A Silver Yarn-Incorporated Song Brocade Fabric with Enhanced Electromagnetic Shielding

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Fabrication of Song Brocade Fabric

- (1)

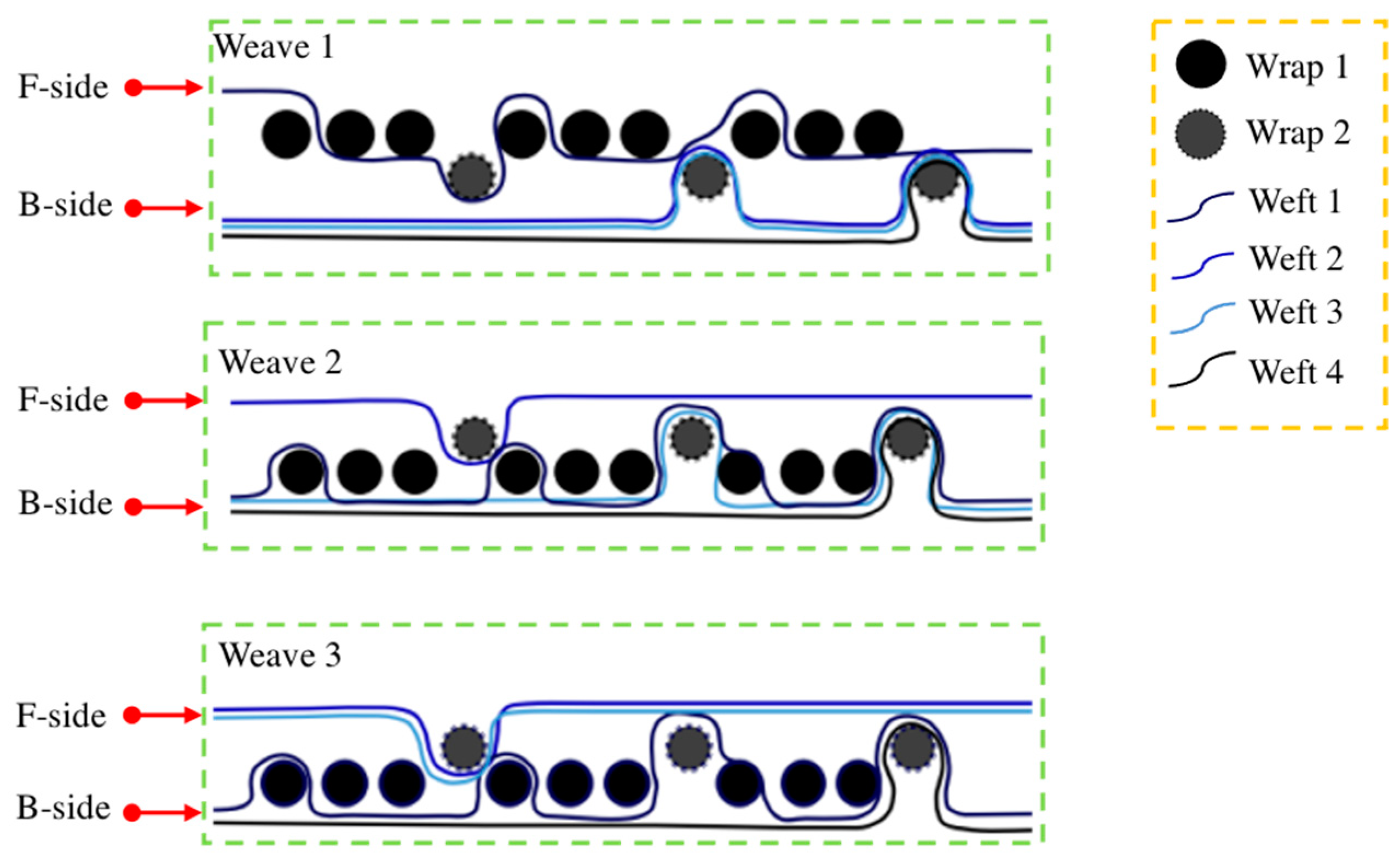

- Weave 1 showed the ground pattern. The surface layer consisted of warp 1 and weft 1 in 2/1 twill, the surface of the fabric showed the mixed color of warp 1 and weft 1. The middle layer consisted of warp 2 and weft 2 and weft 3 in 1/2 twill, and the inner layer consists of warp 2 and weft 4 in 2/1 twill.

- (2)

- Weave 2 was aimed to present the ‘卍’, which was a classical Chinese pattern. The surface layer consisted of warp 2 and weft 2 in 1/2 twill, and the surface of the fabric showed the mixed color of warp 2 and weft 2. The middle layer consisted of warp 1 and weft 1 and weft 3 in 1/2 twill, and the inner layer consisted of warp 1 and weft 4 in 2/1 twill.

- (3)

- Weave 3 showed the cross-hatching pattern. The surface layer consisted of warp 2 and weft 2 and weft 3 in 1/2 twill, and the surface of the fabric showed the mixed color of warp 2 and weft 2 and weft 3. The middle layer consisted of warp 1 and weft 1 and weft 1 in 1/2 twill, and the inner layer consists of warp 1 and weft 4 in 2/1 twill.

2.3. Characterization

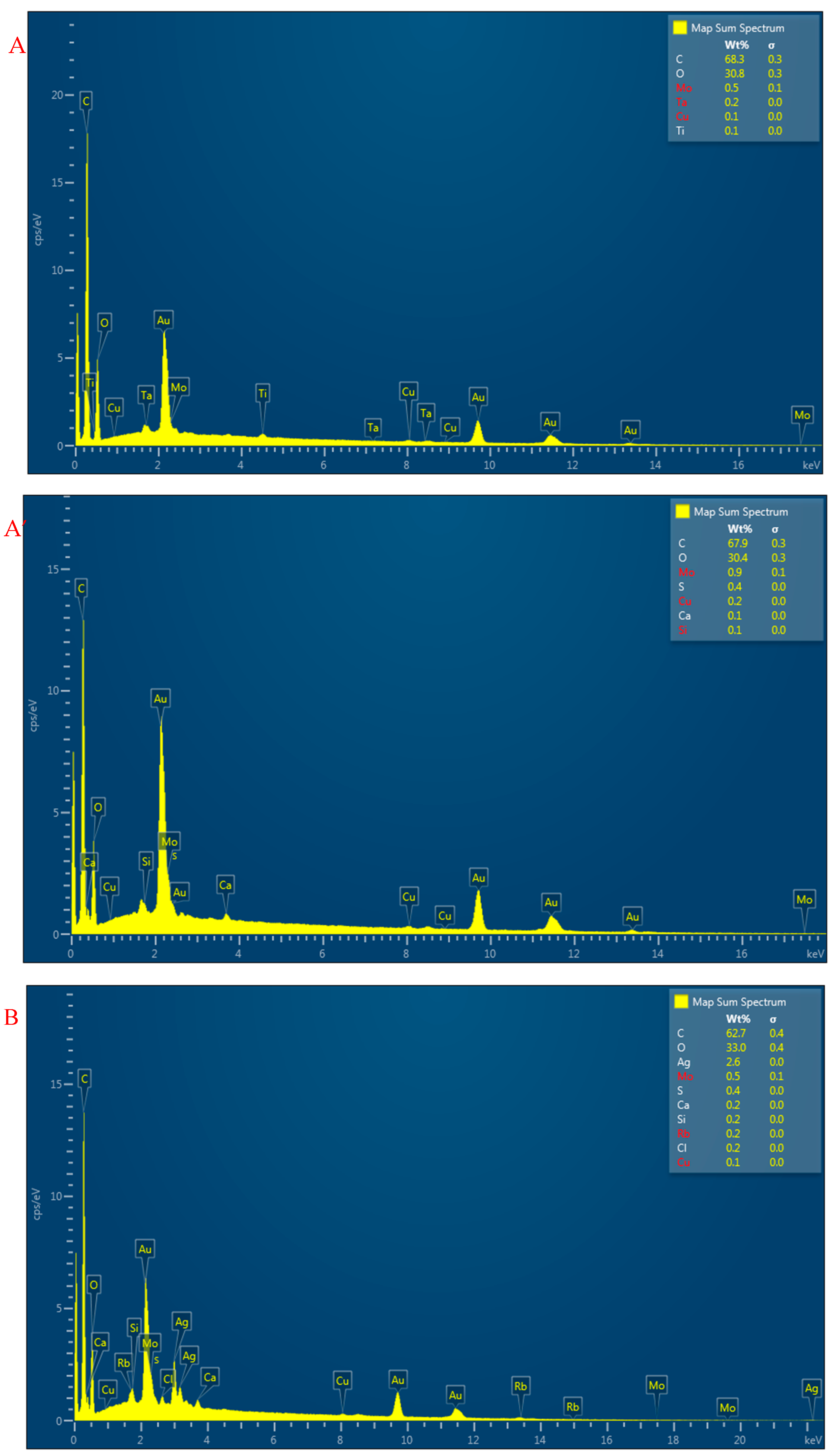

2.3.1. Analysis of the Morphology of the Song Brocade Fabric

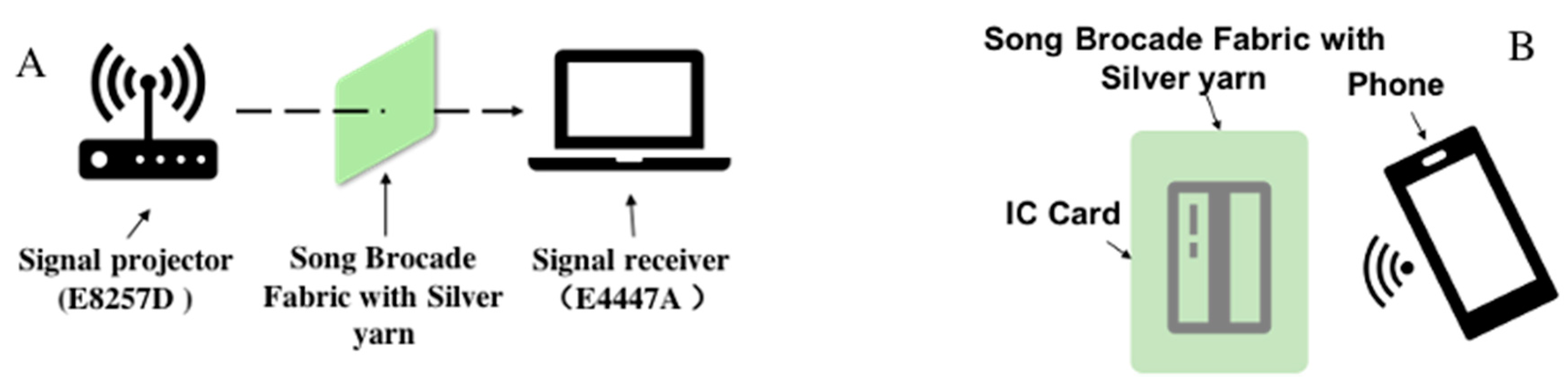

2.3.2. Evaluation of Electromagnetic Shielding Effectiveness (EM SE)

2.3.3. Evaluation of Electrical Conductivity

2.3.4. Evaluation of Ultraviolet (UV) Shielding

2.3.5. Evaluation of Air Permeability

2.3.6. Evaluation of Moisture Evaporation Rate

3. Results and Discussion

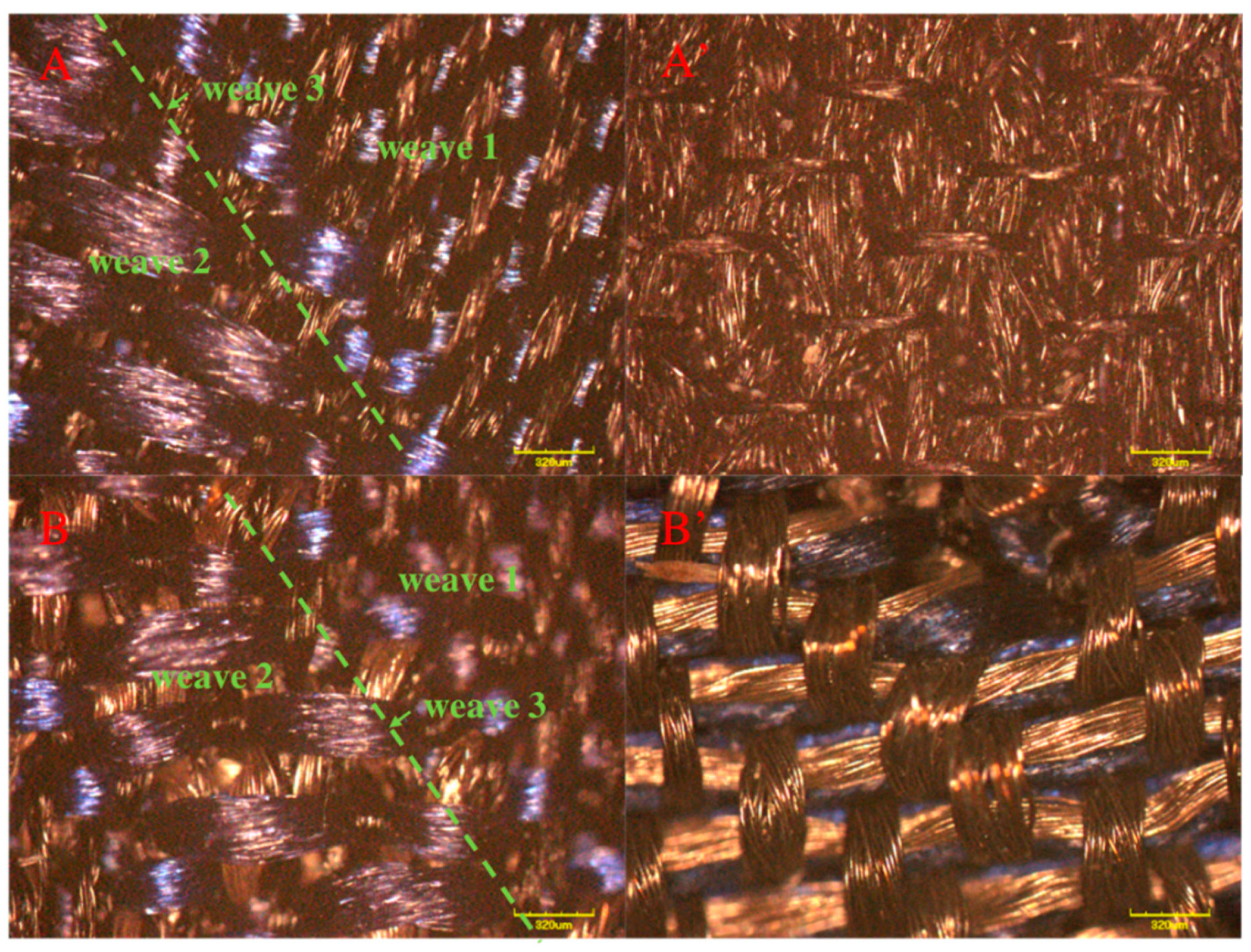

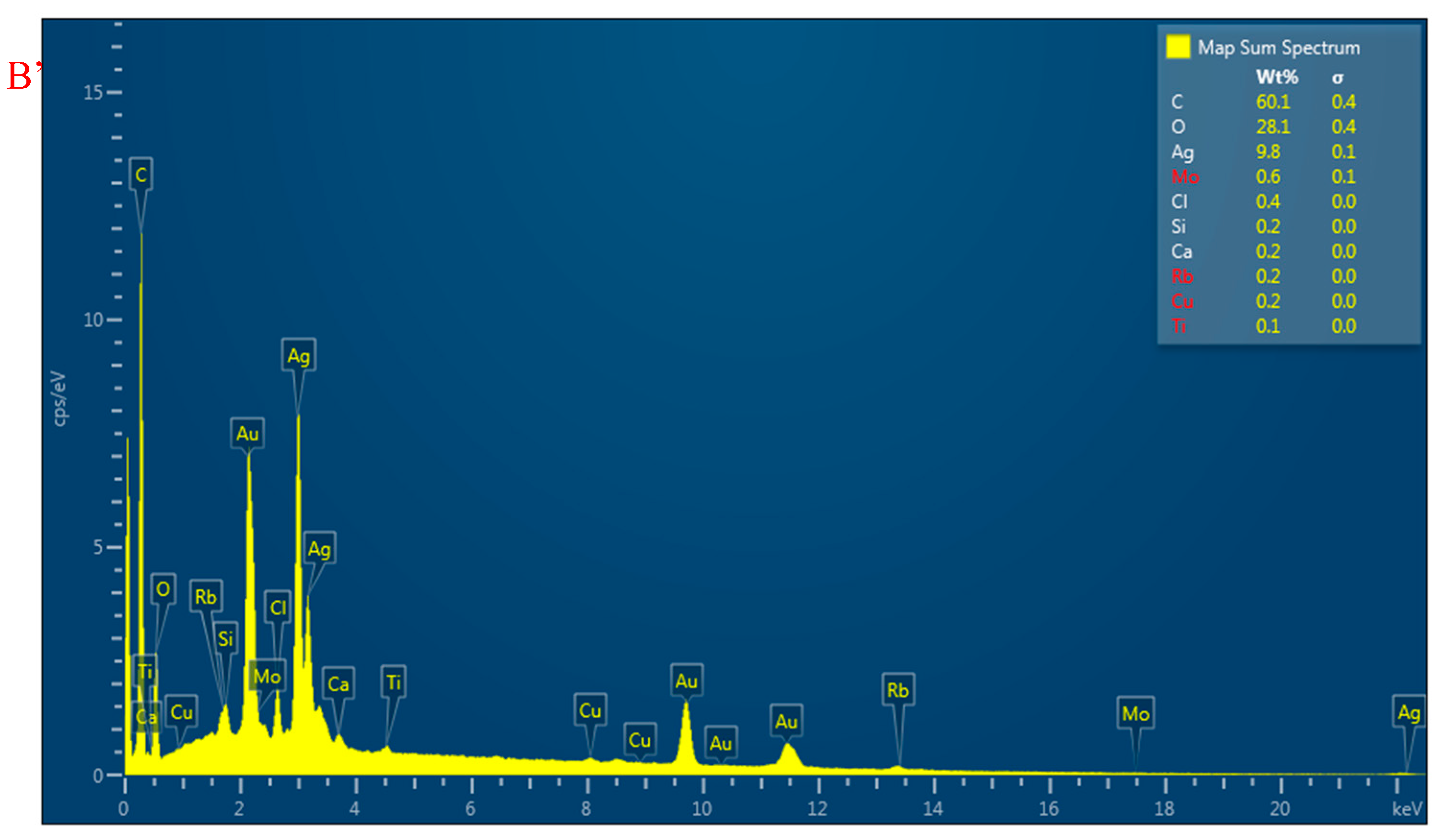

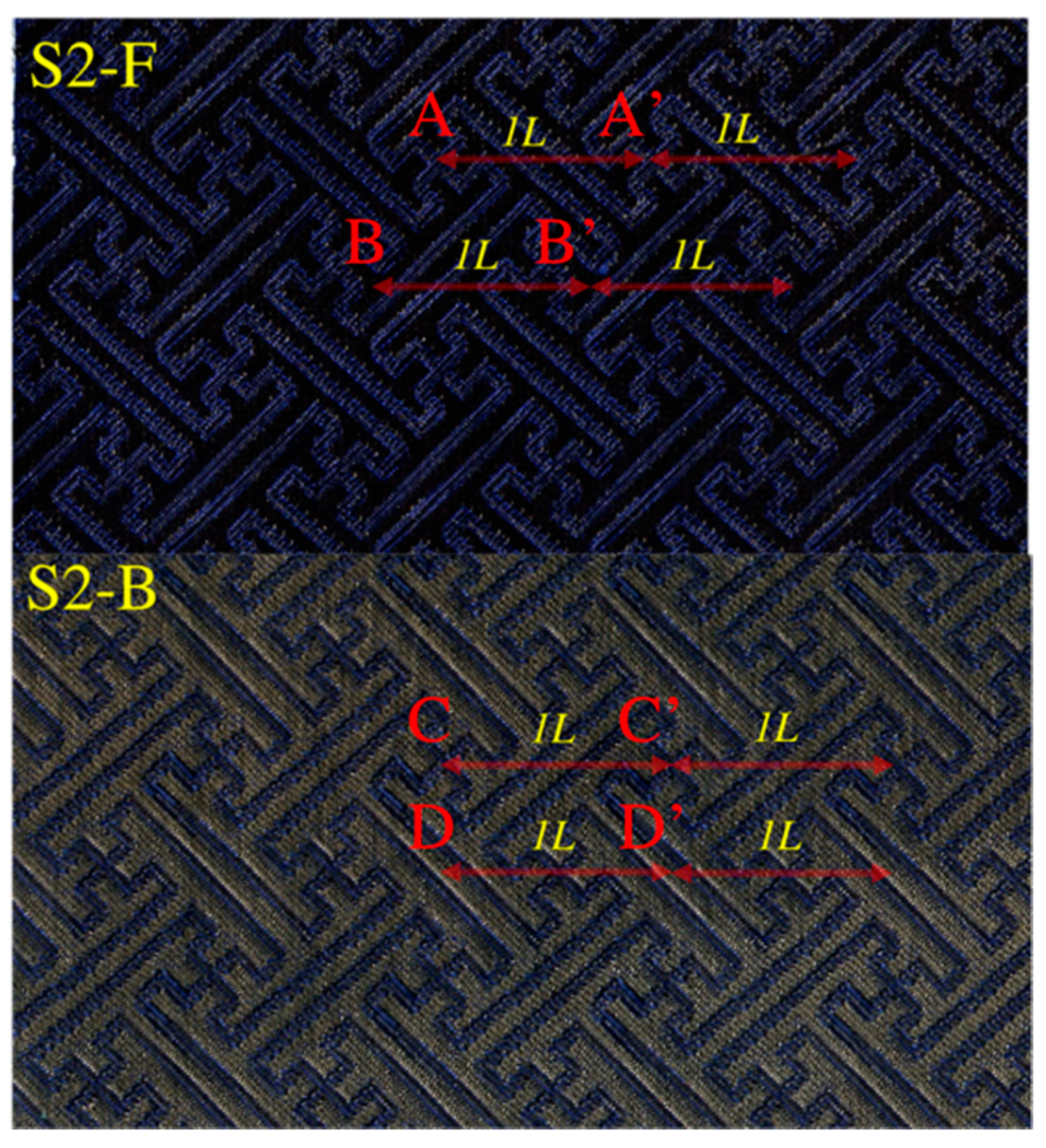

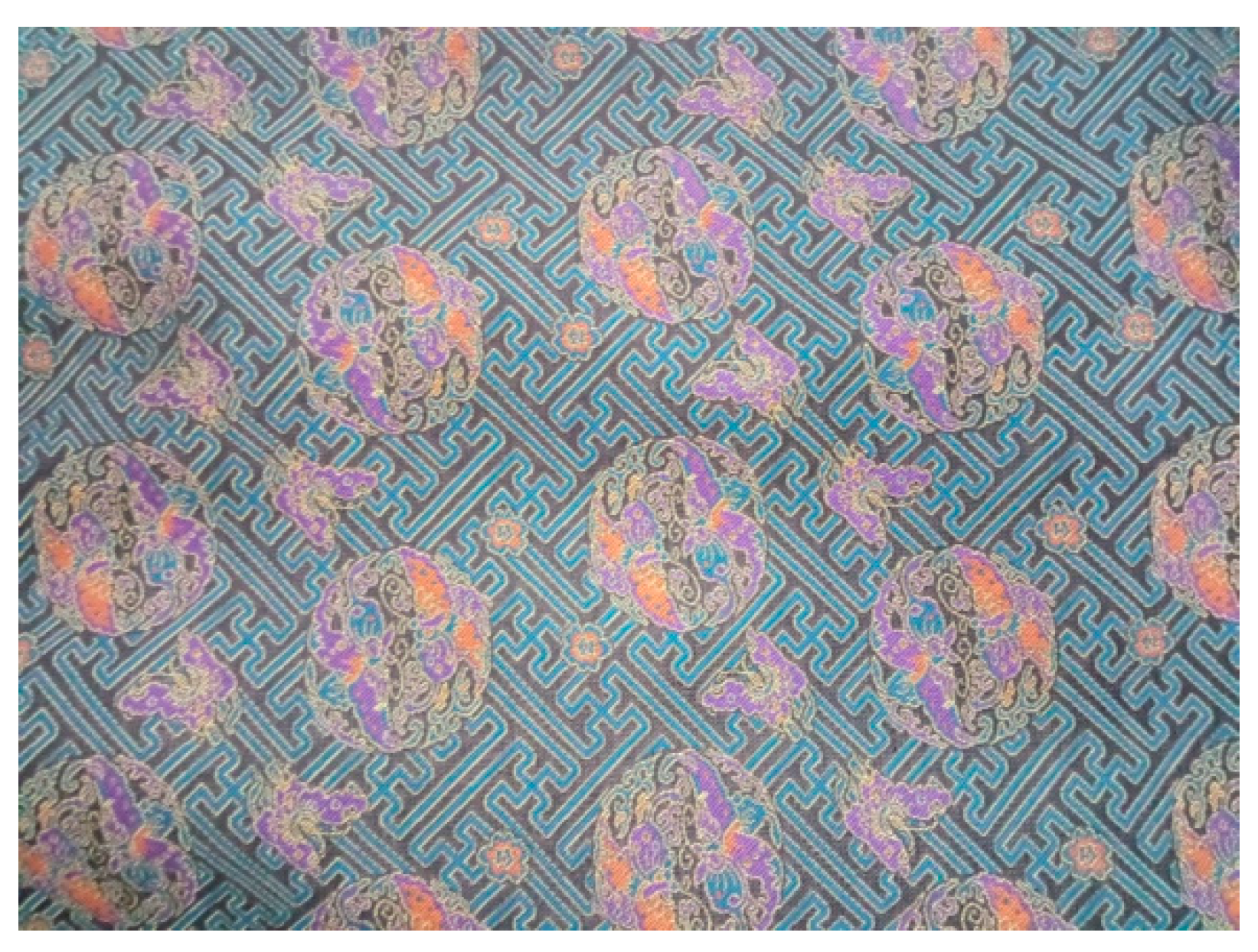

3.1. Morphology of the Designed Pattern

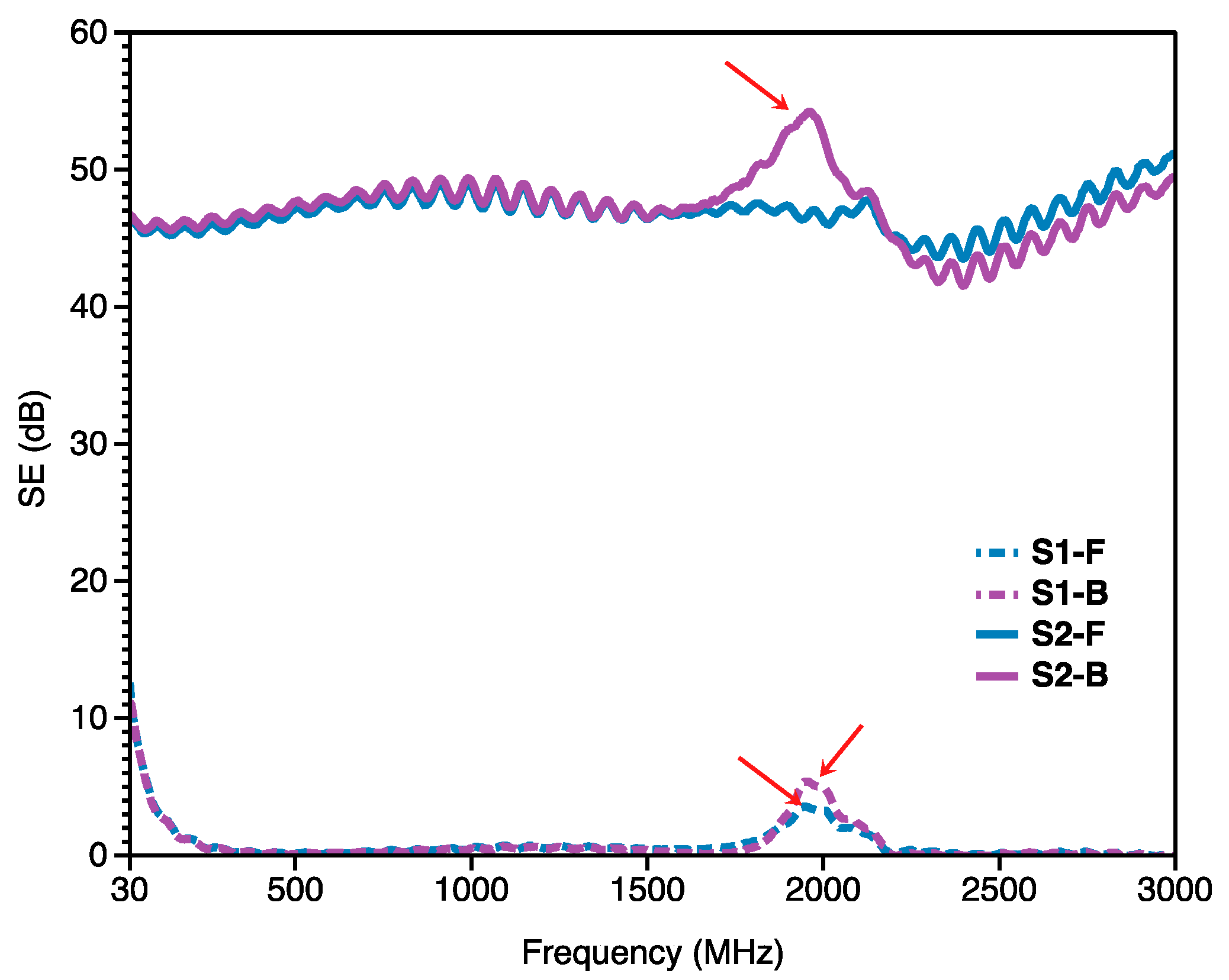

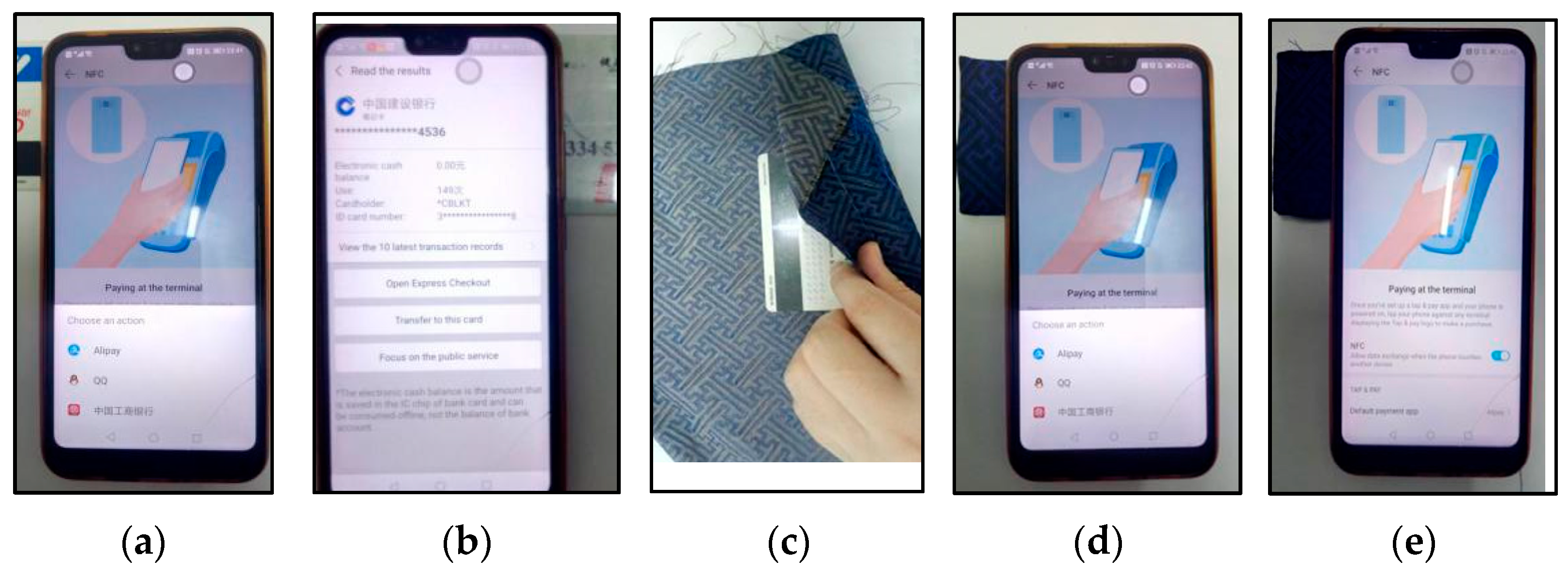

3.2. Analysis of EMI Shielding

3.3. Evaluation of the Conductivity

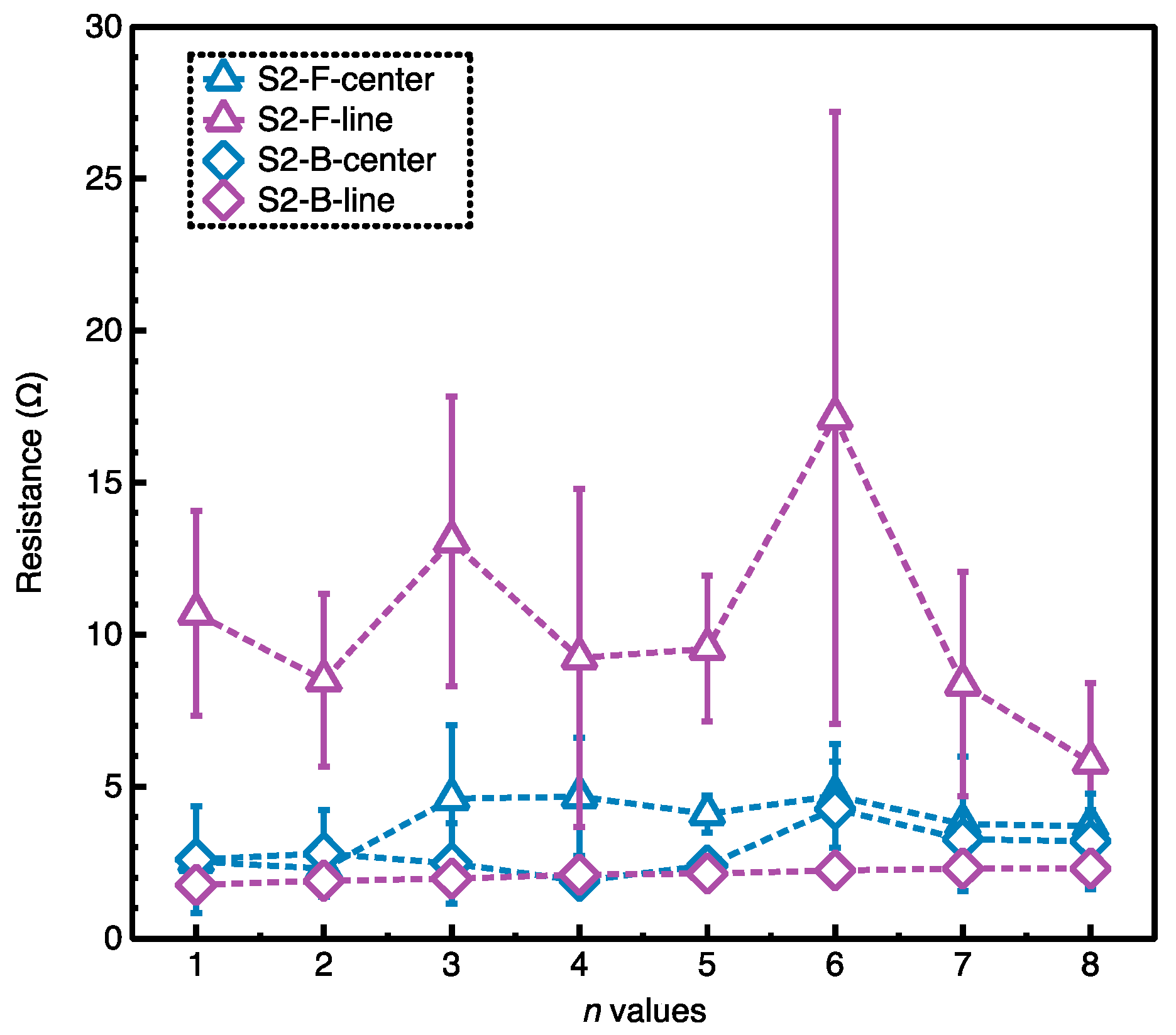

3.4. Evaluation of UV Shielding Property

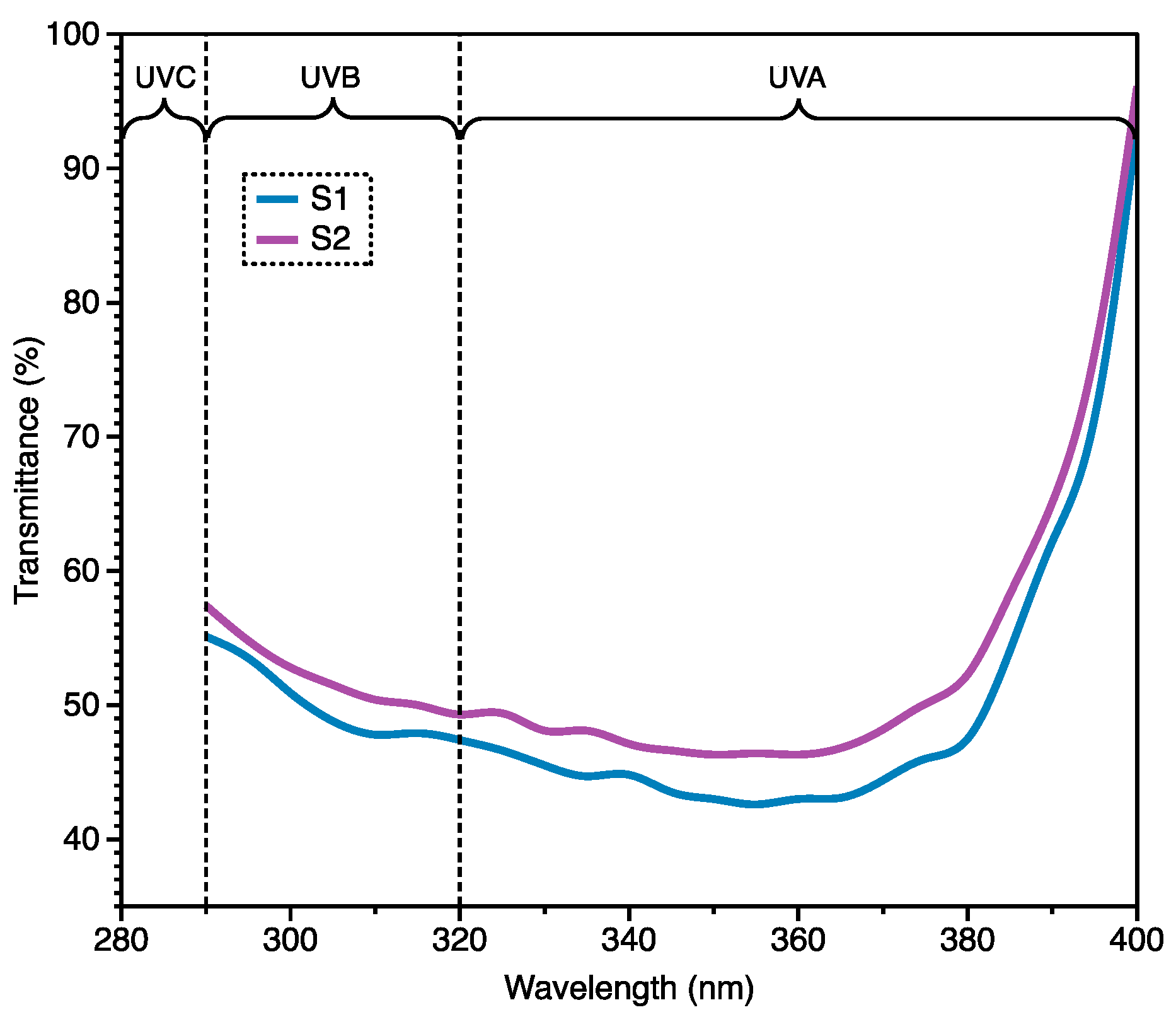

3.5. Air Permeability

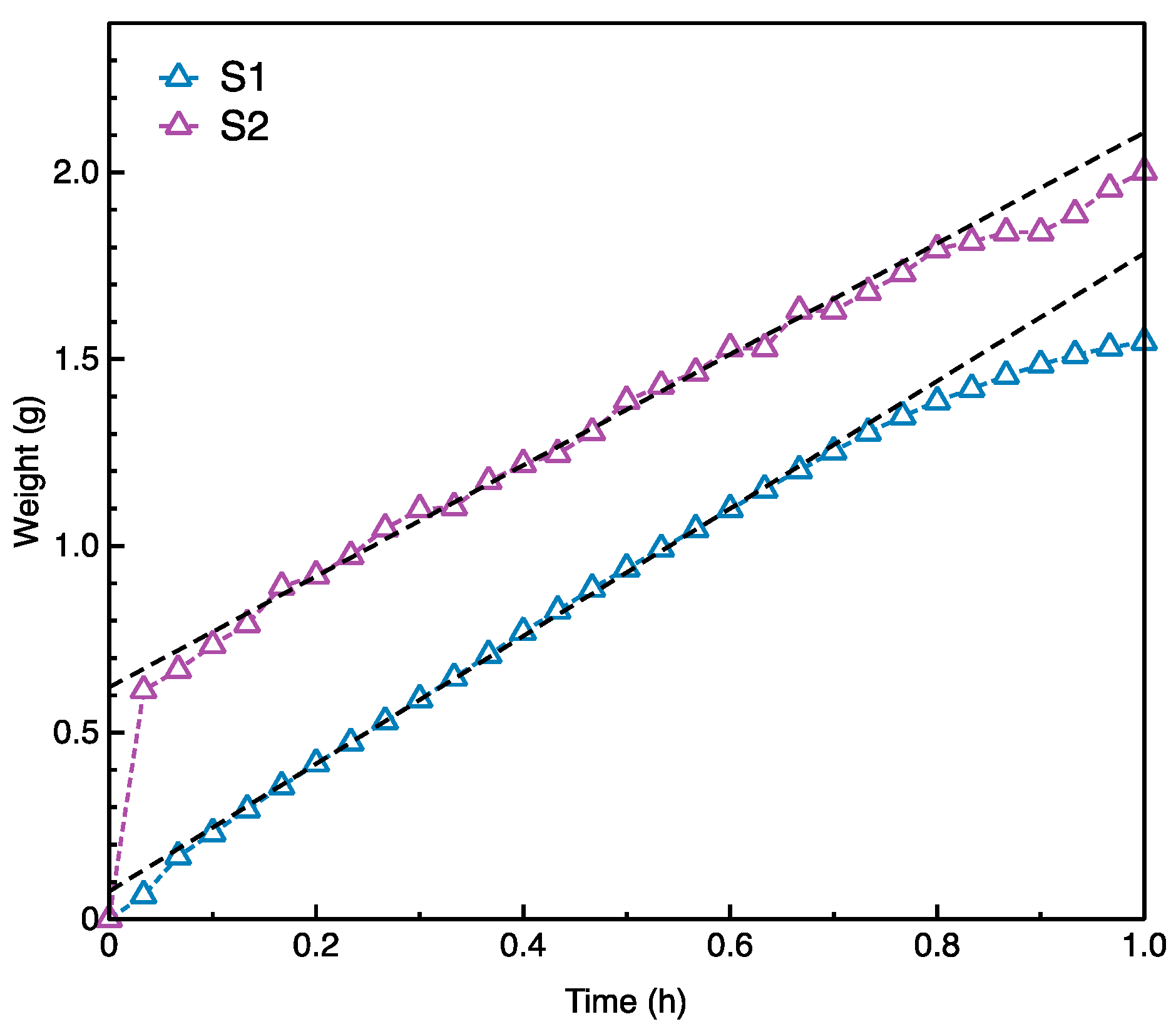

3.6. Evaluation of Water Evaporation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kramarenko, A.V.; Tan, U. Effects of high-frequency electromagnetic fields on human EEG: A brain mapping study. Int. J. Neurosci. 2009, 113, 1007–1019. [Google Scholar] [CrossRef]

- Sırav, B.; Seyhan, N. Effects of GSM Modulated Radio-Frequency Electromagnetic Radiation on Permeability of Blood–Brain Barrier in Male & Female Rats. J. Chem. Neuroanat. 2016, 75, 123–127. [Google Scholar] [CrossRef]

- Cvetković, M.; Poljak, D.; Hirata, A. The Electromagnetic-Thermal Dosimetry for the Homogeneous Human Brain Model. Eng. Anal. Bound. Elem. 2016, 63, 61–73. [Google Scholar] [CrossRef]

- Zhang, X.; Jin, Z. A Kind of Song Brocade Fabric with NFC Data Masking Function Used for Making Purse. IOP Conf. Ser. Mater. Sci. Eng. 2018, 389, 012037. [Google Scholar] [CrossRef]

- Coskun, V.; Ozdenizci, B.; Ok, K. A Survey on Near Field Communication (NFC) Technology. Wirel. Pers. Commun. 2013, 71, 2259–2294. [Google Scholar] [CrossRef]

- Reveilhac, M.; Pasquet, M. Promising Secure Element Alternatives for NFC Technology. In Proceedings of the 2009 First International Workshop on Near Field Communication, Hagenberg, Austria, 24–24 February 2009; pp. 75–80. [Google Scholar] [CrossRef]

- Vagdevi, P.; Nagaraj, D.; Prasad, G.V. Home: IOT Based Home Automation Using NFC. In Proceedings of the 2017 International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC), Palladam, India, 10–11 February 2017; pp. 861–865. [Google Scholar] [CrossRef]

- Palanisamy, S.; Tunakova, V.; Hu, S.; Yang, T.; Kremenakova, D.; Venkataraman, M.; Petru, M.; Militky, J. Electromagnetic Interference Shielding of Metal Coated Ultrathin Nonwoven Fabrics and Their Factorial Design. Polymers 2021, 13, 484. [Google Scholar] [CrossRef]

- Palanisamy, S.; Tunakova, V.; Militky, J. Fiber-Based Structures for Electromagnetic Shielding—Comparison of Different Materials and Textile Structures. Text. Res. J. 2018, 88, 1992–2012. [Google Scholar] [CrossRef]

- Jagatheesan, K.; Ramasamy, A.; Das, A.; Basu, A. Fabrics and Their Composites for Electromagnetic Shielding Applications. Text. Prog. 2015, 47, 87–161. [Google Scholar] [CrossRef]

- Hong, J.; Xu, P.; Xia, H.; Xu, Z.; Ni, Q.-Q. Electromagnetic Interference Shielding Anisotropy Enhanced by CFRP Laminated Structures. Compos. Sci. Technol. 2021, 203, 108616. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Yang, K.; Xiong, X.; Venkataraman, M.; Militky, J.; Mishra, R.; Kremenakova, D. Effect of Silanization on Copper Coated Milife Fabric with Improved EMI Shielding Effectiveness. Mater. Chem. Phys. 2020, 239, 122008. [Google Scholar] [CrossRef]

- Azim, S.S.; Satheesh, A.; Ramu, K.K.; Ramu, S.; Venkatachari, G. Studies on Graphite Based Conductive Paint Coatings. Prog. Org. Coat. 2006, 55, 1–4. [Google Scholar] [CrossRef]

- Yip, J.; Jiang, S.; Wong, C. Characterization of Metallic Textiles Deposited by Magnetron Sputtering and Traditional Metallic Treatments. Surf. Coat. Technol. 2009, 204, 380–385. [Google Scholar] [CrossRef]

- Erdumlu, N.; Saricam, C. Electromagnetic Shielding Effectiveness of Woven Fabrics Containing Cotton/Metal-Wrapped Hybrid Yarns. J. Ind. Text. 2016, 46, 1084–1103. [Google Scholar] [CrossRef]

- Uzun, S.; Han, M.; Strobel, C.J.; Hantanasirisakul, K.; Goad, A.; Dion, G.; Gogotsi, Y. Highly Conductive and Scalable Ti3C2T x -Coated Fabrics for Efficient Electromagnetic Interference Shielding. Carbon 2021, 174, 382–389. [Google Scholar] [CrossRef]

- Yang, K.; Periyasamy, A.P.; Venkataraman, M.; Militky, J.; Kremenakova, D.; Vecernik, J.; Pulíček, R. Resistance against Penetration of Electromagnetic Radiation for Ultra-Light Cu/Ni-Coated Polyester Fibrous Materials. Polymers 2020, 12, 2029. [Google Scholar] [CrossRef]

- Khalili, A.; Mottaghitalab, A.; Hasanzadeh, M.; Mottaghitalab, V. Rejection of Far Infrared Radiation from the Human Body Using Cu–Ni–P–Ni Nanocomposite Electroless Plated PET Fabric. Int. J. Ind. Chem. 2017, 8, 109–120. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Li, W.; Li, L.; Sun, Z.; Jiang, L.; Ma, J.; Chen, S.; Ning, X.; Zhou, F.-L. Lightweight and Highly Conductive Silver Nanoparticles Functionalized Meta-Aramid Nonwoven Fabric for Enhanced Electromagnetic Interference Shielding. J. Mater. Sci. 2021, 56, 6499–6513. [Google Scholar] [CrossRef]

- Gao, Y.-N.; Wang, Y.; Yue, T.-N.; Weng, Y.-X.; Wang, M. Multifunctional Cotton Non-Woven Fabrics Coated with Silver Nanoparticles and Polymers for Antibacterial, Superhydrophobic and High Performance Microwave Shielding. J. Colloid Interface Sci. 2021, 582, 112–123. [Google Scholar] [CrossRef]

- Palanisamy, S.; Tunakova, V.; Militky, J.; Wiener, J. Effect of Moisture Content on the Electromagnetic Shielding Ability of Non-Conductive Textile Structures. Sci. Rep. 2021, 11, 11032. [Google Scholar] [CrossRef]

- Lou, C.-W.; Liu, Y.-L.; Shiu, B.-C.; Peng, H.-K.; Lin, J.-H. Preparation and Evaluation of Polyester-Cotton/Wire Blended Conductive Woven Fabrics for Electromagnetic Shielding. J. Ind. Text. 2021, 152808372199718. [Google Scholar] [CrossRef]

- Lou, C.-W.; Lin, T.A.; Chen, A.-P.; Lin, J.-H. Stainless Steel/Polyester Woven Fabrics and Copper/Polyester Woven Fabrics: Manufacturing Techniques and Electromagnetic Shielding Effectiveness. J. Ind. Text. 2016, 46, 214–236. [Google Scholar] [CrossRef]

- Lin, T.A.; Lin, M.-C.; Lin, T.R.; Sim, K.S.; Lin, J.-H.; Lou, C.-W. High-Strength Protective Polyester Textiles Incorporated with Metallic Materials: Characterizations and Radiation-Shielding Effectiveness. J. Ind. Text. 2020, 152808372090467. [Google Scholar] [CrossRef]

- Lou, C.W.; Lin, C.-M.; Hsing, W.-H.; Chen, A.-P.; Lin, J.-H. Manufacturing Techniques and Electrical Properties of Conductive Fabrics with Recycled Polypropylene Nonwoven Selvage. Text. Res. J. 2011, 81, 1331–1343. [Google Scholar] [CrossRef]

- Peng, H.-K.; Wang, Y.; Li, T.-T.; Lou, C.-W.; Wang, X.; Lin, J.-H. Polysufonamide/Stainless Steel Woven Fabrics: Manufacturing Techniques, Flame Retardance and Electromagnetic Shielding Effectiveness. Fibers Polym. 2020, 21, 775–784. [Google Scholar] [CrossRef]

- Veer, J.; Kothari, V.K. Electromagnetic Shielding Effectiveness of Woven Fabrics Having Metal Coated Zari Wrapped Yarns. Indian J. Fibre Text. Res. 2017, 42, 271–277. [Google Scholar]

- Chen, K.; Lu, D.; Jin, Z.; Su, M.; Jin, J. Song Brocade in the Ming and Qing Dynasties. Cloth. Text. Res. J. 2020, 38, 285–297. [Google Scholar] [CrossRef]

- Glo, J.; Shen, H.; Nie, K. Inheritance of Song Brocade Weaving Technology Based on 3D Technology. J. Silk 2020, 57, 78–83. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Qu, H. Study on the Influence of Song Brocade’s Cultural Identity on Consumers’ Purchase Intention the Mediating Function of Brand Recognition. J. Silk 2020, 57, 11–17. [Google Scholar] [CrossRef]

- Yang, P.; Jin, Z.; Wu, J. The Research on Jacquard Weaving Technology of Self, Adhesive Song Brocade Bag Fabric. J. Silk 2018, 55, 81–85. [Google Scholar] [CrossRef]

- Wang, Z.; Bovik, A.C.; Sheikh, H.R.; Simoncelli, E.P. Image Quality Assessment: From Error Visibility to Structural Similarity. IEEE Trans. Image Process. 2004, 13, 600–612. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Li, J.; Liu, H. A Simple Process for Electroless Plating Nickel–Phosphorus Film on Wood Veneer. Wood Sci. Technol. 2011, 45, 161–167. [Google Scholar] [CrossRef]

- Singh, Y. Electrical resistivity measurements: A review. Int. J. Mod. Phys. Conf. Ser. 2013, 22, 745–756. [Google Scholar] [CrossRef]

- Xu, C.; Hu, J.; Chen, Y.; Yang, Q.; Zhang, Y.; Wang, C.; Chen, K. Rapid Synthesis of Strawberry Microcapsules via Pickering Emulsion Photopolymerization for Use in Multifunctional Fabric Coatings. Prog. Org. Coat. 2021, 152, 106110. [Google Scholar] [CrossRef]

- Liu, H.; Xu, Y. Influence of Nano-ZnO to Finishing on Anti-UV Properties of Silk Fabrics. J. Text. Res. 2016, 37, 104. [Google Scholar]

- Yang, T.; Zhou, W.; Ma, P. Manufacture and Property of Warp-Knitted Fabrics with Polylactic Acid Multifilament. Polymers 2019, 11, 65. [Google Scholar] [CrossRef] [Green Version]

- Chen, D.; Tan, L.; Liu, H.; Tang, F.; Hu, J.; Li, Y. Fabrication of Fast-Absorbing and Quick-Drying Wool Fabrics with Good Washing Durability. Chemsuschem 2010, 3, 1031–1035. [Google Scholar] [CrossRef]

- Peng, H.-K.; Wang, Y.; Li, T.-T.; Lou, C.-W.; He, Q.; Lin, J.-H. Superhydrophobic/Flame Retardant/EMI Shielding Fabrics: Manufacturing Techniques and Property Evaluations. Appl. Sci. 2019, 9, 1914. [Google Scholar] [CrossRef] [Green Version]

- Ramírez-Herrera, C.A.; Gonzalez, H.; de la Torre, F.; Benitez, L.; Cabañas-Moreno, J.G.; Lozano, K. Electrical Properties and Electromagnetic Interference Shielding Effectiveness of Interlayered Systems Composed by Carbon Nanotube Filled Carbon Nanofiber Mats and Polymer Composites. Nanomaterials 2019, 9, 238. [Google Scholar] [CrossRef] [Green Version]

| Yarn Type | Fineness (Denier) | Color |

|---|---|---|

| Raw silk | 1/20/22 den | Black |

| Cooked mulberry silk | 1/20/22 den | Black |

| 5/20/22 den | Blue 1, Blue 2, Blue 3 | |

| PET | 300 den | Brown |

| Ag-PA | 90 den | Black |

| Yarn Code | Yarn Type in the Sample S1 | Yarn Type in the Sample S2 |

|---|---|---|

| Wrap 1 | Raw silk (1/20/22 den) | Raw silk (1/20/22 den) |

| Wrap 2 | Cooked mulberry silk (1/20/22 den) | Ag-PA yarn (90 den) |

| Weft 1 | Cooked mulberry silk (5/20/22 den) | Cooked mulberry silk (5/20/22 den) |

| Weft 2 | Cooked mulberry silk (5/20/22 den) | Cooked mulberry silk (5/20/22 den) |

| Weft 3 | Cooked mulberry silk (5/20/22 den) | Cooked mulberry silk (5/20/22 den) |

| Weft 4 | PET Yarn (300 den) | Ag-PA yarn (90 den) |

| Sample Code | Warp Density (Root/cm) | Weft Density (Root/cm) | Areal Density (g/cm2) | Thickness (mm) |

|---|---|---|---|---|

| S1 | 120 | 120 | 239 | 0.438 |

| S2 | 120 | 120 | 194 | 0.542 |

| Frequency (MHz) | EM SE (dB) | EM SE/t (dB cm−1) | SSE (dB cm3 g−1) | SSE/t (dB cm2 g−1) | SE% |

|---|---|---|---|---|---|

| 30 | 54.1 | 998.155 | 0.015 | 0.279 | 99.99 |

| 100 | 54.6 | 1007.380 | 0.015 | 0.281 | 99.99 |

| 300 | 54.4 | 1003.690 | 0.015 | 0.280 | 99.99 |

| 1000 | 54.6 | 1007.380 | 0.015 | 0.281 | 99.99 |

| 3000 | 52.1 | 961.255 | 0.015 | 0.269 | 99.99 |

| Sample Code | UVA Transmission (%) | UVB Transmission (%) | UPF |

|---|---|---|---|

| S1 | 0.51 ± 0.03 | 0.51 ± 0.02 | 206.64 ± 8.86 |

| S2 | 0.54 ± 0.01 | 0.53 ± 0.02 | 196.22 ± 4.75 |

| Sample Code | Air Permeability (mm/s) |

|---|---|

| S1 | |

| S2 |

| Sample Code | Formula | R2 | Evaporation Rate (g/h) |

|---|---|---|---|

| S1 | y = 0.075 + 1.709x | 0.999 | 1.709 |

| S2 | y = 0.621 + 1.486x | 0.992 | 1.486 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Jin, Z.; Hu, L.; Zhou, X.; Yang, K.; Kremenakova, D.; Militky, J. A Silver Yarn-Incorporated Song Brocade Fabric with Enhanced Electromagnetic Shielding. Materials 2021, 14, 3779. https://doi.org/10.3390/ma14143779

Zhang X, Jin Z, Hu L, Zhou X, Yang K, Kremenakova D, Militky J. A Silver Yarn-Incorporated Song Brocade Fabric with Enhanced Electromagnetic Shielding. Materials. 2021; 14(14):3779. https://doi.org/10.3390/ma14143779

Chicago/Turabian StyleZhang, Xiuling, Zimin Jin, Lizhu Hu, Xinyi Zhou, Kai Yang, Dana Kremenakova, and Jiri Militky. 2021. "A Silver Yarn-Incorporated Song Brocade Fabric with Enhanced Electromagnetic Shielding" Materials 14, no. 14: 3779. https://doi.org/10.3390/ma14143779

APA StyleZhang, X., Jin, Z., Hu, L., Zhou, X., Yang, K., Kremenakova, D., & Militky, J. (2021). A Silver Yarn-Incorporated Song Brocade Fabric with Enhanced Electromagnetic Shielding. Materials, 14(14), 3779. https://doi.org/10.3390/ma14143779