Effect of Size of Coarse Aggregate on Mechanical Properties of Metakaolin-Based Geopolymer Concrete and Ordinary Concrete

Abstract

1. Introduction

2. Experimental Procedures

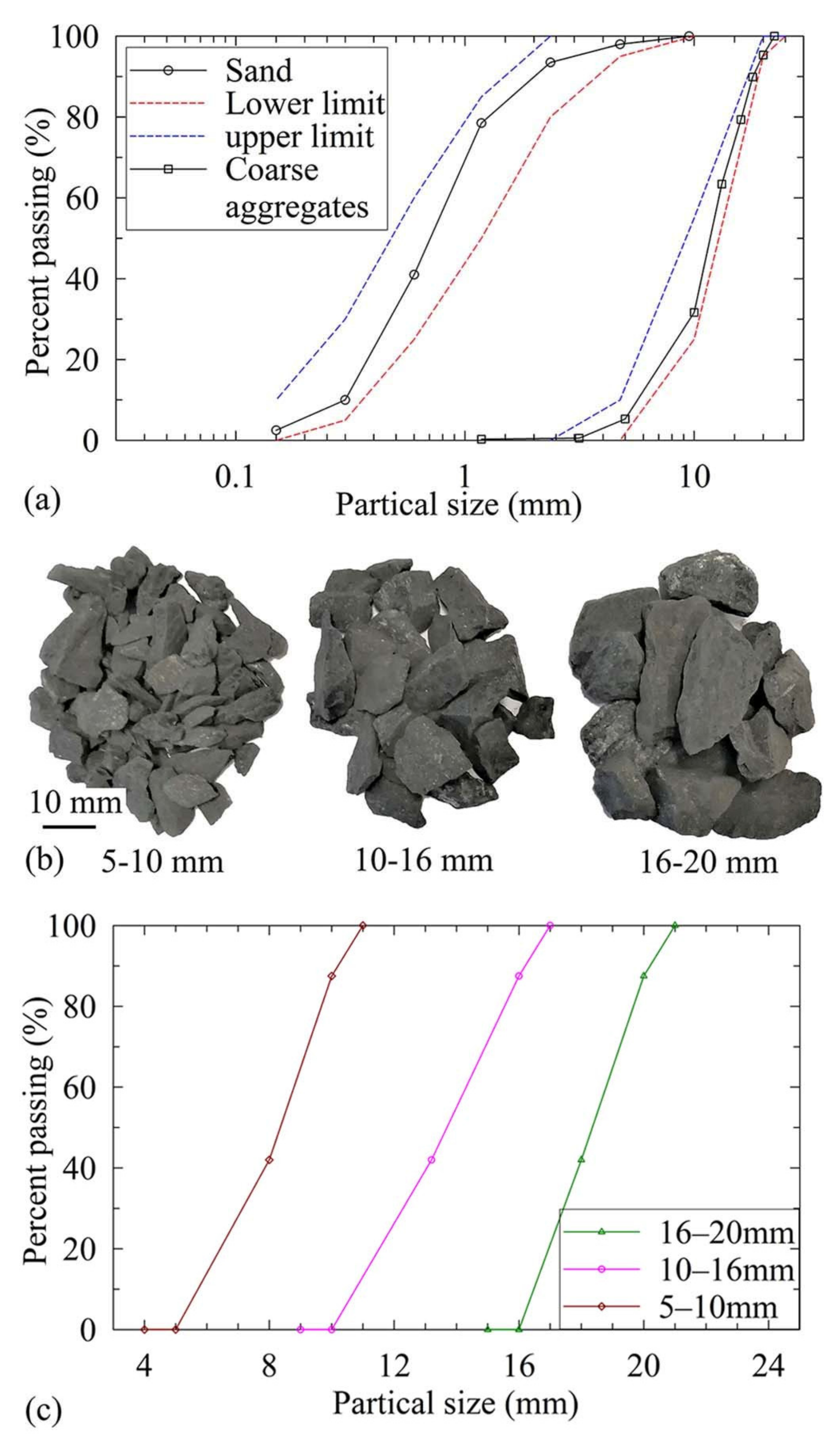

2.1. Materials

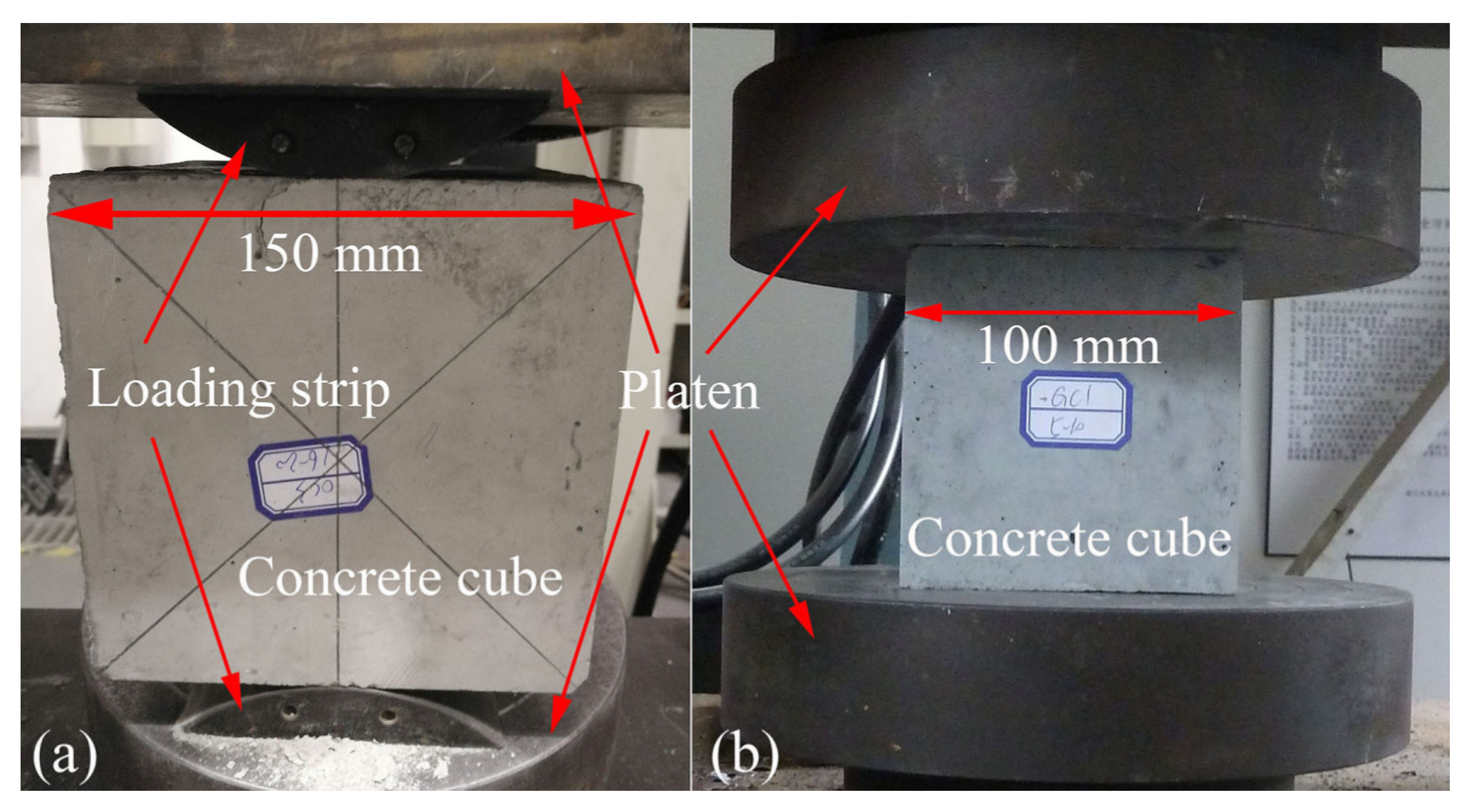

2.2. Test Specimen Preparation

2.3. Microstructural Analysis

3. Results and Discussion

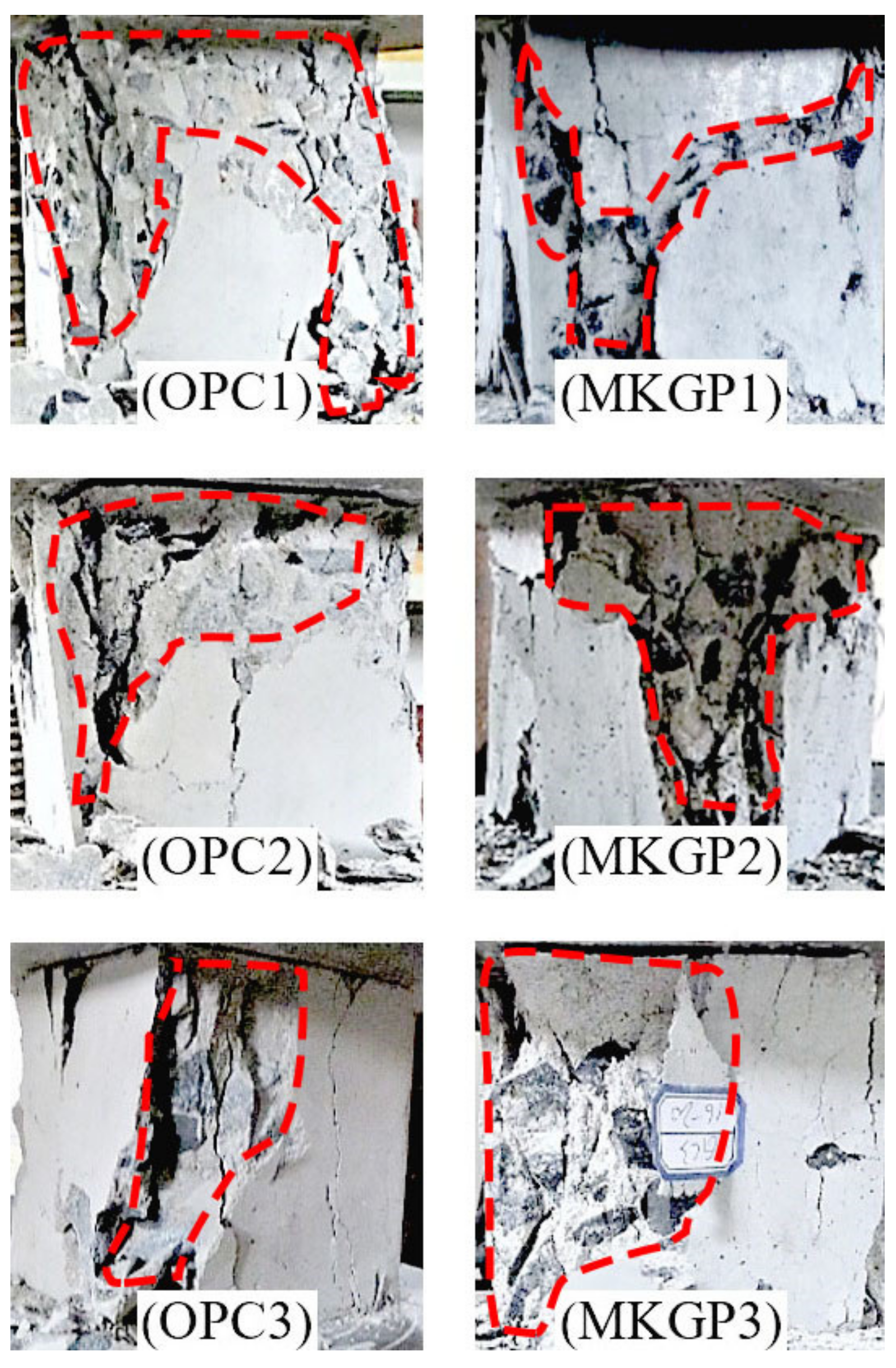

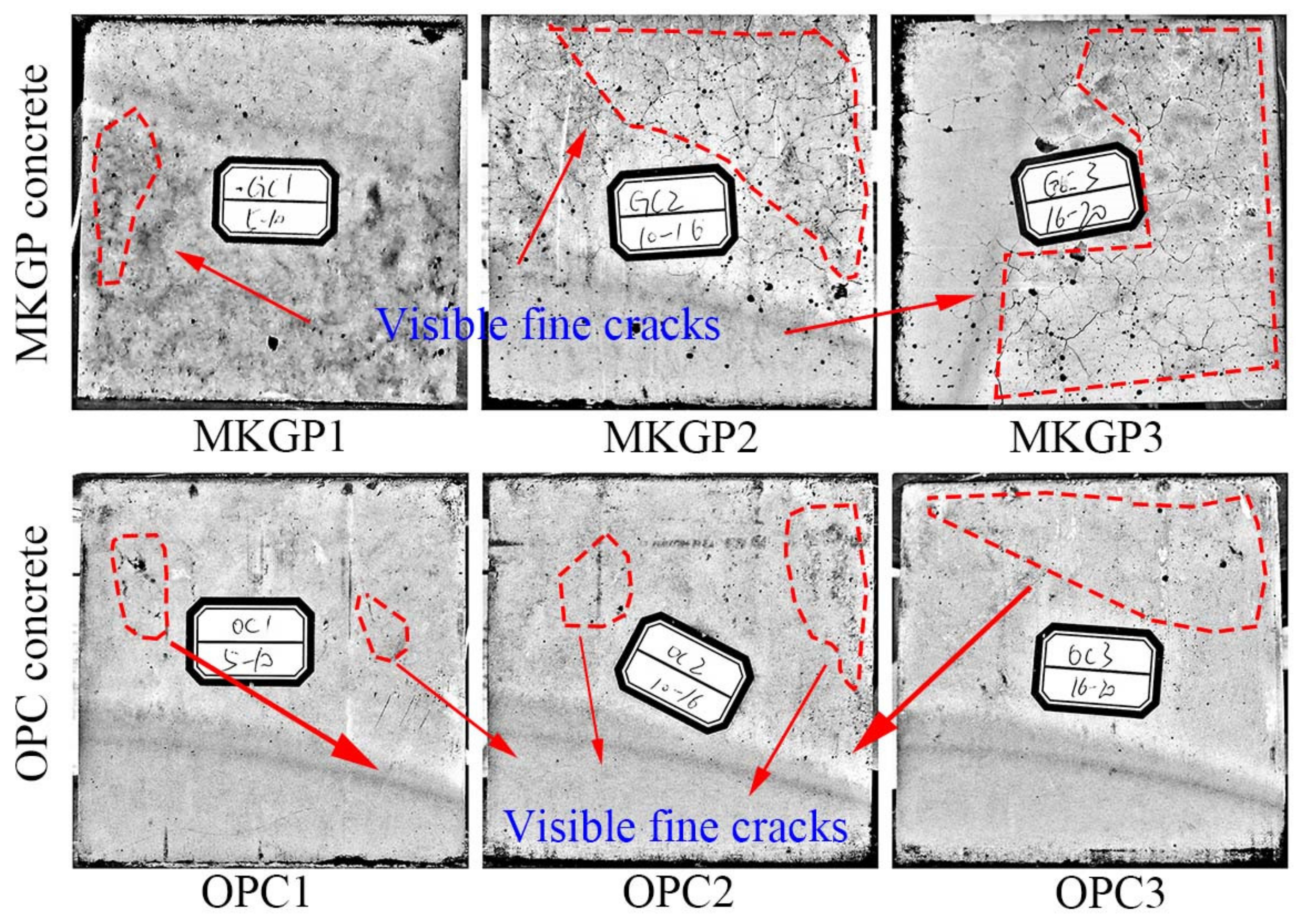

3.1. Failure Behavior

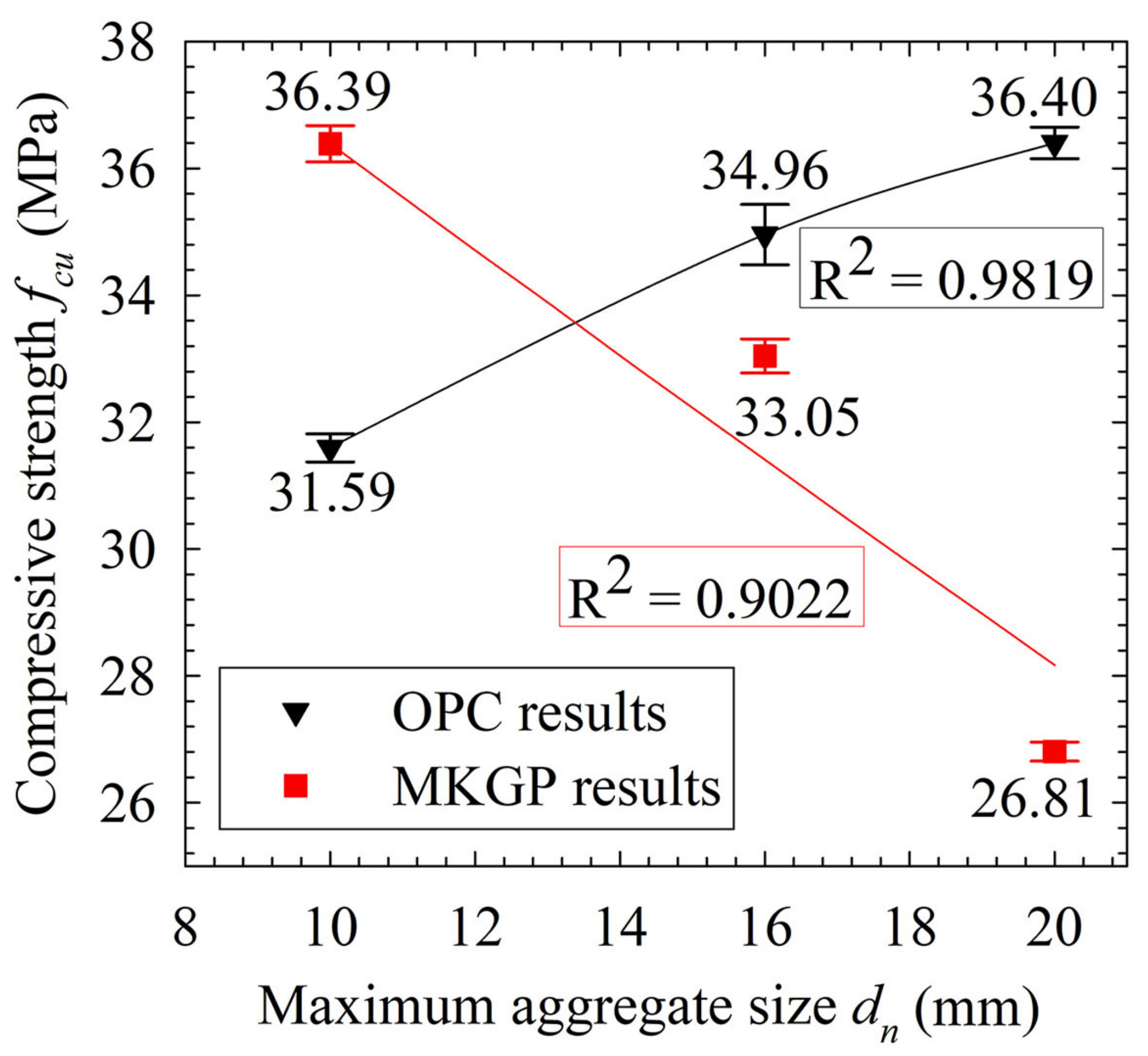

3.2. Compressive Strength

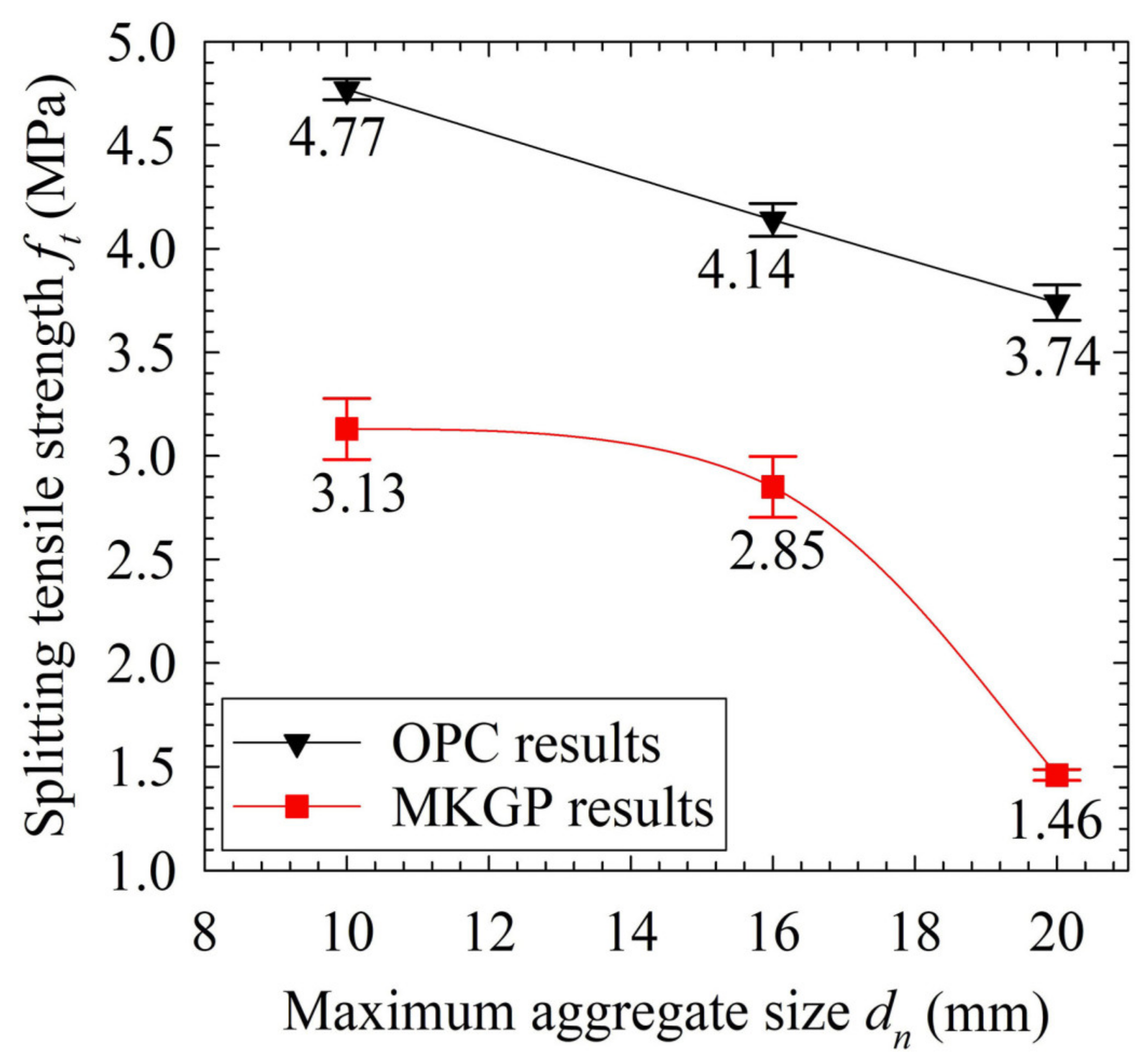

3.3. Splitting Tensile Strength Test Results

3.4. Proposed Empirical Models

3.4.1. Effect on the OPC Concrete

3.4.2. Effect on the MKGP Concrete

3.5. Microstructure Analysis

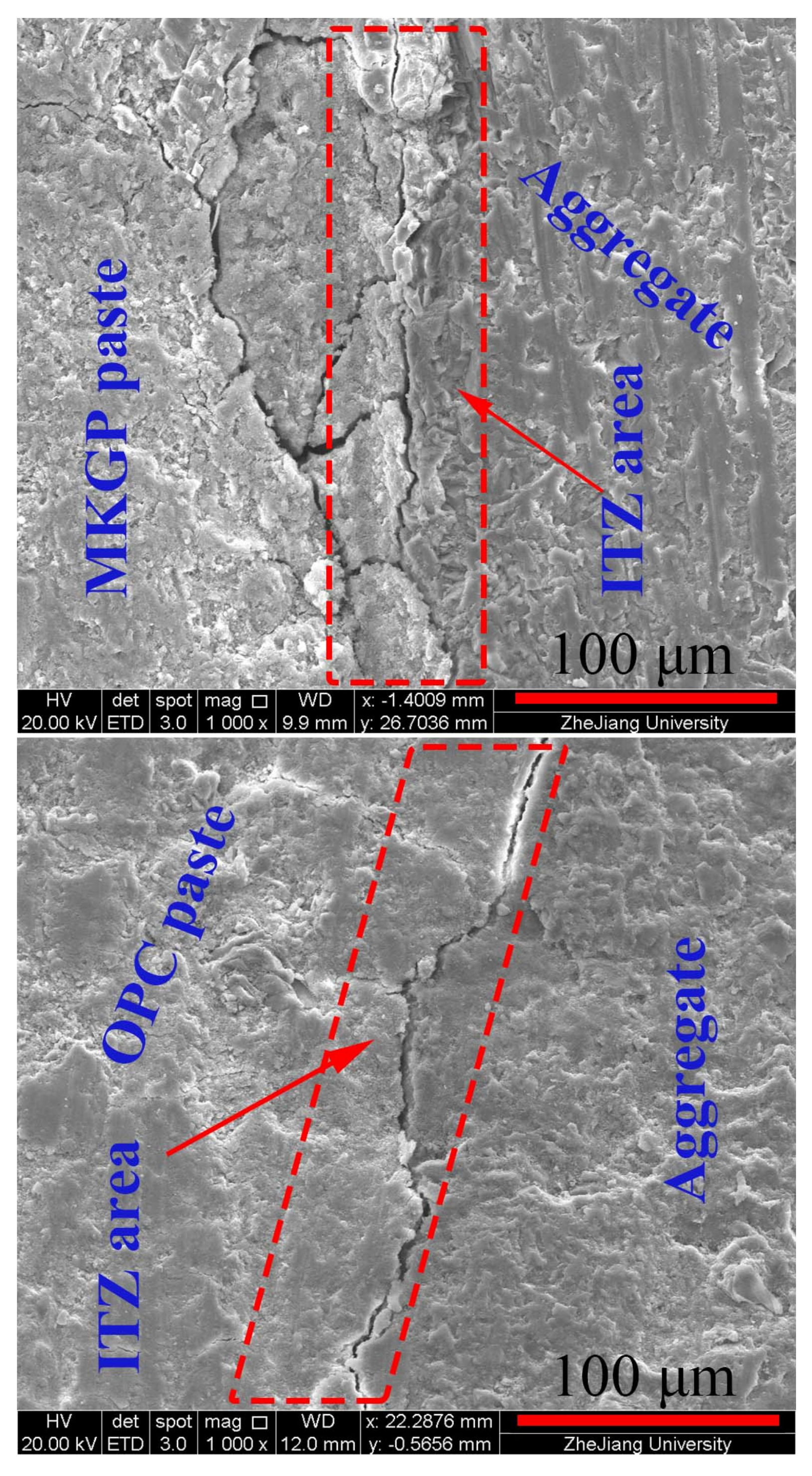

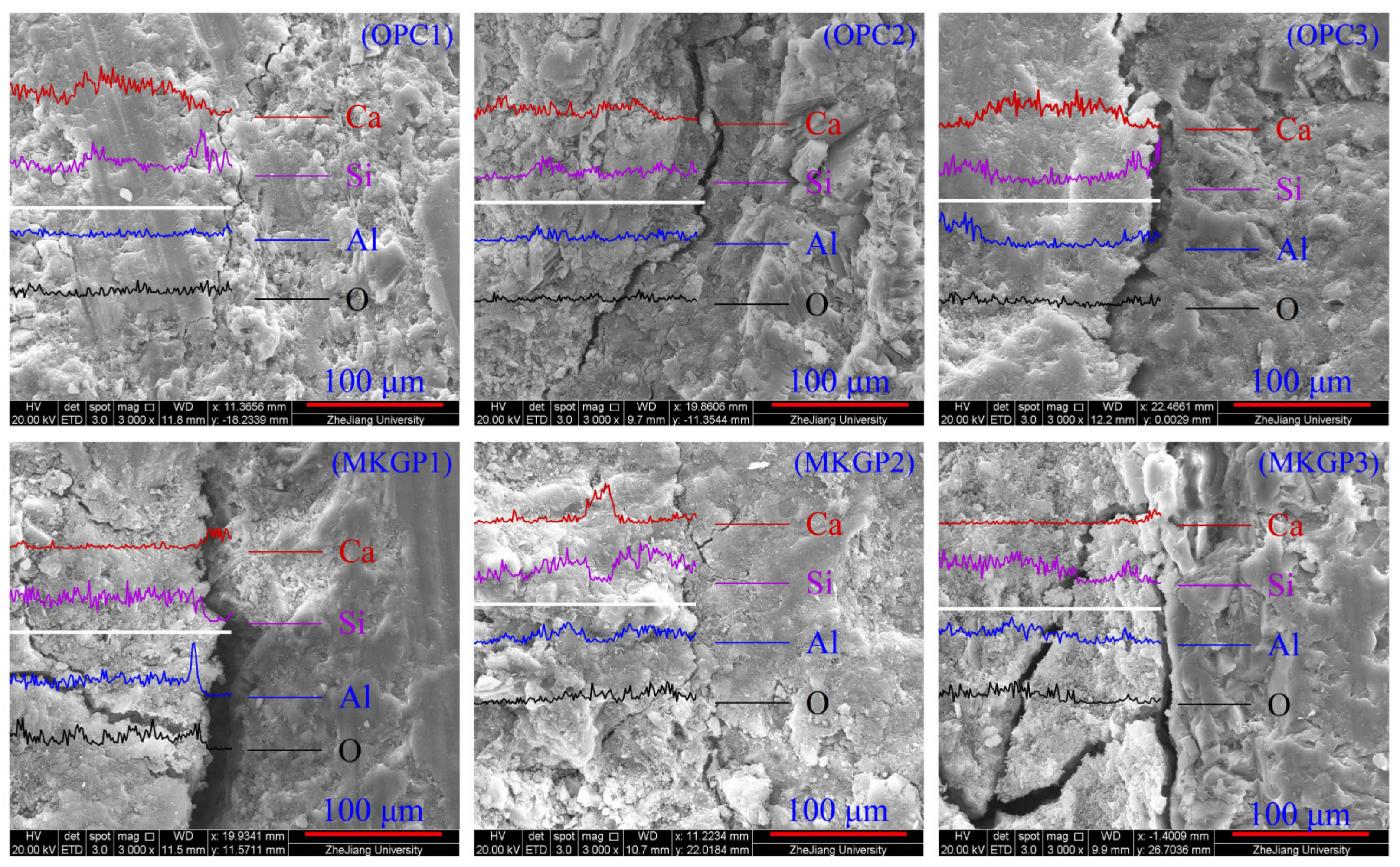

3.5.1. SEM Observation and EDS Analysis

- Portlandite, which the brittle Ca(OH)2;

- Hygrated Ca silicate;

- Hydrated Ca aluminate.

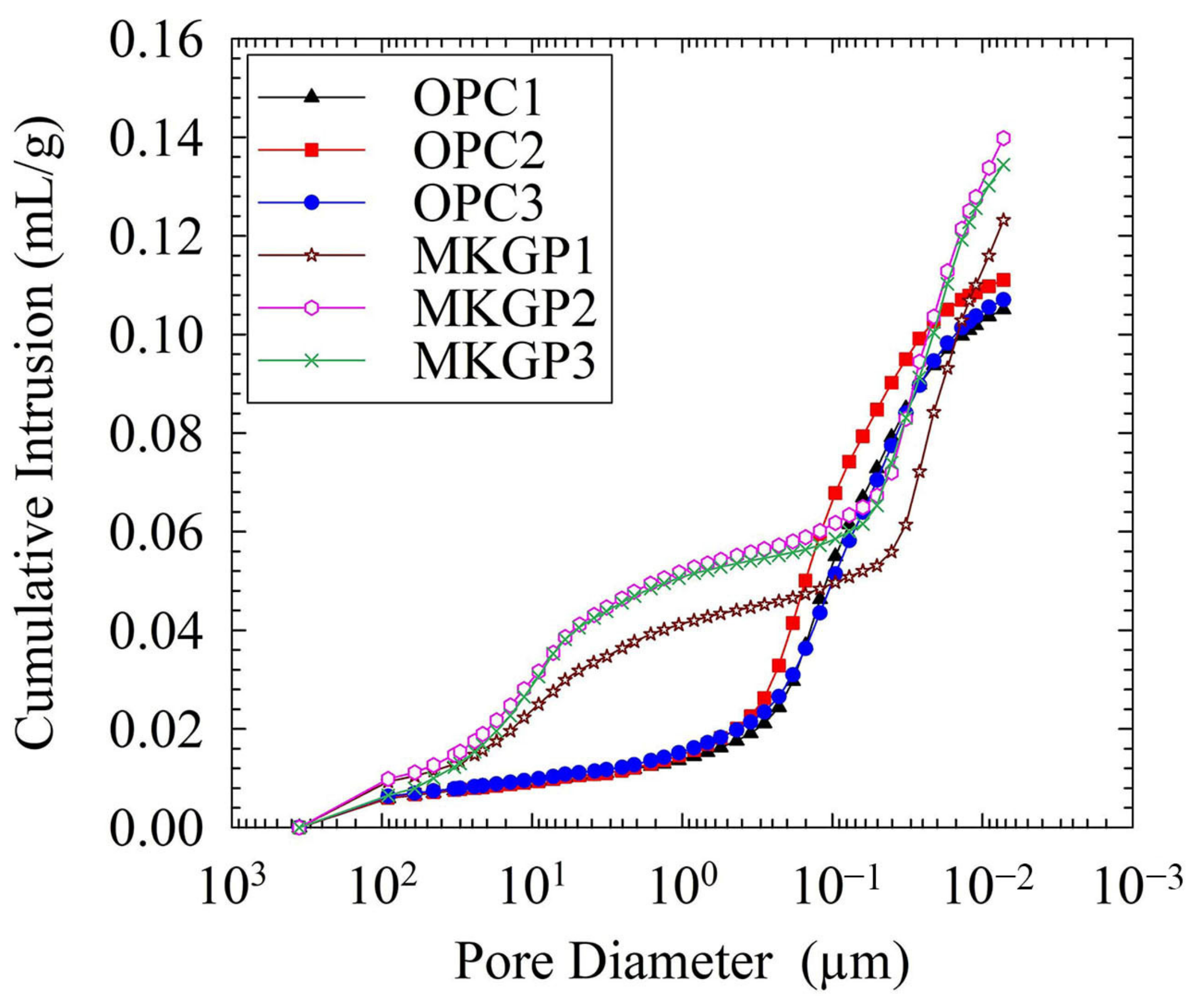

3.5.2. Pore Structure Analysis Using MIP

4. Further Discussion

5. Conclusions

- (1)

- The compressive strength of MKGP concrete and OPC concrete decreased and increased, respectively, as the size of the coarse aggregate increased. This behavior can be explained by the higher shrinkage of the MKGP concrete.

- (2)

- The maximum reduction and increment in compressive strength due to the increase of the size of the coarse aggregate of OPC concrete and MKGP concrete were 13% and 36%, respectively.

- (3)

- The splitting tensile strength decreased in both groups because coarse aggregates with larger sizes yield higher microcracks in the vicinity of the coarse aggregate.

- (4)

- The maximum reduction in the splitting tensile strength due to the increase of the size of the coarse aggregate of OPC concrete and MKGP concrete were 28% and 114%, respectively.

- (5)

- SEM/EDS investigations revealed that the size of the coarse aggregate does not significantly affect the ITZ area in this study. MIP results showed a larger pore diameter with increasing size of the coarse aggregate. The role of paste between coarse aggregates is therefore more pronounced as the size of the coarse aggregate increases.

- (6)

- It can be concluded that the changes in pore structure with the size of the coarse aggregate significantly influences the strength development of the tested specimens. An increase in the size of the coarse aggregate results in a higher shrinkage of MKGP concrete and subsequently results in a larger number of macropores. Hence, the influence of macropores is significant.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Shishkin, A. Recycling of hydrated Portland cement paste into new clinker. Constr. Build. Mater. 2021, 280, 122510. [Google Scholar] [CrossRef]

- Chen, J.; Shen, L.; Song, X.; Shi, Q.; Li, S. An empirical study on the CO2 emissions in the Chinese construction industry. J. Clean. Prod. 2017, 168, 645–654. [Google Scholar] [CrossRef]

- He, Z.; Zhu, X.; Wang, J.; Mu, M.; Wang, Y. Comparison of CO2 emissions from OPC and recycled cement production. Constr. Build. Mater. 2019, 211, 965–973. [Google Scholar] [CrossRef]

- Davidovits, J.; Comrie, D.C.; Paterson, J.H.; Ritcey, D.J. Geopolymeric concretes for environmental protection. Concr. Int. 1990, 12, 30–40. [Google Scholar]

- Smallwood, I.; Wild, S.; Morgan, E. The resistance of metakaolin (MK)–Portland cement (PC) concrete to the thaumasite-type of sulfate attack (TSA)-Programme of research and preliminary results. Cement Concr. Compos. 2003, 25, 931–938. [Google Scholar] [CrossRef]

- Mlinárik, L.; Kopecskó, K. Influence of metakaolin on chemical resistance of concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering (Online); IOP Publishing: Miskolc-Lillafüred, Hungary, 2013; p. 012014. [Google Scholar]

- Nas, M.; Kurbetci, S. Durability properties of concrete containing metakaolin. Adv. Concr. Constr. 2018, 6, 159. [Google Scholar] [CrossRef]

- Morsy, M.; Rashad, A.; El-Nouhy, H. Effect of elevated temperature on physico-mechanical properties of metakaolin blended cement mortar. Struct. Eng. Mech. 2009, 31, 1–10. [Google Scholar] [CrossRef]

- Hrabová, K.; Lehner, P.; Ghosh, P.; Konečný, P.; Teplý, B. Sustainability levels in comparison with mechanical properties and durability of pumice high-performance concrete. Appl. Sci. 2021, 11, 4964. [Google Scholar] [CrossRef]

- Eisa, M.S.; Basiouny, M.E.; Fahmy, E.A. Effect of metakaolin-based geopolymer concrete on the length of rigid pavement slabs. Innov. Infrastruct. Solut. 2021, 6, 91. [Google Scholar] [CrossRef]

- Liu, K.; Wang, S.; Quan, X.; Duan, W.; Nan, Z.; Wei, T.; Xu, F.; Li, B. Study on the mechanical properties and microstructure of fiber reinforced metakaolin-based recycled aggregate concrete. Constr. Build. Mater. 2021, 294, 123554. [Google Scholar] [CrossRef]

- Sucharda, O.; Mateckova, P.; Bilek, V. Non-linear analysis of an RC beam without shear reinforcement with a sensitivity study of the material properties of concrete. Slovak J. Civ. Eng. 2020, 28, 33–43. [Google Scholar] [CrossRef]

- Xu, J.; Corr, D.J.; Shah, S.P. Nanomechanical properties of C-S-H gel/cement grain interface by using nanoindentation and modulus mapping. J. Zhejiang Univ. Sci. A 2015, 16, 38–46. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Effect of aggregate on the fracture behavior of high strength concrete. Constr. Build. Mater. 2004, 18, 585–590. [Google Scholar] [CrossRef]

- Nili, M.; Ehsani, A. Investigating the effect of the cement paste and transition zone on strength development of concrete containing nanosilica and silica fume. Mater. Des. 2015, 75, 174–183. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, W.; Pham, T.M.; Chen, L.; Cui, J.; Shi, Y.; Hao, H. Effect of aggregate size on the dynamic interfacial bond behaviour between basalt fiber reinforced polymer sheets and concrete. Constr. Build. Mater. 2019, 227, 116584. [Google Scholar] [CrossRef]

- Akçaoğlu, T. Determining aggregate size & shape effect on concrete microcracking under compression by means of a degree of reversibility method. Constr. Build. Mater. 2017, 143, 376–386. [Google Scholar] [CrossRef]

- Ćosić, K.; Korat, L.; Ducman, V.; Netinger, I. Influence of aggregate type and size on properties of pervious concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Compression response of normal and high strength pervious concrete. Constr. Build. Mater. 2016, 109, 177–187. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Wang, J.; Hu, M. Influence of aggregate size on compressive strength of pervious concrete. Constr. Build. Mater. 2019, 209, 463–475. [Google Scholar] [CrossRef]

- Lahoti, M.; Narang, P.; Tan, K.H.; Yang, E.-H. Mix design factors and strength prediction of metakaolin-based geopolymer. Ceram. Int. 2017, 43, 11433–11441. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Assessment of important parameters involved in the synthesis of geopolymer composites: A review. Constr. Build. Mater. 2020, 264, 120276. [Google Scholar] [CrossRef]

- Nikoloutsopoulos, N.; Sotiropoulou, A.; Kakali, G.; Tsivilis, S. Physical and Mechanical Properties of Fly Ash Based Geopolymer Concrete Compared to Conventional Concrete. Buildings 2021, 11, 178. [Google Scholar] [CrossRef]

- Joseph, B.; Mathew, G. Influence of aggregate content on the behavior of fly ash based geopolymer concrete. Sci. Iran. 2012, 19, 1188–1194. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, K.; Li, Q.; Wang, J.; Ling, Y. Fabrication and engineering properties of concretes based on geopolymers/alkali-activated binders—A review. J. Clean. Prod. 2020, 258, 120896. [Google Scholar] [CrossRef]

- BS EN 197-1 Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements; British Standard Institution (BSI): Brussels, Belgium, 2011.

- ASTM C618 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2019.

- Gonilho Pereira, C.; Castro-Gomes, J.; Pereira de Oliveira, L. Influence of natural coarse aggregate size, mineralogy and water content on the permeability of structural concrete. Constr. Build. Mater. 2009, 23, 602–608. [Google Scholar] [CrossRef]

- BS EN 12390-2 Testing Hardened Concrete-Part 2: Making and Curing Specimens for Strength Tests; BSI (British Standard Institution): Brussels, Belgium, 2009.

- BS EN 12390-6 Testing Hardened Concrete. Tensile Splitting Strength of Test Specimens; British Standard Institution (BSI): Brussels, Belgium, 2009.

- BS EN 12390-3 Testing Hardened Concrete Part 3: Compressive Strength of Test Specimens; BSI (British Standard Institution): London, UK, 2009.

- Guades, E.J. Experimental investigation of the compressive and tensile strengths of geopolymer mortar: The effect of sand/fly ash (S/FA) ratio. Constr. Build. Mater. 2016, 127, 484–493. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, W.; Pham, T.M.; Hao, H. Effect of aggregate size on bond behaviour between basalt fibre reinforced polymer sheets and concrete. Compos. Part B Eng. 2019, 158, 459–474. [Google Scholar] [CrossRef]

- Torres, A.; Hu, J.; Ramos, A. The effect of the cementitious paste thickness on the performance of pervious concrete. Constr. Build. Mater. 2015, 95, 850–859. [Google Scholar] [CrossRef]

- Guades, E.J. Effect of coarse aggregate size on the compressive behaviour of geopolymer concrete. Eur. J. Environ. Civ. Eng. 2017, 23, 693–709. [Google Scholar] [CrossRef]

- Akçaoğlu, T.; Tokyay, M.; Çelik, T. Effect of coarse aggregate size on interfacial cracking under uniaxial compression. Mater. Lett. 2002, 57, 828–833. [Google Scholar] [CrossRef]

- Akçaoğlu, T.; Tokyay, M.; Çelik, T. Effect of coarse aggregate size and matrix quality on ITZ and failure behavior of concrete under uniaxial compression. Cement Concr. Compos. 2004, 26, 633–638. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.-F.; Jiang, J.-F. Effect of aggregate size on stress-strain behavior of concrete confined by fiber composites. Compos. Struct. 2017, 168, 851–862. [Google Scholar] [CrossRef]

- Kim, J.K.; Yi, S.T.; Park, C.K.; Eo, S.H. Size effect on compressive strength of plain and spirally reinforced concrete cylinders. ACI Struct. J. 1999, 96, 88–94. [Google Scholar] [CrossRef]

- The MathWorks. MATLAB R2018a; User’s Manual; The MathWorks: Natick, MA, USA, 2018. [Google Scholar]

- ACI 318-14 Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2014.

- CEB-FIP Evaluation of the Time-Dependent Behavior of Concrete. Bulletin D’information No 199; CEB Comité Euro international du Béton: Laussane, Switzerland, 1990.

- Al-Bayati, H.K.A.; Tighe, S.L.; Baaj, H.; Al-Bayati, H.K.A. Effect of different treatment methods on the interfacial transition zone microstructure to coarse recycled concrete aggregate. In Proceedings of the TAC 2016: Efficient Transportation-Managing the Demand-2016 Conference and Exhibition of the Transportation Association of Canada, Toronto, ON, Canada, 25–28 September 2016; pp. 1–29. [Google Scholar]

- Peng, H.; Cui, C.; Cai, C.S.; Liu, Y.; Liu, Z. Microstructure and microhardness property of the interface between a metakaolin/GGBFS-based geopolymer paste and granite aggregate. Constr. Build. Mater. 2019, 221, 263–273. [Google Scholar] [CrossRef]

- Van Mier, J. Failure of concrete under uniaxial compression: An overview. Fract. Mech. Concr. Struct. 1998, 2, 1169–1182. [Google Scholar]

- Di Maio, A.; Giaccio, G.; Zerbino, R. Failure mechanism of concrete, combined effects of coarse aggregates and specimen geometry. Constr. Build. Mater. 1996, 10, 571–575. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Dalvand, A.; Mohammadi Firouz, R.; Illikainen, M. Drying shrinkage in alkali-activated binders-a critical review. Constr. Build. Mater. 2018, 190, 533–550. [Google Scholar] [CrossRef]

- Hansen, T.C.; Nielsen, K.E. Influence of aggregate properties on concrete shrinkage. J. Proc. 1965, 62, 783–794. [Google Scholar] [CrossRef]

- Karagüler, M.; Yatağan, M. Effect of aggregate size on the restrained shrinkage of the concrete and mortar. MOJ Civ. Eng. 2018, 4, 2018. [Google Scholar] [CrossRef]

- Perera, D.S.; Uchida, O.; Vance, E.R.; Finnie, K.S. Influence of curing schedule on the integrity of geopolymers. J. Mater. Sci. 2007, 42, 3099–3106. [Google Scholar] [CrossRef]

- Kuenzel, C.; Vandeperre, L.J.; Donatello, S.; Boccaccini, A.R.; Cheeseman, C. Ambient temperature drying shrinkage and cracking in metakaolin-based geopolymers. J. Am. Ceram. Soc. 2012, 95, 3270–3277. [Google Scholar] [CrossRef]

- Zhang, Z.; Yao, X.; Zhu, H.; Chen, Y. Role of water in the synthesis of calcined kaolin-based geopolymer. Appl. Clay Sci. 2009, 43, 218–223. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.-B. Effect of admixtures on properties of alkali-activated slag concrete. Cement Concr. Res. 2000, 30, 1367–1374. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, H.; Zhang, Z. Influence of fly ash on the pore structure and shrinkage characteristics of metakaolin-based geopolymer pastes and mortars. Constr. Build. Mater. 2017, 153, 284–293. [Google Scholar] [CrossRef]

- Neupane, K. Fly ash and GGBFS based powder-activated geopolymer binders: A viable sustainable alternative of portland cement in concrete industry. Mech. Mater. 2016, 103, 110–122. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, L.; Cui, X.; He, Y.; Zheng, G.; Shi, C. Effect of Fuller-fine sand on rheological, drying shrinkage, and microstructural properties of metakaolin-based geopolymer grouting materials. Cement Concr. Compos. 2019, 104, 103381. [Google Scholar] [CrossRef]

- Part, W.K.; Ramli, M.; Cheah, C.B. An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products. Constr. Build. Mater. 2015, 77, 370–395. [Google Scholar] [CrossRef]

| Chemicals | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | TiO2 | Na2O | LOI * |

|---|---|---|---|---|---|---|---|---|---|---|

| OPC | 23.81 | 10.79 | 3.36 | 50.58 | 5.31 | 2.75 | 0.92 | 0.73 | 0.61 | 1.14 |

| MK | 53.29 | 41.64 | 0.53 | 1.09 | 0.28 | - | 0.14 | 1.13 | 0.07 | 1.83 |

| Oxide | SiO2 | Na2O | H2O |

|---|---|---|---|

| Mass content (%) | 26.00 | 8.20 | 65.80 |

| Group | MK | WG | Cement | Coarse Aggregate | Sand | Water | |

|---|---|---|---|---|---|---|---|

| SiO2 | Na2O | ||||||

| OPC | - | - | - | 487 | 1115 | 560 | 208 |

| MKGP | 268 | 92.82 | 106.77 | - | 1115 | 560 | 255 |

| Series | Specimens | Coarse Aggregate Size (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Indiv. * | Ave. * | SD | Indiv. * | Ave. * | SD | ||||

| OPC | OPC1 | OPC-1-1 | 5–10 | 31.80 | 31.59 | 0.22 | 4.82 | 4.77 | 0.05 |

| OPC-1-2 | 31.36 | 4.72 | |||||||

| OPC-1-3 | 31.62 | 4.77 | |||||||

| OPC2 | OPC-2-1 | 10–16 | 34.53 | 34.96 | 0.48 | 4.08 | 4.14 | 0.08 | |

| OPC-2-2 | 34.87 | 4.11 | |||||||

| OPC-2-3 | 35.47 | 4.23 | |||||||

| OPC3 | OPC-3-1 | 16–20 | 36.29 | 36.40 | 0.25 | 3.82 | 3.74 | 0.09 | |

| OPC-3-2 | 36.22 | 3.65 | |||||||

| OPC-3-3 | 36.68 | 3.75 | |||||||

| MKGP | MKGP1 | MKGP-1-1 | 5–10 | 36.11 | 36.39 | 0.29 | 3.00 | 3.13 | 0.15 |

| MKGP-1-2 | 36.68 | 3.29 | |||||||

| MKGP-1-3 | 36.38 | 3.10 | |||||||

| MKGP2 | MKGP-2-1 | 10–16 | 33.27 | 33.05 | 0.27 | 2.69 | 2.85 | 0.15 | |

| MKGP-2-2 | 32.75 | 2.88 | |||||||

| MKGP-2-3 | 33.12 | 2.98 | |||||||

| MKGP3 | MKGP-3-1 | 16–20 | 26.95 | 26.81 | 0.15 | 1.44 | 1.46 | 0.03 | |

| MKGP-3-2 | 26.65 | 1.45 | |||||||

| MKGP-3-3 | 26.82 | 1.49 | |||||||

| Specimens | Calibrated Model () (mm) | Proposed Model () (mm) | ||

|---|---|---|---|---|

| MKGP-1-1 | 35.97 | 3.44 | 1.00 | 0.87 |

| MKGP-1-2 | 35.97 | 3.57 | 0.98 | 0.92 |

| MKGP-1-3 | 35.97 | 3.5 | 0.99 | 0.89 |

| MKGP-2-1 | 30.85 | 2.83 | 0.93 | 0.95 |

| MKGP-2-2 | 30.85 | 2.73 | 0.94 | 1.05 |

| MKGP-2-3 | 30.85 | 2.8 | 0.93 | 1.06 |

| MKGP-3-1 | 27.52 | 1.71 | 1.02 | 0.84 |

| MKGP-3-2 | 27.52 | 1.67 | 1.03 | 0.87 |

| MKGP-3-3 | 27.52 | 1.7 | 1.03 | 0.88 |

| Average | 0.98 | 0.93 | ||

| SD | 0.041 | 0.077 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fazli, H.; Yan, D.; Zhang, Y.; Zeng, Q. Effect of Size of Coarse Aggregate on Mechanical Properties of Metakaolin-Based Geopolymer Concrete and Ordinary Concrete. Materials 2021, 14, 3316. https://doi.org/10.3390/ma14123316

Fazli H, Yan D, Zhang Y, Zeng Q. Effect of Size of Coarse Aggregate on Mechanical Properties of Metakaolin-Based Geopolymer Concrete and Ordinary Concrete. Materials. 2021; 14(12):3316. https://doi.org/10.3390/ma14123316

Chicago/Turabian StyleFazli, Hamed, Dongming Yan, Yajun Zhang, and Qiang Zeng. 2021. "Effect of Size of Coarse Aggregate on Mechanical Properties of Metakaolin-Based Geopolymer Concrete and Ordinary Concrete" Materials 14, no. 12: 3316. https://doi.org/10.3390/ma14123316

APA StyleFazli, H., Yan, D., Zhang, Y., & Zeng, Q. (2021). Effect of Size of Coarse Aggregate on Mechanical Properties of Metakaolin-Based Geopolymer Concrete and Ordinary Concrete. Materials, 14(12), 3316. https://doi.org/10.3390/ma14123316