In-Situ TEM Annealing Observation of Helium Bubble Evolution in Pre-Irradiated FeCoNiCrTi0.2 Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nagase, T.; Rack, P.D.; Noh, J.H.; Egami, T. In-situ TEM observation of structural changes in nano-crystalline CoCrCuFeNi multicomponent high-entropy alloy (HEA) under fast electron irradiation by high voltage electron microscopy (HVEM). Intermetallics 2015, 59, 32–42. [Google Scholar] [CrossRef] [Green Version]

- Nagase, T.; Anada, S.; Rack, P.D.; Noh, J.H.; Yasuda, H.; Mori, H.; Egami, T. Electron-irradiation-induced structural change in Zr-Hf-Nb alloy. Intermetallics 2012, 26, 122–130. [Google Scholar] [CrossRef]

- Lu, C.Y.; Niu, L.L.; Chen, N.J.; Jin, K.; Yang, T.N.; Xiu, P.Y.; Zhang, Y.W.; Gao, F.; Bei, H.B.; Shi, S.; et al. Enhancing radiation tolerance by controlling defect mobility and migration pathways in multicomponent single-phase alloys. Nat. Commun. 2016, 7, 13564. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.P.; Yang, T.F.; Lang, L.; Shan, C.; Deng, H.Q.; Hu, W.Y.; Gao, F. Enhanced radiation tolerance of the Ni-Co-Cr-Fe high-entropy alloy as revealed from primary damage. Acta Mater. 2020, 196, 133–143. [Google Scholar] [CrossRef]

- Lu, C.Y.; Yang, T.N.; Jin, K.; Velisa, G.; Xiu, P.Y.; Peng, Q.; Gao, F.; Zhang, Y.W.; Bei, H.B.; Weber, W.J.; et al. Irradiation effects of medium-entropy alloy NiCoCr with and without pre-indentation. J. Nucl. Mater. 2019, 524, 60–66. [Google Scholar] [CrossRef]

- Yang, L.X.; Ge, H.L.; Zhang, J.; Xiong, T.; Jin, Q.Q.; Zhou, Y.T.; Shao, X.H.; Zhang, B.; Zhu, Z.W.; Zheng, S.J.; et al. High He-ion irradiation resistance of CrMnFeCoNi high-entropy alloy revealed by comparison study with Ni and 304SS. J. Mater. Sci. Technol. 2019, 35, 300–305. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, K.; Feng, Y.H.; Li, Y.S.; Tang, W.Q.; Wei, B.C. Evaluation of radiation response in CoCrFeCuNi high-entropy alloys. Entropy 2018, 20, 835. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, D.; Zhao, S.J.; Sun, J.R.; Tai, P.F.; Sheng, Y.B.; Zhao, Y.L.; Yeli, G.; Lin, W.T.; Liu, S.F.; Kai, W.; et al. Diffusion controlled helium bubble formation resistance of FeCoNiCr high-entropy alloy in the half-melting temperature regime. J. Nucl. Mater. 2019, 526, 151747. [Google Scholar] [CrossRef]

- Lu, Y.P.; Huang, H.F.; Gao, X.Z.; Ren, C.L.; Gaob, J.; Zhang, H.Z.; Zheng, S.J.; Jin, Q.Q.; Zhao, Y.H.; Lu, C.Y.; et al. A promising new class of irradiation tolerant materials: Ti2ZrHfV0.5Mo0.2 high-entropy alloy. J. Mater. Sci. Technol. 2019, 35, 369–373. [Google Scholar] [CrossRef]

- Hu, J.T.; Zhang, J.W.; Zhang, J.J.; Xiao, H.Y.; Xie, L.; Shen, H.H.; Li, P.C.; Sun, G.G.; Zu, X.T. Theoretical combined experimental study of unique He behaviors in high-entropy alloys. Inorg. Chem. 2021, 60, 1388–1397. [Google Scholar] [CrossRef] [PubMed]

- Trinkaus, H.; Singh, B.N. Helium accumulation in metals during irradiation—Where do we stand? J. Nucl. Mater. 2003, 323, 229–242. [Google Scholar] [CrossRef]

- Trinkaus, H. Modeling of helium effects in metals—High-temperature embrittlement. J. Nucl. Mater. 1985, 133, 105–112. [Google Scholar] [CrossRef]

- Duan, J.; He, L.; Fu, Z.; Hoffman, A.; Wen, H. Microstructure, strength and irradiation response of an ultra-fine grained FeNiCoCr multi-principal element alloy. J. Alloys Compd. 2020, 851, 156796. [Google Scholar] [CrossRef]

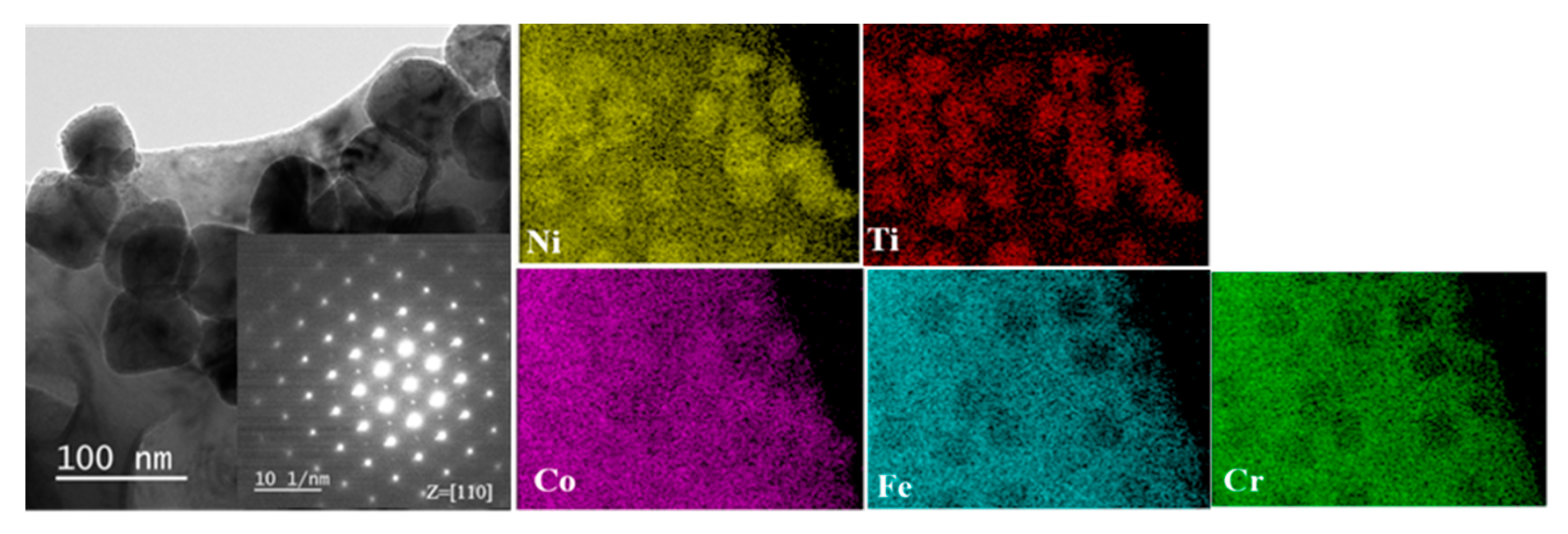

- Han, B.; Wei, J.; Tong, Y.; Chen, D.; Zhao, Y.L.; Wang, J.; He, F.; Yang, T.; Zhao, C.; Shimizu, Y.; et al. Composition evolution of gamma prime nanoparticles in the Ti-doped CoFeCrNi high entropy alloy. Scr. Mater. 2018, 148, 42–46. [Google Scholar] [CrossRef]

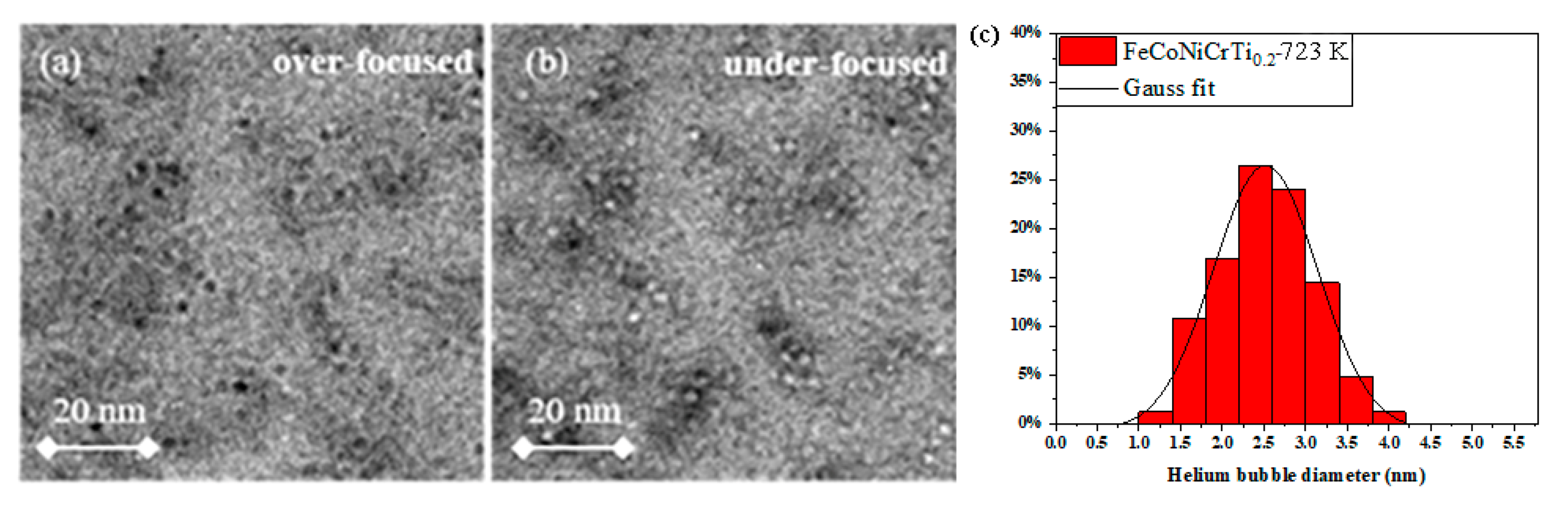

- Chen, D.; Tong, Y.; Wang, J.; Han, B.; Zhao, Y.L.; He, F.; Kai, J.J. Microstructural response of He+ irradiated FeCoNiCrTi0.2 high-entropy alloy. J. Nucl. Mater. 2018, 510, 187–192. [Google Scholar] [CrossRef]

- Chen, D.; Zhao, S.; Sun, J.; Tai, P.; Sheng, Y.; Yeli, G.; Zhao, Y.; Liu, S.; Lin, W.; Kai, W.; et al. Effects of minor alloying addition on He bubble formation in the irradiated FeCoNiCr-based high-entropy alloys. J. Nucl. Mater. 2020, 542, 152458. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.P.; Ran, G.; Wu, L.; Ye, C.; Han, Q.; Wang, H.; Du, H.L. In-situ TEM observation of the evolution of dislocation loops and helium bubbles in a pre helium irradiated FeCrAl alloy during annealing. Prog. Nucl. Energy 2020, 129, 103502. [Google Scholar] [CrossRef]

- Schroeder, H.; Fichtner, P.F.P. On the coarsening mechanisms of helium bubbles—Ostwald ripening versus migration and coalescence. J. Nucl. Mater. 1991, 179, 1007–1010. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Otto, F.; Pharr, G.M.; George, E.P. Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys. Intermetallics 2014, 46, 131–140. [Google Scholar] [CrossRef]

- Chernikov, V.N.; Trinkaus, H.; Ullmaier, H. Helium bubbles in nickel annealed at T > 0.7 T(m). J. Nucl. Mater. 1997, 250, 103–110. [Google Scholar] [CrossRef]

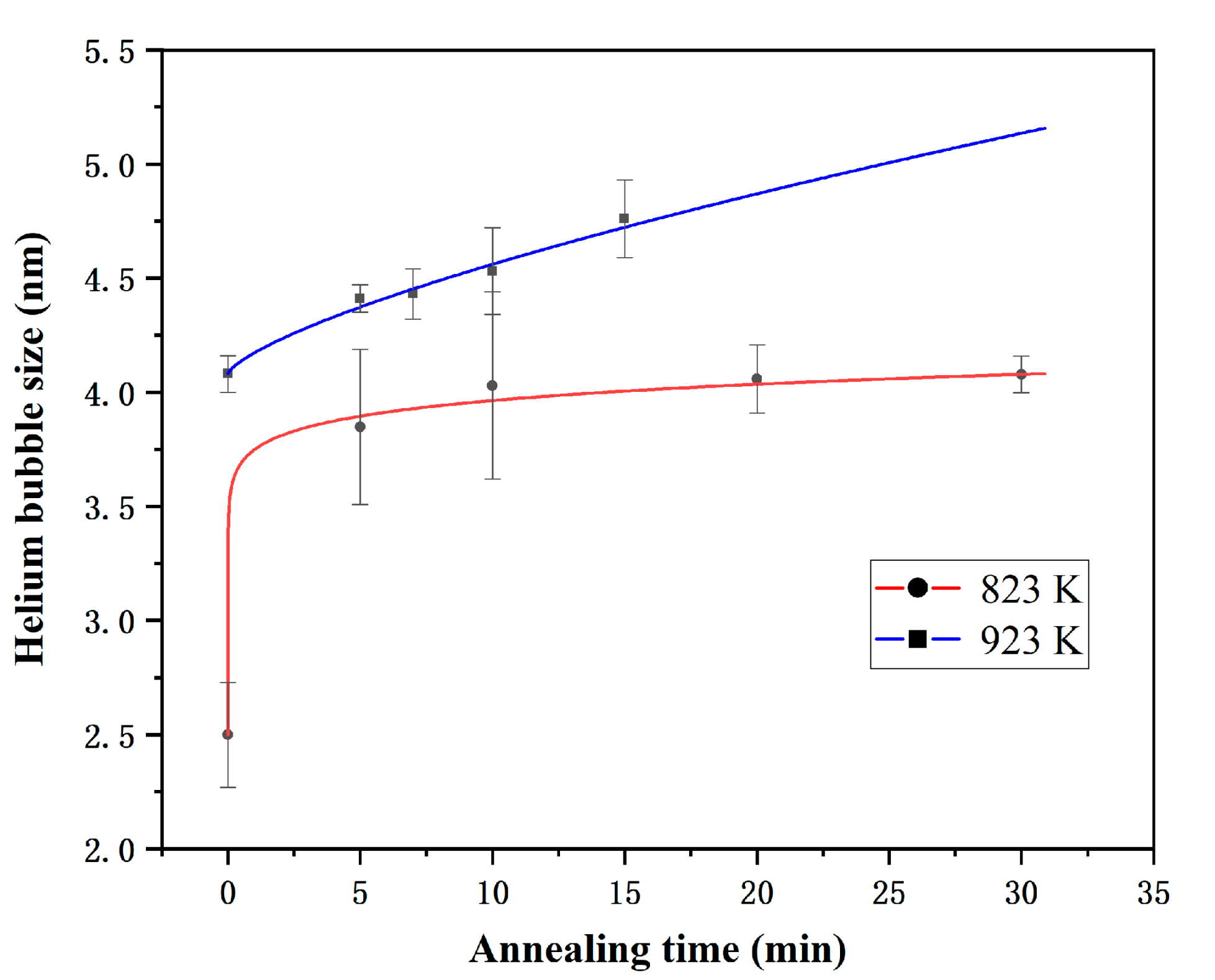

| 823 K | Annealing time (min) | 5 | 10 | 20 | 30 |

| Helium bubble size (nm) | 3.85 ± 0.34 | 4.03 ± 0.41 | 4.06 ± 0.15 | 4.08 ± 0.08 | |

| Areal density of helium bubbles (nm−2) | 1.9 × 10−2 | 2.2 × 10−2 | 1.43 × 10−2 | 1.01 × 10−2 | |

| 923 K | Annealing time (min) | 5 | 7 | 10 | 15 |

| Helium bubble size (nm) | 4.41 ± 0.06 | 4.43 ± 0.11 | 4.53 ± 0.19 | 4.76 ± 0.17 | |

| Areal density of helium bubbles (nm−2) | 6.1 × 10−3 | 6.0 × 10−3 | 5.1 × 10−3 | 4.2 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, H.; Lin, Z.; Jiang, S.; Hu, X.; Zhang, J.; Huang, Z. In-Situ TEM Annealing Observation of Helium Bubble Evolution in Pre-Irradiated FeCoNiCrTi0.2 Alloys. Materials 2021, 14, 3727. https://doi.org/10.3390/ma14133727

He H, Lin Z, Jiang S, Hu X, Zhang J, Huang Z. In-Situ TEM Annealing Observation of Helium Bubble Evolution in Pre-Irradiated FeCoNiCrTi0.2 Alloys. Materials. 2021; 14(13):3727. https://doi.org/10.3390/ma14133727

Chicago/Turabian StyleHe, Huanhuan, Zhiwei Lin, Shengming Jiang, Xiaotian Hu, Jian Zhang, and Zijing Huang. 2021. "In-Situ TEM Annealing Observation of Helium Bubble Evolution in Pre-Irradiated FeCoNiCrTi0.2 Alloys" Materials 14, no. 13: 3727. https://doi.org/10.3390/ma14133727

APA StyleHe, H., Lin, Z., Jiang, S., Hu, X., Zhang, J., & Huang, Z. (2021). In-Situ TEM Annealing Observation of Helium Bubble Evolution in Pre-Irradiated FeCoNiCrTi0.2 Alloys. Materials, 14(13), 3727. https://doi.org/10.3390/ma14133727