Negative Poisson’s Ratio-Spacer Design and Its Thermo-Mechanical Coupling Analysis Considering Specific Force Output

Abstract

:1. Introduction

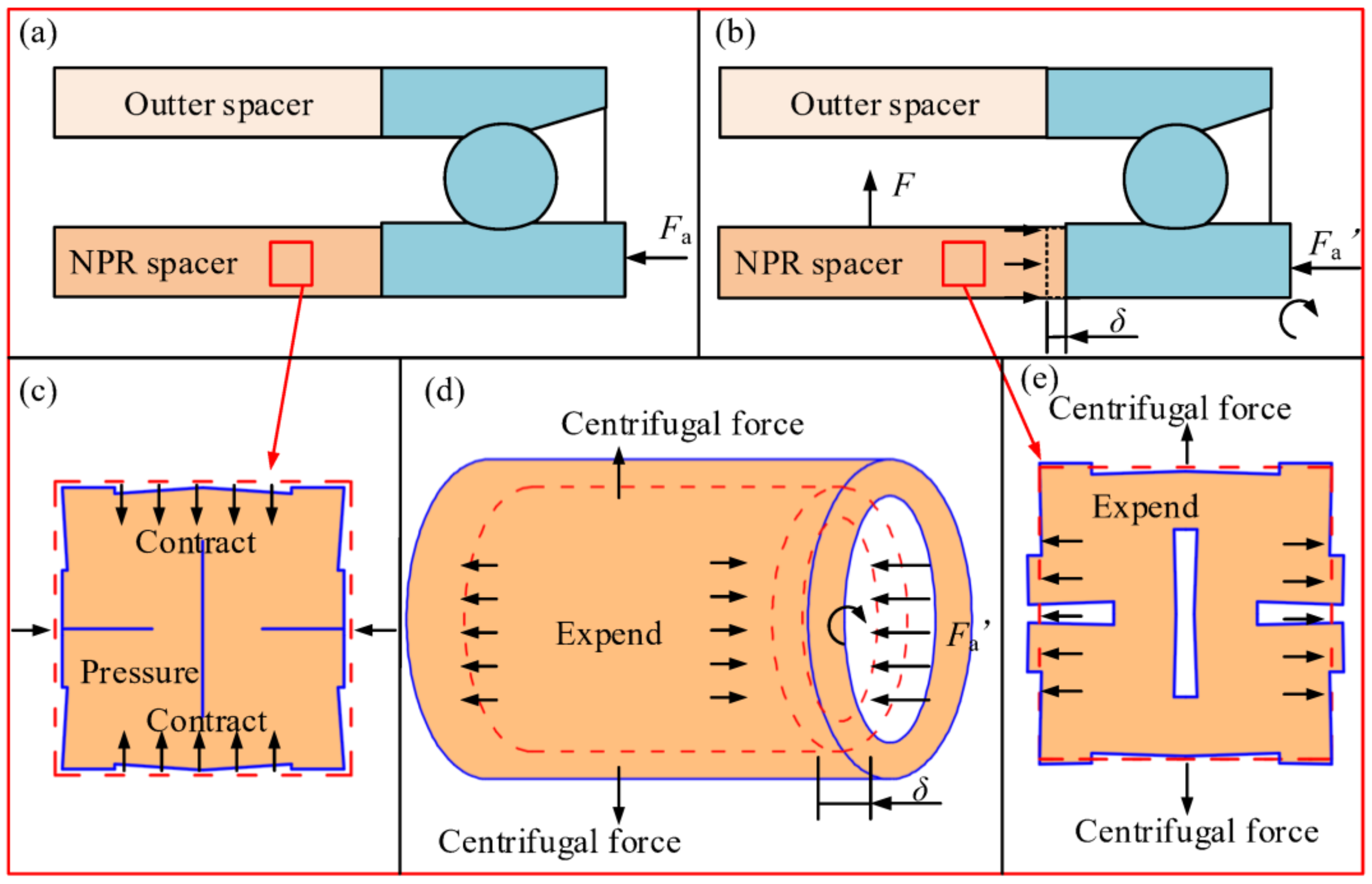

2. Principle of Adaptive Adjustment of Preload

3. Design of 3D NPR Spacer

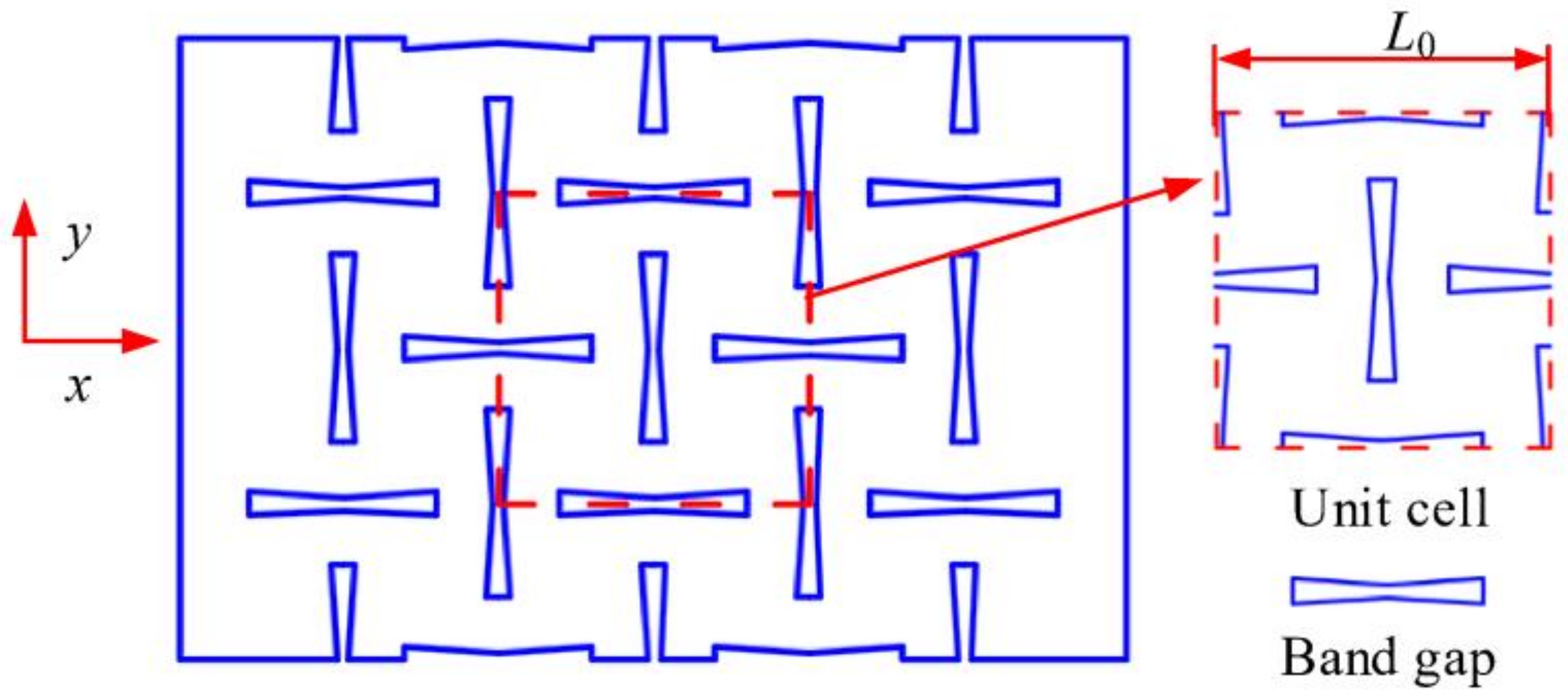

3.1. Design of NPR Cell Structure

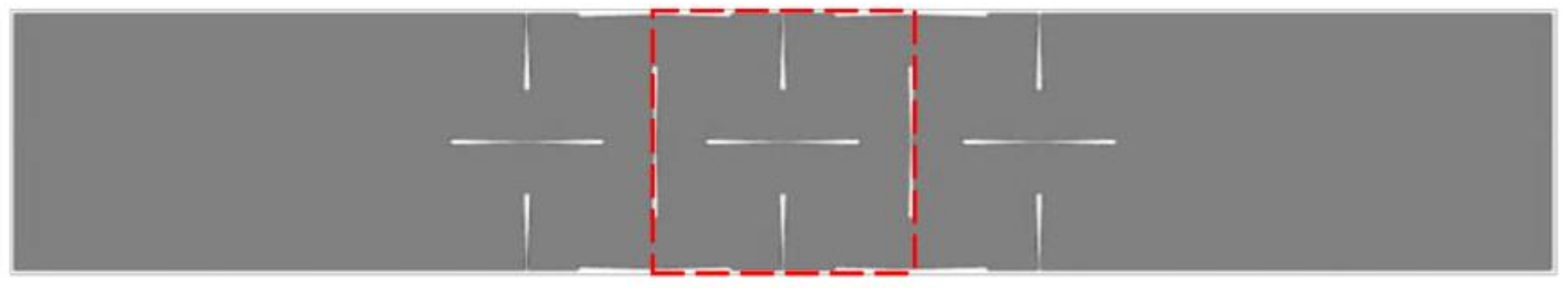

3.2. Three-Dimensional NPR Spacer Model

4. Coupled Thermo-Mechanical Analysis of NPR Spacer

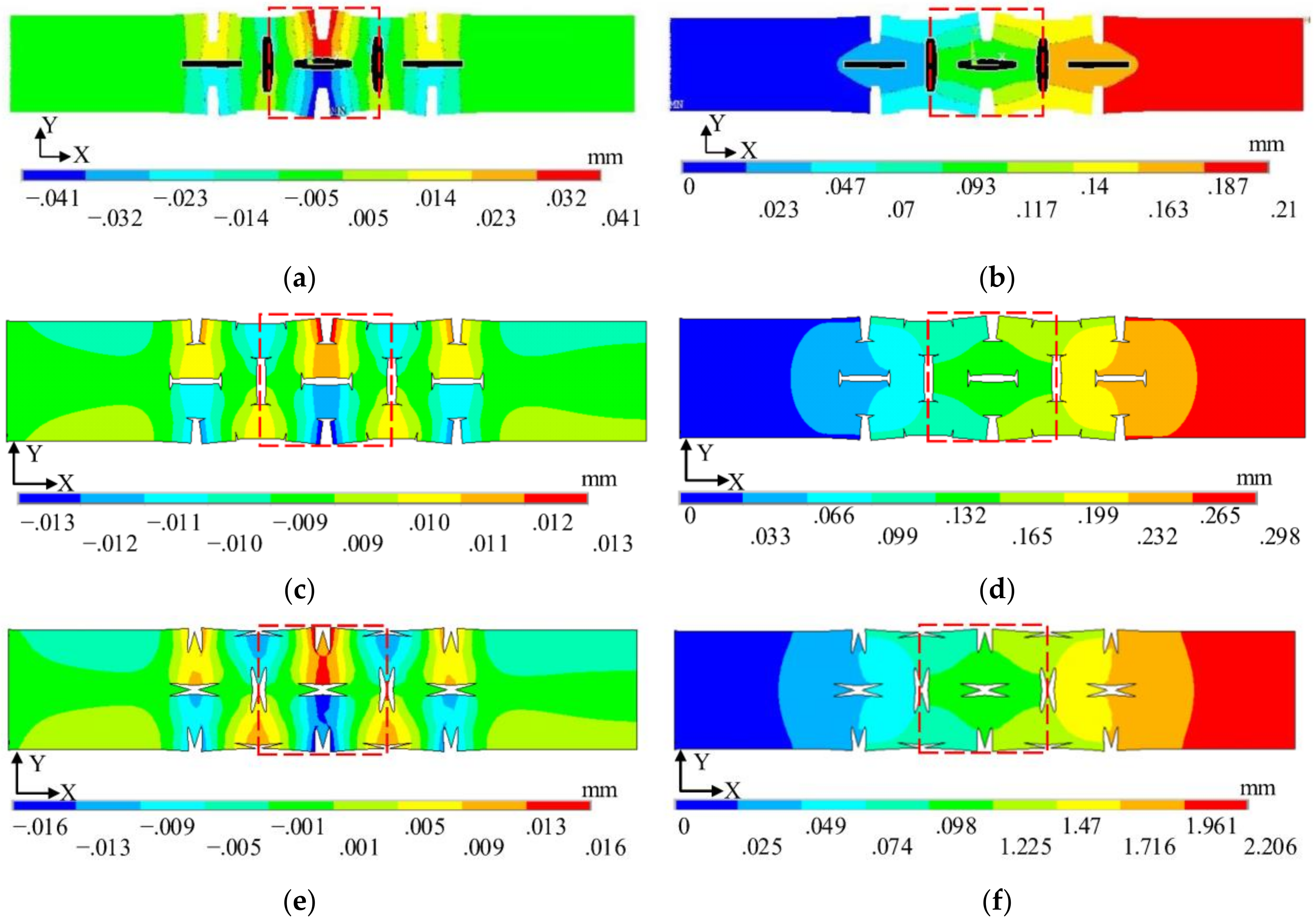

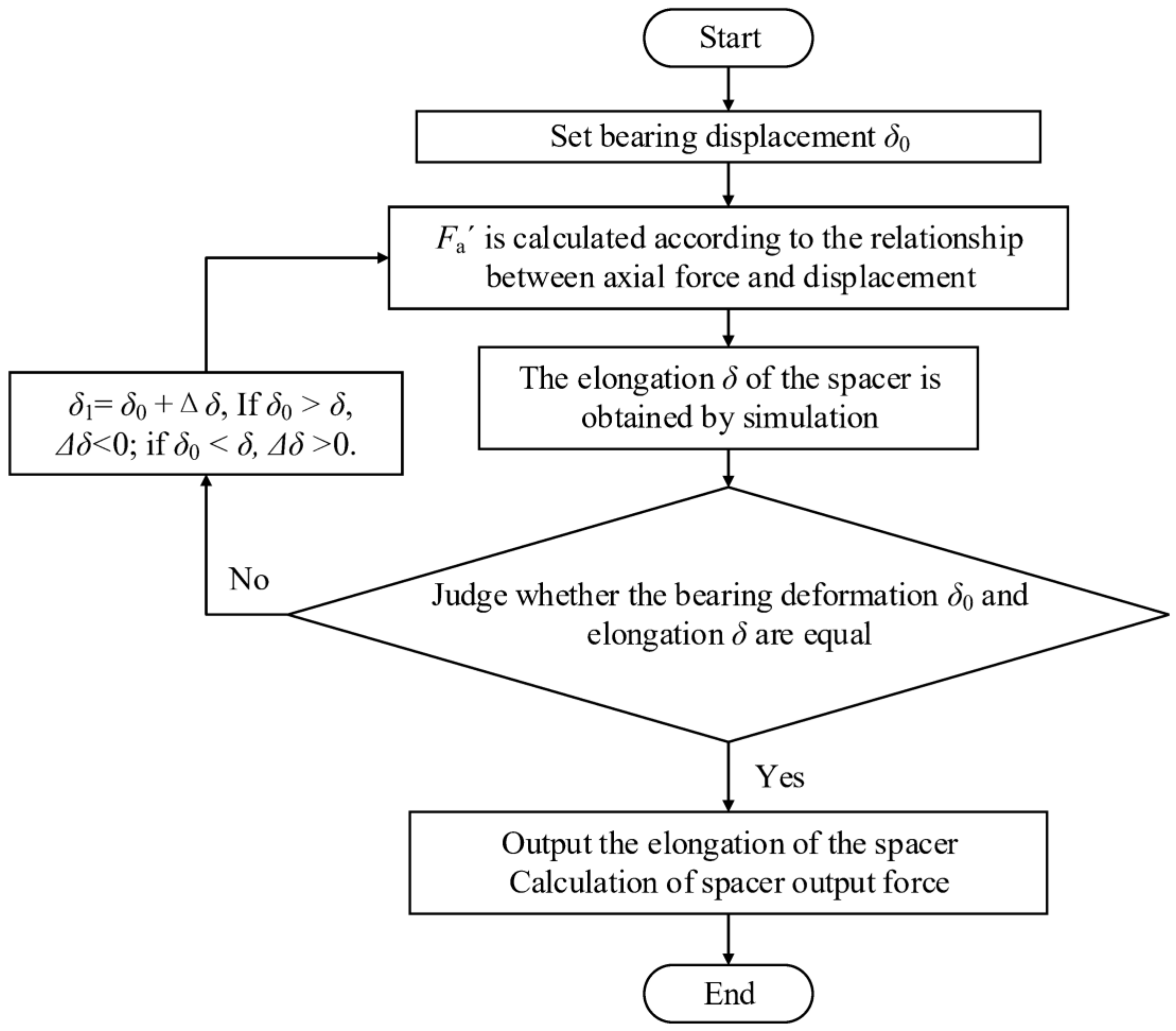

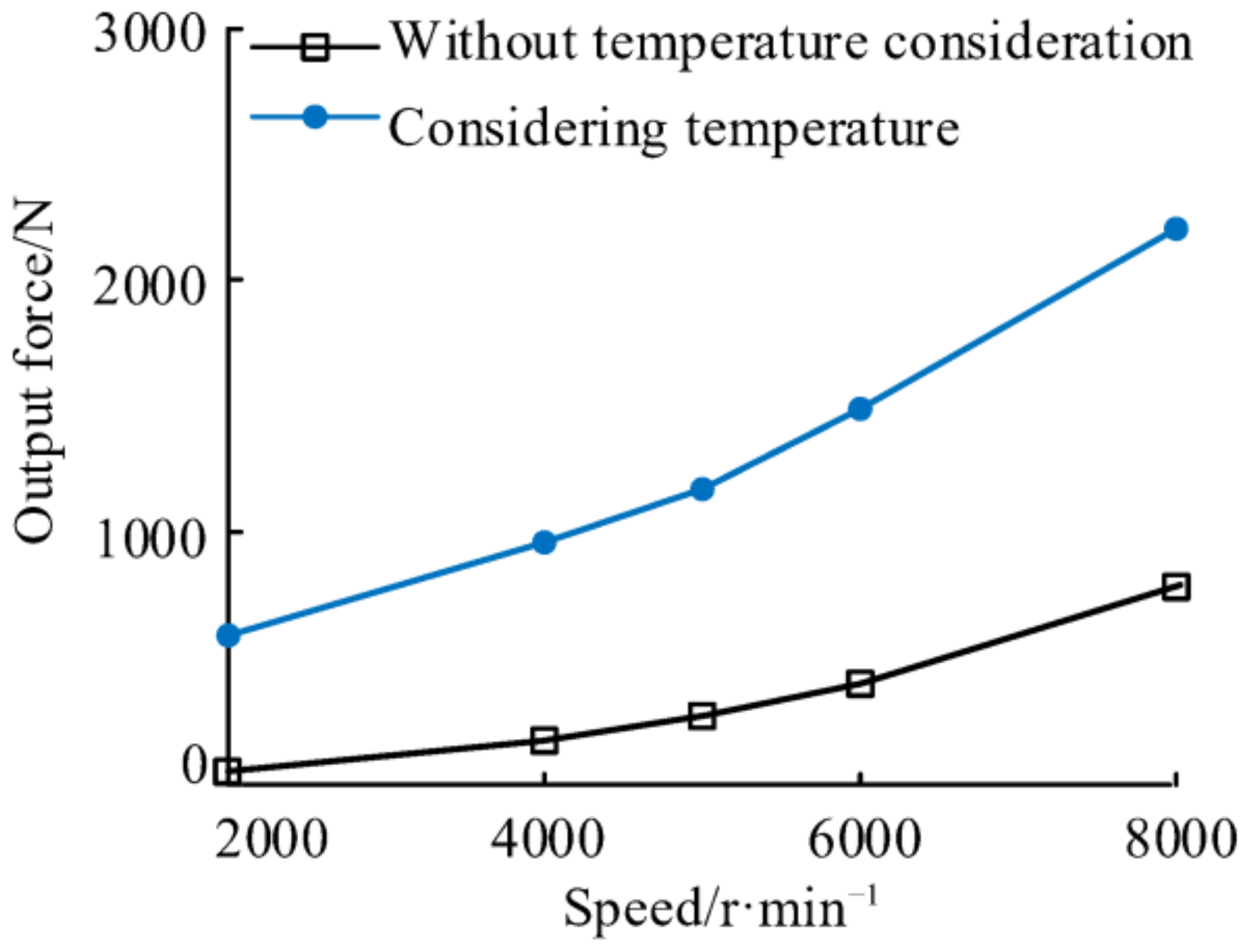

4.1. Calculation of Output Force of NPR Spacer

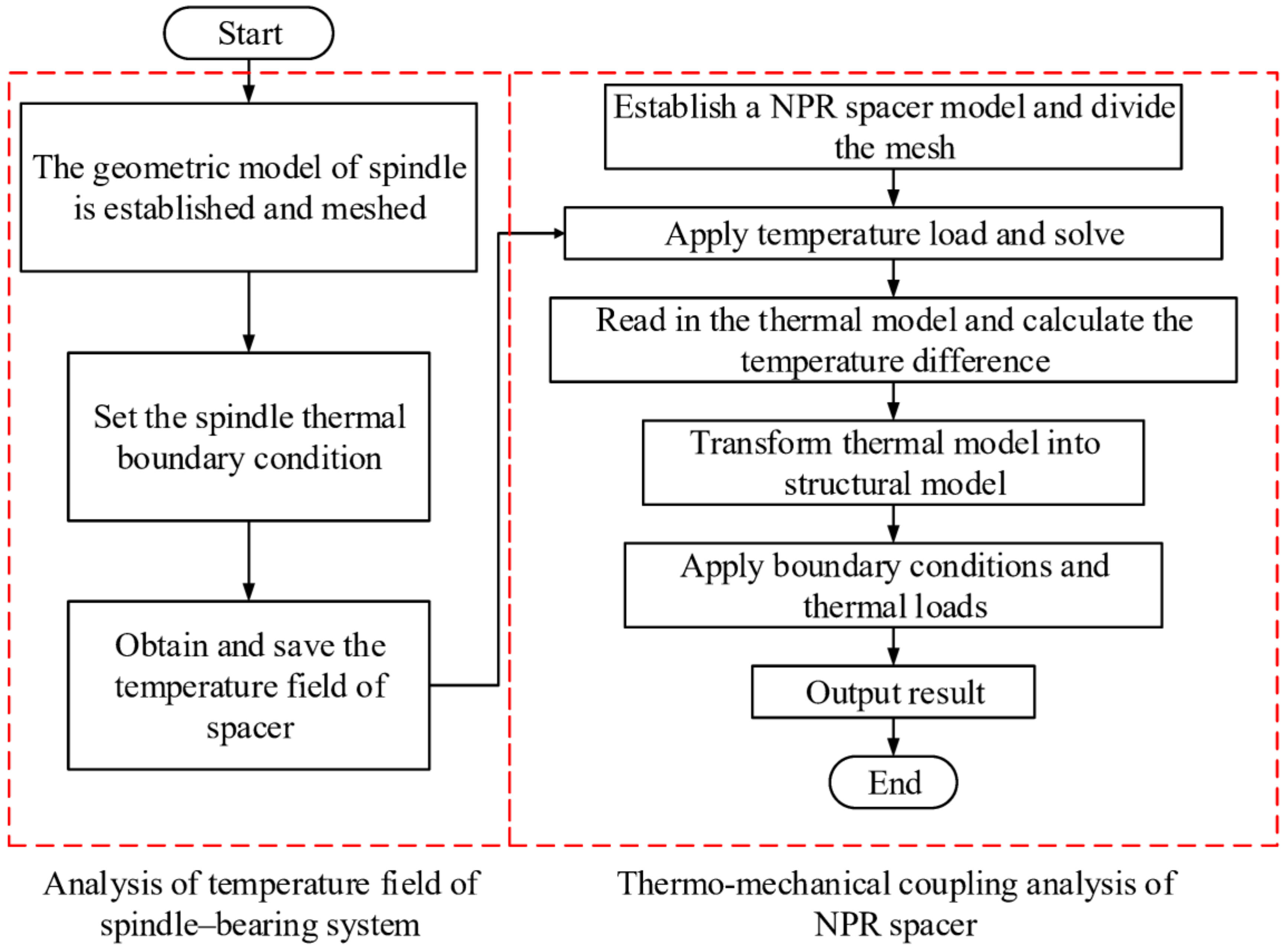

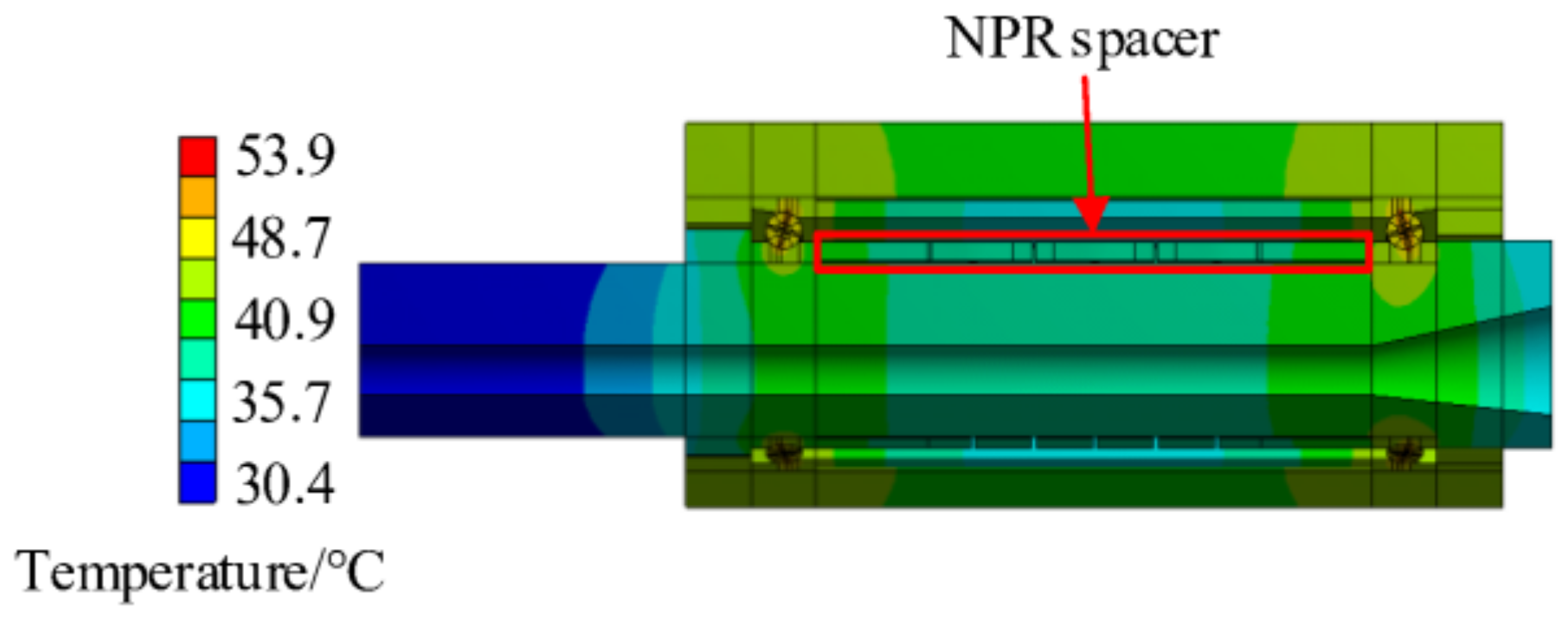

4.2. Thermo-Mechanical Coupling Calculation of NPR Spacer

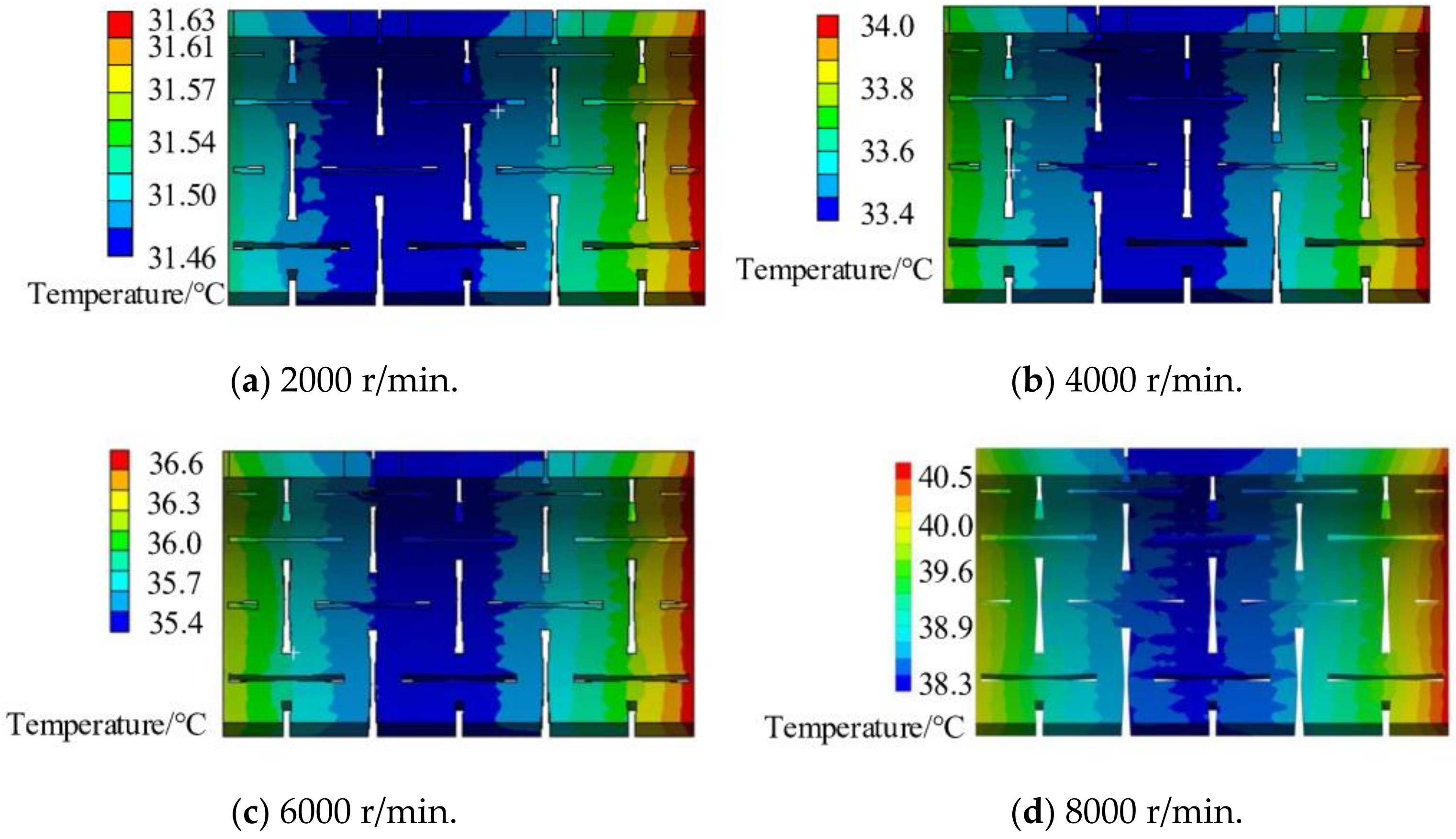

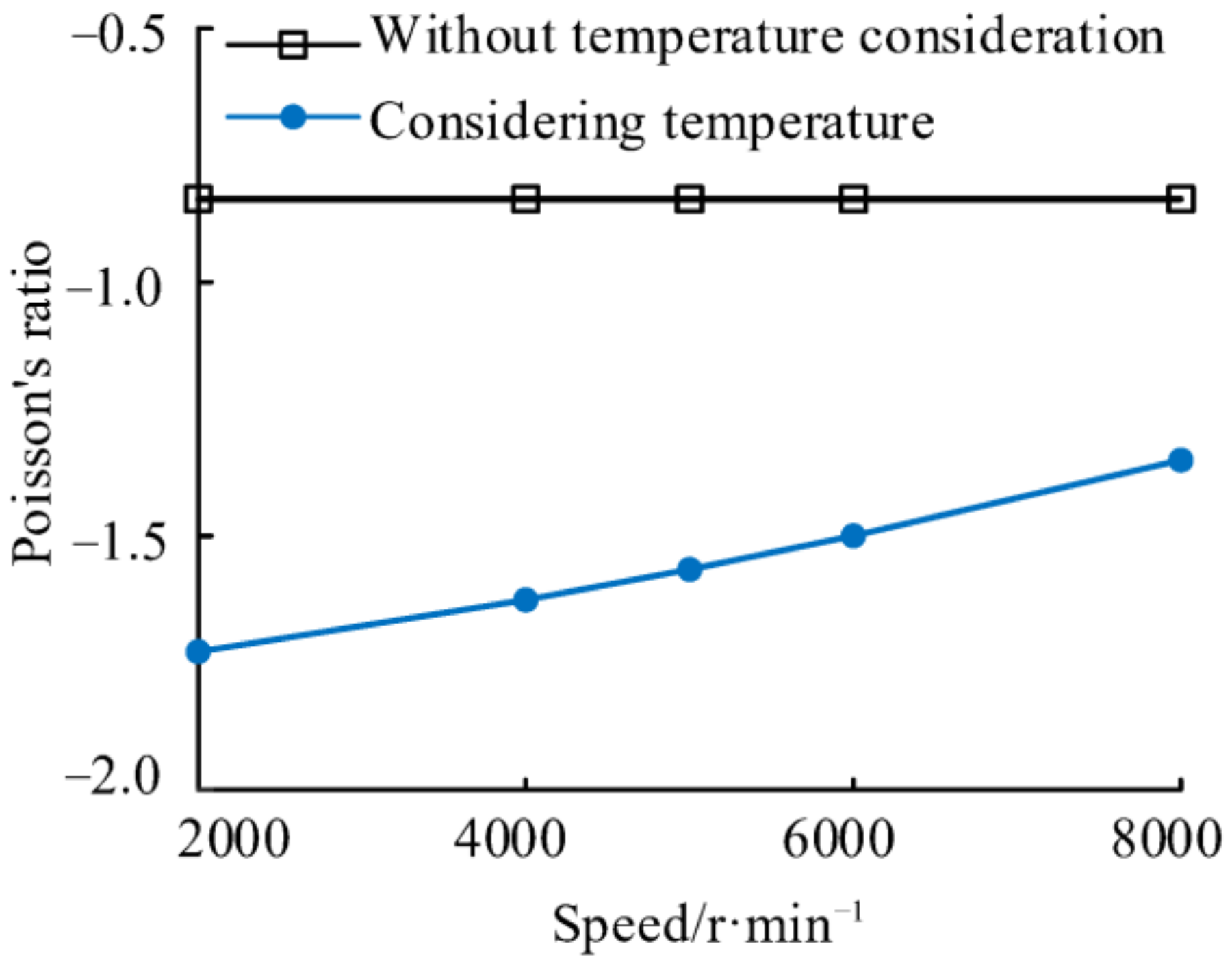

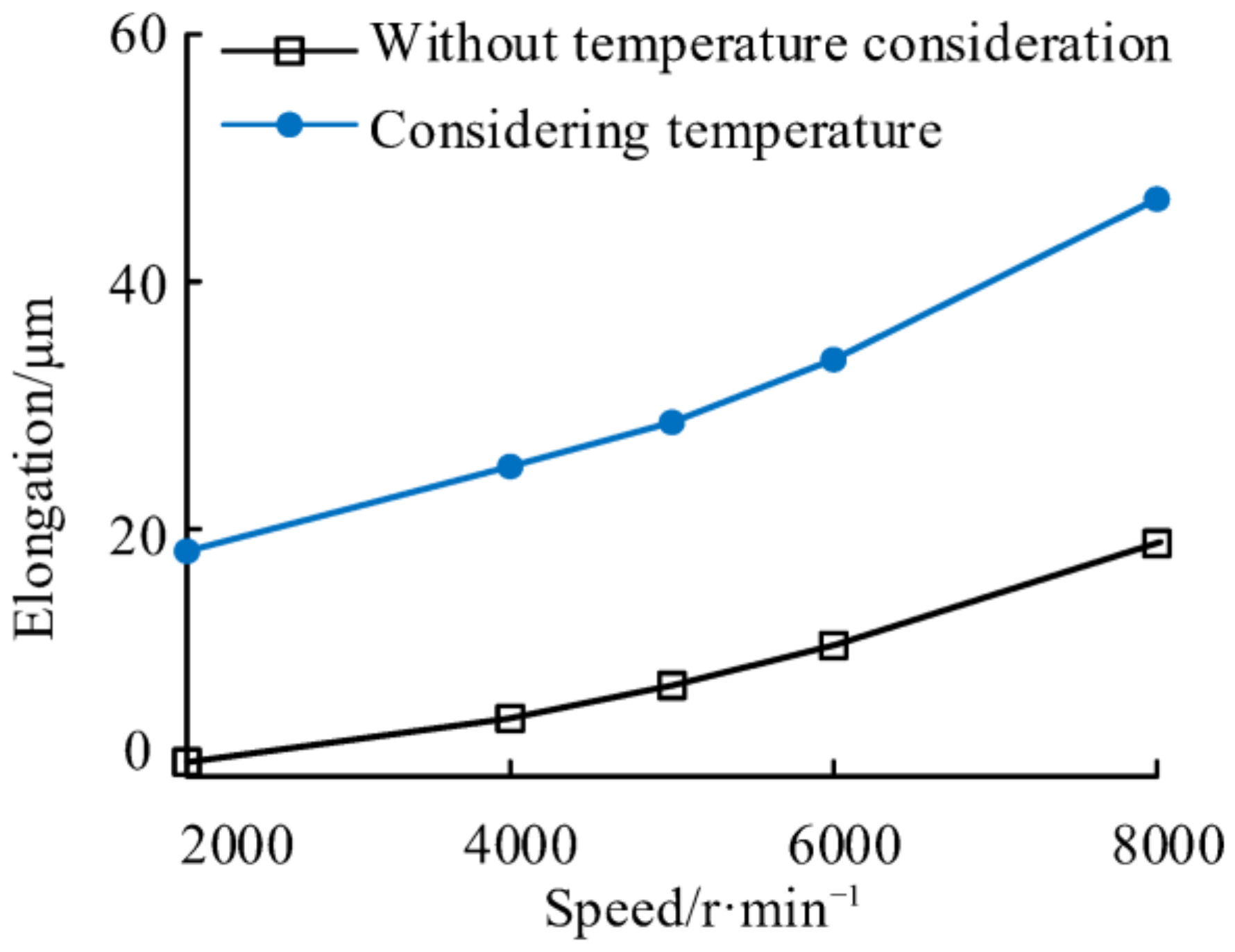

4.3. Result Analysis

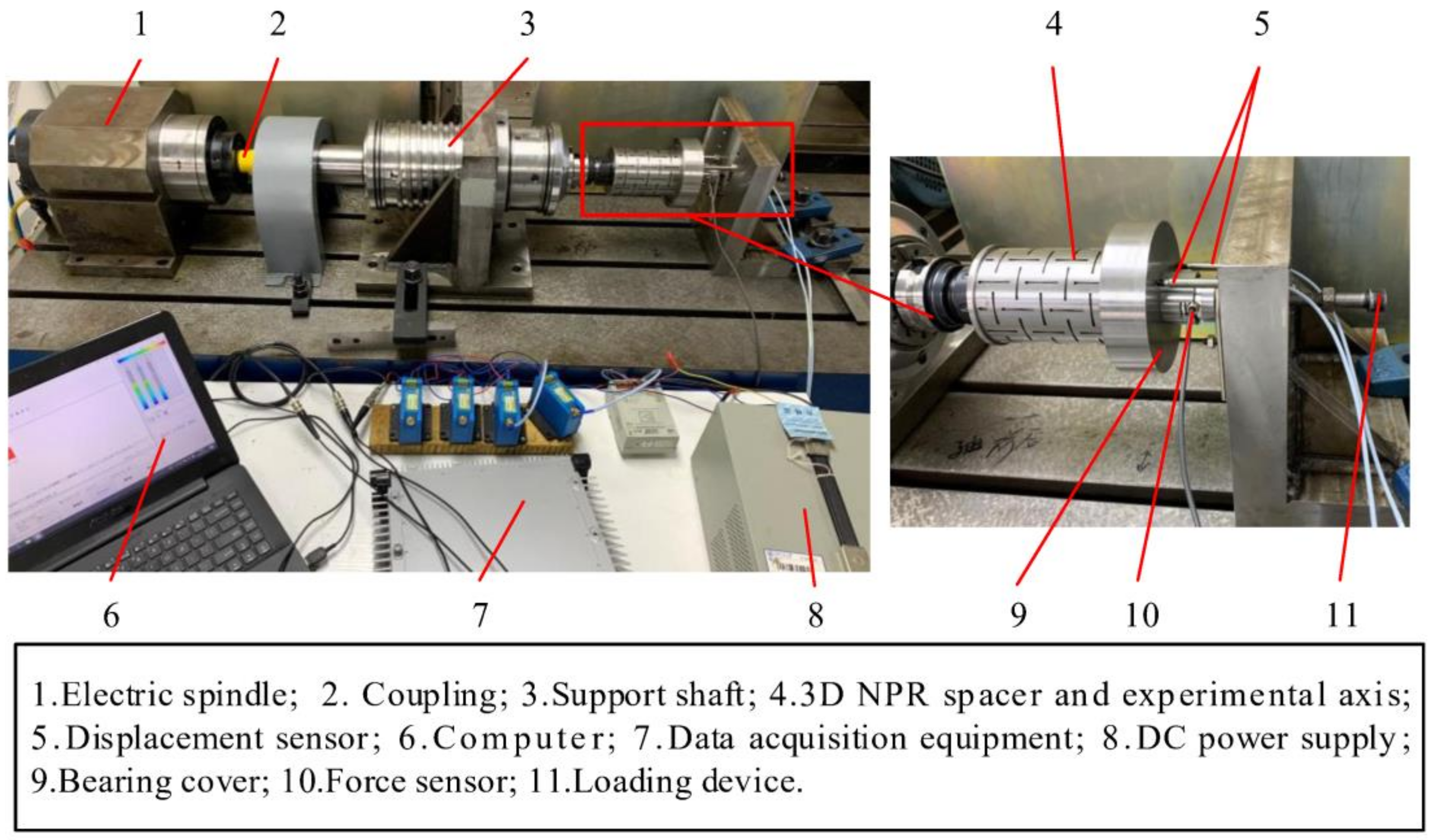

4.4. Discussion of Simulation and Experimental Results

5. Conclusions

- (1)

- Based on the auxetic behavior of the NPR structure, an adaptive adjustment method for bearing preload was proposed. The results show that the 3D NPR spacer with concave hexagonal cell structure has better expansion performance.

- (2)

- Both the deformation characteristics and output force of the 3D NPR structure were discussed in consideration of the effect of heat and centrifugal force, which provides the theoretical basis for variable preload regulation of the bearing. It is found that the thermal effect has relatively larger influences on the axial elongation and output forces of the NPR spacer increase.

- (3)

- Experimental verification was carried out considering the influence of heat, centrifugal force, and axial restraint force. The results show that the standard deviation of output force and axial displacement of NPR spacer is slight. The small deviation between the experimental and simulated values of the output force and axial elongation indicates the possibility of engineering applications utilizing the proposed method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiaohu, L.; Huanfeng, L.; Yanfei, Z.; Jun, H. Investigation of non-uniform preload on the static and rotational performances for spindle bearing system. Int. J. Mach. Tools Manuf. 2016, 106, 11–21. [Google Scholar] [CrossRef]

- Jiang, S.; Mao, H. Investigation of variable optimum preload for a machine tool spindle. Int. J. Mach. Tools Manuf. 2010, 50, 19–28. [Google Scholar] [CrossRef]

- Choi, C.-H.; Lee, C.-M. A variable preload device using liquid pressure for machine tools spindles. Int. J. Precis. Eng. Manuf. 2012, 13, 1009–1012. [Google Scholar] [CrossRef]

- Hwang, Y.-K.; Park, I.-H.; Paik, K.-S.; Lee, C.-M. Development of a variable preload spindle by using an electromagnetic actuator. Int. J. Precis. Eng. Manuf. 2014, 15, 201–207. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, D.; Gao, W.; Chen, Y.; Liu, T.; Tian, Y. Study on variable pressure/position preload spindle-bearing system by using piezoelectric actuators under close-loop control. Int. J. Mach. Tools Manuf. 2018, 125, 68–88. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lee, C.-M. Development of an automatic variable preload device using uniformly distributed eccentric mass for a high-speed spindle. Int. J. Precis. Eng. Manuf. 2017, 18, 1419–1423. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lee, C.-M. Development of variable preload system for machine tool spindle using giant magnetostrictive material Terfenol-D actuator. J. Intell. Mater. Syst. Struct. 2020, 31, 2304–2311. [Google Scholar] [CrossRef]

- Razban, M.; Movahhedy, M.R. A speed-dependent variable preload system for high speed spindles. Precis. Eng. 2015, 40, 182–188. [Google Scholar] [CrossRef]

- Yang, Q.D.; Wang, K.S.; Meng, L.X.; Zhao, H.L. Design method of automatic adjustment of bearing preload based on thermal characteristic of materials. Chin. J. Mech. Eng. 2008, 44, 183–187. [Google Scholar] [CrossRef]

- Greaves, G.N.; Greer, A.L.; Lakes, R.S.; Rouxel, T. Poisson’s ratio and modern materials. Nat. Mater. 2011, 10, 823–836. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Luan, C.; Liaom, G.; Liu, J.; Yao, X.; Fu, J. Progress in Auxetic Mechanical Metamaterials: Structures, Characteristics, Manufacturing Methods, and Applications. Adv. Eng. Mater. 2020, 22, 2000312. [Google Scholar] [CrossRef]

- Wei, Y.-L.; Yang, Q.-S.; Liu, X.; Tao, R. A novel 3D anti-tetrachiral structure with negative Poisson’s ratio. Smart Mater. Struct. 2020, 29, 085003. [Google Scholar] [CrossRef]

- Duan, S.Y.; Xi, L.; Wen, W.B.; Fang, D.N. A novel design method for 3D positive and negative Poisson’s ratio material based on tension-twist coupling effects. Compos. Struct. 2020, 236, 111899. [Google Scholar] [CrossRef]

- Gao, Q.; Liao, W.H.; Wang, L.M. An analytical model of cylindrical double-arrowed honeycomb with negative Poisson’s ratio. Int. J. Mech. Sci. 2020, 173, 105400. [Google Scholar] [CrossRef]

- Rad, M.S.; Prawoto, Y.; Ahmad, Z. Analytical solution and finite element approach to the 3D re-entrant structures of auxetic materials. Mech. Mater. 2014, 74, 76–87. [Google Scholar] [CrossRef]

- Li, D.; Gao, R.; Dong, L.; Lam, W.K.; Zhang, F. A novel 3D re-entrant unit cell structure with negative Poisson’s ratio and tunable stiffness. Smart Mater. Struct. 2019, 29, 045015. [Google Scholar] [CrossRef]

- Wang, W.W.; Dai, S.J.; Zhao, W.Z.; Wang, C.Y.; Ma, T.; Chen, Q.Y. Reliability-based optimization of a novel negative Poisson’s ratio door anti-collision beam under side impact. Thin Wall Struct. 2020, 154, 106863. [Google Scholar] [CrossRef]

- Gatt, R.; Mizzi, L.; Azzopardi, J.I.; Azzopardi, K.M.; Attard, D.; Casha, A.; Briffa, J.; Grima, J.N. Hierarchical Auxetic Me-chanical Metamaterials. Sci. Rep. UK 2015, 5, 8395. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Lu, G.; Chen, Y.; Leong, Y.W. Deformation of the Miura-ori patterned sheet. Int. J. Mech. Sci. 2015, 99, 130–142. [Google Scholar] [CrossRef]

- Bertoldi, K.; Vitelli, V.; Christensen, J.; Van Hecke, M. Flexible mechanical metamaterials. Nat. Rev. Mater. 2017, 2, 17066. [Google Scholar] [CrossRef] [Green Version]

- Taylor, M.; Francesconi, L.; Gerendas, M.; Shanian, A.; Carson, C.; Bertoldi, K. Low Porosity Metallic Periodic Structures with Negative Poisson’s Ratio. Adv. Mater. 2014, 26, 2365–2370. [Google Scholar] [CrossRef] [Green Version]

- Cho, Y.; Shin, J.-H.; Costa, A.; Kim, T.A.; Kunin, V.; Li, J.; Lee, S.Y.; Yang, S.; Han, H.N.; Choi, I.-S.; et al. Engineering the shape and structure of materials by fractal cut. Proc. Natl. Acad. Sci. USA 2014, 111, 17390–17395. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Francesconi, L.; Baldi, A.; Dominguez, G.; Taylor, M. An Investigation of the Enhanced Fatigue Performance of Low-porosity Auxetic Metamaterials. Exp. Mech. 2019, 60, 93–107. [Google Scholar] [CrossRef]

- Chen, W.; Tian, X.; Gao, R.; Liu, S. A low porosity perforated mechanical metamaterial with negative Poisson’s ratio and band gaps. Smart Mater. Struct. 2018, 27, 115010. [Google Scholar] [CrossRef]

- Dong, Y.; Zhou, Z.; Liu, M. Bearing preload optimization for machine tool spindle by the influencing multiple parameters on the bearing performance. Adv. Mech. Eng. 2017, 9, 1687814016689040. [Google Scholar] [CrossRef] [Green Version]

- Lei, M.; Jiang, G.; Yang, J.; Mei, X.; Xia, P.; Shi, H. Improvement of the regression model for spindle thermal elongation by a Boosting-based outliers detection approach. Int. J. Adv. Manuf. Technol. 2018, 99, 1389–1403. [Google Scholar] [CrossRef]

- Fang, B.; Zhang, J.H.; Hong, J.; Zhu, Y.S. Quick calculation method and contact angle analysis for high-speed angular contact ball bearing under combined loads. J. Xi’an Jiaotong Univ. 2017, 51, 115–121. [Google Scholar]

- Heo, H.; Kim, K.; Tessema, A.; Kidane, A.; Ju, J. Thermomechanically Tunable Elastic Metamaterials with Compliant Porous Structures. J. Eng. Mater. Technol. 2018, 140, 021004. [Google Scholar] [CrossRef] [Green Version]

- Li, J.D. Theoretical Analysis and Testing Technology for Axial Operating Stiffness of Machine Tool Spindles. Ph.D. Thesis, Xi’An Jiaotong University, Xi’an, China, 2019. [Google Scholar]

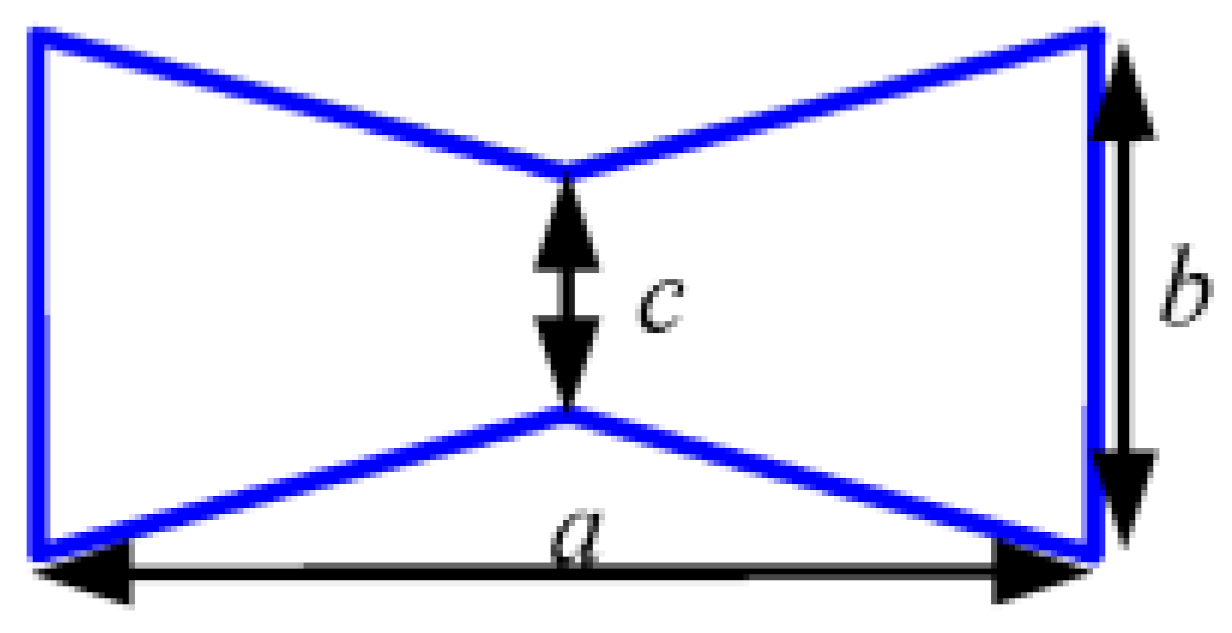

| Type 1 | Type 2 | Type 3 | |

|---|---|---|---|

| Band gaps |  |  |  |

| Structural parameters | a = 20 mm b = 14 mm c = 0.6 mm | l = 20 mm m = 18 mm n = 3.5 mm t = 1.5 mm | k = 20 mm i = 10 mm h = 4 mm j = 2 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Q.; Zhu, Y.; Yan, K.; Cai, Y.; Hong, J. Negative Poisson’s Ratio-Spacer Design and Its Thermo-Mechanical Coupling Analysis Considering Specific Force Output. Materials 2021, 14, 3421. https://doi.org/10.3390/ma14123421

Yuan Q, Zhu Y, Yan K, Cai Y, Hong J. Negative Poisson’s Ratio-Spacer Design and Its Thermo-Mechanical Coupling Analysis Considering Specific Force Output. Materials. 2021; 14(12):3421. https://doi.org/10.3390/ma14123421

Chicago/Turabian StyleYuan, Qianqian, Yongsheng Zhu, Ke Yan, Yiqing Cai, and Jun Hong. 2021. "Negative Poisson’s Ratio-Spacer Design and Its Thermo-Mechanical Coupling Analysis Considering Specific Force Output" Materials 14, no. 12: 3421. https://doi.org/10.3390/ma14123421

APA StyleYuan, Q., Zhu, Y., Yan, K., Cai, Y., & Hong, J. (2021). Negative Poisson’s Ratio-Spacer Design and Its Thermo-Mechanical Coupling Analysis Considering Specific Force Output. Materials, 14(12), 3421. https://doi.org/10.3390/ma14123421