Micro-Shear Bands and Their Enhancement on High Temperature Strength of Mg-Gd-Y-Zr Alloy

Abstract

1. Introduction

2. Experimental Procedures

3. Results

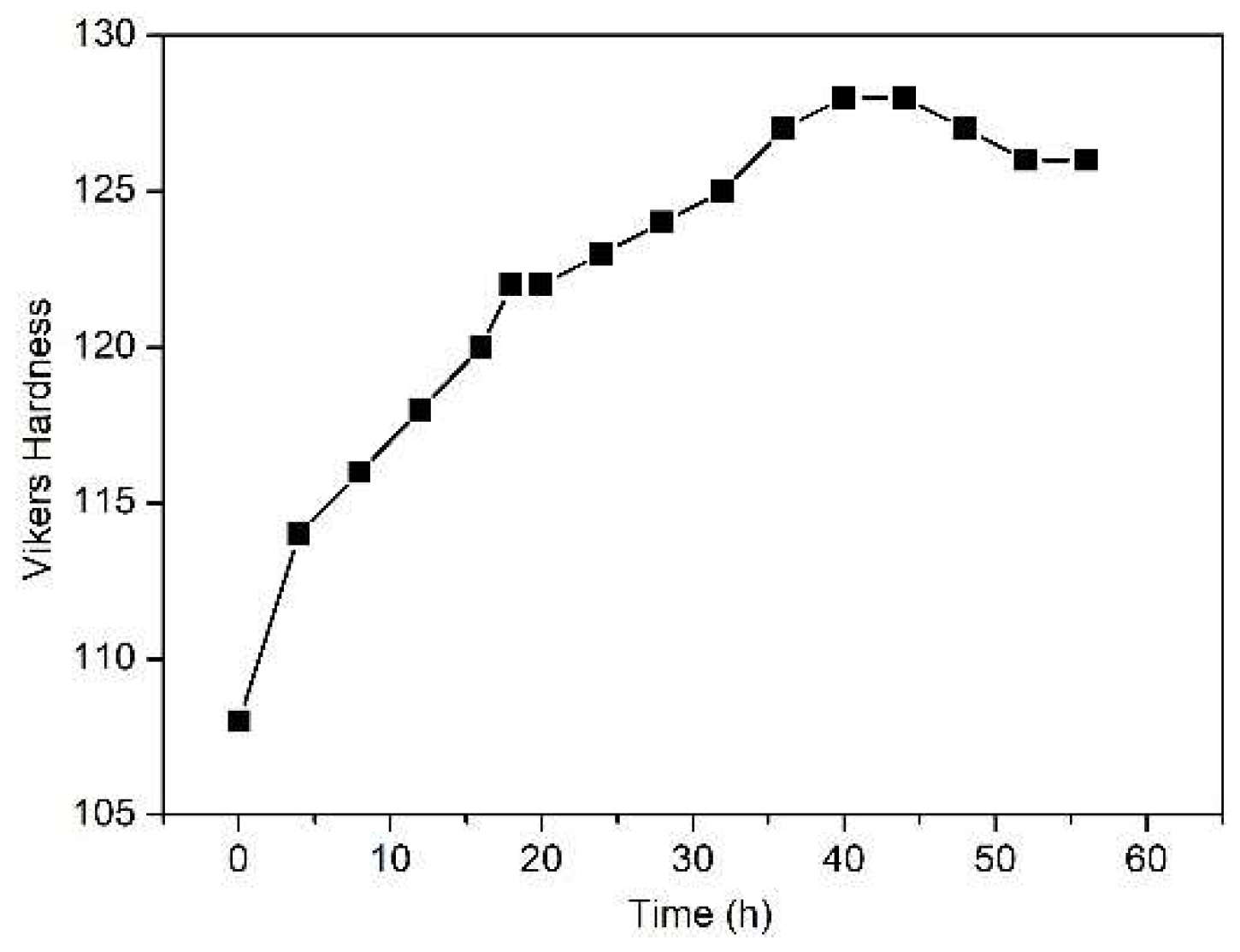

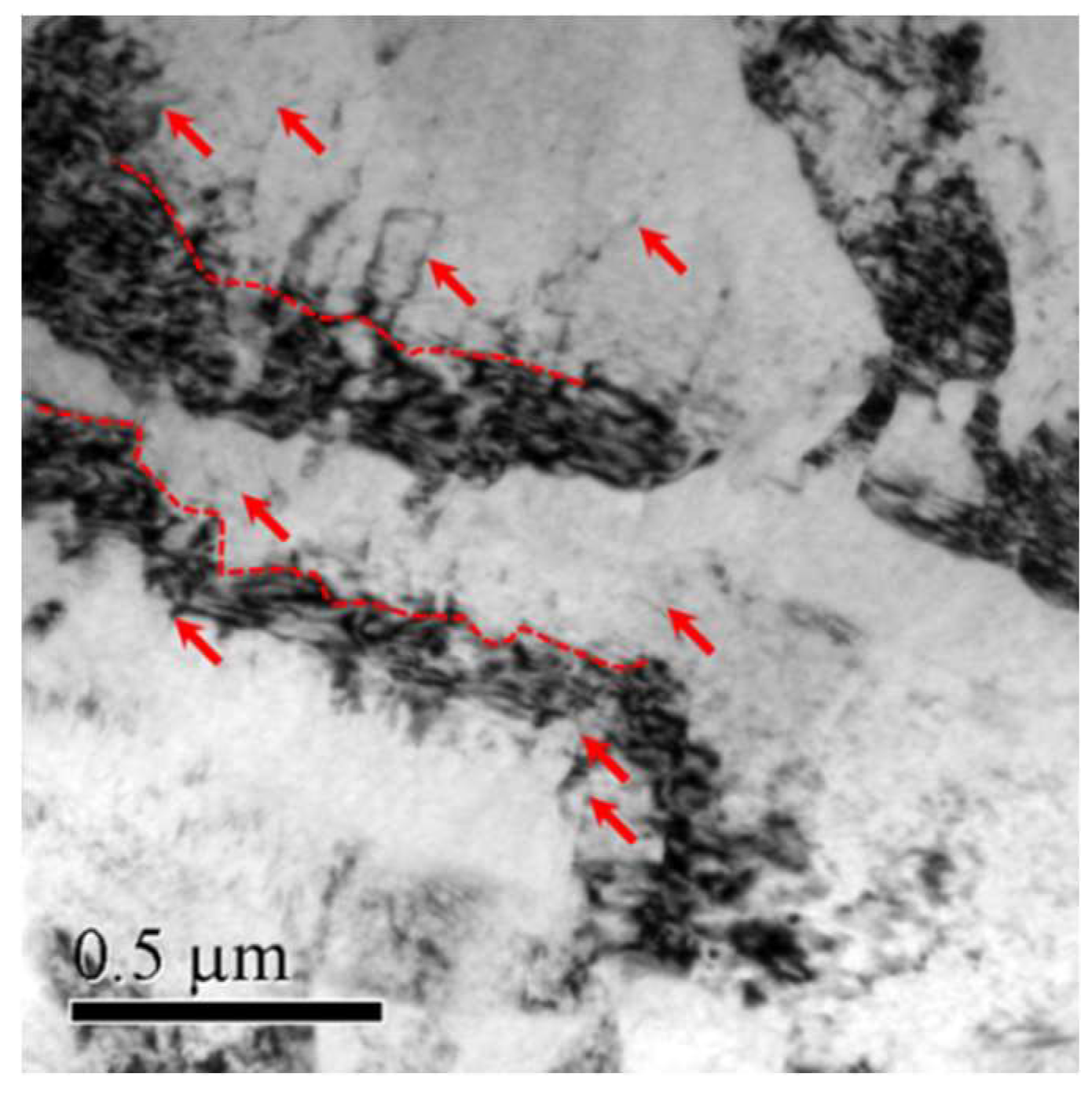

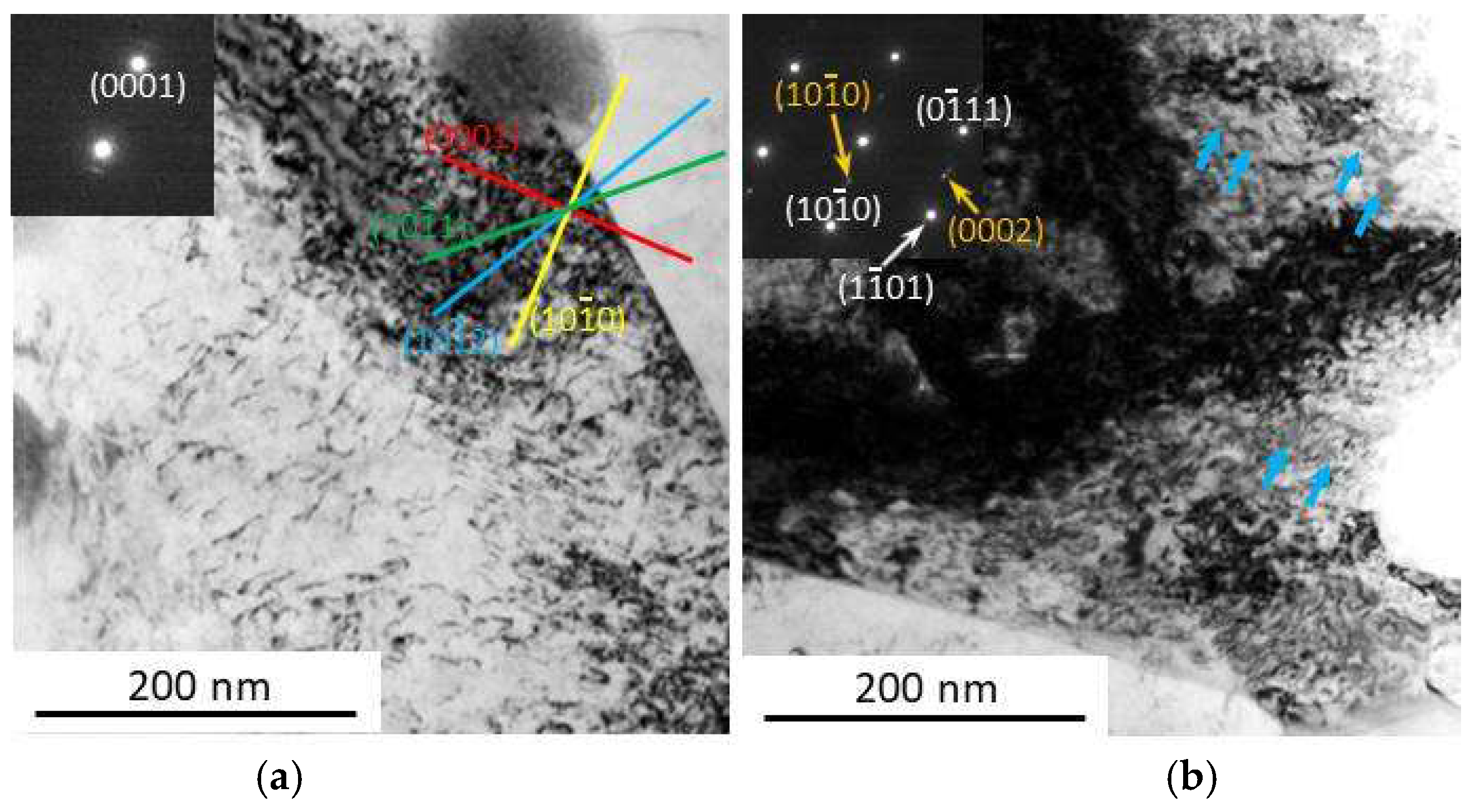

3.1. Microstructure

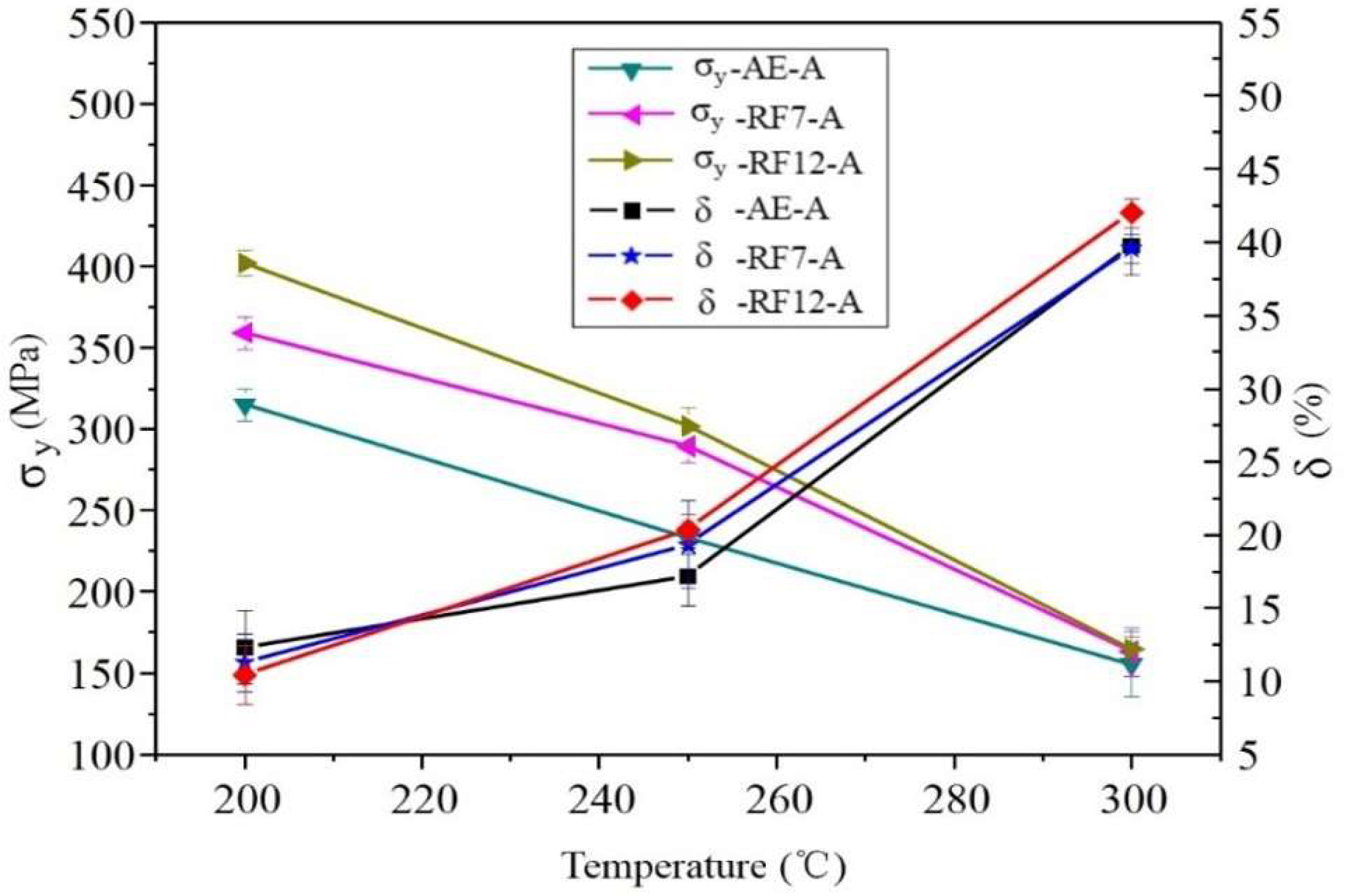

3.2. Mechanical Properties

4. Discussion

5. Conclusions

- The micro-shear bands can effectively hinder dislocation sliding and strengthen the alloy at elevated temperatures. When the temperature is higher than 250 °C, the enhancement effect decreases, which is mainly caused by the activation of grain boundary deformation.

- Due to dislocation-assisted precipitation during tension, the alloy exhibits higher strength at 200 °C than at room temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, G.; Lu, J.; Chan, K.C.; Sun, L.; Zhu, L. Dual-phase nanostructuring as a route to high-strength magnesium alloys. Nature 2017, 545, 80–83. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Zhang, J.; Qin, P.; Liu, S.; Yang, Q.; Meng, J.; Wu, R.; Xie, J. Characterization of elevated-temperature high strength and decent thermal conductivity extruded Mg-Er-Y-Zn alloy containing nano-spaced stacking faults. Mater. Character. 2019, 155, 109823. [Google Scholar] [CrossRef]

- Wang, J.; Luo, L.; Huo, Q.; Shi, Y.; Xiao, Z.; Ye, Y.; Yang, X. Creep behaviors of a highly concentrated Mg-18 wt% Gd binary alloy with and without artificial aging. J. Alloys Compd. 2019, 774, 1036–1045. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, J.; Chen, X.; Zhang, X.; Li, M.J. Fabrication of high-strength AZ80 alloys via multidirectional forging in air with no need of ageing treatment. J. Alloys Compd. 2019, 787, 551–559. [Google Scholar] [CrossRef]

- Wang, D.; Fu, P.; Peng, L.; Wang, Y.; Ding, W. Development of high strength sand cast Mg–Gd–Zn alloy by co-precipitation of the prismatic β′ and β1 phases. Materials Characterization. Mater. Character. 2019, 153, 157–168. [Google Scholar] [CrossRef]

- He, S.M.; Zeng, X.Q.; Peng, L.M.; Gao, X.-Q.; Nie, J.F.; Ding, W.J. Precipitation in a Mg–10Gd–3Y–0.4 Zr (wt.%) alloy during isothermal ageing at 250 °C. J. Alloys Compd. 2006, 421, 309–313. [Google Scholar] [CrossRef]

- Zhu, S.; Yan, H.; Liao, X.; Moody, S.; Sha, G.; Wu, Y.; Ringer, S. Mechanisms for enhanced plasticity in magnesium alloys. Acta Mater. 2015, 82, 344–355. [Google Scholar] [CrossRef]

- Tong, L.; Chu, J.; Jiang, Z.; Kamado, S.; Zheng, M. Ultra-fine grained Mg-Zn-Ca-Mn alloy with simultaneously improved strength and ductility processed by equal channel angular pressing. J. Alloys Compd. 2019, 785, 410–421. [Google Scholar] [CrossRef]

- Jian, W.; Cheng, G.; Xu, W.; Yuan, H.; Tsai, M.; Wang, Q.; Koch, C.; Zhu, Y.; Mathaudhu, S. Ultrastrong Mg alloy via nano-spaced stacking faults. Mater. Res. Lett. 2013, 1, 61–66. [Google Scholar] [CrossRef]

- Wan, Y.; Xu, S.; Liu, C.; Gao, Y.; Jiang, S.; Chen, Z. Enhanced strength and corrosion resistance of Mg-Gd-Y-Zr alloy with ultrafine grains. Mater. Lett. 2018, 213, 274–277. [Google Scholar] [CrossRef]

- Yang, Z.J.; Chen, X.; Liu, C.M.; Gao, Y.H.; Jiang, S.N.; Chen, Z.Y.; Guo, X.Y.; Wan, Y.C. Enhanced Mechanical and Corrosion Performance by Forming Micro Shear Bands in Cold Forged Mg-Gd-Y-Zr Alloy. Materials 2020, 13, 3181. [Google Scholar] [CrossRef] [PubMed]

- Tang, L.; Liu, W.; Ding, Z.; Zhang, D.; Zhao, Y.; Lavernia, E.J.; Zhu, Y. Alloying Mg with Gd and Y: Increasing both plasticity and strength. Comput. Mater. Sci. 2016, 115, 85–91. [Google Scholar] [CrossRef]

- Zhu, L.; Seefeldt, M.; Verlinden, B. Deformation banding in a Nb polycrystal deformed by successive compression tests. Acta materialia. Acta Mater. 2012, 60, 4349–4358. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, M.; Ma, S.; Liaw, P.K.; Zhang, Y.; Qiao, J. Strengthening in Al0. 25CoCrFeNi high-entropy alloys by cold rolling. Mater. Sci. Eng. A 2017, 707, 593–601. [Google Scholar] [CrossRef]

- Sun, H.Q.; Shi, Y.N.; Zhang, M.X.; Lu, K. Plastic strain-induced grain refinement in the nanometer scale in a Mg alloy. Acta Mater. 2007, 55, 975–982. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Fundamentals of superior properties in bulk nanoSPD materials. Mater. Res. Lett. 2016, 4, 1–21. [Google Scholar] [CrossRef]

- Wan, Y.C.; Xiao, H.C.; Jiang, S.N.; Tang, B.; Liu, C.M.; Chen, Z.Y.; Lu, L.W. Microstructure and mechanical properties of semi-continuous cast Mg–Gd–Y–Zr alloy. Mater. Sci. Eng. A 2014, 617, 243–248. [Google Scholar] [CrossRef]

- Nodooshan, H.J.; Wu, G.; Liu, W.; Wei, G.; Li, Y.; Zhang, S. Effect of Gd content on high temperature mechanical properties of Mg-Gd-Y-Zr alloy. Mater. Sci. Eng. A 2016, 651, 840–847. [Google Scholar] [CrossRef]

- Liang, S.; Guan, D.; Chen, L.; Gao, Z.; Tang, H.; Tong, X.; Xiao, R. Precipitation and its effect on age-hardening behavior of as-cast Mg–Gd–Y alloy. Mater. Des. 2011, 32, 361–364. [Google Scholar] [CrossRef]

- Wang, J.; Meng, J.; Zhang, D.; Tang, D. Effect of Y for enhanced age hardening response and mechanical properties of Mg–Gd–Y–Zr alloys. Mater. Sci. Eng. A 2007, 456, 78–84. [Google Scholar] [CrossRef]

- Kamado, S.; Iwasawa, S.; Ohuchi, K.; Kojima, Y.; Ninomiya, R. Age hardening characteristics and high temperature strength of Mg-Gd and Mg-Tb alloys. Keikinzoku 1992, 42, 727–733. [Google Scholar]

- Li, K.J.; Li, Q. Microstructure and superior mechanical properties of cast Mg–12Gd–2Y–0.5Sm–0.5Sb–0.5Zr alloy. Mater. Sci. Eng. A 2011, 528, 5453–5457. [Google Scholar] [CrossRef]

- Xu, W.; Birbilis, N.; Sha, G.; Wang, Y.; Daniels, J.E.; Xiao, Y.; Ferry, M. A high-specific-strength and corrosion-resistant magnesium alloy. Nat. Mater. 2015, 14, 1229. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.X.; Qiu, D.; Rong, Y.H.; Zhang, M.X. TEM study on the microstructural evolution in an Mg–Y–Gd–Zn alloy during ageing. Intermetallics 2013, 40, 45–49. [Google Scholar] [CrossRef]

- Wu, Z.; Curtin, W.A. The origins of high hardening and low ductility in magnesium. Nature 2015, 526, 62. [Google Scholar] [CrossRef] [PubMed]

| Samples | σy (MPa) | σu (MPa) | Δ (%) |

|---|---|---|---|

| AE | 197 | 282 | 29 |

| F-7 | 282 | 332 | 15 |

| F-12 | 337 | 360 | 14 |

| Samples | Temperature (°C) | σy (MPa) | σu (MPa) | Δ (%) |

|---|---|---|---|---|

| AE-A | 20 | 301 | 430 | 4.7 [10] |

| 200 | 315 | 377 | 12.0 | |

| 250 | 233 | 299 | 17.0 | |

| 300 | 156 | 185 | 40.0 | |

| F-12-A | 20 | 386 | 500 | 4.0 |

| 200 | 402 | 450 | 10.4 | |

| 250 | 302 | 334 | 20.4 | |

| 300 | 165 | 198 | 42.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Yang, Z.; Li, J.; Wan, Y. Micro-Shear Bands and Their Enhancement on High Temperature Strength of Mg-Gd-Y-Zr Alloy. Materials 2021, 14, 3262. https://doi.org/10.3390/ma14123262

Xiao H, Yang Z, Li J, Wan Y. Micro-Shear Bands and Their Enhancement on High Temperature Strength of Mg-Gd-Y-Zr Alloy. Materials. 2021; 14(12):3262. https://doi.org/10.3390/ma14123262

Chicago/Turabian StyleXiao, Hongchao, Zhengjiang Yang, Jie Li, and Yingchun Wan. 2021. "Micro-Shear Bands and Their Enhancement on High Temperature Strength of Mg-Gd-Y-Zr Alloy" Materials 14, no. 12: 3262. https://doi.org/10.3390/ma14123262

APA StyleXiao, H., Yang, Z., Li, J., & Wan, Y. (2021). Micro-Shear Bands and Their Enhancement on High Temperature Strength of Mg-Gd-Y-Zr Alloy. Materials, 14(12), 3262. https://doi.org/10.3390/ma14123262