Assessment of Operational Degradation of Pipeline Steels

Abstract

:1. Introduction

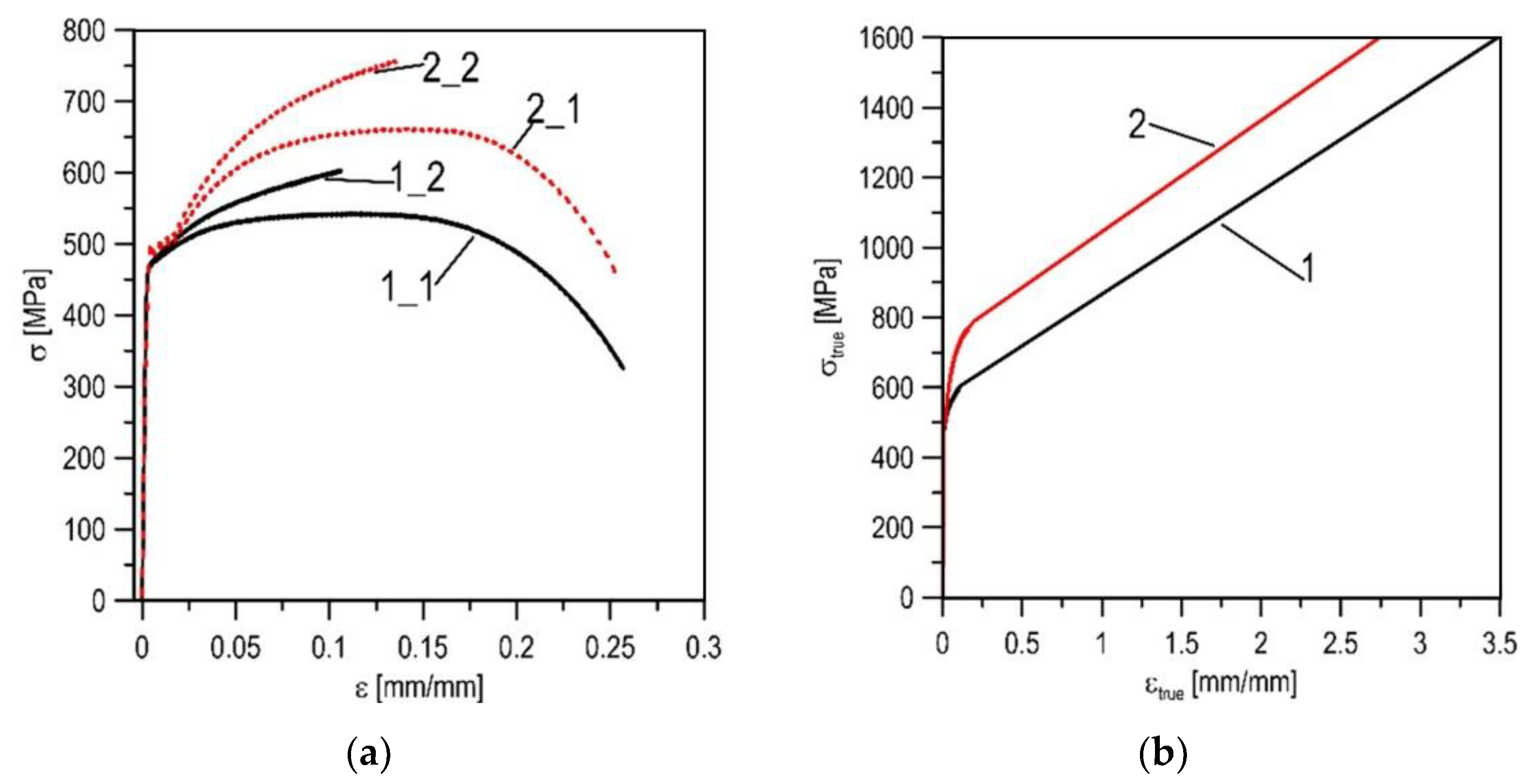

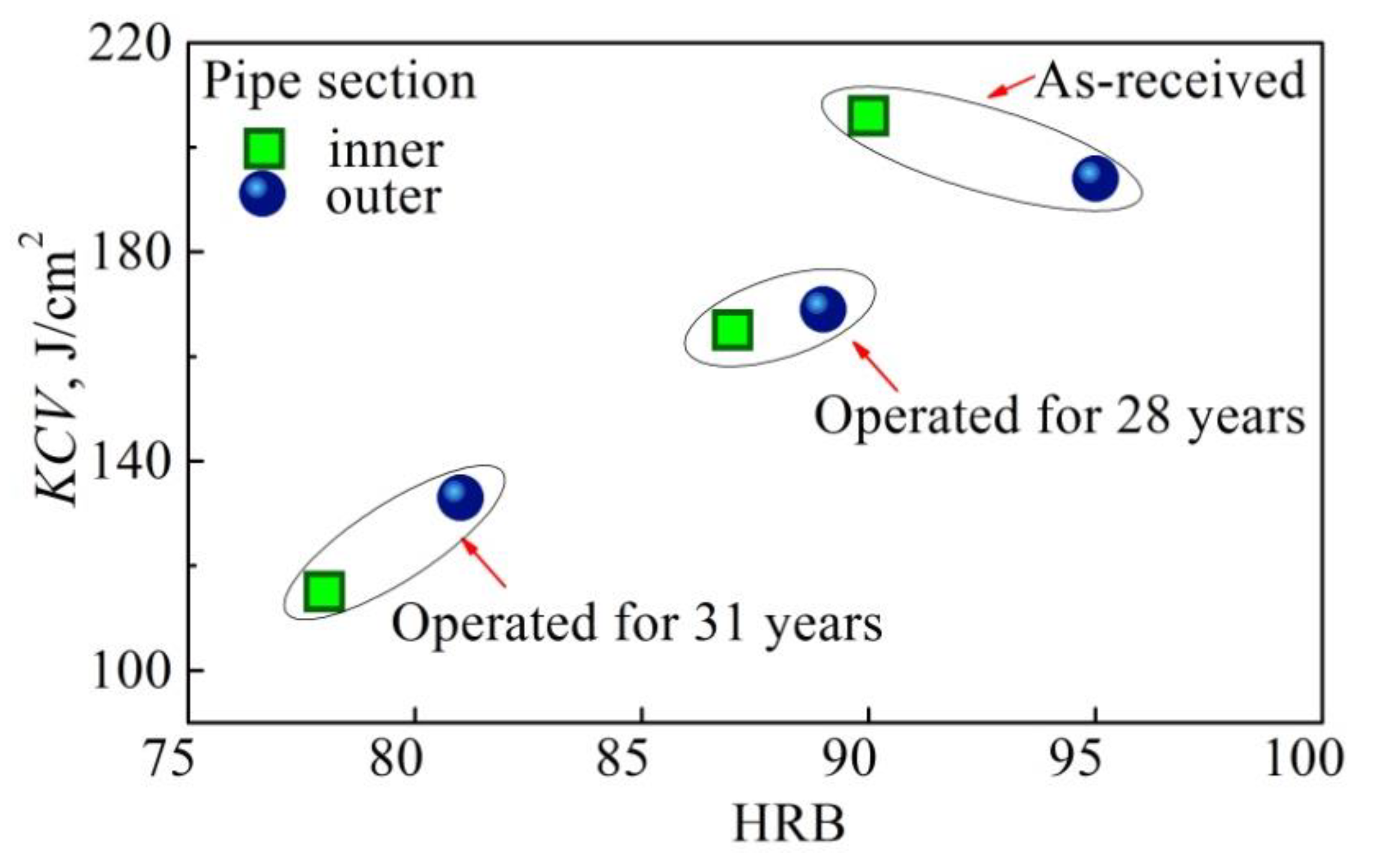

2. Deterioration of Mechanical Properties

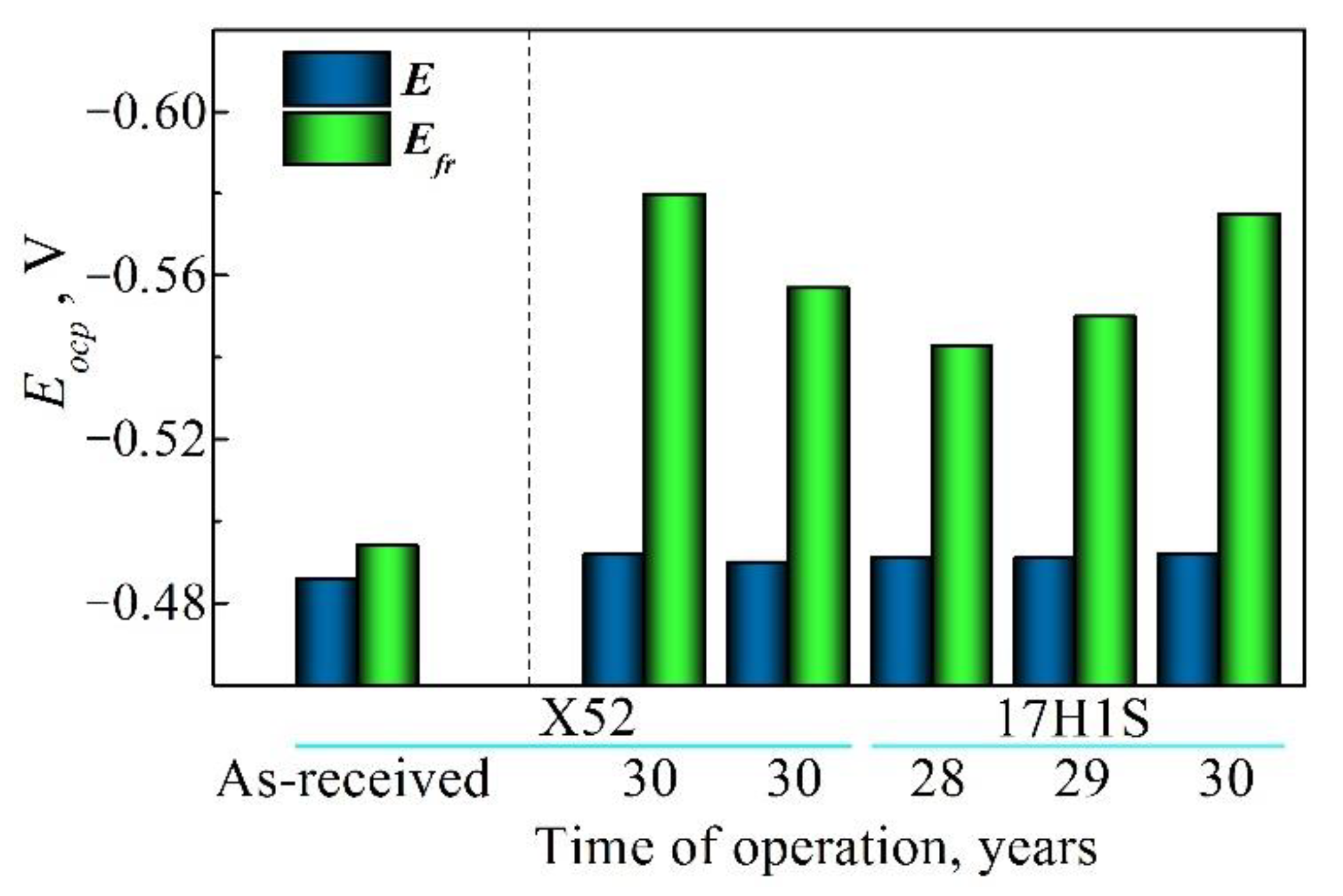

3. Changes in Electrochemical Behaviour

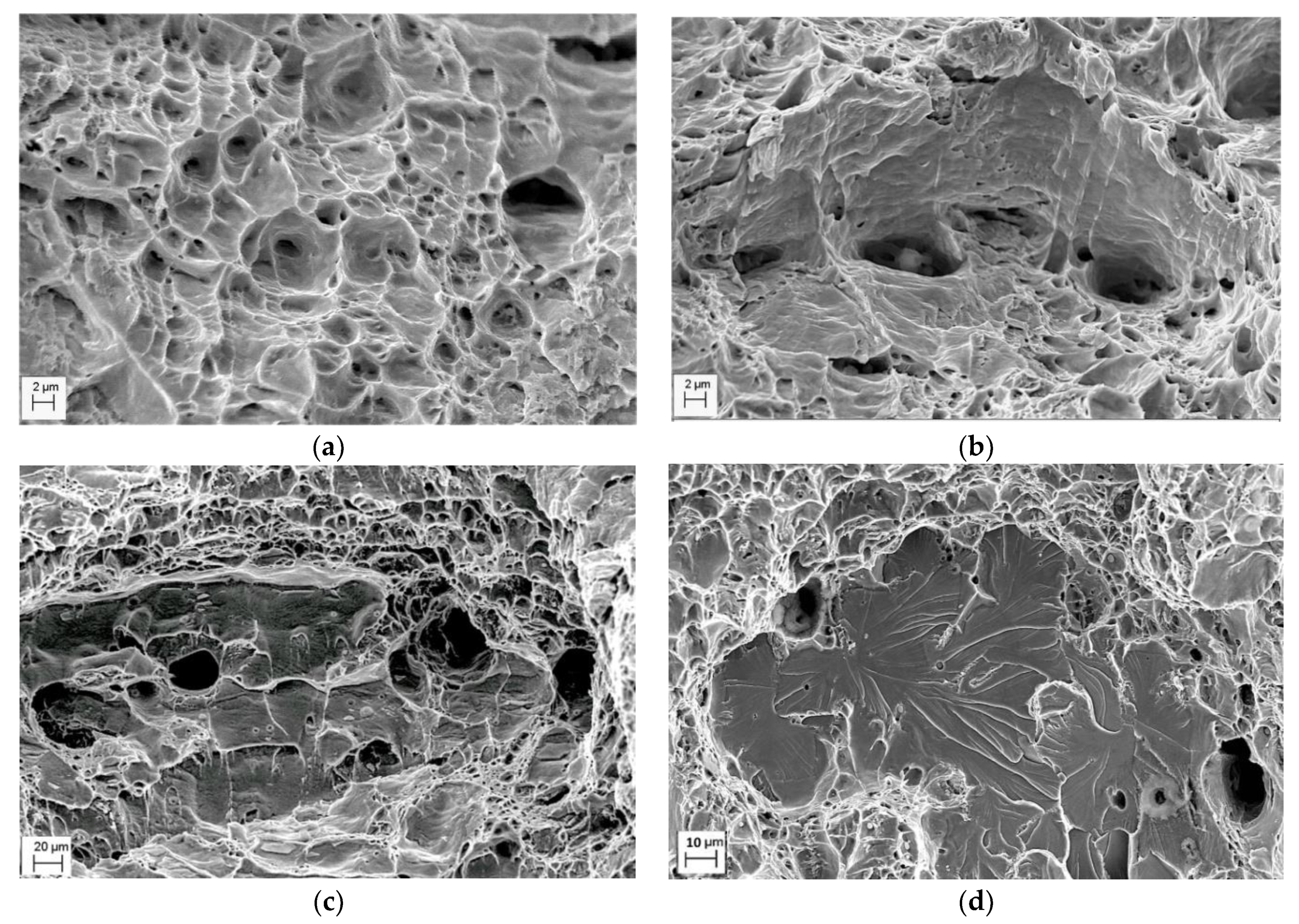

4. Microstructural and Fractographic Signs of Steel Degradation

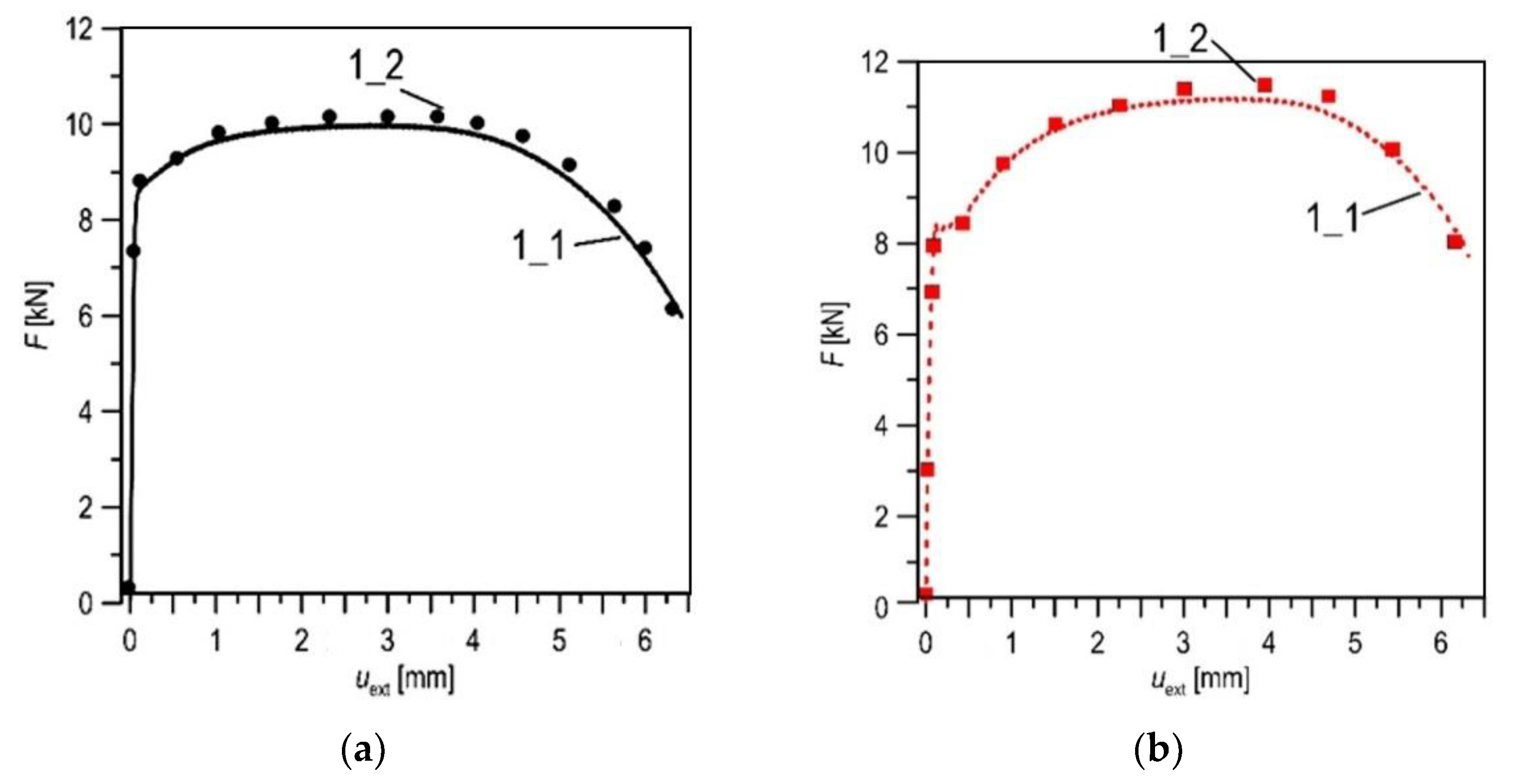

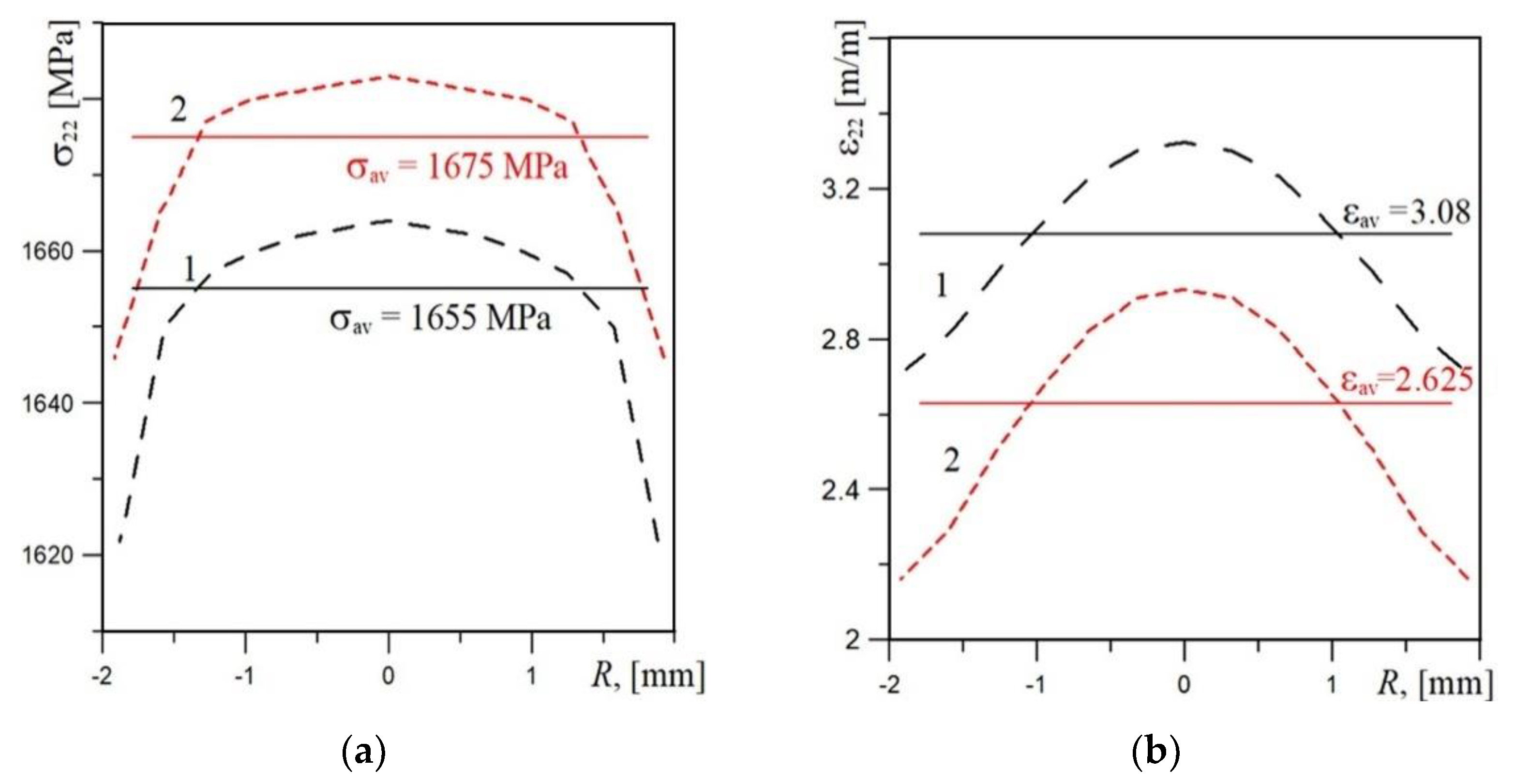

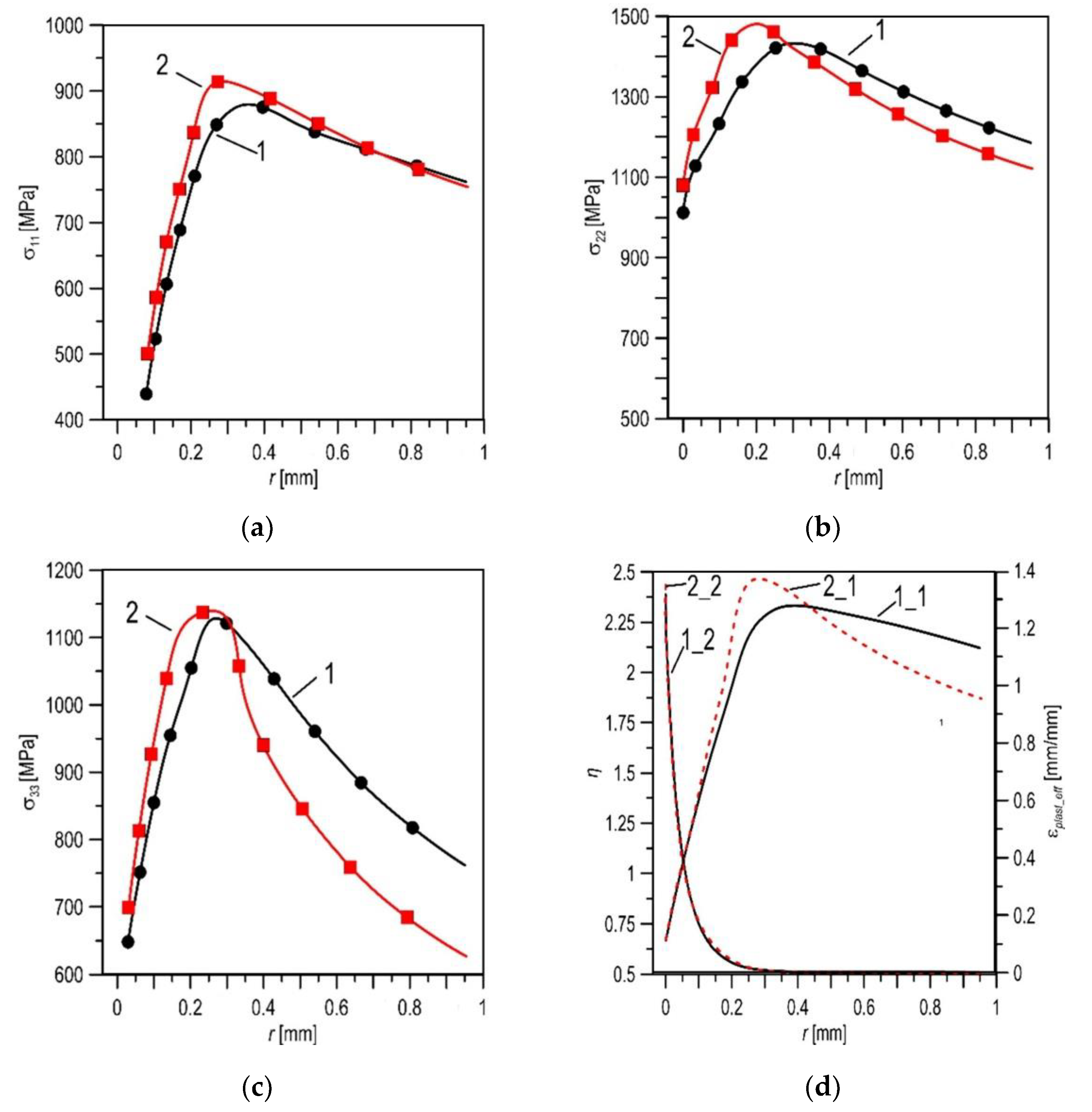

5. The Stress–Strain Analysis of Materials Condition Using the Numerical Simulation Method

6. Sensitivity of Different Indicators of Metal State to Operational Degradation of Steels

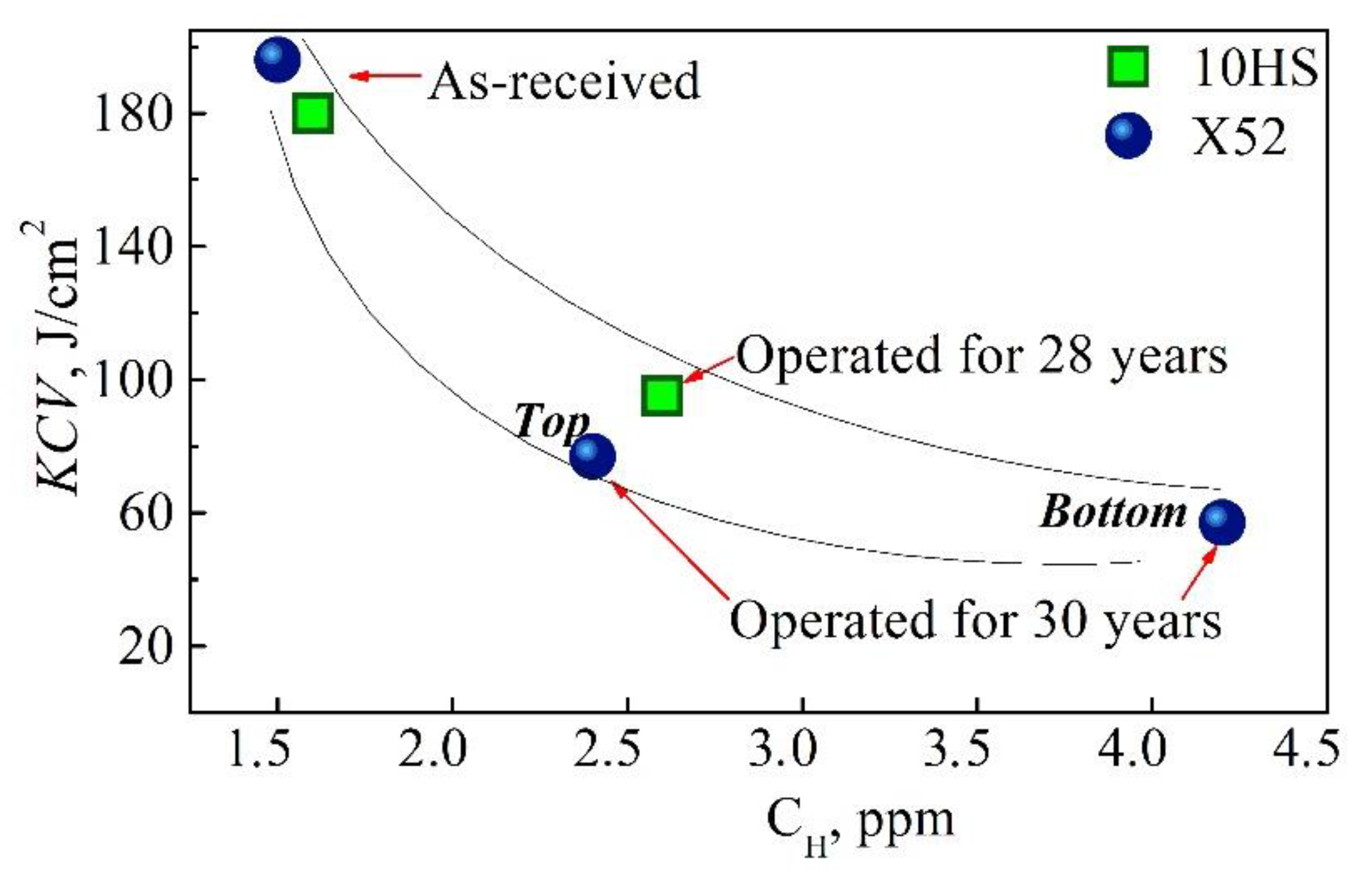

7. Role of Hydrogen in Operational Degradation of Steels

8. Conclusions

- The most significant factor in the loss of resistance to brittle fracture by long-term operated pipe steel is the development of dissipated damaging in the bulk of the material at nano and microscales. This damaging is also a reason for a decrease in fracture resistance under a corrosive-hydrogenating environment action. Hydrogenation of the pipe wall from its inner surface intensifies the operational degradation of steels.

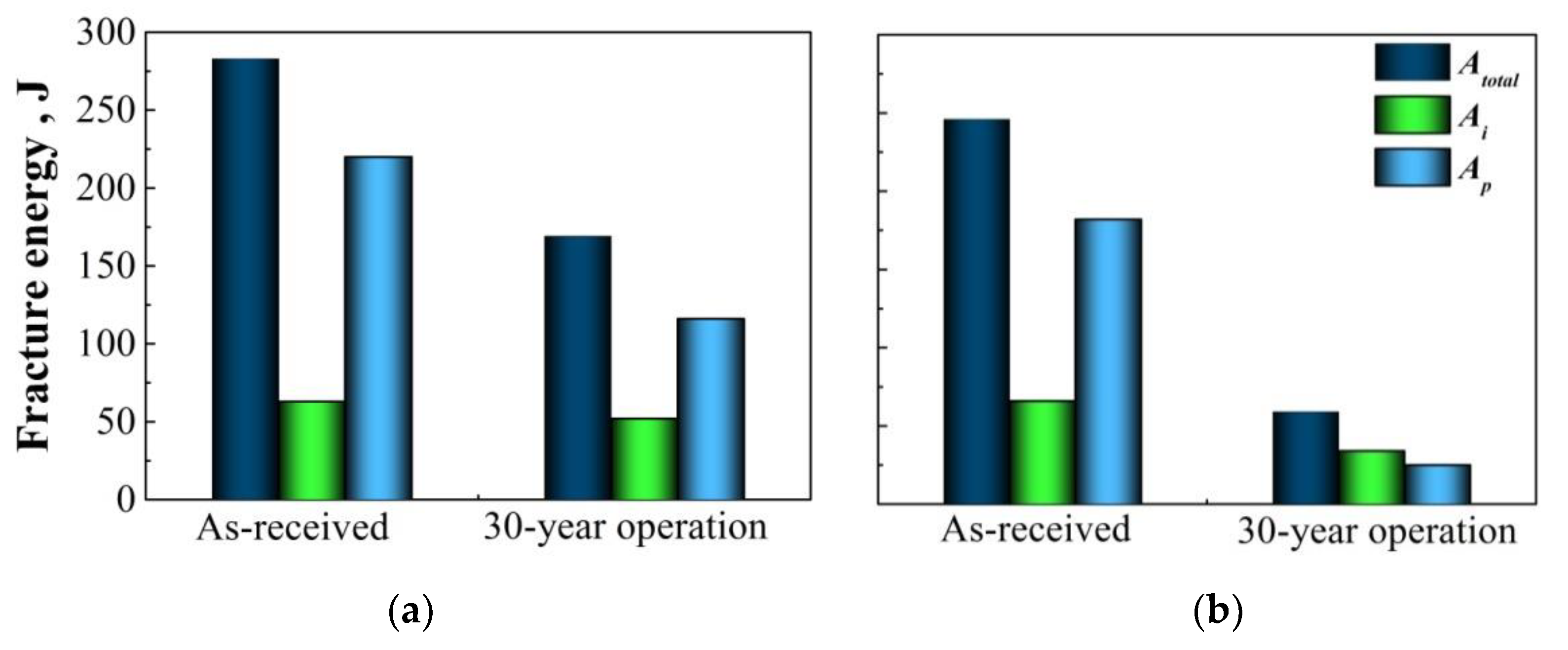

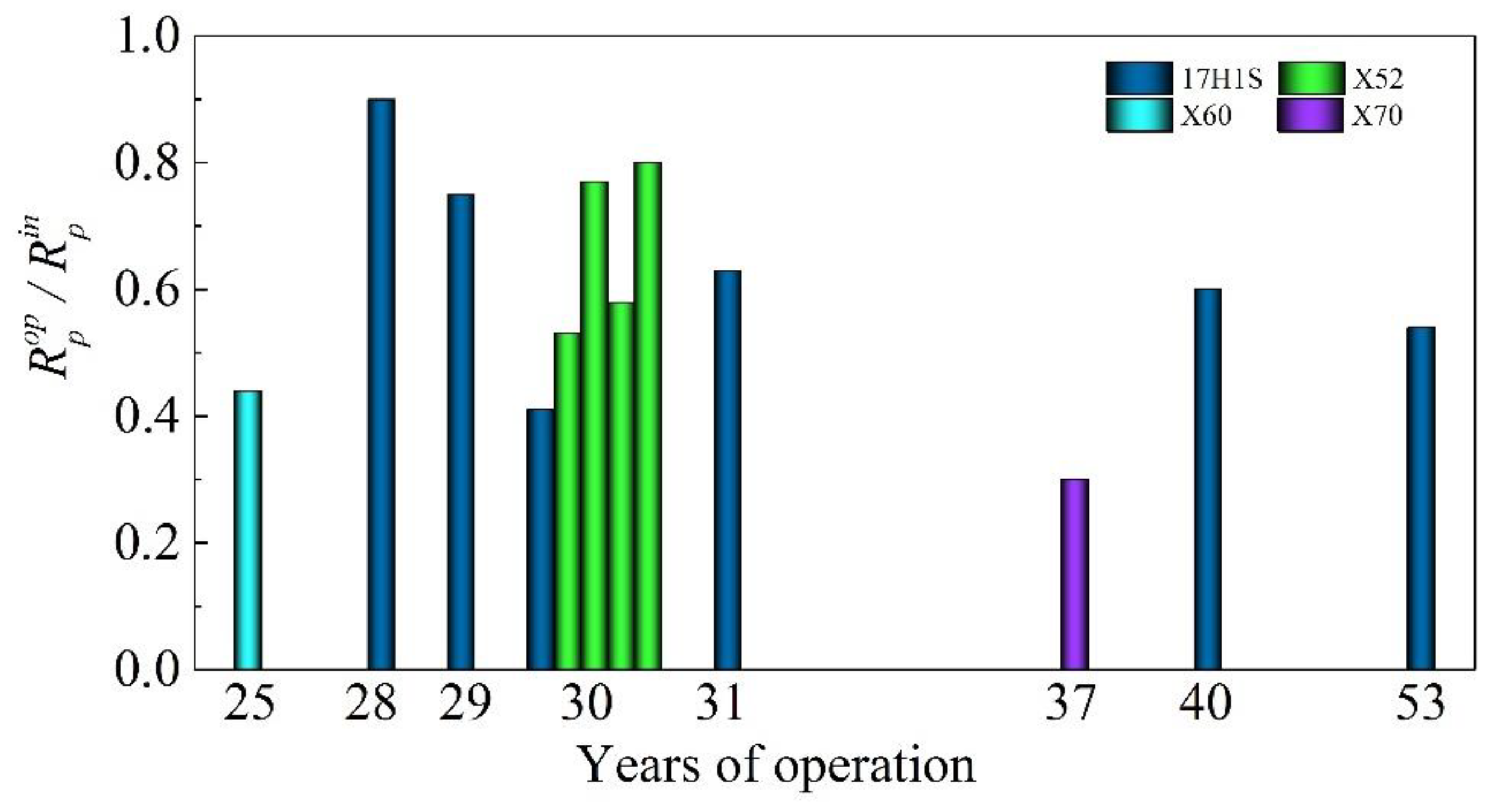

- Impact toughness and fracture toughness are the most sensitive indicators in the evaluation of the operational degradation of pipe steels. In addition, distinguishing the resistance to crack propagation as a component of the total fracture energy makes it possible to increase the sensitivity of these characteristics to steel degradation.

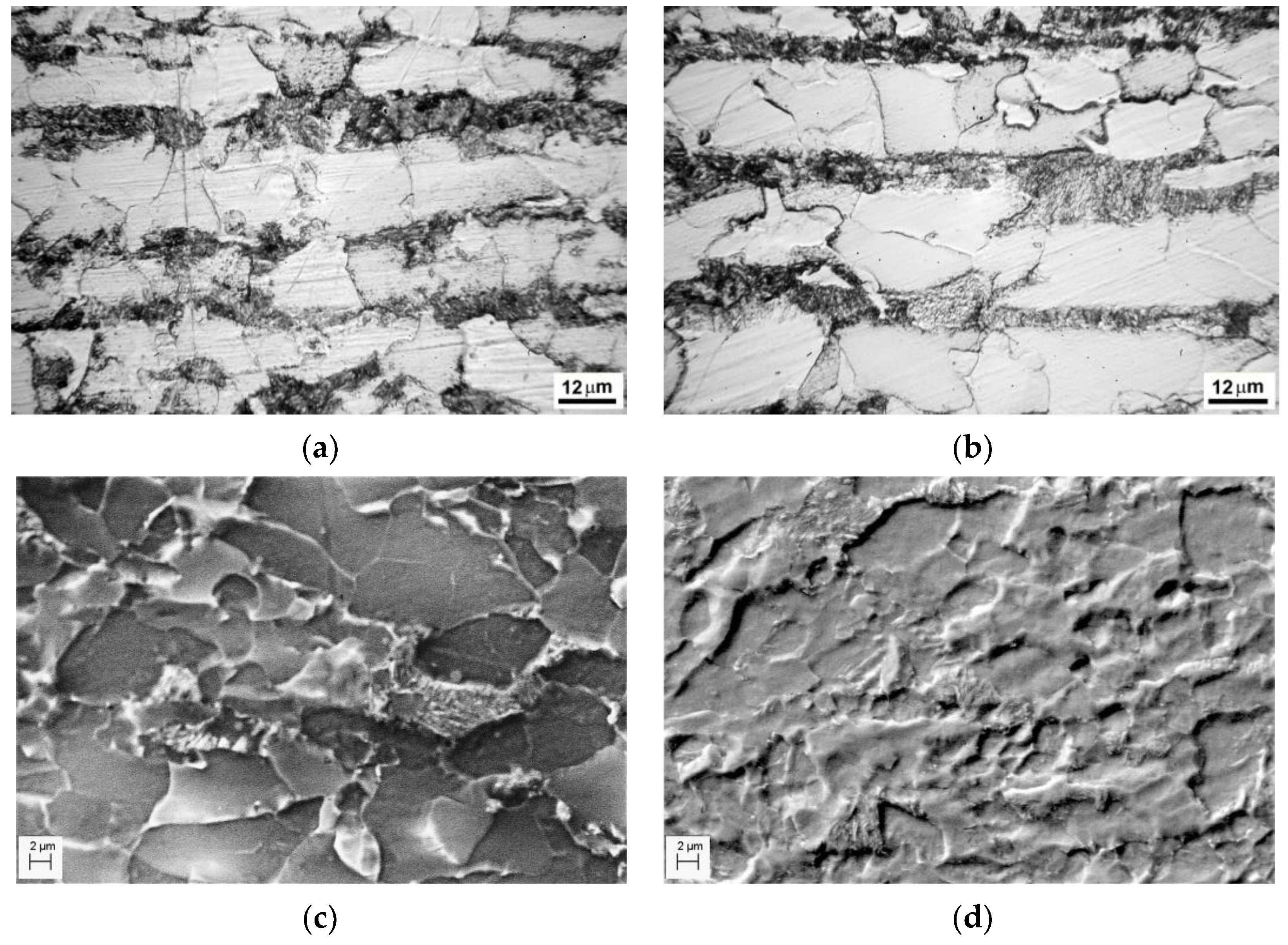

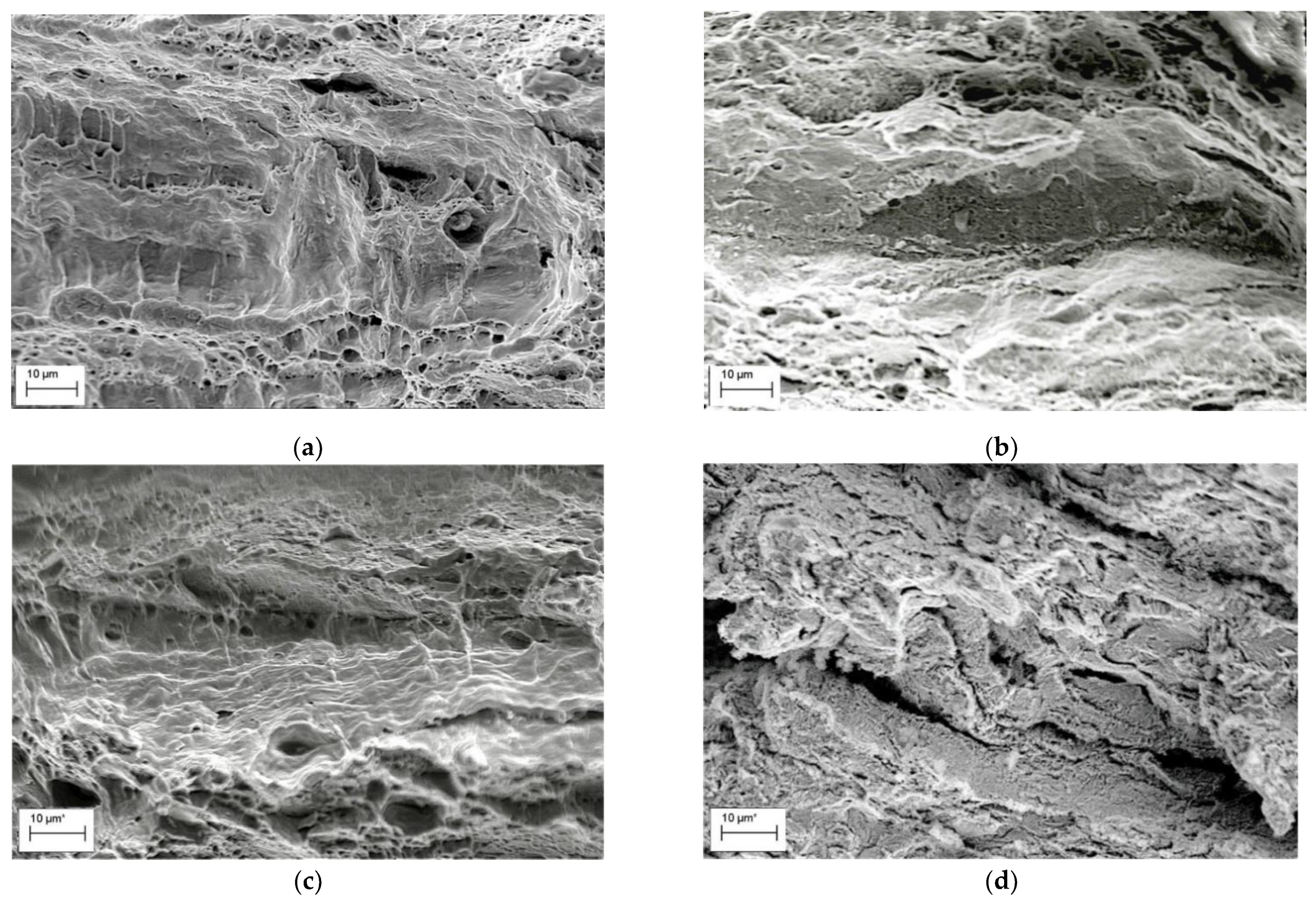

- Steel degradation at the microscale was manifested by the nonuniform etching of boundaries between adjacent bands of ferrite and pearlite, indicating microdamage evolution along the steel texture as a result of the different permeability of hydrogen, accumulated during operation, in pearlite and ferrite. Hydrogen also promoted the occurrence of delaminations and cleavage fragments, which were revealed by fractographic analysis, and evidenced steel embrittlement due to its operational degradation.

- Based on changes in the polarization resistance and surface fracture potential of steels caused by long-term service, their degradation degree can be evaluated.

- The method of numerical simulations based on the precise definition and calibration of the constitutive relationship of the material allows for an accurate assessment of the material condition and an estimate of the strength of the elements, taking into account the stress concentration at crack-like defects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bolzon, G.; Boukharouba, T.; Gabetta, G.; Elboujdaini, M.; Mellas, M. (Eds.) Integrity of pipelines transporting hydrocarbons. In Proceedings of the NATO Advanced Research Workshop on Corrosion Protection of Pipelines Transporting Hydrocarbons, Biskra, Algeria, 26–28 April 2010; Earth and Environmental Science NATO Science for Peace and Security Series C: Environmental Security. Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–322. [Google Scholar]

- Witek, M. Structural integrity of steel pipeline with clusters of corrosion defects. Materials 2021, 14, 852. [Google Scholar] [CrossRef]

- Vodenicharov, S. Degradation of the physical and mechanical properties of pipeline material depending on exploitation term. In Safety, Reliability and Risks Associated with Water, Oil and Gas Pipelines; Pluvinage, G., Elwany, M.H., Eds.; Springer: Dordrecht, The Netherlands, 2008; pp. 299–315. [Google Scholar]

- Ohaeri, E.; Eduok, U.; Szpunar, J. Hydrogen related degradation in pipeline steel: A review. Int. J. Hydrogen Energy 2018, 43, 14584–14617. [Google Scholar] [CrossRef]

- Filippov, G.A.; Livanova, O.V.; Chevskaya, O.N.; Shabalov, I.P. Pipe steel degradation during operation and brittle failure resistance. Metallurgist 2013, 57, 612–622. [Google Scholar] [CrossRef]

- Maruschak, P.O.; Danyliuk, I.M.; Bishchak, R.T.; Vuherer, T. Low temperature impact toughness of the main gas pipeline steel after long-term degradation. Cent. Eur. J. Eng. 2014, 4, 408–415. [Google Scholar] [CrossRef] [Green Version]

- Kharchenko, E.V.; Klysz, S.; Palyukh, V.M.; Kunta, O.E.; Lenkovs’kyi, T.M. Influence of the long-term operation of gas pipelines on the cyclic crack-growth resistance of 17G1S steel. Mater. Sci. 2017, 52, 827–833. [Google Scholar] [CrossRef]

- Hutsaylyuk, V.; Maruschak, P.; Konovalenko, I.; Panin, S.; Bishchak, R.; Chausov, M. Mechanical properties of gas main steels after long-term operation and peculiarities of their fracture surface morphology. Materials 2019, 12, 491. [Google Scholar] [CrossRef] [Green Version]

- Nykyforchyn, H.; Zvirko, O.; Tsyrulnyk, O.; Kret, N. Analysis and mechanical properties characterization of operated gas main elbow with hydrogen assisted large-scale delamination. Eng. Fail. Anal. 2017, 82, 364–377. [Google Scholar] [CrossRef]

- Quej-Ake, L.M.; Rivera-Olvera, J.N.; Domínguez-Aguilar, Y.d.R.; Avelino-Jiménez, I.A.; Garibay-Febles, V.; Zapata-Peñasco, I. Analysis of the physicochemical, mechanical, and electrochemical parameters and their impact on the internal and external SCC of carbon steel pipelines. Materials 2020, 13, 5771. [Google Scholar] [CrossRef]

- Krasovskii, A.Y.; Lokhman, I.V.; Orynyak, I.V. Stress-corrosion failures of main pipelines. Strength Mater. 2012, 44, 129–143. [Google Scholar] [CrossRef]

- Okipnyi, I.; Poberezhny, L.; Zapukhliak, V.; Hrytsanchuk, A.; Poberezhna, L.; Stanetsky, A.; Kravchenko, V.; Rybitskyi, I. Impact of long-term operation on the reliability and durability of transit gas pipelines. Stroj. Casopis. 2020, 70, 115–126. [Google Scholar]

- Koçak, M.; Webster, S.; Janosch, J.J.; Ainsworth, R.A.; Koerc, R. FITNET: Fitness-for-Service. Fracture-Fatique-Creep-Corrosion; GKSS Research Centre Geesthacht GmbH: Stuttgart, Germany, 2008. [Google Scholar]

- Dzioba, I.; Tsyrulnik, O.T. Analysis of the integrity of welded pipes of gas mains by the FITNET procedures. Mater. Sci. 2009, 45, 817–825. [Google Scholar] [CrossRef]

- Dzioba, I.; Lipiec, S. Fracture mechanisms of S355 steel—Experimental research, FEM simulation and SEM observation. Materials 2019, 12, 3959. [Google Scholar] [CrossRef] [Green Version]

- Tsyrul’nyk, O.T.; Slobodyan, Z.V.; Zvirko, O.I.; Hredil, M.I.; Nykyforchyn, H.M.; Gabetta, D. Influence of operation of Kh52 steel on corrosion processes in a model solution of gas condensate. Mater. Sci. 2008, 44, 619–629. [Google Scholar] [CrossRef]

- Dzioba, I. Properties of 13KHMF steel after operation and degradation under the laboratory conditions. Mater. Sci. 2010, 46, 357–364. [Google Scholar] [CrossRef]

- Nechaev, Y.S. Metallic materials for the hydrogen energy industry and main gas pipelines: Complex physical problems of aging, embrittlement, and failure. Uspekhi Fiz. Nauk. 2008, 51, 681–697. [Google Scholar] [CrossRef]

- Alvaro, A.; Wan, D.; Olden, V.; Barnoush, A. Hydrogen enhanced fatigue crack growth rates in a ferritic Fe-3 wt% Si alloy and a X70 pipeline steel. Eng. Fract. Mech. 2019, 219, 106641. [Google Scholar] [CrossRef]

- Maruschak, P.; Prentkovskis, O.; Bishchak, R. Defectiveness of external and internal surfaces of the main oil and gas pipelines after long-term operation. J. Civ. Eng. Manag. 2016, 22, 279–286. [Google Scholar] [CrossRef]

- Jang, J.I.; Choi, Y.; Lee, Y.H.; Kwon, D. Instrumented microindentation studies on long-term aged materials: Work-hardening exponent and yield ratio as new degradation indicators. Mater. Sci. Eng. A 2005, 395, 295–300. [Google Scholar] [CrossRef]

- Nykyforchyn, H.; Tsyrulnyk, O.; Zvirko, O.; Krechkovska, H. Non-destructive evaluation of brittle fracture resistance of operated gas pipeline steel using electrochemical fracture surface analysis. Eng. Fail. Anal. 2019, 104, 617–625. [Google Scholar] [CrossRef]

- Nykyforchyn, H. In-service degradation of pipeline steels. In Degradation Assessment and Failure Prevention of Pipeline Systems. Lecture Notes in Civil Engineering; Bolzon, G., Gabetta, G., Nykyforchyn, H., Eds.; Springer: Cham, Switzerland, 2021; Volume 102, pp. 15–29. [Google Scholar]

- Zvirko, O.; Tsyrulnyk, O. Non-destructive electrochemical evaluation of pipeline degradation. In Degradation Assessment and Failure Prevention of Pipeline Systems. Lecture Notes in Civil Engineering; Bolzon, G., Gabetta, G., Nykyforchyn, H., Eds.; Springer: Cham, Switzerland, 2021; Volume 102, pp. 31–44. [Google Scholar]

- Krechkovska, H.; Hredil, M.; Student, O. Structural and fractographic features of gas pipeline steel degradation. In Degradation Assessment and Failure Prevention of Pipeline Systems. Lecture Notes in Civil Engineering; Bolzon, G., Gabetta, G., Nykyforchyn, H., Eds.; Springer: Cham, Switzerland, 2021; Volume 102, pp. 45–59. [Google Scholar]

- Dzioba, I.; Zvirko, O.; Lipiec, S. Assessment of operational degradation of pipeline steel based on true stress–strain diagrams. In Degradation Assessment and Failure Prevention of Pipeline Systems. Lecture Notes in Civil Engineering; Bolzon, G., Gabetta, G., Nykyforchyn, H., Eds.; Springer: Cham, Switzerland, 2021; Volume 102, pp. 175–187. [Google Scholar]

- Astm, E. Standard Test Method for Measurement of Fracture Toughness ASTM. Annu. Book Stand. 1820, 3, 1. [Google Scholar]

- Zvirko, O.I.; Kret, N.V.; Tsyrulnyk, O.T.; Vengrynyuk, T.P. Influence of textures of pipeline steels after operation on their brittle fracture resistance. Mater. Sci. 2018, 54, 400–405. [Google Scholar] [CrossRef]

- Niu, Y.; Jia, S.; Liu, Q.; Tong, S.; Li, B.; Ren, Y.; Wang, B. Influence of effective grain size on low temperature toughness of high-strength pipeline steel. Materials 2019, 12, 3672. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Bao, Y.; Lee, Y.-W.; Bai, Y. Calibration of seven fracture models. Int. J. Mech. Sci. 2005, 47, 719–743. [Google Scholar] [CrossRef]

- Neimitz, A.; Gałkiewicz, J.; Lipiec, S.; Dzioba, I. Estimation of the onset of crack growth in ductile materials. Materials 2018, 11, 2026. [Google Scholar] [CrossRef] [Green Version]

- Neimitz, A.; Gałkiewicz, J.; Dzioba, I. Calibration of constitutive equations under conditions of large strains and stress triaxiality. Archives of Civil and Engineering. Arch. Civ. Mech. Eng. 2018, 18, 1123–1135. [Google Scholar] [CrossRef]

- Dzioba, I.; Gajewski, M.; Neimitz, A. Studies of fracture processes in Cr-Mo-V ferritic steel with various types of microstructures. Int. J. Press. Vessel. Pip. 2010, 87, 575–586. [Google Scholar] [CrossRef]

- Neimitz, A.; Gałkiewicz, J.; Dzioba, I. The ductile to cleavage transition in ferritic Cr-Mo-V steel: A detailed microscopic and numerical analysis. Eng. Fract. Mech. 2010, 77, 2504–2526. [Google Scholar] [CrossRef]

- Nykyforchyn, H.M.; Student, O.Z.; Markov, A.D. Abnormal behavior of high-temperature degradation of the weld metal of low-alloy steel welded joints. Mater. Sci. 2007, 43, 77–84. [Google Scholar] [CrossRef]

- Nykyforchyn, H.; Lunarska, E.; Tsyrulnyk, O.; Nikiforov, K.; Gabetta, G. Effect of the long-term service of the gas pipeline on the properties of the ferrite–pearlite steel. Mater. Corros. 2009, 9, 716–725. [Google Scholar] [CrossRef]

- Lunarska, E.; Polanskiy, A. Kinetic measurements of hydrogen distribution between different states in exploited steels. Adv. Mater. Sci. 2008, 8, 124–129. [Google Scholar] [CrossRef] [Green Version]

- Cabrini, M.; Sinigaglia, E.; Spinelli, C.; Tarenzi, M.; Testa, C.; Bolzoni, F.M. hydrogen embrittlement evaluation of micro alloyed steels by means of J-Integral curve. Materials 2019, 12, 1843. [Google Scholar] [CrossRef] [PubMed] [Green Version]

200 °C,

200 °C,  400 °C,

400 °C,  600 °C.

600 °C.

200 °C,

200 °C,  400 °C,

400 °C,  600 °C.

600 °C.

| Pipe Steel | D, mm | t, mm | Time of Operation, Years | σY, MPa | σUTS, Mpa | RA, % | Elongation, % | KCV, J/cm2 | J0.2, kN/m | |

|---|---|---|---|---|---|---|---|---|---|---|

| 17H1S (X52 strength grade) | 275 | 10 | 0 (as-received) | 301 | 470 | 65.9 | 21.2 | 255 | ||

| 1220 | 12 | 380 | 624 | 72.0 | 23.9 | 129 | ||||

| 1420 | 17 | 413 | 564 | 74.0 | 29.0 | 348 | ||||

| 1420 | 17 | 30 | 368 | 541 | 55.3 | 26.3 | 175 | |||

| 1220 | 12 | 36 | 453 | 606 | 64.0 | 21.0 | 110 | |||

| 529 | 8 | 38 | 357 | 520 | 73.1 | 25.4 | 154 | |||

| 529 | 7 | 40 | 302 | 515 | 69.2 | 26.3 | 125 | |||

| 529 | 7 | 51 | 449 | 610 | 67.0 | 24.5 | 56/33 * | |||

| X52 | 408 | 12 | 0 | 355 | 475 | 72.9 | 22.7 | 350 | 412 | |

| 275 | 12 | 30 | Pipe 1 | 268 | 451 | 64.4 | 20.8 | 189 | 127 | |

| 275 | 10 | Pipe 2 | 362 | 536 | 54.6 | 29.7 | 173 | 79 | ||

| X60 | 529 | 14 | 0 | 510 | 592 | 81.9 | 23.2 | 342 | ||

| 1420 | 17 | 25 | 502 | 633 | 71.1 | 18.5 | 225 | |||

| X70 | 1420 | 17 | 0 | 521 | 615 | 73.4 | 22.3 | 277 | ||

| 1420 | 17 | 37 | 547 | 641 | 74.5 | 23.0 | 350/310 * | |||

| Steel | State/Operation Time | KCV, J/cm2 | |||

|---|---|---|---|---|---|

| Axial | Tangential | Radial | |||

| 17H1S | As-received | 152 | 129 | – | |

| Operated | 29 years | – | 113 | 19 | |

| 36 years | – | 84 | 38 | ||

| X60 | As-received | 342 | 326 | 58 | |

| Operated | 25 years | 326 | 214 | 37 | |

| Steel | Operation Time, Years | Corrosion Potential Ecorr, V | Corrosion Current Density icorr, μA/cm2 | Tafel Constants, V | |

|---|---|---|---|---|---|

| bc | ba | ||||

| 17H1S | 0 (as-received) | –0.683 | 1.85 | –0.090 | 0.062 |

| 30 | –0.687 | 4.20 | –0.083 | 0.058 | |

| X60 | 0 | –0.664 | 1.81 | –0.090 | 0.063 |

| 25 | –0.696 | 3.86 | –0.090 | 0.056 | |

| X70 | 0 | –0.518 | 0.67 | –0.089 | 0.061 |

| 37 | –0.642 | 2.24 | –0.088 | 0.060 | |

| Du [mm] | 0.8 mm | 1.0 mm | 1.2 mm | 1.4 mm | 1.6 mm |

|---|---|---|---|---|---|

| max σ22 [MPa] | 1445.61 a | 1436.32 | 1428.82 | 1423.21 | 1407.77 |

| 1444.52 b | 1469.03 | 1480.68 | 1482.71 | 1493.61 | |

| r (max σ22) [mm] | 0.240 | 0.287 | 0.337 | 0.317 | 0.424 |

| 0.109 | 0.158 | 0.186 | 0.194 | 0.236 | |

| max η | 2.408 | 2.341 | 2.311 | 2.303 | 2.303 |

| 2.455 | 2.441 | 2.465 | 2.459 | 2.461 | |

| r (max η) [mm] | 0.308 | 0.287 | 0.337 | 0.671 | 0.623 |

| 0.244 | 0.293 | 0.273 | 0.326 | 0.455 |

| Steel State | X52 (As-Received) | Operated Pipe 1 | Operated Pipe 2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Top | Bottom | Top | Bottom | ||||||

| out | in | out | in | out | in | out | in | ||

| CH, ppm | 1.5 | 1.2 | 0.7 | 1.5 | 1.4 | 1.7 | 2.8 | 3.1 | 5.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nykyforchyn, H.; Zvirko, O.; Dzioba, I.; Krechkovska, H.; Hredil, M.; Tsyrulnyk, O.; Student, O.; Lipiec, S.; Pala, R. Assessment of Operational Degradation of Pipeline Steels. Materials 2021, 14, 3247. https://doi.org/10.3390/ma14123247

Nykyforchyn H, Zvirko O, Dzioba I, Krechkovska H, Hredil M, Tsyrulnyk O, Student O, Lipiec S, Pala R. Assessment of Operational Degradation of Pipeline Steels. Materials. 2021; 14(12):3247. https://doi.org/10.3390/ma14123247

Chicago/Turabian StyleNykyforchyn, Hryhoriy, Olha Zvirko, Ihor Dzioba, Halyna Krechkovska, Myroslava Hredil, Oleksandr Tsyrulnyk, Oleksandra Student, Sebastian Lipiec, and Robert Pala. 2021. "Assessment of Operational Degradation of Pipeline Steels" Materials 14, no. 12: 3247. https://doi.org/10.3390/ma14123247

APA StyleNykyforchyn, H., Zvirko, O., Dzioba, I., Krechkovska, H., Hredil, M., Tsyrulnyk, O., Student, O., Lipiec, S., & Pala, R. (2021). Assessment of Operational Degradation of Pipeline Steels. Materials, 14(12), 3247. https://doi.org/10.3390/ma14123247