The Influence of Tool Shape and Process Parameters on the Mechanical Properties of AW-3004 Aluminium Alloy Friction Stir Welded Joints

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Used

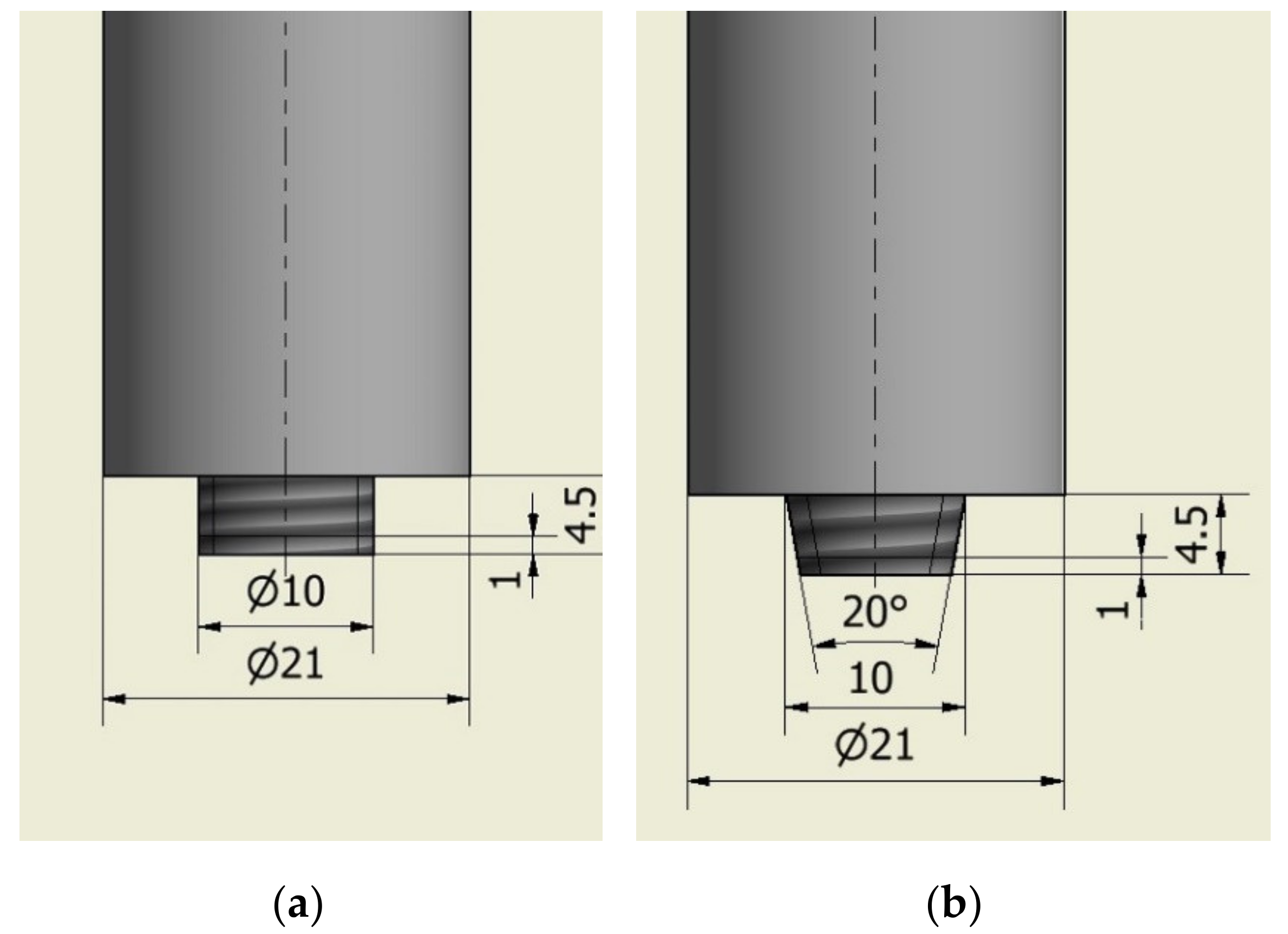

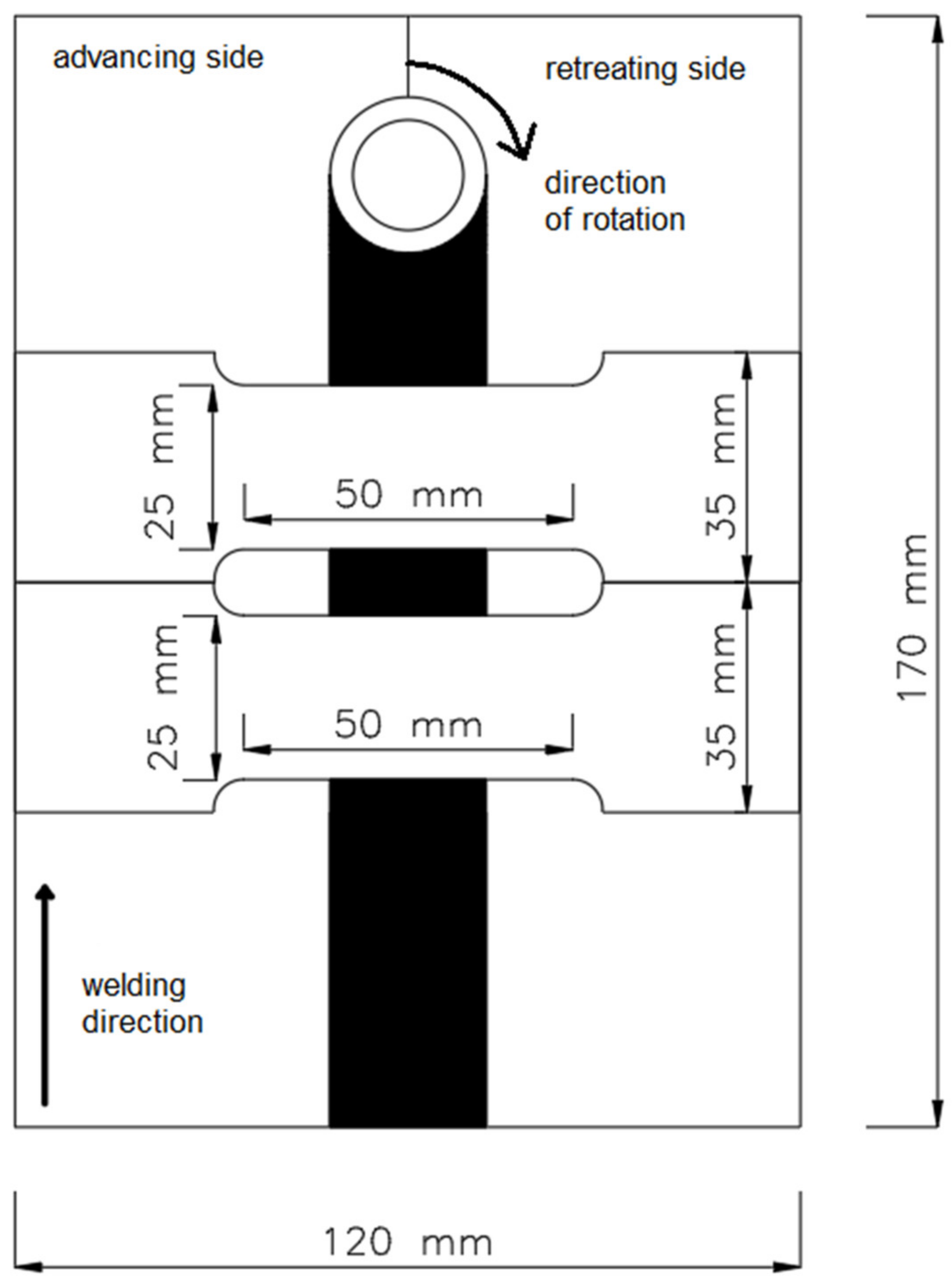

2.2. Welding Process

2.3. Examination Procedure

3. Results and Discussion

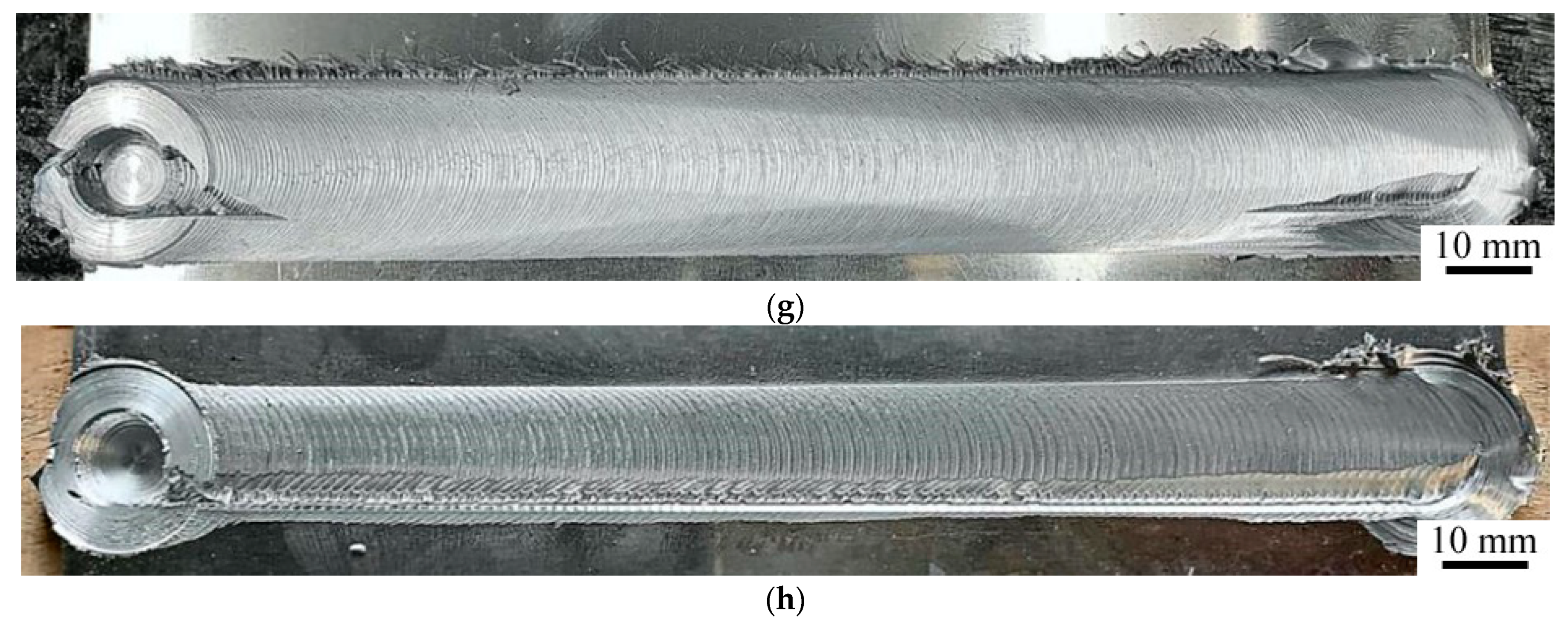

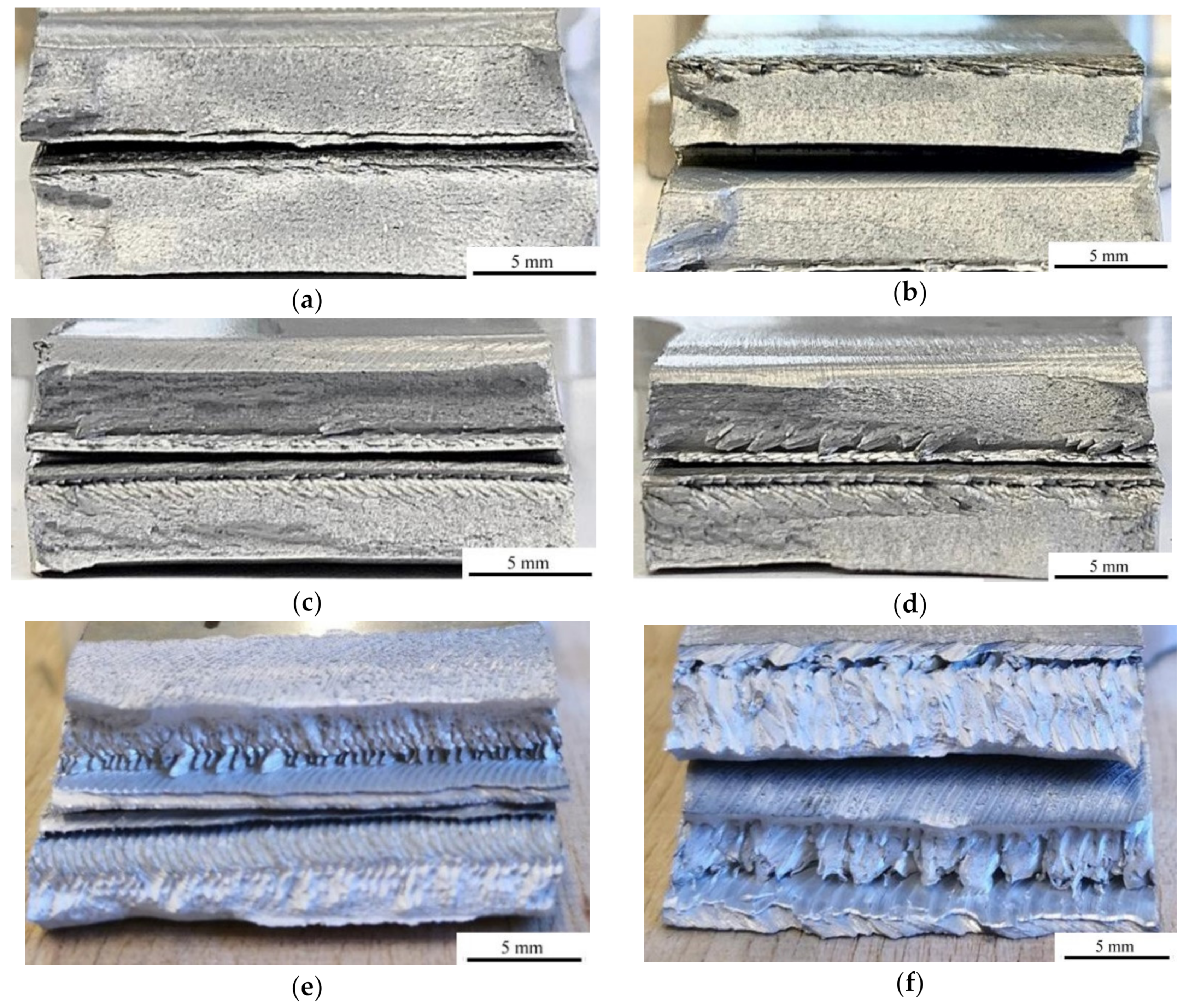

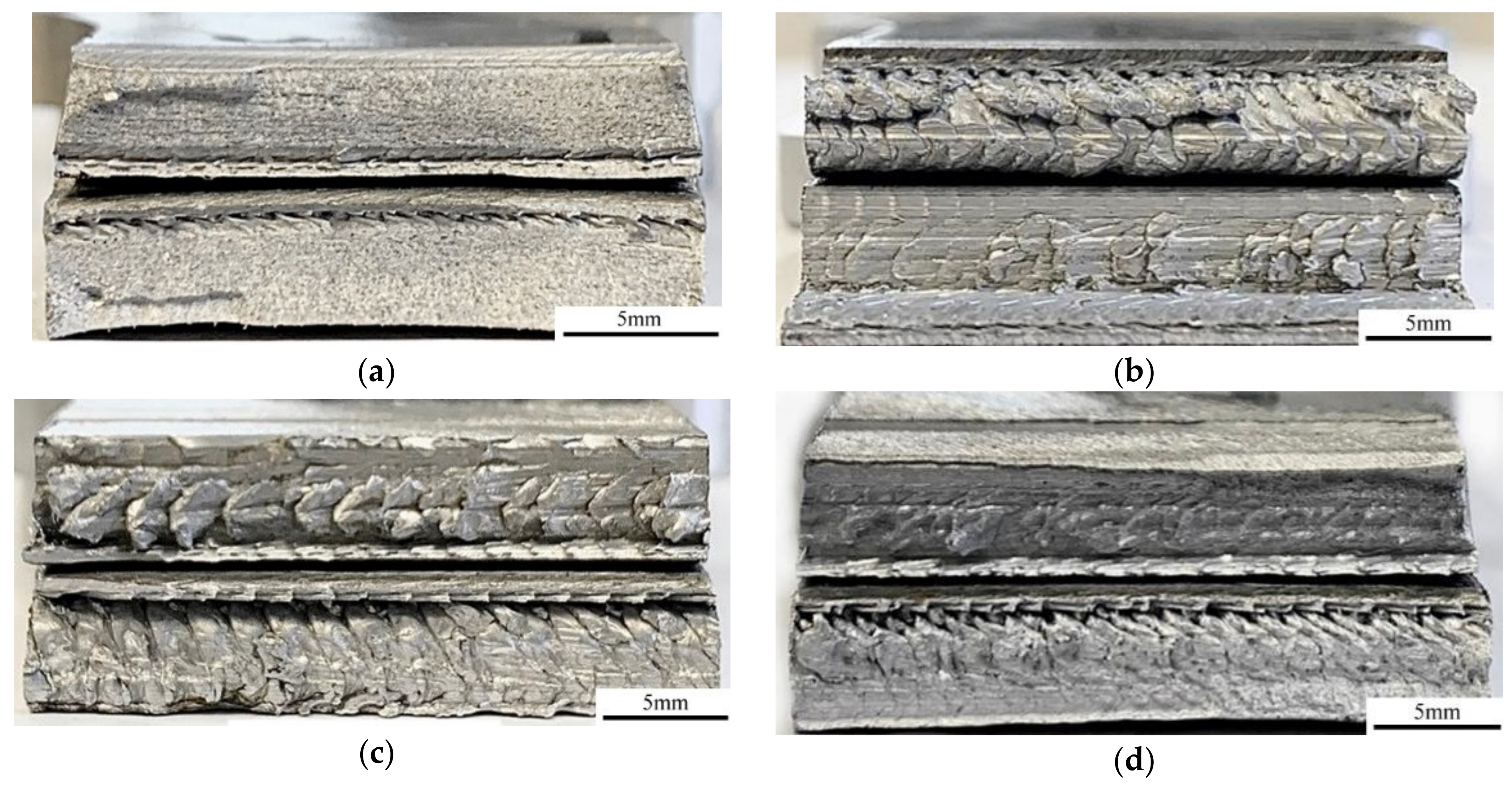

3.1. Visual Tests (VT)

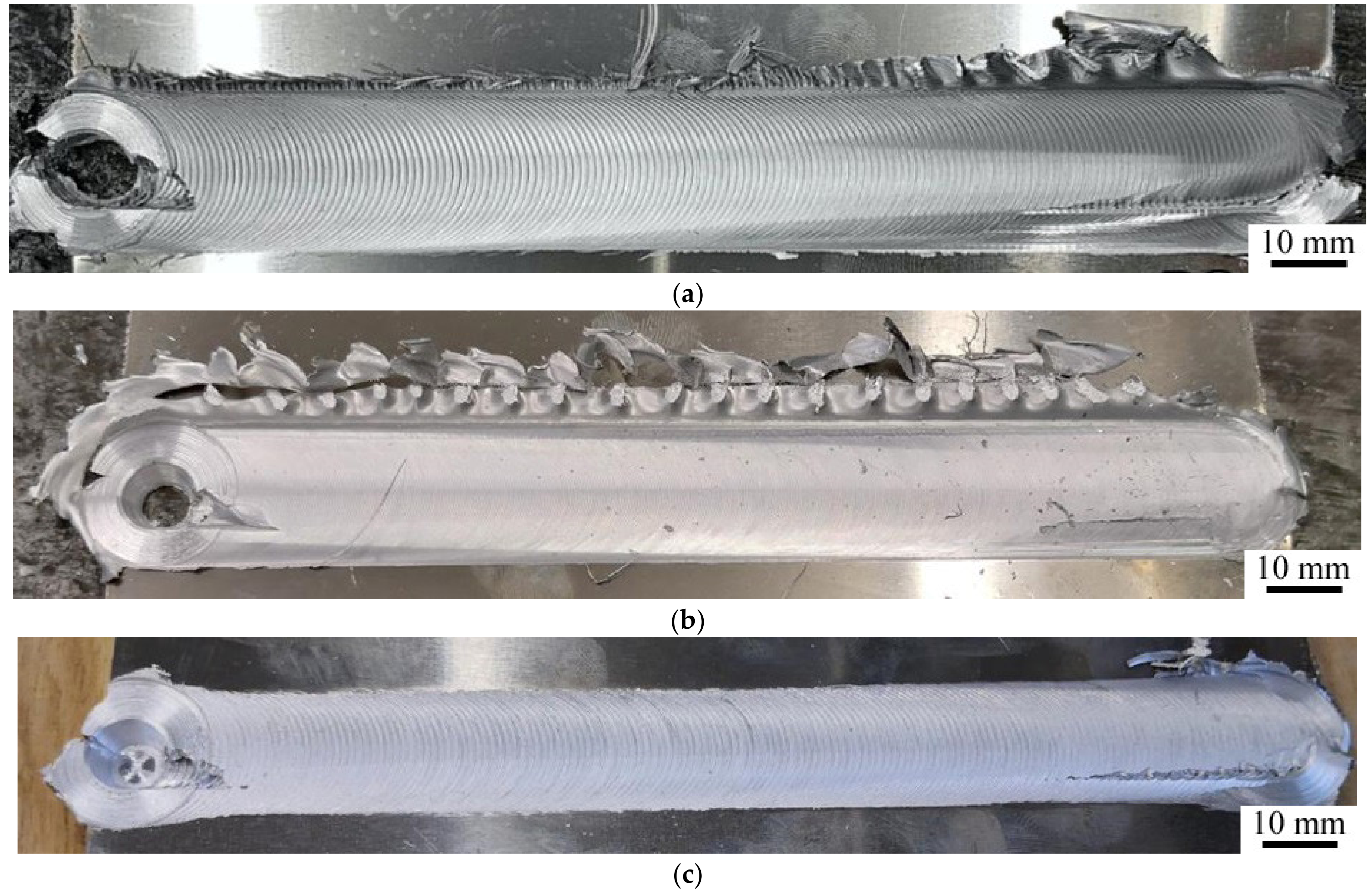

3.1.1. Comparison of the Tool Pin’s Shape

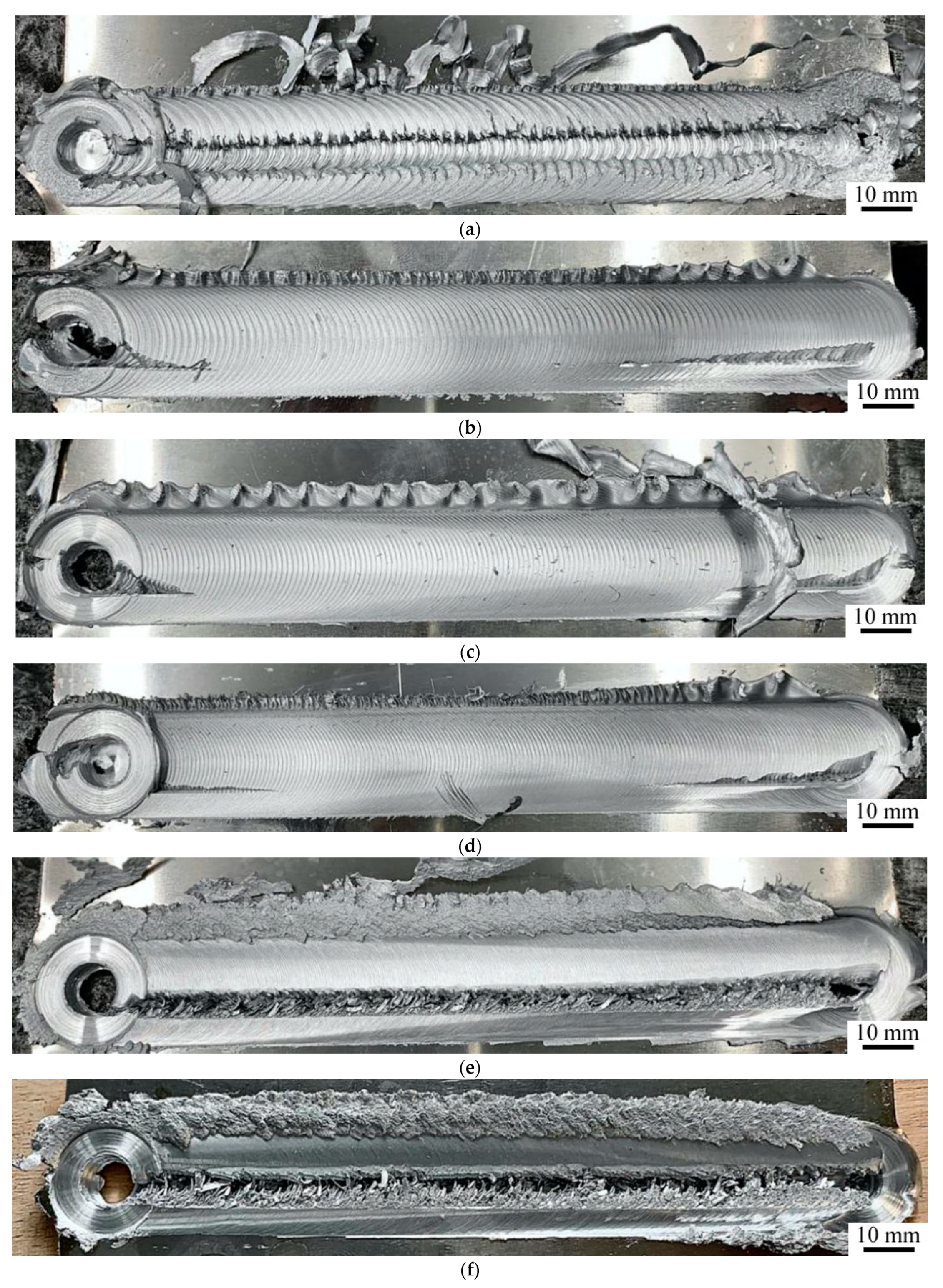

3.1.2. Comparison of the Welding Parameters

3.2. Tensile Strength Tests

3.2.1. Comparison of the Tool Pin’s Shape

3.2.2. Comparison of the Welding Parameters

4. Summary

- Most of the joints were produced with material outflow on the retreating side. The lowest amount was observed in the joints made with a tapered threaded tool pin.

- Tensile strength and elongation figures were higher for joints made with a cylindrical threaded tool pin than those made with a tapered threaded pin. The latter showed voids and lack of penetration.

- The tapered pin and insufficient heat generation were unable to produce a sound joint.

- On the basis of the tensile strength tests, the best result was achieved at the same rotational speed and welding speed of 300 mm/min. However, the results for different joints were similar and there are a variety of welding speeds that make it possible to obtain good mechanical properties at a rotational speed of 475 rpm, ranging from about 150 to 475 mm/min.

- At the same welding speed, the best joint was produced at a rotational speed of 290 rpm. Nevertheless, its tensile strength was lower than that of the joint made with 475 rpm and 300 mm/min.

- Rotational speed may be the key parameter in improving welding conditions and the mechanical properties of aluminium alloy joints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chuchała, D.; Dobrzyński, M.; Pimenov, D.Y.; Orłowski, K.A.; Królczyk, G.; Giasin, K. Surface roughness evaluation in thin EN AW-6086-T6 alloy plates after face milling process with different strategies. Materials 2021, 14, 3036. [Google Scholar] [CrossRef]

- Zhou, G.X.; Lang, Y.J.; Du, X.Z.; Mao, H.; Li, J.B.; Wang, S.; Qiao, L.; Cai, H. Dynamic mechanical response and weldability of high strength 7A62 aluminum alloy. J. Phys. Conf. Ser. 2020, 15073, 32028. [Google Scholar] [CrossRef]

- Shanavas, S.; Dhas, J.E.R.; Murugan, N. Weldability of marine grade AA 5052 aluminum alloy by underwater friction stir welding. Int. J. Adv. Manuf. Technol. 2018, 95, 4535–4546. [Google Scholar] [CrossRef]

- Shah, U.; Liu, X. Effect of ultrasonic energy on the spot weldability of aluminum alloy AA6061. Mater. Des. 2020, 192, 108690. [Google Scholar] [CrossRef]

- Bodukuri, A.K.; Eswaraiah, K.; Rajendar, K.; Siddartha, A. Comparison of Aluminum Alloy 5083 properties on TIGW and FSW processes. Mater. Today Proc. 2017, 4, 10197–10201. [Google Scholar] [CrossRef]

- Tamasgavabari, R.; Reza Ebrahimi, A.; Mehdi Abbasi, S.; Reza Yazdipour, A. The effect of harmonic vibration with a frequency below the resonant range on the mechanical properties of AA-5083-H321 aluminum alloy GMAW welded parts. Mater. Sci. Eng. A 2018, 736, 248–257. [Google Scholar] [CrossRef]

- Li, S.; Mi, G.; Wang, C. A study on laser beam oscillating welding characteristics for the 5083 aluminum alloy: Morphology, microstructure and mechanical properties. J. Manuf. Process. 2020, 53, 12–20. [Google Scholar] [CrossRef]

- Varshney, D.; Kumar, K. Application and use of different aluminium alloys with respect to workability, strength and welding parameter optimization. Ain Shams Eng. J. 2021, 12, 1143–1152. [Google Scholar] [CrossRef]

- Zhu, Q.; Yu, H.; Zhang, J.; Li, M.; Hu, X. Experimental study on TIG welding properties of 6061 and 7003 aluminum alloys. IOP Conf. Ser. Earth Environ. Sci. 2021, 621, 12060. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Çam, G. Prospects of laser beam welding and friction stir welding processes for aluminum airframe structural applications. J. Manuf. Process. 2018, 36, 571–600. [Google Scholar] [CrossRef]

- Cabibbo, M.; Forcellese, A.; Santecchia, E.; Paoletti, C.; Spigarelli, S.; Simoncini, M. New approaches to friction stir welding of aluminum light-alloys. Metals 2020, 10, 233. [Google Scholar] [CrossRef] [Green Version]

- Prasad, L.; Mohan, L.; Raturi, H.P.; Kumar, V. A comparative study on mechanical and dry sliding wear behaviour of Al 7075-T6 welded joints fabricated by FSW, TIG and MIG. In Innovative Design, Analysis and Development Practices in Aerospace and Automotive Engineering (I-DAD 2018). Lecture Notes in Mechanical Engineering; Chandrasekhar, U., Yang, L.J., Gowthaman, S., Eds.; Springer: Singapore, 2019. [Google Scholar]

- Rayes, M.M.; Soliman, M.S.; Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Abdel-mawla, M.M. Effect of feed rate in FSW on the mechanical and microstructural properties of AA5754 joints. Adv. Mater. Sci. Eng. 2019, 2019, 4156176. [Google Scholar] [CrossRef] [Green Version]

- Mohamed Nishath, P.; Sekar, K. Boulevard for effective consumption of power and energy in friction stir welding. Mater. Today Proc. 2020, 22, 1489–1498. [Google Scholar] [CrossRef]

- Chaudhary, B.; Patel, V.; Ramkumar, P.L.; Vora, J. Temperature distribution during friction stir welding of AA2014 aluminum alloy: Experimental and statistical analysis. Trans. Indian Inst. Met. 2019, 72, 969–981. [Google Scholar] [CrossRef]

- Sevvel, P.; Babu, S.D.D.; Kumar, R.S. Peak temperature correlation and temperature distribution during joining of AZ80A Mg alloy by FSW—A numerical and experimental investigation. Stroj. Vestn. J. Mech. E 2020, 66, 395–407. [Google Scholar] [CrossRef]

- Zlatanovic, D.L.; Balos, S.; Bergmann, J.P.; Rasche, S.; Pecanac, M.; Goel, S. Influence of tool geometry and process parameters on properties of friction stir spot welded multiple AA 5754 aluminium sheets. Materials 2021, 14, 1157. [Google Scholar] [CrossRef]

- MohammadiSefat, M.; Ghazanfari, H.; Blais, C. Friction Stir Welding of 5052-H18 aluminum alloy: Modeling and process parameter optimization. J. Mater. Eng. Perform. 2021, 30, 1838–1850. [Google Scholar] [CrossRef]

- Verma, S.; Misra, J.P. Effect of process parameters on temperature and force distribution during friction stir welding of armor-marine grade aluminum alloy. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2020, 235, 144–154. [Google Scholar] [CrossRef]

- Shah, P.H.; Badheka, V.J. Friction stir welding of aluminium alloys: An overview of experimental findings—Process, variables, development and applications. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 233, 1191–1226. [Google Scholar] [CrossRef]

- Tamadon, A.; Baghestani, A.; Bajgholi, M.E. Influence of WC-based pin tool profile on microstructure and mechanical properties of AA1100 FSW welds. Technologies 2020, 8, 34. [Google Scholar] [CrossRef]

- Kaushik, P.; Kumar Dwivedi, D. Effect of tool geometry in dissimilar Al-steel Friction Stir Welding. J. Manuf. Process. 2020, in press. [Google Scholar] [CrossRef]

- Su, H.; Xue, L.; Wu, C. Optimizing the tool pin with three flats in friction stir welding of aluminum alloy. Int. J. Adv. Manuf. Technol. 2020, 108, 721–733. [Google Scholar] [CrossRef]

- Mazurkiewicz, K.; Bober, M. The influence of a tool shape in the FSW method of Al alloy on weld quality. Weld. Technol. Rev. 2018, 90, 920. [Google Scholar] [CrossRef]

- Eyvazian, A.; Hamouda, A.M.; Aghajani Derazkola, H.; Elyasi, M. Study on the effects of tool tile angle, offset and plunge depth on friction stir welding of poly(methyl methacrylate) T-joint. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2019, 234, 773–787. [Google Scholar] [CrossRef]

- Sharma, N.; Siddiquee, A.N.; Khan, Z.A.; Mohammed, M.T. Material stirring during FSW of Al–Cu: Effect of pin profile. Mater. Manuf. Process. 2017, 33, 786–794. [Google Scholar] [CrossRef]

- Dimopoulos, A.; Vairis, A.; Vidakis, N.; Petousis, M. On the Friction Stir Welding of Al 7075 thin sheets. Metals 2021, 11, 57. [Google Scholar] [CrossRef]

- Mardalizadeh, M.; Khandaei, M.; Safarkhanian, M.A. Influence of travel speed on the microstructural evaluation and mechanical characteristics of bobbin tool friction stir-welded thick AA5456-H112 plates. J. Adhes. Sci. Technol. 2020, 35, 1–20. [Google Scholar] [CrossRef]

- Fuse, K.; Badheka, V. Hybrid self-reacting friction stir welding of AA 6061-T6 aluminium alloy with cooling assisted approach. Metals 2021, 11, 16. [Google Scholar] [CrossRef]

- Bocchi, S.; D’Urso, G.; Giardini, C. The effect of heat generated on mechanical properties of friction stir welded aluminum alloys. Int. J. Adv. Manuf. Technol. 2021, 112, 1513–1528. [Google Scholar] [CrossRef]

- Deng, H.; Chen, Y.; Jia, Y.; Pang, Y.; Zhang, T.; Wang, S.; Yin, L. Microstructure and mechanical properties of dissimilar NiTi/Ti6Al4V joints via back-heating assisted friction stir welding. J. Manuf. Process. 2021, 64, 379–391. [Google Scholar] [CrossRef]

- Gao, S.; Wu, C.S.; Padhy, G.K. Effect of leading ultrasonic vibrations on the welding forces of friction stir lap welding. Int. J. Adv. Manuf. Technol. 2019, 104, 3181–3189. [Google Scholar] [CrossRef]

- Ma, Z.; Sun, X.; Ji, S.; Wang, Y.; Yue, Y. Influences of ultrasonic on friction stir welding of Al/Ti dissimilar alloys under different welding conditions. Int. J. Adv. Manuf. Technol. 2021, 112, 2573–2582. [Google Scholar] [CrossRef]

- Singh, V.P.; Patel, S.K.; Kuriachen, B.; Suman, S. Investigation of general welding defects found during friction-stir welding (FSW) of aluminium and its alloys. In Advances in Additive Manufacturing and Joining; Lecture Notes on Multidisciplinary Industrial Engineering; Shunmugam, M., Kanthababu, M., Eds.; Springer: Singapore, 2020. [Google Scholar]

- Padhy, G.K.; Wu, C.S.; Gao, S. Friction stir based welding and processing technologies—Processes, parameters, microstructure and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Cao, J.; Shen, J.; dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Mahdy, A.M.A.; Alsaleh, N.A.; Ahmed, E. Heat input and mechanical properties investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA7020. Metals 2021, 11, 68. [Google Scholar] [CrossRef]

- Andrade, D.G.; Leitão, C.; Dialami, N.; Chiumenti, M.; Rodrigues, D.M. Analysis of contact conditions and its influence on strain rate and temperature in friction stir welding. Int. J. Mech. Sci. 2021, 191, 106095. [Google Scholar] [CrossRef]

- Prasad Mahto, R.; Kumar, R.; Kanta Pal, S. Characterizations of weld defects, intermetallic compounds and mechanical properties of friction stir lap welded dissimilar alloys. Mater. Charact. 2020, 160, 110115. [Google Scholar] [CrossRef]

- Abidi, M.H.; Ali, N.; Ibrahimi, H.; Anjum, S.; Bajaj, D.; Siddiquee, A.N.; Alkahtani, M.; Rehman, A.U. T-FSW of dissimilar aerospace grade aluminium alloys: Influence of second pass on weld defects. Metals 2020, 10, 525. [Google Scholar] [CrossRef] [Green Version]

- Mroczka, K.; Wójcicka, A.; Pietras, A. Characteristics of dissimilar FSW welds of aluminum alloys 2017A and 7075 on the basis of multiple layer research. J. Mater. Eng. Perform. 2013, 22, 2698–2705. [Google Scholar] [CrossRef] [Green Version]

- Nagesh, G.; Nageswara Rao, K.; Kanishk, K.; Anurag, K.M.; Abhinav, N. Investigation of mechanical properties on non-ferrous alloys of copper and brass joints made by friction stir welding. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1057, 12062. [Google Scholar] [CrossRef]

- Turkan, M.; Karakas, Ö. Two different finite element models investigation of the plunge stage in joining AZ31B magnesium alloy with friction stir welding. SN Appl. Sci. 2021, 3, 165. [Google Scholar] [CrossRef]

- Kar, A.; Malopheyev, S.; Mironov, S.; Kaibyshev, R.; Suwas, S.; Kailas, S.V. A new method to elucidate fracture mechanism and microstructure evolution in titanium during dissimilar friction stir welding of aluminum and titanium. Mater. Charact. 2021, 171, 110791. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Eyvazian, A.; Simchi, A. Modeling and experimental validation of material flow during FSW of polycarbonate. Mater. Today Commun. 2020, 22, 100796. [Google Scholar] [CrossRef]

- Zafar, A.; Awang, M.; Khan, S.R. Friction Stir Welding of polymers: An Overview. Lect. Notes Mech. Eng. 2017, 19–36. [Google Scholar] [CrossRef]

- Kumar, N.; Kotadiya, D.; Badheka, V.J.; Gadakh, V.S. Effect of process parameters on tensile strength in FSW of aluminium and stainless steel. In Advances in Manufacturing Processes; Lecture Notes in Mechanical Engineering; Dave, H.K., Nedelcu, D., Eds.; Springer: Singapore, 2021. [Google Scholar]

- Iwaszko, J.; Kudła, K. Characterization of Cu/SiC surface composite produced by friction stir processing. B Pol. Acad. Sci. Tech. 2020, 68, 555–564. [Google Scholar] [CrossRef]

- Prasetya, L.W.; Prabowo, A.R.; Ubaidillah, I.I.; Binti Nordin, N.A. Design of crashworthy attenuator structures as a part of vehicle safety against impact: Application of waste aluminum can-based material. Theor. App. Mech. Lett. 2021, in press. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Chen, X.G. Improvement in the mechanical properties and creep resistance of Al-Mn-Mg 3004 alloy with Sc and Zr addition. Mater. Sci. Eng. A 2018, 729, 196–207. [Google Scholar] [CrossRef]

- EN 573-3:2019-12. Aluminum and Aluminum Alloys—Chemical Composition and Types of Wrought Products—Part 3: Chemical Composition and Types of Articles; European Committee for Standardization: Brussels, Belgium.

- EN 4852: 2016+A1:2018. Aluminium and Aluminum Alloys—Sheet, Strip and Plate—Part 2: Mechanical Properties; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- EN ISO 17637:2017. Non-Destructive Testing of Welds—Visual Testing of Fusion-Welded Joints; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- EN ISO 6892-1:2020. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; ISO: Geneva, Switzerland, 2020. [Google Scholar]

- Kosturek, R.; Śnieżek, L.; Torzewski, J.; Ślęzak, T.; Wachowski, M.; Szachogłuchowicz, I. Research on the properties and low cycle fatigue of Sc-modified AS2519-T62 FSW joint. Materials 2020, 13, 5226. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.P.; Robson, J.D.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar] [CrossRef]

- Kubit, A.; Drabczyk, M.; Trzepiecinski, T.; Bochnowski, W.; Kaščák, Ľ.; Slota, J. Fatigue life assessment of refill friction stir spot welded Alclad 7075-T6 aluminium alloy joints. Metals 2020, 10, 633. [Google Scholar] [CrossRef]

- Tomków, J.; Janeczek, A.; Rogalski, G.; Wolski, A. Underwater local cavity welding of S460N steel. Materials 2020, 13, 5535. [Google Scholar] [CrossRef] [PubMed]

- Kubit, A.; Trzepiecinski, T. A fully coupled thermo-mechanical numerical modelling of the refill friction stir spot welding process in Alclad 7075-T6 aluminium alloy sheets. Arch. Civ. Mech. Eng. 2020, 20, 117. [Google Scholar] [CrossRef]

- Skowrońska, B.; Chmielewski, T.; Kulczyk, M.; Skiba, J.; Przybysz, S. Microstructural investigation of a friction-welded 316L stainless steel with ultrafine-grained structure obtained by hydrostatic extrusion. Materials 2021, 14, 1537. [Google Scholar] [CrossRef] [PubMed]

- Kosturek, R.; Śnieżek, L.; Torzewski, J.; Wachowski, M. Research on the Friction Stir Welding of Sc-modified AA2519 extrusion. Metals 2019, 9, 1024. [Google Scholar] [CrossRef] [Green Version]

| Mg (%) | Mn (%) | Fe (%) | Si (%) | Cu (%) | Zn (%) | Al (%) | Tensile Strength, Rm (MPa) | Elongation, A50 (%) |

|---|---|---|---|---|---|---|---|---|

| 0.80–1.30 | 1.00–1.50 | ≤0.70 | ≤0.30 | ≤0.25 | ≤0.25 | balance | ≥155 | ≥16 |

| Symbol of the Specimen | Welding Speed (mm/min) | Rotational Speed (rpm) | The Tool Pin’ Shape |

|---|---|---|---|

| CW1 | 300 | 115 | Cylindrical threaded |

| CW2 | 155 | ||

| CW3 | 205 | ||

| CW4 | 290 | ||

| CW5 | 360 | ||

| CW6 | 680 | ||

| CW7 | 925 | ||

| CR1 | 95 | 475 | |

| CR2 | 150 | ||

| CR3 | 235 | ||

| CR4 | 300 | ||

| CR5 | 375 | ||

| CR6 | 475 | ||

| CR7 | 600 | ||

| TR1 | 150 | Tapered threaded | |

| TR2 | 235 | ||

| TR3 | 300 | ||

| TR4 | 375 | ||

| TR5 | 475 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janeczek, A.; Tomków, J.; Fydrych, D. The Influence of Tool Shape and Process Parameters on the Mechanical Properties of AW-3004 Aluminium Alloy Friction Stir Welded Joints. Materials 2021, 14, 3244. https://doi.org/10.3390/ma14123244

Janeczek A, Tomków J, Fydrych D. The Influence of Tool Shape and Process Parameters on the Mechanical Properties of AW-3004 Aluminium Alloy Friction Stir Welded Joints. Materials. 2021; 14(12):3244. https://doi.org/10.3390/ma14123244

Chicago/Turabian StyleJaneczek, Anna, Jacek Tomków, and Dariusz Fydrych. 2021. "The Influence of Tool Shape and Process Parameters on the Mechanical Properties of AW-3004 Aluminium Alloy Friction Stir Welded Joints" Materials 14, no. 12: 3244. https://doi.org/10.3390/ma14123244

APA StyleJaneczek, A., Tomków, J., & Fydrych, D. (2021). The Influence of Tool Shape and Process Parameters on the Mechanical Properties of AW-3004 Aluminium Alloy Friction Stir Welded Joints. Materials, 14(12), 3244. https://doi.org/10.3390/ma14123244