Mechanical and Microstructural Characteristics of Calcium Sulfoaluminate Cement Exposed to Early-Age Carbonation Curing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

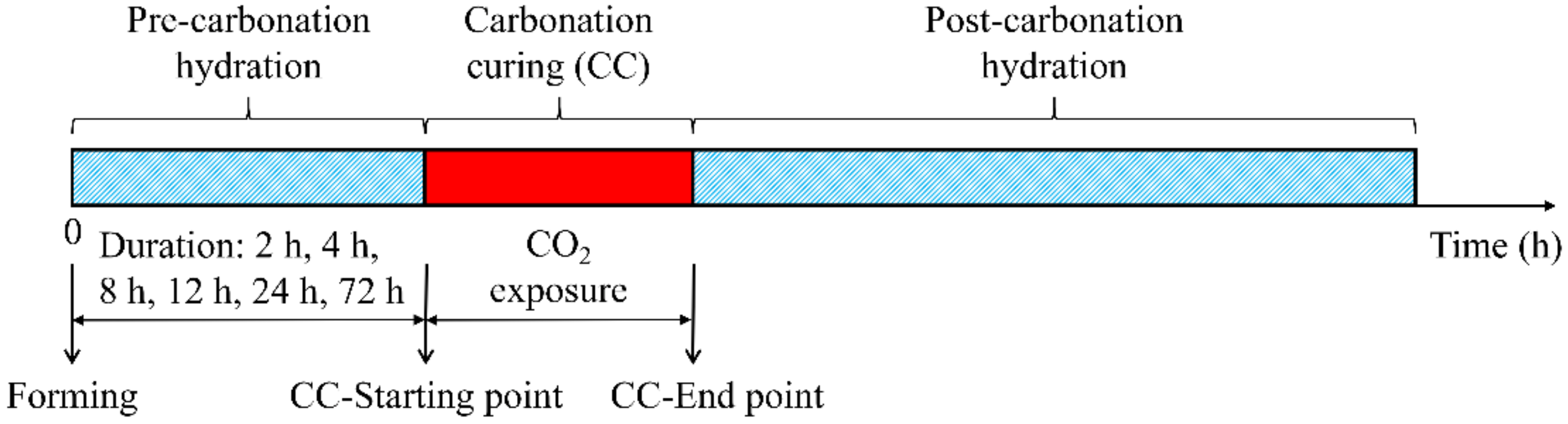

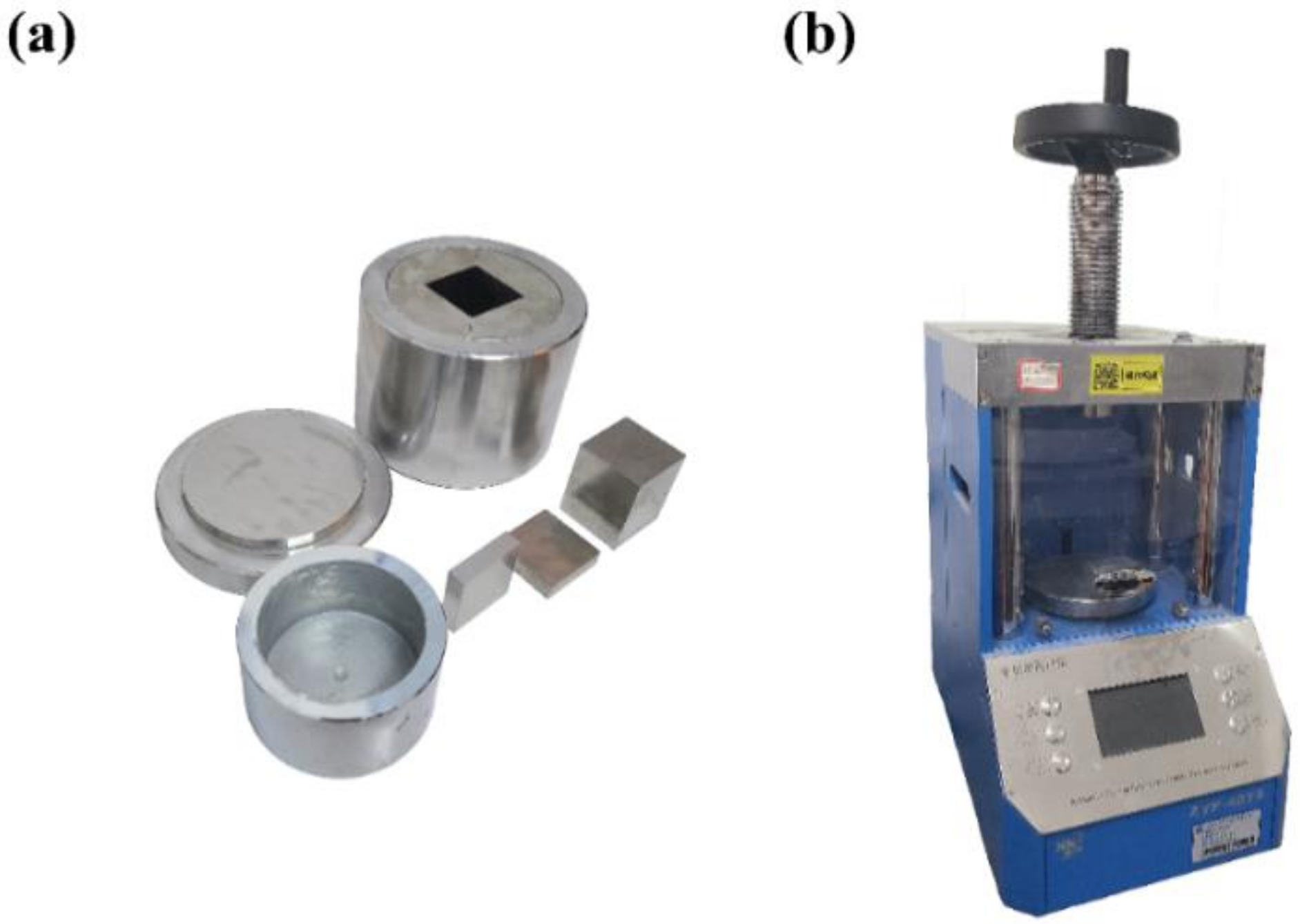

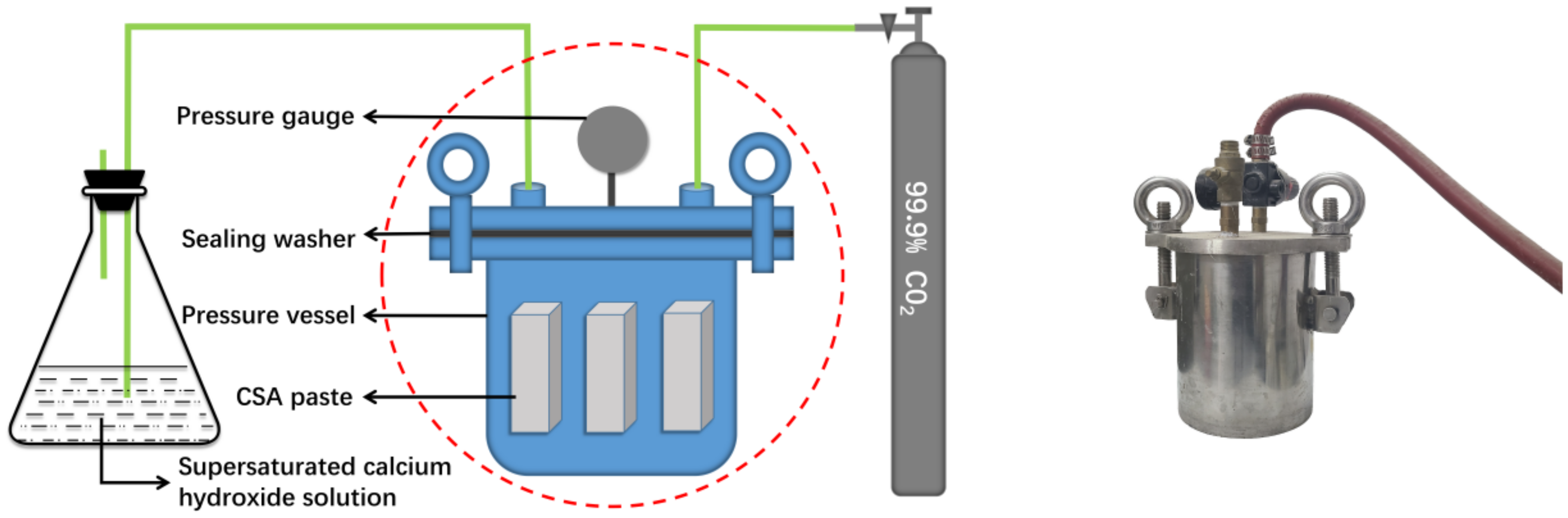

2.2. Test Methods and Sample Preparation

3. Results and Discussion

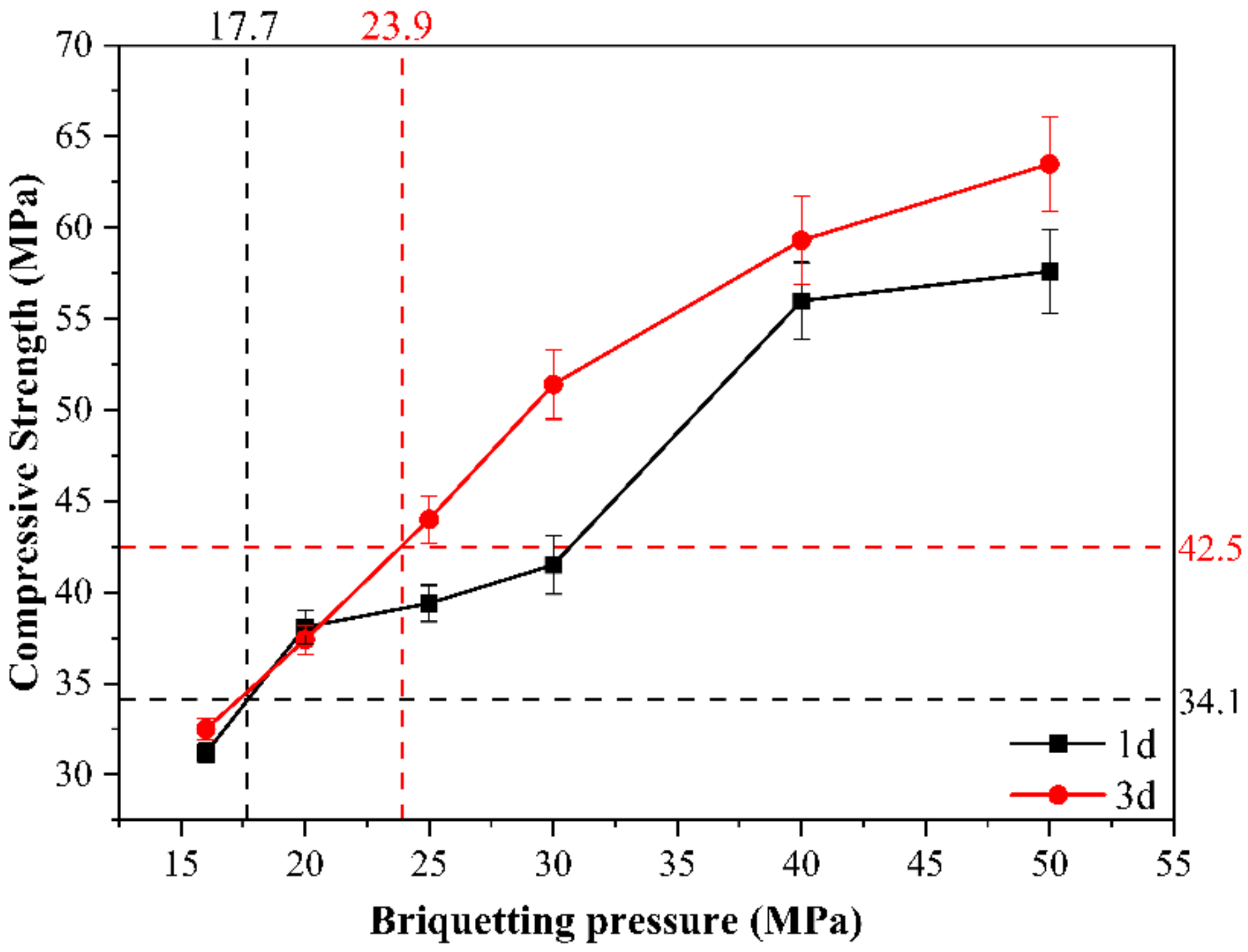

3.1. Briquetting Pressure

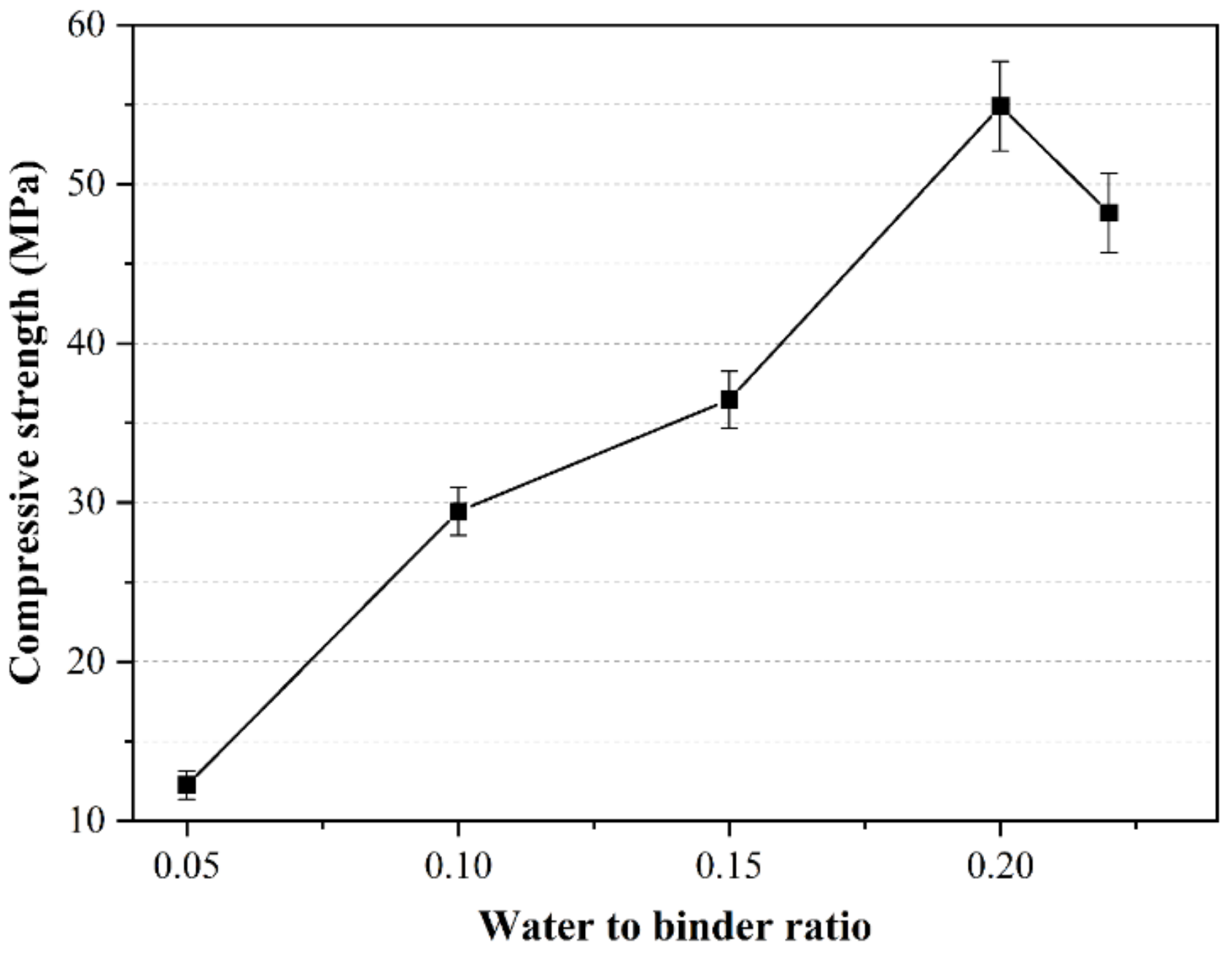

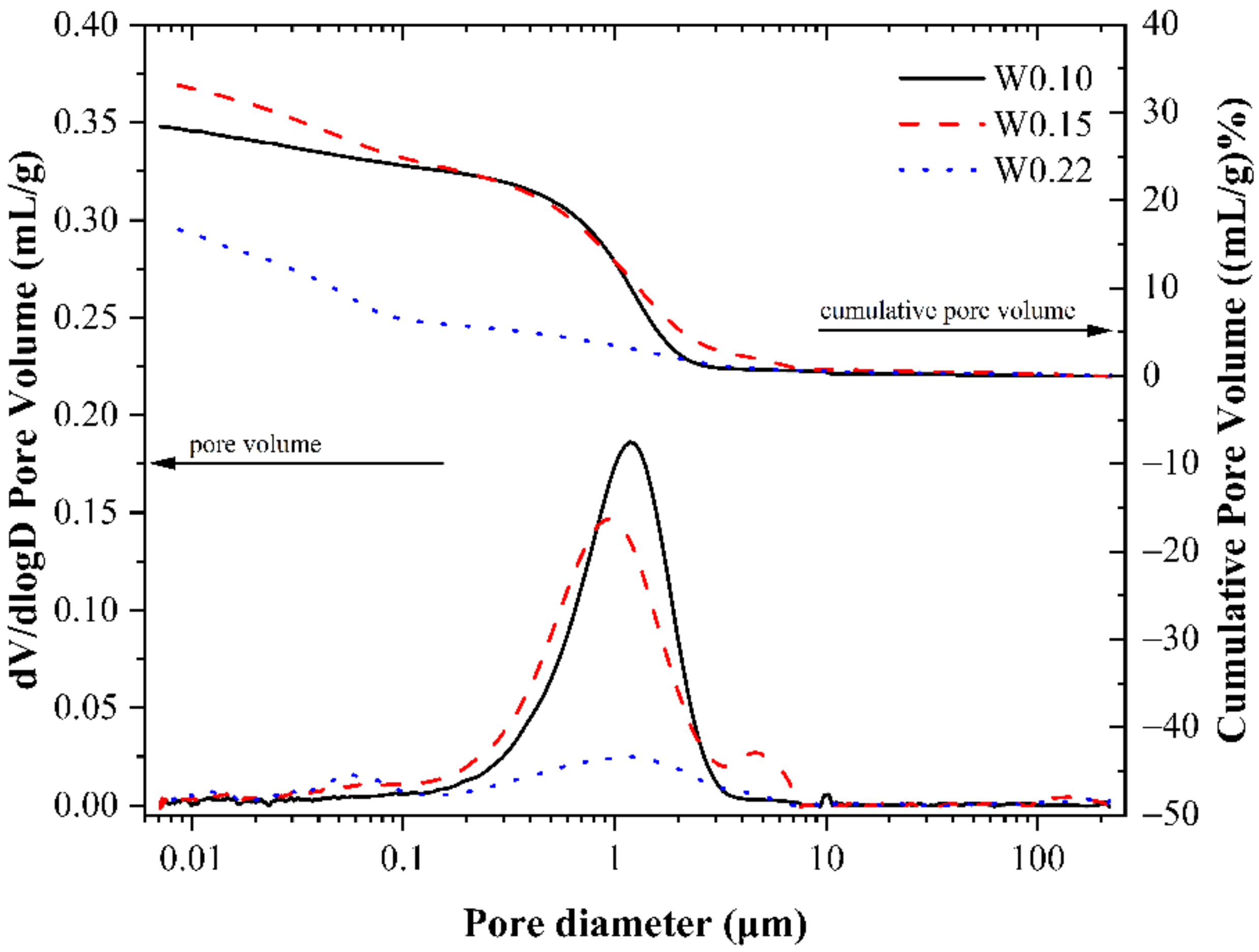

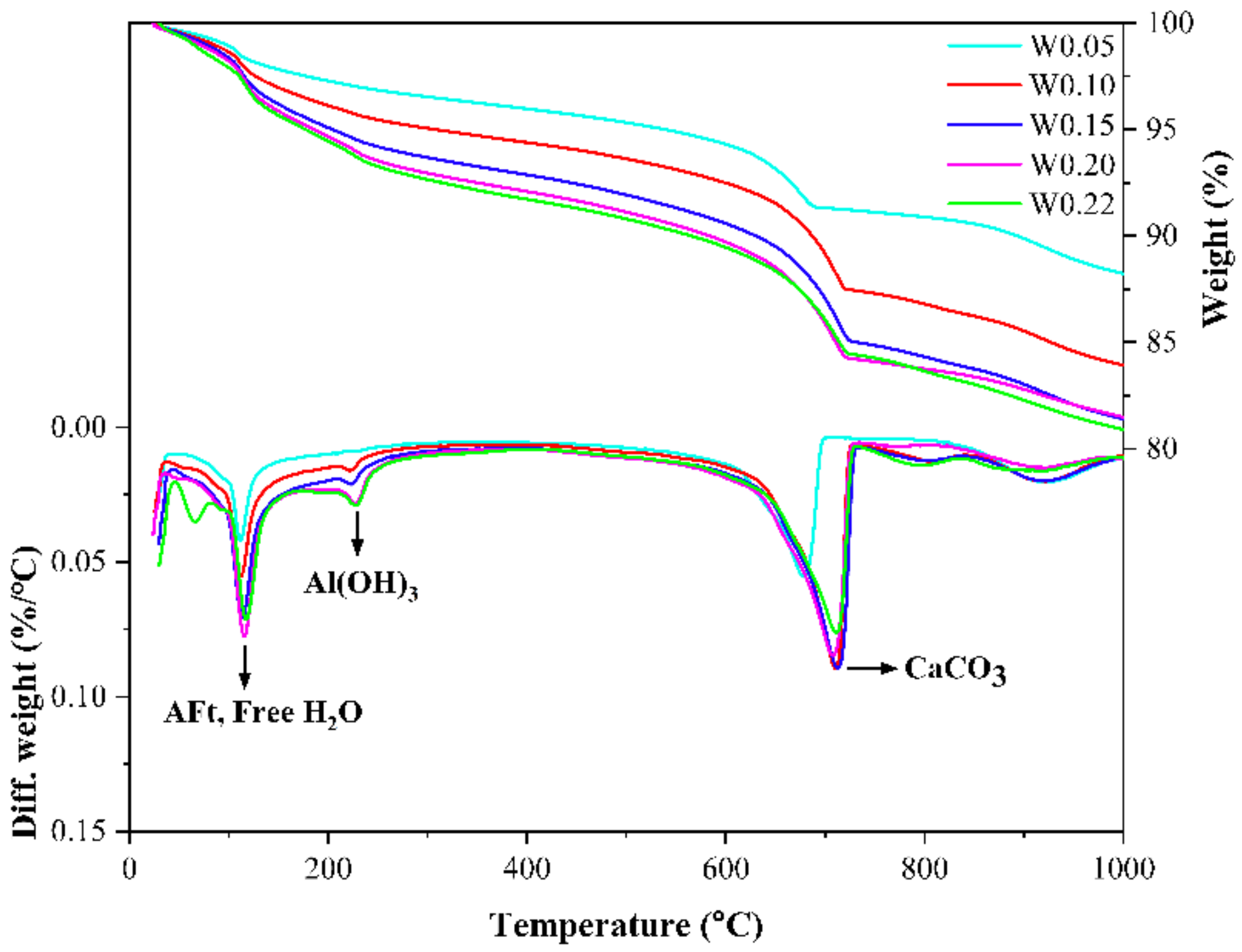

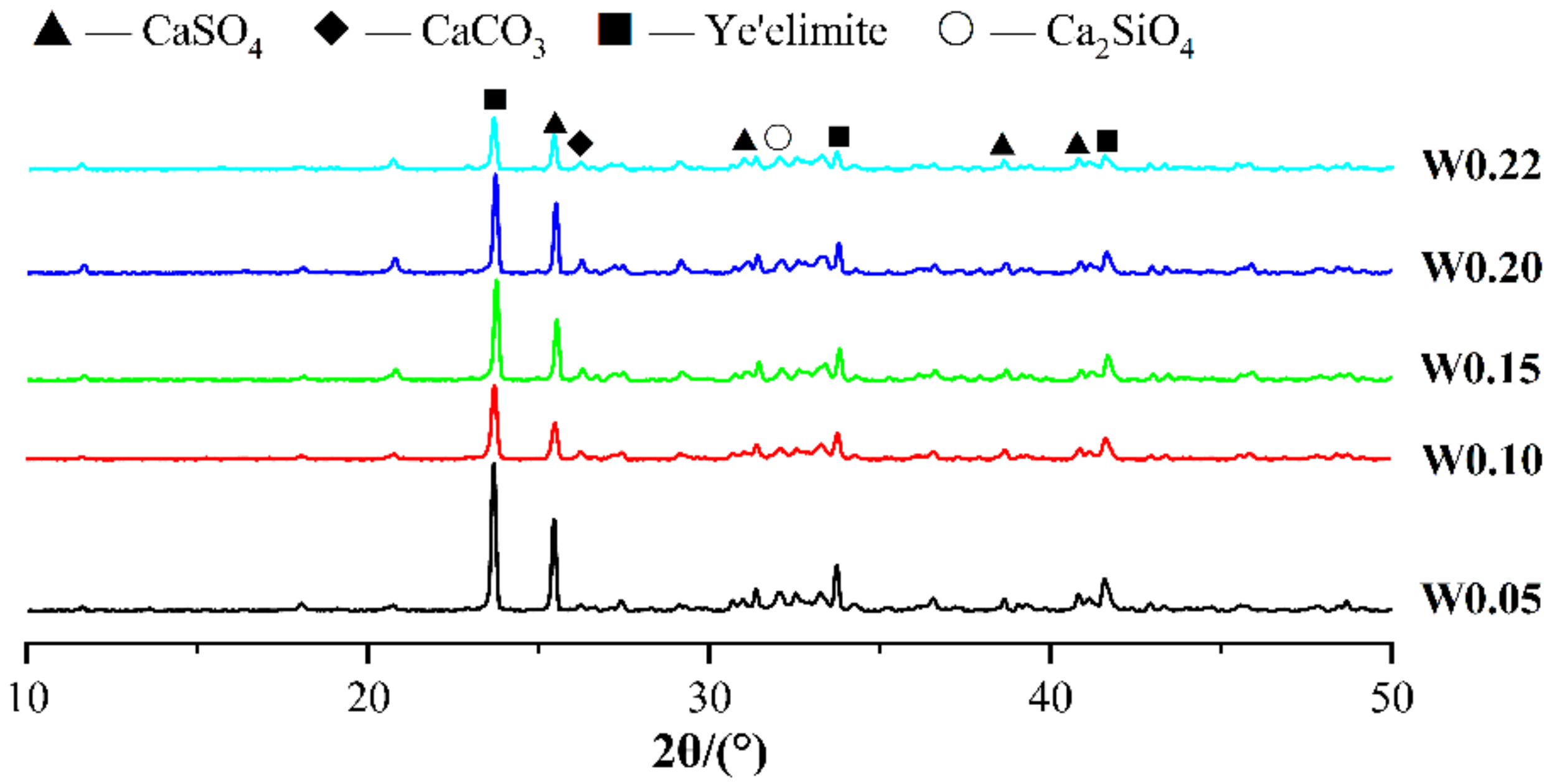

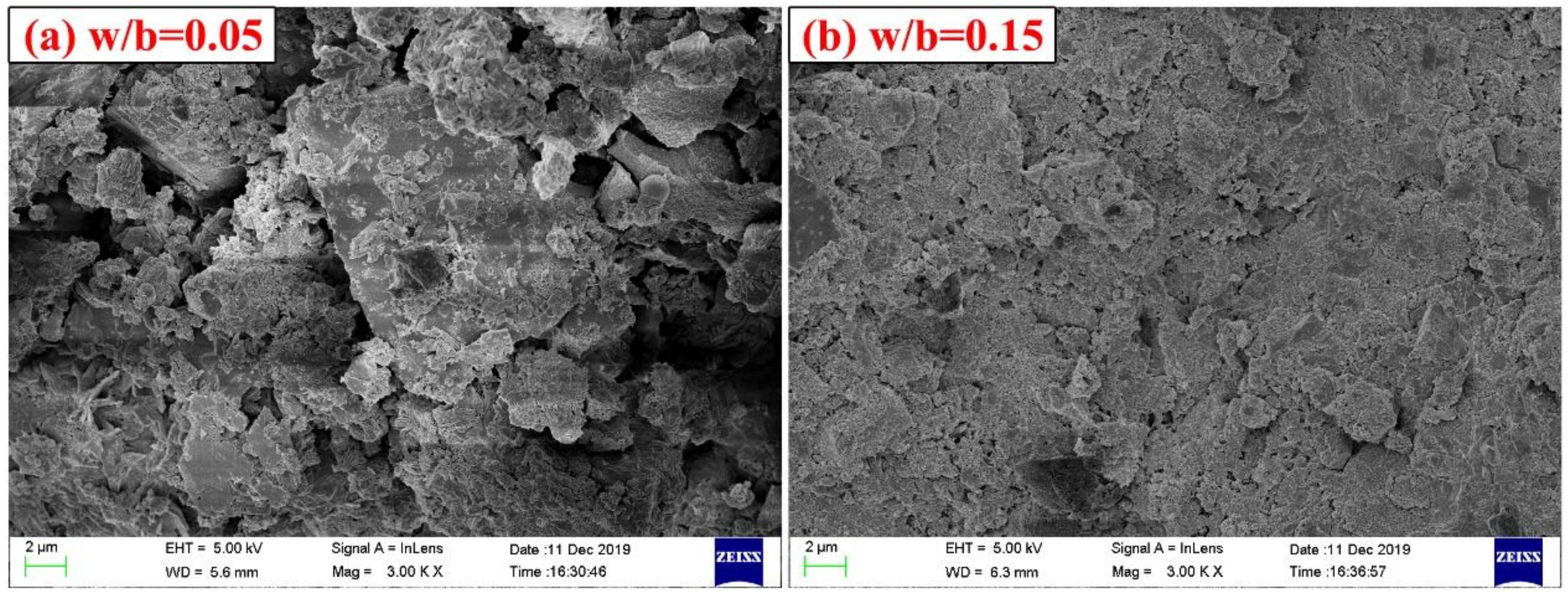

3.2. Water-to-Binder Ratio

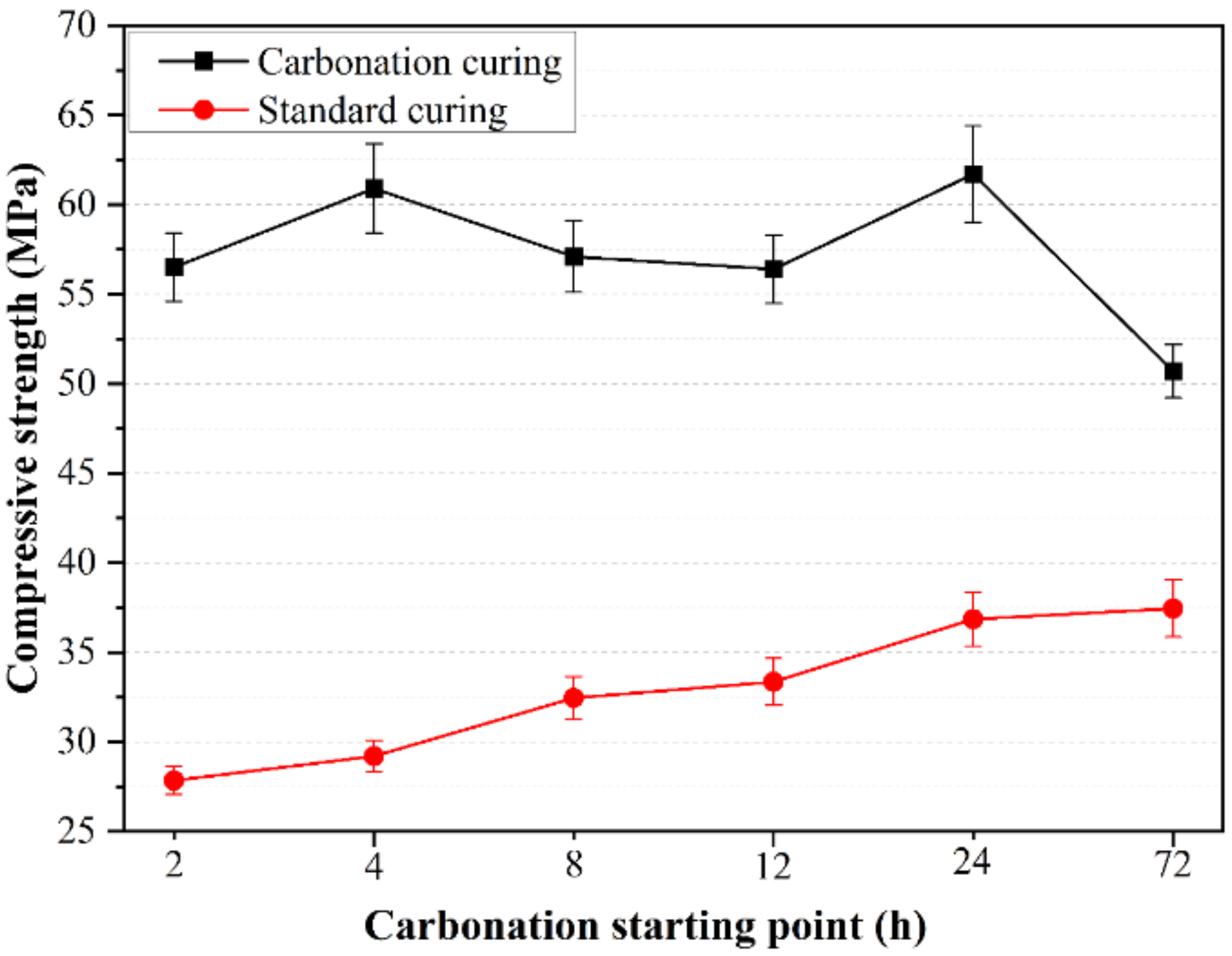

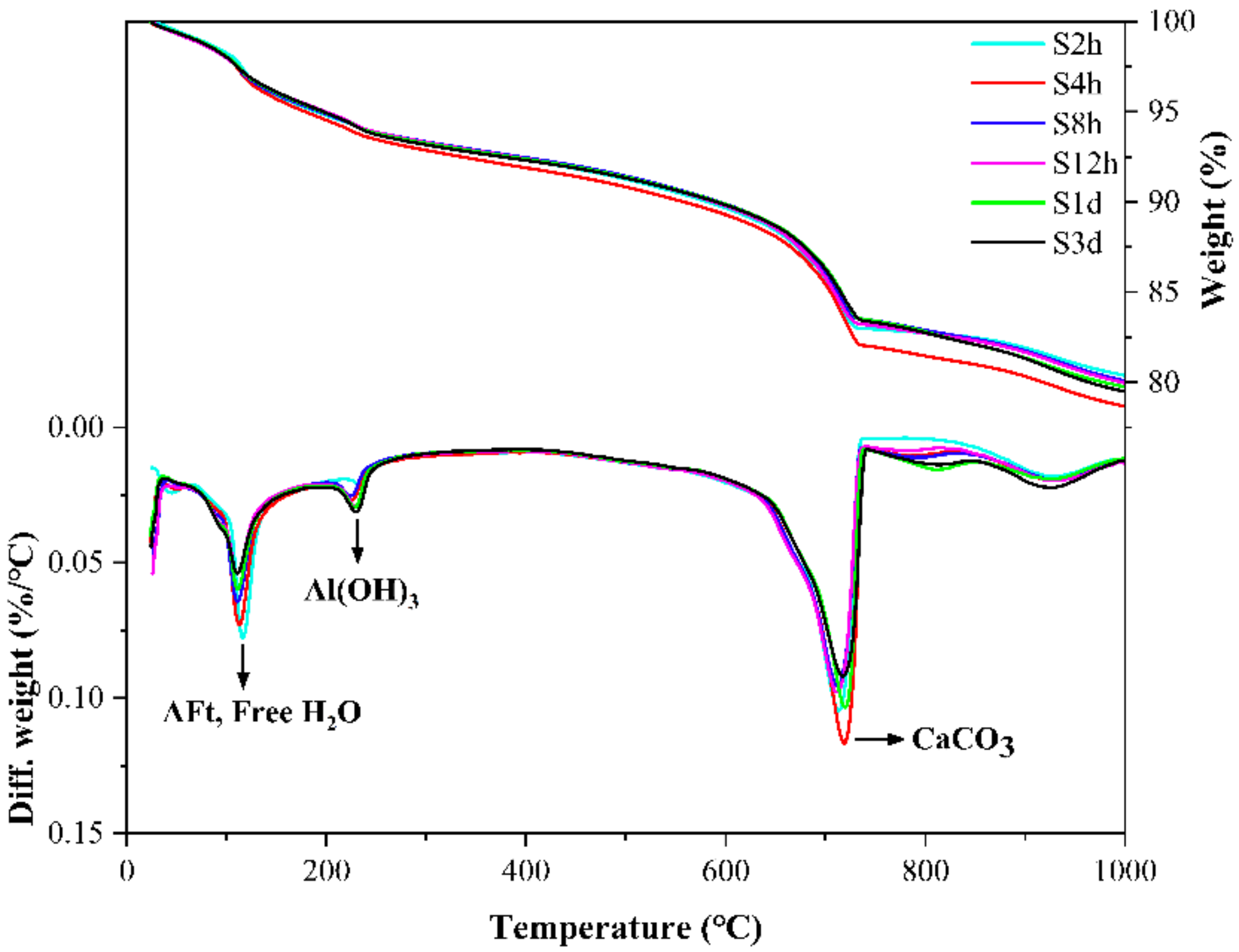

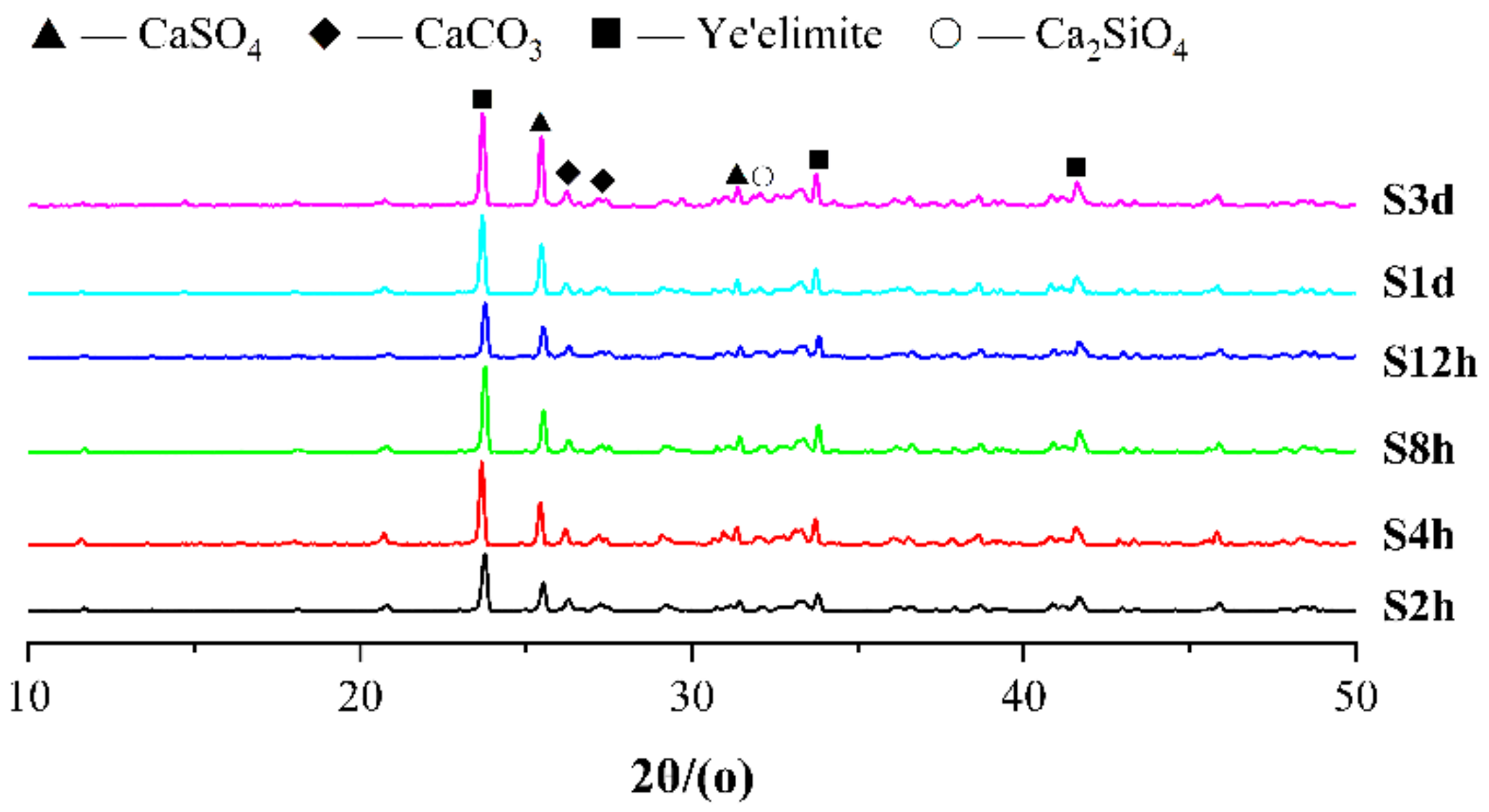

3.3. Carbonation Starting Time Point

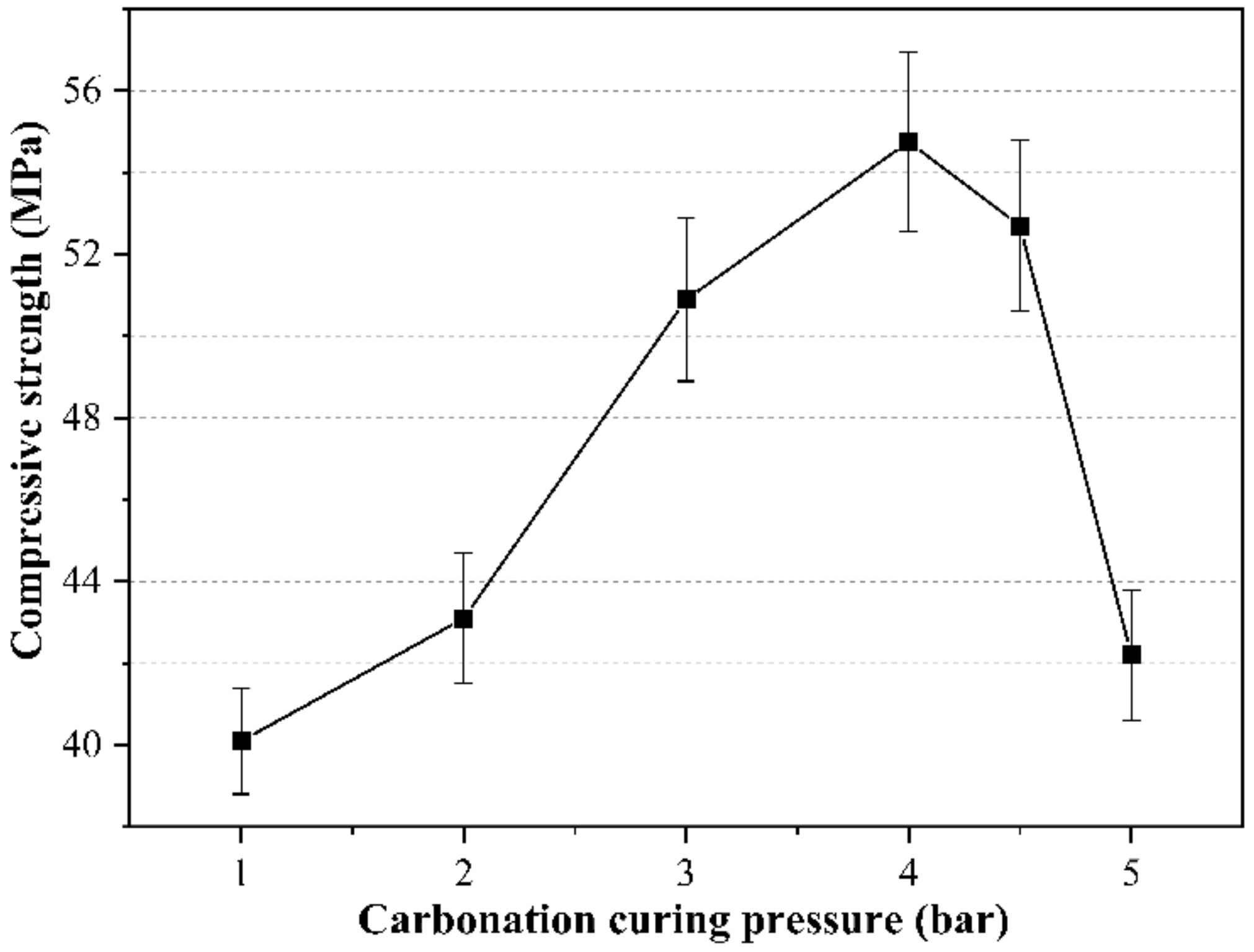

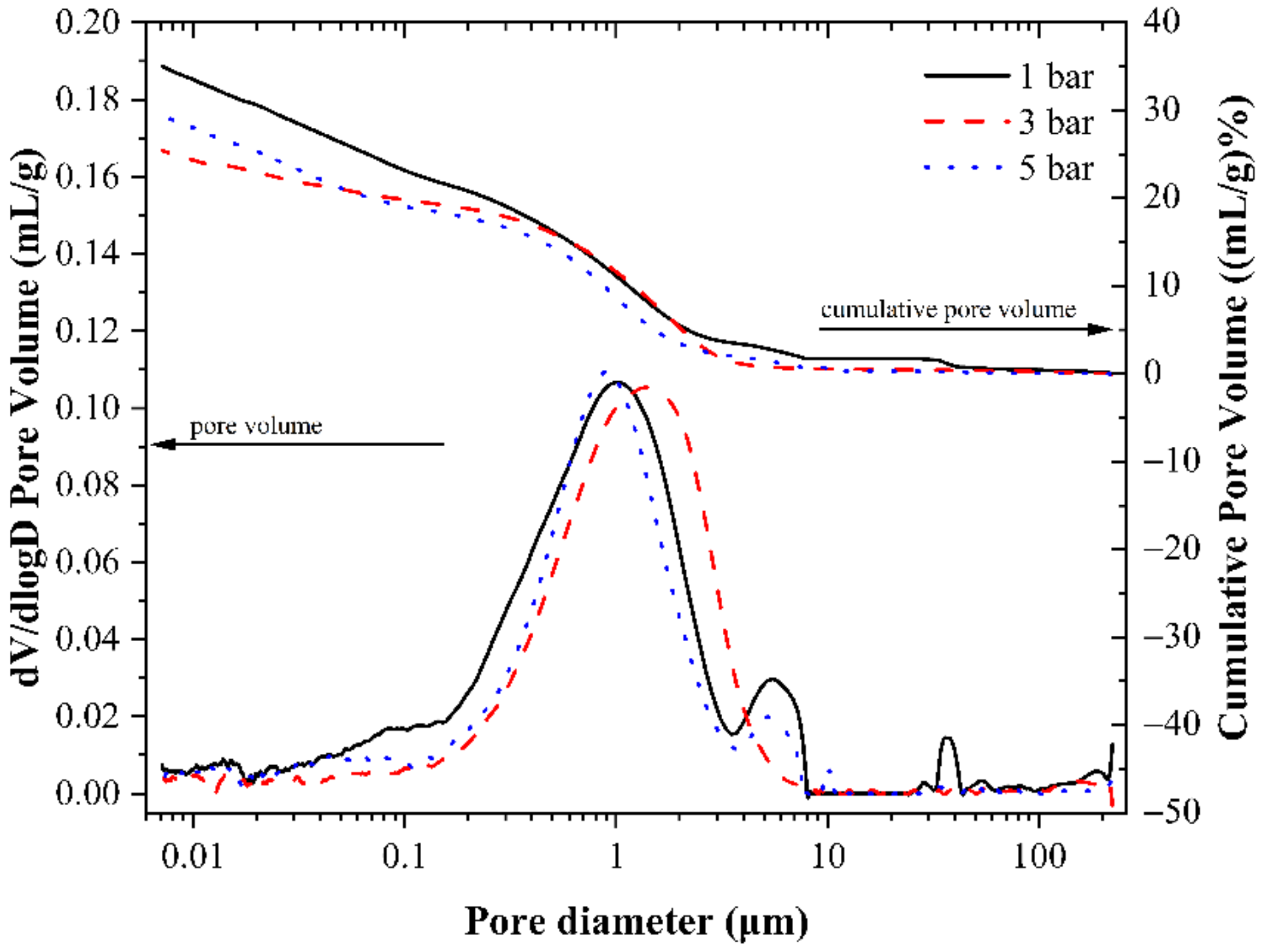

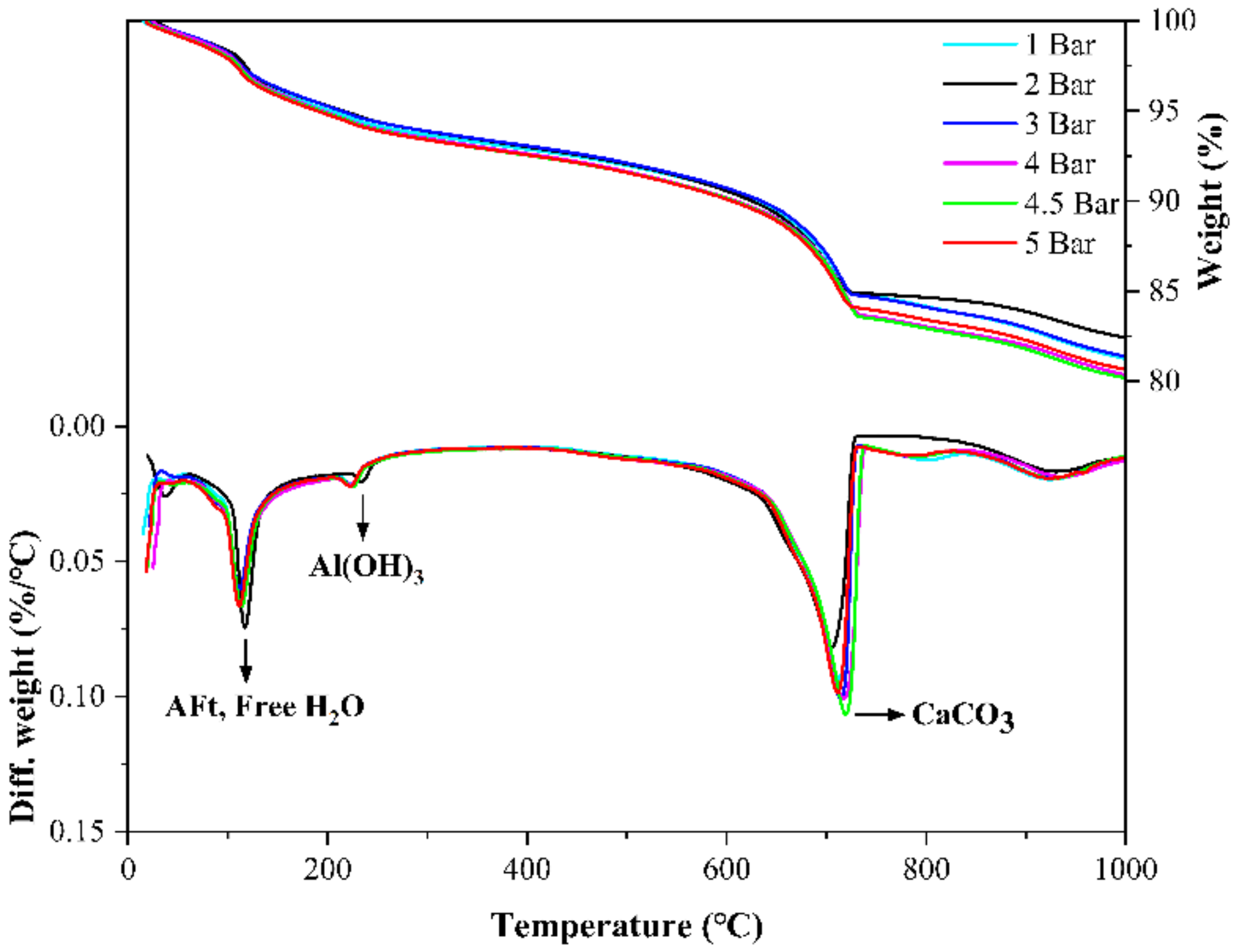

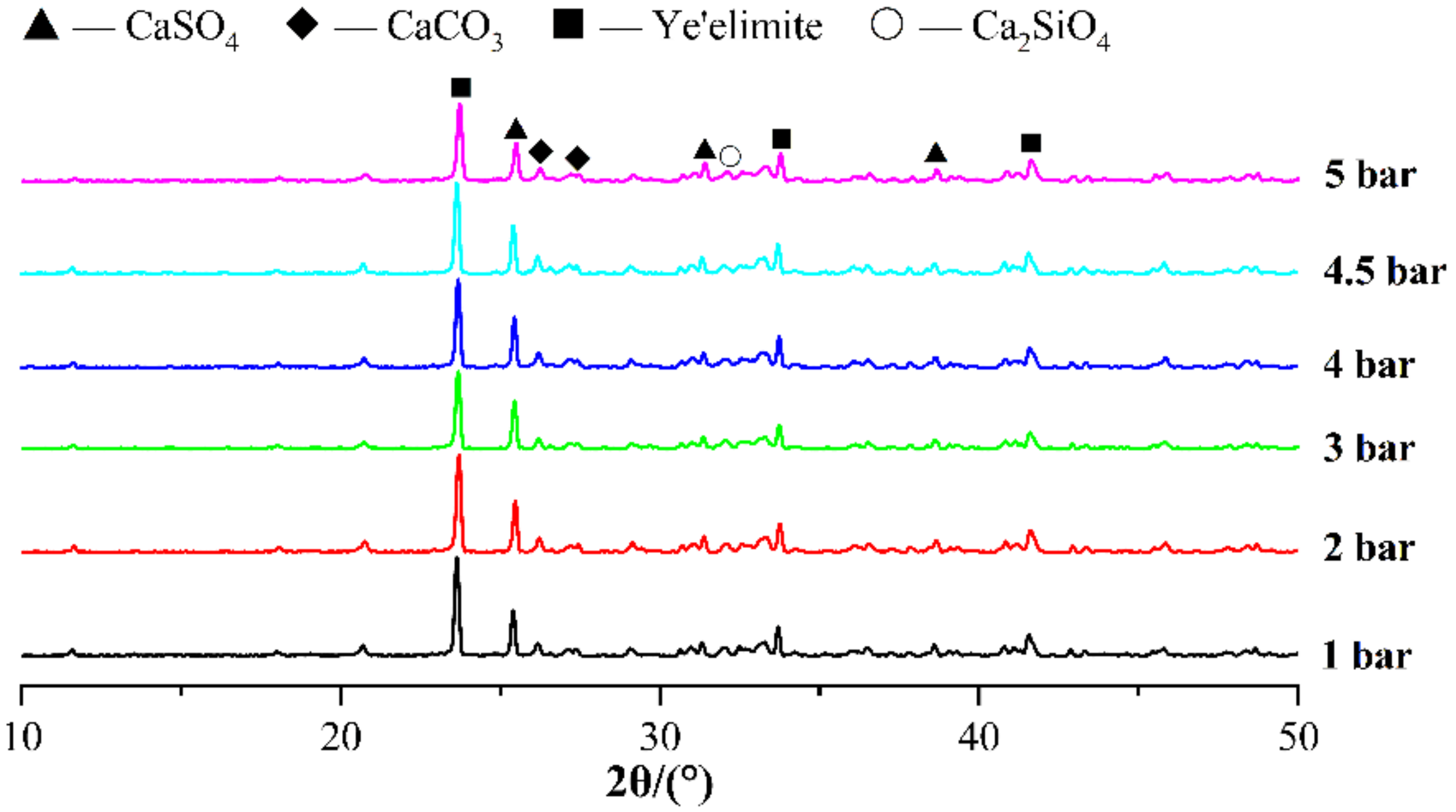

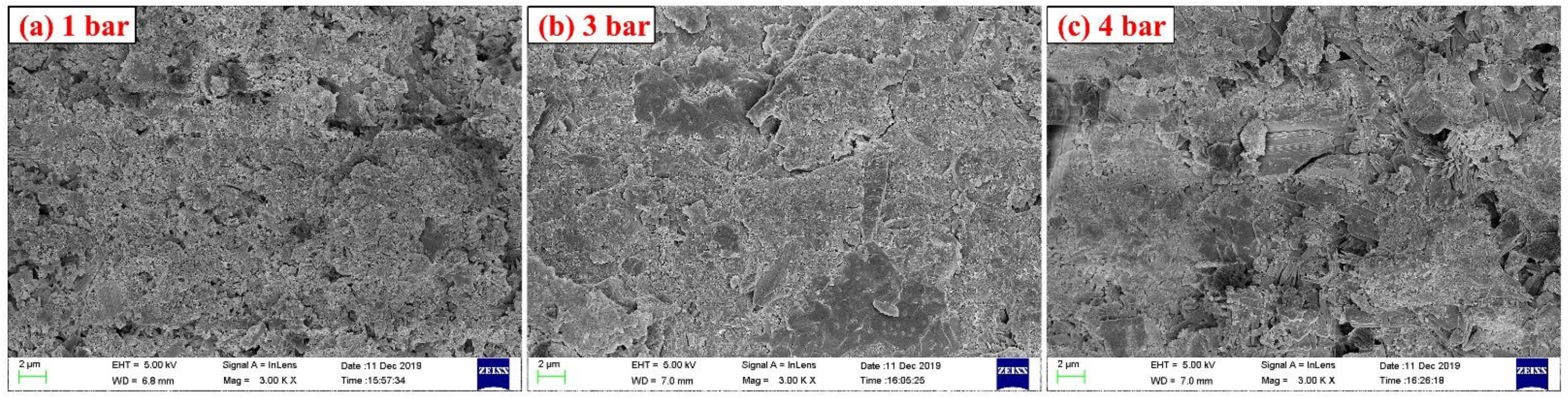

3.4. Carbonation Curing Pressure

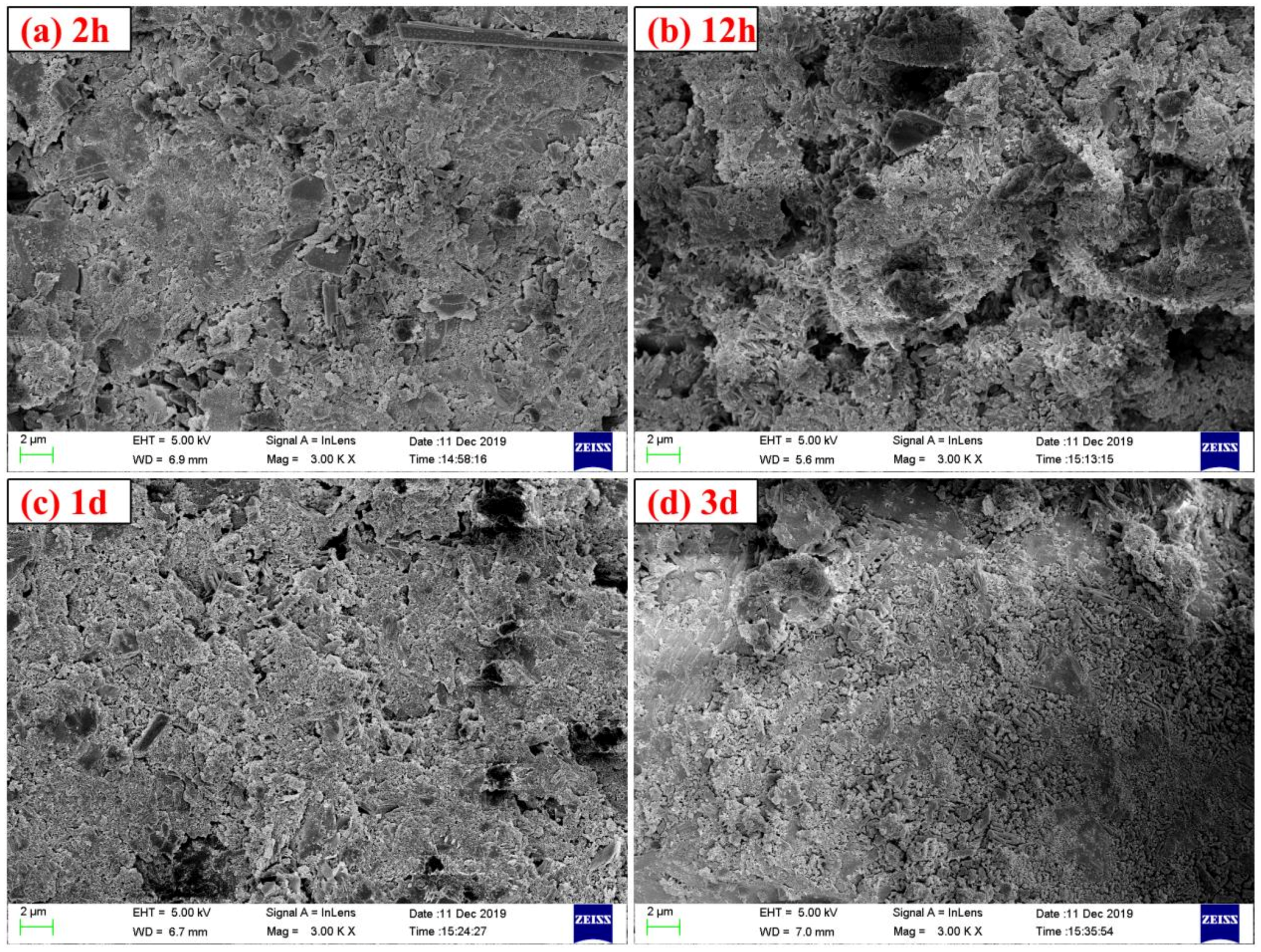

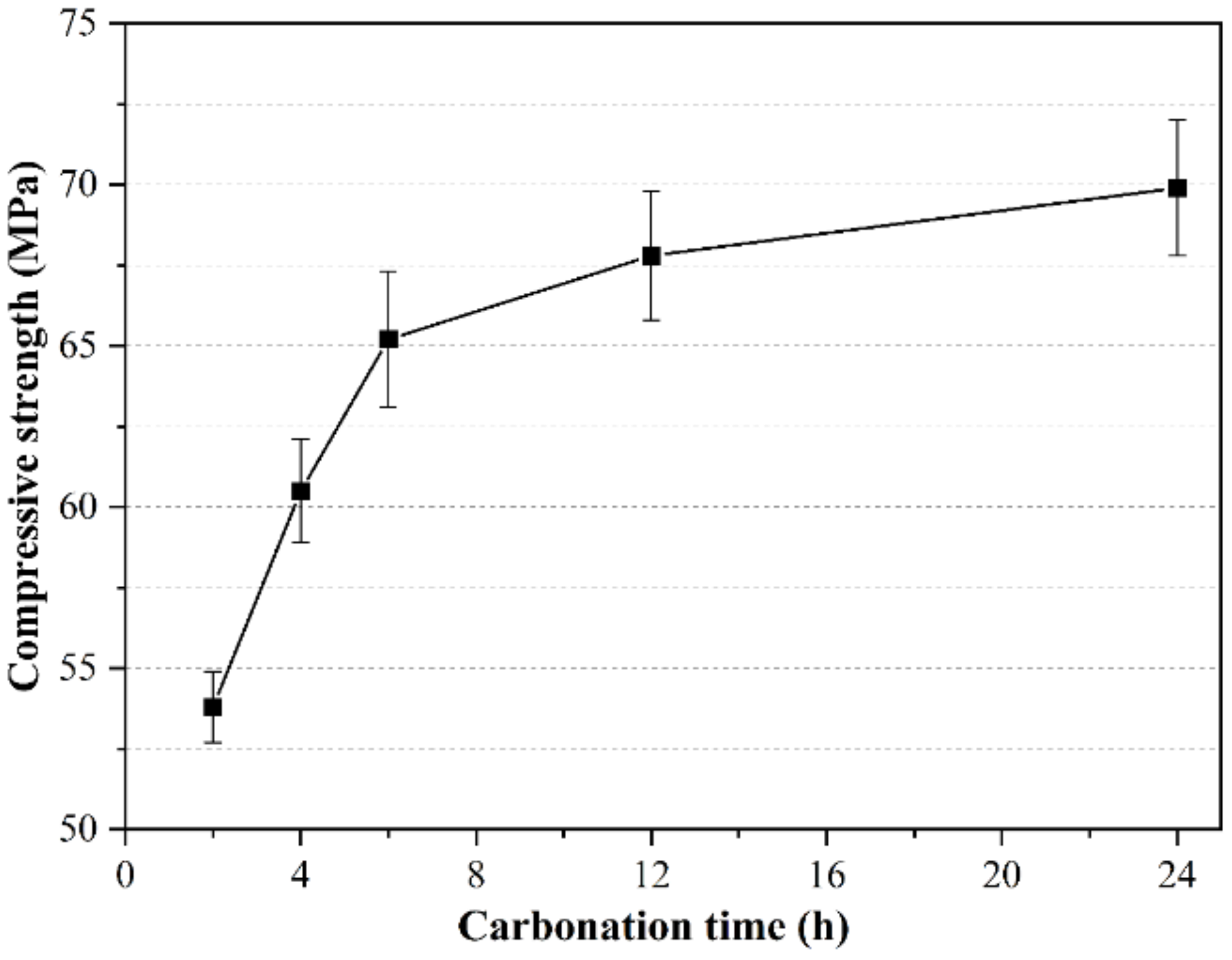

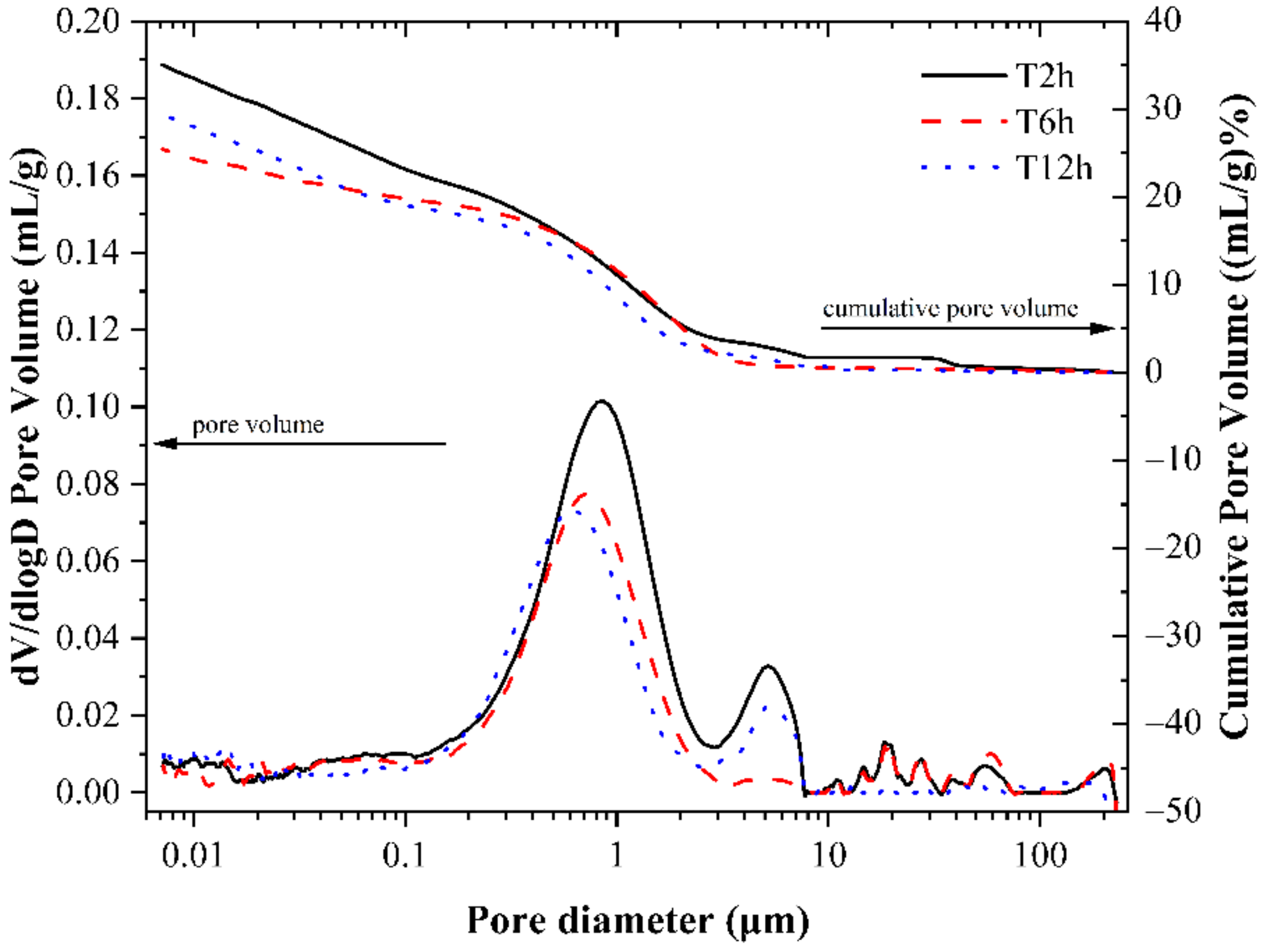

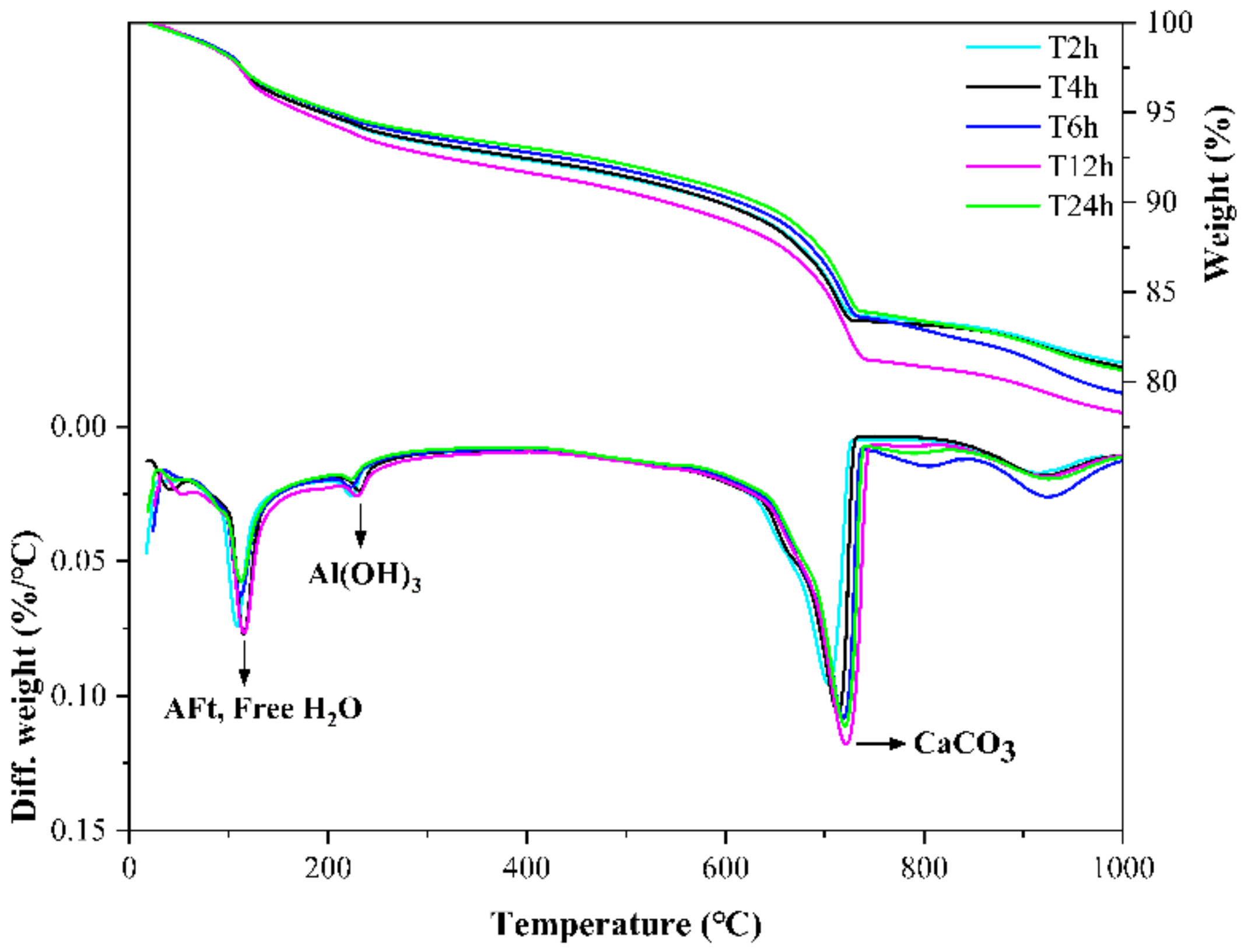

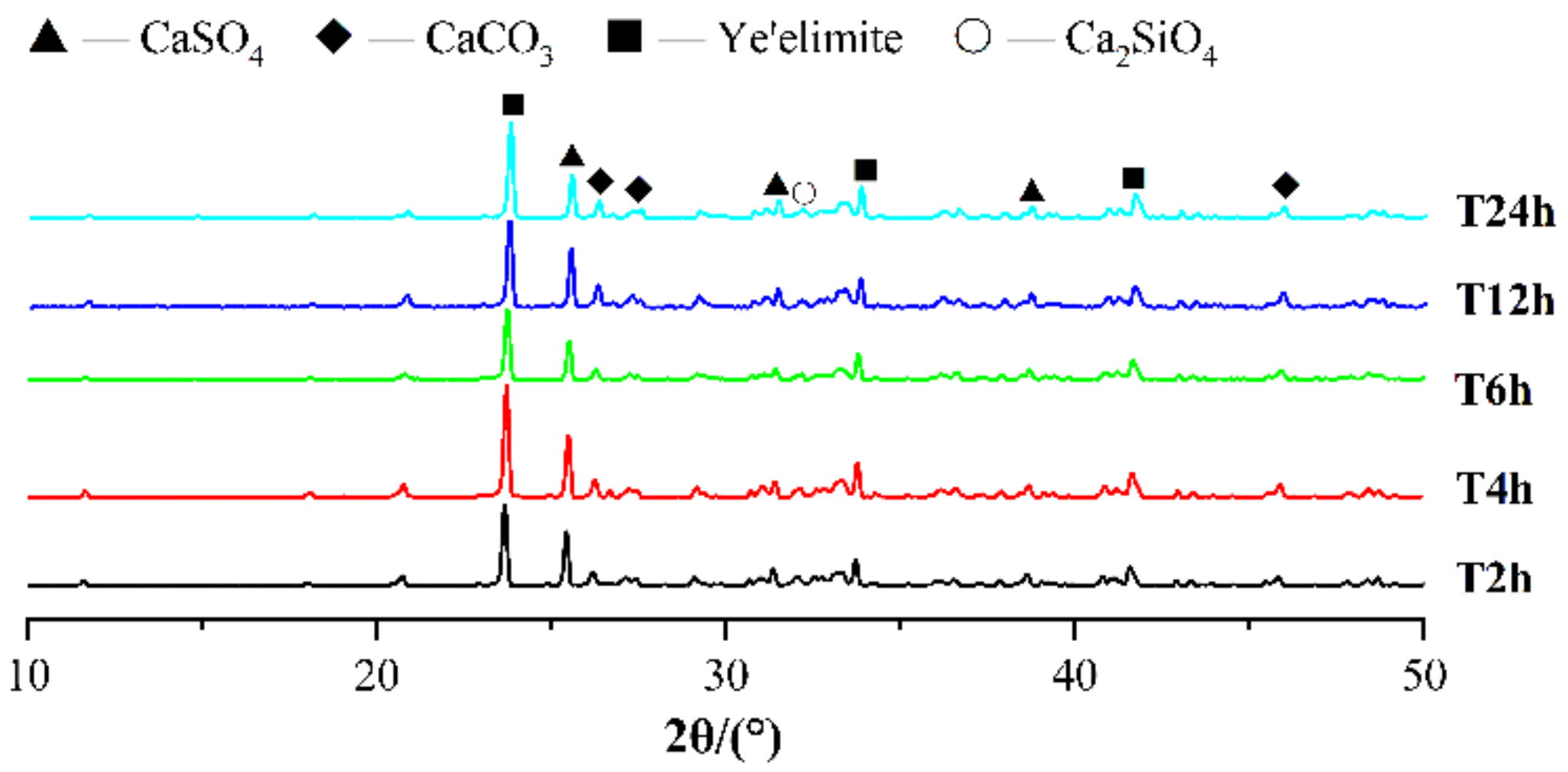

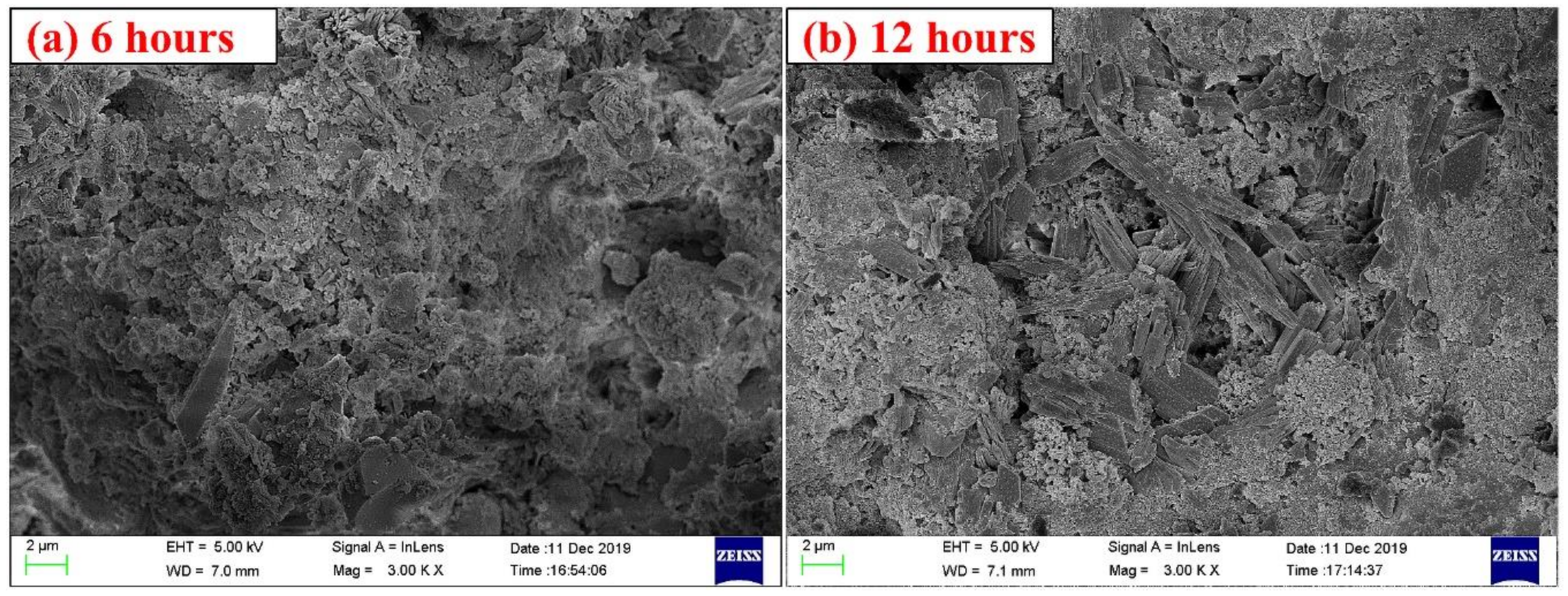

3.5. Carbonation Curing Time

4. Conclusions

- Early-age carbonation curing can effectively promote the hardening speed of CSA cement, greatly improving the early strength.

- Early-age carbonation curing can reduce the cumulative porosity of the CSA cement paste and refine the pore diameter distribution, resulting in a more uniform pore diameter distribution.

- The optimized performance mainly depends on two aspects of physics and chemistry. The first is the physical pressurization of carbonation curing; more importantly, it accelerates the carbonization reaction to produce amorphous calcium carbonate (CaCO3) and aluminum hydroxide (AH3) gel, which makes the microstructure of the CSA cement paste more compact.

- The technical parameters for early-age carbonation curing of CSA cement are recommended as follows: a w/b ratio of 0.15–0.22, carbonization curing for 6–12 h after 4 h initial hydration, with carbonization curing pressure at 3–4 bar.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, J.X.; Cen, K. A preliminary calculation of cement carbon dioxide in China from 1949 to 2050. Mitig. Adapt. Strateg. Glob. Chang. 2019, 24, 1343–1362. [Google Scholar] [CrossRef]

- Lin, B.Q.; Zhang, Z.H. Carbon emissions in China’s cement industry: A sector and policy analysis. Renew. Sustain. Energy Rev. 2016, 58, 1387–1394. [Google Scholar] [CrossRef]

- Zhan, J.L. China’s Cement Industry Implicit Carbon Dioxide Emissions Research; Springer: Singapore, 2016; pp. 265–274. [Google Scholar]

- Liu, Y.; Zhuge, Y.; Chow, C.W.K.; Keegan, A.; Li, D.; Pham, P.N.; Huang, J.; Siddique, R. Properties and microstructure of concrete blocks incorporating drinking water treatment sludge exposed to early-age carbonation curing. J. Clean. Prod. 2020, 261, 121257. [Google Scholar] [CrossRef]

- Liang, C.F.; Pan, B.H.; Ma, Z.M.; He, Z.H.; Duan, Z.H. Utilization of CO2 curing to enhance the properties of recycled aggregate and prepared concrete: A review. Cem. Concr. Compos. 2020, 105, 103446. [Google Scholar] [CrossRef]

- Chen, T.F.; Gao, X.J.; Qin, L. Mathematical modeling of accelerated carbonation curing of Portland cement paste at early age. Cem. Concr. Res. 2019, 120, 187–197. [Google Scholar] [CrossRef]

- Sharma, D.; Goyal, S. Accelerated carbonation curing of cement mortars containing cement kiln dust: An effective way of CO2 sequestration and carbon footprint reduction. J. Clean. Prod. 2018, 192, 844–854. [Google Scholar] [CrossRef]

- Bundit, K.; Quoc, P.; Norbert, M.; Wichit, P.; Thongchai, S.J.A.S. Early Age carbonation of fiber-cement composites under real processing conditions: A parametric investigation. Appl. Sci. 2018, 8, 190. [Google Scholar]

- Pizzol, V.D.; Mendes, L.M.; Frezzatti, L.; Savastano, H., Jr.; Tonoli, G.H.D. Effect of accelerated carbonation on the microstructure and physical properties of hybrid fiber-cement composites. Miner. Eng. 2014, 59, 101–106. [Google Scholar] [CrossRef]

- Zhang, D.; Ghouleh, Z.; Shao, Y.X. Review on carbonation curing of cement-based materials. J. CO2 Util. 2017, 21, 119–131. [Google Scholar] [CrossRef]

- Jang, J.G.; Kim, G.M.; Kim, H.J.; Lee, H.K. Review on recent advances in CO2 utilization and sequestration technologies in cement-based materials. Constr. Build. Mater. 2016, 127, 762–773. [Google Scholar] [CrossRef]

- Rostami, V.; Shao, Y.X.; Boyd, A.J.; He, Z. Microstructure of cement paste subject to early carbonation curing. Cem. Concr. Res. 2012, 42, 186–193. [Google Scholar] [CrossRef]

- Zhang, D.; Cai, X.H.; Jaworska, B. Effect of pre-carbonation hydration on long-term hydration of carbonation-cured cement-based materials. Constr. Build. Mater. 2020, 231, 117122. [Google Scholar] [CrossRef]

- Almeida, A.E.F.S.; Tonoli, G.H.D.; Santos, S.F.; Savastano, H. Improved durability of vegetable fiber reinforced cement composite subject to accelerated carbonation at early age. Cem. Concr. Compos. 2013, 42, 49–58. [Google Scholar] [CrossRef]

- Shi, C.J.; Liu, M.; He, P.P.; Ou, Z.H. Factors affecting kinetics of CO2 curing of concrete. J. Sustain. Cem. Based Mater. 2012, 1, 24–33. [Google Scholar] [CrossRef]

- Chen, T.F.; Gao, X.J. Effect of carbonation curing regime on strength and microstructure of Portland cement paste. J. CO2 Util. 2019, 34, 74–86. [Google Scholar] [CrossRef]

- Siddique, S.; Naqi, A.; Jang, J.G. Influence of water to cement ratio on CO2 uptake capacity of belite-rich cement upon exposure to carbonation curing. Cem. Concr. Compos. 2020, 111, 103616. [Google Scholar] [CrossRef]

- Qin, L.; Gao, X.J.; Chen, T.F. Influence of mineral admixtures on carbonation curing of cement paste. Constr. Build. Mater. 2019, 212, 653–662. [Google Scholar] [CrossRef]

- Neves Junior, A.; Ferreira, S.R.; Toledo Filho, R.D.; Fairbairn, E.d.M.R.; Dweck, J. Effect of early age curing carbonation on the mechanical properties and durability of high initial strength Portland cement and lime-pozolan composites reinforced with long sisal fibres. Compos. Part B Eng. 2019, 163, 351–362. [Google Scholar] [CrossRef]

- Berger, S.; Coumes, C.C.D.; Champenois, J.-B.; Douillard, T.; Le Bescop, P.; Aouad, G.; Damidot, D. Stabilization of ZnCl2-containing wastes using calcium sulfoaluminate cement: Leaching behaviour of the solidified waste form, mechanisms of zinc retention. J. Hazard. Mater. 2011, 194, 268–276. [Google Scholar] [CrossRef]

- Liao, Y.S.; Wei, X.S.; Li, G.W. Early hydration of calcium sulfoaluminate cement through electrical resistivity measurement and microstructure investigations. Constr. Build. Mater. 2011, 25, 1572–1579. [Google Scholar] [CrossRef]

- Telesca, A.; Marroccoli, M.; Pace, M.L.; Tomasulo, M.; Valenti, G.L.; Monteiro, P.J.M. A hydration study of various calcium sulfoaluminate cements. Cem. Concr. Compos. 2014, 53, 224–232. [Google Scholar] [CrossRef]

- Ye, Z.M.; Chang, J.; Huang, S.F.; Lu, L.C.; Chen, W.; Cheng, X. Study on early hydration of sulfoaluminate cement using an electrical resistivity method. Adv. Cem. Res. 2008, 20, 161–165. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, Y.; Geng, C. Sulfoaluminate cement: An alternative to portland cement. Adv. Mater. Res. 2012, 368–373, 478–484. [Google Scholar] [CrossRef]

- Kapustin, F.L.; Ponomarenko, A.A.; Oleinik, V.N. Sulfoaluminate cements composition and properties. Solid State Phenom. 2017, 265, 734–737. [Google Scholar] [CrossRef]

- Deng, H.Y.; Wei, X.C.; Liu, S.Y.; Li, S.; Cai, X.H. Influence of different lithium compounds on hydration and mechanical properties of calcium sulfoaluminate cement. Materials 2020, 13, 3465. [Google Scholar] [CrossRef]

- Sulphoaluminate Cement; GB/T 20472-2006; General Administration of Quality Supervision, Inspection and Quarantine of PR China: Beijing, China, 2006. (In Chinese)

- Ding, L. Manufacture of Steel Slag Water-Permeable Pavement Brick through Carbonation Curing. Master’s Thesis, University of Jinan, Jinan, China, 2010. (In Chinese). [Google Scholar]

- Li, Z.; He, Z.; Shao, Y.X. Early age carbonation heat and products of tricalcium silicate paste subject to carbon dioxide curing. Materials 2018, 11, 730. [Google Scholar] [CrossRef] [Green Version]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 | TiO2 | CO2 | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| 6.03 | 18.77 | 2.44 | 47.56 | 1.75 | 0.77 | 0.08 | 16.22 | 0.9 | 5.11 | 99.63 |

| Test Content | SSA (m2/kg) | Setting Time (min) | Flexural Strength (MPa) | Compressive Strength (MPa) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Initial | Final | 6 h | 1 Day | 3 Days | 6 h | 1 Day | 3 Days | ||

| Standard requirement | ≥350 | ≥12 | ≤180 | 4.0 | 5.5 | 6.0 | 20.0 | 35.0 | 42.5 |

| Measured value | 446 | 22 | 38 | 6.7 | 7.4 | 8.5 | 30.1 | 44.5 | 50.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Wei, X.; Cai, X.; Deng, H.; Li, B. Mechanical and Microstructural Characteristics of Calcium Sulfoaluminate Cement Exposed to Early-Age Carbonation Curing. Materials 2021, 14, 3515. https://doi.org/10.3390/ma14133515

Wang W, Wei X, Cai X, Deng H, Li B. Mechanical and Microstructural Characteristics of Calcium Sulfoaluminate Cement Exposed to Early-Age Carbonation Curing. Materials. 2021; 14(13):3515. https://doi.org/10.3390/ma14133515

Chicago/Turabian StyleWang, Weikang, Xuanchun Wei, Xinhua Cai, Hongyang Deng, and Bokang Li. 2021. "Mechanical and Microstructural Characteristics of Calcium Sulfoaluminate Cement Exposed to Early-Age Carbonation Curing" Materials 14, no. 13: 3515. https://doi.org/10.3390/ma14133515

APA StyleWang, W., Wei, X., Cai, X., Deng, H., & Li, B. (2021). Mechanical and Microstructural Characteristics of Calcium Sulfoaluminate Cement Exposed to Early-Age Carbonation Curing. Materials, 14(13), 3515. https://doi.org/10.3390/ma14133515