Simultaneously Enhanced Thermal Conductivity and Breakdown Performance of Micro/Nano-BN Co-Doped Epoxy Composites

Abstract

:1. Introduction

2. Sample Preparation and Experiments

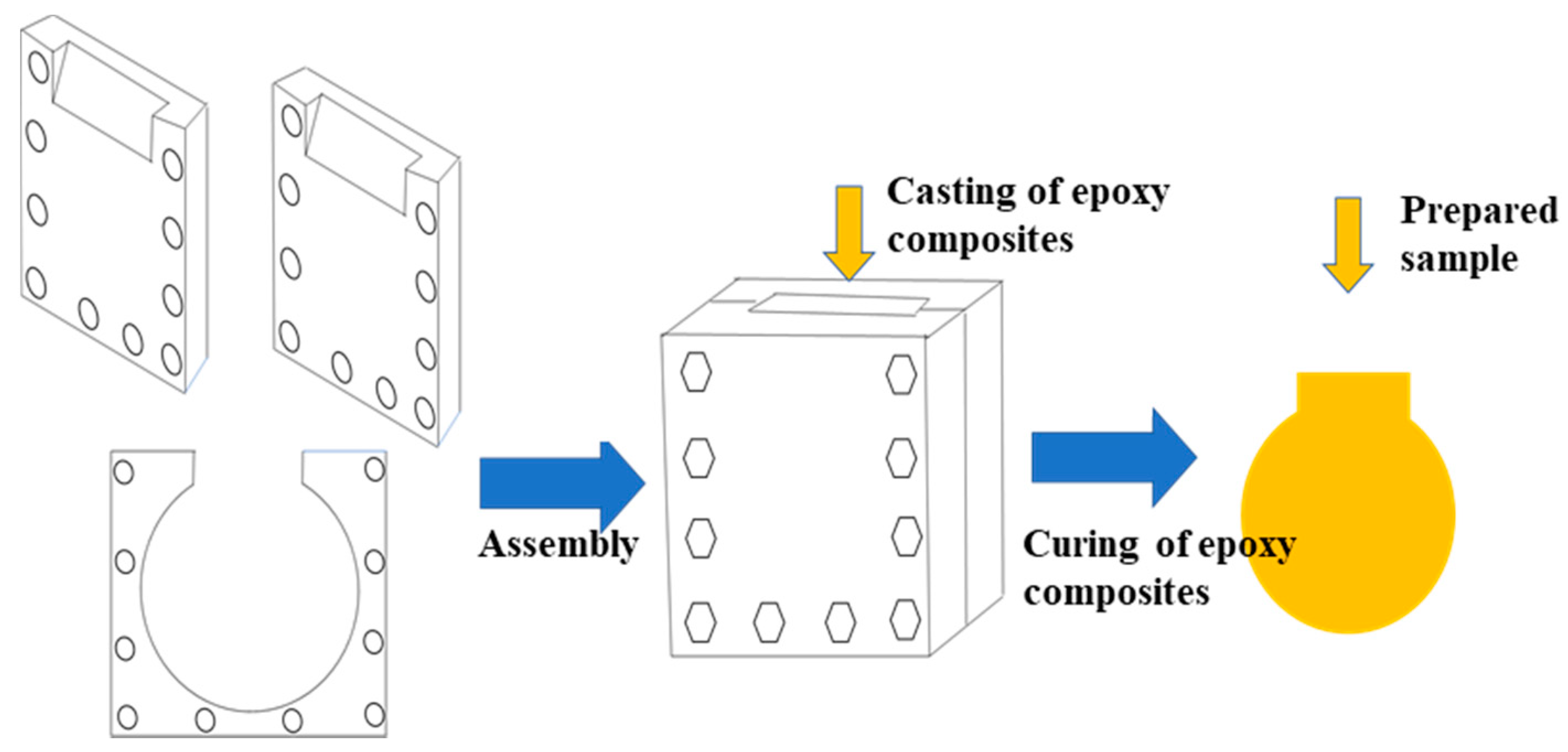

2.1. Sample Preparation

2.2. Experiments

3. Results and Discussions

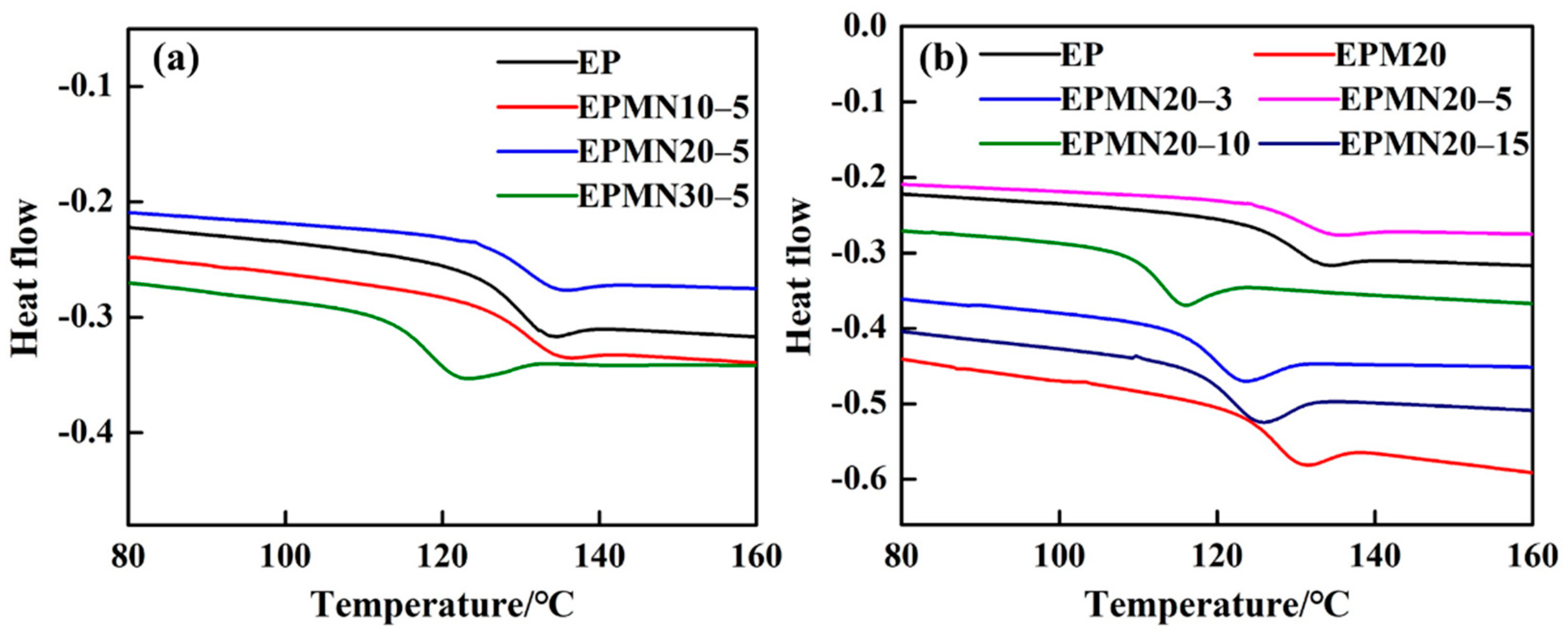

3.1. Effects of Micro/Nano-BN Co-Doping on Microstructure of Epoxy Composites

3.2. Effects of Micro/Nano-BN Co-Doping on Dielectric Properties of Epoxy Composites

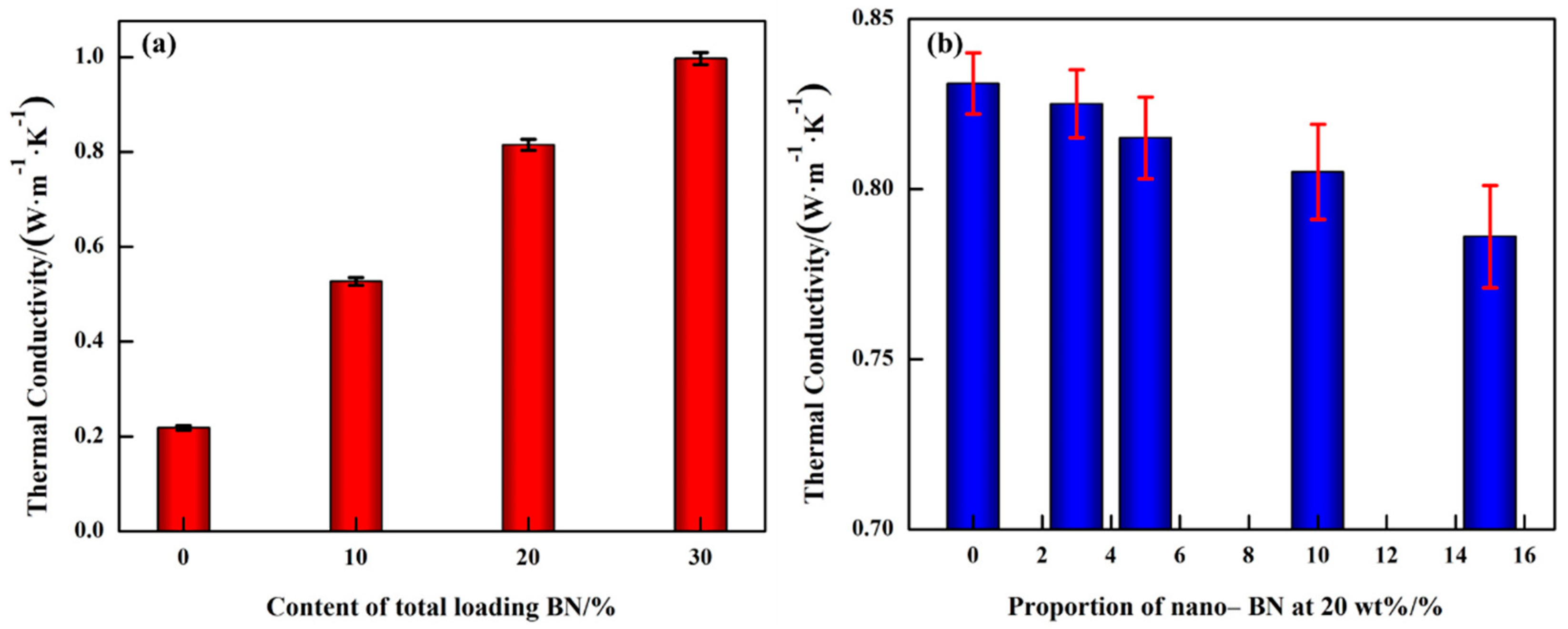

3.3. Effects of Micro/Nano-BN Co-Doping on Thermal Conductivity of Epoxy Composites

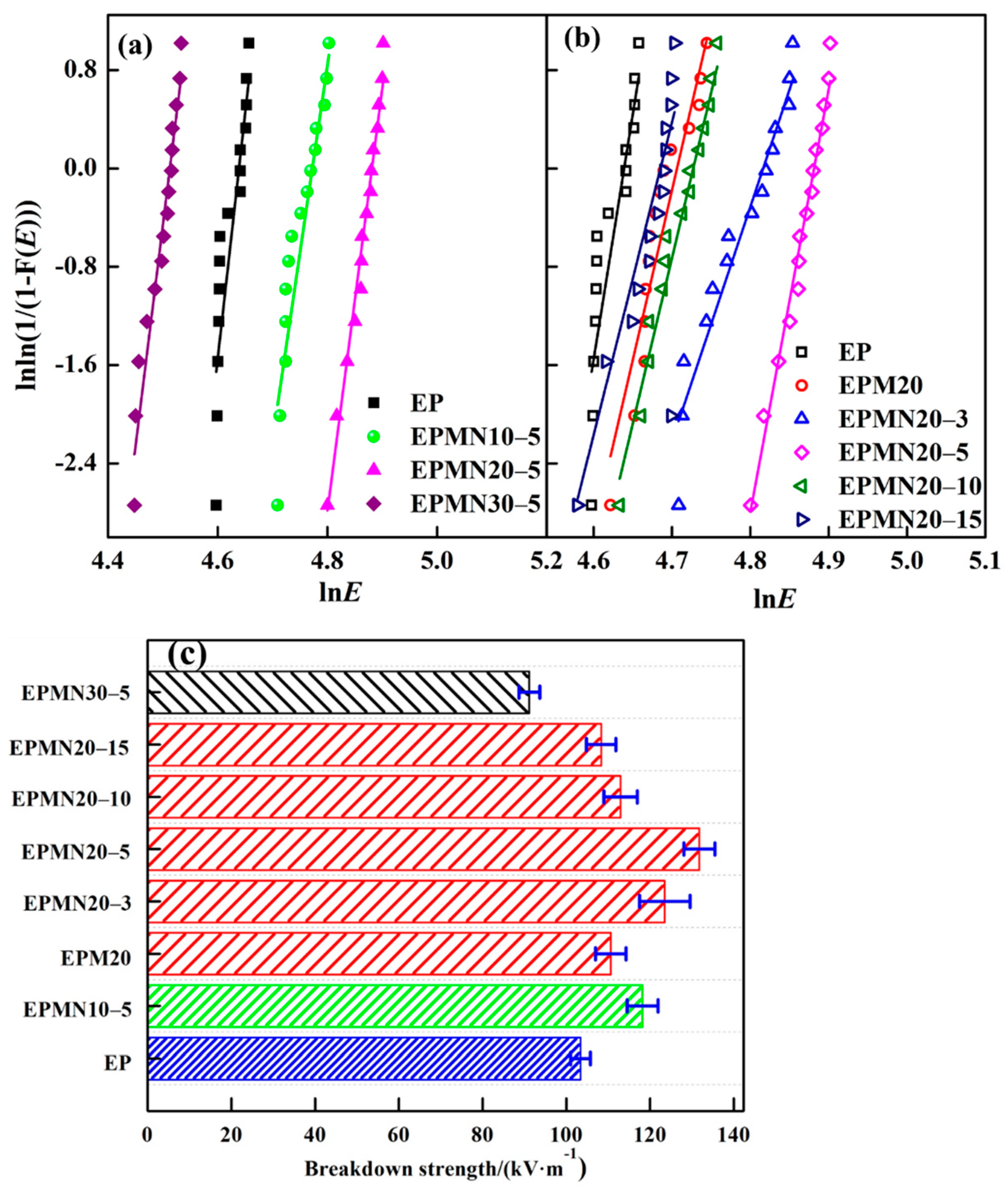

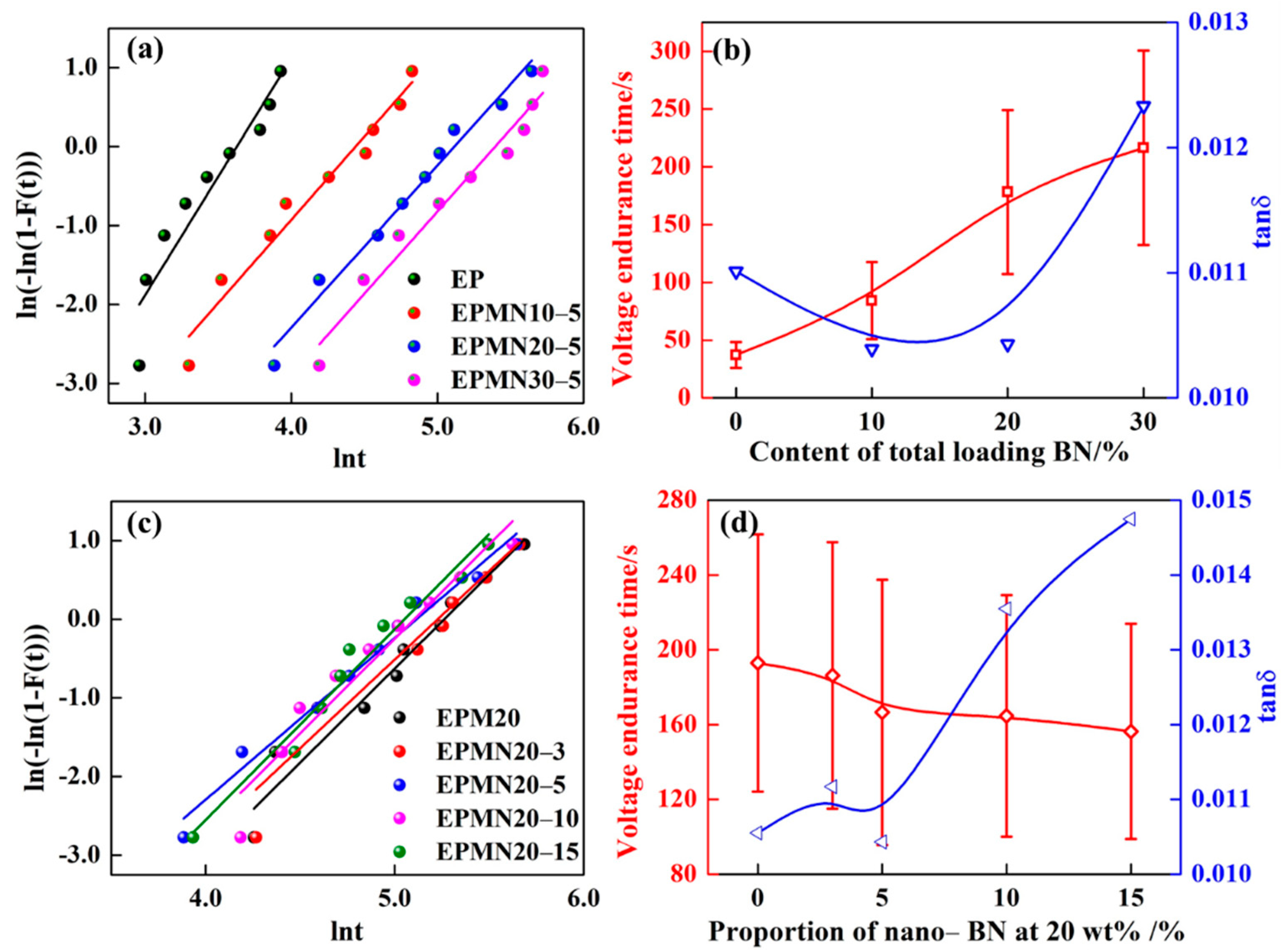

3.4. Effects of Micro/Nano-BN Co-Doping on Breakdown Performance of Epoxy Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- She, X.; Huang, A.Q.; Burgos, R. Review of Solid-State Transformer Technologies and Their Application in Power Distribution Systems. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 186–198. [Google Scholar] [CrossRef]

- Wang, D.; Tian, J.; Mao, C.; Lu, J.; Duan, Y.; Qiu, J.; Cai, H. A 10-kV/400-V 500-kVA Electronic Power Transformer. IEEE Trans. Ind. Electron. 2016, 63, 6653–6663. [Google Scholar] [CrossRef]

- Eslamian, M.; Vahidi, B. Thermal analysis of cast-resin dry-type transformers. Energy Convers. Manag. 2011, 52, 2479–2488. [Google Scholar] [CrossRef]

- Eslamian, M.; Vahidi, B.; Hosseinian, S.H. Analytical calculation of detailed model parameters of cast resin dry-type transformers. Energy Convers. Manag. 2011, 52, 2565–2574. [Google Scholar] [CrossRef]

- Xiao, M.; Du, B.X. Effects of High Thermal Conductivity on Temperature Rise of Epoxy Cast Windings for Power Transformer. IEEE Dielectr. Electr. Insul. 2016, 23, 2413–2420. [Google Scholar] [CrossRef]

- Du, B.X.; Xiao, M. Thermal Accumulation and Tracking Failure Process of BN-filler Epoxy-matrix Composite. IEEE Dielectr. Electr. Insul. 2013, 20, 2270–2276. [Google Scholar] [CrossRef]

- Mo, H.; Huang, X.; Liu, F.; Yang, K.; Li, S.T.; Jiang, P.K. Nanostructured electrical insulating epoxy thermosets with high thermal conductivity, high thermal stability, high glass transition temperatures and excellent dielectric properties. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 906–915. [Google Scholar] [CrossRef]

- Wang, S.H.; Yu, S.H.; Li, J.Y.; Li, S.T. Effects of Functionalized Nano-TiO2 on the Molecular Motion in Epoxy Resin-Based Nanocomposites. Materials 2020, 13, 163. [Google Scholar] [CrossRef] [Green Version]

- Wu, K.; Wang, Z.; Zhao, C.; Huang, Y.W.; Li, J.Y.; Li, S.T. Surface treeing and segmented worm model of tracking behavior in MgO/Epoxy nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2067–2075. [Google Scholar] [CrossRef]

- Li, S.; Huang, Y.; Min, D.; Qu, G.; Niu, H.; Li, Z.; Wang, W.W.; Li, J.Y.; Liu, W.F. Synergic effect of adsorbed gas and charging on surface flashover. Sci. Rep. 2019, 9, 5464. [Google Scholar] [CrossRef]

- Kusunose, T.; Yagi, T.; Firoz, S.H.; Sekino, T. Fabrication of epoxy/silicon nitride nanowire composites and evaluation of their thermal conductivity. J. Mater. Chem. A 2013, 1, 3440–3445. [Google Scholar] [CrossRef]

- Taheri, S.; Gholami, A.; Fofana, I.; Taheri, H. Modeling and simulation of transformer loading capability and hot spot temperature under harmonic conditions. Electr. Power Syst. Res. 2012, 86, 68–75. [Google Scholar] [CrossRef]

- Shi, J.J.; Gou, W.; Yuan, H.; Zhao, T.; Huang, A.Q. Research on Voltage and Power Balance Control for Cascaded Modular Solid-State Transformer. IEEE Trans. Power Electron. 2011, 26, 1154–1166. [Google Scholar] [CrossRef]

- Gong, Y.; Zhou, W.Y.; Kou, Y.J.; Xu, L.; Wu, H.; Zhao, W. Heat conductive h-BN/CTPB/epoxy with enhanced dielectric properties for potential high-voltage applications. High Volt. 2017, 2, 172–178. [Google Scholar] [CrossRef]

- Shigue, C.Y.; Santos, R.G.; Baldan, C.A.; Ruppert-Filho, E. Monitoring the epoxy curing by the dielectric thermal analysis method. IEEE Trans. Appl. Supercond. 2004, 14, 1173–1176. [Google Scholar] [CrossRef]

- Pathumudy, R.D.; Prabhu, K.N. Thermal interface materials for cooling microelectronic systems: Present status and future challenges. J. Mater. Sci. Mater. Electron. 2021, 32, 1–28. [Google Scholar] [CrossRef]

- Zou, D.X.; Huang, X.Y.; Zhu, Y.K.; Chen, J.; Jiang, P. Boron nitride nanosheets endow the traditional dielectric polymer composites with advanced thermal management capability. Compos. Sci. Technol. 2019, 177, 88–95. [Google Scholar] [CrossRef]

- Gao, D.; Yu, L.; Li, M.; Wang, S.; Dai, Y. Thermal conductive epoxy adhesive with binary filler system of surface modified hexagonal boron nitride and α-aluminum oxide. J. Mater. Sci. Mater. Electron. 2020, 31, 14681–14690. [Google Scholar] [CrossRef]

- Liu, X.M.; Xiao, M.; Du, B.X.; Chen, L.; Zhang, J.; Gong, Z.; Wu, Y.X.; Li, J.; Wang, Y.N.; Cao, J.M. Thermal and Electrical Properties of Nanoparticle Oriented Epoxy/BN/SiC Composites for Superconducting Magnet. IEEE Trans. Appl. Supercond. 2019, 29, 4900805. [Google Scholar] [CrossRef]

- Xiao, H.; Chen, F.; Zhang, Z.P.; Ming, Z.R.; Zhang, Q. Dihydromyricetin modification of boron nitride micro-sheets and construction of multilayer thermal conduction pathways in glass fiber reinforced epoxy composites. Compos. Part B Eng. 2021, 215, 108770. [Google Scholar] [CrossRef]

- Wang, Z.; Meng, G.; Wang, L.; Tian, L.; Chen, S.; Wu, G.; Kong, B.; Cheng, Y.H. Simultaneously enhanced dielectric properties and through-plane thermal conductivity of epoxy composites with alumina and boron nitride nanosheets. Sci. Rep. 2021, 11, 2495. [Google Scholar] [CrossRef]

- Han, Y.; Shi, X.; Yang, X.; Guo, Y.; Zhang, J.; Kong, J.; Gu, J.W. Enhanced thermal conductivities of epoxy nanocomposites via incorporating in-situ fabricated hetero-structured SiC-BNNS fillers. Compos. Sci. Technol. 2020, 187, 107944. [Google Scholar] [CrossRef]

- Weng, L.; Wang, H.B.; Zhang, X.R.; Liu, L.; Zhang, H. Preparation and properties of boron nitride/epoxy composites with high thermal conductivity and electrical insulation. J. Mater. Sci. Mater. Electron. 2018, 29, 14267–14276. [Google Scholar] [CrossRef]

- Roy, M.; Nelson, J.K.; Reed, C.W.; Schadler, L.S.; Reed, C.W.; Keefe, R. Polymer nanocomposite dielectrics—The role of the interface. IEEE Dielectr. Electr. Insul. 2005, 12, 1273. [Google Scholar] [CrossRef]

- Tanaka, T.; Kozako, M.; Fuse, N.; Ohki, Y. Proposal of a multi-core model for polymer nanocomposite dielectrics. IEEE Dielectr. Electr. Insul. 2005, 12, 669–681. [Google Scholar] [CrossRef]

- Tian, F.Q.; Lei, Q.Q.; Wang, X.; Wang, Y. Investigation of Electrical Properties of LDPE/ZnO Nanocomposite Dielectrics. IEEE Dielectr. Electr. Insul. 2012, 19, 763–769. [Google Scholar] [CrossRef]

- Ferreira, A.; Cardoso, P.; Klosterman, D.; Covas, J.A.; Hattum, J.; Vaz, F.; Lanceros-Mendez, S. Effect of filler dispersion on the electromechanical response of epoxy/vapor-grown carbon nanofiber composites. Smart Mater. Struct. 2012, 21, 075008. [Google Scholar] [CrossRef]

- Wang, Z.; Iizuka, T.; Kozako, M.; Ohki, Y.; Tanaka, T. Development of epoxy/BN composites with high thermal conductivity and sufficient dielectric breakdown strength partI—Sample preparations and thermal conductivity. IEEE Dielectr. Electr. Insul. 2011, 18, 1963–1972. [Google Scholar] [CrossRef]

- Sliozberg, Y.; Andzelm, J.; Hatter, C.B.; Anasoric, B.; Gogotsib, Y.; Halla, A. Interface binding and mechanical properties of MXene-epoxy nanocomposites. Compos. Sci. Technol. 2020, 192, 108124. [Google Scholar] [CrossRef]

- Kochetov, R.; Andritsch, T.; Morshuis, P.H.; Smit, J.J. Anomalous Behaviour of the Dielectric Spectroscopy Response of Nanocomposites. IEEE Dielectr. Electr. Insul. 2012, 19, 107–117. [Google Scholar] [CrossRef]

- Jang, I.; Shin, K.H.; Yang, I.; Kim, H.; Kim, J.; Kim, W.; Jeon, S.; Kim, J. Enhancement of thermal conductivity of BN/epoxy composite through surface modification with silane coupling agents. Colloids Surf. A 2017, 518, 64–72. [Google Scholar] [CrossRef]

- Fang, L.J.; Wu, C.; Qian, R.; Xie, L.; Yang, K.; Jiang, P. Nano-micro structure of functionalized boron nitride and aluminum oxide for epoxy composites with enhanced thermal conductivity and breakdown strength. RSC Adv. 2014, 4, 21010–21017. [Google Scholar] [CrossRef]

- Jonscher, A.K. Dielectric relaxation in solids. J. Phys. D Appl. Phys. 1999, 32, 57–70. [Google Scholar] [CrossRef]

- Jonscher, A.K. A new understanding of the dielectric relaxation of solids. J. Mater. Sci. 1981, 16, 2037–2060. [Google Scholar] [CrossRef]

- Dai, C.; Chen, X.; Wang, Q.; Awais, M.; Zhu, G.; Shi, Y.; Paramane, A.; Tanaka, Y. Electrical and thermal performances of epoxy-based micro–nano hybrid composites at different electric fields and temperatures. Nanotechnology 2021, 32, 315715. [Google Scholar] [CrossRef]

- Tang, Y.; Ge, G.; Li, Y.; Huang, L. Effect of Al2O3 with different nanostructures on the insulating properties of epoxy-based composites. Materials 2020, 13, 4235. [Google Scholar] [CrossRef]

- Chen, C.; Xue, Y.; Li, X.; Wen, Y.; Liu, J.; Xue, Z.; Shi, D.; Zhou, X.; Xie, X.; Mai, Y. High-performance epoxy/binary spherical alumina composite as underfill material for electronic packaging. Compos. Part A Appl. Sci. Manuf. 2019, 118, 67–74. [Google Scholar] [CrossRef]

- Huang, X.Y.; Zheng, Y.; Jiang, P. Influence of nanoparticle surface treatment on the electrical properties of cycloaliphatic epoxy nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 635. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Li, S.; Akram, S.; Mehmood, M.; Yeoh, G.; Hussain, S. Effect of micro-nano additives on breakdown, surface tracking and mechanical performance of ethylene propylene diene monomer for high voltage insulation. J. Mater. Sci. Mater. Electron. 2019, 30, 14061–14071. [Google Scholar] [CrossRef]

- Jin, W. Dielectric Physics [M], 2nd ed.; China Machine Press: Beijing, China, 1997. (In Chinese) [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Xiang, J.; Wang, S.; Yan, Z.; Cheng, Z.; Fu, H.; Li, J. Simultaneously Enhanced Thermal Conductivity and Breakdown Performance of Micro/Nano-BN Co-Doped Epoxy Composites. Materials 2021, 14, 3521. https://doi.org/10.3390/ma14133521

Zhang C, Xiang J, Wang S, Yan Z, Cheng Z, Fu H, Li J. Simultaneously Enhanced Thermal Conductivity and Breakdown Performance of Micro/Nano-BN Co-Doped Epoxy Composites. Materials. 2021; 14(13):3521. https://doi.org/10.3390/ma14133521

Chicago/Turabian StyleZhang, Chuang, Jiao Xiang, Shihang Wang, Zhimin Yan, Zhuolin Cheng, Hang Fu, and Jianying Li. 2021. "Simultaneously Enhanced Thermal Conductivity and Breakdown Performance of Micro/Nano-BN Co-Doped Epoxy Composites" Materials 14, no. 13: 3521. https://doi.org/10.3390/ma14133521

APA StyleZhang, C., Xiang, J., Wang, S., Yan, Z., Cheng, Z., Fu, H., & Li, J. (2021). Simultaneously Enhanced Thermal Conductivity and Breakdown Performance of Micro/Nano-BN Co-Doped Epoxy Composites. Materials, 14(13), 3521. https://doi.org/10.3390/ma14133521