A Two-Dimensional Model for Pin-Load Distribution and Failure Analysis of Composite Bolted Joints

Abstract

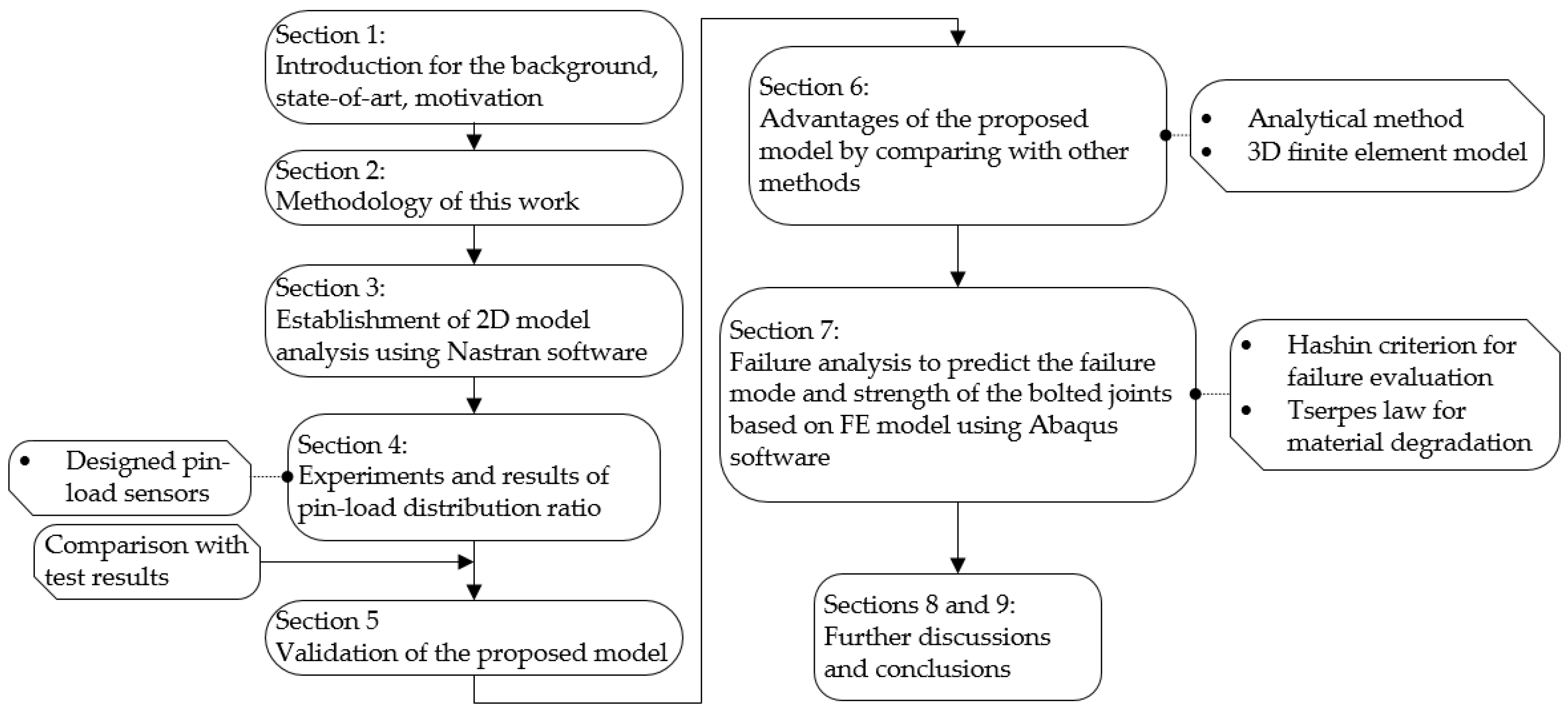

:1. Introduction

2. Methodology

3. Two-Dimensional Model for the Pin-Load Analysis

3.1. Structure Description

3.2. Finite Element Model

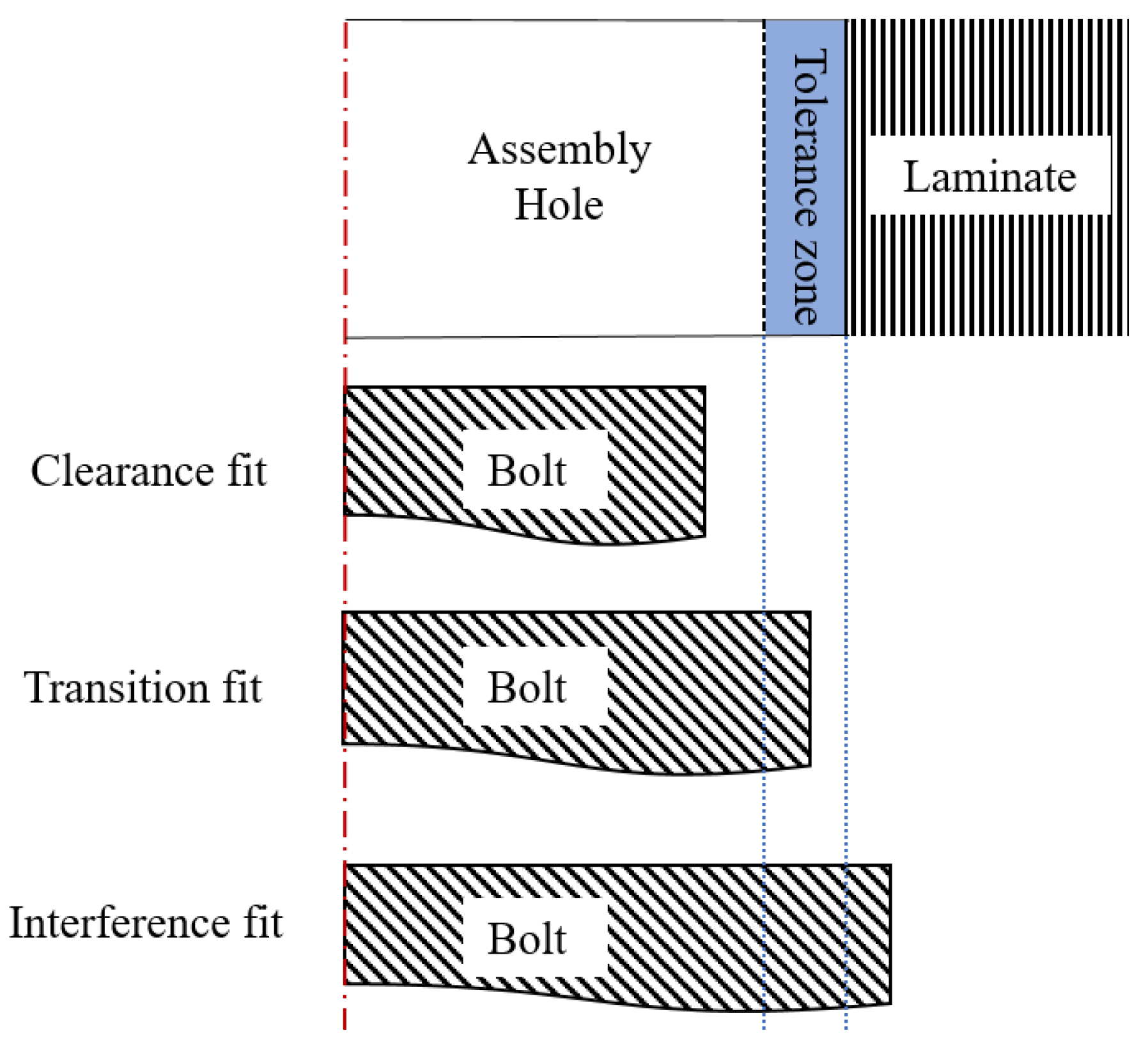

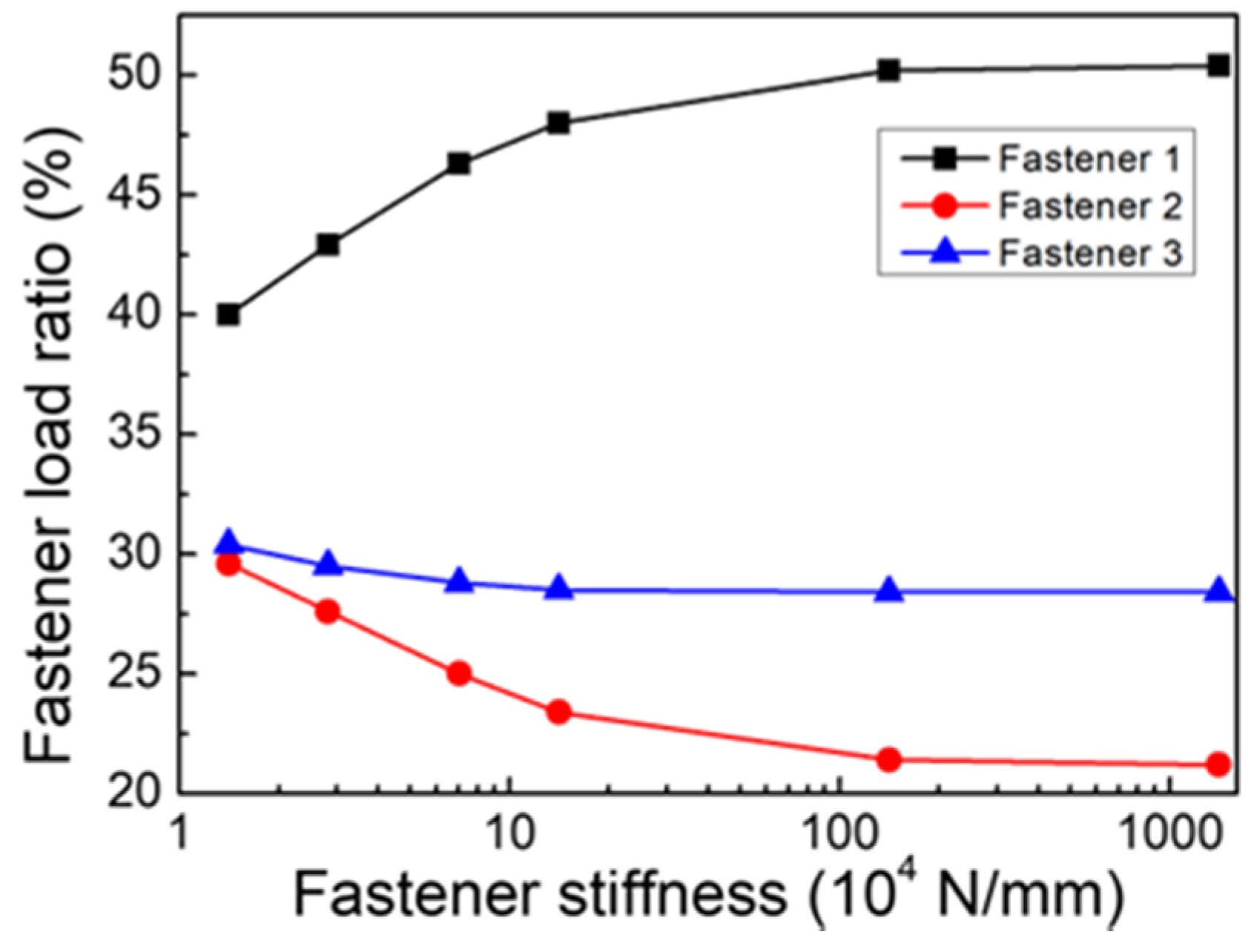

3.3. Calculation of the Fastener’s Stiffness

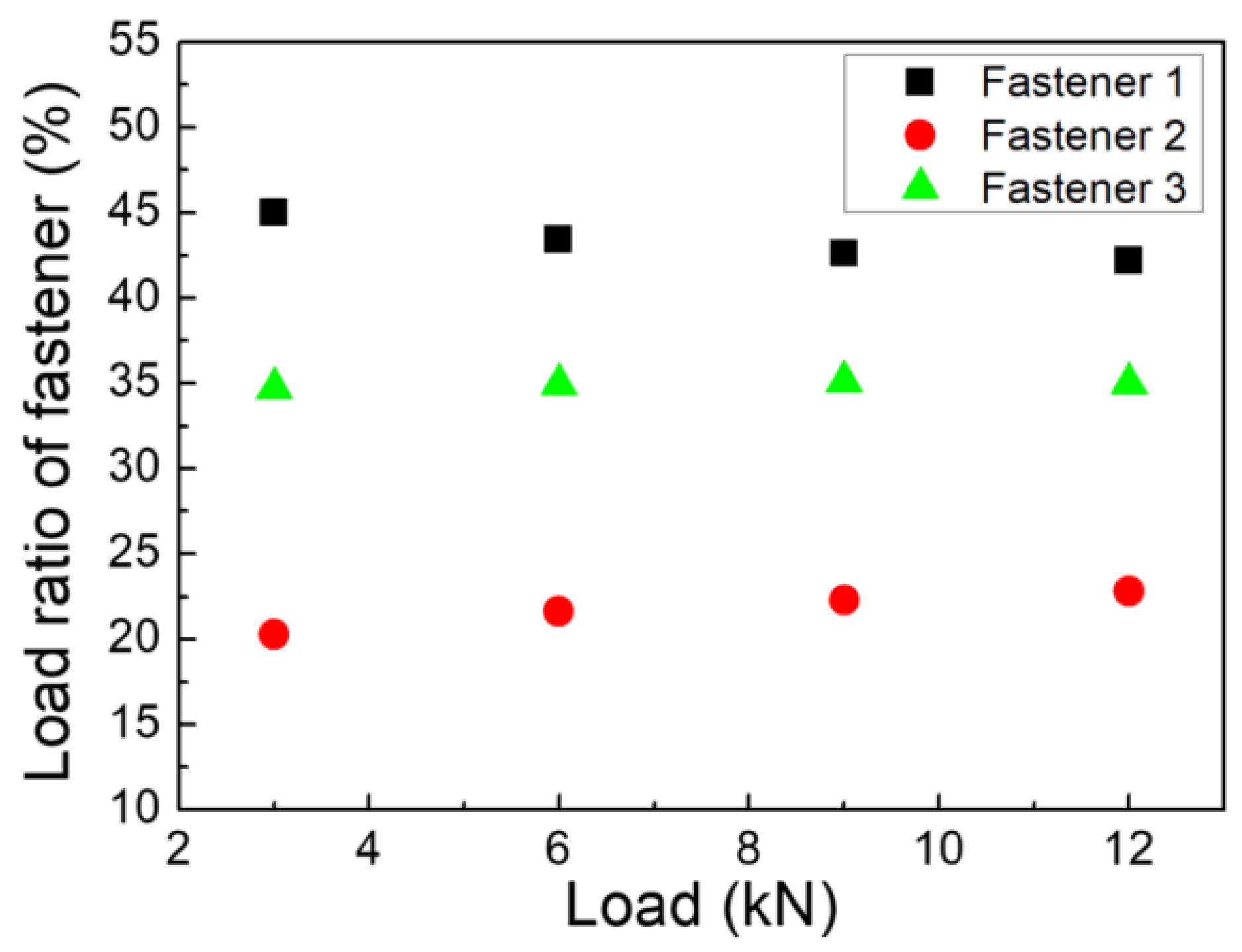

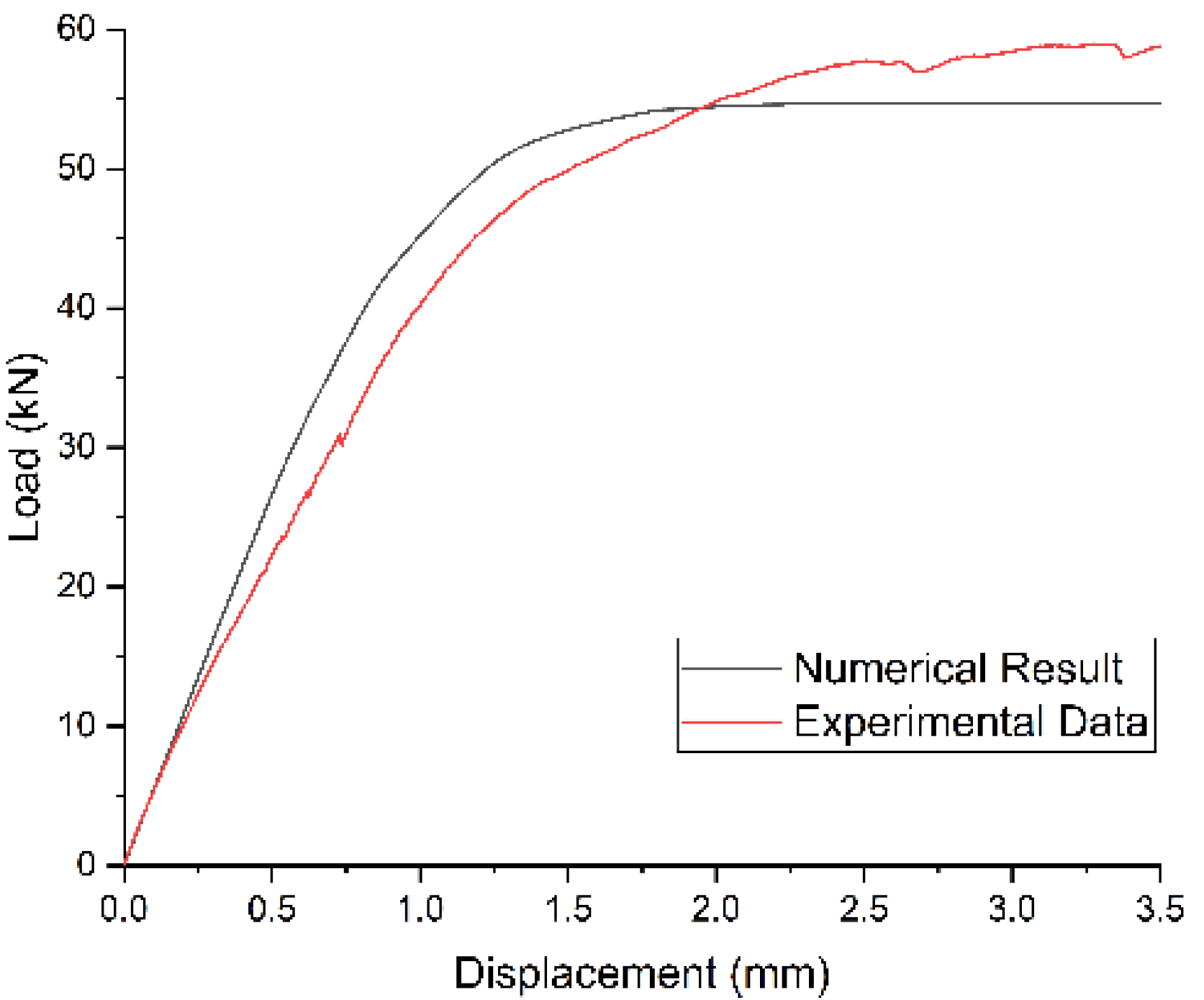

4. Experimental Results

5. Validation of the Proposed Model

6. Comparison with Other Methods for Determining Pin-Load Distribution

7. Failure Analysis of the Bolted Joints

- (a)

- Fiber tensile failure (σ1 > 0):

- (b)

- Fiber compressive failure (σ1 < 0):

- (c)

- Matrix tensile failure (σ2 + σ3 > 0):

- (d)

- Matrix compressive failure (σ2 + σ3 < 0):

8. Discussion

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gong, Y.; Zhang, B.; Zhao, L.; Zhang, J.; Hu, N.; Zhang, C. R-curve behaviour of the mixed-mode I/II delamination in carbon/epoxy laminates with unidirectional and multidirectional interfaces. Compos. Struct. 2019, 223, 110949. [Google Scholar] [CrossRef]

- Zhao, L.; Gong, Y.; Qin, T.; Mehmood, S.; Zhang, J. Failure prediction of out-of-plane woven composite joints using cohesive element. Compos. Struct. 2013, 106, 407–416. [Google Scholar] [CrossRef]

- Song, E.; Liu, W.; Xie, M.; Hong, H.; Chi, J. Investigation of the influence of jointed member stiffness on fastener load distribution for composite multiple-bolted joint. Aircr. Des. 2005, 29–32. [Google Scholar] [CrossRef]

- Sharos, P.A.; Egan, B.; McCarthy, C.T. An analytical model for strength prediction in multi-bolt composite joints at various loading rates. Compos. Struct. 2014, 116, 300–310. [Google Scholar] [CrossRef]

- Xu, X.W.; Man, H.C.; Yue, T.M. Strength prediction of composite laminates with multiple elliptical holes. Int. J. Solids Struct. 2000, 37, 2887–2900. [Google Scholar] [CrossRef]

- McCarthy, M.A.; McCarthy, C.T.; Padhi, G.S. A simple method for determining the effects of bolt–hole clearance on load distribution in single-column multi-bolt composite joints. Compos. Struct. 2006, 73, 78–87. [Google Scholar] [CrossRef]

- Li, H.; Gu, R.; Zhao, X. Global sensitivity analysis of load distribution and displacement in multi-bolt composite joints. Compos. Part B Eng. 2017, 116, 200–210. [Google Scholar] [CrossRef]

- Olmedo, A.; Santiuste, C.; Barbero, E. An analytical model for the secondary bending prediction in single-lap composite bolted-joints. Compos. Struct. 2014, 111, 354–361. [Google Scholar] [CrossRef]

- Gray, P.J.; McCarthy, C.T. An analytical model for the prediction of through-thickness stiffness in tension-loaded composite bolted joints. Compos. Struct. 2012, 94, 2450–2459. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, X.; Wang, Y.; Gao, H.; Bao, Y.; Li, R. An enhanced spring-mass model for stiffness prediction in single-lap composite joints with considering assembly gap and gap shimming. Compos. Struct. 2018, 187, 18–26. [Google Scholar] [CrossRef]

- Tsai, K.H.; Hwan, C.L.; Lin, M.J.; Huang, Y.S. Finite element based point stress criterion for predicting the notched strengths of composite plates. J. Mech. 2012, 28, 401–406. [Google Scholar] [CrossRef]

- Gray, P.J.; McCarthy, C.T. A global bolted joint model for finite element analysis of load distributions in multi-bolt composite joints. Compos. Part B Eng. 2010, 41, 317–325. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, F.; Zhao, L.; Zhi, J.; Zhou, L.; Fei, B. Influence of end distances on the failure of composite bolted joints. J. Reinf. Plast. Comp. 2015, 34, 388–404. [Google Scholar] [CrossRef]

- Chutima, S.; Blackie, A.P. Effect of pitch distance, row spacing, end distance and bolt diameter on multi-fastened composite joints. Compos. Part A Appl. Sci. Manuf. 1996, 27, 105–110. [Google Scholar] [CrossRef]

- Abd-Elhady, A.; Abu-Sinna, A.; Atta, M.; Sallam, H.E.M. Identification of damage stages in bolted metallic joints for different joint geometries and tightening torques using statistical analysis. Adv. Struct. Eng. 2020, 23, 911–923. [Google Scholar] [CrossRef]

- McCarthy, C.T.; Gray, P.J. An analytical model for the prediction of load distribution in highly torqued multi-bolt composite joints. Compos. Struct. 2011, 93, 287–298. [Google Scholar] [CrossRef]

- Liu, F.; Shan, M.; Zhao, L.; Zhang, J. Probabilistic bolt load distribution analysis of composite single-lap multi-bolt joints considering random bolt-hole clearances and tightening torques. Compos. Struct. 2018, 194, 12–20. [Google Scholar] [CrossRef]

- Liu, F.; Lu, X.; Zhao, L.; Zhang, J.; Hu, N.; Xu, J. An interpretation of the load distributions in highly torqued single-lap composite bolted joints with bolt-hole clearances. Compos. Part B Eng. 2018, 138, 194–205. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. The Influence of single lap geometry in adhesive and hybrid joints on their load carrying capacity. Materials 2019, 12, 1884. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Golewski, P.; Sadowski, T. Investigation of the effect of chamfer size on the behaviour of hybrid joints made by adhesive bonding and riveting. Int. J. Adhes. Adhes. 2017, 77, 174–182. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, P. Effect of tolerance in the fitting of rivets in the holes of double lap joints subjected to uniaxial tension. Key Eng. Mater. 2014, 607, 49–54. [Google Scholar] [CrossRef]

- Zhao, L.; Fang, Z.; Liu, F.; Shan, M.; Zhang, J. A modified stiffness method considering effects of hole tensile deformation on bolt load distribution in multi-bolt composite joints. Compos. Part B Eng. 2019, 171, 264–271. [Google Scholar] [CrossRef]

- Li, X.; Xie, Z.; Zhao, W.; Zhang, Y.; Gong, Y.; Hu, N. Failure prediction of irregular arranged multi-bolt composite repair based on finite fracture mechanics model. Eng. Fract. Mech. 2021, 242, 107456. [Google Scholar] [CrossRef]

- Liu, F.; Lu, X.; Zhao, L.; Zhang, J.; Xu, J.; Hu, N. Investigation of bolt load redistribution and its effect on failure prediction in double-lap, multi-bolt composite joints. Compos. Struct. 2018, 202, 397–405. [Google Scholar] [CrossRef]

- Zhou, S.; Yang, C.; Tian, K.; Wang, D.; Sun, Y.; Guo, L.; Zhang, J. Progressive failure modelling of double-lap of composite bolted joints based on Puck’s criterion. Eng. Fract. Mech. 2019, 206, 233–249. [Google Scholar] [CrossRef]

- Liu, P.; Cheng, X.; Wang, S.; Liu, S.; Cheng, Y. Numerical analysis of bearing failure in countersunk composite joints using 3D explicit simulation method. Compos. Struct. 2016, 138, 30–39. [Google Scholar] [CrossRef]

- Bao, H.; Liu, G. Progressive failure analysis on scaled open-hole tensile composite laminates. Compos. Struct. 2016, 150, 173–180. [Google Scholar] [CrossRef]

- Abdelhady, A.A.; Mubaraki, M.; Sallam, H.E.M. Progressive failure prediction of pinned joint in quasi-isotropic laminates used in pipelines. Lat. Am. J. Solids Struct. 2018, 15. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, F.; Zhao, L.; Shan, M. Investigation on characteristic length testing methods for failure prediction of composite multi-bolt joints. J. Reinf. Plast. Comp. 2015, 34, 636–648. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, F.; Zhao, L.; Chen, Y.; Fei, B. A progressive damage analysis based characteristic length method for multi-bolt composite joints. Compos. Struct. 2014, 108, 915–923. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, F.; Zhao, L.; Fei, B. A novel characteristic curve for failure prediction of multi-bolt composite joints. Compos. Struct. 2014, 108, 129–136. [Google Scholar] [CrossRef]

- Liu, F.; Zhao, L.; Mehmood, S.; Zhang, J.; Fei, B. A modified failure envelope method for failure prediction of multi-bolt composite joints. Compos. Sci. Technol. 2013, 83, 54–63. [Google Scholar] [CrossRef]

- Liu, F.; Fang, Z.; Zhao, L.; Zhang, J.; Hu, N. A failure-envelope-based method for the probabilistic failure prediction of composite multi-bolt double-lap joints. Compos. Part B Eng. 2019, 172, 593–602. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, S.; Zhang, J.; Huang, W.; Cheng, Y.; Zhang, J. Effect of damage on failure mode of multi-bolt composite joints using failure envelope method. Compos. Struct. 2017, 160, 8–15. [Google Scholar] [CrossRef]

- Camanho, P.P.; Lambert, M. A design methodology for mechanically fastened joints in laminated composite materials. Compos. Sci. Technol. 2006, 66, 3004–3020. [Google Scholar] [CrossRef]

- Camanho, P.P.; Matthews, F.L. A Progressive Damage Model for Mechanically Fastened Joints in Composite Laminates. J. Compos. Mater. 1999, 33, 2248–2280. [Google Scholar] [CrossRef]

- Hu, X.F.; Haris, A.; Ridha, M.; Tan, V.B.C.; Tay, T.E. Progressive failure of bolted single-lap joints of woven fibre-reinforced composites. Compos. Struct. 2018, 189, 443–454. [Google Scholar] [CrossRef]

- Choi, J.; Hasheminia, S.M.; Chun, H.; Park, J.; Chang, H.S. Failure load prediction of composite bolted joint with clamping force. Compos. Struct. 2018, 189, 247–255. [Google Scholar] [CrossRef]

- Huth, H. Influence of Fastener Flexibility on the Prediction of Load Transfer and Fatigue Life for Multiple-Row Joints; Potter, J.M., Ed.; ASTM International: West Conshohocken, PA, USA, 1986. [Google Scholar]

- Hashin, Z. Fatigue failure criteria for unidirectional fiber composites. J. Appl. Mech. Trans. ASME 1981, 48, 846–852. [Google Scholar] [CrossRef]

- Tserpes, K.I.; Labeas, G.; Papanikos, P.; Kermanidis, T. Strength prediction of bolted joints in graphite/epoxy composite laminates. Compos. Part. B Eng. 2002, 33, 521–529. [Google Scholar] [CrossRef]

| Longitudinal Young’s modulus E1/MPa | 131,000 | Longitudinal tensile strength Xt/MPa | 1170 |

| Transverse Young’s modulus E2/MPa | 8110 | Longitudinal compressive strength Xc/MPa | 859 |

| In-plane shear modulus G12/MPa | 3660 | Transverse tensile strength Yt/MPa | 23.6 |

| Poisson’s ratio ν12 | 0.34 | Transverse compressive strength Yc/MPa | 139 |

| Thickness of each layer/mm | 0.15 | Shear strength S12/MPa | 62.2 |

| Shear Stiffness (N/mm) | Load Ratio of Fastener 1 | Test Result | Error |

|---|---|---|---|

| 1.41 × 104 | 40.0% | 43.3% | −7.7% |

| 1.99 × 104 | 38.8% | −10.4% | |

| 2.83 × 104 | 42.9% | −1.0% | |

| 7.07 × 104 | 46.3% | 6.8% | |

| 1.41 × 105 | 48.0% | 10.9% | |

| 1.41 × 106 | 50.2% | 15.8% | |

| 1.41 × 108 | 50.4% | 16.5% |

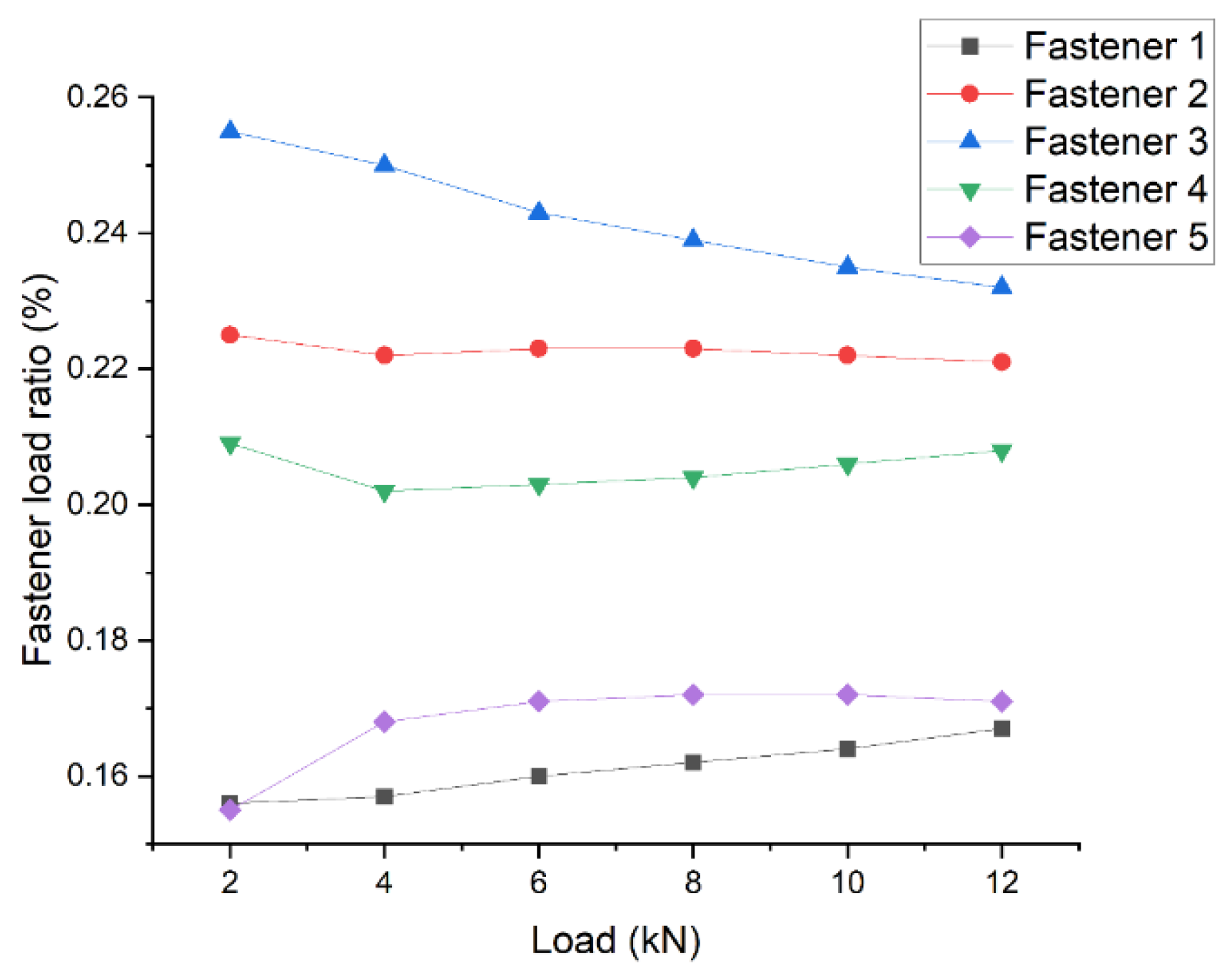

| Fastener No. | Fastener 1 | Fastener 2 | Fastener 3 | Fastener 4 | Fastener 5 |

|---|---|---|---|---|---|

| Test | 16.7% | 22.1% | 23.2% | 20.0% | 17.1% |

| Results from 2D model | 17.1% | 20.9% | 22.3% | 19.7% | 20.2% |

| Relative error | 2.6% | −5.4% | −3.9% | −5.5% | 18.1% |

| Fastener No. | Load Ratio/% |

|---|---|

| 1 | 34.5 |

| 2 | 31.0 |

| 3 | 34.5 |

| Fastener No. | Load Ratio/% |

|---|---|

| 1 | 43.01 |

| 2 | 25.45 |

| 3 | 30.54 |

| Longitudinal tensile strength | Longitudinal compressive strength | Transverse tensile strength | Transverse compressive strength | Longitudinal shear strength |

| 3259 MPa | 1626 MPa | 54.6 MPa | 25.3 MPa | 147 MPa |

| Transverse shear strength | Longitudinal tensile fracture energy | Longitudinal compressive fracture energy | Transverse tensile fracture energy | Transverse compressive fracture energy |

| 102 MPa | 120 J/m2 | 240 J/m2 | 0.33 J/m2 | 1 J/m2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Gong, Y.; Xiao, H.; Gao, Y.; Liang, E. A Two-Dimensional Model for Pin-Load Distribution and Failure Analysis of Composite Bolted Joints. Materials 2021, 14, 3646. https://doi.org/10.3390/ma14133646

Li B, Gong Y, Xiao H, Gao Y, Liang E. A Two-Dimensional Model for Pin-Load Distribution and Failure Analysis of Composite Bolted Joints. Materials. 2021; 14(13):3646. https://doi.org/10.3390/ma14133646

Chicago/Turabian StyleLi, Binkai, Yu Gong, Hao Xiao, Yukui Gao, and Enquan Liang. 2021. "A Two-Dimensional Model for Pin-Load Distribution and Failure Analysis of Composite Bolted Joints" Materials 14, no. 13: 3646. https://doi.org/10.3390/ma14133646

APA StyleLi, B., Gong, Y., Xiao, H., Gao, Y., & Liang, E. (2021). A Two-Dimensional Model for Pin-Load Distribution and Failure Analysis of Composite Bolted Joints. Materials, 14(13), 3646. https://doi.org/10.3390/ma14133646