Selected Methods and Applications of Anti-Friction and Anti-Wear Surface Texturing

Abstract

1. Introduction

2. Selected Methods of Surface Texturing

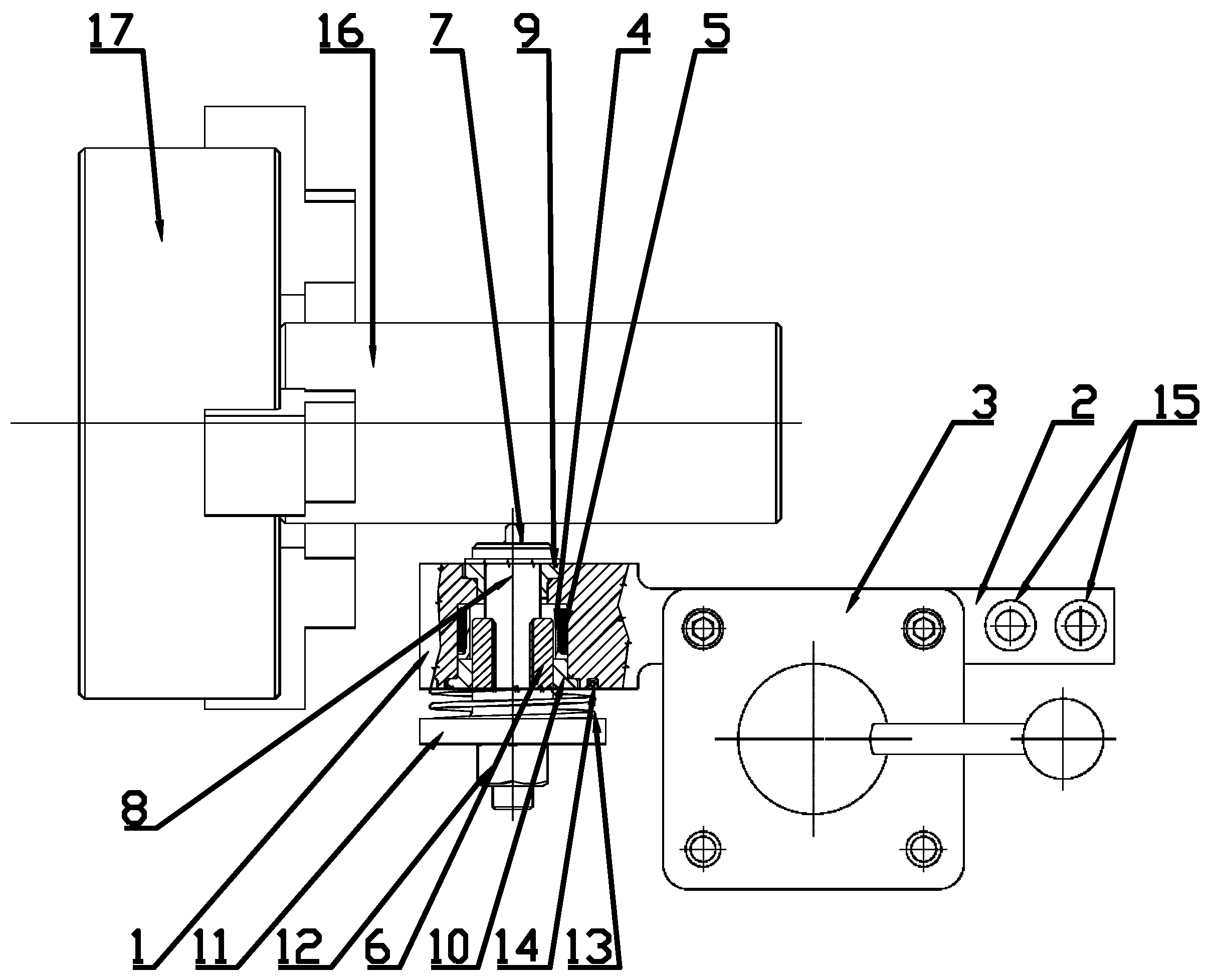

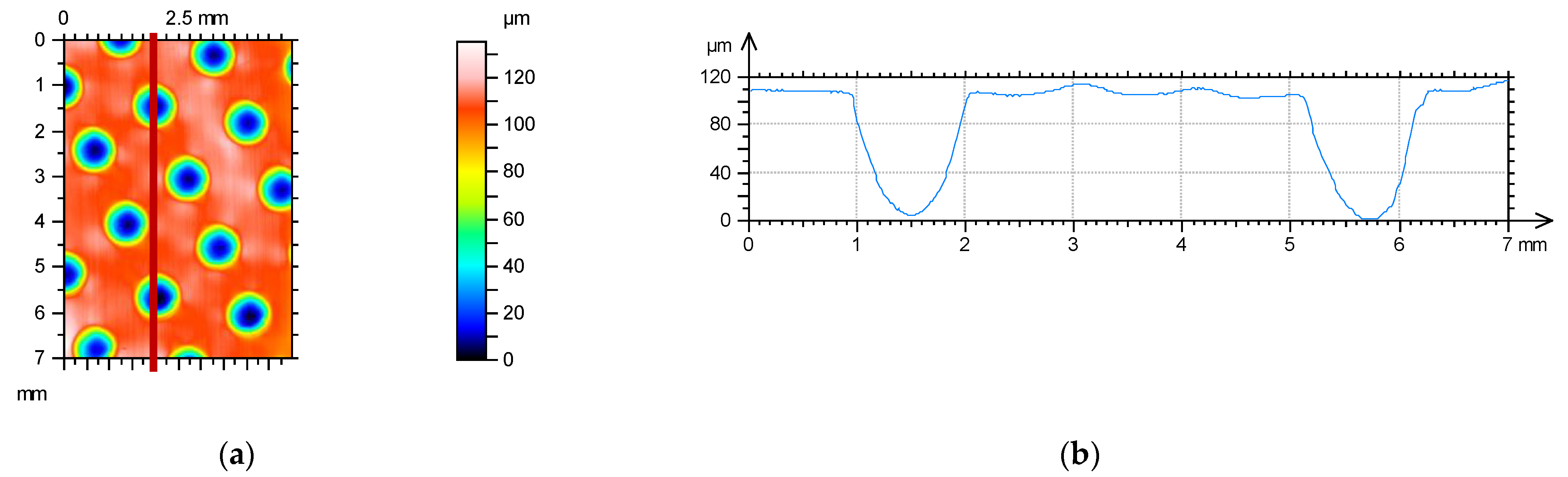

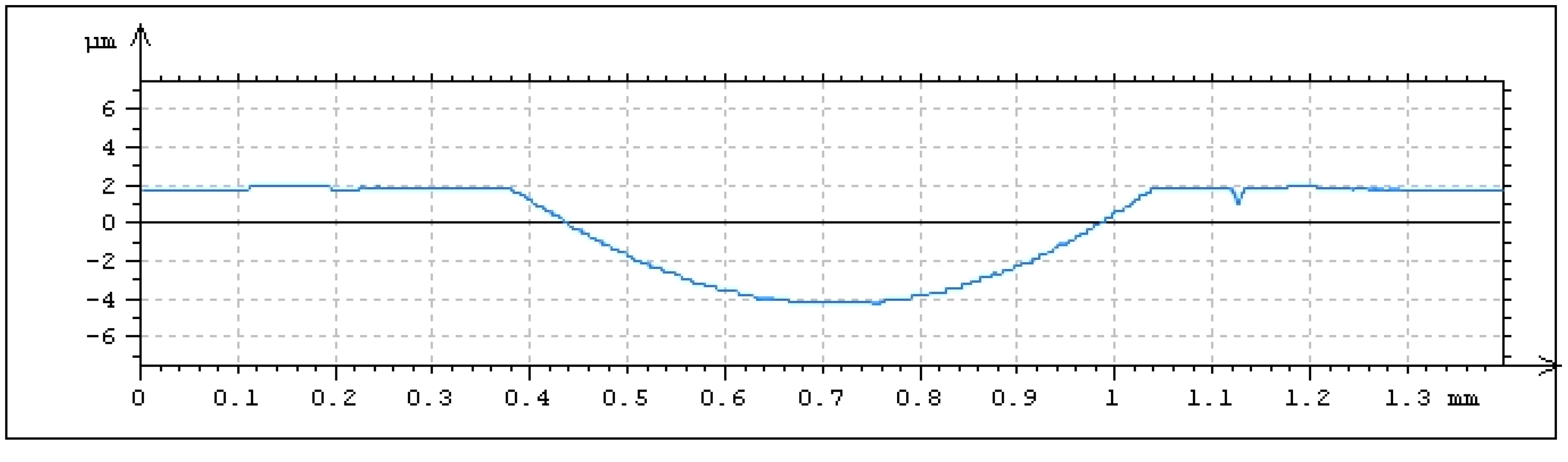

2.1. Burnishing

- No heat-affected zone around the dimples;

- The layers covering formed surface are not thinned, just pressed into the base material without affecting layer integrity;

- Fast process.

- Positioning of the tool and the machined surface requires great precision because it affects the depth of the dimples.

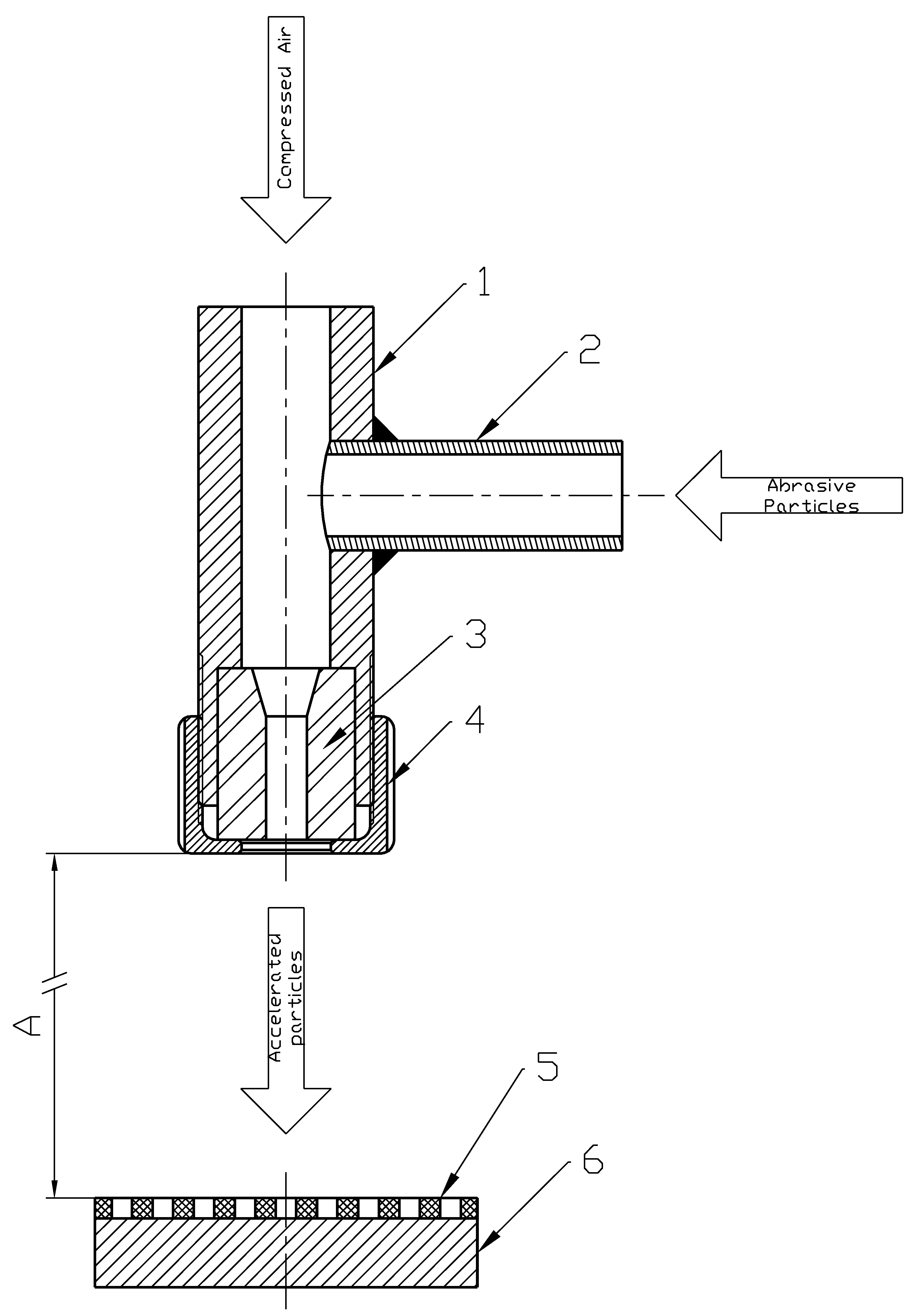

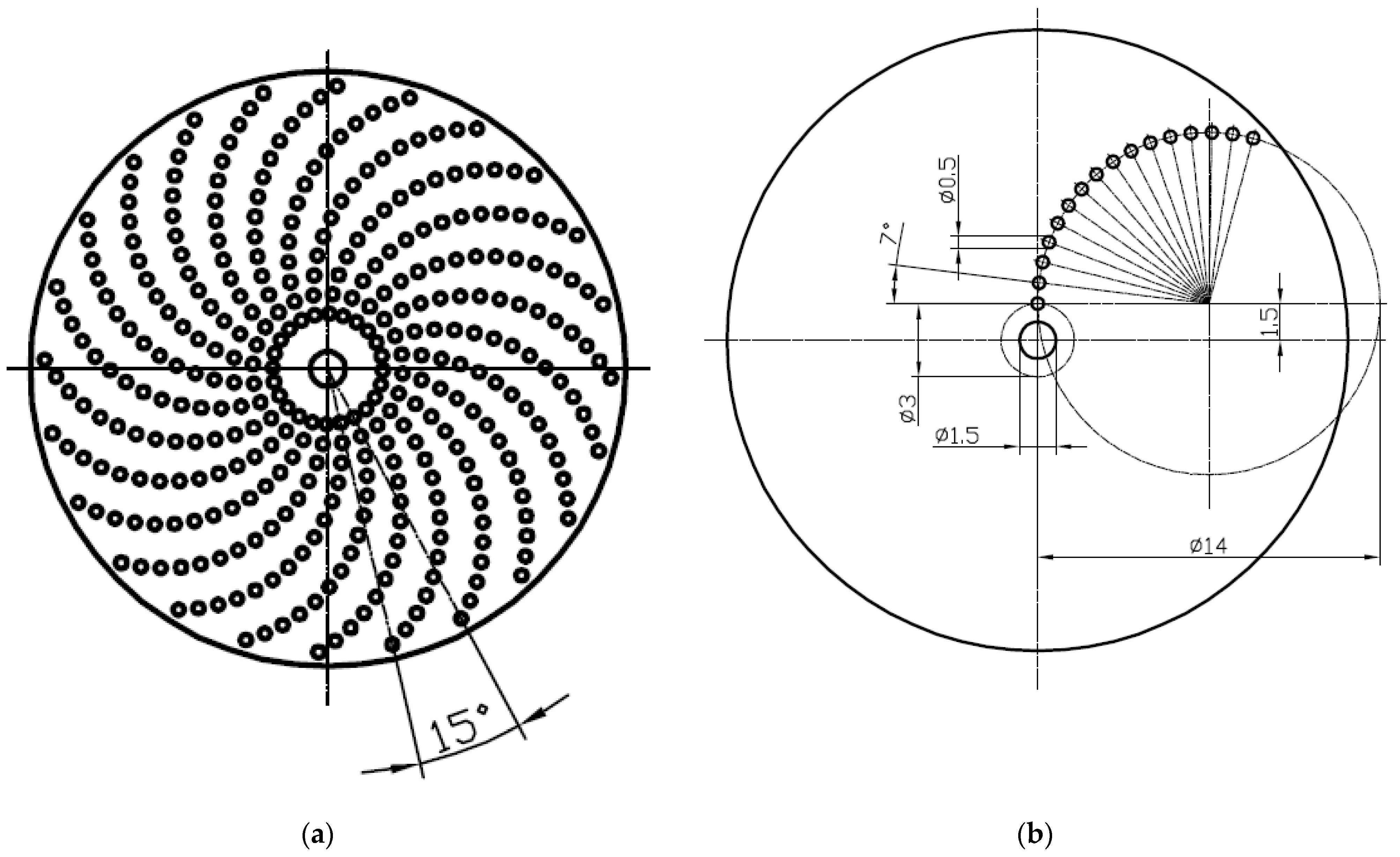

2.2. Abrasive Jet Machining

- No heat-affected zone around dimples;

- Fast process;

- The possibility of using multiple used masks;

- No burrs around the dimples;

- Nontoxic process;

- Multiple usage of the abrasive particles;

- Possibility of performing in a typical abrasive blasting stand.

- Required precision in mask positioning.

3. Tribological Applications of Surface Texturing

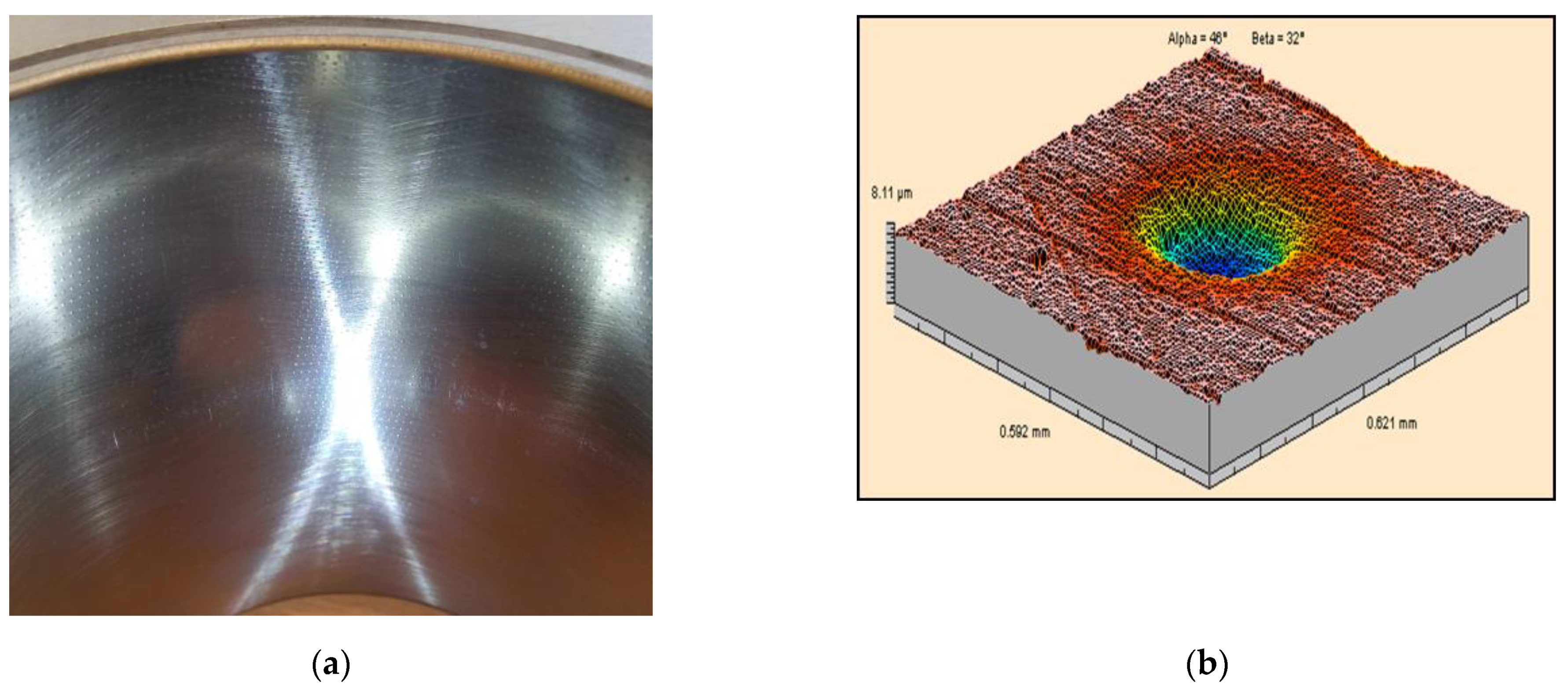

3.1. The Effect of the Presence of Burnished Dimples on Wear Improvement

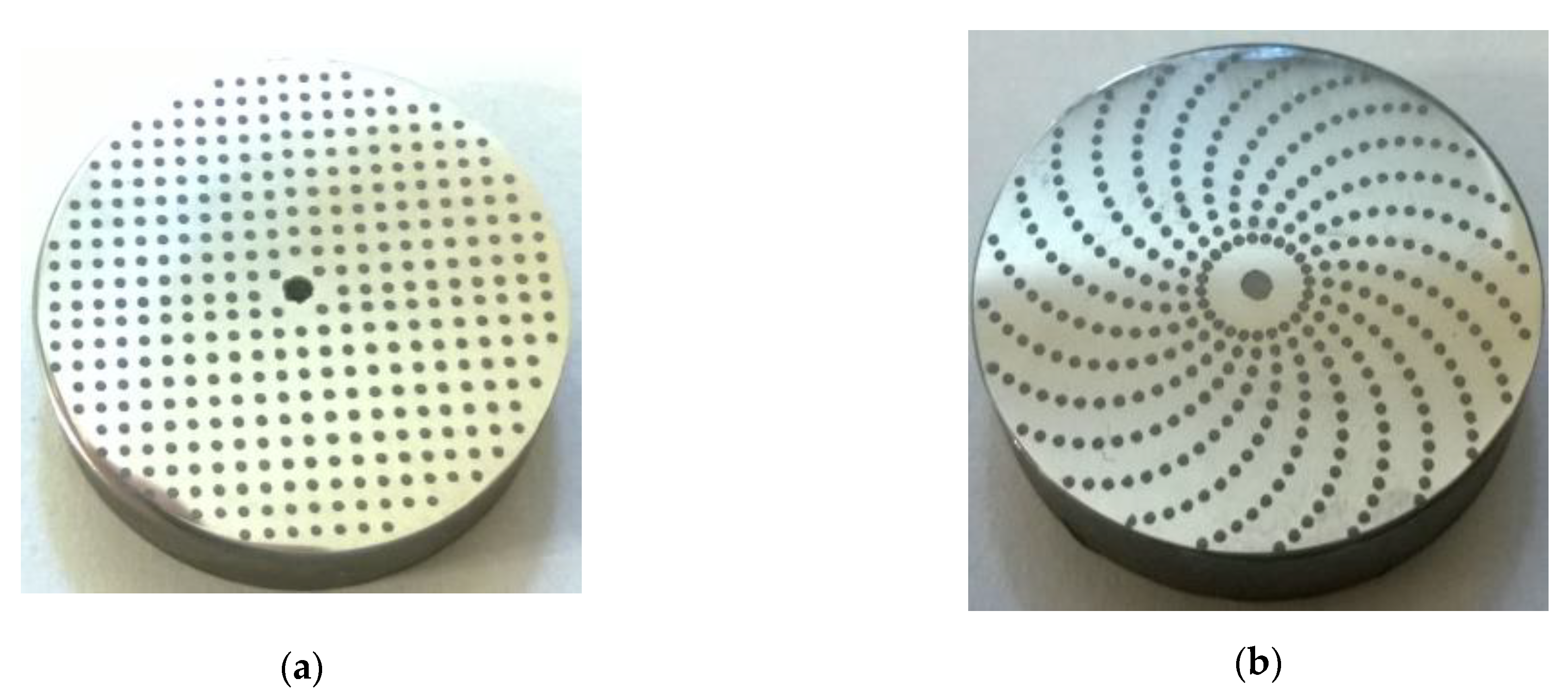

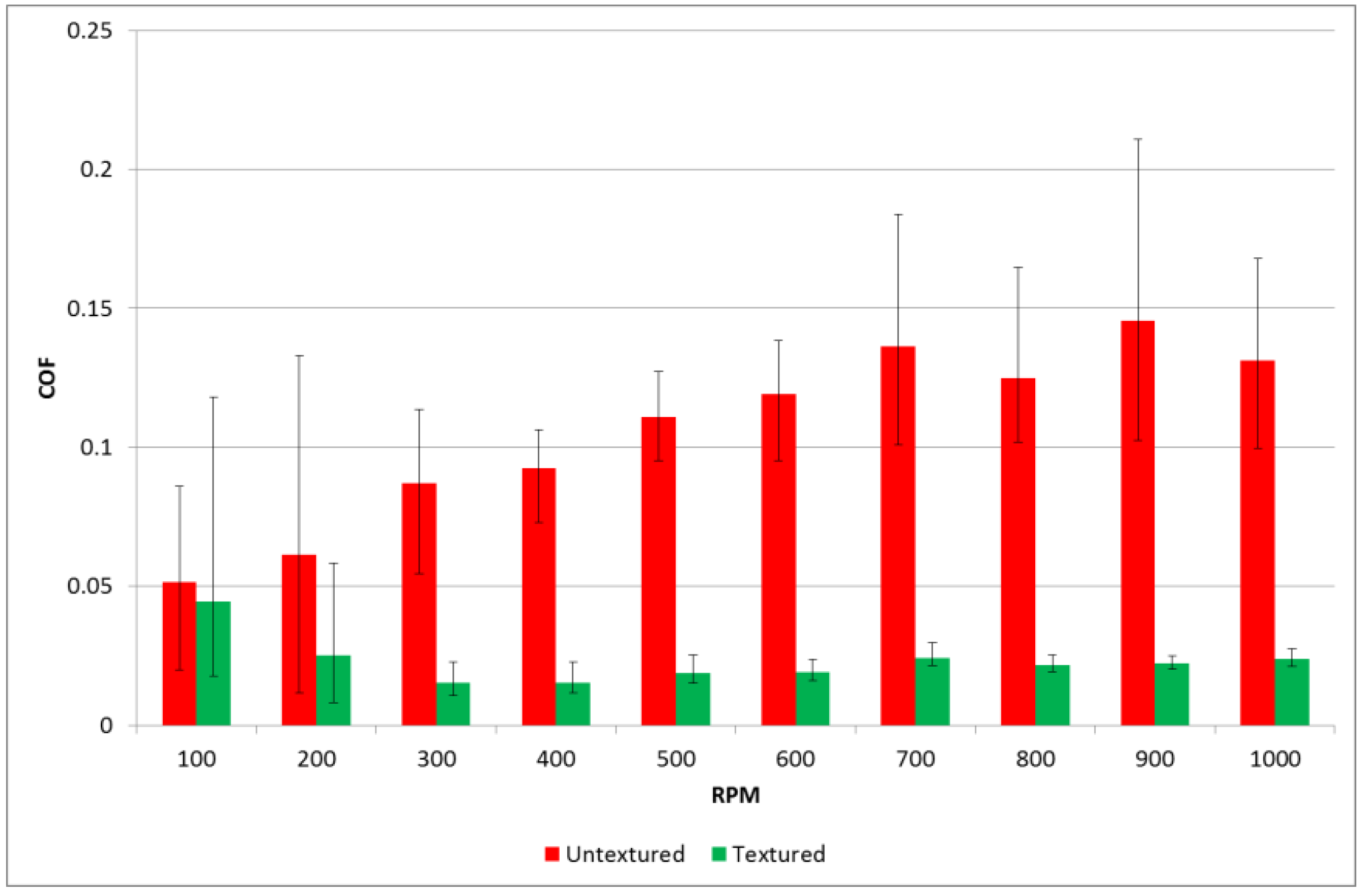

3.2. The Effect of Surface Texturing by Abrasive Jet Machining on Friction Reduction

4. Conclusions

- Burnishing changes the treated surface by plastic deformation. Dimple size and shape are the result of the shape of the tool. The burnishing process is fast. The zone near the dimples is not affected by heat. The positioning of the tool with regard to the treated surface needs high precision. Therefore, special devices for surface texturing by the burnishing process should be developed.

- Abrasive jet machining is an interesting alternative to laser texturing. The erosion process caused by speeded abrasive particles was used. Abrasive jet machining can be applied for all types of materials. Similar to burnishing, this process is fast and the zone around the oil pockets is not influenced by heat. In addition, burrs around dimples were not created and multiple usages of masks and abrasives are possible. However, precision in the positioning of the masks is needed.

- Surface texturing by burnishing of the block from bronze caused a decrease in the total linear wear of ring-on-block assembly up to four times. The beneficial effect of surface texturing was related to an increase in running-in time. This effect depends on the oil capacity. Dimples were traps for wear debris, leading to wear reduction. The dimensions of the dimples should be selected taking the operating conditions into consideration.

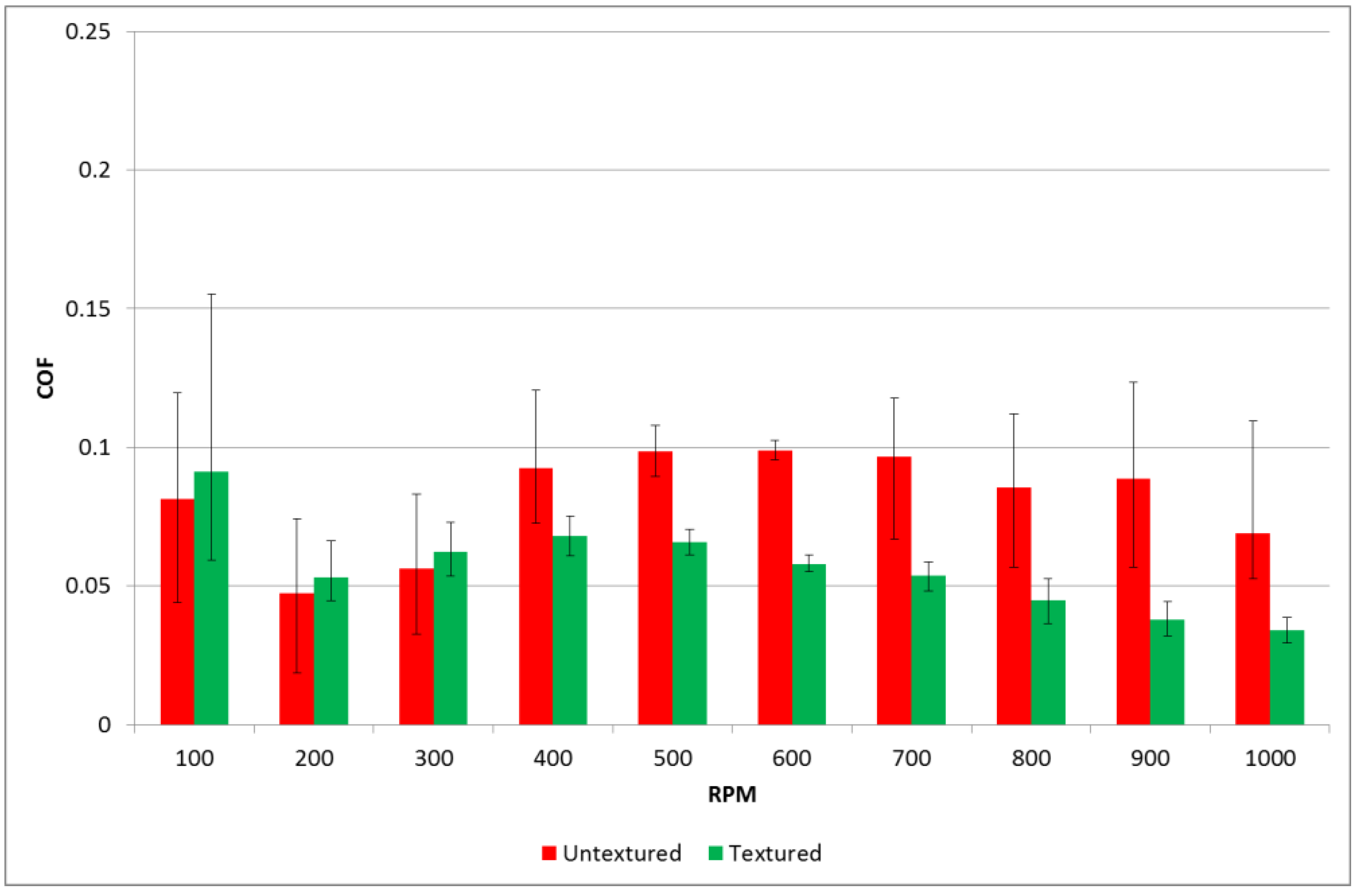

- Disc surface texturing of the steel disc caused a decrease in the coefficient of friction of the pin-on-disc pair in unidirectional sliding up to five times. This beneficial effect was larger for higher speeds and smaller normal load. In addition, surface texturing led to lower variations of the coefficients of friction, especially for high sliding speeds.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chung, Y. Micro- and Nanoscale Phenomena in Tribology; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Etsion, I. State of the art in laser surface texturing. ASME J. Tribol. 2005, 125, 248–253. [Google Scholar] [CrossRef]

- Nilsson, B.; Rosen, B.-G.; Thomas, T.R.; Wiklund, D. Oil pockets and surface topography: Mechanism of friction reduction. In Proceedings of the XI International Colloquium on Surfaces, Chemnitz, Germany, 2–3 February 2004. [Google Scholar]

- Erdemir, A. Review of engineered tribological interfaces for improved boundary lubrication. Tribol. Int. 2005, 38, 249–256. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Grützmacher, P.G.; Gachot, C.; Costa, H. Surface Texturing in Machine Elements—A Critical Discussion for Rolling and Sliding Contacts. Adv. Eng. Mater. 2019, 21, 1900194. [Google Scholar] [CrossRef]

- Costa, H.; Hutchings, I.M. Some innovative surface texturing techniques for tribological purposes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 429–448. [Google Scholar] [CrossRef]

- Garcia-Giron, A.; Romano, J.; Liang, Y.; Dashtbozorg, B.; Dong, H.; Penchev, P.; Dimov, S. Combined surface hardening and laser patterning approach for functionalising stainless steel surfaces. Appl. Surf. Sci. 2018, 439, 516–524. [Google Scholar] [CrossRef]

- Du, Q.; Ai, J.; Qin, Z.; Liu, J.; Zeng, X. Fabrication of superhydrophobic/superhydrophilic patterns on polyimide surface by ultraviolet laser direct texturing. J. Mater. Process. Technol. 2018, 251, 188–196. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. The Friction Reducing Effect of Square-Shaped Surface Textures under Lubricated Line-Contacts—An Experimental Study. Lubricants 2016, 4, 26. [Google Scholar] [CrossRef]

- Pawlus, P.; Galda, L.; Dzierwa, A.; Koszela, W. Abrasive wear resistance of textured steel rings. Wear 2009, 267, 1873–1882. [Google Scholar] [CrossRef]

- Arizmendi, M.; Jiménez, A.; Cumbicus, W.E.; Estrems, M.; Artano, M. Modelling of elliptical dimples generated by five-axis milling for surface texturing. Int. J. Mach. Tools Manuf. 2019, 137, 79–95. [Google Scholar] [CrossRef]

- Chen, X.; Qu, N.; Fang, X.; Zhu, D. Reduction of undercutting in electrochemical micro-machining of micro-dimple arrays by utilizing oxygen produced at the anode. Surf. Coat. Technol. 2015, 277, 44–51. [Google Scholar] [CrossRef]

- Abhishek, K.; Hiremath, S.S.; Karunanidhi, S. A novel approach to produce holes with high degree of cylindricity through Micro-Abrasive Jet Machining (μ-AJM). CIRP J. Manuf. Sci. Technol. 2018, 21, 110–119. [Google Scholar] [CrossRef]

- Huang, H.; Yan, J. Multi-scale dimple creation on metallic glass by a two-step method involving nanoindentation and polishing. Appl. Surf. Sci. 2018, 462, 565–574. [Google Scholar] [CrossRef]

- Koszela, W. Tool for the Micro Oil Pockets Forming on Flat and Cylindrical Surfaces. PL 218011 B1, 30.09.2014. (in Polish).

- Koszela, W. Head for Creastion of Oil Pockets on Surfaces of Cylinder Liners. PL 217855 B1, 29.08.2014. (in Polish).

- Haldar, B.; Ghara, T.; Ansari, R.; Das, S.; Saha, P. Abrasive jet system and its various applications in abrasive jet machining, erosion testing, shot-peening, and fast cleaning. Mater. Today Proc. 2018, 5, 13061–13068. [Google Scholar] [CrossRef]

- Park, D.-S.; Cho, M.-W.; Lee, H.; Cho, W.-S. Micro-grooving of glass using micro-abrasive jet machining. J. Mater. Process. Technol. 2004, 146, 234–240. [Google Scholar] [CrossRef]

- Koszela, W.; Dzierwa, A.; Gałda, L.; Pawlus, P. Experimental investigation of oil pockets effect on abrasive wear resistance. Tribol. Int. 2012, 46, 145–153. [Google Scholar] [CrossRef]

- Koszela, W.; Pawlus, P.; Gałda, L. The effect of oil pockets size and distribution on wear in lubricated sliding. Wear 2007, 263, 1585–1592. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. Determination of oil demand for textured surfaces under conformal contact conditions. Tribol. Int. 2016, 93, 602–613. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. The effect of both surfaces textured on improvement of tribological properties of sliding elements. Tribol. Int. 2017, 113, 182–188. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. Comparing tribological effects of various chevron-based surface textures under lubricated unidirectional sliding. Tribol. Int. 2020, 146, 106205. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wos, S.; Koszela, W.; Pawlus, P. Selected Methods and Applications of Anti-Friction and Anti-Wear Surface Texturing. Materials 2021, 14, 3227. https://doi.org/10.3390/ma14123227

Wos S, Koszela W, Pawlus P. Selected Methods and Applications of Anti-Friction and Anti-Wear Surface Texturing. Materials. 2021; 14(12):3227. https://doi.org/10.3390/ma14123227

Chicago/Turabian StyleWos, Slawomir, Waldemar Koszela, and Pawel Pawlus. 2021. "Selected Methods and Applications of Anti-Friction and Anti-Wear Surface Texturing" Materials 14, no. 12: 3227. https://doi.org/10.3390/ma14123227

APA StyleWos, S., Koszela, W., & Pawlus, P. (2021). Selected Methods and Applications of Anti-Friction and Anti-Wear Surface Texturing. Materials, 14(12), 3227. https://doi.org/10.3390/ma14123227