Strength Analysis and Stress-Strain Deformation Behavior of 3 mol% Y-TZP and 21 wt.% Al2O3-3 mol% Y-TZP

Abstract

:1. Introduction

2. Stress-Strain Deformation Behavior of ZrO2-Based Ceramics

2.1. Effect of t→m Phase Transition

2.2. Effect of Domain Switching

2.3. Al2O3-Y-TZP Composites

2.4. The Goal of the Research

3. Experimental

4. Results and Discussion

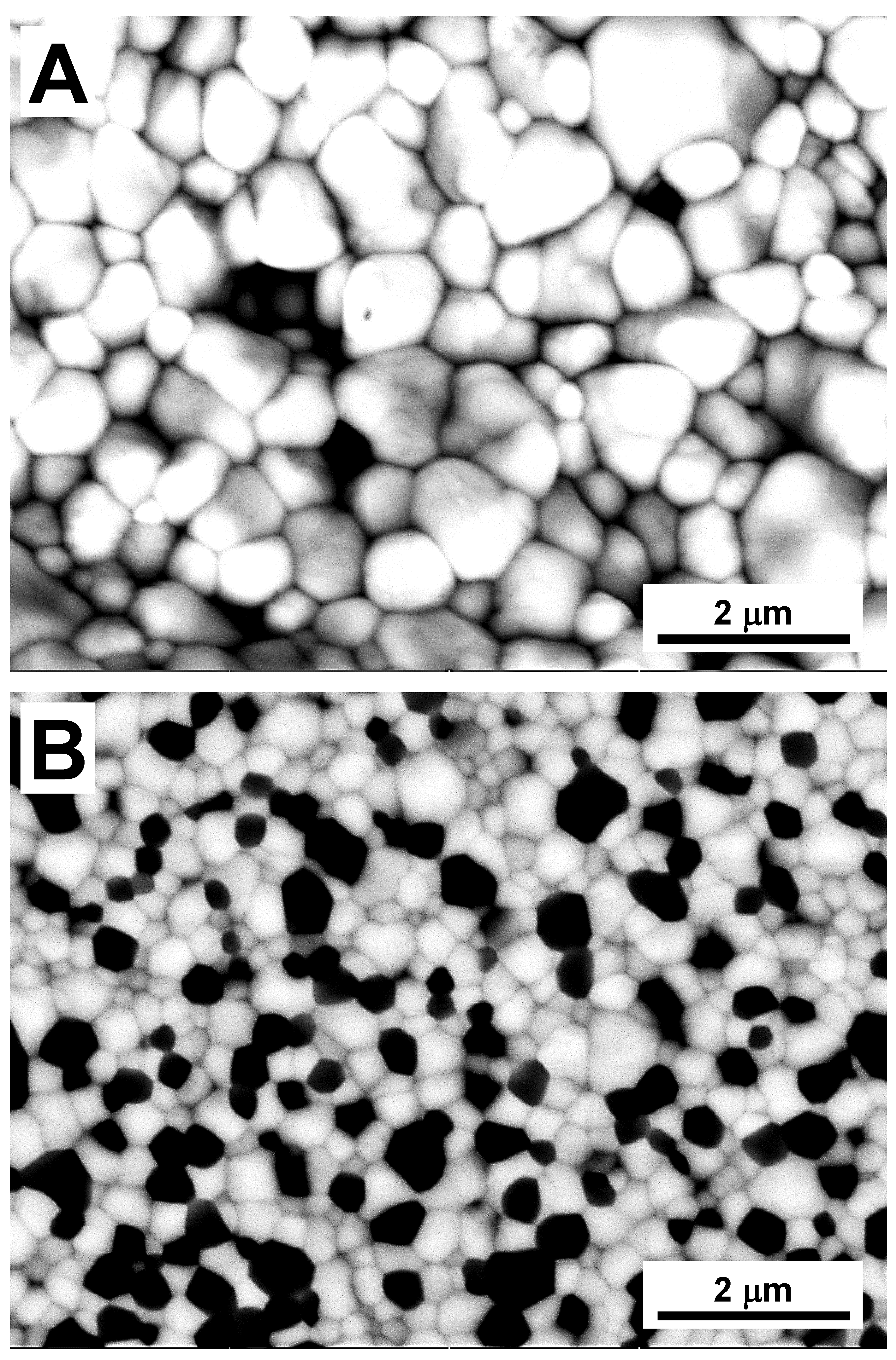

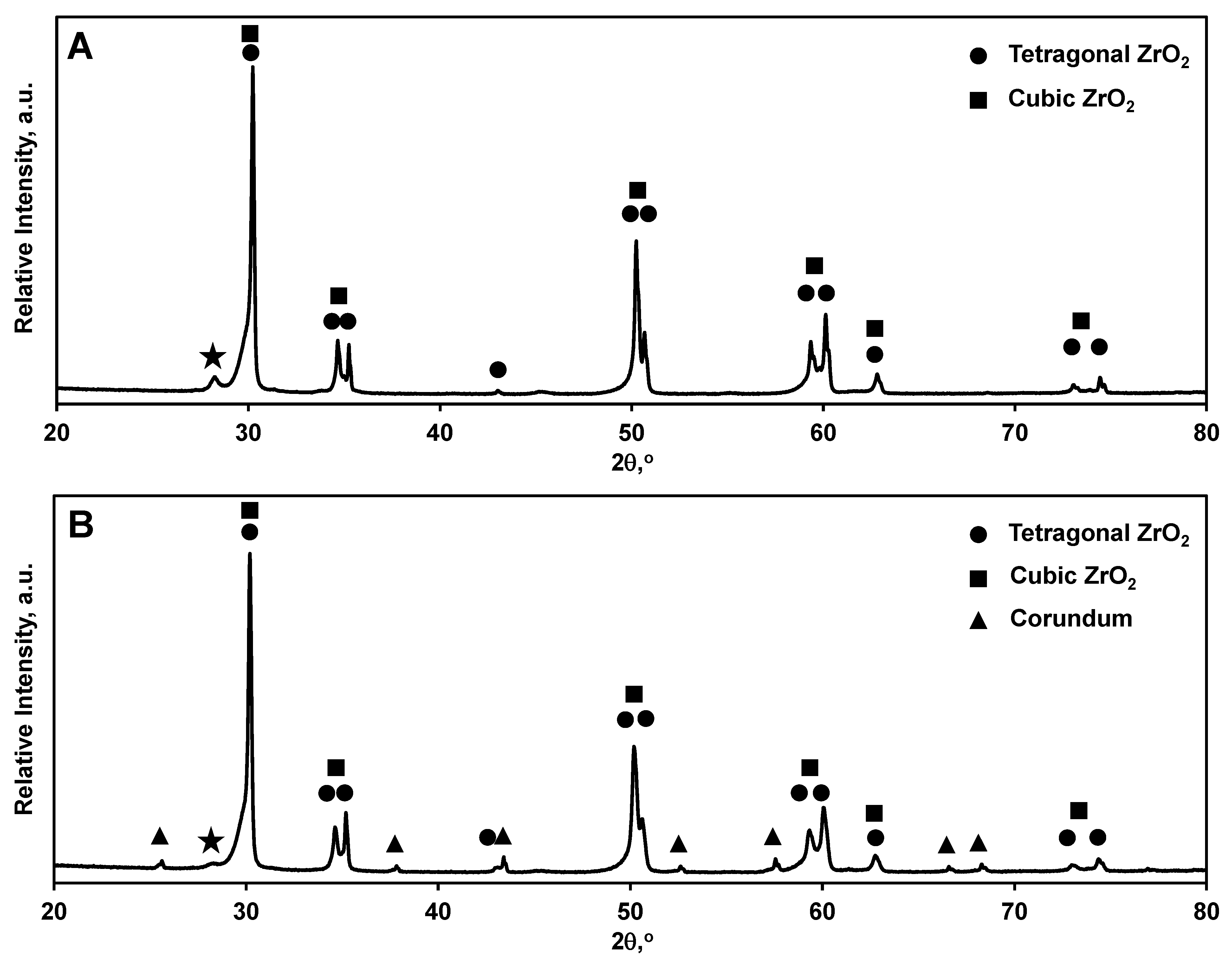

4.1. Density, Grain Size, and Phase Composition of Y-TZP and ATZ

4.2. Hardness and Young’s Modulus

4.3. Flexural Strength and Weibull Statistics

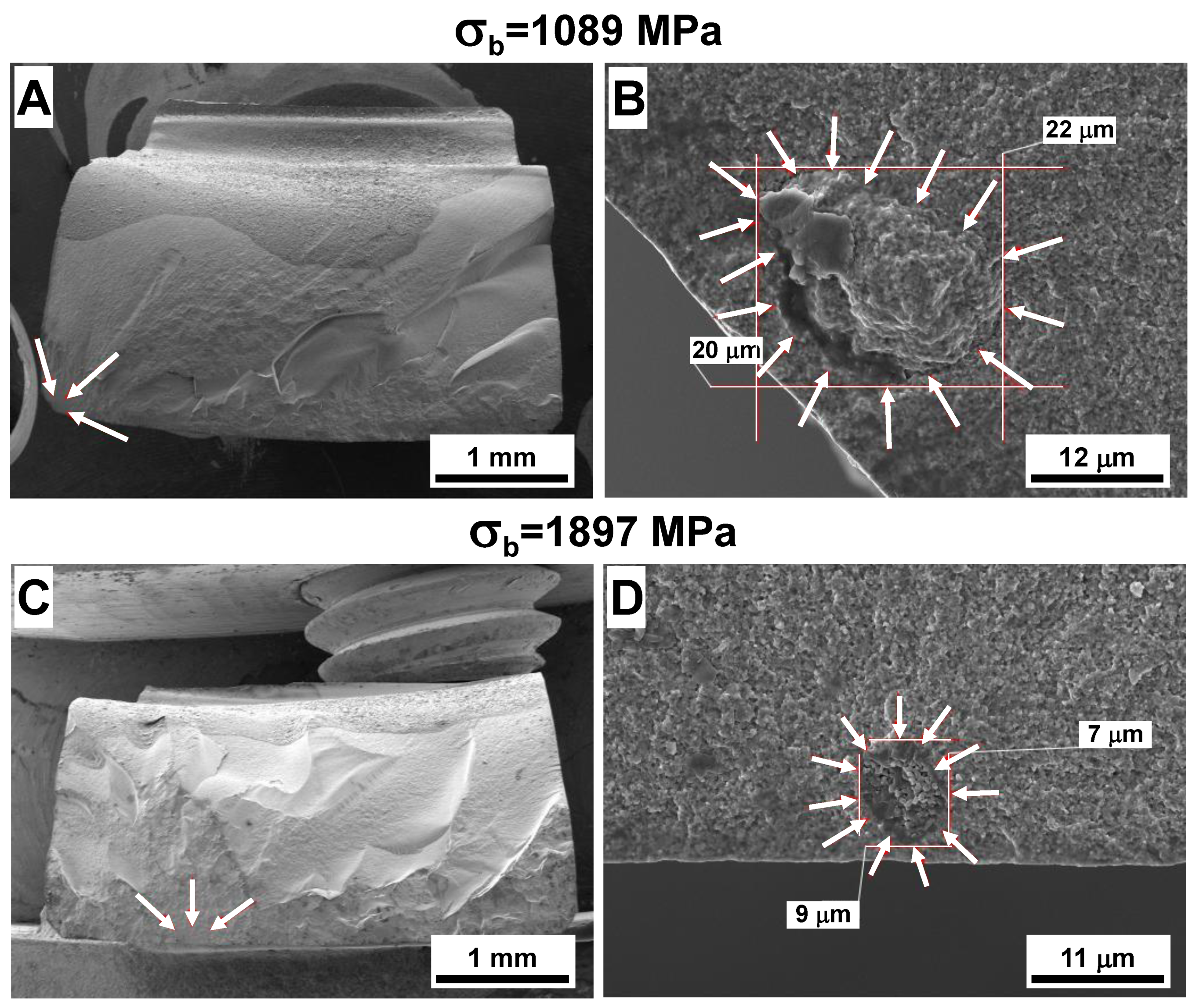

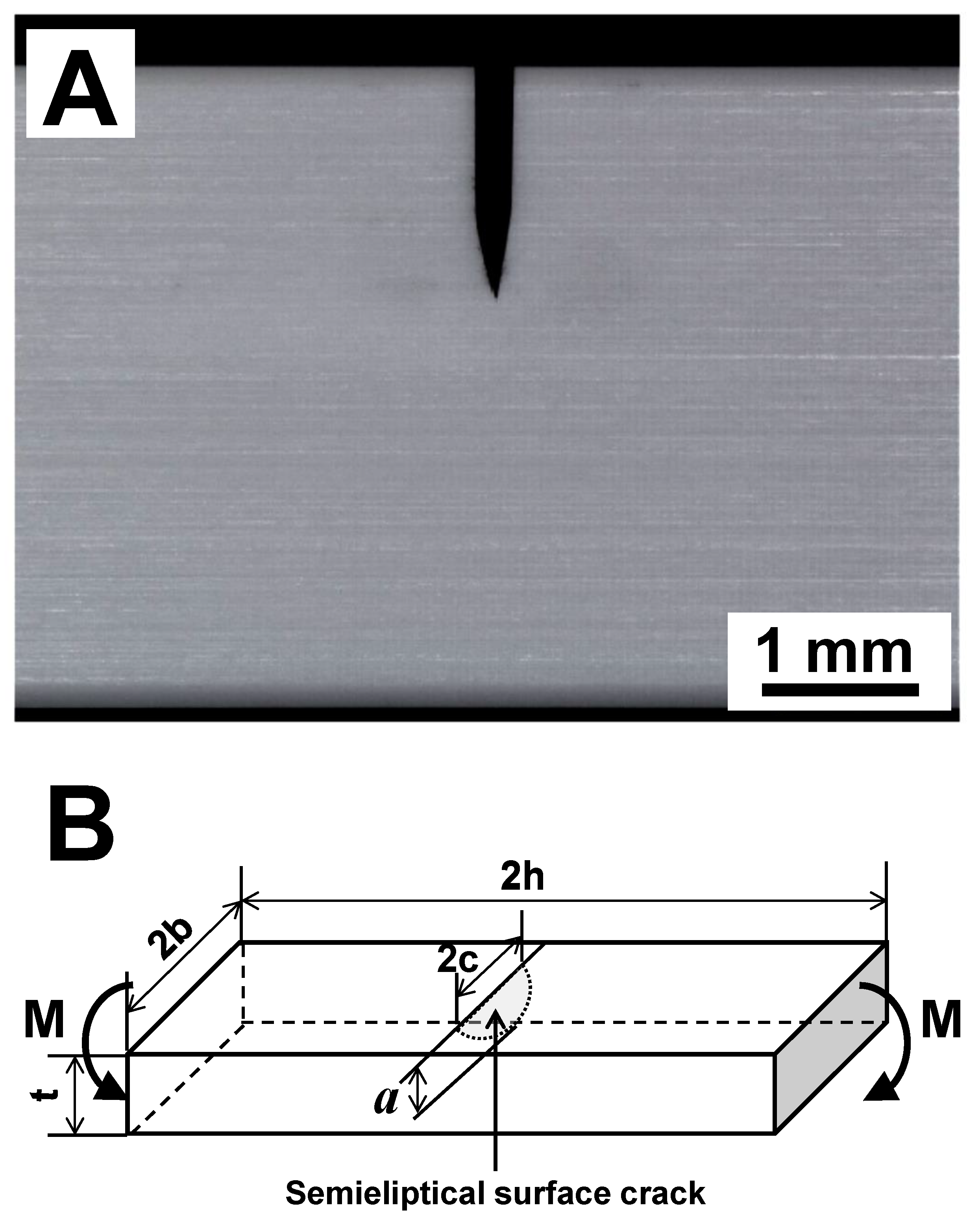

4.4. Fracture Surface Analysis and Sensitivity of Weibull Parameters to Critical Defect Size Distribution

4.5. Fracture Toughness

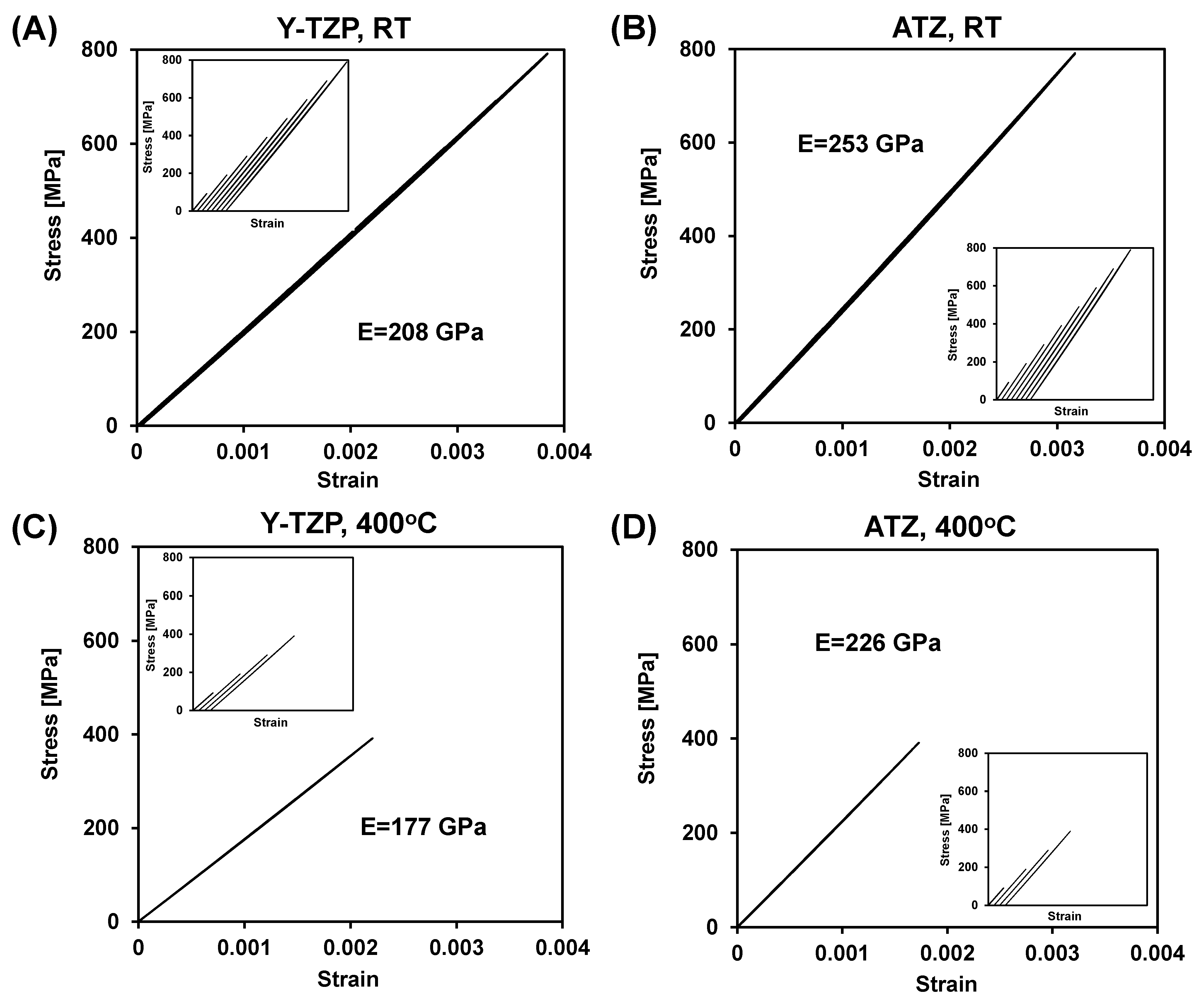

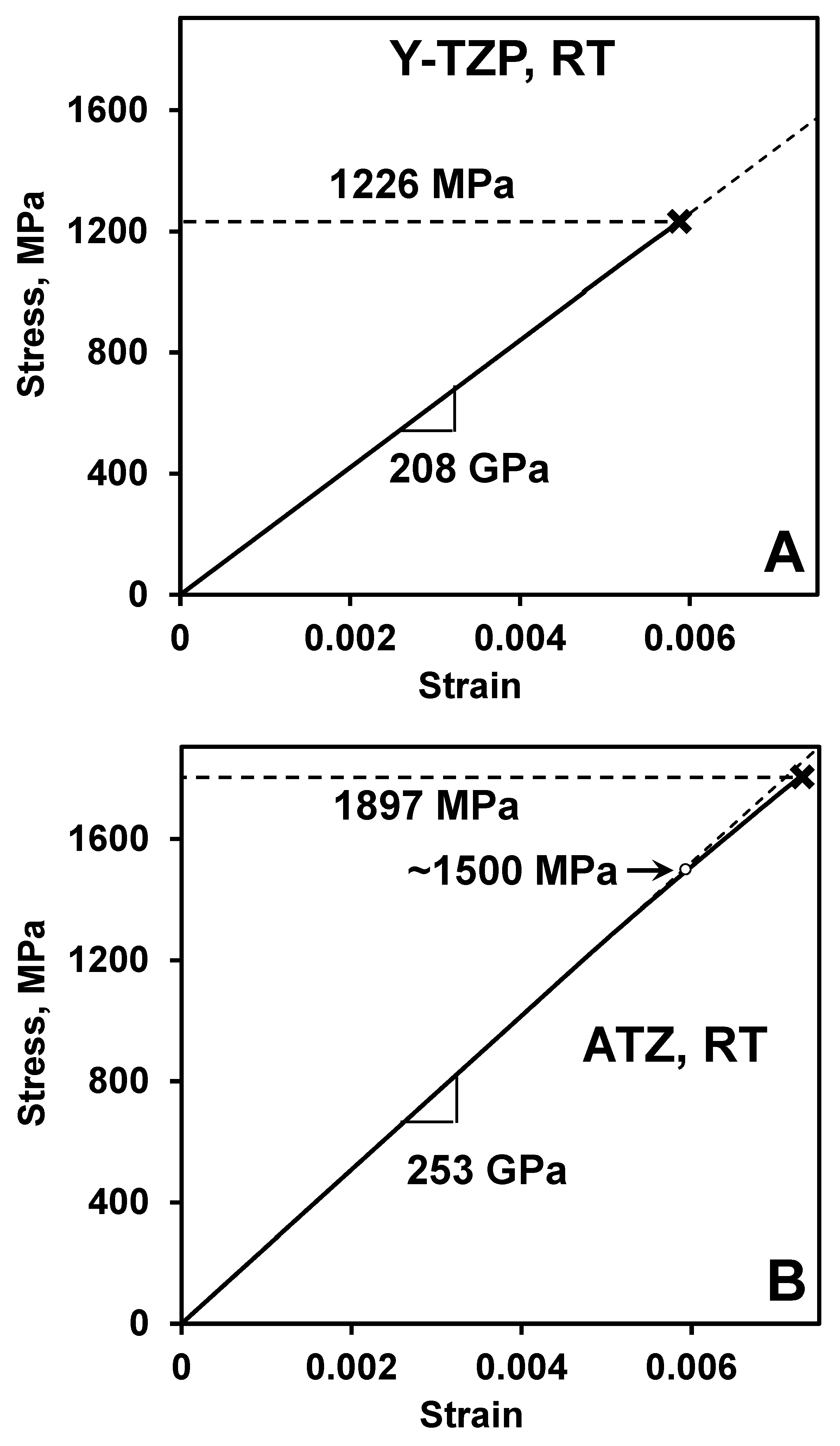

4.6. Stress-Strain Deformation Behavior in Bending

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garvie, R.C.; Hannink, R.H.; Pascoe, R.T. Ceramic Steel. Nature 1975, 258, 703. [Google Scholar] [CrossRef]

- Kelly, J.R.; Denry, I. Stabilized zirconia as a structural ceramic: An overview. Dent. Mater. 2008, 24, 289–298. [Google Scholar] [CrossRef] [PubMed]

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The Tetragonal-Monoclinic Transformation in Zirconia: Lessons Learned and Future Trends. J. Am. Ceram. Soc. 2009, 92, 1901–1920. [Google Scholar] [CrossRef]

- Soubelet, C.G.; Albano, M.P. Mechanical properties and aging behaviour of Y-TZP with 64S bioglass additions for dental restorations. Adv. Appl. Ceram. 2019, 118, 329–339. [Google Scholar] [CrossRef]

- Zou, J.; Zhong, Y.; Eriksson, M.; Liu, L.; Shen, Z. Tougher zirconia nanoceramics with less yttria. Adv. Appl. Ceram. 2018, 118, 9–15. [Google Scholar] [CrossRef] [Green Version]

- Gjurin, S.Z.; Özcan, M.; Oblak, C. Zirconia ceramic fixed partial dentures after cyclic fatigue tests and clinical evaluation: A systematic review. Adv. Appl. Ceram. 2019, 118, 62–69. [Google Scholar] [CrossRef]

- Han, J.; Zhao, J.; Shen, Z. Zirconia ceramics in metal-free implant dentistry. Adv. Appl. Ceram. 2016, 116, 138–150. [Google Scholar] [CrossRef] [Green Version]

- Mondal, B.; Kundu, S. Novel synthesis of advanced composites of α-Al2O3 reinforced with Ce TZP through co-precipitation process. Adv. Appl. Ceram. 2006, 105, 222–227. [Google Scholar] [CrossRef]

- Li, D.; Liu, Y.; Zhong, Y.; Liu, L.; Adolfsson, E.; Shen, Z. Dense and strong ZrO2 ceramics fully densified in <15 min. Adv. Appl. Ceram. 2019, 118, 23–29. [Google Scholar]

- Virkar, A.V.; Matsumo, R.L.K. Ferroelastic domain switching as a toughening mechanism in tetragonal zirconia. J. Am. Ceram. Soc. 1986, 69, C-224–C-226. [Google Scholar] [CrossRef]

- Ruiz, L.; Readey, M.J. Effect of heat treatment on grain size, phase assemblage, and mechanical properties of 3 mol% Y-TZP. J. Am. Ceram. Soc. 1996, 79, 2331–2340. [Google Scholar] [CrossRef]

- Basu, B.; Vleugels, J.; Van Der Biest, O. ZrO2–Al2O3 composites with tailored toughness. J. Alloy. Compd. 2004, 372, 278–284. [Google Scholar] [CrossRef]

- Pezzotti, G.; Sergo, V.; Sbaizero, O.; Muraki, N.; Meriani, S.; Nishida, T. Strengthening contribution arising from residual stresses in Al2O3/ZrO2 composites: A piezo-Spectroscopy investigation. J. Eur. Ceram. Soc. 1999, 19, 247–253. [Google Scholar] [CrossRef]

- Shikata, R.; Urata, Y.; Shiono, T.; Nishikawa, T. Mechanical properties and characterization of ZrO2-Al2O3 composites with high fracture strength. J. Jpn. Soc. Powder Powder Met. 1991, 38, 369–373. [Google Scholar] [CrossRef] [Green Version]

- Swain, M.; Rose, L.R.F. Strength Limitations of Transformation-Toughened Zirconia Alloys. J. Am. Ceram. Soc. 1986, 69, 511–518. [Google Scholar] [CrossRef]

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation Toughening in Zirconia-Containing Ceramics. J. Am. Ceram. Soc. 2004, 83, 461–487. [Google Scholar] [CrossRef]

- Zeng, Z.; Liu, Y.; Zhang, Y.; Zhou, Z.; Liu, X. Ferroelastic domain switching toughening in Ce–Y–La co-stabilized zirconia ceramics obtained from coated starting powders. J. Alloy. Compd. 2020, 820, 153177. [Google Scholar] [CrossRef]

- Mcmeeking, R.M.; Evans, A. Mechanics of Transformation-Toughening in Brittle Materials. J. Am. Ceram. Soc. 1982, 65, 242–246. [Google Scholar] [CrossRef]

- Chen, I.-W.; Reyes-Morel, P.E. Transformation Plasticity and Transformation Toughening in Mg-PSZ and Ce-TZP. In Symposium E—Advances in Structural Ceramics; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 1986; Volume 78, pp. 75–88. [Google Scholar]

- Chen, I.-W.; Morel, P.E.R. Implications of Transformation Plasticity in ZrO2-Containing Ceramics: I, Shear and Dilatation Effects. J. Am. Ceram. Soc. 1986, 69, 181–189. [Google Scholar] [CrossRef]

- Lankford, J. Plastic Deformation of Partially Stabilized Zirconia. J. Am. Ceram. Soc. 1983, 66, c212–c213. [Google Scholar] [CrossRef]

- Lankford, J.; Page, R.A.; Rabenberg, L. Deformation mechanisms in yttria-stabilized zirconia. J. Mater. Sci. 1988, 23, 4144–4156. [Google Scholar] [CrossRef]

- Orlovskaya, N.; Gogotsi, Y.; Reece, M.; Cheng, B.; Gibson, I. Ferroelasticity and hysteresis in LaCoO3 based perovskites. Acta Mater. 2002, 50, 715–723. [Google Scholar] [CrossRef]

- Cain, M.; Bennington, S.M.; Lewis, M.H.; Hull, S.; Cain, M.; Bennington, S.M.; Lewis, M.H.; Hull, S. Study of the ferroelastic transformation in zirconia by neutron diffraction. Philos. Mag. B 1994, 69, 499–507. [Google Scholar] [CrossRef]

- Spierings, A.; Schneider, M.J.; Eggenberger, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Mendelson, M.I. Average Grain Size in Polycrystalline Ceramics. J. Am. Ceram. Soc. 1969, 52, 443–446. [Google Scholar] [CrossRef]

- EN 843-2. Advanced Technical Ceramics—Mechanical Properties of Monolithic Ceramics at Room Temperature. Part 2: Deter-Mination of Young’s Modulus, Shear Modulus and Poisson’s Ratio; CEN: Brussels, Belgium, 2006. [Google Scholar]

- EN 843-1. Advanced Technical Ceramics—Mechanical Properties of Monolithic Ceramics at Room Temperature—Part 1: Determination of Flexural Strength; CEN: Brussels, Belgium, 2006. [Google Scholar]

- Orlovskaja, N.; Peterlik, H.; Marczewski, M.; Kromp, K. The validity of Weibull estimators-experimental verification. J. Mater. Sci. 1997, 32, 1903–1907. [Google Scholar] [CrossRef]

- Kalidindi, S.; Abusafieh, A.; El-Danaf, E. Accurate characterization of machine compliance for simple compression testing. Exp. Mech. 1997, 37, 210–215. [Google Scholar] [CrossRef]

- Advanced Technical Ceramics—Test Methods for Determination of Fracture Toughness of Monolithic Ceramics. Part 5. Single-Edge V-Notch Beam (SEVNB) Method; CEN/TS 14425-5; CEN: Brussels, Belgium, 2006.

- Newman, J.; Raju, I. An empirical stress-intensity factor equation for the surface crack. Eng. Fract. Mech. 1981, 15, 185–192. [Google Scholar] [CrossRef]

- Ghatee, M.; Shariat, M.H.; Irvine, J.T.S. Investigation of electrical and mechanical properties of 3YSZ/8YSZ composite electrolytes. Solid State Ion. 2009, 180, 57–62. [Google Scholar] [CrossRef]

- Paterson, A.; Stevens, R. Phase analysis of sintered yttria–zirconia ceramics by x-ray diffraction. J. Mater. Res. 1986, 1, 295–299. [Google Scholar] [CrossRef]

- Lin, J.-D.; Duh, J.-G. Fracture toughness and hardness of ceria- and yttria-doped tetragonal zirconia ceramics. Mater. Chem. Phys. 2003, 78, 253–261. [Google Scholar] [CrossRef]

- Gupta, N.; Mallik, P.; Basu, B. Y-TZP ceramics with optimized toughness: New results. J. Alloy. Compd. 2004, 379, 228–232. [Google Scholar] [CrossRef]

- Kaya, C. Al2O3–Y-TZP/Al2O3 functionally graded composites of tubular shape from nano-sols using double-step electrophoretic deposition. J. Eur. Ceram. Soc. 2003, 23, 1655–1660. [Google Scholar] [CrossRef]

- Ho, C.J.; Liu, H.C.; Tuan, W.H. Effect of abrasive grinding on the strength of Y-TZP. J. Eur. Ceram. Soc. 2009, 29, 2665–2669. [Google Scholar] [CrossRef]

- Sivanesan, S.; Loong, T.H.; Namasivayam, S.N.; Fouladi, M.H. Two-Stage Sintering of Alumina-Y-TZP (Al2O3/Y-TZP) Composites. Key Eng. Mater. 2019, 814, 12–18. [Google Scholar] [CrossRef]

- Jue, J.F.; Virkar, A.V. Fabrication, Microstructural Characterization, and Mechanical Properties of Polycrystalline t′-Zirconia. J. Am. Ceram. Soc. 1990, 73, 3650–3657. [Google Scholar] [CrossRef]

- Wiik, K.; Fossdal, A.; Sagdahl, L.; Lein, H.L.; Menon, M.; Faaland, S.; Wærnhus, I.; Orlovskaya, N.; Einarsrud, M.-A.; Grande, T. LaFeO3 and LaCoO3 Based Perovskites: Preparation and Properties of Dense Oxygen Permeable Membranes. In Mixed Ionic Electronic Conducting Perovskites for Advanced Energy Systems; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2004; pp. 75–85. [Google Scholar]

- Vullum, P.E.; Holmestad, R.; Lein, H.L.; Mastin, J.; Einarsrud, M.-A.; Grande, T. Monoclinic Ferroelastic Domains in LaCoO3-Based Perovskites. Adv. Mater. 2007, 19, 4399–4403. [Google Scholar] [CrossRef]

- Lein, H.L.; Andersen, Ø.S.; Vullum, P.E.; Lara-Curzio, E.; Holmestad, R.; Einarsrud, M.A.; Grande, T. Mechanical properties of mixed conducting La0.5Sr0.5Fe1−xCoxO3−δ (0 ≤ x ≤ 1) materials. J. Solid State Electrochem. 2006, 10, 635–642. [Google Scholar] [CrossRef]

- Martin, A.; Khansur, N.H.; Webber, K.G. Electric field-induced changes in the ferroelastic behavior of (Na1/2Bi1/2) TiO3-BaTiO3. J. Eur. Ceram. Soc. 2018, 38, 4623–4630. [Google Scholar] [CrossRef]

- Webber, K.; Aulbach, E.; Key, T.; Marsilius, M.; Granzow, T.; Rödel, J.; Webber, K.; Aulbach, E.; Key, T.; Marsilius, M.; et al. Temperature-dependent ferroelastic switching of soft lead zirconate titanate. Acta Mater. 2009, 57, 4614–4623. [Google Scholar] [CrossRef]

| Property | Y-TZP | ATZ |

|---|---|---|

| Density, g/cm3 | 6.05 | 5.48 |

| Porosity, % | 0.8 | 0.04 |

| Grain size, μm | 0.735 ± 0.021 | 0.414 ± 0.023 |

| Tetragonal phase fraction of t-ZrO2, % | 87 | 87 |

| Roughness Ra (machining #1), μm | 0.1 | 0.08 |

| Roughness Ra (machining #2), μm | 0.58 | 0.56 |

| [33,34] | ||

| Property | Y-TZP | ATZ |

|---|---|---|

| Hardness, GPa | 12.08 ± 0.21 | 13.91± 0.24 |

| Young modulus (IET), GPa | 211 ± 0.57 | 254 ± 0.19 |

| Flexural strength, MPa | 1106 ± 111 | 1503 ± 229 |

| Fracture toughness, MPa·m1/2 (SEVNB) | 5.38 ± 0.09 | 5.02 ± 0.41 |

| Fracture toughness, MPa·m1/2 (estimated from fracture origin dimensions) | 7.1 | 6.4 |

| Young modulus (slope), GPa | 208 | 253 |

| Composition | m (mixed) | σ0 (mixed), MPa | m (machin. 1) | σ0 (machin. 1), MPa | m (machin. 2) | σ0 (machin. 2), MPa |

|---|---|---|---|---|---|---|

| Y-TZP | 13.4 | 1139 | 26.7 | 1145 | 11.4 | 1132 |

| ATZ | 7.2 | 1536 | 7.1 | 1599 | 7.1 | 1474 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vladislavova, L.; Smolorz, T.; Orlovskaya, N.; Lugovy, M.; Reece, M.J.; Kӧbel, S.; Kopia, A.; Makowska, M.; Graule, T.; Blugan, G. Strength Analysis and Stress-Strain Deformation Behavior of 3 mol% Y-TZP and 21 wt.% Al2O3-3 mol% Y-TZP. Materials 2021, 14, 3903. https://doi.org/10.3390/ma14143903

Vladislavova L, Smolorz T, Orlovskaya N, Lugovy M, Reece MJ, Kӧbel S, Kopia A, Makowska M, Graule T, Blugan G. Strength Analysis and Stress-Strain Deformation Behavior of 3 mol% Y-TZP and 21 wt.% Al2O3-3 mol% Y-TZP. Materials. 2021; 14(14):3903. https://doi.org/10.3390/ma14143903

Chicago/Turabian StyleVladislavova, Liliya, Tomasz Smolorz, Nina Orlovskaya, Mykola Lugovy, Michael J. Reece, Stefan Kӧbel, Agnieszka Kopia, Malgorzata Makowska, Thomas Graule, and Gurdial Blugan. 2021. "Strength Analysis and Stress-Strain Deformation Behavior of 3 mol% Y-TZP and 21 wt.% Al2O3-3 mol% Y-TZP" Materials 14, no. 14: 3903. https://doi.org/10.3390/ma14143903

APA StyleVladislavova, L., Smolorz, T., Orlovskaya, N., Lugovy, M., Reece, M. J., Kӧbel, S., Kopia, A., Makowska, M., Graule, T., & Blugan, G. (2021). Strength Analysis and Stress-Strain Deformation Behavior of 3 mol% Y-TZP and 21 wt.% Al2O3-3 mol% Y-TZP. Materials, 14(14), 3903. https://doi.org/10.3390/ma14143903