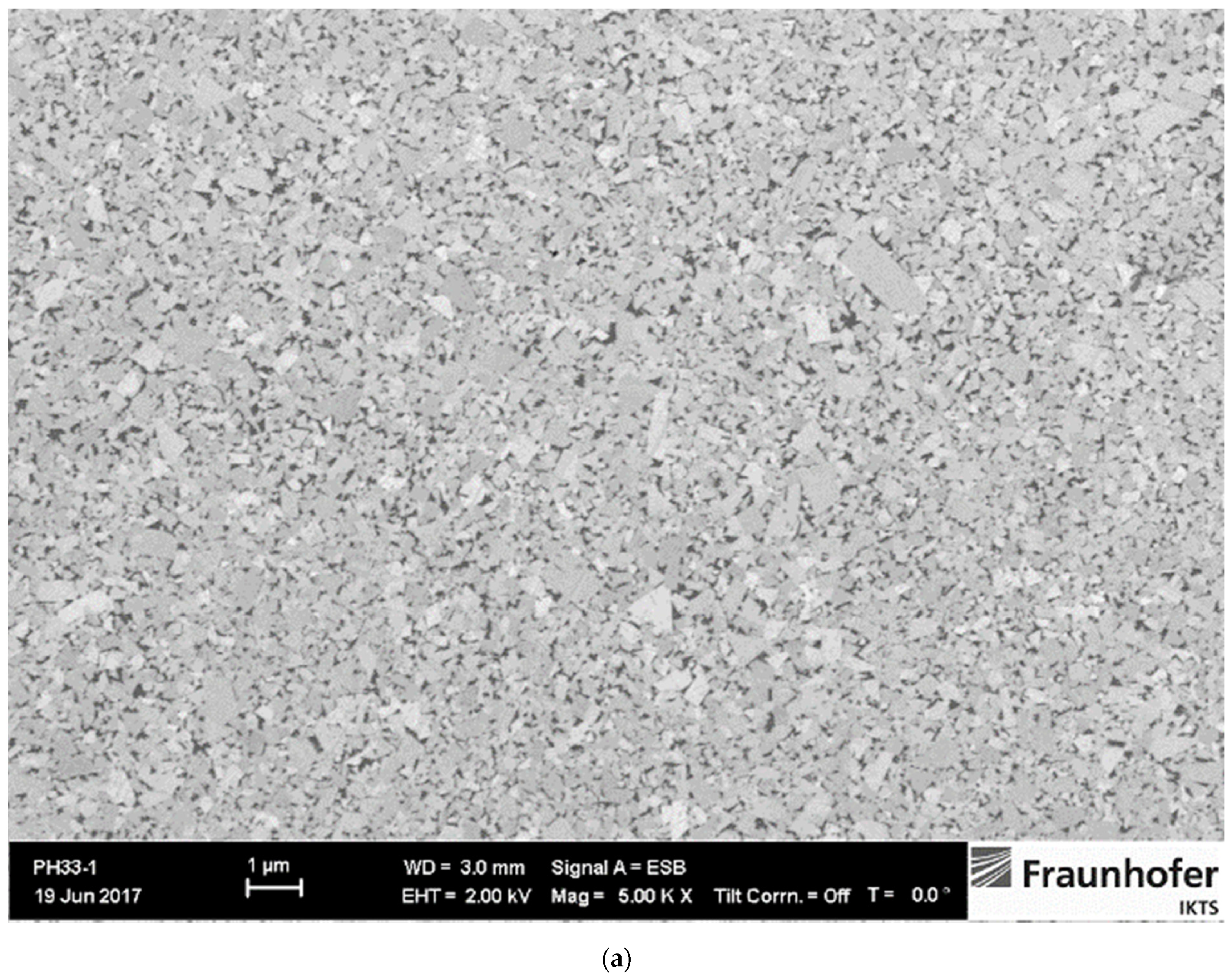

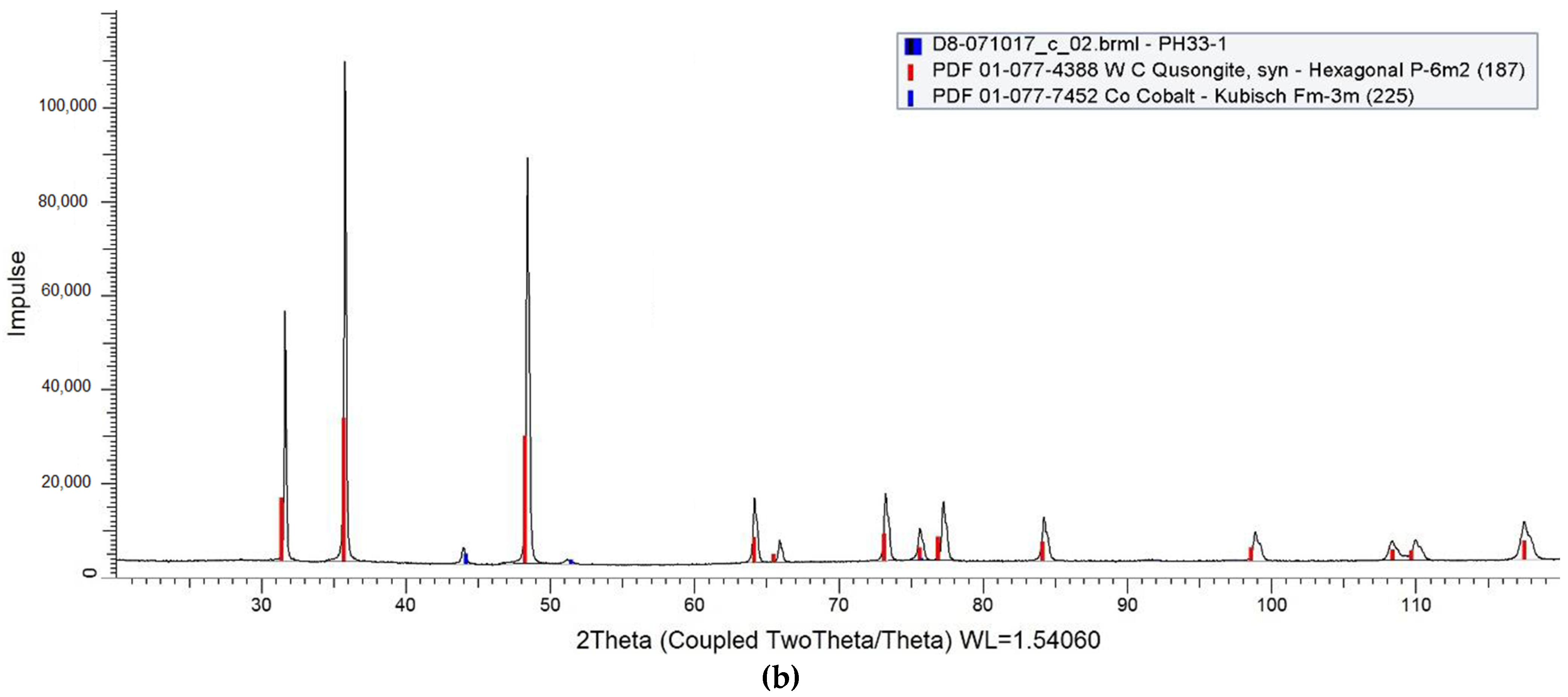

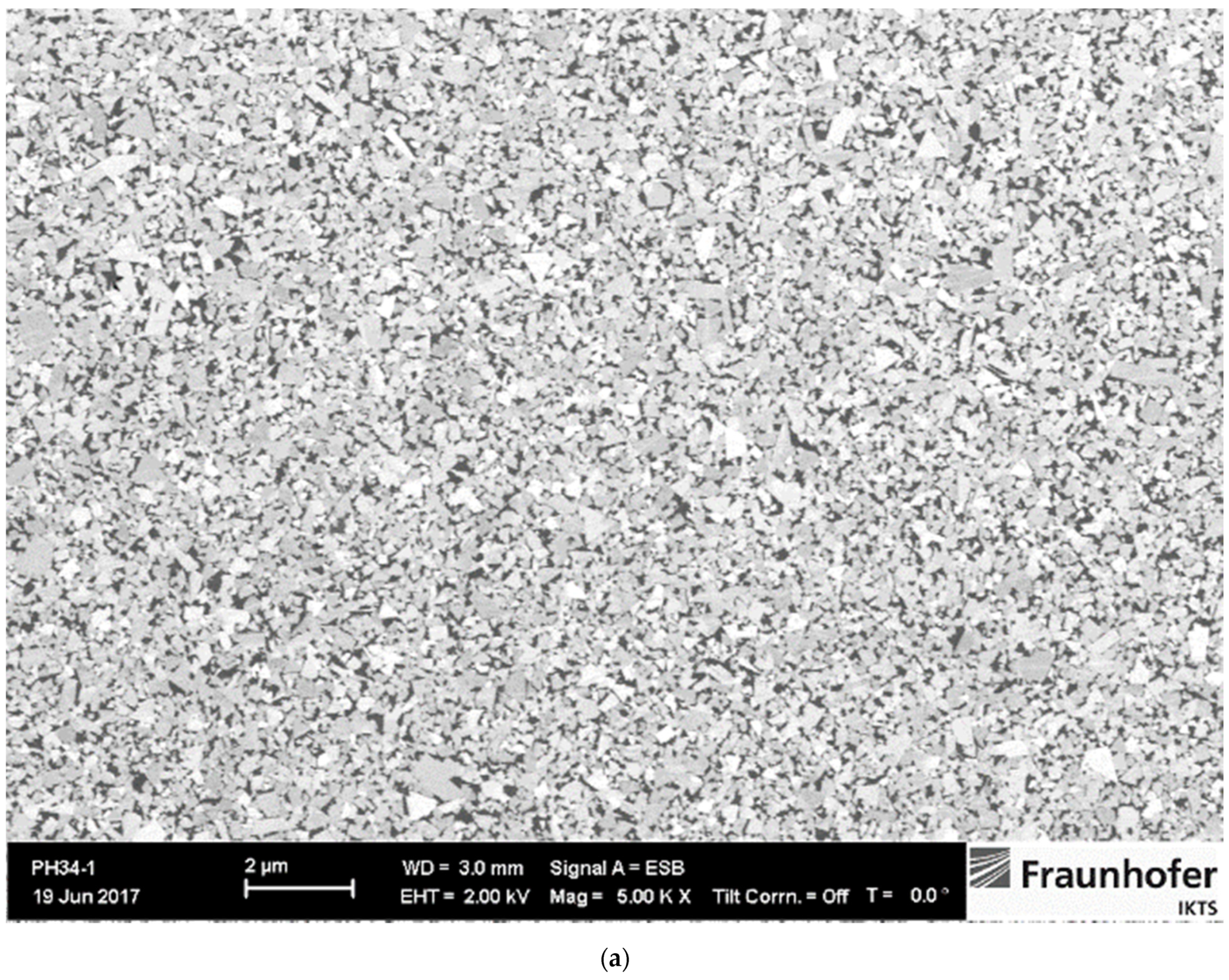

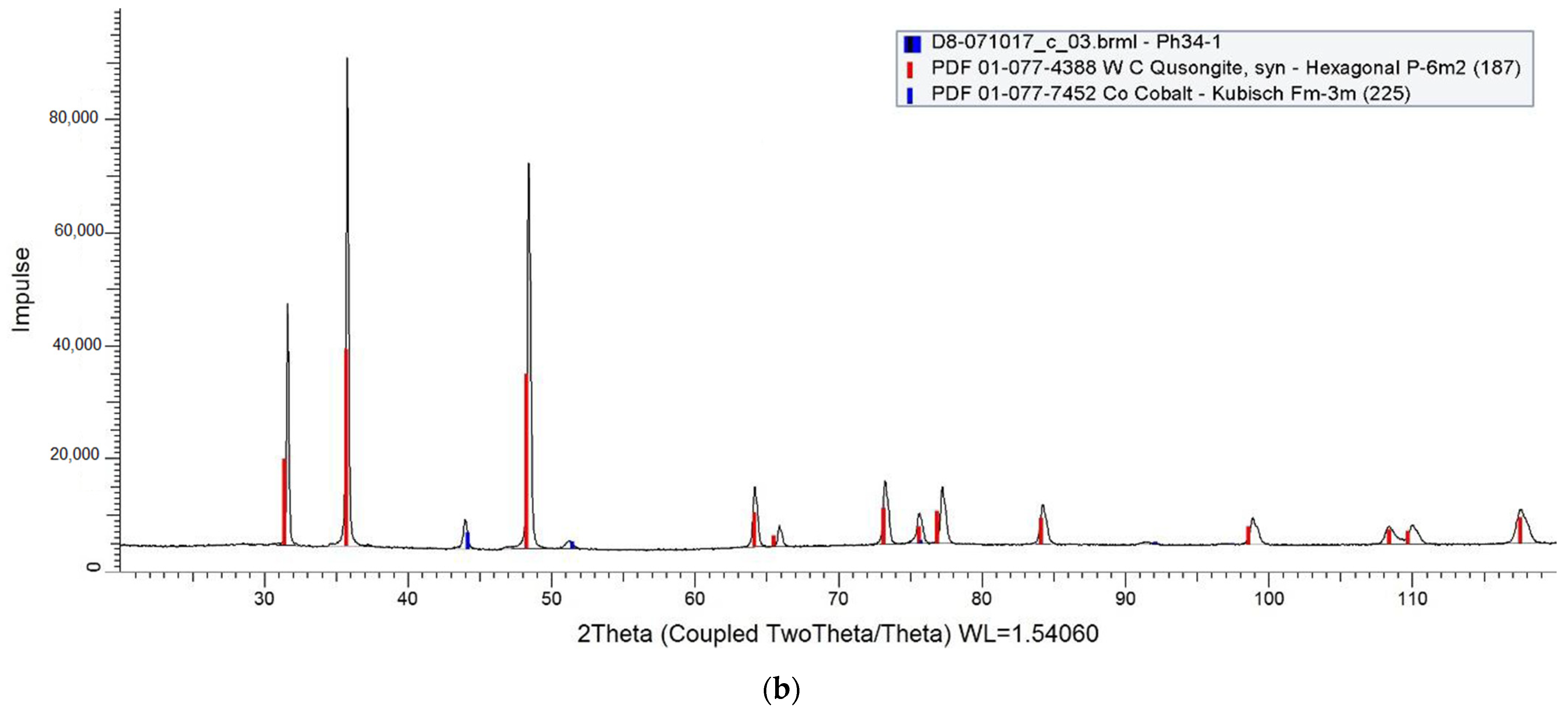

3.1. Microstructural Characteristics of Consolidated Samples

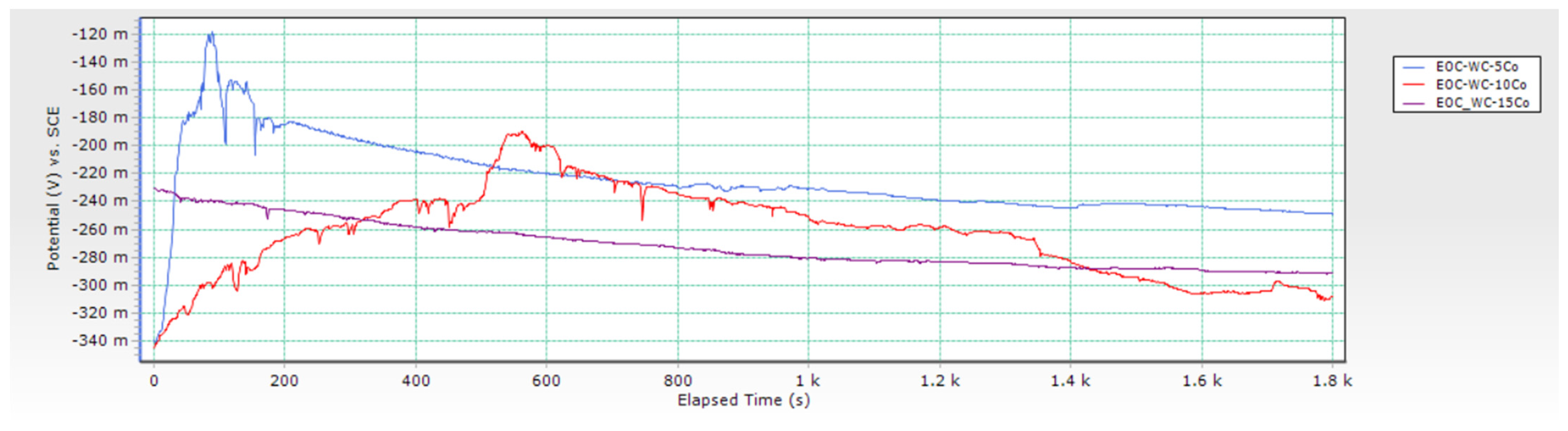

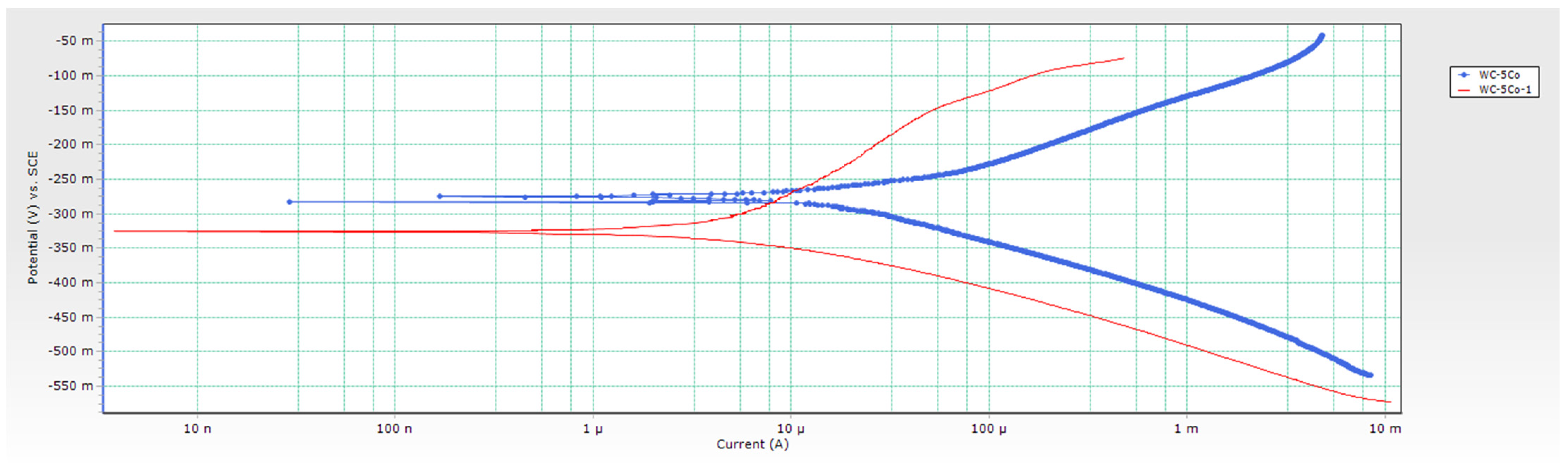

3.2. Results of DC Techniques

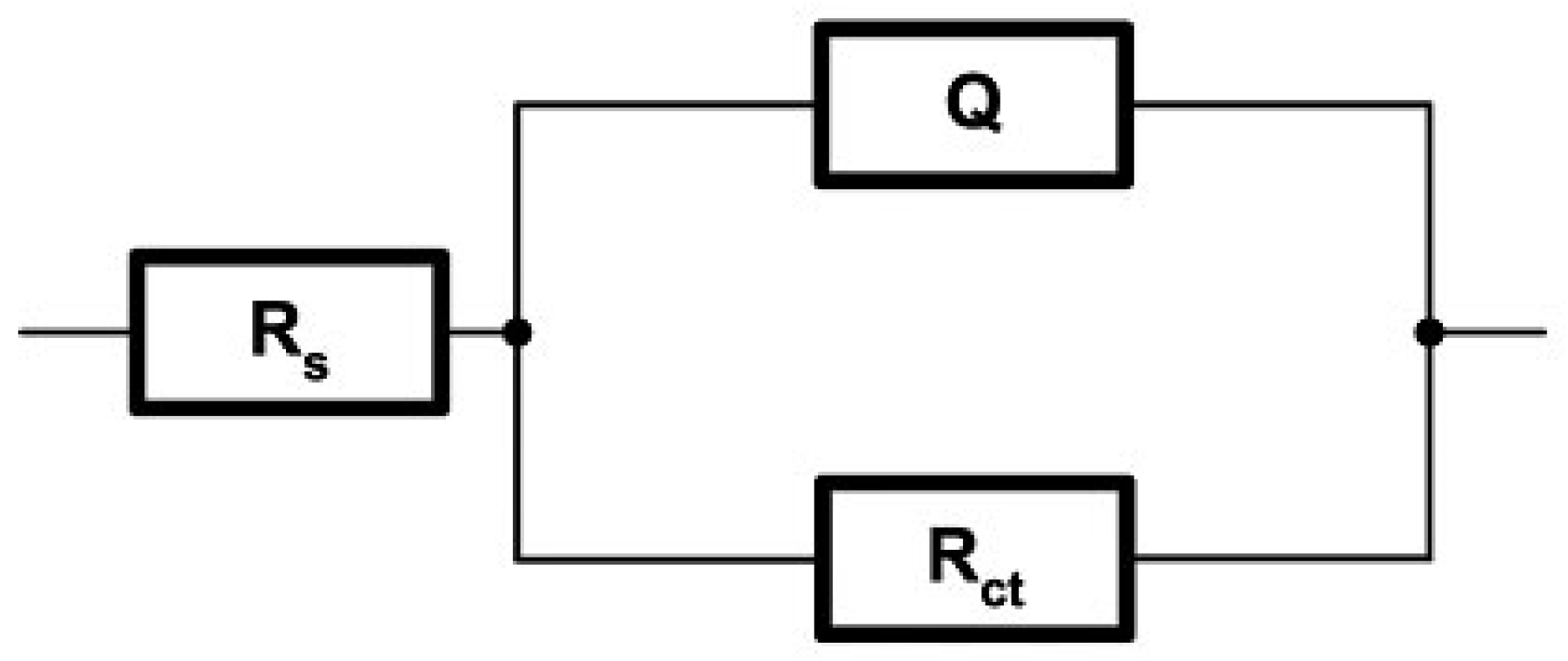

3.3. Results of Electrochemical Impedance Spectroscopy EIS

4. Analysis and Discussion

4.1. Influence of Co Content on the Corrosion Resistance of Nanostructured WC-Co Hardmetals

4.2. Influence of Co Binder Chemical Nature on the Corrosion Resistance of Nanostructured WC-Co Hardmetals

5. Conclusions

- (1)

- Fully dense nanostructured hardmetals with a WC grain size dWC ≤ 200 nm were developed utilizing the single-cycle sinter-HIP process. For different Co contents, a homogeneous microstructure of equal and uniform grain size without microstructural defects in the form of carbide agglomerates, abnormal grain growth, or Co lakes was successfully obtained.

- (2)

- The importance of GGIs content adjustment was established as a key factor of obtaining a homogeneous microstructure with WC grain size retained at the same values as in starting mixtures of different Co binder content.

- (3)

- The Co content in the starting mixture proved to have a significant influence on the electrochemical corrosion resistance of nanostructured hardmetals in acidic solution. A noticeable trend of polarization resistance Rp decrease, and current density icorr and corrosion rate vcorr increase has been established with increasing Co content. Nanostructured hardmetals with the grain size dWC ˂ 200 nm showed the same corrosion behavior as coarser grain-size conventional WC hardmetals depending on the Co content.

- (4)

- The chemical composition of the Co binder showed a significant influence. Samples with lower relative magnetic saturation related to lower added C content and more W dissolved in the Co binder showed better corrosion resistance. Significant differences in magnetic saturation for samples with the same Co content lead to more pronounced differences in the corrosion rates. A slight difference in magnetic saturation and WC grain size changed the Taffel curves.

- (5)

- Co content was shown to be the dominant influential factor governing electrochemical corrosion resistance of nanostructured hardmetals when compared to the chemical composition of the Co binder and WC grain size. Samples with lower Co content exhibited lower corrosion rates.

- (6)

- The slight increase of GGIs content, Cr3C2, and VC did not improved the corrosion resistance significantly for the samples with the same Co content. Higher content of Cr3C2 dissolved in the binder contributed to a lower corrosion rate. Slight VC increase did not contribute to corrosion resistance. Superior corrosion resistance is attributed to W and C dissolved in the Co binder, lower magnetic saturation, or WC grain size of the sintered sample.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Konadu, D.S.; van der Merwe, J.; Potgieter, J.H.; Potgieter-Vermaak, S.; Machio, C.N. The corrosion behaviour of WC-VC-Co hardmetals in acidic media. Corros. Sci. 2010, 52, 3118–3125. [Google Scholar] [CrossRef]

- Alar, Ž.; Alar, V.; Fabijanić, T.A. Electrochemical Corrosion Behavior of Near-Nano and Nanostructured WC-Co Cemented Carbides. Metals 2017, 7, 69. [Google Scholar] [CrossRef]

- Hochstrasser-Kurz, S.; Mueller, Y.; Latkoczy, C.; Virtanen, S.; Schmutz, P. Analytical characterisation of the corrosion mechanism and inductively coupled plasma mass spectroscopy. Corros. Sci. 2007, 49, 2002–2020. [Google Scholar] [CrossRef]

- Zhang, L.; Wan, Q.; Huang, B.; Liu, Z.; Zhu, J. Effects of WC Grain Sizes and Aggressive Media on the Electrochemical Corrosion Behaviours of WC-Co Cemented Carbides. In Proceedings of the EURO PM2015-HM-Modelling and Characterisation, Reims, France, 4–7 September 2015. [Google Scholar]

- Tarrag’, J.M.; Fargas, G.; Isern, L.; Dorvlo, S.; Tarres, E.; Muller, C.M.; Jim’enez-Piqu’e, E.; Llanes, L. Microstructural influence on tolerance to corrosion-induced damage in hardmetals. Mater. Des. 2016, 111, 36–43. [Google Scholar] [CrossRef]

- Fabijanić, T.A.; Pötschke, J.; Alar, V.; Alar, Ž. Influence of C Content on Electrochemical Corrosion Resistance of Nanostructured Hardmetals. In Proceedings of the EURO PM2017, Milano, Italy, 10 October 2017. [Google Scholar]

- Fabijanić, T.A.; Sakoman, M.; Kurtela, M.; Marciuš, M. Electrochemical Corrosion Resistance of Nanostructured Hardmetals in Acid Media. In Proceedings of the EURO PM2018, Bilbao, Spain, 14–18 October 2018. [Google Scholar]

- Human, A.M.; Exner, H.E. Electrochemical behavior of tungsten-carbide hardmetals. Mater. Sci. Eng. A 1996, 209, 180–191. [Google Scholar] [CrossRef]

- Human, A.M. The Corrosion of Tungsten Carbide-Based Cemented Carbides. Ph.D. Thesis, Technische Hochschule Darmstadt, Darmstadt, Germany, 1994. [Google Scholar]

- Tarrago, J.M.; Fargas, G.; Jimenez-Pique, E.; Felip, A.; Isern, L.; Coureaux, D.; Roal, J.J.; Al-Dawery, I.; Fair, J.; Llanes, L. Corrosion damage in WC–Co cemented carbides: Residual strength assessment and 3D FIB-FESEM tomography characterization. Powder Metall. 2014, 57, 5. [Google Scholar] [CrossRef]

- Sacks, N. The Wear and Corrosive-Wear Response of Tungsten Carbide-Cobalt Hardmetals under Woodcutting and Three Body Abrasion Conditions. Ph.D. Thesis, Faculty of Engineering of the University of Erlangen-Nürnberg, Erlangen, Germany, 2002. [Google Scholar]

- Tarrago, J.M.; Fargas, G.; Jimenez-Pique, E.; Dorvlo, S.; Llanes, L. Influence of Carbide Grain Size on the Corrosion damage in WC–Co cemented carbides: Electrochemical Measurement, residual strength and 3D FIB/FESEM characterisation of Induced Damage. In Proceedings of the World PM2016, Hamburg, Germany, 9–13 October 2016; pp. 509–514. [Google Scholar]

- Hashiva, M.; Kubo, Y. The Influence of Carbon Content and Additions of Growth Inhibitors (V, Cr) on the Formation of Melt in WC-Co and WC-Ni alloys. In Proceedings of the 17th Plansee Seminar 2009, Reutte, Austria, 29 May 2009; Plansee Group: Reutte, Austria, 2009. HM 55/1–HM 55/17. [Google Scholar]

- Toller, L. Alternative Binder Hardmetals for Steel Turning; Uppsala University: Uppsala, Sweden, 2017. [Google Scholar]

- Peterson, A. Cemented Carbide Sintering: Constitutive Relations and Microstructural Evolution. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2004. [Google Scholar]

- Sutthiruangwong, S.; Mori, G. Corrosion properties of Co-based cemented carbides in acidic solutions. Int. J. Refract. Met. Hard Mater. 2003, 21, 135–145. [Google Scholar] [CrossRef]

- Imasato, S.; Sakaguchi, S.; Okada, T.; Hayashi, Y. Effect of WC Grain Size on Corrosion Resistance of WC-Co Cemented Carbide. J. Jpn. Soc. Powder Powder Metall. 2001, 48, 609–615. [Google Scholar] [CrossRef][Green Version]

- Gille, G.; Szesny, B.; Dreyer, G.; van den Berg, H.; Schmidt, J.; Gestrich, T.; Leitner, G. Submicron and ultrafine grained hardmetals for microdrills and metal cutting inserts. Int. J. Refract. Met. Hard Mater. 2002, 20, 3–22. [Google Scholar] [CrossRef]

- Roebuck, B.; Gee, M.; Bennett, E.G.; Morrell, R. A National Measurement Good Practice Guide No. 20 Mechanical Tests for Hardmetals; National Physical Laboratory: Teddington, UK, 1999; Revised February 2009. [Google Scholar]

- Sakoman, M.; Ćorić, D.; Šnajdar Musa, M. Plasma-Assisted Chemical Vapor Deposition of TiBN Coatings on Nanostructured Cemented WC-Co. Metals 2020, 10, 1680. [Google Scholar] [CrossRef]

- Sakoman, M. Development of PACVD Coatings on Nanostructured Hardmetals; Faculty of Mechanical Engineering and Naval Architecture: Zagreb, Republika Hrvatska, 2020. [Google Scholar]

- Fabijanić, T.A.; Kurtela, M.; Škrinjarić, I.; Pötschke, J.; Mayer, M. Electrochemical corrosion resistance of Ni and Co bonded near-nano and nanostructured cemented carbides. Metals 2020, 10, 224. [Google Scholar] [CrossRef]

- Sutthiruangwong, S.; Mori, G. Influence of refractory metal carbide addition on corrosion properties of cemented carbides. Mater. Manuf. Process. 2005, 20, 47–56. [Google Scholar] [CrossRef]

- Mori, G.; Zitter, H.; Lackner, A.; Schretter, M. Influencing the Corrosion Resistance of Cemented Carbides by addition of Cr2C3, TiC and TaC. In Proceedings of the 15th International Plansee Seminar, Reutte, Austria, 15–17 May 2001; Volume 2. [Google Scholar]

- Kellner, F.J.J.; Hildebrand, H.; Virtanen, S. Effect of WC grain size on the corrosion behavior of WC–Co based hardmetals in alkaline solutions. Int. J. Refrac. Met. Hard Mater. 2009, 27, 806–812. [Google Scholar] [CrossRef]

- Tomlinson, W.J.; Ayerst, N.J. Anodic polarization and corrosion of WC-Co hardmetals containing small amounts of Cr3C2 and/or VC. J. Mater. Sci. 1989, 24, 2348–2352. [Google Scholar] [CrossRef]

- Fabijanić, T.A.; Pötschke, J.; Alar, V.; Alar, Ž. Potentials of nanostructured WC–Co hardmetal as reference material for Vickers hardness. Int. J. Refrac. Met. Hard Mater. 2015, 50, 126–132. [Google Scholar] [CrossRef]

- Machio, C.N.; Konadu, D.S.; Potgieter, J.H.; Potgieter-Vermaak, S.; van der Merwe, J. Corrosion of WC-VC-Co Hardmetal in Neutral Chloride Containing Media; Hindawi Publishing Corporation: London, UK, 2013. [Google Scholar]

| Mixture | Starting WC Powder | Grain Size dBET, nm | Specific Surface, m2/g | Co, wt.% | GGI, wt.% |

|---|---|---|---|---|---|

| WC-5Co | WC DN 4-0 (H.C. Starck) | 95 | 3.92 | 5 | 0.3% VC 160 (H. C. Starck) 0.5% Cr3C2 160 (H. C. Starck) |

| WC-10Co | 10 | 0.5% VC 160 (H. C. Starck) 0.75% Cr3C2 160 (H. C. Starck) | |||

| WC-15Co | 15 | 0.75% VC 160 (H. C. Starck) 1.13% Cr3C2 160 (H. C. Starck) |

| Sample | Density, g/cm3 | Relative Density, % | Magnetic Saturation, µTm3/kg | Rel. Magnetic Saturation, % | Coercive Force, kA/m | ISO Porosity | dWC, nm | ||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | |||||||

| WC-5Co | 14.91 | 100.0 | 8.4 | 92 | 52.0 | A00 | B00 | C00 | 187 |

| WC-10Co | 14.31 | 100.0 | 14.8 | 79 | 40.0 | A00 | B00 | C00 | 198 |

| WC-15Co | 13.84 | 100.0 | 22.3 | 79 | 37.0 | A00 | B00 | C00 | 192 |

| Sample | Ts [°C] | Ecorr vs. SCE [mV] | Rp [Ωcm2] | βa [mV/dec] | βc [mV/dec] | icorr [μA/cm2] | vcorr [mm/y] |

|---|---|---|---|---|---|---|---|

| WC-5Co | 20 ± 2 | −249 | 654.5 | 75.31 | 90.37 | 20.7 | 0.1748 |

| WC-10Co | 20 ± 2 | −308 | 452.8 | 98.34 | 97.67 | 36.6 | 0.3888 |

| WC-15Co | 20 ± 2 | −291 | 349.9 | 120.19 | 86.95 | 50.8 | 0.4162 |

| Sample | Ts [°C] | Rs [Ωcm2] | Q | n1 | Rp/Rct [Ωcm2] |

|---|---|---|---|---|---|

| WC-5Co | 20 ± 2 | 4.022 | 1.761·10−3 | 0.745 | 1.101·10−3 |

| WC-10Co | 20 ± 2 | 4.504 | 2.213·10−3 | 0.725 | 8.068·10−2 |

| WC-15Co | 20 ± 2 | 5.797 | 2.552·10−3 | 0.683 | 4.657·10−2 |

| Sample | GGI, wt.% | Added C, wt.% | Density, g/cm3 | ρ, % | Relative Magnetic Saturation, % | Coercive Force, kA/m | vcorr [mm/y] |

|---|---|---|---|---|---|---|---|

| WC-5Co-1 | 0.41%VC, 0.80% Cr3C2 | 0.150 | 14.96 | 100 | 48.0 | 44.9 | 0.1181 |

| WC-5Co | 0.30%VC, 0.50% Cr3C2 | 0.275 | 14.91 | 100 | 92.0 | 52.0 | 0.1748 |

| Sample | GGI, wt.% | Added C, wt.% | Density, g/cm3 | ρ, % | Relative Magnetic Saturation, % | Coercive Force, kA/m | vcorr [mm/y] |

|---|---|---|---|---|---|---|---|

| WC-10Co-1 | 0.37%VC, 0.72% Cr3C2 | 0.225 | 14.35 | 100 | 74.7 | 35.1 | 0.3463 |

| WC-10Co | 0.5%VC, 0.75% Cr3C2 | 0.250 | 14.32 | 100 | 79.0 | 40.0 | 0.3888 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aleksandrov Fabijanić, T.; Kurtela, M.; Sakoman, M.; Šnajdar Musa, M. Influence of Co Content and Chemical Nature of the Co Binder on the Corrosion Resistance of Nanostructured WC-Co Hardmetals in Acidic Solution. Materials 2021, 14, 3933. https://doi.org/10.3390/ma14143933

Aleksandrov Fabijanić T, Kurtela M, Sakoman M, Šnajdar Musa M. Influence of Co Content and Chemical Nature of the Co Binder on the Corrosion Resistance of Nanostructured WC-Co Hardmetals in Acidic Solution. Materials. 2021; 14(14):3933. https://doi.org/10.3390/ma14143933

Chicago/Turabian StyleAleksandrov Fabijanić, Tamara, Marin Kurtela, Matija Sakoman, and Mateja Šnajdar Musa. 2021. "Influence of Co Content and Chemical Nature of the Co Binder on the Corrosion Resistance of Nanostructured WC-Co Hardmetals in Acidic Solution" Materials 14, no. 14: 3933. https://doi.org/10.3390/ma14143933

APA StyleAleksandrov Fabijanić, T., Kurtela, M., Sakoman, M., & Šnajdar Musa, M. (2021). Influence of Co Content and Chemical Nature of the Co Binder on the Corrosion Resistance of Nanostructured WC-Co Hardmetals in Acidic Solution. Materials, 14(14), 3933. https://doi.org/10.3390/ma14143933