Impact of Design Parameters on the Ratio of Compressive to Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate

Abstract

:1. Introduction

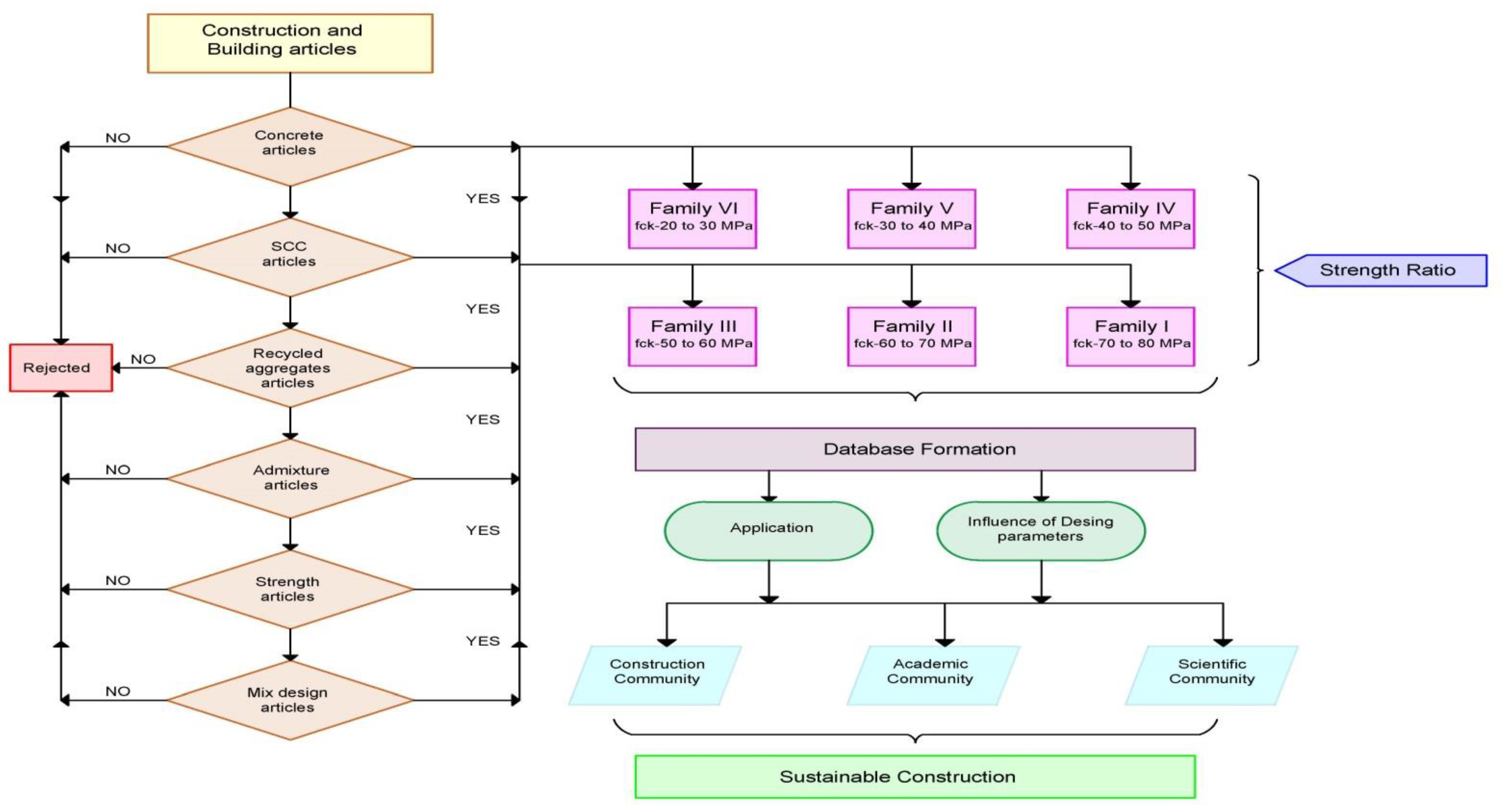

2. Review Methodology

2.1. Search Strategies

2.2. Data Extraction

3. Design Parameters from Literature

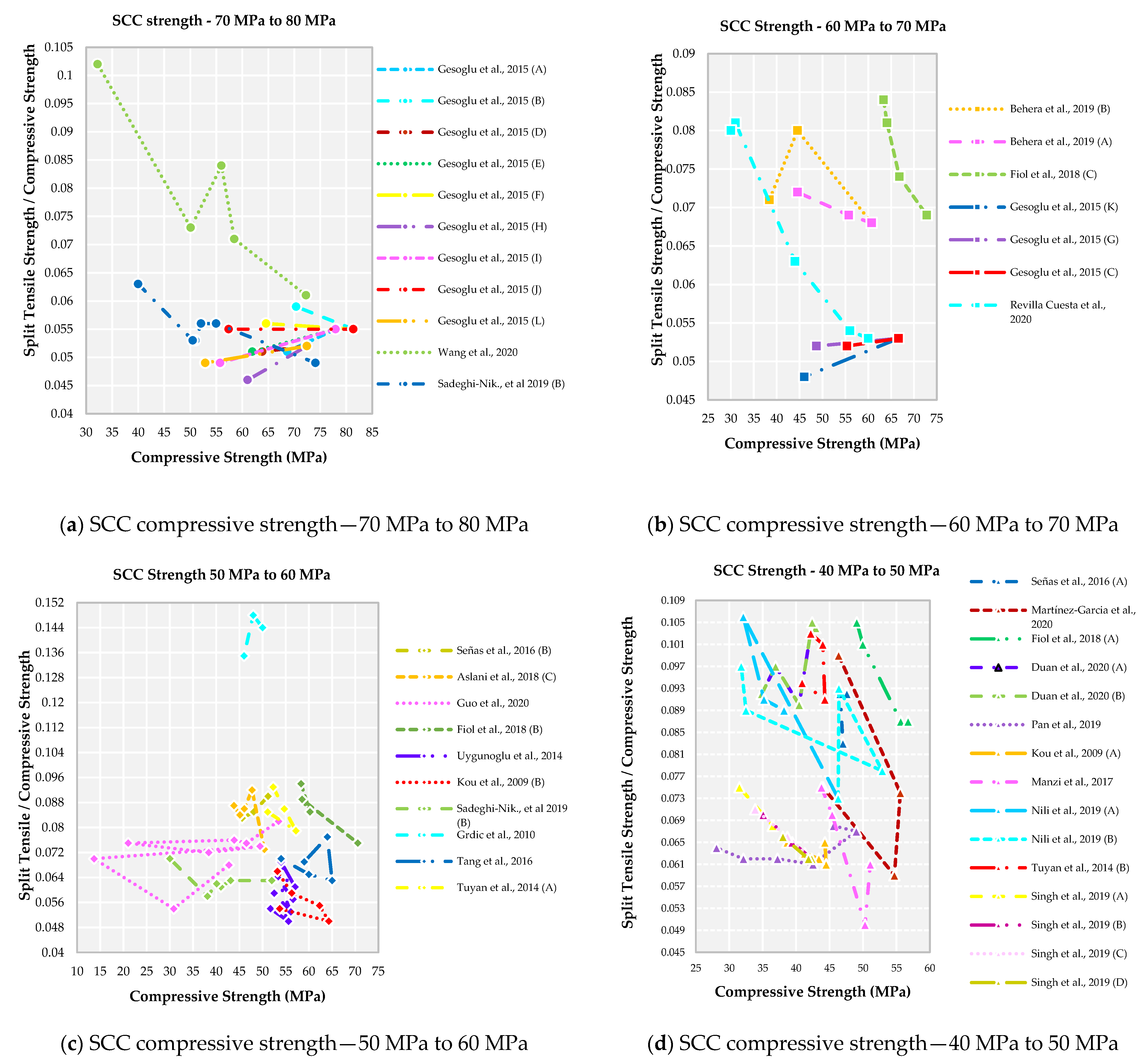

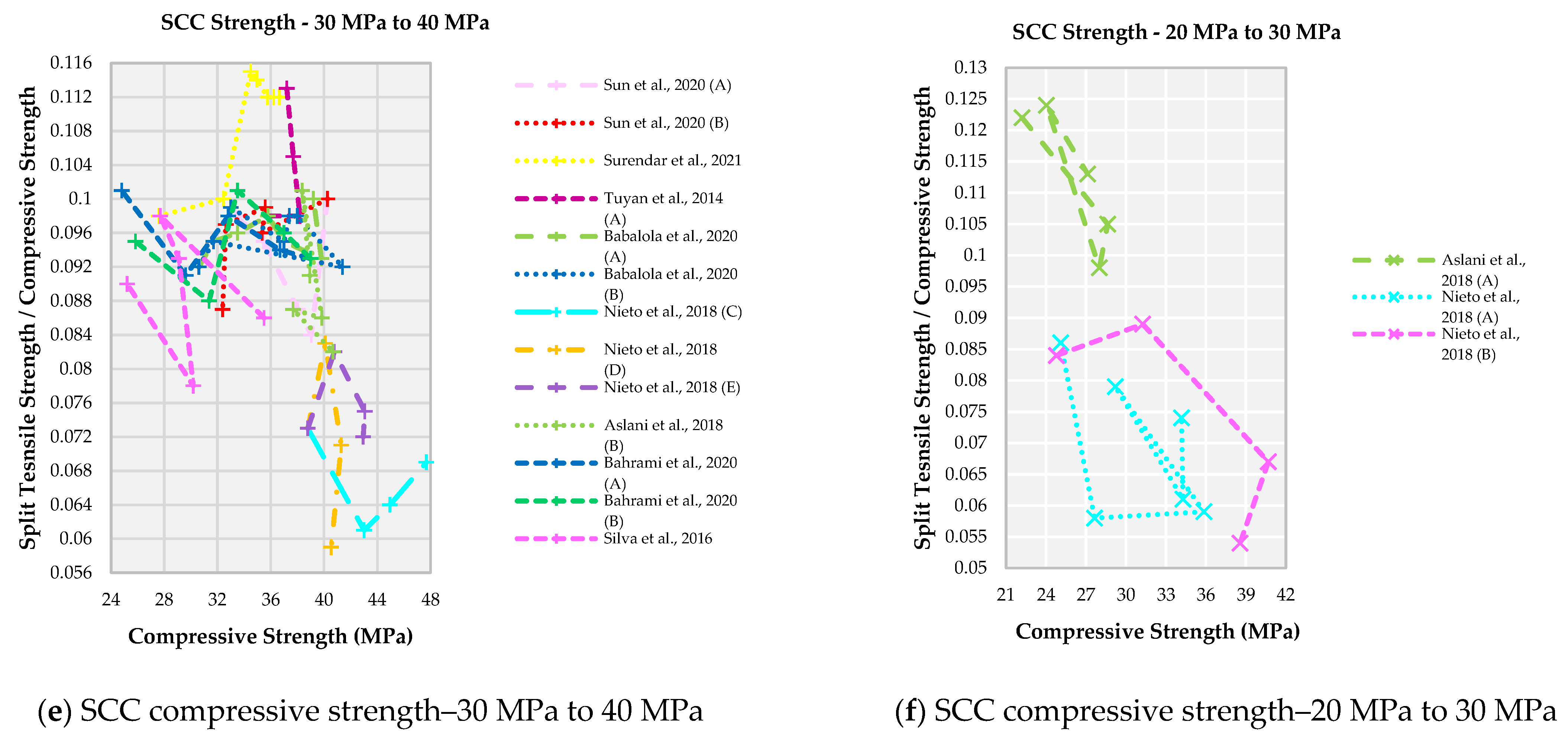

Relationship between Compressive Strength and Split Tensile Strength to Compressive Strength Ratio for Different SCC Grades

4. Impact of Design Parameters on Strength Ratio

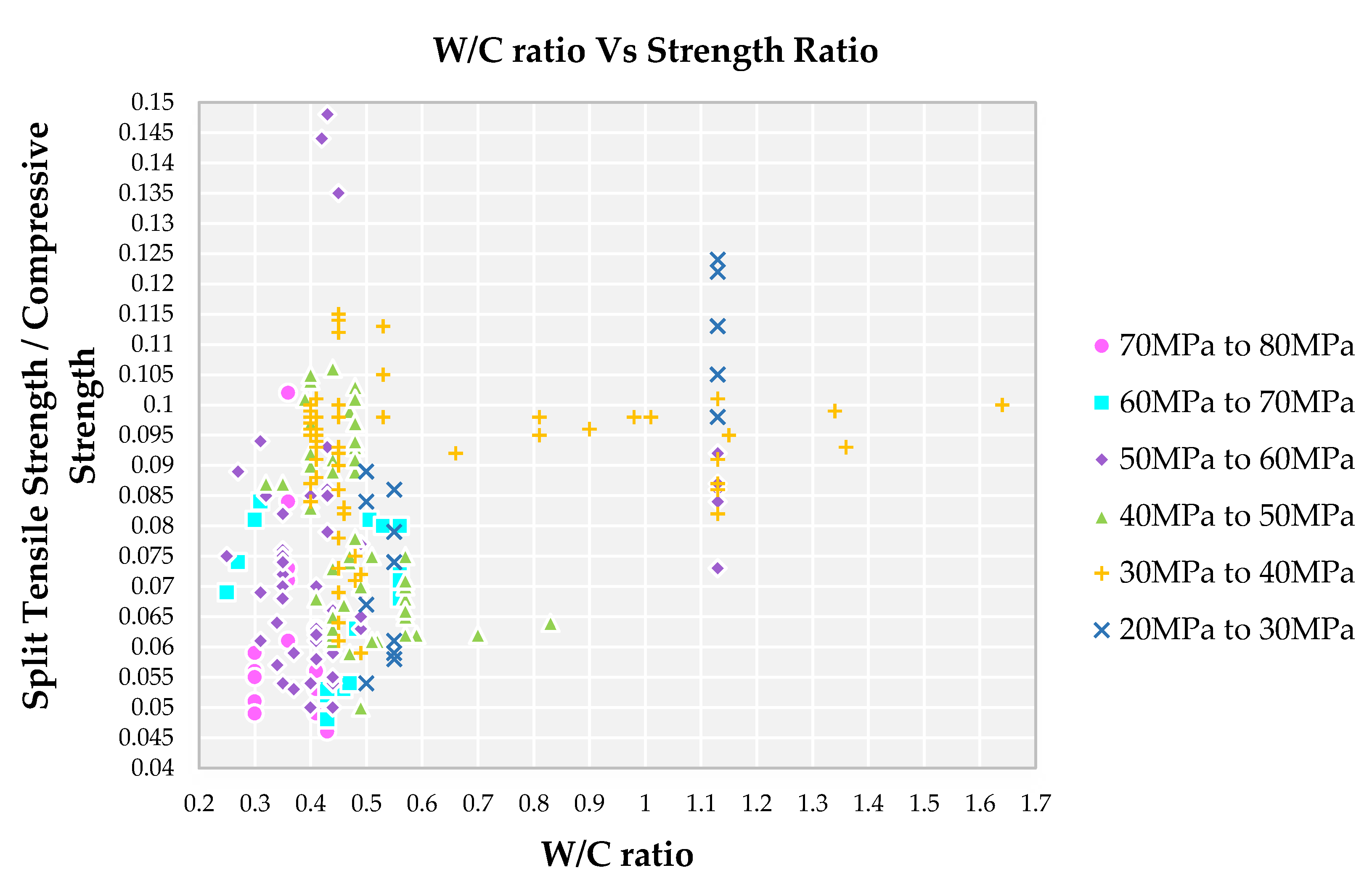

4.1. Impact of W/C Ratio on Strength Ratio

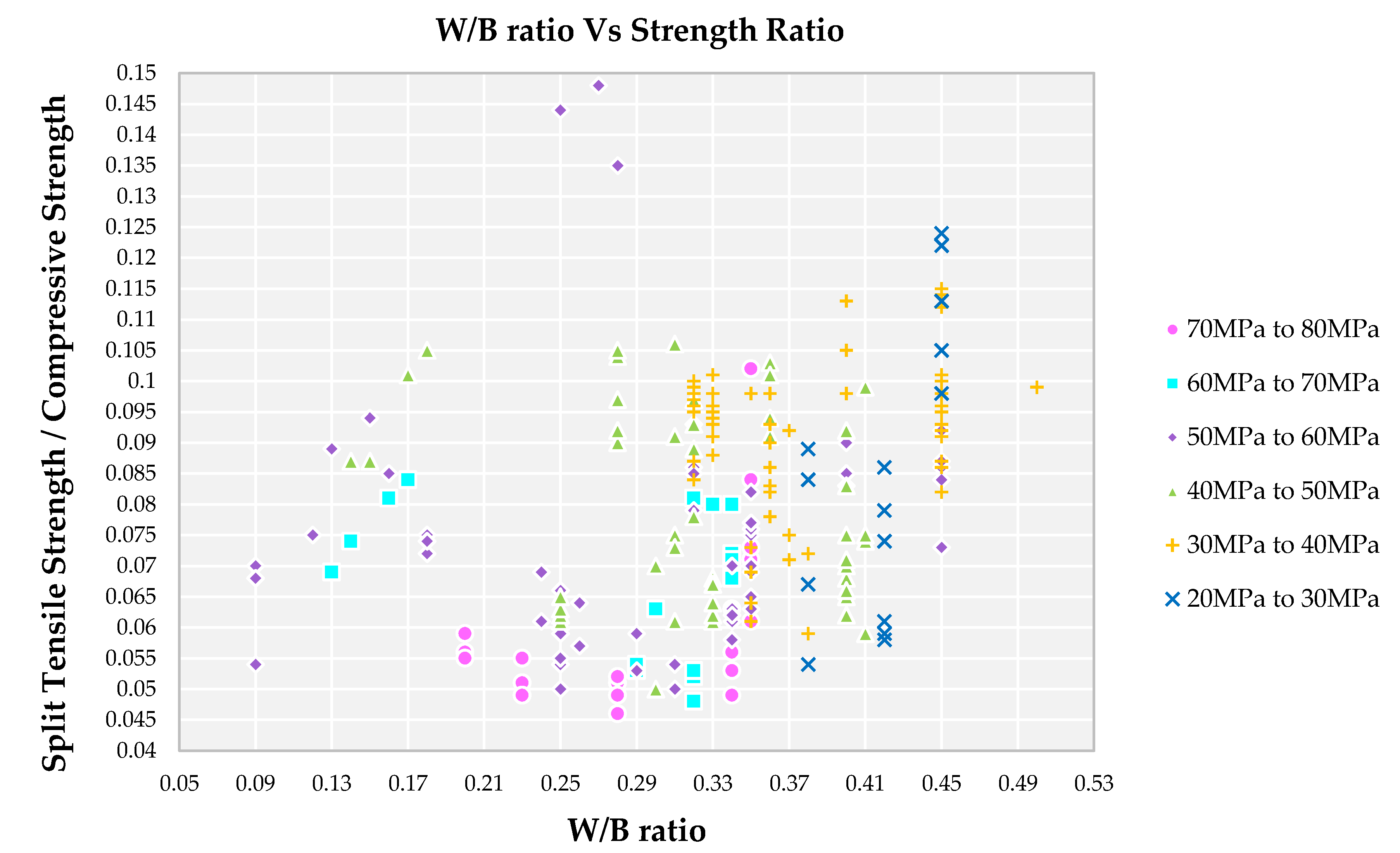

4.2. Impact of W/B Ratio on Strength Ratio

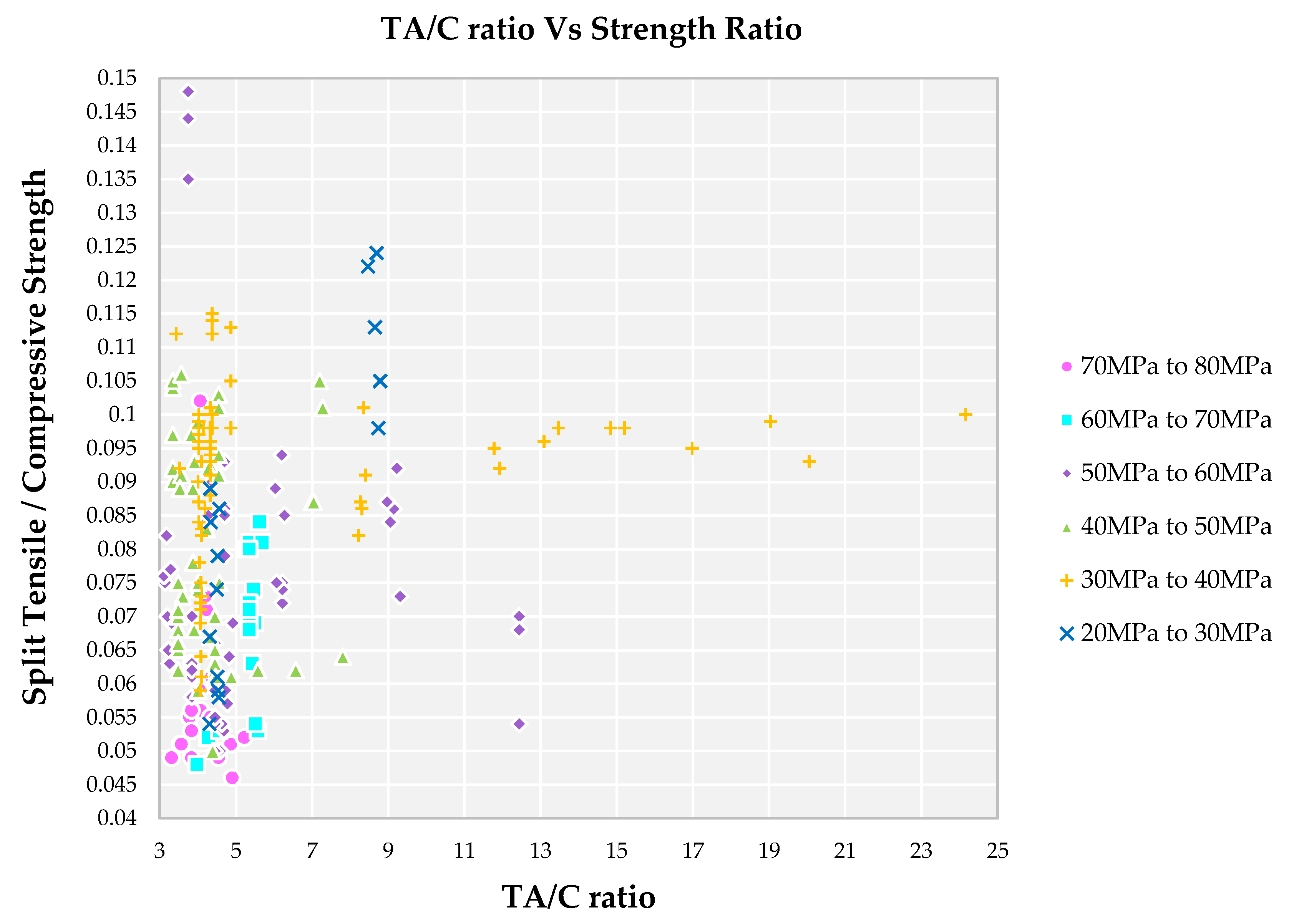

4.3. Impact of TA/C Ratio on Strength Ratio

4.4. Impact of FA/CA Ratio on Strength Ratio

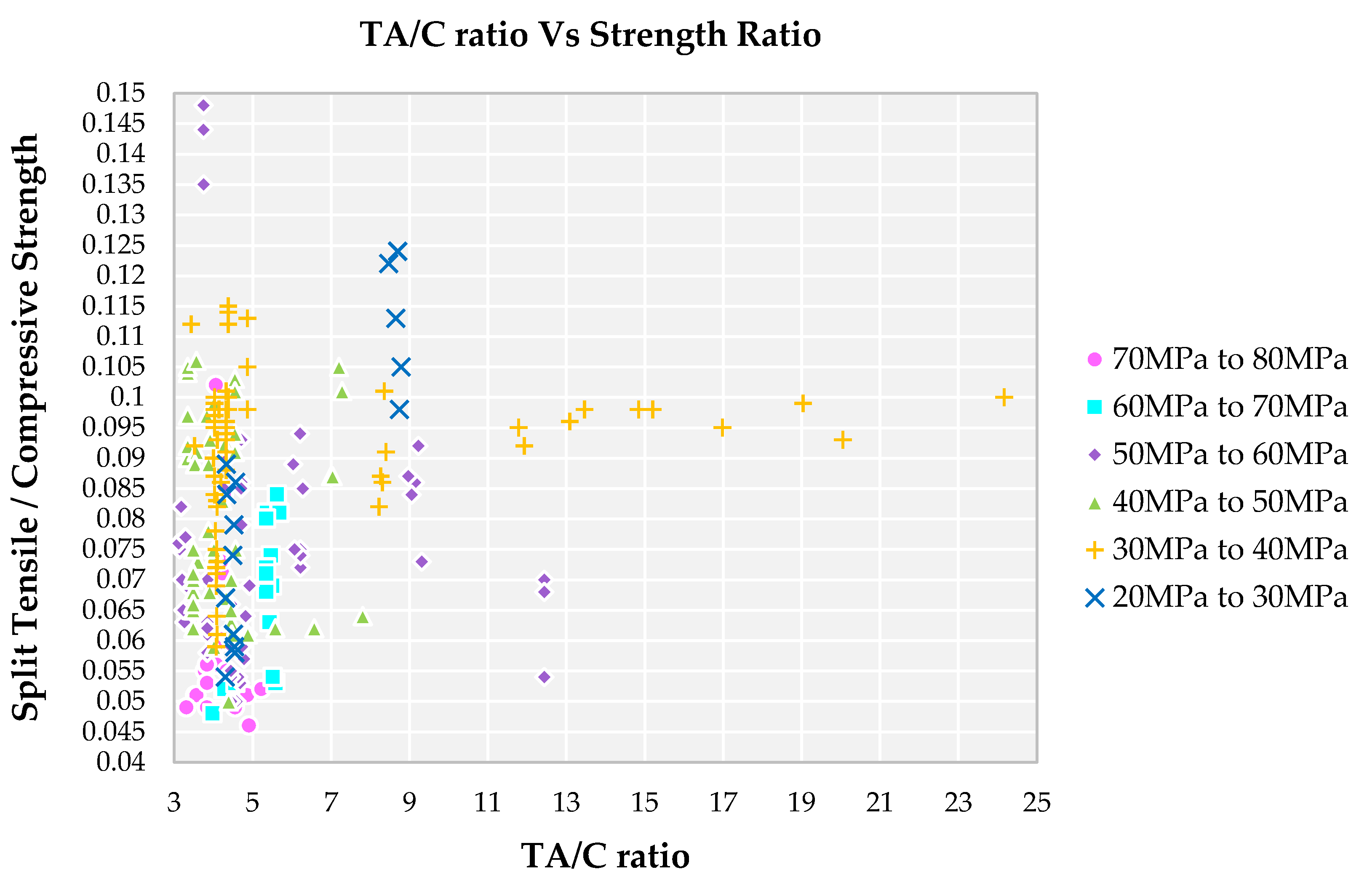

4.5. Impact of TA/C Ratio on Strength Ratio

4.6. Impact of Superplasticizer Weight on Strength Ratio

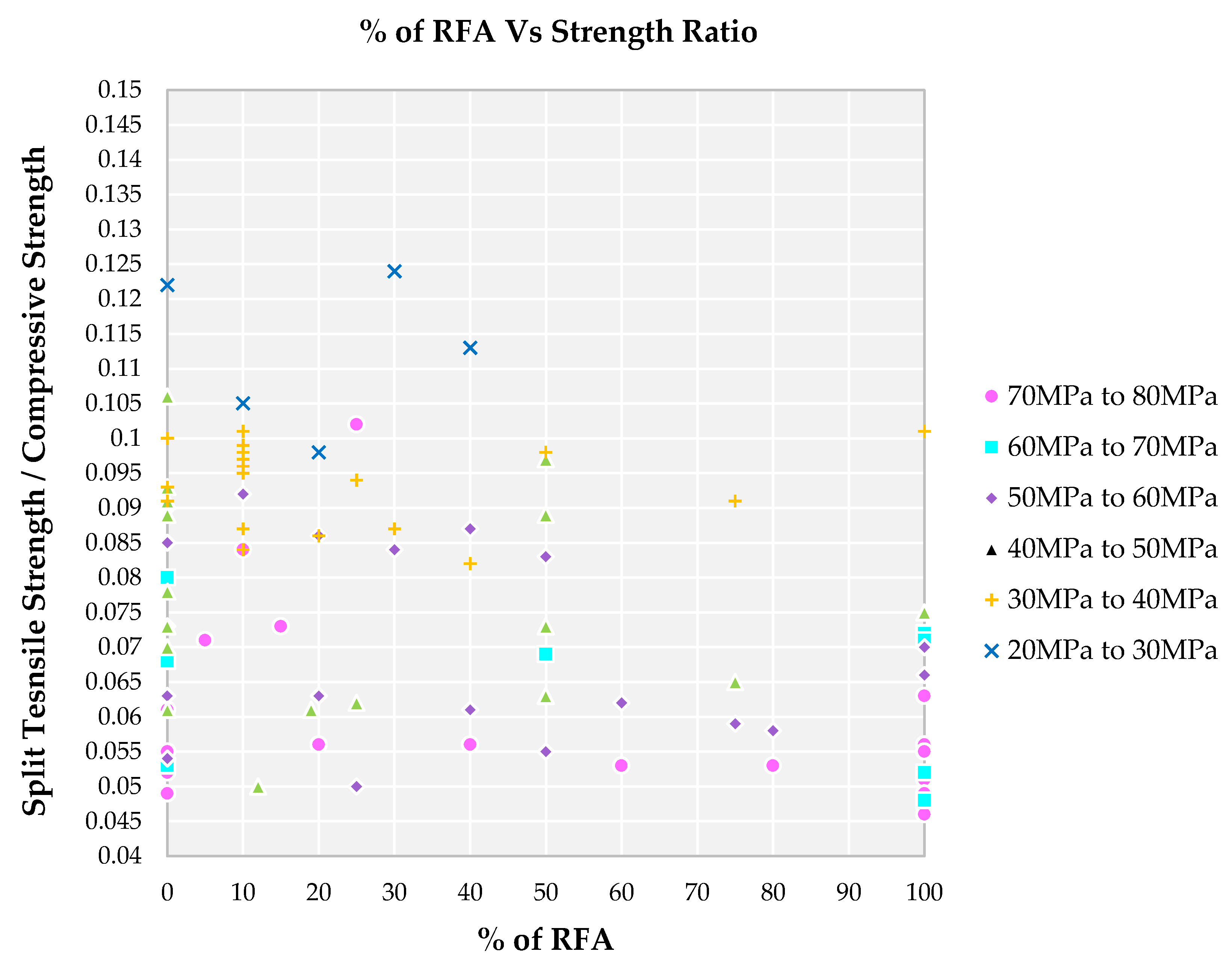

4.7. Impact of Percentage of RFA on Strength Ratio

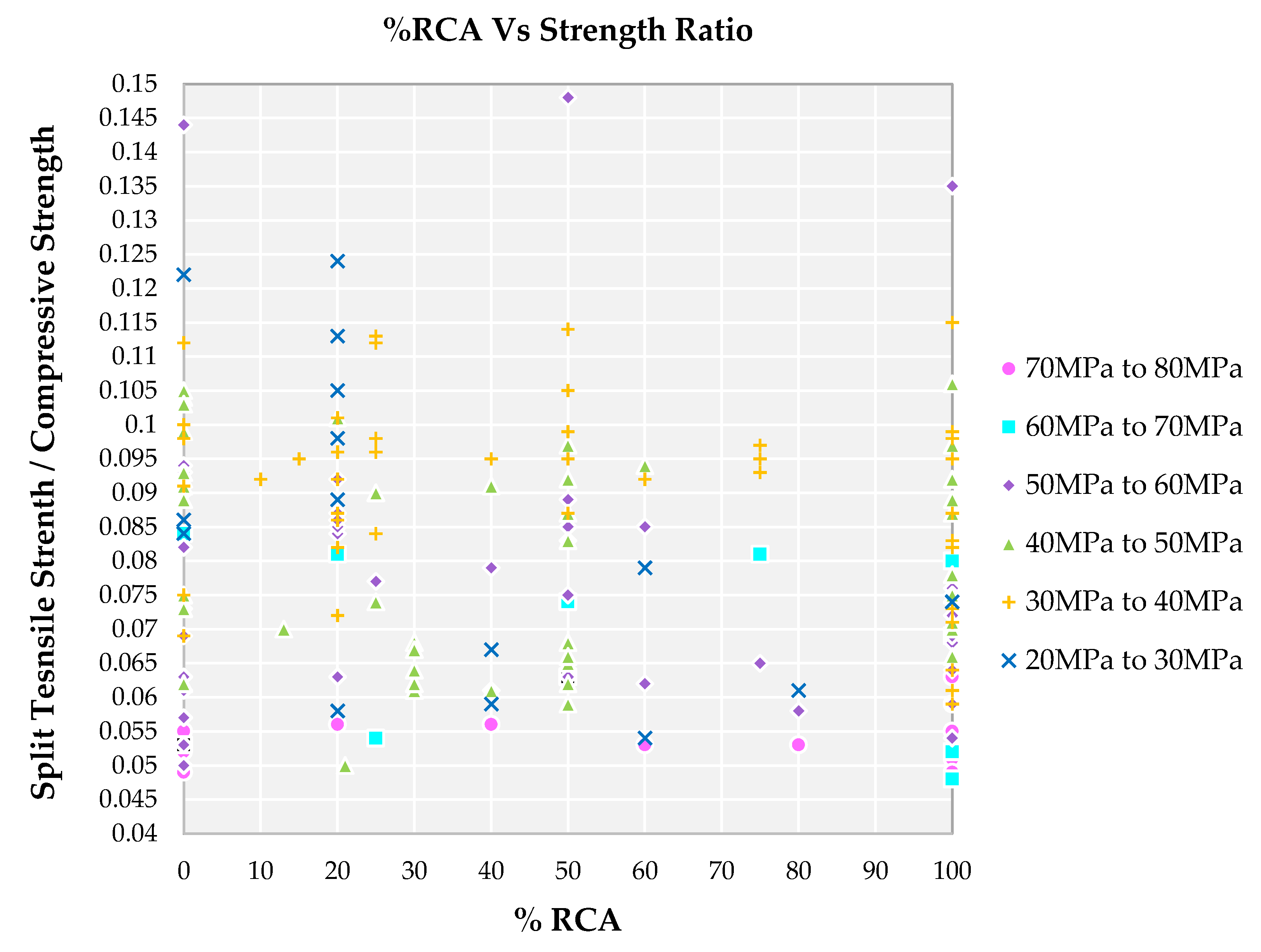

4.8. Impact of Percentage of RCA on Strength Ratio

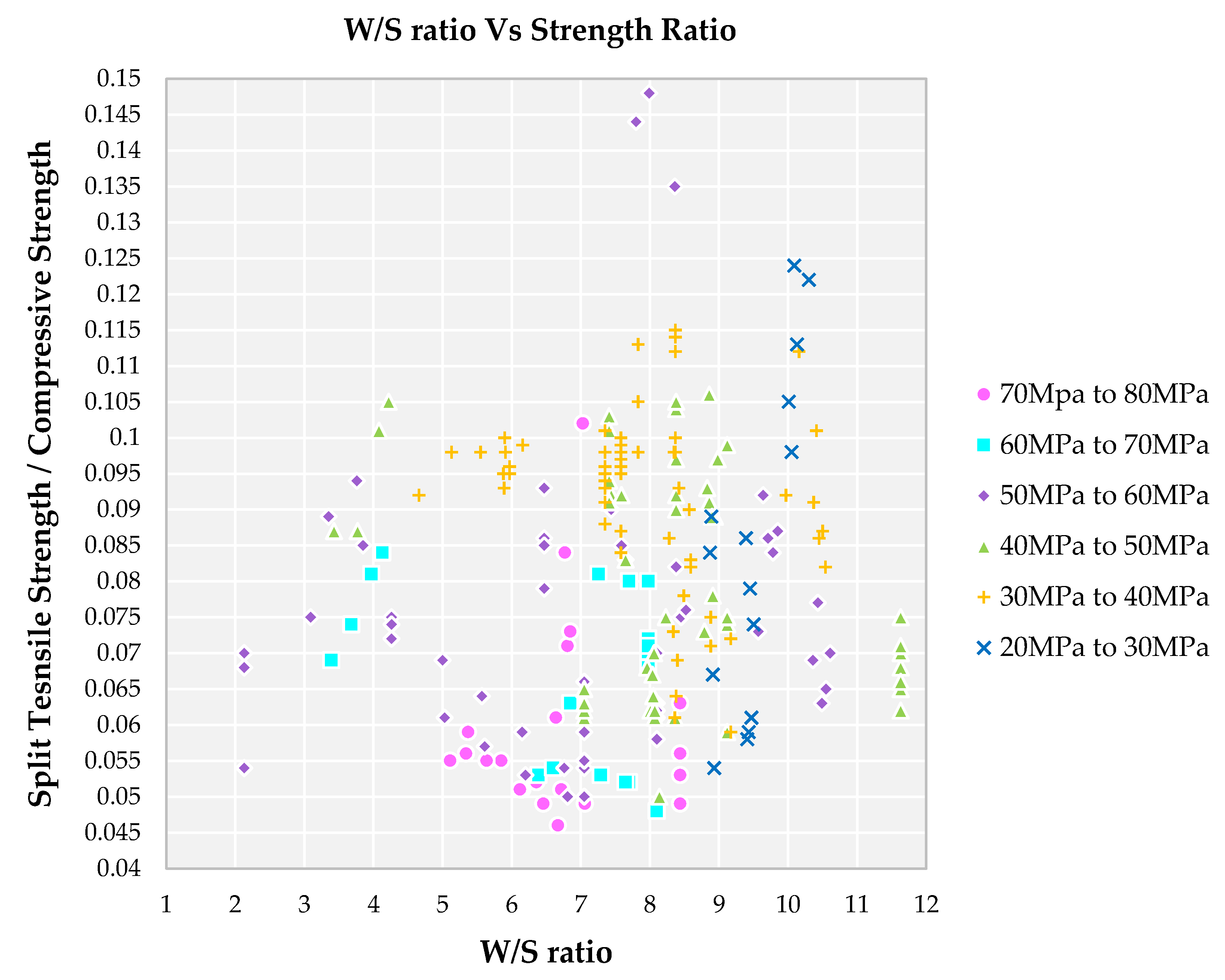

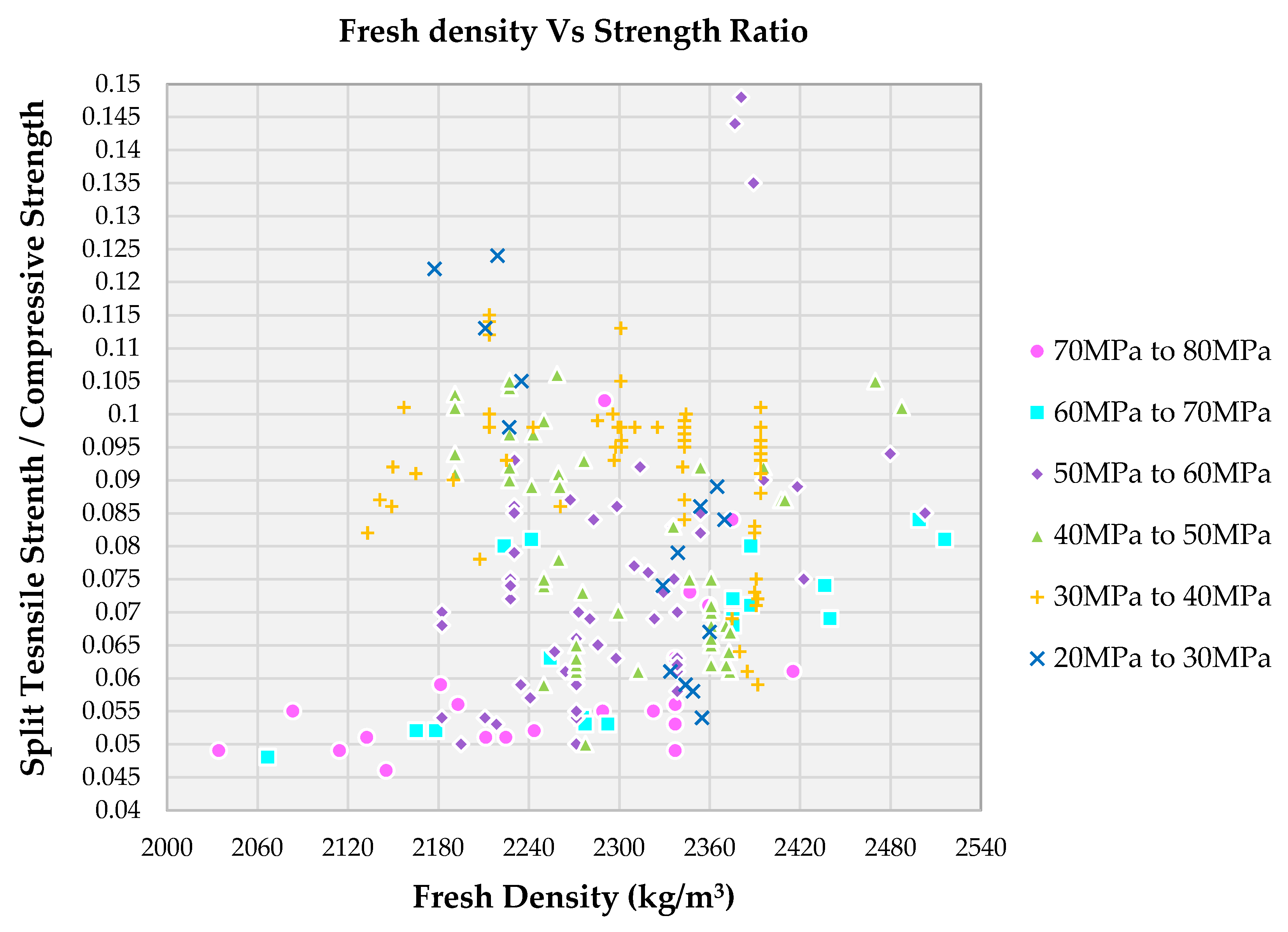

4.9. Impact of Fresh Density on Strength Ratio

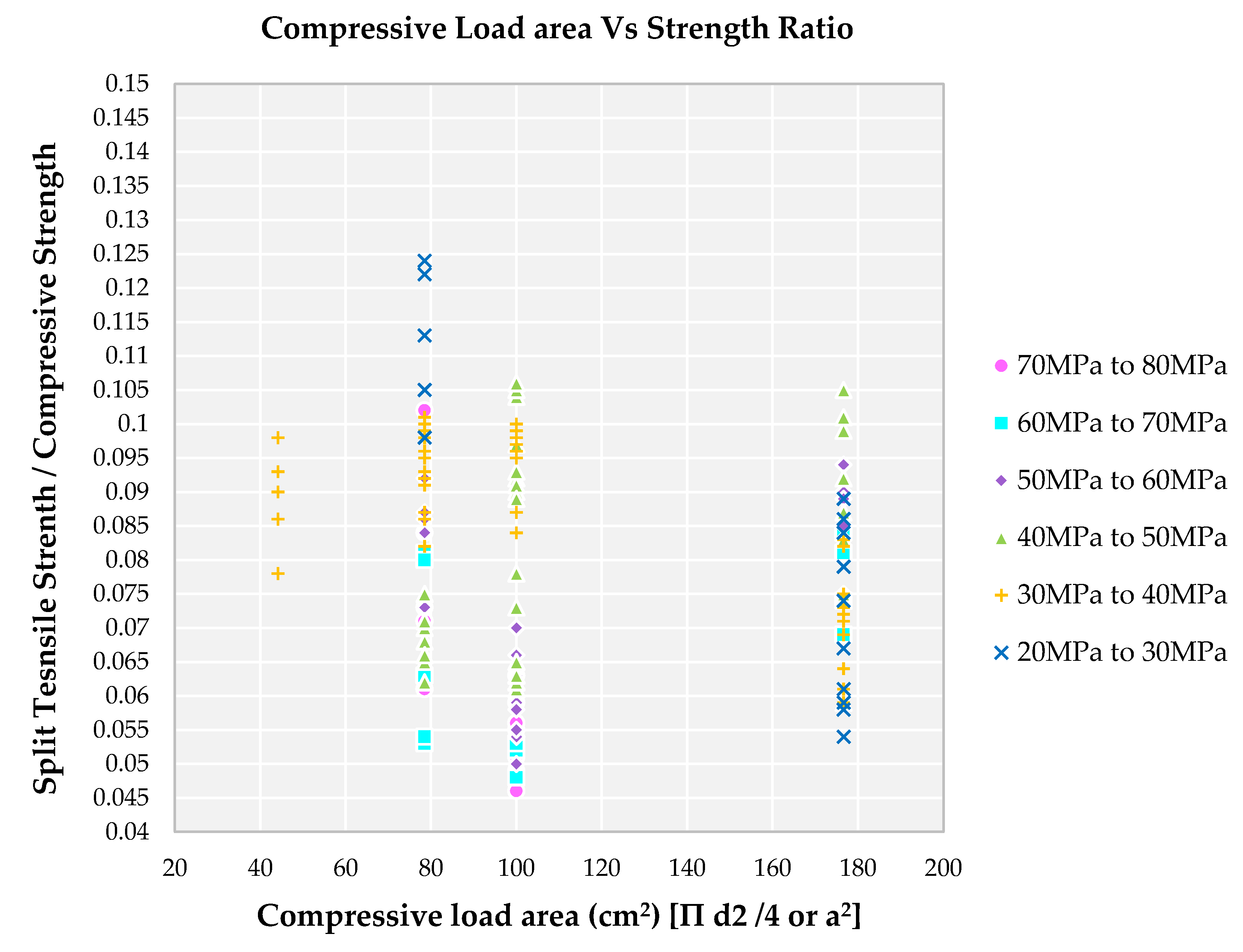

4.10. Impact of Compressive Load Area of RCA on Strength Ratio

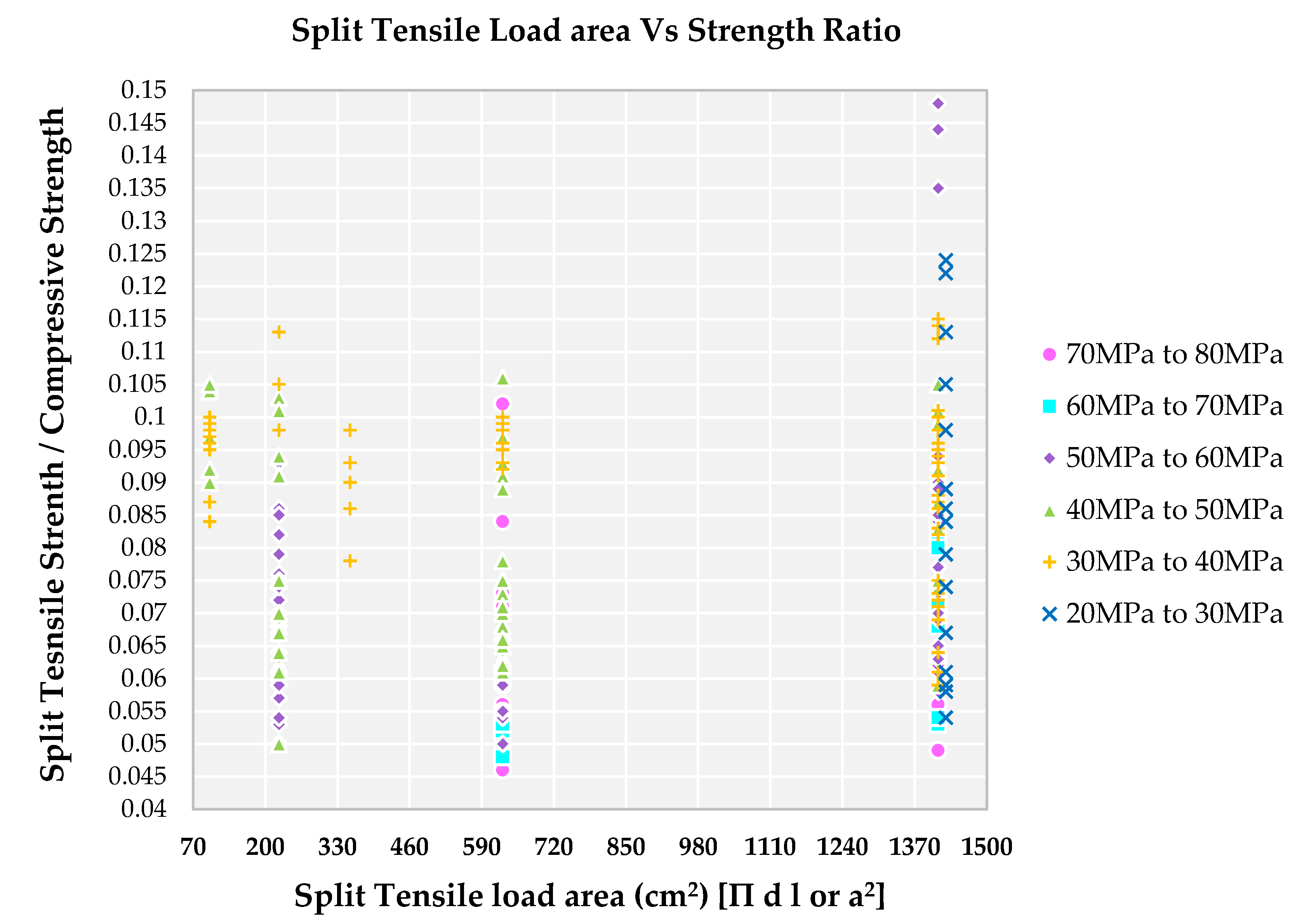

4.11. Impact of Split Tensile Load Area on Strength Ratio

5. Sustainable Construction

6. Conclusions

- Increase in W/C ratio, decrease in strength of SCC (or increase in the family from I to VI). A lower W/C ratio results in a lower strength ratio for a higher family (family I, II and III).

- Increase in W/B ratio, decrease in strength of SCC (or increase in the family from I to VI). A lower W/B ratio results in a lower strength ratio for a higher family (family I, II and III). A higher W/B ratio results in a higher strength ratio for lower families (family IV, V and VI).

- FA/CA in the ratio of 1.5 to 3.0 is observed for all the families. Lower the strength ratio higher the family and higher the FA/CA ratio lower families (IV, V and VI).

- TA/C in the ratio of 3.0 to 7.0 is observed for all the families. Higher TA/C ratio, lower families (IV, V and VI) are observed for higher strength ratio. Lower the TA/C ratio, higher families (I, II and III) are observed for lower strength ratio.

- Lower strength ratio results for higher families (I, II and III) result in the usage of SP from 2.0 kg to 7.0 kg and in similar usage of SP, there is a higher strength ratio for lower families (IV, V and VI). Hence, there is no clear relationship between strength ratio and usage of SP in kg.

- W/S ratio is lower (in the range of 3.0 to 8.0) resulting in a lower strength ratio for higher families (I, II and III). Higher W/S ratio, above 9.0, results in lower families (IV, V and VI).

- Lower level of replacement of NFA by RFA is observed for all families. A 100% replacement is observed in higher families only.

- A 50% replacement of NCA by RCA is observed for all the families, showing a lesser difference in strength ratio. A 100% replacement is observed for all the families.

- Lower fresh density for higher families (I, II and III) results in a lower strength ratio and higher strength ratio is from higher fresh density for lower families (IV, V and VI).

- Higher compressive load area results in a higher strength ratio for lower families (IV, V and VI) and a lower strength ratio is from higher families (I, II and III) leading to the lower compressive load area.

- Similar to compressive load area results, the higher the split tensile strength load area, the higher the strength ratio for lower families (IV, V and VI). A lower split tensile load area, the lower the strength ratio from higher families (I, II, III).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, A.; Arora, S.; Sharma, V.; Bhardwaj, B. Workability Retention and Strength Development of Self-Compacting Recycled Aggregate Concrete Using Ultrafine Recycled Powders and Silica Fume. J. Hazard. ToxicRadioact. Waste 2019, 23, 04019016. [Google Scholar] [CrossRef]

- Ahmad, M.; Zhao, Z.-Y.; Li, H. Revealing stylized empirical interactions among construction sector, urbanization, energy consumption, economic growth and CO2 emissions in China. Sci. Total. Environ. 2019, 657, 1085–1098. [Google Scholar] [CrossRef]

- Eurostat. Recycling Rate of Waste Excluding Major Mineral Wastes. Available online: https://ec.europa.eu/eurostat/tgm/refreshTableAction.do?tab=table&plugin=1&pcode=ten00106&language=en (accessed on 24 April 2019).

- RILEM Technical Committee. Final report of RILEM TC 205-DSC: Durability of self-compacting concrete. Mater. Struct. 2007, 41, 225–233. [Google Scholar] [CrossRef]

- Mokhtari, Z.; Hekmatdoost, A.; Nourian, M. Antioxidant efficacy of vitamin D. J. Parathyr. Diesase. 2017, 5, 11–16. [Google Scholar]

- RILEM. Self-Compacting Concrete—State-of-the-Art Report of RILEM TC 174-SCC. Skarendahl, Å., Petersson, Ö., Eds.; 2000. Available online: https://www.rilem.net/publication/publication/87 (accessed on 24 April 2019).

- Eurostat. Recovery Rate of Construction and Demolition Waste. Available online: https://ec.europa.eu/eurostat/cache/metadata/en/cei_wm040_esmsip2.htm (accessed on 1 May 2021).

- Fischer, C.; Werge, M. EU as a Recycling Society Present Recycling Levels of Municipal Waste and Construction & Demolition Waste in the EU European Topic Centre on Sustainable Consumption and Production Højbro Plads 4 DK-1200 Copenhagen K. 2009. Available online: http://avfallnorge.web123.no/article_docs/EUgjenvinningsstudie.pdf (accessed on 25 April 2019).

- Song, Q.; Yu, R.; Wang, X.; Rao, S.; Shui, Z. A novel Self-Compacting Ultra-High Performance Fibre Reinforced Concrete (SCUHPFRC) derived from compounded high-active powders. Constr. Build. Mater. 2018, 158, 883–893. [Google Scholar] [CrossRef]

- Ozawa, K.; Maekawa, K.; Kunishima, M.; Okamura, H. Development of High Performance Concrete Based on the Durbaility Design of Concrete Structures. Proc. Second. East Asia-Pac. Conf. Struct. Eng. Constr. 1989, 1, 445–450. [Google Scholar]

- Okamura, H.; Ozawa, K. Self-Compactable High-Performance Concrete in Japan. Spec. Publ. 1996, 159, 31–44. [Google Scholar] [CrossRef]

- Bahrami, N.; Zohrabi, M.; Mahmoudy, S.A.; Akbari, M. Optimum recycled concrete aggregate and micro-silica content in self-compacting concrete: Rheological, mechanical and microstructural properties. J. Build. Eng. 2020, 31, 101361. [Google Scholar] [CrossRef]

- Türkmen, I.; Kantarcı, A. Effects of expanded perlite aggregate and different curing conditions on the physical and mechanical properties of self-compacting concrete. Build. Environ. 2007, 42, 2378–2383. [Google Scholar] [CrossRef]

- Salesa, Á.; Pérez-Benedicto, J.Á.; Esteban, L.M.; Vicente-Vas, R.; Orna-Carmona, M. Physico-mechanical properties of multi-recycled self-compacting concrete prepared with precast concrete rejects. Constr. Build. Mater. 2017, 153, 364–373. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.-C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Bostanci, S.C.; Limbachiya, M.; Kew, H. Use of recycled aggregates for low carbon and cost effective concrete construction. J. Clean. Prod. 2018, 189, 176–196. [Google Scholar] [CrossRef] [Green Version]

- Yu, B.; Wang, J.; Li, J.; Lu, W.; Li, C.Z.; Xu, X. Quantifying the potential of recycling demolition waste generated from urban renewal: A case study in Shenzhen, China. J. Clean. Prod. 2020, 247, 119127. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular Economy on Construction and Demolition Waste: A Literature Review on Material Recovery and Production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef]

- Martínez-García, R.; Guerra-Romero, M.I.; Morán-del Pozo, J.M.; Brito, J.D.; Juan-Valdés, A. Recycling Aggregates for Self-Compacting Concrete Production: A Feasible Option. Materials 2020, 13, 868. [Google Scholar] [CrossRef] [Green Version]

- Pacheco, J.; de Brito, J.; Chastre, C.; Evangelista, L. Experimental investigation on the variability of the main mechanical properties of concrete produced with coarse recycled concrete aggregates. Constr. Build. Mater. 2019, 201, 110–120. [Google Scholar] [CrossRef]

- Modani, P.O.; Mohitkar, V.M. Self-Compacting Concrete with Recycled Aggregate: A Solution for Sustainable Development. Int. J. Civ. Struct. Eng. 2014, 430–440. [Google Scholar] [CrossRef]

- Taffese, W.Z. Suitability Investigation of Recycled Concrete Aggregates for Concrete Production: An Experimental Case Study. Adv. Civ. Eng. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; de Brito, J.; Martínez-Abella, F.; González-Taboada, I.; Silva, P. Study of the rheology of self-compacting concrete with fine recycled concrete aggregates. Constr. Build. Mater. 2015, 96, 491–501. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mater. 2020, 236, 117540. [Google Scholar] [CrossRef]

- Gonçalves, T.; Silva, R.V.; De Brito, J.; Fernández, J.M.; Esquinas, A.R. Mechanical and durability performance of mortars with fine recycled concrete aggregates and reactive magnesium oxide as partial cement replacement. Cem. Concr. Compos. 2020, 105, 103420. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.M.; Martín-Pascual, J.; Martín-Morales, M.; Valverde-Palacios, I.; Zamorano, M. Effects of water to cement ratio, recycled fine aggregate and air entraining/plasticizer admixture on masonry mortar properties. Constr. Build. Mater. 2020, 230, 116929. [Google Scholar] [CrossRef]

- Herbudiman, B.; Saptaji, A.M. Self-Compacting Concrete with Recycled Traditional Roof Tile Powder. Procedia Eng. 2013, 54, 805–816. [Google Scholar] [CrossRef] [Green Version]

- Esquinas, A.R.; Ramos, C.; Jiménez, J.R.; Fernández, J.M.; De Brito, J.M.C.L. Mechanical behaviour of self-compacting concrete made with recovery filler from hot-mix asphalt plants. Constr. Build. Mater. 2017, 131, 114–128. [Google Scholar] [CrossRef]

- Xavier, B.; Verzegnassi, E.; Bortolozo, A.D.; Alves, S.M.; Lintz, R.C.; Andreia Gachet, L.; Osório, W.R. Fresh and Hardened States of Distinctive Self-Compacting Concrete with Marble- and Phyllite-Powder Aggregate Contents. J. Mater. Civ. Eng. 2020, 32, 04020065. [Google Scholar] [CrossRef]

- Khaleel, O.R.; Razak, H.A. Mix design method for self compacting metakaolin concrete with different properties of coarse aggregate. Mater. Des. 2014, 53, 691–700. [Google Scholar] [CrossRef] [Green Version]

- Rajhans, P.; Gupta, P.K.; Kumar, R.R.; Panda, S.K.; Nayak, S. EMV mix design method for preparing sustainable self compacting recycled aggregate concrete subjected to chloride environment. Constr. Build. Mater. 2019, 199, 705–716. [Google Scholar] [CrossRef]

- Mohammed, S.I.; Najim, K.B. Mechanical strength, flexural behavior and fracture energy of Recycled Concrete Aggregate self-compacting concrete. Structures 2020, 23, 34–43. [Google Scholar] [CrossRef]

- Revathi, P.; Selvi, R.S.; Velin, S.S. Investigations on Fresh and Hardened Properties of Recycled Aggregate Self Compacting Concrete. J. Inst. Eng. Ser. A 2013, 94, 179–185. [Google Scholar] [CrossRef]

- Silva, Y.F.; Robayo, R.A.; Mattey, P.E.; Delvasto, S. Properties of self-compacting concrete on fresh and hardened with residue of masonry and recycled concrete. Constr. Build. Mater. 2016, 124, 639–644. [Google Scholar] [CrossRef]

- Ferreira, R.L.; Anjos, M.A.; Nóbrega, A.K.; Pereira, J.E.; Ledesma, E.F. The role of powder content of the recycled aggregates of CDW in the behaviour of rendering mortars. Constr. Build. Mater. 2019, 208, 601–612. [Google Scholar] [CrossRef]

- Kumar, G.S. Influence of fluidity on mechanical and permeation performances of recycled aggregate mortar. Constr. Build. Mater. 2019, 213, 404–412. [Google Scholar] [CrossRef]

- Dhir, R.K.; De Brito, J.; Silva, R.V.; Lye, C.Q. Use of Recycled Aggregates in Mortar. In Sustainability of Construction Materials; Khatib, J., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2019; pp. 143–179. [Google Scholar]

- Zhang, J.; Shi, C.; Li, Y.; Pan, X.; Poon, C.-S.; Xie, Z. Influence of carbonated recycled concrete aggregate on properties of cement mortar. Constr. Build. Mater. 2015, 98, 1–7. [Google Scholar] [CrossRef]

- Eurostat. Municipal Waste Landfilled, Incinerated, Recycled and Composted in the EU-28, 1995 to 2017. Available online: https://ec.europa.eu/eurostat/statistics-explained/images/1/11/Municipal_waste_landfilled%2C_incinerated%2C_recycled_and_composted_in_the_EU-28%2C_1995_to_2017.png (accessed on 27 April 2019).

- Martínez-García, R.; Jagadesh, P.; Fraile-Fernández, F.J.; Pozo, J.M.M.-D.; Juan-Valdés, A. Influence of Design Parameters on Fresh Properties of Self-Compacting Concrete with Recycled Aggregate—A Review. Materials 2020, 13, 5749. [Google Scholar] [CrossRef]

- Aggarwal, P.; Siddique, R.; Aggarwal, Y.; Gupta, S.M. Self-Compacting Concrete-Procedure for Mix Design. Leonardo Electron. J. Pract. Technol. 2008, 12, 15–24. [Google Scholar]

- Obi Lawrence, E. Empirical Investigation of the Effects of Water Quality on Concrete Compressive Strength. Int. J. Constr. Res. Civ. Eng. 2016, 2, 30–35. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Prentice Hall; Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Arιoglu, N.; Girgin, Z.C.; Arιoglu, E. Evaluation of Ratio between Splitting Tensile Strength and Compressive Strength for Concretes up to 120 MPa and its Application in Strength Criterion. ACI Mater. J. 2006, 103, 18–24. [Google Scholar] [CrossRef]

- Uddin, A.; Jameel, M.; Sobuz, H.R.; Hasan, N.M.S.; Islam, S.; Amanat, K.M. The Effect of Curing Time on Compressive Strength of Composite Cement Concrete. Appl. Mech. Mater. 2012, 204–208, 4105–4109. [Google Scholar] [CrossRef]

- Bortolotti, L. First Cracking Load of Concrete Subjected to Direct Tension. ACI Mater. J. 1991, 88, 70–73. [Google Scholar]

- Johnston, I.W. Strength of Intact Geomechanical Materials. J. Geotech. Eng. 1985, 111, 730–749. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Öz, H.Ö.; Taha, I.; Yasemin, M.T. Failure characteristics of self-compacting concretes made with recycled aggregates. Constr. Build. Mater. 2015, 98, 334–344. [Google Scholar] [CrossRef]

- Sadeghi-Nik, A.; Berenjian, J.; Alimohammadi, S.; Lotfi-Omran, O.; Sadeghi-Nik, A.; Karimaei, M. The Effect of Recycled Concrete Aggregates and Metakaolin on the Mechanical Properties of Self-Compacting Concrete Containing Nanoparticles. Iran. J. Sci. Technol. Trans. Civ. Eng. 2018, 43, 503–515. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Ma, Y.; Guo, S. Fresh and mechanical performance and freeze-thaw durability of steel fiber-reinforced rubber self-compacting concrete (SRSCC). J. Clean. Prod. 2020, 277, 123180. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Manso, J.M. Effect of fine recycled concrete aggregate on the mechanical behavior of self-compacting concrete. Constr. Build. Mater. 2020, 263, 120671. [Google Scholar] [CrossRef]

- Fiol, F.; Thomas, C.; Muñoz, C.; Ortega-López, V.; Manso, J.M. The influence of recycled aggregates from precast elements on the mechanical properties of structural self-compacting concrete. Constr. Build. Mater. 2018, 182, 309–323. [Google Scholar] [CrossRef]

- Behera, M.; Minocha, A.K.; Bhattacharyya, S.K. Flow behavior, microstructure, strength and shrinkage properties of self-compacting concrete incorporating recycled fine aggregate. Constr. Build. Mater. 2019, 228, 116819. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Wan, D.L.Y.; Muselin, G. Development of high-performance self-compacting concrete using waste recycled concrete aggregates and rubber granules. J. Clean. Prod. 2018, 182, 553–566. [Google Scholar] [CrossRef]

- Guo, Z.; Jiang, T.; Zhang, J.; Kong, X.; Chen, C.; Lehman, D.E. Mechanical and durability properties of sustainable self-compacting concrete with recycled concrete aggregate and fly ash, slag and silica fume. Constr. Build. Mater. 2020, 231, 117115. [Google Scholar] [CrossRef]

- Señas, L.; Priano, C.; Marfil, S. Influence of recycled aggregates on properties of self-consolidating concretes. Constr. Build. Mater. 2016, 113, 498–505. [Google Scholar] [CrossRef] [Green Version]

- Uygunoğlu, T.; Topçu, I.B.; Çelik, A.G. Use of waste marble and recycled aggregates in self-compacting concrete for environmental sustainability. J. Clean. Prod. 2014, 84, 691–700. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- Grdic, Z.J.; Toplicic-Curcic, G.A.; Despotovic, I.M.; Ristic, N.S. Properties of self-compacting concrete prepared with coarse recycled concrete aggregate. Constr. Build. Mater. 2010, 24, 1129–1133. [Google Scholar] [CrossRef]

- Tang, W.C.; Ryan, P.C.; Cui, H.Z.; Liao, W. Properties of Self-Compacting Concrete with Recycled Coarse Aggregate. Adv. Mater. Sci. Eng. 2016, 2016, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Tuyan, M.; Mardani-Aghabaglou, A.; Ramyar, K. Freeze–thaw resistance, mechanical and transport properties of self-consolidating concrete incorporating coarse recycled concrete aggregate. Mater. Des. 2014, 53, 983–991. [Google Scholar] [CrossRef]

- Manzi, S.; Mazzotti, C.; Bignozzi, M.C. Self-compacting concrete with recycled concrete aggregate: Study of the long-term properties. Constr. Build. Mater. 2017, 157, 582–590. [Google Scholar] [CrossRef]

- Nili, M.; Sasanipour, H.; Aslani, F. The Effect of Fine and Coarse Recycled Aggregates on Fresh and Mechanical Properties of Self-Compacting Concrete. Materials 2019, 12, 1120. [Google Scholar] [CrossRef] [Green Version]

- Duan, Z.; Singh, A.; Xiao, J.; Hou, S. Combined use of recycled powder and recycled coarse aggregate derived from construction and demolition waste in self-compacting concrete. Constr. Build. Mater. 2020, 254, 119323. [Google Scholar] [CrossRef]

- Pan, Z.; Zhou, J.; Jiang, X.; Xu, Y.; Jin, R.; Ma, J.; Zhuang, Y.; Diao, Z.; Zhang, S.; Si, Q.; et al. Investigating the effects of steel slag powder on the properties of self-compacting concrete with recycled aggregates. Constr. Build. Mater. 2019, 200, 570–577. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Properties of concrete prepared with crushed fine stone, furnace bottom ash and fine recycled aggregate as fine aggregates. Constr. Build. Mater. 2009, 23, 2877–2886. [Google Scholar] [CrossRef]

- Babalola, O.E.; Awoyera, P.O.; Tran, M.T.; Le, D.-H.; Olalusi, O.B.; Viloria, A.; Ovallos-Gazabon, D. Mechanical and durability properties of recycled aggregate concrete with ternary binder system and optimized mix proportion. J. Mater. Res. Technol. 2020, 9, 6521–6532. [Google Scholar] [CrossRef]

- Sun, C.; Chen, Q.; Xiao, J.; Liu, W. Utilization of waste concrete recycling materials in self-compacting concrete. Resour. Conserv. Recycl. 2020, 161, 104930. [Google Scholar] [CrossRef]

- Surendar, M.; Ananthi, G.B.G.; Sharaniya, M.; Deepak, M.; Soundarya, T. Mechanical properties of concrete with recycled aggregate and M−sand. Mater. Today Proc. 2021, 44, 1723–1730. [Google Scholar] [CrossRef]

- Nieto, D.; Dapena, E.; Alaejos, P.; Olmedo, J.; Pérez, D. Properties of Self-Compacting Concrete Prepared with Coarse Recycled Concrete Aggregates and Different Water:Cement Ratios. J. Mater. Civ. Eng. 2019, 31, 04018376. [Google Scholar] [CrossRef]

- Ramge, P.; Proske, T.; Kühne, H.-C. Segregation of Coarse Aggregates in Self-Compacting Concrete. In Design, Production and Placement of Self-Consolidating Concrete; Springer: Dordrecht, The Netherlands, 2010; Volume 1, pp. 113–125. [Google Scholar]

- Solak, A.M.; Tenza-Abril, A.J.; García-Vera, V.E. Influence of The Segregation Phenomenon on Structural Efficiency of Lightweight Aggregate Concretes. Materials 2020, 13, 5754. [Google Scholar] [CrossRef]

- Wong, H.S.; Buenfeld, N.R. Determining the water–cement ratio, cement content, water content and degree of hydration of hardened cement paste: Method development and validation on paste samples. Cem. Concr. Res. 2009, 39, 957–965. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, M.S.; Mohamed, S.A.; Johari, M.A.M. Influence of Superplasticizer Compatibility on the Setting Time, Strength and Stiffening Characteristics of Concrete. Adv. Appl. Sci. 2016, 1, 30–36. [Google Scholar] [CrossRef]

- Lin, W.-T. Effects of sand/aggregate ratio on strength, durability, and microstructure of self-compacting concrete. Constr. Build. Mater. 2020, 242, 118046. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Effect of mineral admixtures on properties of recycled aggregate concrete at high temperature. Constr. Build. Mater. 2018, 184, 361–373. [Google Scholar] [CrossRef]

- Workability, Testing, and Performance of Self-Consolidating Concrete. ACI Mater. J. 1999, 96, 346–353. [CrossRef]

- Yardimci, M.Y.; Baradan, B.; Taşdemir, M.A. Effect of fine to coarse aggregate ratio on the rheology and fracture energy of steel fibre reinforced self-compacting concretes. Sadhana 2014, 39, 1447–1469. [Google Scholar] [CrossRef]

- Hanehara, S.; Yamada, K. Interaction between cement and chemical admixture from the point of cement hydration, absorption behaviour of admixture, and paste rheology. Cem. Concr. Res. 1999, 29, 1159–1165. [Google Scholar] [CrossRef]

- Okamura, H.; Ouchi, M. Self-Compacting Concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Janowska-Renkas, E. The effect of superplasticizers’ chemical structure on their efficiency in cement pastes. Constr. Build. Mater. 2013, 38, 1204–1210. [Google Scholar] [CrossRef]

- Aiad, I.; El-Aleem, S.A.; El-Didamony, H. Effect of delaying addition of some concrete admixtures on the rheological properties of cement pastes. Cem. Concr. Res. 2002, 32, 1839–1843. [Google Scholar] [CrossRef]

- Corradi, M.; Khurana, R.; Magarotto, R. Zero Energy Concrete for Sustainable Precast Concrete Production. In Proceedings of the Role of Concrete In Sustainable Development: Sustainable Development: Proceedings of the International Symposium dedicated to Professor Surendra Shah, Northwestern University, USA, Dundee, UK, 3–4 September 2003; pp. 451–461. [Google Scholar]

- Huang, F.; Li, H.; Yi, Z.; Wang, Z.; Xie, Y. The rheological properties of self-compacting concrete containing superplasticizer and air-entraining agent. Constr. Build. Mater. 2018, 166, 833–838. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Almalki, A. Influence of mixing time and superplasticizer dosage on self-consolidating concrete properties. J. Mater. Res. Technol. 2020, 9, 6101–6115. [Google Scholar] [CrossRef]

- Yalley, P.P.; Sam, A. Effect of Sand Fines and Water/Cement Ratio on Concrete Properties. Civ. Eng. Res. J. 2018, 4. [Google Scholar] [CrossRef] [Green Version]

- Rozière, E.; Granger, S.; Turcry, P.; Loukili, A. Influence of paste volume on shrinkage cracking and fracture properties of self-compacting concrete. Cem. Concr. Compos. 2007, 29, 626–636. [Google Scholar] [CrossRef] [Green Version]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Mohseni, E.; Saadati, R.; Kordbacheh, N.; Parpinchi, Z.S.; Tang, W. Engineering and microstructural assessment of fibre-reinforced self-compacting concrete containing recycled coarse aggregate. J. Clean. Prod. 2017, 168, 605–613. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R.; Lublóy, É. Performance of Self-Compacting High-Performance Concrete Produced with Waste Materials after Exposure to Elevated Temperature. J. Mater. Civ. Eng. 2020, 32, 05019004. [Google Scholar] [CrossRef]

- Santos, S.; da Silva, P.R.; de Brito, J. Self-compacting concrete with recycled aggregates—A literature review. J. Build. Eng. 2019, 22, 349–371. [Google Scholar] [CrossRef]

- Pereira-De-Oliveira, L.A.; Nepomuceno, M.C.S.; Castro-Gomes, J.P.; Vila, M.D.F.C. Permeability properties of self-compacting concrete with coarse recycled aggregates. Constr. Build. Mater. 2014, 51, 113–120. [Google Scholar] [CrossRef]

- Panda, K.; Bal, P. Properties of Self Compacting Concrete Using Recycled Coarse Aggregate. Procedia Eng. 2013, 51, 159–164. [Google Scholar] [CrossRef] [Green Version]

- Xiao, J.; Li, W.; Sun, Z.; Lange, D.; Shah, S.P. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cem. Concr. Compos. 2013, 37, 276–292. [Google Scholar] [CrossRef]

- Del Viso, J.R.; Carmona, J.R.; Ruiz, G. Shape and size effects on the compressive strength of high-strength concrete. Cem. Concr. Res. 2008, 38, 386–395. [Google Scholar] [CrossRef]

- Talaat, A.; Emad, A.; Tarek, A.; Masbouba, M.; Essam, A.; Kohail, M. Factors affecting the results of concrete compression testing: A review. Ain Shams Eng. J. 2020. [Google Scholar] [CrossRef]

- van Vliet, M.R.A.; van Mier, J.G.M. Experimental Investigation of Concrete Fracture under Uniaxial Compression—Van Vliet—1996—Mechanics of Cohesive-frictional Materials—Wiley Online Library. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/%28SICI%291099-1484%28199601%291%3A1%3C115%3A%3AAID-CFM6%3E3.0.CO%3B2-U (accessed on 7 May 2021).

- Kim, J.-K.; Yi, S.-T. Application of size effect to compressive strength of concrete members. Sadhana 2002, 27, 467–484. [Google Scholar] [CrossRef] [Green Version]

- Carneiro, F.L.; Barcellos, A. Tensile Strength of Concrete. RILEM Bull. 1949, 13, 98–125. [Google Scholar]

- Nilson, S. The Tensile Strength of Concrete Determined by Splitting Tests on Cubes. RILEM Bull. 1961, 11, 63–67. [Google Scholar]

- Ince, R.; Gor, M.; Eren, M.E.; Alyamaç, K.E. The Effect of Size on the Splitting Strength of Cubic Concrete Members. Strain 2014, 51, 135–146. [Google Scholar] [CrossRef]

- Gao, M.; Beig, G.; Song, S.; Zhang, H.; Hu, J.; Ying, Q.; Liang, F.; Liu, Y.; Wang, H.; Lu, X.; et al. The impact of power generation emissions on ambient PM2.5 pollution and human health in China and India. Environ. Int. 2018, 121, 250–259. [Google Scholar] [CrossRef] [PubMed]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Esquinas, A.R.; Ledesma, E.F.; Otero, R.; Jiménez, J.R.; Fernández, J.M. Mechanical behaviour of self-compacting concrete made with non-conforming fly ash from coal-fired power plants. Constr. Build. Mater. 2018, 182, 385–398. [Google Scholar] [CrossRef]

- Jagadesh, P.; Ramachandramurthy, A.; Murugesan, R. Evaluation of mechanical properties of Sugar Cane Bagasse Ash concrete. Constr. Build. Mater. 2018, 176, 608–617. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M. Properties of self-compacting portland pozzolana and limestone blended cement concretes containing different replacement levels of slag. Mater. Struct. 2011, 44, 1399–1410. [Google Scholar] [CrossRef]

| Authors | Design Parameters | Strength (MPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | Fresh Density (kg/m3) | Compressive Load Area (cm2) | Split tensile Load Area (cm2) | Fck | Fsk | |

| Gesoglu et al., 2015 (A) [48] | 0.30 | 0.23 | 3.80 | 1.79 | 6.29 | 5.85 | - | 0 | 2322.8 | 100.0 | 628 | 77.96 | 4.25 |

| 0.30 | 0.23 | 3.54 | 1.79 | 4.95 | 6.16 | - | 100 | 2211.6 | 100.0 | 628 | 68.67 | 3.50 | |

| Gesoglu et al., 2015 (B) [48] | 0.30 | 0.20 | 4.34 | 2.04 | 7.00 | 5.11 | - | 0 | 2289.2 | 100.0 | 628 | 81.40 | 4.46 |

| 0.30 | 0.20 | 4.05 | 2.04 | 6.26 | 5.37 | - | 100 | 2181.7 | 100.0 | 628 | 70.39 | 4.13 | |

| Gesoglu et al., 2015 (D) [48] | 0.43 | 0.28 | 5.22 | 2.46 | 4.55 | 6.36 | - | 0 | 2243.8 | 100.0 | 628 | 72.47 | 3.75 |

| 0.43 | 0.28 | 4.87 | 2.46 | 4.09 | 6.72 | - | 100 | 2132.7 | 100.0 | 628 | 63.89 | 3.24 | |

| Gesoglu et al., 2015 (E) [48] | 0.30 | 0.23 | 3.80 | 1.79 | 6.29 | 5.85 | 0 | - | 2322.8 | 100.0 | 628 | 77.96 | 4.25 |

| 0.30 | 0.23 | 3.57 | 1.79 | 4.51 | 6.12 | 100 | - | 2224.9 | 100.0 | 628 | 61.97 | 3.15 | |

| Gesoglu et al., 2015 (F) [48] | 0.30 | 0.20 | 4.34 | 2.04 | 7.00 | 5.11 | 0 | - | 2289.2 | 100.0 | 628 | 81.40 | 4.46 |

| 0.30 | 0.20 | 4.08 | 2.04 | 4.20 | 5.34 | 100 | - | 2193.2 | 100.0 | 628 | 64.61 | 3.59 | |

| Gesoglu et al., 2015 (H) [48] | 0.43 | 0.28 | 5.22 | 2.46 | 4.55 | 6.36 | 0 | - | 2243.8 | 100.0 | 628 | 72.47 | 3.75 |

| 0.43 | 0.28 | 4.91 | 2.46 | 2.70 | 6.67 | 100 | - | 2145.5 | 100.0 | 628 | 61.04 | 2.81 | |

| Gesoglu et al., 2015 (I) [48] | 0.30 | 0.23 | 3.80 | 1.79 | 6.29 | 5.85 | 0 | 0 | 2322.8 | 100.0 | 628 | 77.96 | 4.25 |

| 0.30 | 0.23 | 3.31 | 1.79 | 3.44 | 6.46 | 100 | 100 | 2114.6 | 100.0 | 628 | 55.76 | 2.72 | |

| Gesoglu et al., 2015 (J) [48] | 0.30 | 0.20 | 4.34 | 2.04 | 7.00 | 5.11 | 0 | 0 | 2289.2 | 100.0 | 628 | 81.40 | 4.46 |

| 0.30 | 0.20 | 3.79 | 2.04 | 3.79 | 5.64 | 100 | 100 | 2083.5 | 100.0 | 628 | 57.41 | 3.16 | |

| Gesoglu et al., 2015 (L) [48] | 0.43 | 0.28 | 5.22 | 2.46 | 4.55 | 6.36 | 0 | 0 | 2243.8 | 100.0 | 628 | 72.47 | 3.75 |

| 0.43 | 0.28 | 4.55 | 2.46 | 2.62 | 7.06 | 100 | 100 | 2034.4 | 100.0 | 628 | 52.92 | 2.59 | |

| Wang et al., 2020 [50] | 0.36 | 0.35 | 4.37 | 2.309 | 6.50 | 6.64 | 0 | - | 2415.5 | 78.5 | 628 | 72.30 | 4.43 |

| 0.36 | 0.35 | 4.23 | 2.174 | 6.50 | 6.81 | 5 | - | 2359.5 | 78.5 | 628 | 58.50 | 4.15 | |

| 0.36 | 0.35 | 4.27 | 2.174 | 6.50 | 6.77 | 10 | - | 2374.9 | 78.5 | 628 | 56.00 | 4.70 | |

| 0.36 | 0.35 | 4.20 | 2.174 | 6.50 | 6.85 | 15 | - | 2346.9 | 78.5 | 628 | 50.10 | 3.67 | |

| 0.36 | 0.35 | 4.07 | 2.174 | 6.50 | 7.03 | 25 | - | 2290.5 | 78.5 | 628 | 32.20 | 3.30 | |

| Sadeghi-Nik., et al. 2019 (B) [49] | 0.41 | 0.34 | 3.84 | 2.180 | 7.00 | 8.44 | 0 | 0 | 2337.3 | 100.0 | 1413 | 74.10 | 3.60 |

| 0.41 | 0.34 | 3.84 | 2.180 | 7.00 | 8.44 | 20 | 20 | 2337.3 | 100.0 | 1413 | 55.00 | 3.10 | |

| 0.41 | 0.34 | 3.84 | 2.180 | 7.00 | 8.44 | 40 | 40 | 2337.3 | 100.0 | 1413 | 52.10 | 2.90 | |

| 0.41 | 0.34 | 3.84 | 2.180 | 7.00 | 8.44 | 60 | 60 | 2337.3 | 100.0 | 1413 | 51.00 | 2.70 | |

| 0.41 | 0.34 | 3.84 | 2.180 | 7.00 | 8.44 | 80 | 80 | 2337.3 | 100.0 | 1413 | 50.50 | 2.70 | |

| 0.41 | 0.34 | 3.84 | 2.180 | 7.00 | 8.44 | 100 | 100 | 2337.3 | 100.0 | 1413 | 40.00 | 2.50 | |

| Authors | Design Parameters | Strength (MPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | Fresh Density (kg/m3) | Compressive Load Area (cm2) | Split Tensile Load Area (cm2) | Fck | Fsk | |

| Gesoglu et al., 2015 (C) [48] | 0.430 | 0.32 | 4.563 | 2.148 | 3.11 | 7.29 | - | 0 | 2322.8 | 78.50 | 1413 | 66.63 | 3.50 |

| 0.430 | 0.32 | 4.252 | 2.148 | 2.55 | 7.70 | - | 100 | 2211.6 | 78.50 | 1413 | 55.38 | 2.89 | |

| Gesoglu et al., 2015 (G) [48] | 0.430 | 0.32 | 4.563 | 2.148 | 3.11 | 7.29 | 0 | - | 2289.2 | 78.50 | 1413 | 66.63 | 3.50 |

| 0.430 | 0.32 | 4.288 | 2.148 | 1.82 | 7.65 | 100 | - | 2181.7 | 78.50 | 1413 | 48.69 | 2.53 | |

| Gesoglu et al., 2015 (K) [48] | 0.430 | 0.32 | 4.563 | 2.148 | 3.11 | 7.29 | 0 | 0 | 2243.8 | 78.50 | 1413 | 66.63 | 3.50 |

| 0.430 | 0.32 | 3.978 | 2.148 | 1.78 | 8.10 | 100 | 100 | 2132.7 | 100.00 | 628 | 46.04 | 2.20 | |

| Revilla Cuesta et al., 2020 [51] | 0.459 | 0.29 | 5.583 | 3.833 | 6.60 | 6.39 | - | 0 | 2322.8 | 100.00 | 628 | 60.00 | 3.20 |

| 0.470 | 0.29 | 5.516 | 3.767 | 6.60 | 6.60 | - | 25 | 2224.9 | 100.00 | 628 | 56.00 | 3.03 | |

| 0.482 | 0.30 | 5.433 | 3.683 | 6.60 | 6.85 | - | 50 | 2289.2 | 100.00 | 628 | 44.00 | 2.75 | |

| 0.506 | 0.32 | 5.367 | 3.617 | 6.60 | 7.26 | - | 75 | 2193.2 | 100.00 | 628 | 31.00 | 2.50 | |

| 0.530 | 0.33 | 5.283 | 3.533 | 6.60 | 7.70 | - | 100 | 2243.8 | 100.00 | 628 | 30.00 | 2.40 | |

| Fiol et al., 2018 (C) [52] | 0.310 | 0.17 | 5.625 | 2.031 | 1.80 | 4.13 | - | 0 | 2145.5 | 176.63 | 1413 | 63.36 | 5.30 |

| 0.300 | 0.16 | 5.688 | 2.031 | 1.80 | 3.97 | - | 20 | 2322.8 | 176.63 | 1413 | 64.13 | 5.21 | |

| 0.270 | 0.14 | 5.469 | 2.094 | 2.25 | 3.68 | - | 50 | 2114.6 | 176.63 | 1413 | 66.82 | 4.95 | |

| 0.250 | 0.13 | 5.500 | 2.250 | 2.85 | 3.39 | - | 100 | 2289.2 | 176.63 | 1413 | 72.81 | 5.00 | |

| Behera et al., 2019 (A) [53] | 0.560 | 0.34 | 5.350 | 2.960 | 5.23 | 7.98 | 0 | - | 2083.5 | 225.00 | 1413 | 60.76 | 4.13 |

| 0.560 | 0.34 | 5.350 | 2.960 | 5.23 | 7.98 | 50 | - | 2243.8 | 225.00 | 1413 | 55.76 | 3.82 | |

| 0.560 | 0.34 | 5.350 | 2.960 | 5.23 | 7.98 | 100 | - | 2034.4 | 225.00 | 1413 | 44.54 | 3.20 | |

| Behera et al., 2019 (B) [53] | 0.560 | 0.34 | 5.350 | 2.960 | 5.23 | 7.98 | 0 | - | 2415.5 | 225.00 | 1413 | 60.76 | 4.13 |

| 0.560 | 0.34 | 5.350 | 2.960 | 3.15 | 7.98 | 0 | - | 2359.5 | 225.00 | 1413 | 44.54 | 3.56 | |

| 0.560 | 0.34 | 5.350 | 2.960 | 4.20 | 7.98 | 100 | - | 2374.9 | 225.00 | 1413 | 38.41 | 2.71 | |

| Authors | Design Parameters | Strength (MPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | Fresh Density (kg/m3) | Compressive Load Area (cm2) | Split Tensile Load Area (cm2) | Fck | Fsk | |

| Señas et al., 2016 (B) [56] | 0.40 | 0.40 | 4.373 | 2.566 | 4.15 | 7.44 | 0 | 0 | 2395.8 | 176.63 | 1413 | 51.20 | 4.60 |

| 0.40 | 0.40 | 4.272 | 2.566 | 4.98 | 7.59 | 0 | 50 | 2353.9 | 176.63 | 1413 | 48.10 | 4.10 | |

| 0.40 | 0.40 | 4.229 | 2.523 | 5.81 | 7.65 | 50 | 50 | 2336.0 | 176.63 | 1413 | 45.60 | 3.80 | |

| Aslani et al., 2018 (C) [54] | 1.13 | 0.45 | 9.311 | 5.090 | 3.75 | 9.57 | 0 | 0 | 2329.4 | 78.50 | 1413 | 50.39 | 3.70 |

| 1.13 | 0.45 | 9.225 | 5.050 | 2.95 | 9.64 | 10 | 20 | 2313.9 | 78.50 | 1413 | 47.74 | 4.38 | |

| 1.13 | 0.45 | 9.139 | 5.010 | 3.55 | 9.71 | 20 | 20 | 2298.4 | 78.50 | 1413 | 46.06 | 3.98 | |

| 1.13 | 0.45 | 9.054 | 4.960 | 3.75 | 9.78 | 30 | 20 | 2283.1 | 78.50 | 1413 | 45.13 | 3.79 | |

| 1.13 | 0.45 | 8.968 | 4.920 | 3.95 | 9.85 | 40 | 20 | 2267.6 | 78.50 | 1413 | 43.82 | 3.80 | |

| Guo et al., 2020 [55] | 0.35 | 0.35 | 3.177 | 1.510 | 4.02 | 8.38 | - | 0 | 2354.0 | 225.00 | 225 | 53.45 | 4.39 |

| 0.35 | 0.35 | 3.143 | 1.510 | 4.16 | 8.45 | - | 50 | 2336.4 | 225.00 | 225 | 46.54 | 3.49 | |

| 0.35 | 0.35 | 3.110 | 1.510 | 4.72 | 8.52 | - | 100 | 2319.2 | 225.00 | 225 | 43.89 | 3.32 | |

| 0.35 | 0.18 | 6.219 | 3.019 | 4.78 | 4.26 | - | 100 | 2227.9 | 225.00 | 225 | 21.00 | 1.57 | |

| 0.35 | 0.18 | 6.219 | 3.019 | 5.67 | 4.26 | - | 100 | 2227.9 | 225.00 | 225 | 38.38 | 2.75 | |

| 0.35 | 0.18 | 6.219 | 3.019 | 6.86 | 4.26 | - | 100 | 2227.9 | 225.00 | 225 | 49.44 | 3.66 | |

| 0.35 | 0.09 | 12.438 | 6.038 | 7.40 | 2.13 | - | 100 | 2182.4 | 225.00 | 225 | 13.64 | 0.96 | |

| 0.35 | 0.09 | 12.438 | 6.038 | 7.28 | 2.13 | - | 100 | 2182.4 | 225.00 | 225 | 30.84 | 1.67 | |

| 0.35 | 0.09 | 12.438 | 6.038 | 7.57 | 2.13 | - | 100 | 2182.4 | 225.00 | 225 | 42.75 | 2.89 | |

| Fiol et al., 2018 (B) [52] | 0.31 | 0.15 | 6.207 | 2.241 | 1.80 | 3.76 | - | 0 | 2479.9 | 176.63 | 1413 | 58.30 | 5.50 |

| 0.32 | 0.16 | 6.276 | 2.241 | 1.80 | 3.85 | - | 20 | 2502.8 | 176.63 | 1413 | 60.25 | 5.15 | |

| 0.27 | 0.13 | 6.034 | 2.310 | 2.25 | 3.35 | - | 50 | 2418.2 | 176.63 | 1413 | 58.52 | 5.20 | |

| 0.25 | 0.12 | 6.069 | 2.483 | 2.85 | 3.09 | - | 100 | 2422.5 | 176.63 | 1413 | 70.56 | 5.32 | |

| Uygunoglu et al., 2014 [57] | 0.31 | 0.24 | 4.874 | 2.057 | 10.80 | 5.03 | - | 0 | 2264.4 | 225.00 | 225 | 57.00 | 3.50 |

| 0.31 | 0.24 | 4.920 | 2.057 | 10.80 | 5.00 | - | 100 | 2280.5 | 225.00 | 225 | 54.00 | 3.70 | |

| 0.34 | 0.26 | 4.777 | 2.017 | 9.50 | 5.61 | - | 0 | 2241.0 | 225.00 | 225 | 56.60 | 3.20 | |

| 0.34 | 0.26 | 4.823 | 2.017 | 9.50 | 5.57 | - | 100 | 2257.1 | 225.00 | 225 | 53.20 | 3.40 | |

| 0.37 | 0.29 | 4.683 | 1.977 | 8.10 | 6.20 | - | 0 | 2218.6 | 225.00 | 225 | 56.10 | 3.00 | |

| 0.37 | 0.29 | 4.729 | 1.977 | 8.10 | 6.15 | - | 100 | 2234.7 | 225.00 | 225 | 52.50 | 3.10 | |

| 0.40 | 0.31 | 4.586 | 1.937 | 6.80 | 6.81 | - | 0 | 2195.1 | 225.00 | 225 | 55.60 | 2.80 | |

| 0.40 | 0.31 | 4.631 | 1.937 | 6.80 | 6.76 | - | 100 | 2210.9 | 225.00 | 225 | 51.70 | 2.80 | |

| Kou et al., 2009 (B) [58] | 0.44 | 0.25 | 4.447 | 1.947 | 8.50 | 7.05 | 0 | - | 2271.6 | 100.00 | 628 | 53.70 | 2.90 |

| 0.44 | 0.25 | 4.447 | 1.888 | 8.50 | 7.05 | 25 | - | 2271.6 | 100.00 | 628 | 64.30 | 3.20 | |

| 0.44 | 0.25 | 4.447 | 1.829 | 8.50 | 7.05 | 50 | - | 2271.6 | 100.00 | 628 | 62.30 | 3.40 | |

| 0.44 | 0.25 | 4.447 | 1.771 | 8.50 | 7.05 | 75 | - | 2271.6 | 100.00 | 628 | 56.30 | 3.30 | |

| 0.44 | 0.25 | 4.447 | 1.709 | 8.50 | 7.05 | 100 | - | 2271.6 | 100.00 | 628 | 53.20 | 3.50 | |

| Sadeghi-Nik., et al. 2019 (B) [49] | 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 0 | 0 | 2338.6 | 100.00 | 1413 | 52.00 | 3.30 |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 20 | 20 | 2338.6 | 100.00 | 1413 | 43.10 | 2.70 | |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 40 | 40 | 2338.6 | 100.00 | 1413 | 41.00 | 2.50 | |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 60 | 60 | 2338.6 | 100.00 | 1413 | 40.10 | 2.50 | |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 80 | 80 | 2338.6 | 100.00 | 1413 | 38.10 | 2.20 | |

| 0.41 | 0.34 | 3.843 | 2.176 | 7.00 | 8.10 | 100 | 100 | 2338.6 | 100.00 | 1413 | 30.00 | 2.10 | |

| Grdic et al., 2010 [59] | 0.42 | 0.25 | 3.748 | 2.098 | 4.00 | 7.80 | - | 0 | 2376.8 | 225.00 | 1413 | 50.00 | 7.20 |

| 0.43 | 0.27 | 3.748 | 2.098 | 4.00 | 7.99 | - | 50 | 2380.9 | 225.00 | 1413 | 48.00 | 7.10 | |

| 0.45 | 0.28 | 3.748 | 2.098 | 4.00 | 8.36 | - | 100 | 2389.1 | 225.00 | 1413 | 46.00 | 6.20 | |

| Tang et al., 2016 [60] | 0.49 | 0.35 | 3.315 | 1.831 | 4.50 | 10.36 | - | 0 | 2323.3 | 225.00 | 1413 | 59.00 | 4.10 |

| 0.49 | 0.35 | 3.285 | 1.831 | 4.50 | 10.43 | - | 25 | 2309.9 | 225.00 | 1413 | 64.00 | 4.90 | |

| 0.49 | 0.35 | 3.258 | 1.831 | 4.50 | 10.49 | - | 50 | 2297.9 | 225.00 | 1413 | 65.00 | 4.10 | |

| 0.49 | 0.35 | 3.231 | 1.831 | 4.50 | 10.55 | - | 75 | 2285.9 | 225.00 | 1413 | 60.00 | 3.90 | |

| 0.49 | 0.35 | 3.202 | 1.831 | 4.50 | 10.61 | - | 100 | 2273.0 | 225.00 | 1413 | 54.00 | 3.80 | |

| Tuyan et al., 2014 (A) [61] | 0.43 | 0.32 | 4.708 | 2.365 | 4.90 | 6.47 | - | 0 | 2230.5 | 225.00 | 225 | 52.30 | 4.86 |

| 0.43 | 0.32 | 4.708 | 2.365 | 5.50 | 6.47 | - | 20 | 2230.5 | 225.00 | 225 | 54.70 | 4.69 | |

| 0.43 | 0.32 | 4.708 | 2.365 | 5.70 | 6.47 | - | 40 | 2230.5 | 225.00 | 225 | 57.20 | 4.51 | |

| 0.43 | 0.32 | 4.708 | 2.365 | 6.20 | 6.47 | - | 60 | 2230.5 | 225.00 | 225 | 51.10 | 4.33 | |

| Authors | Design Parameters | Strength (MPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | Fresh Density (kg/m3) | Compressive Load Area (cm2) | Split Tensile Load Area (cm2) | Fck | Fsk | |

| Señas et al., 2016 (A) [56] | 0.40 | 0.40 | 4.37 | 2.57 | 2.91 | 7.44 | 0 | 0 | 2395.8 | 176.63 | 1413 | 47.60 | 4.40 |

| 0.40 | 0.40 | 4.27 | 2.57 | 5.40 | 7.59 | 0 | 50 | 2353.9 | 176.63 | 1413 | 46.60 | 4.30 | |

| 0.40 | 0.40 | 4.23 | 2.52 | 6.23 | 7.65 | 50 | 50 | 2336.0 | 176.63 | 1413 | 47.00 | 3.90 | |

| Martínez-García et al., 2020 [19] | 0.47 | 0.41 | 4.01 | 2.26 | 3.20 | 9.12 | - | 0 | 2250.0 | 176.63 | 1413 | 46.36 | 4.60 |

| 0.47 | 0.41 | 4.01 | 2.26 | 4.00 | 9.12 | - | 25 | 2250.0 | 176.63 | 1413 | 55.58 | 4.10 | |

| 0.47 | 0.41 | 4.01 | 2.26 | 4.80 | 9.12 | - | 50 | 2250.0 | 176.63 | 1413 | 54.70 | 3.20 | |

| 0.47 | 0.41 | 4.01 | 2.26 | 5.40 | 9.12 | - | 100 | 2250.0 | 176.63 | 1413 | 44.04 | 3.30 | |

| Fiol et al., 2018 (A) [52] | 0.40 | 0.18 | 7.20 | 2.60 | 1.80 | 4.22 | - | 0 | 2470.0 | 176.63 | 1413 | 49.09 | 5.17 |

| 0.39 | 0.17 | 7.28 | 2.60 | 1.80 | 4.08 | - | 20 | 2487.5 | 176.63 | 1413 | 49.98 | 5.06 | |

| 0.35 | 0.15 | 7.00 | 2.68 | 2.25 | 3.77 | - | 50 | 2407.5 | 176.63 | 1413 | 55.64 | 4.85 | |

| 0.32 | 0.14 | 7.04 | 2.88 | 2.85 | 3.43 | - | 100 | 2410.0 | 176.63 | 1413 | 56.75 | 4.92 | |

| Duan et al., 2020 (A) [64] | 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 0 | 2227.2 | 100.00 | 100 | 42.91 | 4.45 | |

| 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 0 | 2227.2 | 100.00 | 100 | 42.41 | 4.44 | ||

| 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 25 | 2227.2 | 100.00 | 100 | 40.45 | 3.64 | ||

| 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 50 | 2227.2 | 100.00 | 100 | 36.93 | 3.60 | ||

| 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 100 | 2227.2 | 100.00 | 100 | 34.85 | 3.20 | ||

| Duan et al., 2020 (B) [64] | 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 0 | 2227.2 | 100.00 | 100 | 42.91 | 4.45 | |

| 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 0 | 2227.2 | 100.00 | 100 | 42.41 | 4.44 | ||

| 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 25 | 2227.2 | 100.00 | 100 | 40.45 | 3.64 | ||

| 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 50 | 2227.2 | 100.00 | 100 | 36.93 | 3.60 | ||

| 0.40 | 0.28 | 3.35 | 1.53 | 1.53 | 8.38 | 100 | 2227.2 | 100.00 | 100 | 34.85 | 3.20 | ||

| Pan et al., 2019 [65] | 0.41 | 0.33 | 3.90 | 1.81 | 1.16 | 7.96 | - | 30 | 2370.8 | 225.00 | 225 | 45.60 | 3.10 |

| 0.46 | 0.33 | 4.33 | 2.01 | 1.16 | 8.04 | - | 30 | 2373.7 | 225.00 | 225 | 49.00 | 3.30 | |

| 0.52 | 0.33 | 4.88 | 2.26 | 1.16 | 8.07 | - | 30 | 2373.4 | 225.00 | 225 | 42.53 | 2.60 | |

| 0.59 | 0.33 | 5.58 | 2.59 | 1.16 | 8.01 | - | 30 | 2371.9 | 225.00 | 225 | 37.22 | 2.30 | |

| 0.70 | 0.33 | 6.57 | 3.05 | 1.16 | 8.07 | - | 30 | 2371.1 | 225.00 | 225 | 32.11 | 2.00 | |

| 0.83 | 0.33 | 7.81 | 3.62 | 1.16 | 8.05 | - | 30 | 2372.9 | 225.00 | 225 | 28.10 | 1.80 | |

| Kou et al., 2009 (A) [66] | 0.44 | 0.25 | 4.45 | 1.95 | 8.50 | 7.05 | 0 | - | 2271.6 | 100.00 | 628 | 44.30 | 2.90 |

| 0.44 | 0.25 | 4.45 | 1.89 | 8.50 | 7.05 | 25 | - | 2271.6 | 100.00 | 628 | 44.50 | 2.70 | |

| 0.44 | 0.25 | 4.45 | 1.83 | 8.50 | 7.05 | 50 | - | 2271.6 | 100.00 | 628 | 43.40 | 2.70 | |

| 0.44 | 0.25 | 4.45 | 1.77 | 8.50 | 7.05 | 75 | - | 2271.6 | 100.00 | 628 | 41.30 | 2.60 | |

| 0.44 | 0.25 | 4.45 | 1.71 | 8.50 | 7.05 | 100 | - | 2271.6 | 100.00 | 628 | 38.70 | 2.50 | |

| Manzi et al., 2017 [62] | 0.51 | 0.31 | 4.57 | 1.66 | 4.90 | 8.23 | 0 | 0 | 2346.6 | 225.00 | 225 | 43.80 | 3.30 |

| 0.49 | 0.30 | 4.45 | 2.56 | 5.25 | 8.06 | 12 | 13 | 2299.4 | 225.00 | 225 | 45.40 | 3.20 | |

| 0.49 | 0.30 | 4.39 | 2.43 | 5.25 | 8.14 | 19 | 21 | 2277.7 | 225.00 | 225 | 50.30 | 2.50 | |

| 0.51 | 0.31 | 4.47 | 2.79 | 5.60 | 8.36 | 0 | 40 | 2312.7 | 225.00 | 225 | 51.10 | 3.10 | |

| Nili et al., 2019 (A) [63] | 0.44 | 0.31 | 3.61 | 2.80 | 3.34 | 8.79 | 0 | 0 | 2275.8 | 100.00 | 628 | 46.30 | 3.40 |

| 0.44 | 0.31 | 3.57 | 2.78 | 3.89 | 8.86 | 0 | 100 | 2258.9 | 100.00 | 628 | 32.10 | 3.40 | |

| 0.44 | 0.31 | 3.57 | 2.78 | 3.89 | 8.86 | 50 | 0 | 2259.7 | 100.00 | 628 | 35.20 | 3.20 | |

| 0.44 | 0.32 | 3.53 | 2.75 | 3.89 | 8.94 | 50 | 100 | 2241.9 | 100.00 | 628 | 38.20 | 3.40 | |

| Nili et al., 2019 (B) [63] | 0.44 | 0.31 | 3.61 | 2.81 | 3.34 | 8.79 | 0 | 0 | 2275.8 | 100.00 | 628 | 46.30 | 3.40 |

| 0.48 | 0.32 | 3.91 | 3.04 | 3.47 | 8.83 | 0 | 0 | 2276.7 | 100.00 | 628 | 46.40 | 4.30 | |

| 0.48 | 0.32 | 3.87 | 3.01 | 3.85 | 8.91 | 0 | 100 | 2259.9 | 100.00 | 628 | 52.90 | 4.10 | |

| 0.48 | 0.32 | 3.88 | 3.01 | 4.24 | 8.90 | 50 | 0 | 2260.7 | 100.00 | 628 | 32.50 | 2.90 | |

| 0.48 | 0.32 | 3.83 | 2.98 | 4.62 | 8.98 | 50 | 100 | 2242.9 | 100.00 | 628 | 31.80 | 3.10 | |

| Tuyan et al., 2014 (B) [61] | 0.48 | 0.36 | 4.55 | 2.26 | 3.30 | 7.41 | - | 0 | 2191.1 | 225.00 | 225 | 42.20 | 4.33 |

| 0.48 | 0.36 | 4.55 | 2.26 | 3.40 | 7.41 | - | 20 | 2191.1 | 225.00 | 225 | 44.00 | 4.44 | |

| 0.48 | 0.36 | 4.55 | 2.26 | 3.50 | 7.41 | - | 40 | 2191.1 | 225.00 | 225 | 44.30 | 4.01 | |

| 0.48 | 0.36 | 4.55 | 2.26 | 3.70 | 7.41 | - | 60 | 2191.1 | 225.00 | 225 | 40.90 | 3.85 | |

| Singh et al., 2019 (A) [1] | 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 0 | 2361.0 | 78.50 | 628 | 42.34 | 2.62 |

| 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 50 | 2361.0 | 78.50 | 628 | 36.49 | 2.49 | |

| 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 100 | 2361.0 | 78.50 | 628 | 31.53 | 2.37 | |

| Singh et al., 2019 (B) [1] | 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 0 | 2361.0 | 78.50 | 628 | 42.34 | 2.62 |

| 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 50 | 2361.0 | 78.50 | 628 | 39.42 | 2.55 | |

| 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 100 | 2361.0 | 78.50 | 628 | 35.08 | 2.46 | |

| Singh et al., 2019 (C) [1] | 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 0 | 2361.0 | 78.50 | 628 | 42.34 | 2.62 |

| 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 50 | 2361.0 | 78.50 | 628 | 38.69 | 2.54 | |

| 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 100 | 2361.0 | 78.50 | 628 | 33.88 | 2.42 | |

| Singh et al., 2019 (D) [1] | 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 0 | 2361.0 | 78.50 | 628 | 42.34 | 2.62 |

| 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 50 | 2361.0 | 78.50 | 628 | 41.85 | 2.61 | |

| 0.57 | 0.40 | 3.49 | 1.88 | 1.23 | 11.63 | - | 100 | 2361.0 | 78.50 | 628 | 38.02 | 2.52 | |

| Authors | Design Parameters | Strength (MPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | Fresh Density (kg/m3) | Compressive Load Area (cm2) | Split Tensile Load Area (cm2) | Fck | Fsk | |

| Aslani et al., 2018 (B) [54] | 1.13 | 0.45 | 8.40 | 5.09 | 4.40 | 10.37 | 0 | 0 | 2165.2 | 78.50 | 1413.00 | 38.93 | 3.54 |

| 1.13 | 0.45 | 8.36 | 5.05 | 3.95 | 10.41 | 10 | 20 | 2157.3 | 78.50 | 1413.00 | 38.36 | 3.89 | |

| 1.13 | 0.45 | 8.31 | 5.01 | 4.15 | 10.45 | 20 | 20 | 2149.2 | 78.50 | 1413.00 | 39.85 | 3.43 | |

| 1.13 | 0.45 | 8.27 | 4.96 | 4.35 | 10.50 | 30 | 20 | 2141.3 | 78.50 | 1413.00 | 37.68 | 3.27 | |

| 1.13 | 0.45 | 8.22 | 4.92 | 4.55 | 10.54 | 40 | 20 | 2133.2 | 78.50 | 1413.00 | 40.68 | 3.34 | |

| Bahrami et al., 2020 (A) [12] | 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | - | - | 2394.0 | 225.00 | 1413.00 | 38.99 | 3.61 |

| 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | 25 | - | 2394.0 | 225.00 | 1413.00 | 36.70 | 3.45 | |

| 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | 50 | - | 2394.0 | 225.00 | 1413.00 | 32.80 | 3.22 | |

| 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | 75 | - | 2394.0 | 225.00 | 1413.00 | 29.60 | 2.70 | |

| 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | 100 | - | 2394.0 | 225.00 | 1413.00 | 24.80 | 2.50 | |

| Bahrami et al., 2020 (B) [12] | 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | - | - | 2394.0 | 225.00 | 1413.00 | 38.99 | 3.61 |

| 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | - | 25 | 2394.0 | 225.00 | 1413.00 | 37.00 | 3.55 | |

| 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | - | 50 | 2394.0 | 225.00 | 1413.00 | 33.51 | 3.38 | |

| 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | - | 75 | 2394.0 | 225.00 | 1413.00 | 31.36 | 2.76 | |

| 0.41 | 0.33 | 4.33 | 3.00 | 3.80 | 7.35 | - | 100 | 2394.0 | 225.00 | 1413.00 | 25.83 | 2.46 | |

| Silva et al., 2016 [34] | 0.45 | 0.36 | 4.19 | 2.51 | 2.88 | 8.28 | - | 0 | 2261.0 | 44.16 | 353.25 | 35.50 | 3.05 |

| 0.45 | 0.36 | 4.14 | 2.51 | 2.88 | 8.35 | - | 25 | 2242.9 | 44.16 | 353.25 | 27.69 | 2.70 | |

| 0.45 | 0.36 | 4.10 | 2.51 | 2.89 | 8.42 | - | 50 | 2225.3 | 44.16 | 353.25 | 29.11 | 2.71 | |

| 0.45 | 0.36 | 4.10 | 2.51 | 2.89 | 8.49 | - | 75 | 2207.6 | 44.16 | 353.25 | 30.18 | 2.35 | |

| 0.45 | 0.36 | 4.00 | 2.51 | 2.90 | 8.57 | - | 100 | 2190.0 | 44.16 | 353.25 | 25.21 | 2.28 | |

| Sun et al., 2020 (A) [68] | 0.40 | 0.32 | 4.03 | 1.95 | 2.40 | 7.58 | 0 | 0 | 2344.4 | 100.00 | 100.00 | 40.26 | 4.03 |

| 0.40 | 0.32 | 4.03 | 1.95 | 2.42 | 7.58 | 10 | 0 | 2343.4 | 100.00 | 100.00 | 39.05 | 3.28 | |

| 0.40 | 0.32 | 4.03 | 1.95 | 2.44 | 7.58 | 10 | 25 | 2343.4 | 100.00 | 100.00 | 38.04 | 3.32 | |

| 0.40 | 0.32 | 4.03 | 1.95 | 2.46 | 7.58 | 10 | 50 | 2343.4 | 100.00 | 100.00 | 35.46 | 3.37 | |

| 0.40 | 0.32 | 4.03 | 1.95 | 2.48 | 7.58 | 10 | 100 | 2343.4 | 100.00 | 100.00 | 33.35 | 3.28 | |

| Sun et al., 2020 (B) [68] | 0.40 | 0.32 | 4.03 | 1.95 | 2.40 | 7.58 | 0 | 0 | 2344.4 | 100.00 | 100.00 | 40.26 | 4.03 |

| 0.40 | 0.32 | 4.03 | 1.95 | 2.62 | 7.58 | 10 | 0 | 2343.4 | 100.00 | 100.00 | 35.36 | 3.41 | |

| 0.40 | 0.32 | 4.03 | 1.95 | 2.85 | 7.58 | 10 | 25 | 2343.4 | 100.00 | 100.00 | 35.58 | 3.53 | |

| 0.40 | 0.32 | 4.03 | 1.95 | 3.28 | 7.58 | 10 | 50 | 2343.4 | 100.00 | 100.00 | 32.63 | 3.17 | |

| 0.40 | 0.32 | 4.03 | 1.95 | 3.72 | 7.58 | 10 | 100 | 2343.4 | 100.00 | 100.00 | 32.39 | 2.81 | |

| Surendar et al., 2021 [69] | 0.45 | 0.45 | 3.43 | 1.81 | 1.90 | 10.16 | - | 0 | 1854.0 | 225.00 | 1413.00 | 36.66 | 4.12 |

| 0.45 | 0.45 | 4.38 | 1.81 | 1.90 | 8.37 | - | 10 | 2213.9 | 225.00 | 1413.00 | 36.22 | 4.07 | |

| 0.45 | 0.45 | 4.38 | 1.81 | 1.90 | 8.37 | - | 15 | 2213.9 | 225.00 | 1413.00 | 35.77 | 4.00 | |

| 0.45 | 0.45 | 4.38 | 1.81 | 1.90 | 8.37 | - | 20 | 2213.9 | 225.00 | 1413.00 | 34.95 | 3.98 | |

| 0.45 | 0.45 | 4.38 | 1.81 | 1.90 | 8.37 | - | 25 | 2213.9 | 225.00 | 1413.00 | 34.50 | 3.96 | |

| 0.45 | 0.45 | 4.38 | 1.81 | 1.90 | 8.37 | - | 50 | 2213.9 | 225.00 | 1413.00 | 32.44 | 3.23 | |

| 0.45 | 0.45 | 4.38 | 1.81 | 1.90 | 8.37 | - | 75 | 2213.9 | 225.00 | 1413.00 | 27.60 | 2.70 | |

| Tuyan et al., 2014 (A) [61] | 0.53 | 0.4 | 4.87 | 2.18 | 2.20 | 7.83 | - | 0 | 2301.1 | 225.00 | 225.00 | 37.20 | 4.19 |

| 0.53 | 0.4 | 4.87 | 2.18 | 2.40 | 7.83 | - | 20 | 2301.1 | 225.00 | 225.00 | 37.70 | 3.95 | |

| 0.53 | 0.4 | 4.87 | 2.18 | 2.70 | 7.83 | - | 40 | 2301.1 | 225.00 | 225.00 | 38.20 | 3.73 | |

| 0.53 | 0.4 | 4.87 | 2.18 | 3.00 | 7.83 | - | 60 | 2301.1 | 225.00 | 225.00 | 35.80 | 3.52 | |

| Babalolaa et al., 2020 (A) [67] | 0.45 | 0.45 | 3.52 | 1.23 | 3.46 | 9.97 | - | 0 | 2149.9 | 78.50 | 628.00. | 30.60 | 2.80 |

| 0.81 | 0.45 | 11.78 | 4.81 | 2.30 | 5.97 | - | 100 | 2301.6 | 78.50 | 628.00 | 31.70 | 3.00 | |

| 0.90 | 0.45 | 13.09 | 5.35 | 2.30 | 5.97 | - | 100 | 2301.6 | 78.50 | 628.00 | 33.50 | 3.20 | |

| 1.01 | 0.45 | 14.84 | 6.06 | 2.29 | 5.91 | - | 100 | 2299.4 | 78.50 | 628.00 | 35.80 | 3.50 | |

| 1.15 | 0.45 | 16.98 | 6.94 | 2.28 | 5.88 | - | 100 | 2297.7 | 78.50 | 628.00 | 37.00 | 3.52 | |

| 1.36 | 0.45 | 20.05 | 8.19 | 2.27 | 5.89 | - | 100 | 2296.8 | 78.50 | 628.00 | 39.80 | 3.70 | |

| 1.64 | 0.45 | 24.17 | 9.87 | 2.26 | 5.90 | - | 100 | 2295.9 | 78.50 | 628.00 | 39.20 | 3.91 | |

| Babalolaa et al., 2020 (B) [67] | 0.45 | 0.45 | 3.52 | 1.23 | 3.46 | 9.97 | - | 0 | 2149.9 | 78.50 | 628.00 | 30.60 | 2.80 |

| 0.81 | 0.45 | 11.78 | 4.81 | 2.30 | 5.97 | - | 100 | 2301.6 | 78.50 | 628.00 | 31.70 | 3.00 | |

| 0.66 | 0.37 | 11.93 | 4.87 | 2.82 | 4.66 | - | 100 | 2342.2 | 78.50 | 628.00 | 41.40 | 3.82 | |

| 0.81 | 0.35 | 13.46 | 5.50 | 2.62 | 5.13 | - | 100 | 2325.4 | 78.50 | 628.00 | 38.00 | 3.74 | |

| 0.98 | 0.40 | 15.20 | 6.21 | 2.43 | 5.55 | - | 100 | 2310.5 | 78.50 | 628.00 | 37.40 | 3.68 | |

| 1.15 | 0.45 | 16.98 | 6.94 | 2.28 | 5.88 | - | 100 | 2297.7 | 78.50 | 628.00 | 37.00 | 3.52 | |

| 1.34 | 0.50 | 19.04 | 7.78 | 2.14 | 6.16 | - | 100 | 2285.7 | 78.50 | 628.00 | 33.00 | 3.28 | |

| Nieto et al., 2019 (C) [70] | 0.45 | 0.35 | 4.11 | 2.33 | 6.10 | 8.34 | - | 0 | 2390.0 | 176.63 | 1413.00 | 38.78 | 2.82 |

| 0.45 | 0.35 | 4.09 | 2.33 | 6.10 | 8.36 | - | 20 | 2385.0 | 176.63 | 1413.00 | 43.01 | 2.63 | |

| 0.45 | 0.35 | 4.08 | 2.33 | 6.10 | 8.38 | - | 40 | 2380.0 | 176.63 | 1413.00 | 44.96 | 2.88 | |

| 0.45 | 0.35 | 4.07 | 2.33 | 6.10 | 8.40 | - | 60 | 2375.0 | 176.63 | 1413.00 | 47.69 | 3.27 | |

| Nieto et al., 2019 (D) [70] | 0.45 | 0.35 | 4.11 | 2.33 | 6.10 | 8.34 | - | 0 | 2390.0 | 176.63 | 1413.00 | 38.78 | 2.82 |

| 0.46 | 0.36 | 4.09 | 2.33 | 6.10 | 8.59 | - | 20 | 2390.0 | 176.63 | 1413.00 | 40.09 | 3.33 | |

| 0.48 | 0.37 | 4.08 | 2.33 | 6.10 | 8.88 | - | 40 | 2391.0 | 176.63 | 1413.00 | 41.30 | 2.95 | |

| 0.49 | 0.38 | 4.07 | 2.33 | 6.10 | 9.17 | - | 60 | 2392.0 | 176.63 | 1413.00 | 40.54 | 2.40 | |

| Nieto et al., 2019 (E) [70] | 0.45 | 0.35 | 4.11 | 2.33 | 6.10 | 8.34 | - | 0 | 2390.0 | 176.63 | 1413.00 | 38.78 | 2.82 |

| 0.46 | 0.36 | 4.09 | 2.33 | 6.10 | 8.59 | - | 20 | 2390.0 | 176.63 | 1413.00 | 40.78 | 3.34 | |

| 0.48 | 0.37 | 4.08 | 2.33 | 6.10 | 8.88 | - | 40 | 2391.0 | 176.63 | 1413.00 | 43.07 | 3.24 | |

| 0.49 | 0.38 | 4.07 | 2.33 | 6.10 | 9.17 | - | 60 | 2392.0 | 176.63 | 1413.00 | 42.94 | 3.08 | |

| Authors | Design Parameters | Strength (MPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/C | W/B | TA/C | FA/CA | SP (kg) | W/S (%) | % RFA | % RCA | Fresh Density (kg/m3) | Compressive Load Area (cm2) | Split Tensile Load Area (cm2) | Fck | Fsk | |

| Aslani et al., 2018 (A) [54] | 1.13 | 0.45 | 8.47 | 5.09 | 3.35 | 10.30 | 0 | 0 | 2177.6 | 78.50 | 1426.5 | 22.21 | 2.71 |

| 1.13 | 0.45 | 8.79 | 5.05 | 4.35 | 10.01 | 10 | 20 | 2235.2 | 78.50 | 1426.5 | 28.63 | 3.02 | |

| 1.13 | 0.45 | 8.74 | 5.01 | 4.75 | 10.05 | 20 | 20 | 2227.1 | 78.50 | 1426.5 | 28.01 | 2.75 | |

| 1.13 | 0.45 | 8.69 | 4.96 | 4.95 | 10.09 | 30 | 20 | 2219.2 | 78.50 | 1426.5 | 24.03 | 2.97 | |

| 1.13 | 0.45 | 8.65 | 4.92 | 5.35 | 10.13 | 40 | 20 | 2211.1 | 78.50 | 1426.5 | 27.13 | 3.07 | |

| Nieto et al., 2019 (A) [70] | 0.55 | 0.42 | 4.56 | 2.59 | 5.50 | 9.39 | - | 0 | 2354.0 | 176.63 | 1426.5 | 25.11 | 2.15 |

| 0.55 | 0.42 | 4.55 | 2.59 | 5.50 | 9.41 | - | 20 | 2349.0 | 176.63 | 1426.5 | 27.65 | 1.61 | |

| 0.55 | 0.42 | 4.54 | 2.59 | 5.50 | 9.43 | - | 40 | 2344.0 | 176.63 | 1426.5 | 35.86 | 2.12 | |

| 0.55 | 0.42 | 4.52 | 2.59 | 5.50 | 9.45 | - | 60 | 2339.0 | 176.63 | 1426.5 | 29.20 | 2.31 | |

| 0.55 | 0.42 | 4.51 | 2.59 | 5.50 | 9.47 | - | 80 | 2334.0 | 176.63 | 1426.5 | 34.29 | 2.10 | |

| 0.55 | 0.42 | 4.50 | 2.59 | 5.50 | 9.50 | - | 100 | 2329.0 | 176.63 | 1426.5 | 34.17 | 2.52 | |

| Nieto et al., 2019 (B) [70] | 0.50 | 0.38 | 4.34 | 2.46 | 5.80 | 8.87 | - | 0 | 2370.0 | 176.63 | 1426.5 | 24.78 | 2.07 |

| 0.50 | 0.38 | 4.33 | 2.46 | 5.80 | 8.89 | - | 20 | 2365.0 | 176.63 | 1426.5 | 31.25 | 2.78 | |

| 0.50 | 0.38 | 4.31 | 2.46 | 5.80 | 8.91 | - | 40 | 2360.0 | 176.63 | 1426.5 | 40.69 | 2.74 | |

| 0.50 | 0.38 | 4.30 | 2.46 | 5.80 | 8.93 | - | 60 | 2355.0 | 176.63 | 1426.5 | 38.56 | 2.08 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-García, R.; Jagadesh, P.; Búrdalo-Salcedo, G.; Palencia, C.; Fernández-Raga, M.; Fraile-Fernández, F.J. Impact of Design Parameters on the Ratio of Compressive to Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate. Materials 2021, 14, 3480. https://doi.org/10.3390/ma14133480

Martínez-García R, Jagadesh P, Búrdalo-Salcedo G, Palencia C, Fernández-Raga M, Fraile-Fernández FJ. Impact of Design Parameters on the Ratio of Compressive to Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate. Materials. 2021; 14(13):3480. https://doi.org/10.3390/ma14133480

Chicago/Turabian StyleMartínez-García, Rebeca, P. Jagadesh, Gabriel Búrdalo-Salcedo, Covadonga Palencia, María Fernández-Raga, and Fernando J. Fraile-Fernández. 2021. "Impact of Design Parameters on the Ratio of Compressive to Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate" Materials 14, no. 13: 3480. https://doi.org/10.3390/ma14133480

APA StyleMartínez-García, R., Jagadesh, P., Búrdalo-Salcedo, G., Palencia, C., Fernández-Raga, M., & Fraile-Fernández, F. J. (2021). Impact of Design Parameters on the Ratio of Compressive to Split Tensile Strength of Self-Compacting Concrete with Recycled Aggregate. Materials, 14(13), 3480. https://doi.org/10.3390/ma14133480