Investigation of Ib-Values for Determining Fracture Modes in Fiber-Reinforced Composite Materials by Acoustic Emission

Abstract

1. Introduction

2. Experimental

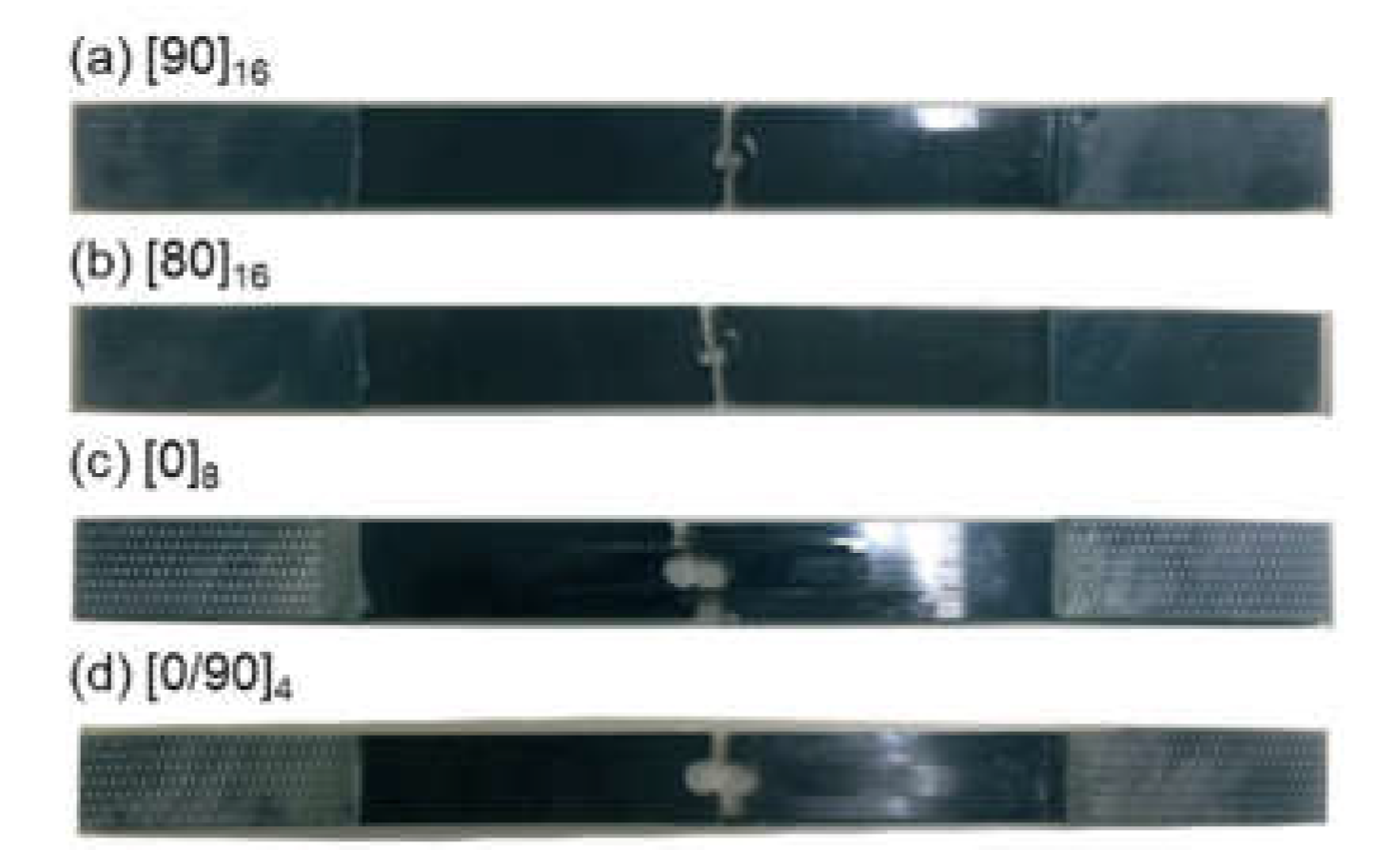

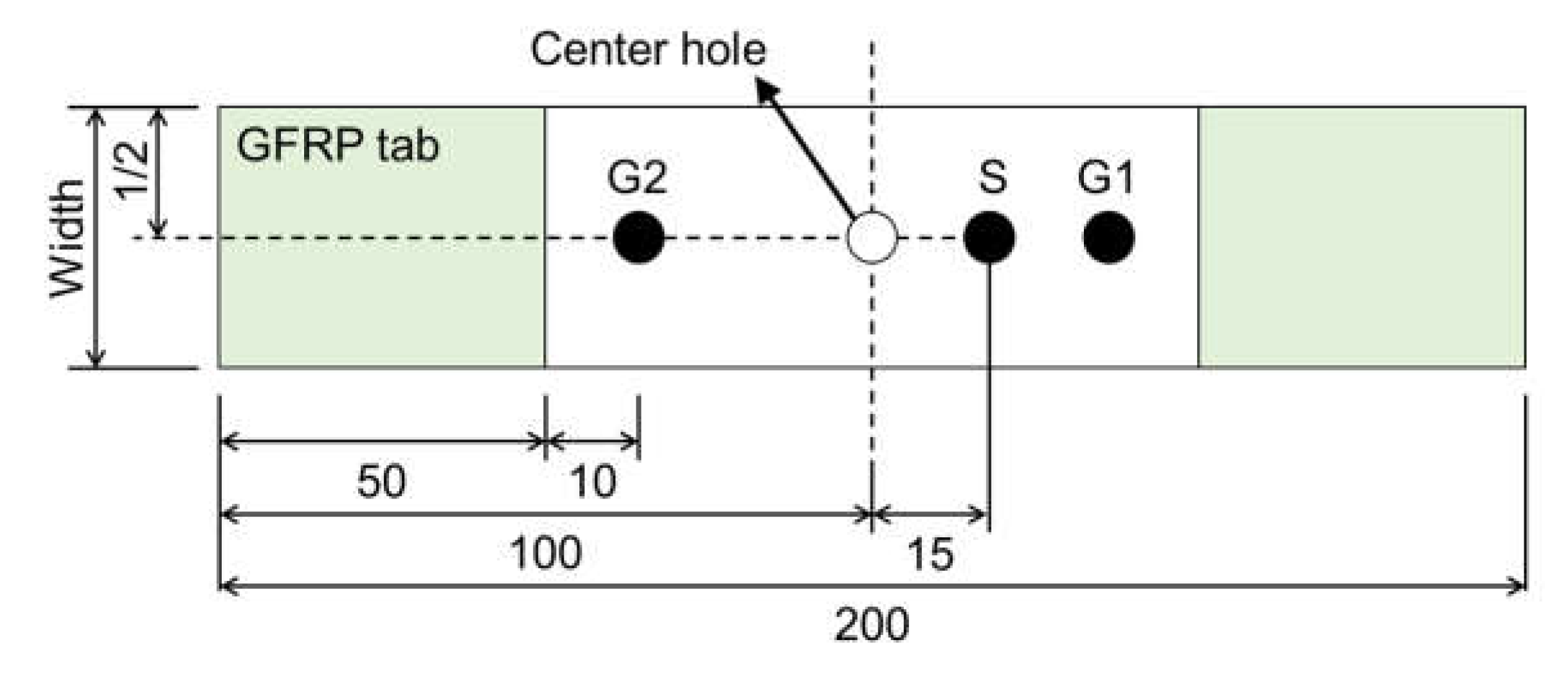

2.1. Materials and Specimen Preparation

2.2. Acoustic Emission Testing

2.3. Analysis of b- and Ib-Values

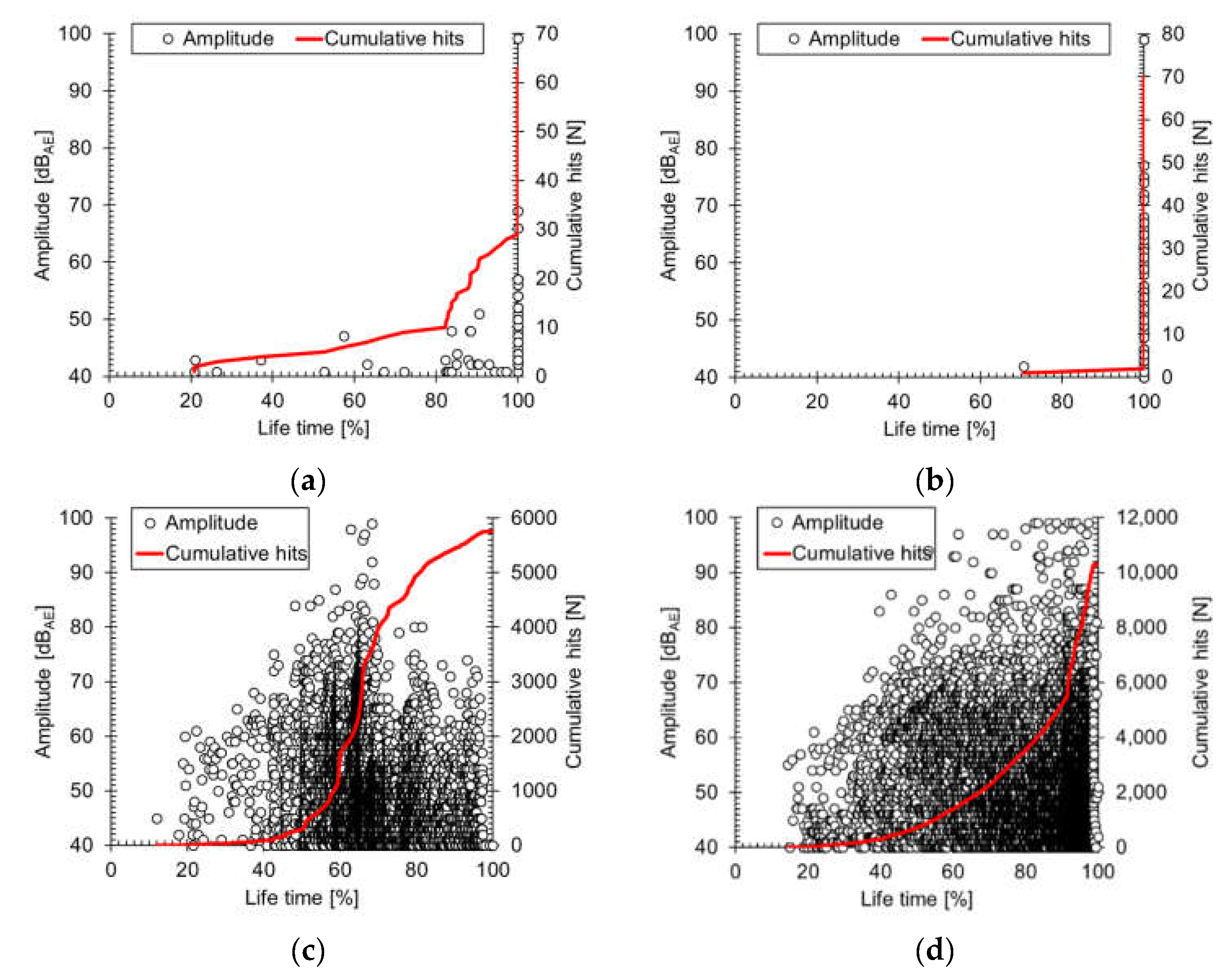

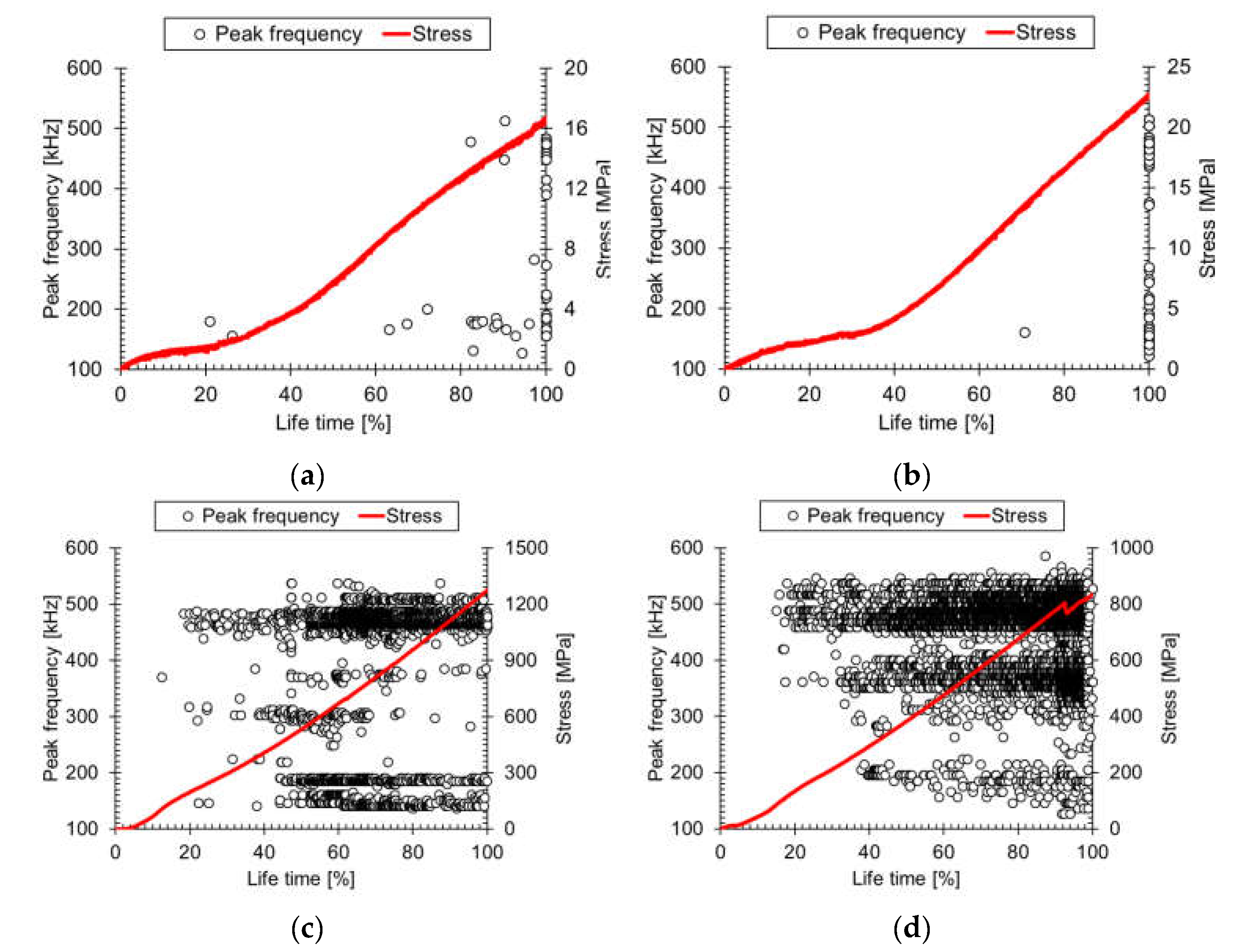

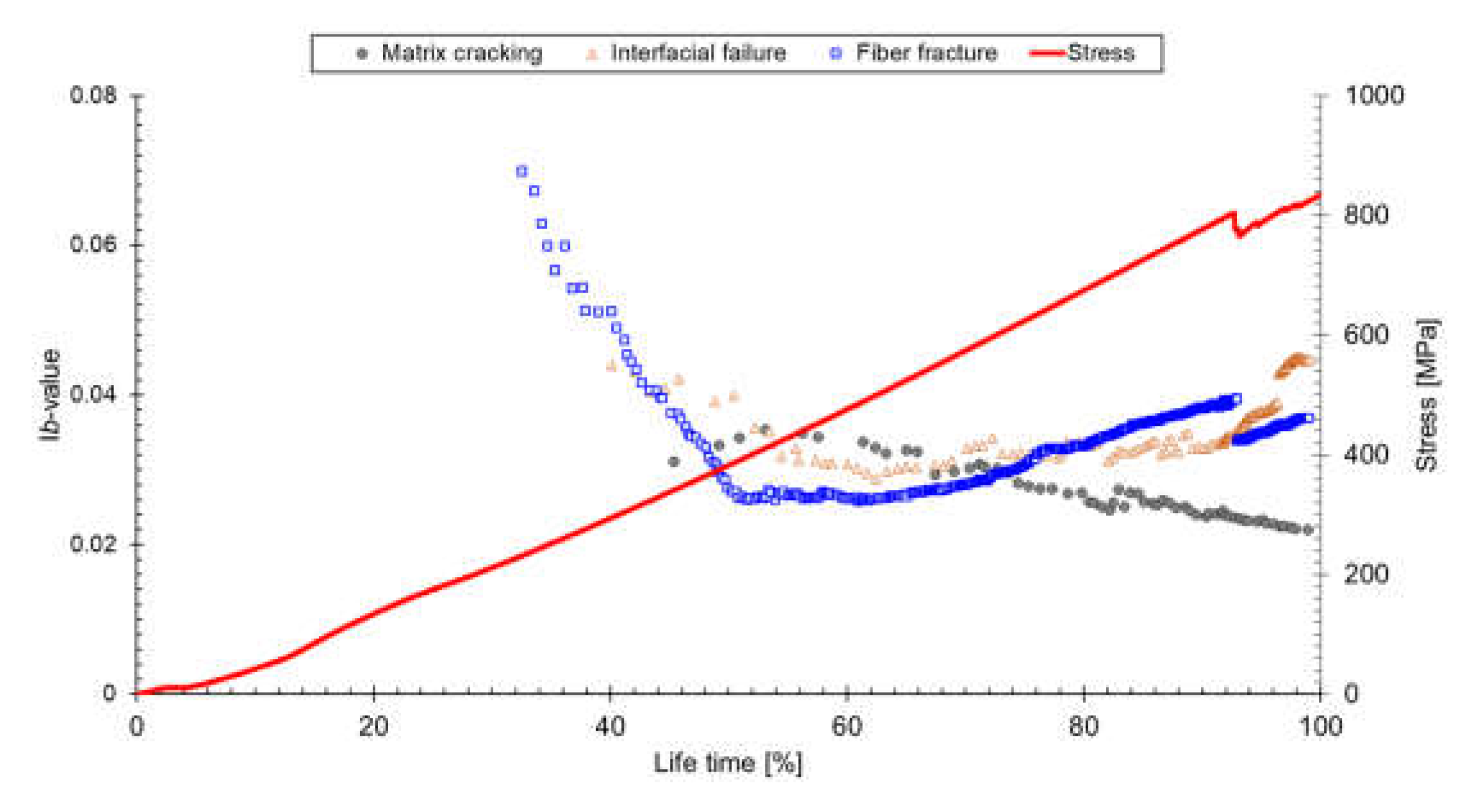

3. Results and Discussion

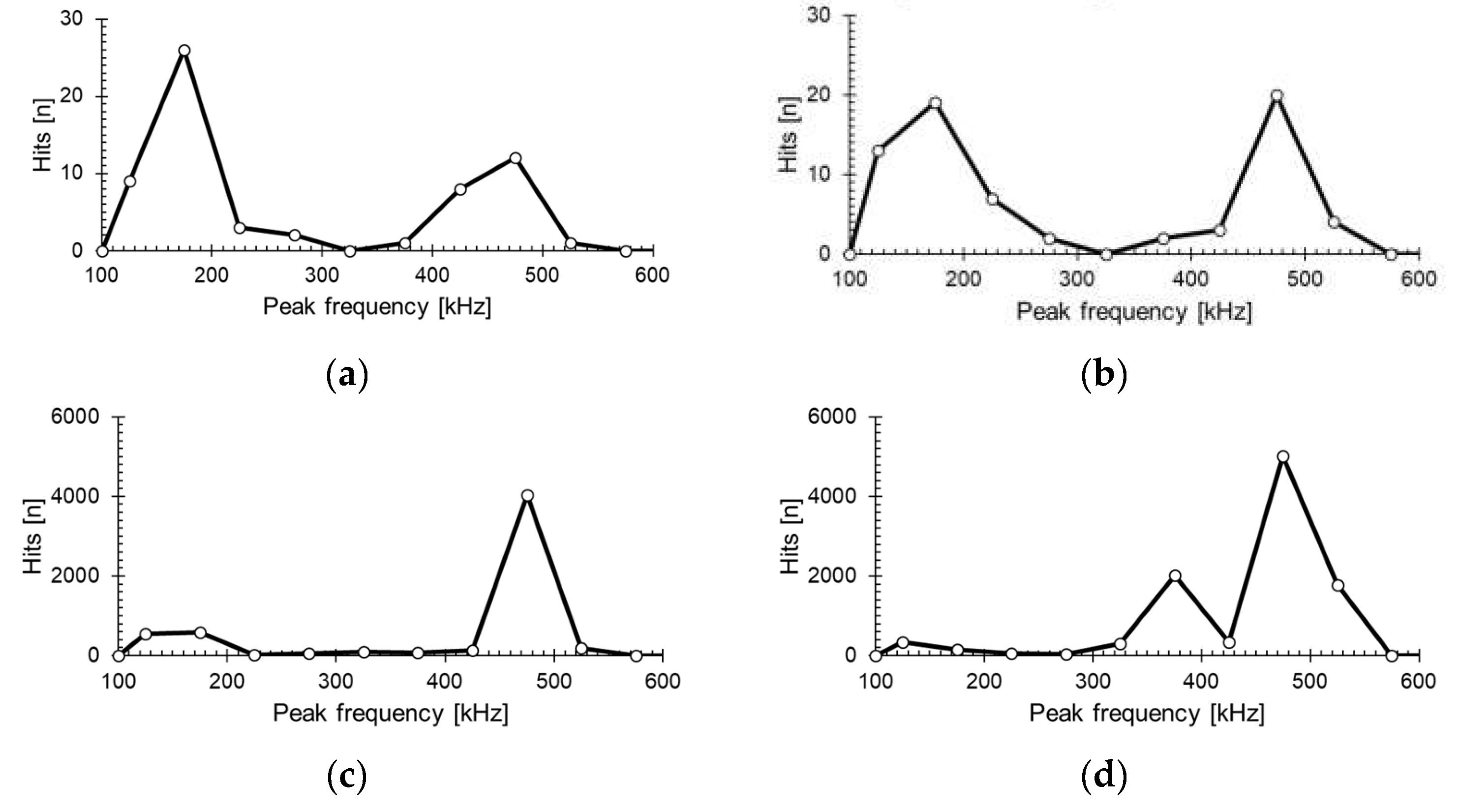

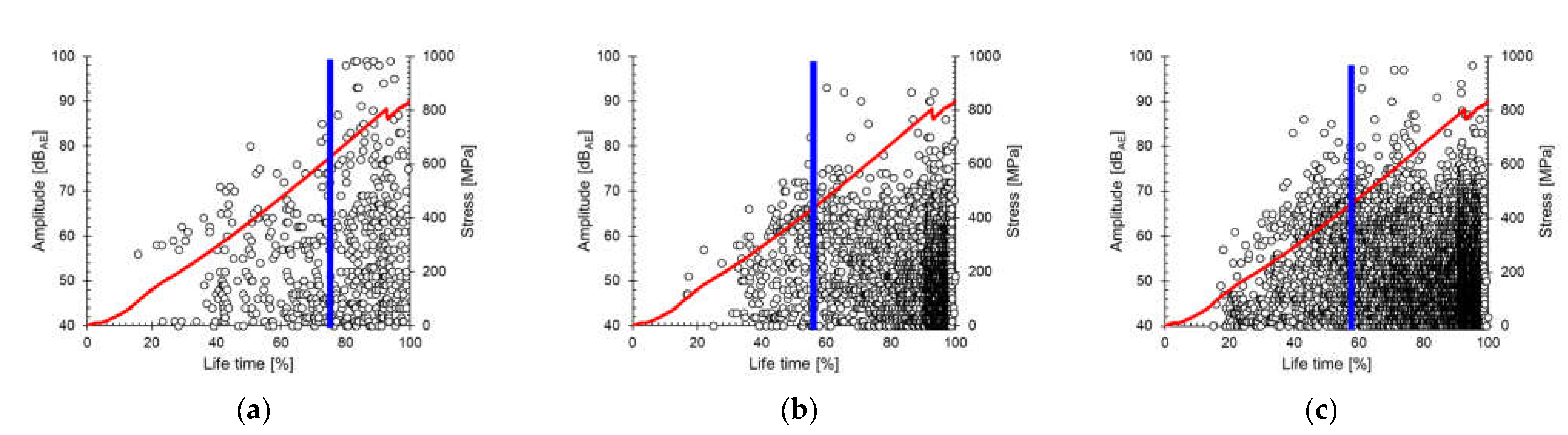

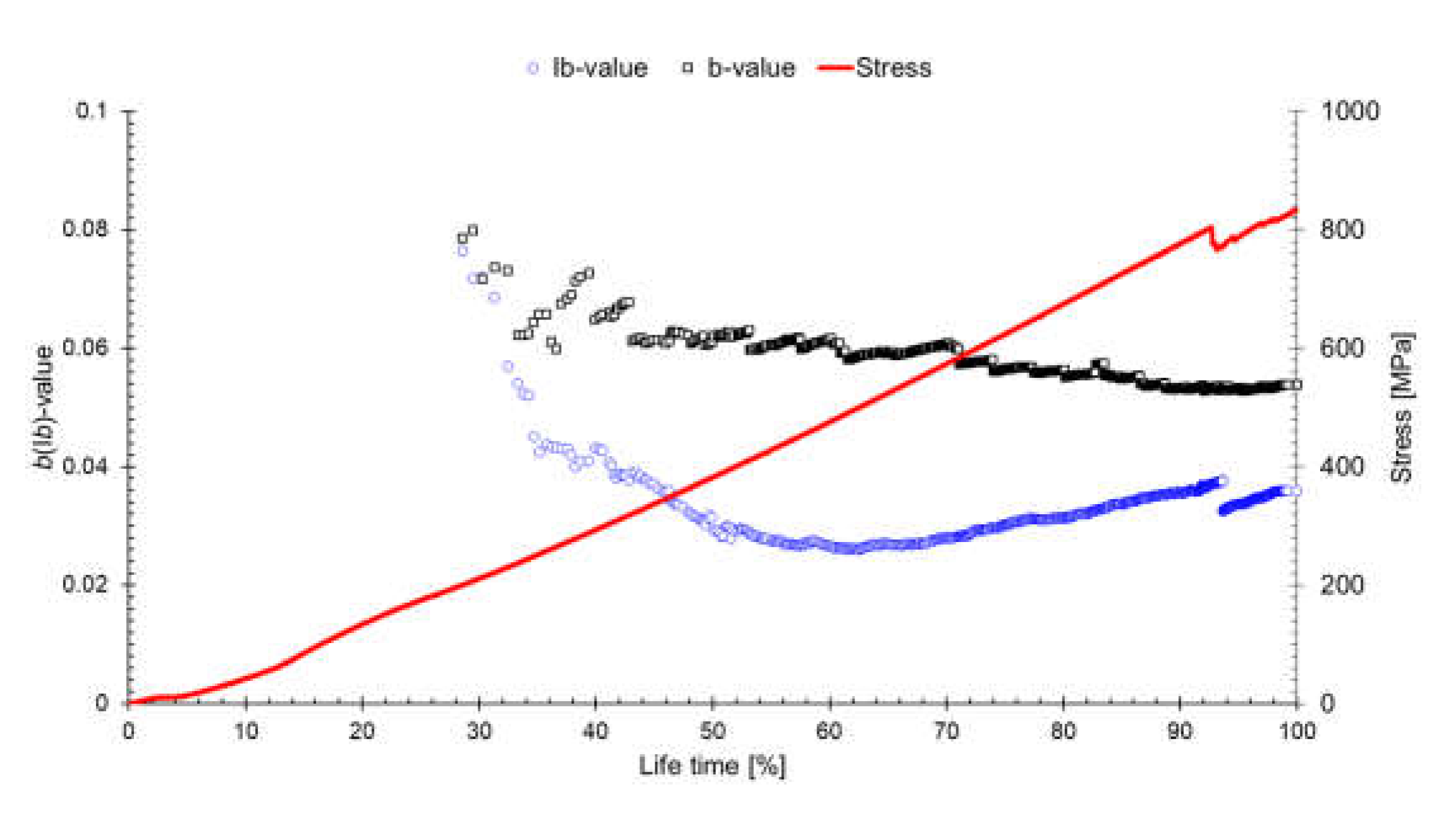

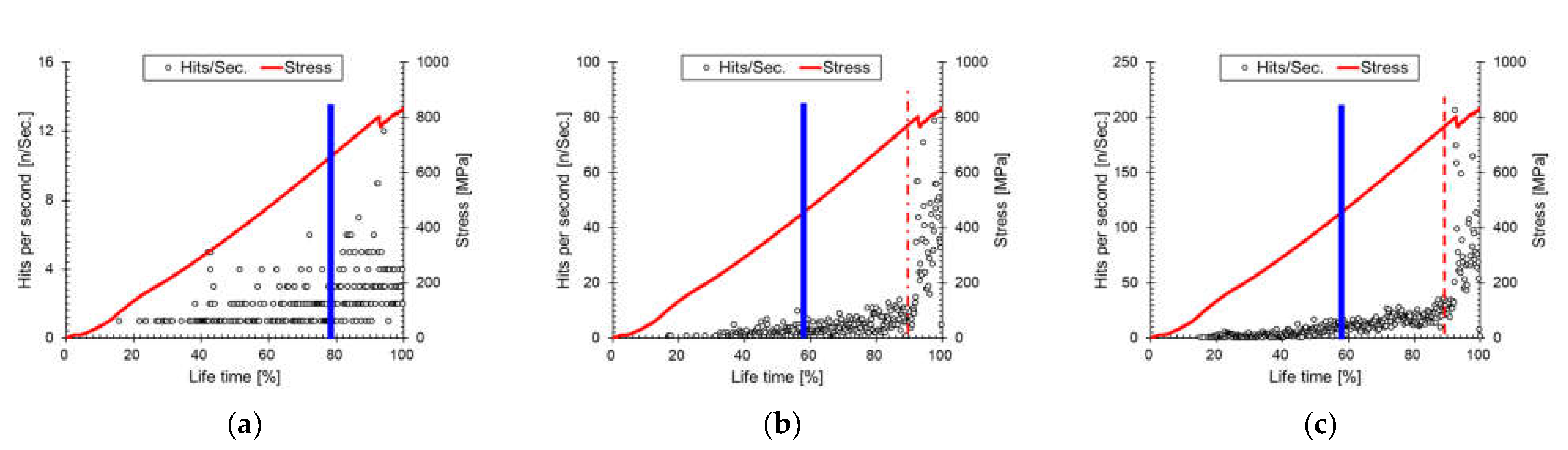

3.1. Classification of Fracture Modes

3.2. Classification of Fracture Modes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chand, S. Carbon fibers for composites. J. Mater. Sci. 2000, 35, 1303–1313. [Google Scholar] [CrossRef]

- Luan, C.; Movva, S.; Wang, K.; Yao, X.; Zhang, C.; Wang, B. Towards next-generation fiber-reinforced polymer composites: A perspective on multifunctionality. Funct. Compos. Struct. 2019, 1, 042002. [Google Scholar] [CrossRef]

- Friedrich, K.M.; Almajid, A.A. Manufacturing Aspects of Advanced Polymer Composites for Automotive Applications. Appl. Compos. Mater. 2012, 20, 107–128. [Google Scholar] [CrossRef]

- Lakshmi, N. Composites Market—Global Forecast To 2024; Marketsandmarkets: Northbrook, IL, USA, 2019. [Google Scholar]

- Pinho, S.; Robinson, P.; Iannucci, L. Fracture toughness of the tensile and compressive fibre failure modes in laminated composites. Compos. Sci. Technol. 2006, 66, 2069–2079. [Google Scholar] [CrossRef]

- Tan, W.; Naya, F.; Yang, L.; Chang, T.; Falzon, B.; Zhan, L.; Molina-Aldareguía, J.; González, C.; Llorca, J. The role of interfacial properties on the intralaminar and interlaminar damage behaviour of unidirectional composite laminates: Experimental characterization and multiscale modelling. Compos. Part B Eng. 2018, 138, 206–221. [Google Scholar] [CrossRef]

- Na, W.; Kwon, D.; Yu, W.-R. X-ray computed tomography observation of multiple fiber fracture in unidirectional CFRP under tensile loading. Compos. Struct. 2018, 188, 39–47. [Google Scholar] [CrossRef]

- Na, W.; Lee, G.; Sung, M.; Han, H.N.; Yu, W.-R. Prediction of the tensile strength of unidirectional carbon fiber composites considering the interfacial shear strength. Compos. Struct. 2017, 168, 92–103. [Google Scholar] [CrossRef]

- Minakuchi, S.; Takeda, N.; Takeda, S.-I.; Nagao, Y.; Franceschetti, A.; Liu, X. Life cycle monitoring of large-scale CFRP VARTM structure by fiber-optic-based distributed sensing. Compos. Part A Appl. Sci. Manuf. 2011, 42, 669–676. [Google Scholar] [CrossRef]

- Friedrich, S.M.; Wu, A.S.; Thostenson, E.T.; Chou, T.-W. Damage mode characterization of mechanically fastened composite joints using carbon nanotube networks. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2003–2009. [Google Scholar] [CrossRef]

- Kordatos, E.; Aggelis, D.; Matikas, T. Monitoring mechanical damage in structural materials using complimentary NDE techniques based on thermography and acoustic emission. Compos. Part B Eng. 2012, 43, 2676–2686. [Google Scholar] [CrossRef]

- LeBlanc, B.; Niezrecki, C.; Avitabile, P.; Chen, J.; Sherwood, J. Damage detection and full surface characterization of a wind turbine blade using three-dimensional digital image correlation. Struct. Health Monit. 2013, 12, 430–439. [Google Scholar] [CrossRef]

- Gan, C.S.; Tan, L.Y.; Chia, C.C.; Mustapha, F.; Lee, J.-R.; Bin Mustapha, F. Nondestructive detection of incipient thermal damage in glass fiber reinforced epoxy composite using the ultrasonic propagation imaging. Funct. Compos. Struct. 2019, 1, 025006. [Google Scholar] [CrossRef]

- Nakamura, H.; Ohtsu, M.; Enoki, M.; Mizutani, Y.; Shigeishi, M.; Inaba, H.; Nakano, M.; Shiotani, T.; Yuyama, S.; Sugimoto, S. Practical Acoustic Emission Testing; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Sause, M.G. In Situ Monitoring of Fiber-Reinforced Composites: Theory, Basic Concepts, Methods, and Applications; Springer: Berlin/Heidelberg, Germany, 2016; Volume 242. [Google Scholar]

- Grosse, C.U.; Ohtsu, M. Acoustic Emission Testing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Ono, K.; Gallego, A. Attenuation of Lamb Waves in CFRP Plates. J. Acoust. Emiss. 2012, 30, 109–124. [Google Scholar]

- Ni, Q.-Q.; Iwamoto, M. Wavelet transform of acoustic emission signals in failure of model composites. Eng. Fract. Mech. 2002, 69, 717–728. [Google Scholar] [CrossRef]

- Suzuki, H.; Kinjo, T.; Hayashi, Y.; Takemoto, M.; Ono, K.; Hayashi, Y. Wavelet transform of acoustic emission signals. J. Acoust. Emiss. 1996, 14, 69–84. [Google Scholar]

- De Groot, P.J.; Wijnen, P.A.; Janssen, R.B. Real-time frequency determination of acoustic emission for different fracture mechanisms in carbon/epoxy composites. Compos. Sci. Technol. 1995, 55, 405–412. [Google Scholar] [CrossRef]

- Godin, N.; Huguet, S.; Gaertner, R.; Salmon, L. Clustering of acoustic emission signals collected during tensile tests on unidirectional glass/polyester composite using supervised and unsupervised classifiers. NDT E Int. 2004, 37, 253–264. [Google Scholar] [CrossRef]

- Ramirez-Jimenez, C.; Papadakis, N.; Reynolds, N.; Gan, T.; Purnell, P.; Pharaoh, M. Identification of failure modes in glass/polypropylene composites by means of the primary frequency content of the acoustic emission event. Compos. Sci. Technol. 2004, 64, 1819–1827. [Google Scholar] [CrossRef]

- Liu, P.; Gu, Z.; Peng, X.; Zheng, J. Finite element analysis of the influence of cohesive law parameters on the multiple delamination behaviors of composites under compression. Compos. Struct. 2015, 131, 975–986. [Google Scholar] [CrossRef]

- Debski, H.; Rozylo, P.; Teter, A. Buckling and limit states of thin-walled composite columns under eccentric load. Thin-Walled Struct. 2020, 149, 106627. [Google Scholar] [CrossRef]

- Gutenberg, B. The energy of earthquakes. Q. J. Geol. Soc. 1956, 112, 1–14. [Google Scholar] [CrossRef]

- Shiotani, T. Evaluation of long-term stability for rock slope by means of acoustic emission technique. NDT E Int. 2006, 39, 217–228. [Google Scholar] [CrossRef]

- Colombo, I.S.; Main, I.G.; Forde, M.C. Assessing Damage of Reinforced Concrete Beam Using “b -value” Analysis of Acoustic Emission Signals. J. Mater. Civ. Eng. 2003, 15, 280–286. [Google Scholar] [CrossRef]

- Jung, D.; Lee, B.-S.; Yu, W.-R.; Na, W. Effect of propagation distance on acoustic emission of carbon fiber/epoxy composites. Struct. Health Monit. 2021. [Google Scholar] [CrossRef]

- Jung, D.Y.; Mizutani, Y.; Todoroki, A.; Suzuki, Y. Frequency Dependence of the b-Value Used for Acoustic Emission Analysis of Glass Fiber Reinforced Plastics. Open J. Compos. Mater. 2017, 7, 117–129. [Google Scholar] [CrossRef][Green Version]

- Jung, D.; Yu, W.-R.; Na, W. Use of acoustic emission b(Ib)-values to quantify damage in composites. Compos. Commun. 2020, 22, 100499. [Google Scholar] [CrossRef]

- Jung, D.; Mizutani, Y.; Todoroki, A.; Na, W. Effect of Ultraviolet Irradiation on the Material Properties and Acoustic Emission of a Fiber-reinforced Composite. Fibers Polym. 2021, 1–10. [Google Scholar] [CrossRef]

- Jiao, J.; He, C.; Wu, B.; Fei, R.; Wang, X. Application of wavelet transform on modal acoustic emission source location in thin plates with one sensor. Int. J. Press. Vessel. Pip. 2004, 81, 427–431. [Google Scholar] [CrossRef]

- Sry, V.; Jung, D.Y.; Mizutani, Y.; Endo, G.; Todoroki, A. Effect of preload treatment on elastic modulus of braided synthetic fiber rope for static loading. J. Text. Inst. 2021, 112, 286–292. [Google Scholar] [CrossRef]

- Rao, M.V.M.S.; Prasanna Lakshmi, K.J. Analysis of b-value and improved b-value of acoustic emissions accompanying rock fracture. Curr. Sci. 2005, 89, 1577–1582. [Google Scholar]

- Garcea, S.; Mavrogordato, M.; Scott, A.; Sinclair, I.; Spearing, S. Fatigue micromechanism characterisation in carbon fibre reinforced polymers using synchrotron radiation computed tomography. Compos. Sci. Technol. 2014, 99, 23–30. [Google Scholar] [CrossRef]

| Stacking Sequence | Matrix Cracking | Interfacial Failure | Fiber Fracture |

|---|---|---|---|

| [90]16 | ○ | × | × |

| [80]16 | ○ | ○ | × |

| [0]8 | ○ | ○ | ○ |

| [0/90]8 | ○ | ○ | ○ |

| Stacking Sequence | Width | Length | Thickness | Center Hole |

|---|---|---|---|---|

| [90]16 | 20 | 200 | 3.6 | 4 |

| [80]16 | 20 | 200 | 3.6 | 4 |

| [0]8 | 16 | 200 | 1.8 | 6 |

| [0/90]8 | 16 | 200 | 1.8 | 6 |

| Parameters | Unit | [90]16 | [80]16 | [0]8 | [0/90]4 |

|---|---|---|---|---|---|

| Total test time | sec | 522 | 581 | 611 | 494 |

| Failure stress | MPa | 16.6 | 22.7 | 1275 | 834 |

| Failure strain | % | 0.87 | 0.97 | 1.01 | 0.82 |

| First AE hit time | sec | 108.72 | 70.61 | 73 | 71.58 |

| Total AE hits | - | 63 | 70 | 5754 | 10,282 |

| Maximum. amplitude | dBAE | 99 | 99 | 99 | 99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, D.; Yu, W.-R.; Na, W. Investigation of Ib-Values for Determining Fracture Modes in Fiber-Reinforced Composite Materials by Acoustic Emission. Materials 2021, 14, 3641. https://doi.org/10.3390/ma14133641

Jung D, Yu W-R, Na W. Investigation of Ib-Values for Determining Fracture Modes in Fiber-Reinforced Composite Materials by Acoustic Emission. Materials. 2021; 14(13):3641. https://doi.org/10.3390/ma14133641

Chicago/Turabian StyleJung, Doyun, Woong-Ryeol Yu, and Wonjin Na. 2021. "Investigation of Ib-Values for Determining Fracture Modes in Fiber-Reinforced Composite Materials by Acoustic Emission" Materials 14, no. 13: 3641. https://doi.org/10.3390/ma14133641

APA StyleJung, D., Yu, W.-R., & Na, W. (2021). Investigation of Ib-Values for Determining Fracture Modes in Fiber-Reinforced Composite Materials by Acoustic Emission. Materials, 14(13), 3641. https://doi.org/10.3390/ma14133641