Angle of Insertion and Torsional Resistance of Nickel–Titanium Rotary Instruments

Abstract

:1. Introduction

2. Materials and Methods

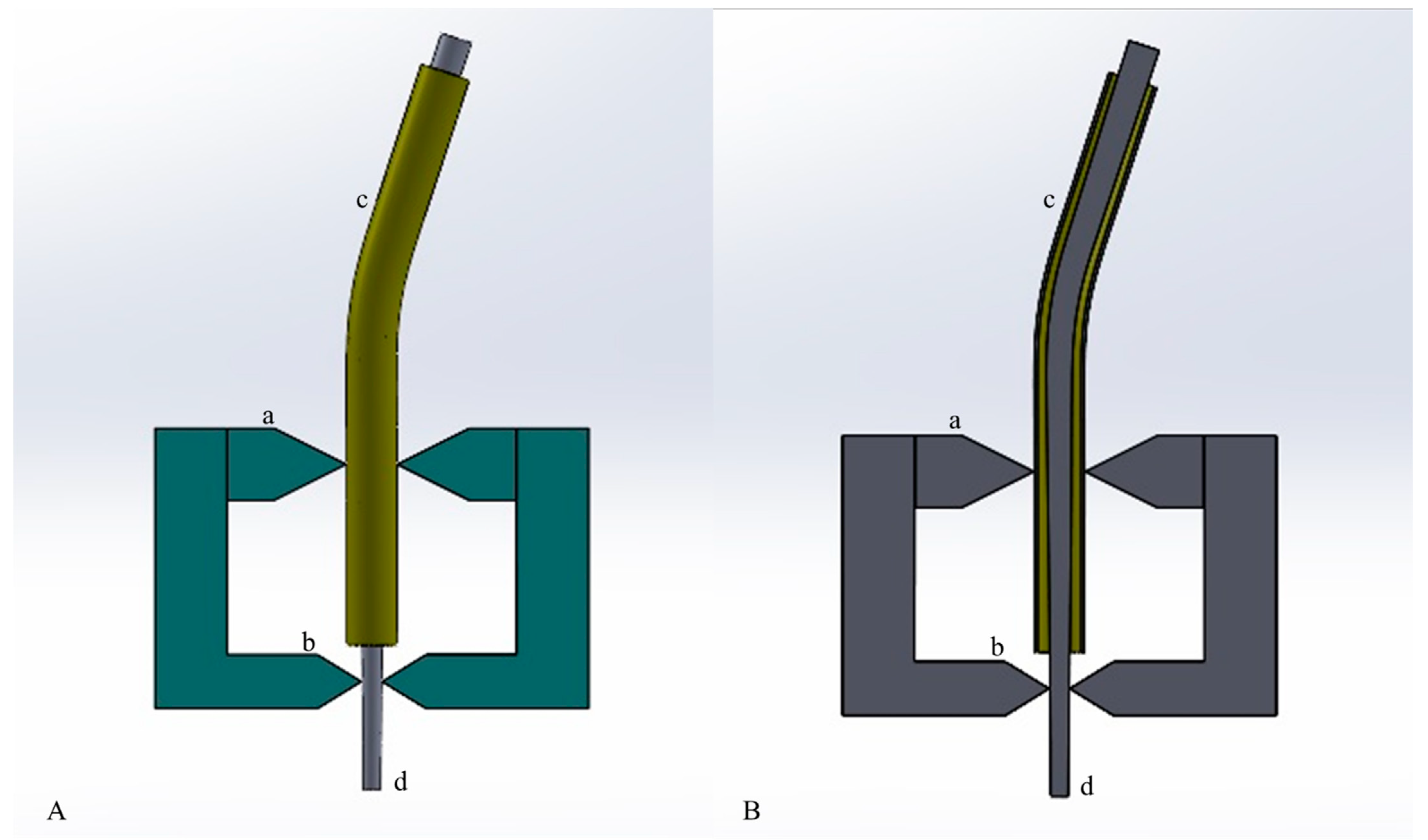

2.1. Static Torsional Test with Different Angle of Insertion

2.2. Fragment Length Measurement

2.3. Statistical Analysis

2.4. Scanning Electron Microscopy Observation

3. Results

3.1. Torque to Fracture (TtF) with Different Angle of Insertion

3.2. Fragment Length (FL) Measurement

3.3. Scanning Electron Microscopy Observation and Fractographic Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Madarati, A.A.; Hunter, M.J.; Dummer, P.M. Management of intracanal separated instruments. J. Endod. 2013, 39, 569–581. [Google Scholar] [CrossRef] [PubMed]

- Seven, N.; Cora, S. Effectiveness of different irrigation systems in the presence of intracanal-separated file. Microsc. Res. Tech. 2019, 82, 238–243. [Google Scholar] [CrossRef] [PubMed]

- Wohlgemuth, P.; Cuocolo, D.; Vandrangi, P.; Sigurdsson, A. Effectiveness of the GentleWave System in Removing Separated Instruments. J. Endod. 2015, 41, 1895–1898. [Google Scholar] [CrossRef]

- Spili, P.; Parashos, P.; Messer, H.H. The impact of instrument fracture on outcome of endodontic treatment. J. Endod. 2005, 31, 845–850. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, M.K.; Kohli, M.R.; Kim, J.S. A retrospective clinical study of incidence of root canal instrument separation in an endodontics graduate program: A PennEndo database study. J. Endod. 2006, 32, 1048–1052. [Google Scholar] [CrossRef]

- Sattapan, B.; Nervo, G.J.; Palamara, J.E.; Messer, H.H. Defects in rotary nickel-titanium files after clinical use. J. Endod. 2000, 26, 161–165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sattapan, B.; Palamara, J.E.; Messer, H.H. Torque during canal instrumentation using rotary nickel-titanium files. J. Endod. 2000, 26, 156–160. [Google Scholar] [CrossRef] [Green Version]

- Gambarini, G.; Miccoli, G.; Di Nardo, D.; Del Giudice, A.; Mazzoni, A.; Seracchiani, M.; Testarelli, L. Torsional resistance of two new heat treated nickel titanium rotary instruments: An in vitro evaluation. Pesquisa Brasileira em Odontopediatria e Clinica Integrada 2020, 20, 1–7. [Google Scholar] [CrossRef]

- Baek, S.H.; Lee, C.J.; Versluis, A.; Kim, B.M.; Lee, W.; Kim, H.C. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J. Endod. 2011, 37, 1283–1286. [Google Scholar] [CrossRef] [PubMed]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef] [Green Version]

- Gambarini, G.; Seracchiani, M.; Zanza, A.; Miccoli, G.; Del Giudice, A.; Testarelli, L. Influence of shaft length on torsional behavior of endodontic nickel-titanium instruments. Odontology 2021, 109, 568–573. [Google Scholar] [CrossRef] [PubMed]

- Seracchiani, M.; Miccoli, G.; Reda, R.; Zanza, A.; Obino, F.V.; Bhandi, S.; Gambarini, G. and Testarelli, L. A comprehensive in vitro comparison of mechanical properties of two rotary endodontic instruments. World J. Dent. 2020, 11, 185–188. [Google Scholar]

- Gambarini, G.; Cicconetti, A.; Nardo, D.D.; Miccoli, G.; Zanza, A.; Testarelli, L.; Seracchiani, M. Influence of different heat treatments on torsional and cyclic fatigue resistance of nickel-titanium rotary files: A comparative study. Appl. Sci. 2020, 10, 5604. [Google Scholar] [CrossRef]

- Ng, Y.L.; Mann, V.; Rahbaran, S.; Lewsey, J.; Gulabivala, K. Outcome of primary root canal treatment: Systematic review of the literature—Part 1. Effects of study characteristics on probability of success. Int. Endod. J. 2007, 40, 921–939. [Google Scholar] [CrossRef] [PubMed]

- Ng, Y.L.; Mann, V.; Rahbaran, S.; Lewsey, J.; Gulabivala, K. Outcome of primary root canal treatment: Systematic review of the literature—Part 2. Influence of clinical factors. Int. Endod. J. 2008, 41, 6–31. [Google Scholar] [CrossRef]

- Munari, L.S.; Bowles, W.R.; Fok, A.S.L. Relationship between Canal Enlargement and Fracture Load of Root Dentin Sections. Dent Mater. 2019, 35, 818–824. [Google Scholar] [CrossRef]

- Yuan, K.; Niu, C.; Xie, Q.; Jiang, W.; Gao, L.; Huang, Z.; Ma, R. Comparative evaluation of the impact of minimally invasive preparation vs. conventional straight-line preparation on tooth biomechanics: A finite element analysis. Eur. J. Oral Sci. 2016, 124, 591–596. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Liu, Y.; Wang, Z.; Yang, T.; Liang, Y.; Gao, Z.; Fang, C.; Zhang, Y. Effect of Access Cavities and Canal Enlargement on Biomechanics of Endodontically Treated Teeth: A Finite Element Analysis. J. Endod. 2020, 46, 1501–1507. [Google Scholar] [CrossRef]

- Silva, E.; Pinto, K.; Ferreira, C.; Belladonna, F.; De-Deus, G.; Dummer, P.; Versiani, M. Current status on minimal access cavity preparations: A critical analysis and a proposal for a universal nomenclature. Int. Endod. J. 2020, 53, 1618–1635. [Google Scholar] [CrossRef]

- Pedullà, E.; La Rosa, G.R.M.; Virgillito, C.; Rapisarda, E.; Kim, H.C.; Generali, L. Cyclic Fatigue Resistance of Nickel-titanium Rotary Instruments according to the Angle of File Access and Radius of Root Canal. J. Endod. 2020, 46, 431–436. [Google Scholar] [CrossRef] [PubMed]

- Wolters, W.J.; Duncan, H.F.; Tomson, P.L.; Karim, I.E.; McKenna, G.; Dorri, M.; Stangvaltaite, L.; van der Sluis, L.W.M. Minimally invasive endodontics: A new diagnostic system for assessing pulpitis and subsequent treatment needs. Int. Endod. J. 2017, 50, 825–829. [Google Scholar] [CrossRef]

- Bürklein, S.; Schäfer, E. Minimally invasive endodontics. Quintessence Int. 2015, 46, 119–124. [Google Scholar]

- Clark, D.; Khademi, J. Modern molar endodontic access and directed dentin conservation. Dent. Clin. N. Am. 2010, 54, 249–273. [Google Scholar] [CrossRef]

- Sabeti, M.; Kazem, M.; Dianat, O.; Bahrololumi, N.; Beglou, A.; Rahimipour, K.; Dehnavi, F. Impact of Access Cavity Design and Root Canal Taper on Fracture Resistance of Endodontically Treated Teeth: An Ex Vivo Investigation. J. Endod. 2018, 44, 1402–1406. [Google Scholar] [CrossRef]

- Patel, S.; Rhodes, J. A practical guide to endodontic access cavity preparation in molar teeth. Br. Dent. J. 2007, 203, 133–140. [Google Scholar] [CrossRef]

- Krishan, R.; Paqué, F.; Ossareh, A.; Kishen, A.; Dao, T.; Friedman, S. Impacts of Conservative Endodontic Cavity on Root Canal Instrumentation Efficacy and Resistance to Fracture Assessed in Incisors, Premolars, and Molars. J. Endod. 2014, 40, 1160–1166. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seracchiani, M.; Miccoli, G.; Di Nardo, D.; Zanza, A.; Cantore, M.; Gambarini, G.; Testarelli, L. Effect of Flexural Stress on Torsional Resistance of NiTi Instruments. J. Endod. 2021, 47, 472–476. [Google Scholar] [CrossRef] [PubMed]

- Gambarini, G.; Miccoli, G.; Seracchiani, M.; Khrenova, T.; Donfrancesco, O.; D’Angelo, M.; Galli, M.; Di Nardo, D.; Testarelli, L. Role of the Flat-Designed Surface in Improving the Cyclic Fatigue Resistance of Endodontic NiTi Rotary Instruments. Materials 2019, 12, 2523. [Google Scholar] [CrossRef] [Green Version]

- Thompson, S.A. An overview of nickel-titanium alloys used in dentistry. Int. Endod. J. 2000, 33, 297–310. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zanza, A.; Seracchiani, M.; Di Nardo, D.; Reda, R.; Gambarini, G.; Testarelli, L. A Paradigm Shift for Torsional Stiffness of Nickel-Titanium Rotary Instruments: A Finite Element Analysis. J. Endod. 2021, 47, 1149–1156. [Google Scholar] [CrossRef] [PubMed]

- Di Nardo, D.; Gambarini, G.; Seracchiani, M.; Mazzoni, A.; Zanza, A.; Giudice, A.; D’Angelo, M.; Testarelli, L. Influence of different cross-section on cyclic fatigue resistance of two nickel-titanium rotary instruments with same heat treatment: An in vitro study. Saudi Endod. J. 2020, 10, 221–225. [Google Scholar]

- Loska, S.; Basiaga, M.; Pochrząst, M.; Łukomska-Szymańska, M.; Walke, W.; Tyrlik-Held, J. Comparative characteristics of endodontic drills. Acta Bioeng. Biomech. 2015, 17, 75–83. [Google Scholar] [PubMed]

- Bumbalek, M.; Joska, Z.; Pokorny, Z.; Sedlak, J.; Majerik, J.; Neumann, V.; Klima, K. Cyclic Fatigue of Dental NiTi Instruments after Plasma Nitriding. Materials 2021, 14, 2155. [Google Scholar] [CrossRef] [PubMed]

| F-One Blue 25/04 | HeroShaper 25/04 | |||||

|---|---|---|---|---|---|---|

| Group A1 (Straight-Line Access) | Group A2 (10°-Angled Access) | Group A3 (20°-Angled Access) | Group B1 (Straight-Line Access) | Group B2 (10°-Angled Access) | Group B3 (20°-Angled Access) | |

| TtF (Ncm) | 0.57 ± 0.03 | 0.61 ± 0.02 | 0.78 ± 0.02 | 0.80 ± 0.07 | 1.05 ± 0.04 | 1.30 ± 0.06 |

| Fragment Length (mm) | 3.04 ± 0.2 | 3.35 ± 0.09 | 3.26 ± 0.18 | 3.10 ± 0.08 | 3.06 ± 0.4 | 3.21 ± 0.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Nardo, D.; Zanza, A.; Seracchiani, M.; Donfrancesco, O.; Gambarini, G.; Testarelli, L. Angle of Insertion and Torsional Resistance of Nickel–Titanium Rotary Instruments. Materials 2021, 14, 3744. https://doi.org/10.3390/ma14133744

Di Nardo D, Zanza A, Seracchiani M, Donfrancesco O, Gambarini G, Testarelli L. Angle of Insertion and Torsional Resistance of Nickel–Titanium Rotary Instruments. Materials. 2021; 14(13):3744. https://doi.org/10.3390/ma14133744

Chicago/Turabian StyleDi Nardo, Dario, Alessio Zanza, Marco Seracchiani, Orlando Donfrancesco, Gianluca Gambarini, and Luca Testarelli. 2021. "Angle of Insertion and Torsional Resistance of Nickel–Titanium Rotary Instruments" Materials 14, no. 13: 3744. https://doi.org/10.3390/ma14133744

APA StyleDi Nardo, D., Zanza, A., Seracchiani, M., Donfrancesco, O., Gambarini, G., & Testarelli, L. (2021). Angle of Insertion and Torsional Resistance of Nickel–Titanium Rotary Instruments. Materials, 14(13), 3744. https://doi.org/10.3390/ma14133744